Fuel gas graded and segmented distribution combustion device and fuel gas graded and segmented distribution method thereof

A combustion device and gas grading technology, applied in combustion methods, gas fuel burners, burners, etc., can solve the problems of easy vibration of the burner system, insufficient low nitrogen effect, poor safety, etc., to reduce the average temperature and Peak temperature, effect of reducing average and peak flame temperature, increasing fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

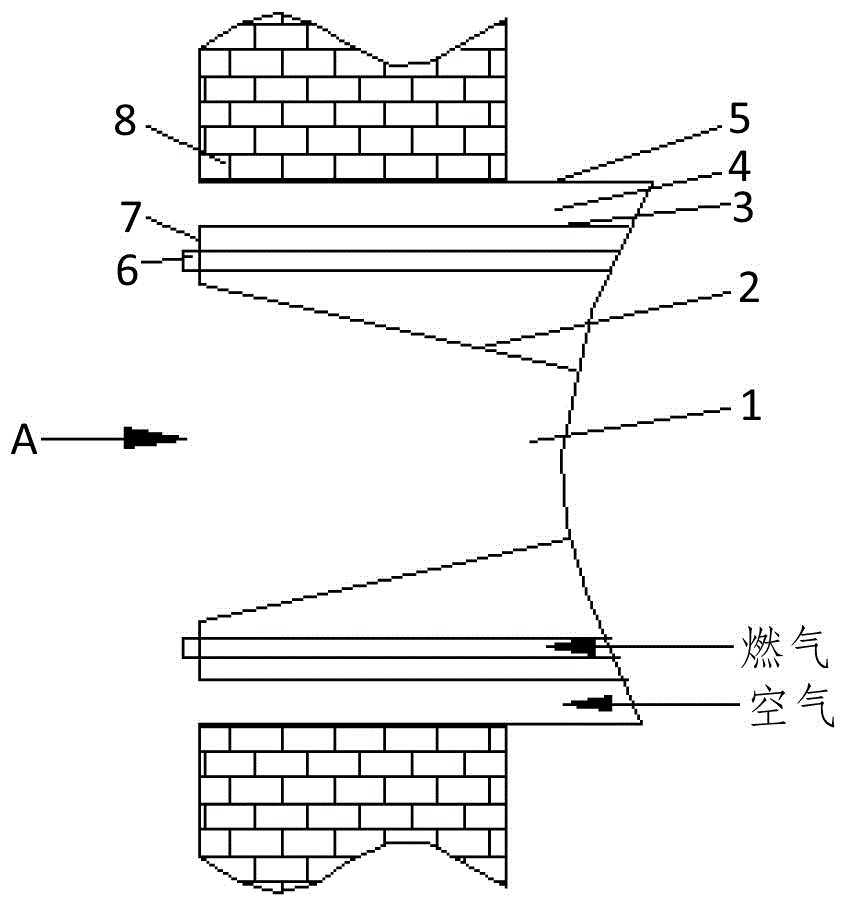

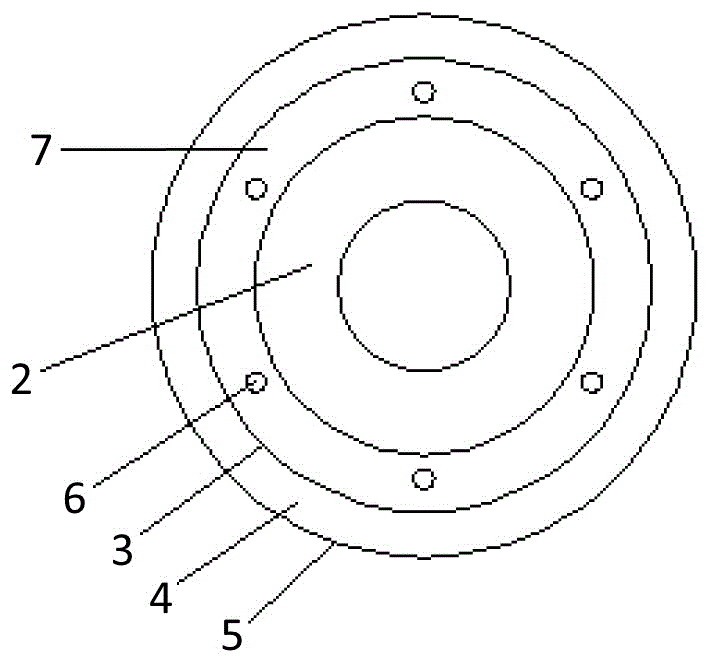

[0018] Figure 1 ~ Figure 4 It is a schematic diagram of the structure of a gas staged and segmented combustion device, figure 1 It is a structural schematic diagram of an embodiment of a group of outer gas guns (one group, six outer gas guns), image 3 It is a structural schematic diagram of an embodiment of two groups of outer gas guns (two groups, 6 outer gas guns are arranged in the inner layer, and 10 outer gas guns are arranged in the outer layer); it can be seen from the diagram that a gas combustion device with staged and segmented configuration includes The burner 1, the throat 2 and the refractory material layer 8 on the periphery of the combustion device placed on the central axis of the combustion device are characterized in that: the burner 1, the throat 2, the outer gas gun 6, the inner The ring tube 3, the outer ring tube 5 and the refractory material layer 8 are arranged coaxially and symmetrically from the inside to the outside: an outer tube perpendicular to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com