Double-bionic tree-shaped pipe bundle type condenser of umbrella-shaped air cooling area

An air-cooled zone and condenser technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of affecting the performance of the condenser and the large air resistance of the evacuation pipeline, and achieves obvious energy saving effect and no air extraction. The effect of short reheat and large heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

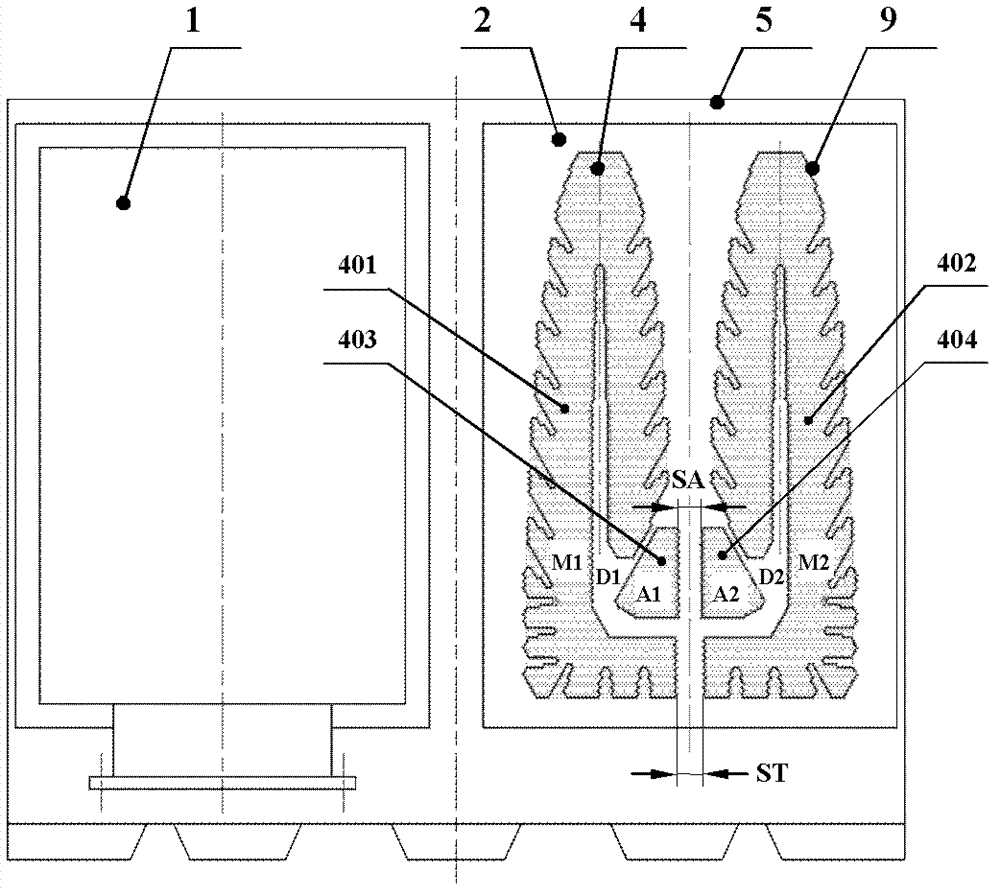

[0034] figure 1 It is a structural schematic diagram of a condenser according to an embodiment of the present invention. figure 2 It is a left view structural schematic diagram of the condenser of Embodiment 1 of the present invention, in figure 2 In , the right front water chamber is disassembled to show the arrangement of the heat exchange tubes of the condenser end tube plate. image 3 It is a schematic sectional view (half side) of the three-dimensional structure of the condenser of Embodiment 1 of the present invention.

[0035] exist figure 1 , figure 2 and image 3 Among them, condenser water chamber 1 is divided into front water chamber and rear water chamber, each with 2 pieces, condenser end tube plate 2 is divided into front end tube plate and rear end tube plate, each with 2 pieces, middle tube plate 3 It is arranged symmetrically on both sides, with 11 pieces on each side, the middle tube plate 3 has 2×11=22 pieces, and several heat exchange tubes 4 (in th...

Embodiment 2

[0047] Figure 9 It is a structural schematic diagram (half side) of the mid-section of the condenser of Embodiment 2 of the present invention. exist Figure 9 Among them, the tube bundle of the half-side condenser in this embodiment is a double bionic tree-shaped tube bundle of an umbrella-shaped air-cooling zone symmetrically arranged, and each bionic tree-shaped tube bundle (independent main cooling tube bundle unit) consists of 5575 heat exchange tubes Composition, each adjacent tapered air-cooled area tube bundle (independent air-cooled tube bundle unit) is composed of 391 heat exchange tubes, and the tube bundle arrangement of the half-side condenser in this embodiment has a total of 11932 heat exchange tubes. There are 23864 heat exchange tubes in the condenser.

[0048] exist Figure 9 Among them, the air-cooled steam baffle assembly 7 and the two tapered air-cooled zone tube bundles (A1 and A2) and the evacuation pipe 6 form an "umbrella" shape. The difference from...

Embodiment 3

[0052] Figure 10 It is a schematic diagram (half side) of the middle section structure of the condenser of embodiment three of the present invention, Figure 11 yes Figure 10 A schematic diagram of the local structure.

[0053] exist Figure 10 and Figure 11 Among them, the air-cooled steam baffle assembly 7, the air-cooled connecting pipe 12, the two tapered air-cooled zone tube bundles and the evacuation pipe 6 form an "umbrella" shape, wherein the upper steam baffle 701 and the air-cooled connecting pipe 12 are shaped like an "umbrella" The vertical steam baffle 702 and the evacuation pipeline 6 are shaped like a "vertical" in the middle of the word "umbrella". There is a certain gap between the two vertical steam baffles 702, and 703 is "umbrella". The Chinese-shaped horizontal steam plate is shaped like a "horizontal" in the middle of the word "umbrella". The upper space of " font communicates with the air-cooling connecting pipe. exist Figure 10 and Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com