Method for quantitatively identifying performance degradation degree of rolling bearing

A rolling bearing and degradation degree technology, which is applied in the field of identification of rolling bearing performance degradation degree, can solve problems such as identification of degradation degree that is difficult to deal with ambiguity, and achieve the effect of preventing major accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Use simulation to simulate vibration signals including the effects of bearing dimensions, rotational speed, load distribution, transfer functions, and oscillation damping.

[0089] x ( t ) = Σ i = 1 M { A 0 · cos [ 2 π f m ( iT + τ i ) ] } · { e - B ( t - iT - τ i ) cos [ 2 ...

Embodiment 2

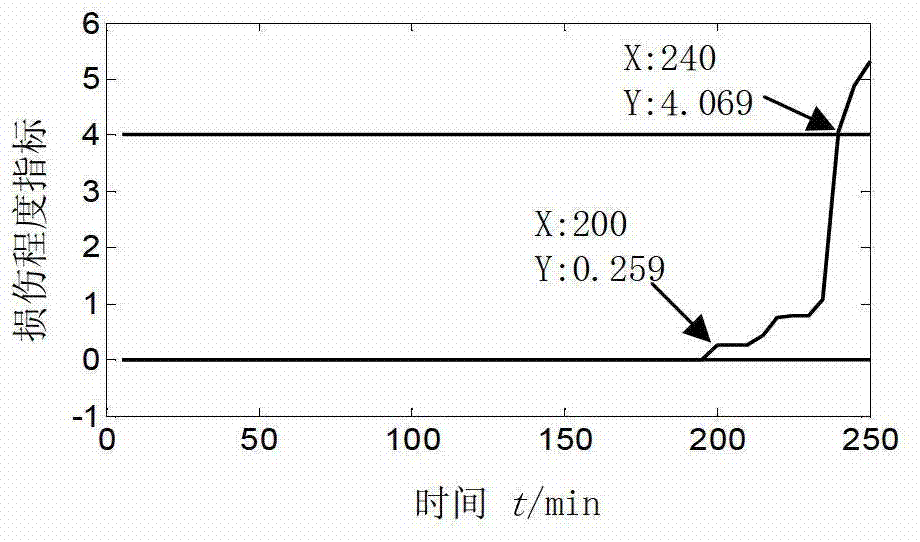

[0097] In order to verify the correctness of the method described in this paper, the test is carried out on a full-life fatigue testing machine. The model of the experimental bearing is 30311, and the model of the supporting bearing is N312. The bearing parameters are shown in Table 1. The experimental platform is designed as a simply supported beam structure. The tapered roller bearings at both ends are experimental bearings, and the cylindrical roller bearings in the middle are support bearings. The experimental speed is 1500r / min, the axial load is 15kN, and the radial load is 27kN. The whole life test is carried out in accordance with the industry standard JB / T 50013-2000. The sampling frequency is 10000Hz, one sample is stored every 5 minutes, and each sample contains 32768 vibration values. In this experiment, the rolling bearing finally failed due to the outer ring failure.

[0098] Table 1 Dimensional parameters of experimental bearings and support bearings

[0099]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com