Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Reduce heat treatment energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium-containing high-boron high-chromium wear-resistant alloy and preparation method thereof

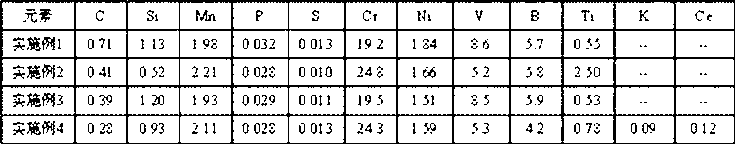

The invention provides a vanadium-containing high-boron high-chromium wear-resistant alloy and a preparation method thereof, belonging to the technical field of wear-resistant materials. The alloy is characterized in that a strengthening phase is iron chromium boride and VC, the volume fraction of the strengthening phase is 15 to 40%, and chemical components of the alloy comprise, by weight, 0.10 to 0.80% of C, 0.5 to 1.5% of Si , 0.5 to 3.0% of Mn, 2.0 to 28.0% of Cr, 0.5 to 3.0% of Ni, 0.5 to 6.0% of B, 0.5 to 10.0% of V, 0.5 to 3.0% of Ti, less than 0.04% of P and less than 0.04% of S, with the balance being Fe and unavoidable impurities. The alloy provided by the invention can be directly used after electric-furnace smelting, casting forming, polishing and cleaning and removal of stress at a temperature of 200 to 650 DEG C and has the advantages of simple preparation process, low energy consumption, good strength, hardness, toughness and wear resistance, oxidation resistance, corrosion resistance, etc.

Owner:SICHUAN UNIV

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

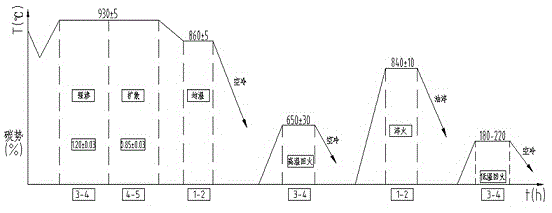

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Boron-contained high-chromium high-speed steel roller material and heat treatment method thereof

InactiveCN101805869ALow costReduce the amount addedFurnace typesHeat treatment furnacesImpurityMaterials science

The invention discloses a boron-contained high-chromium high-speed steel roller material and a heat treatment method thereof. The boron-contained high-chromium high-speed steel roller material comprises the chemical compositions by mass percentage: 2.6-3.0 of C, 2.0-2.8 of Mo, 1.0-1.5 of W, 0.6-1.0 of Nb, 1.0-1.5 of V, 24-28 of Cr, 0.5-0.8 of B, 0.7-1.2 of Ni, 0.5-1.0 of Si, 0.5-1.2 of Mn, 0.008-0.015 of Ca, 0.06-0.08 of Zn, 0.02-0.05 of Ta, 0.03-0.06 of RE, 0.04-0.10 of K and the balance of Fe and inevitable trace impurities. The roller material is finely processed into a roller by smelting, outside furnace deterioration, casting and heat treatment. The roller material has the advantages of high hardness, good abrasion resistance, long service life, no high-temperature heat treatment, simple and convenient process, low energy consumption, and the like, thereby having favorable economic benefits by being popularized and applied.

Owner:BEIJING UNIV OF TECH

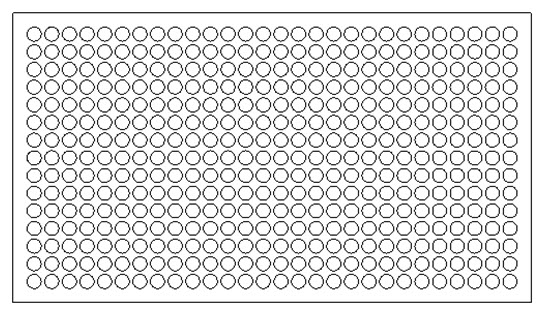

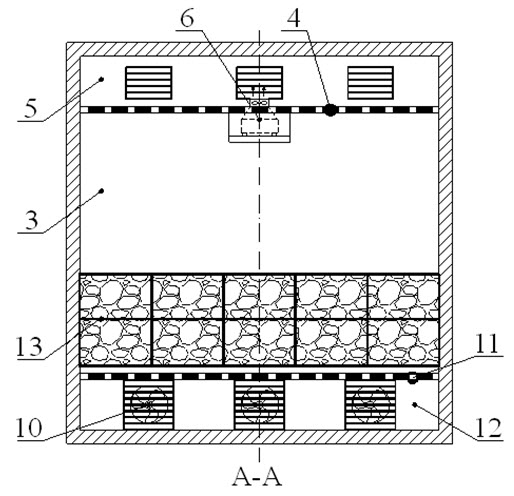

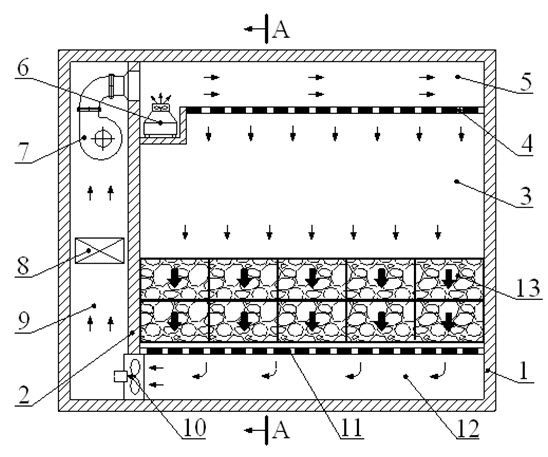

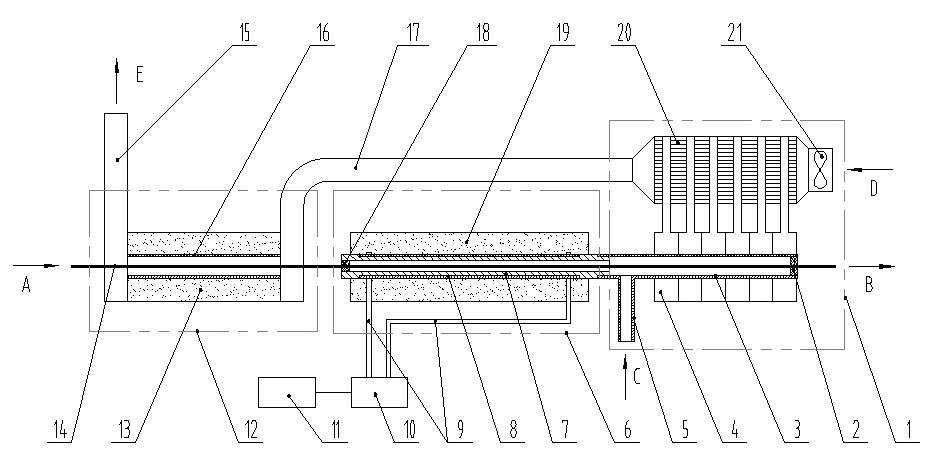

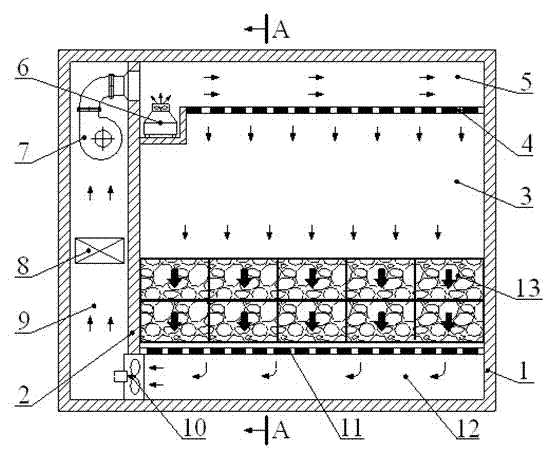

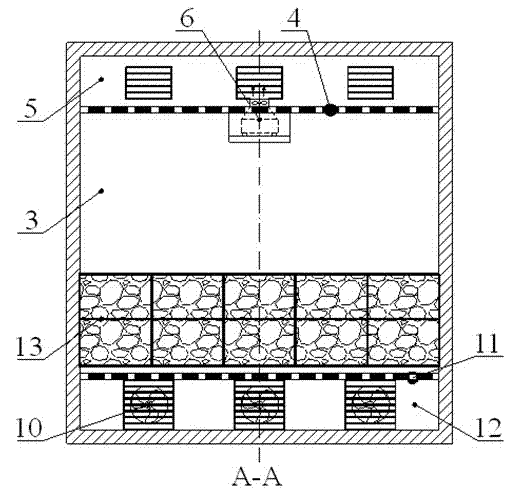

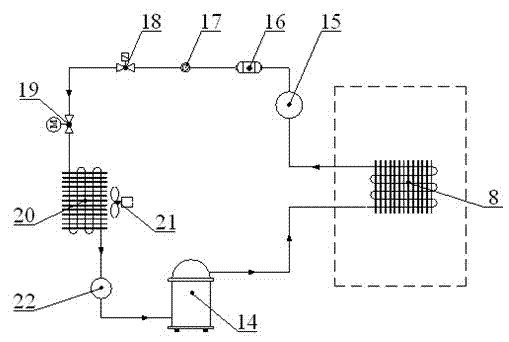

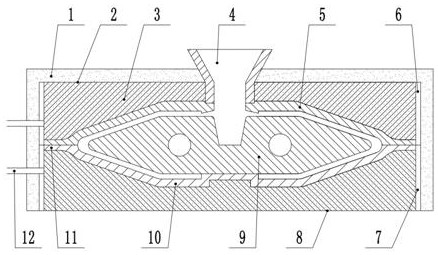

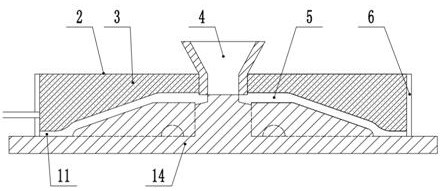

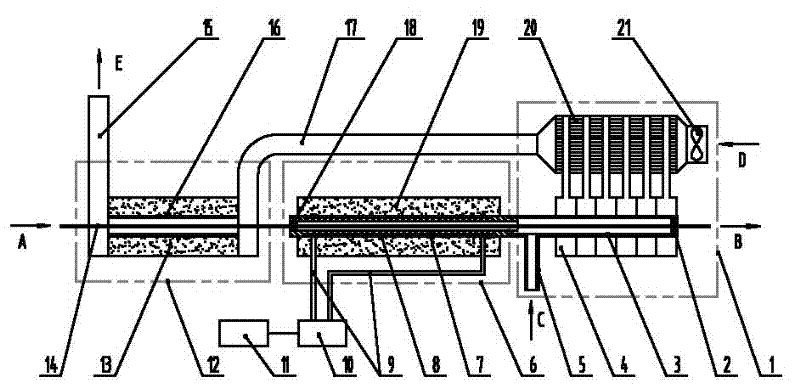

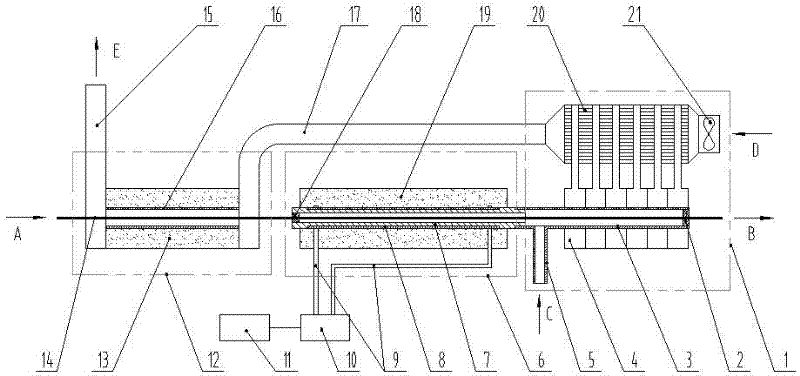

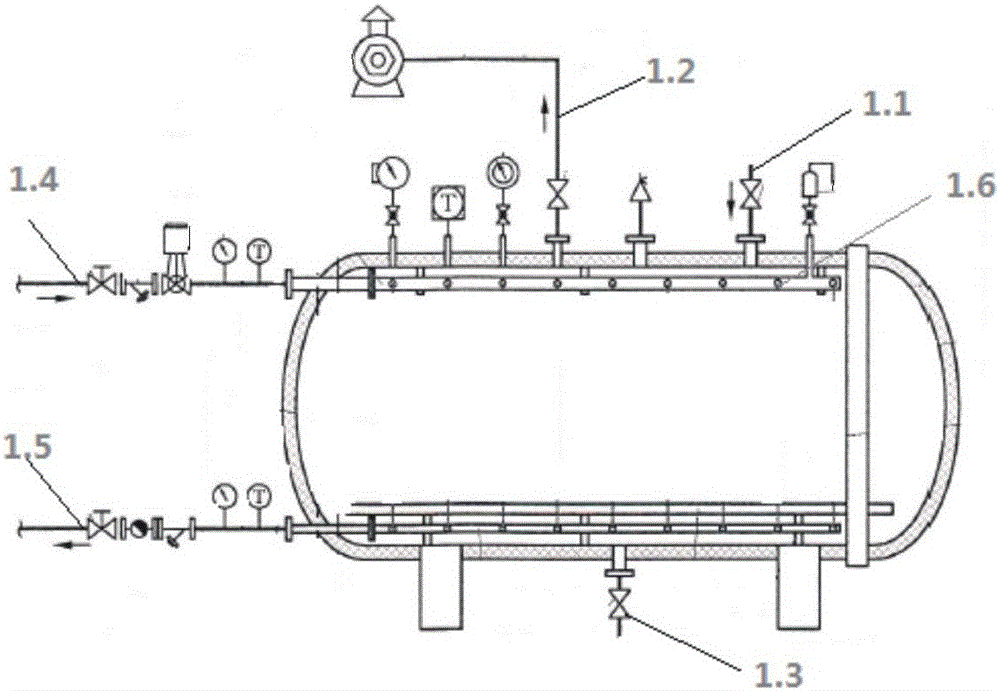

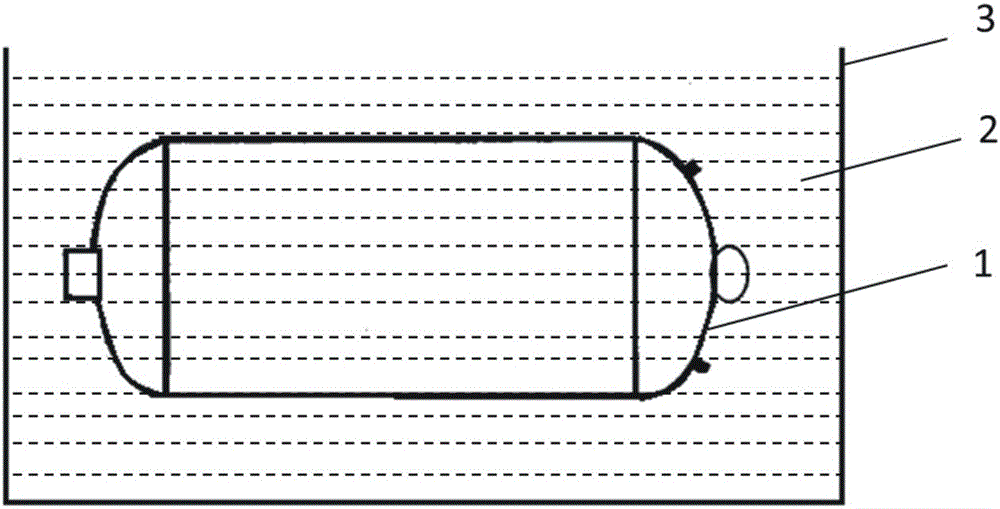

Heat pump type pressure gradient fruit vegetable heat treatment library

ActiveCN101919436AReduce heat treatment energy consumptionShorten the timeFood processingFruits/vegetable preservation by heatingThermodynamicsAir treatment

The invention discloses a heat pump type pressure gradient fruit vegetable heat treatment library. The library is composed of a library entry, a heat pump system, a circulation air system and a humidifying system, the library entry is divided into four parts of air treatment, air supply plenum, fruit vegetable heat treatment and return air plenum. The upper end and the lower end of the clapboard are respectively provided with three centrifugal fans and three pressure gradient fans, an air supply homogenizing plate and a return air floor plate are respectively arranged at the upper part and the lower part in the library, and a fruit vegetable heat treatment chamber is formed between the two plates. An air supply plenum chamber is formed between the air supply homogenizing plate and the upper top wall of the library entry, and a return air plenum chamber is formed between the return air floor plate and the lower bottom of the library entry. The condenser of the heat pump system is arranged in an air treatment chamber, a centrifugal humidifier is arranged above the right side of the clapboard, and the return air floor plate is placed with a fruit vegetable box. Pressure gradient air supply is adopted, so that treatment time can be reduced. The invention adopts heat pump heat source, the heat pump can supply 3-5 units of heat into the library while a compressor consumes every 1 unit electricity; compared with the electric heating method, fruit vegetable heat treatment energy consumption can be obviously reduced, and energy conservation effect of the system is obvious.

Owner:TIANJIN UNIV

Heat treatment-dehydration-fertilizer making method for town sewage and sludge

InactiveCN101186423ALow costReduce heat treatment energy consumptionSludge treatment by de-watering/drying/thickeningBio-organic fraction processingHumic acidChemistry

A heat treatment-dehydration-making fertilizer method of urban sewage and sludge is provided, which pertains to the treatment filed of solid waste. Sodium hydroxide is added into dewatered sludge and stirred, hypoxic steam with temperature and pressure more than 250 DEG C and 4MPa is input, the temperature is raised to 120-140 DEG C for 40-100 min; the temperature is reduced to less than 100 DEG C, dehydrated liquid and dehydrated sludge cake with amount decreased are obtained after dehydration; the dehydrated liquid is treated by sand filtration and microfiltration, then whole filtration is carried out and the concentrated solution with humic acid more than 3wt percent is obtained; the humic acid liquid fertilizer is obtained after the concentrated solution is added with additive. The invention can greatly reduce the expenses of sludge heat treatment; water content of the obtained dehydrated sludge cake is less than 60 percent and the total solid reduces by 35 percent; the heavy mental content of the obtained humic acid liquid fertilizer is low, the pH value keeps in the range of weak alkaline and the pathogen is inactivated; the method is safe and efficient, complies with Fertilizer Application Guideline of National Ministry of Agriculture and can be widely applied to harmless, quantitative reduction and resource utilization treatment of urban sewage and sludge.

Owner:TSINGHUA UNIV

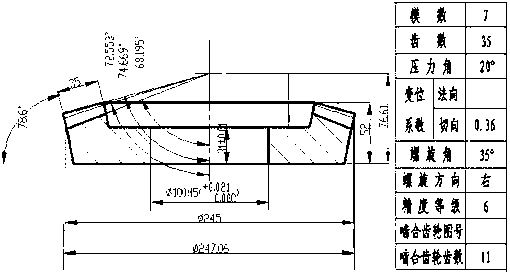

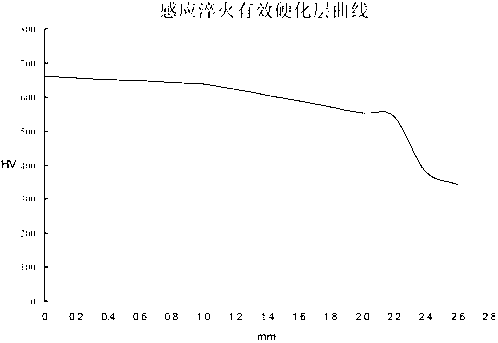

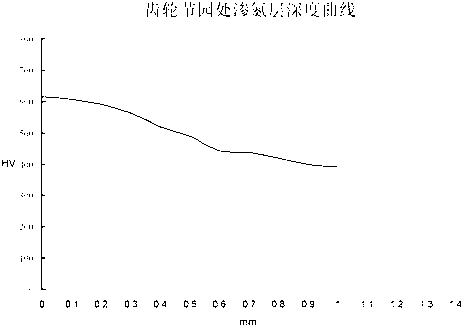

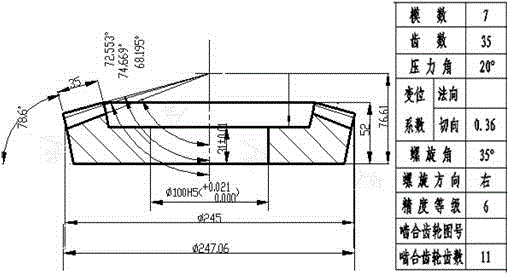

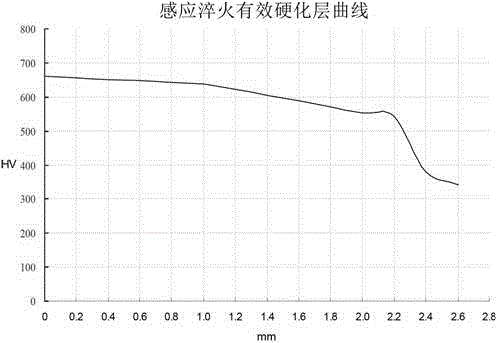

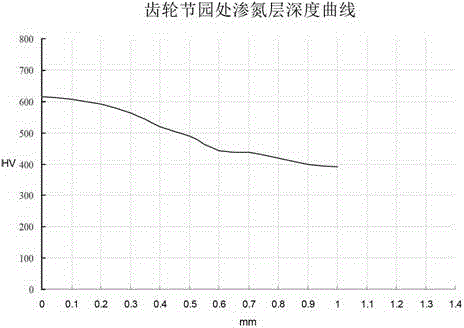

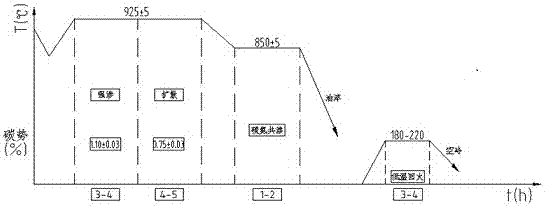

Anti-fatigue manufacturing method of spiral bevel gear

The invention relates to a novel composite surface-enhanced spiral bevel gear production process system based on a current anti-fatigue manufacturing method system and integrating induction quenching and gas nitriding. The invention aims to provide a composite surface-enhanced cyclo-palloid spiral bevel gear manufacturing method with heated precision of 4 to 6 levels and achieving the purpose that the theory contact zone meshed strength is meshed with carburizing and quenching strength. The invention aims to further provide a new spiral bevel gear production technology which can not only embody the current anti-fatigue high-end gear manufacturing method purpose, but also agree with the complete software and hardware match of a roadmap of heat treatment technology development in China.

Owner:天津市天瑞硬化工程有限公司

Energy-saving stainless steel wire hydrogen retreat furnace

InactiveCN101988148ASmall hearthReduce heat transferFurnace typesHeat treatment furnacesHydrogenMetallurgy

Owner:江西华立金属制品有限公司

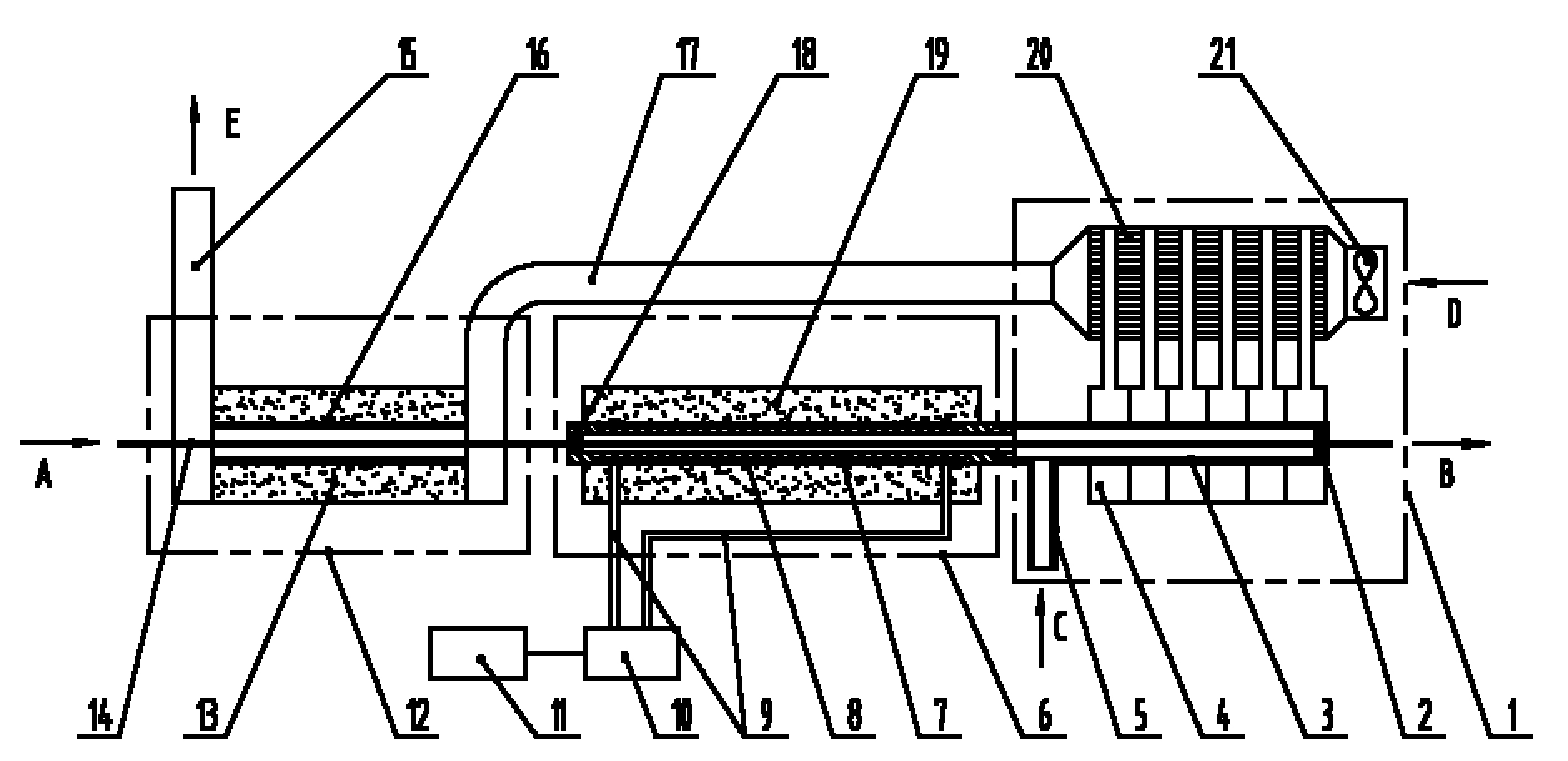

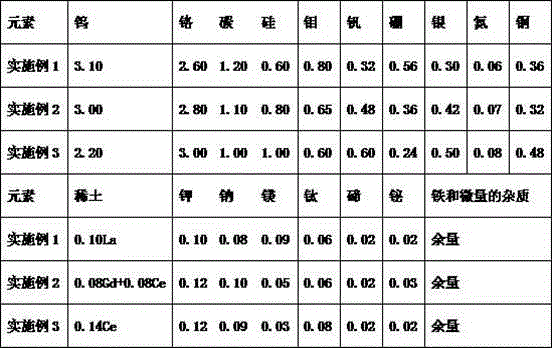

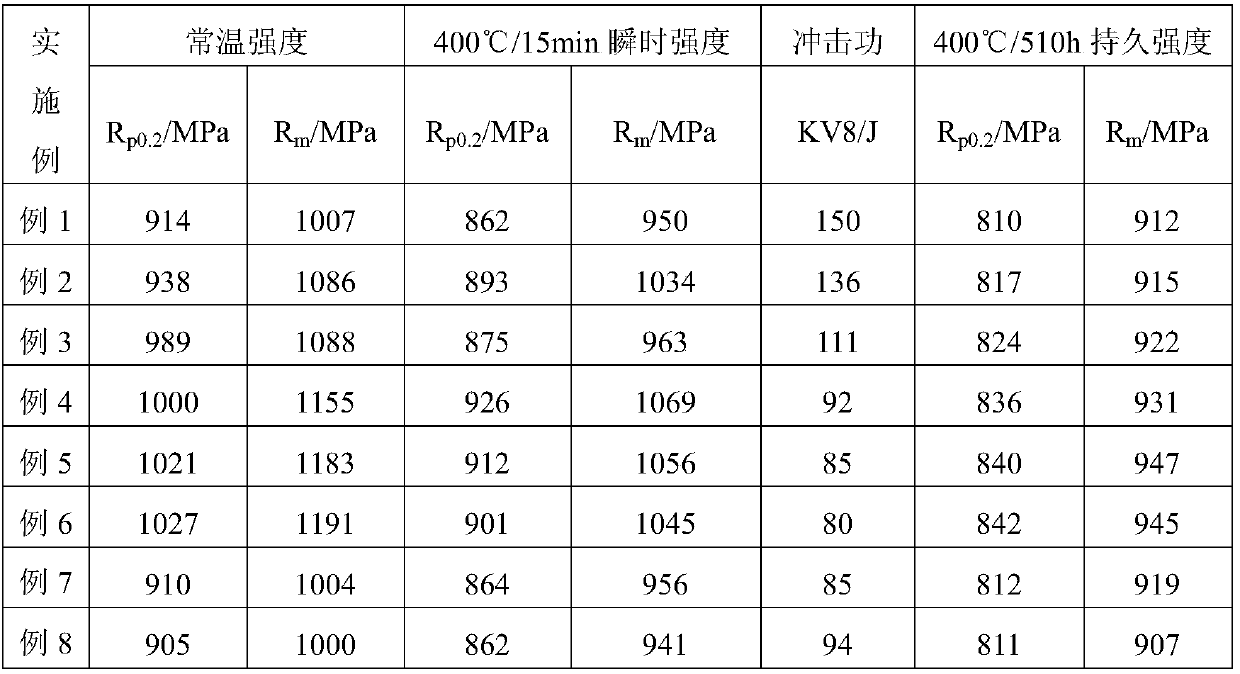

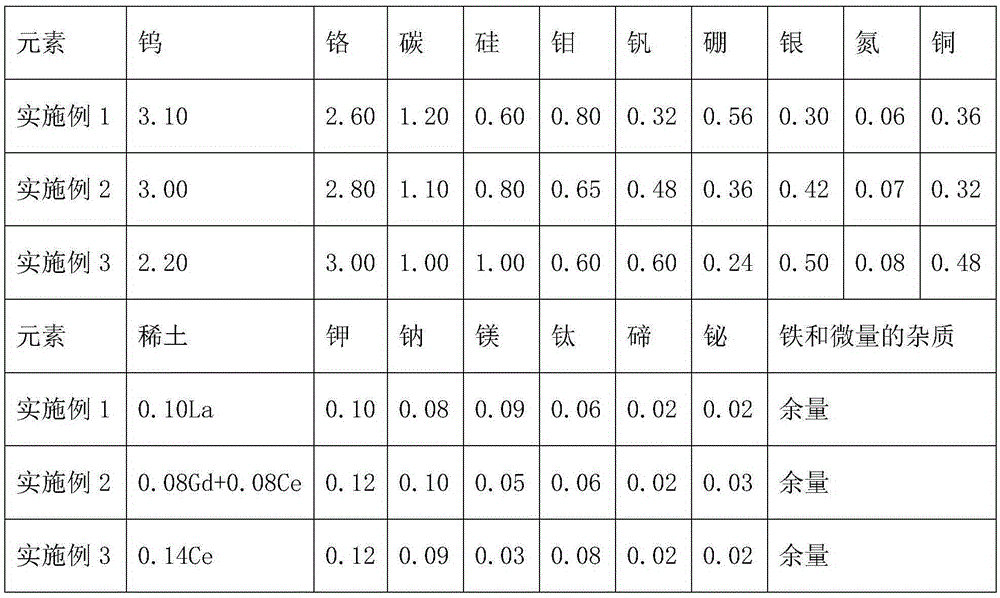

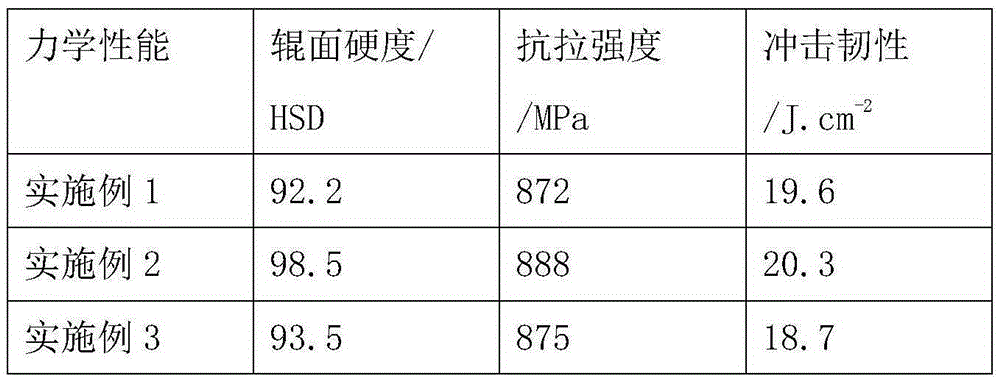

High-speed steel roll and preparation method thereof

The invention discloses a high-speed steel roll and a preparation method thereof, belonging to the technical field of steel rolling. Particularly, the high-speed steel roll comprises the following chemical compositions in percentage by mass: 2.00-3.20% of tungsten, 2.00-3.00% of chromium, 1.00-1.20% of carbon, 0.60-1.00% of silicon, 0.50-0.80% of molybdenum, 0.20-0.60% of vanadium, 0.20-0.60% of boron, 0.20-0.60% of silver, 0.05-0.10% of nitrogen, 0.20-0.60% of copper, 0.08-0.16% of rare earth, 0.04-0.10% of magnesium, 0.04-0.10% of titanium, 0.10-0.20% of potassium, 0.08-0.16% of sodium, 0.02-0.04% of tellurium, 0.02-0.04% of bismuth, and the balance of iron and inevitable trace impurities of which the content is less than 0.01%. According to the high-speed steel roll material disclosed by the invention, the macro-hardness of the roll surface has a qualitative leap; compared with the prior art, the high-speed steel roll material has the advantage that the tensile strength and impact toughness are greatly increased and improved.

Owner:山东格新精工有限公司

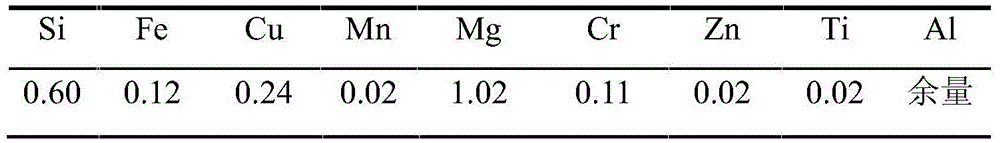

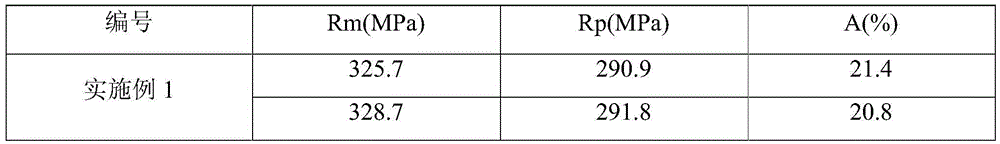

Technological method for carrying out solid solution and aging thermal treatment on 6061 aluminum alloy

ActiveCN105568187AGood mechanical propertiesReduce heat treatment energy consumption6061 aluminium alloyMetal

The invention discloses a technological method for carrying out solid solution and ageing treatment on a 6061 aluminum alloy, and belongs to the technical field of metal material thermal treatment. The technological method specifically comprises the following steps: (1) homogenizing treatment: carrying out homogenizing treatment and carrying out air-cooling to the room temperature while providing current to a 6061 aluminum alloy cast ingot; (2) thermal extrusion; (3) solid solution treatment: carrying out solid solution treatment and carrying out water-cooling at the room temperature while providing current to square billet; and (4) ageing treatment: carrying out the ageing treatment while providing current to the square billet. According to the technological method, the current intensity, the heating temperature and the heat preservation time of the homogenizing treatment, the solid solution treatment and the ageing treatment are reasonably controlled, so that a workpiece with excellent mechanical properties is finally obtained on the premise of remarkably reducing energy consumption of the thermal treatment, and therefore, the technological method is an aluminum alloy continuous solid solution and ageing treatment technological method which is suitable for quickly heating and reducing energy consumption, and is applied to industrial production.

Owner:NORTHEASTERN UNIV

Testing method for rapidly measuring decarburized layer after water passing

InactiveCN104359726AGuaranteed uniformityReduce heat treatment energy consumptionPreparing sample for investigationMaterial analysis by optical meansFast measurementMeasurement cost

The invention relates to a testing method for rapidly measuring a decarburized layer after water passing. The testing method comprises steps as follows: sample taking: bearing steel passing water is cut with a metallographic method to obtain a sample; sample preparation: the surface of the sample is ground and polished with the metallographic method; immersion corrosion: the ground and polished sample is immersed in a nitric acid and alcohol solution with the concentration of 3%, the sample is corroded, the corroded sample is cleaned and dried to display the texture structure of the bearing steel; and observation: the corroded sample is observed and measured under an optical microscope. By means of the method, a metallographic evaluating worker can be assisted in performing rapid judgment, normalizing heat treatment for obtaining a hot rolling texture for decarburized layer measurement is not required, and a laboratory can be assisted in rapidly completing the metallographic detection at a high speed; and energy consumption for heat treatment is reduced, environmental protection is facilitated, manual work is further saved, the measurement cost is reduced, the detection period is shortened, and the production efficiency is improved.

Owner:NANJING IRON & STEEL CO LTD

Heat pump type pressure gradient fruit vegetable heat treatment library

ActiveCN101919436BReduce heat treatment energy consumptionShorten the timeFood processingFruits/vegetable preservation by heatingThermodynamicsAir treatment

The invention discloses a heat pump type pressure gradient fruit vegetable heat treatment library. The library is composed of a library entry, a heat pump system, a circulation air system and a humidifying system, the library entry is divided into four parts of air treatment, air supply plenum, fruit vegetable heat treatment and return air plenum. The upper end and the lower end of the clapboard are respectively provided with three centrifugal fans and three pressure gradient fans, an air supply homogenizing plate and a return air floor plate are respectively arranged at the upper part and the lower part in the library, and a fruit vegetable heat treatment chamber is formed between the two plates. An air supply plenum chamber is formed between the air supply homogenizing plate and the upper top wall of the library entry, and a return air plenum chamber is formed between the return air floor plate and the lower bottom of the library entry. The condenser of the heat pump system is arranged in an air treatment chamber, a centrifugal humidifier is arranged above the right side of the clapboard, and the return air floor plate is placed with a fruit vegetable box. Pressure gradient air supply is adopted, so that treatment time can be reduced. The invention adopts heat pump heat source, the heat pump can supply 3-5 units of heat into the library while a compressor consumes every 1 unit electricity; compared with the electric heating method, fruit vegetable heat treatment energy consumption can be obviously reduced, and energy conservation effect of the system is obvious.

Owner:TIANJIN UNIV

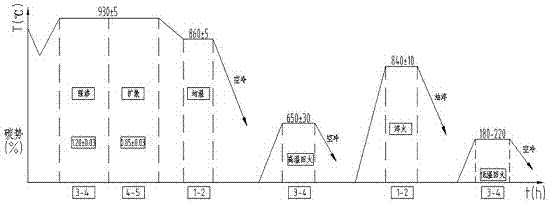

Composite carburization quenching technology for gear

InactiveCN103643200AImprove fatigue strengthImprove wear resistanceSolid state diffusion coatingFurnace typesHeavy dutyQuenching

A disclosed composite carburization quenching technology for a gear comprises the following steps: 1) performing strong carburization; 2) performing diffusion; 3) cooing to 560-580 DEG C, staying at the constant temperature for 1-2 h and cooling; 4) quenching and heating, wherein the first-stage quenching temperature is 865-870 DEG C and the second-stage quenching temperature is 835-845 DEG C; and 5) tempering with a temperature of 260-265 DEG C. The provided composite carburization quenching technology for the gear is reduced in heat processing energy consumption and helps to improve the performances of heavy-duty gears.

Owner:常熟市东风齿轮厂

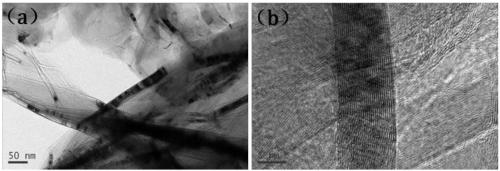

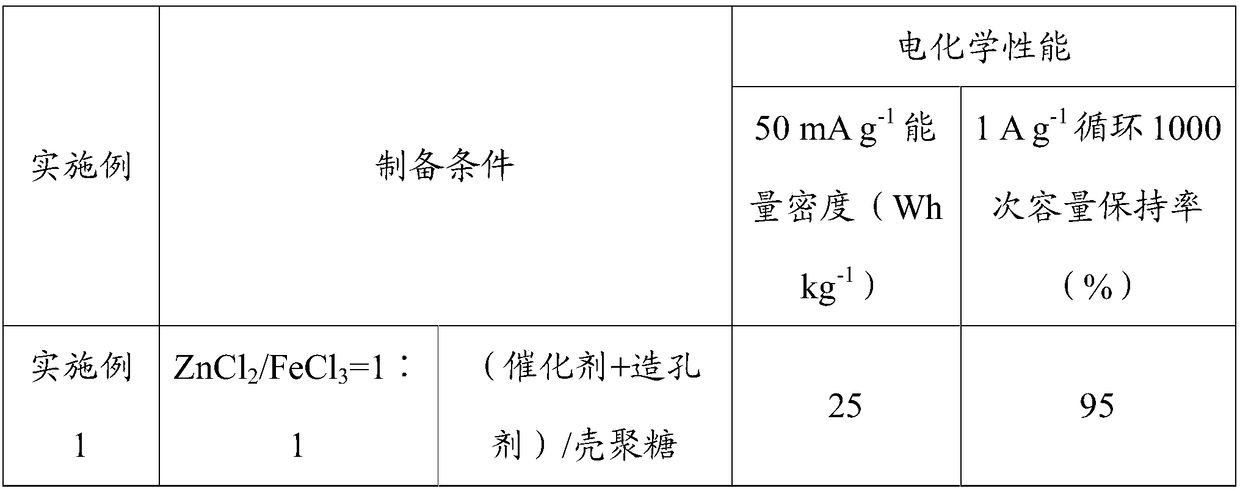

Lithium ion capacitor and its preparation method

ActiveCN106952736BSimple processReduce manufacturing costGraphiteHybrid capacitor electrodesCapacitancePorous carbon

The invention provides a lithium ion capacitor and a preparation method therefor. The lithium ion capacitor comprises a positive electrode material and a negative electrode material, wherein the positive electrode material is a porous carbon material, and the negative electrode material is a graphitized carbon material. The porous carbon material and the graphitized carbon material take a pore forming agent and / or catalyst and a carbon source as the raw materials, and are prepared through thermal treatment. The preparation method comprises the steps: assembling the negative electrode material and a lithium piece into a semi-battery, performing the circulation for three times under the condition of a 50 mA / g current, and carrying out the discharging till the voltage is 0.01V; disassembling the semi-battery to obtain a graphitized carbon negative electrode piece, in which lithium is embedded in advance; enabling the negative electrode piece with the lithium and the porous carbon positive electrode material to respectively serve as the negative electrode and the positive electrode of the lithium ion capacitor, and carrying out the assembling with electrolyte and a diaphragm to form the lithium ion capacitor. According to the invention, the positive electrode material is large in capacity, and the negative electrode material has a certain voltage platform, is large in capacity, is better in multiplying performance, and enables the performance of the capacitor to be excellent.

Owner:CENT SOUTH UNIV

Integral thermal-treatment processing method for closed type torsion beam of car

ActiveCN107460294AUniform tissueTaking into account strengthFurnace typesHeat treatment furnacesBench testEngineering

The invention discloses an integral thermal-treatment processing method for a closed type torsion beam of a car. The integral thermal-treatment processing method comprises the following steps of 1) blanking; 2) stamping; 3) thermal treatment; 4) laser welding; and 5) welding. The integral thermal-treatment processing method adopts an annealing slow-cooling process and removes processing stress, so that the texture of the torsion beam is uniform. The closed type torsion beam, produced by the integral thermal-treatment processing method, of the car has tensile strength being 700-750 MPa, Rp 0.2 reaching 600-650 MPa, elongation greater than or equal to 18%, excellent ductility and toughness, and gives consideration to strength of the torsion beam body. The fatigue life according to a bench test is greater than 0.2 million of times, durability is excellent, generation of fatigue cracks in an operating process can be inhibited to the greatest extent, production cost is effectively reduced, and production efficiency is improved. The integral thermal-treatment processing method solves the technical problem that the high-strength steel closed type torsion beam in the car industry cannot reach the standards, reduces the possibility that deformation appears in a torsion beam thermal treatment process, and reduces thermal treatment energy consumption.

Owner:天人汽车底盘(芜湖)股份有限公司

Differential-temperature heat treating method for roller

ActiveCN105296735AImprove hardness uniformityGood heart tissueFurnace typesHeat treatment furnacesHardnessHigh velocity

The invention discloses a differential-temperature heat treating method for a roller, and relates to the technical field of heat treating. The differential-temperature heat treating method includes the steps of a technological preparation stage, a preheating stage, a differential-temperature preheating stage, a high-speed temperature rising stage and a high-temperature heat preservation stage. According to the differential-temperature heat treating method, the preheating temperature is low and is 480 DEG C to 500 DEG C, the constant temperature before high-speed temperature rising is 800 DEG C to 850 DEG C, a stage-type temperature rising mode is adopted for the high-speed temperature rising stage, three temperature rising nodes exist, heat preservation is carried out for two minutes every time one temperature node is achieved, high-temperature heat preservation is divided two stages, and the heat preservation time and the temperature of the two stages are different. The roller prepared with the heat treating method has high hardness evenness and the good core microstructure, energy consumption of heat treatment can be reduced, and the production cost of an enterprise can be reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

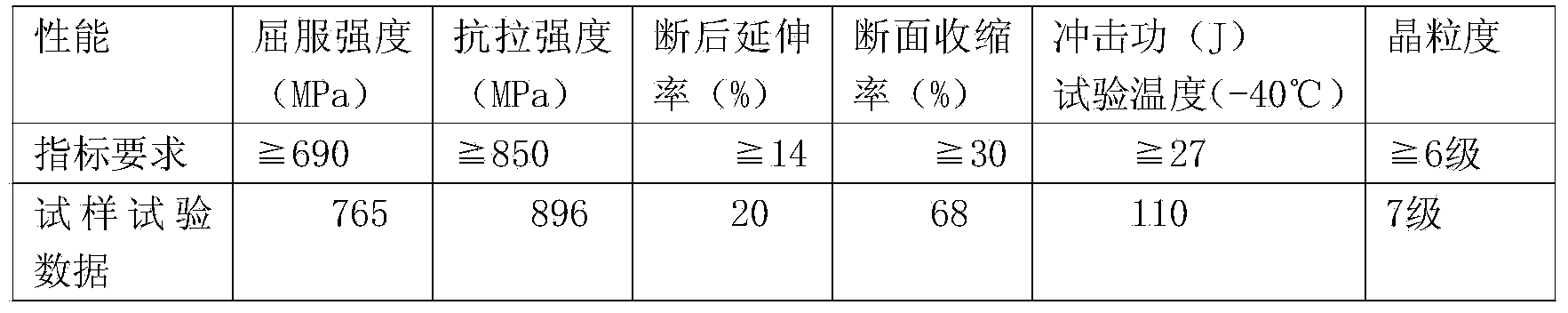

Heat treatment technology for forging coupler yoke

InactiveCN103710498AReduce heat treatment energy consumptionStable mechanical propertiesFurnace typesHeat treatment furnacesPerformance indexHeating furnace

The invention discloses a heat treatment technology for forging a coupler yoke. Coupler yoke forging steel is 25MnCrNiMoA low-alloy steel. The heat treatment technology comprises the following steps: (1) quenching, to be specific, putting the machined coupler yoke forging steel in a heating furnace, heating to 910-930 DEG C, carrying out heat preservation for 200 minutes, and then directly carrying out intense water cooling; and (2) tempering, to be specific, putting the quenched coupler yoke forging steel in a tempering furnace, heating to 530-570 DEG C, carrying out heat preservation for 220 minutes, and then carrying out water cooling. The heat treatment technology for forging the coupler yoke, provided by the invention, is reasonable in technological design and can be used for obtaining the coupler yoke which has a relatively stable microstructure and is balanced and stable in mechanical performance indexes.

Owner:HEBEI LUYOU RAILWAY LOCOMOTIVE & ROLLING STOCK PARTS

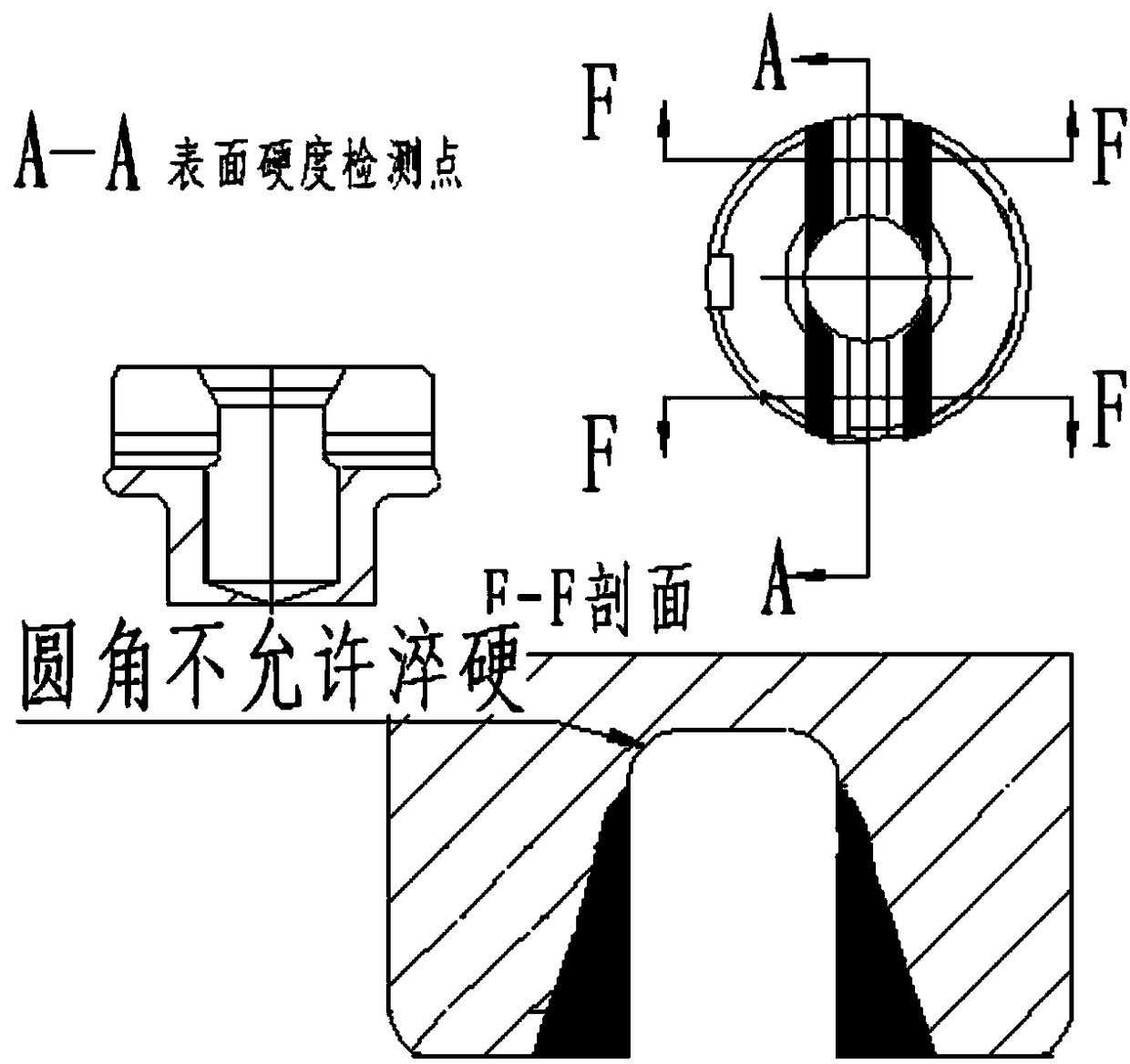

Induction heat treatment method for camshaft end piece

InactiveCN108823390AIncrease stiffnessIncrease shock loadIncreasing energy efficiencyFurnace typesEngineeringInduction hardening

The invention discloses an induction heat treatment method for a camshaft end piece. An induction heating apparatus with a magnetic field concentrating device is adopted to inductively quench and temper the notch and the outer circle of the camshaft end piece. The method includes the following steps: sleeving the induction coil of the induction heating device outside the notch and the outer circleof the camshaft end piece, performing heating under a certain direct-current voltage and a direct current, cooling the end piece by a quenching medium, keeping the temperature at a certain value to carry out tempering, and performing air cooling. The induction heat treatment method for the camshaft end piece improves the overall rigidity of the camshaft, reduces friction, makes the camshaft end piece withstand a high valve impact load, reduces the heat treatment energy consumption by 30%, makes the surface hardness and the hardened layer depth meet technical requirements of the product, and achieves the purposes of energy saving, emission reduction and consumption reduction.

Owner:上海上大热处理有限公司

Anti-fatigue manufacturing method of spiral bevel gear

ActiveCN103223577BConsistent resultsReduce heat treatment energy consumptionProcess systemsTechnology development

The invention relates to a novel composite surface-enhanced spiral bevel gear production process system based on a current anti-fatigue manufacturing method system and integrating induction quenching and gas nitriding. The invention aims to provide a composite surface-enhanced cyclo-palloid spiral bevel gear manufacturing method with heated precision of 4 to 6 levels and achieving the purpose that the theory contact zone meshed strength is meshed with carburizing and quenching strength. The invention aims to further provide a new spiral bevel gear production technology which can not only embody the current anti-fatigue high-end gear manufacturing method purpose, but also agree with the complete software and hardware match of a roadmap of heat treatment technology development in China.

Owner:天津市天瑞硬化工程有限公司

A kind of roller differential temperature heat treatment method

ActiveCN105296735BImprove hardness uniformityImprove mechanical propertiesFurnace typesHeat treatment furnacesTwo temperatureTemperature difference

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Heat treatment method for automobile transmission gear

ActiveCN104894506BAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method for preparing boracic low-alloy high-speed steel rolls

InactiveCN101623751BReduce heat treatment energy consumptionShort cycleFurnace typesHeat treatment furnacesRoom temperatureAlloy

The invention relates to a method for preparing boracic low-alloy high-speed steel rolls, which is characterized by comprising the following steps: firstly carrying out metal mold casting of the roll, wherein a roll body is made of boracic low-alloy high-speed steel, and a roll core is made of ductile cast iron; putting the roll into a heating furnace at the temperature of lower than 200 DEG C after rough machining, preserving heat for 1-3 hours, then heating to the temperature of 520-580 DEG C at the temperature rising speed of 15-25 DEG C per hour, and air cooling after heat preservation; and then, putting the roll into the heating furnace at the temperature of lower than 300 DEG C again, preserving heat for 1-2 hours, then heating to the temperature of 480-510 DEG C at the temperature rising speed of 28-40 DEG C per hour, cooling the furnace to the temperature of lower than 180 DEG C after heat preservation, and air cooling to the room temperature. The method not only has low energy consumption and a short heating processing period, but also has good use effect when being used for the heating processing of the boracic low-alloy high-speed steel roll.

Owner:BEIJING UNIV OF TECH

Overall Heat Treatment Processing Method of Enclosed Torsion Beam of Car

ActiveCN107460294BUniform tissueTaking into account strengthFurnace typesHeat treatment furnacesBench testEngineering

The invention discloses an integral thermal-treatment processing method for a closed type torsion beam of a car. The integral thermal-treatment processing method comprises the following steps of 1) blanking; 2) stamping; 3) thermal treatment; 4) laser welding; and 5) welding. The integral thermal-treatment processing method adopts an annealing slow-cooling process and removes processing stress, so that the texture of the torsion beam is uniform. The closed type torsion beam, produced by the integral thermal-treatment processing method, of the car has tensile strength being 700-750 MPa, Rp 0.2 reaching 600-650 MPa, elongation greater than or equal to 18%, excellent ductility and toughness, and gives consideration to strength of the torsion beam body. The fatigue life according to a bench test is greater than 0.2 million of times, durability is excellent, generation of fatigue cracks in an operating process can be inhibited to the greatest extent, production cost is effectively reduced, and production efficiency is improved. The integral thermal-treatment processing method solves the technical problem that the high-strength steel closed type torsion beam in the car industry cannot reach the standards, reduces the possibility that deformation appears in a torsion beam thermal treatment process, and reduces thermal treatment energy consumption.

Owner:天人汽车底盘(芜湖)股份有限公司

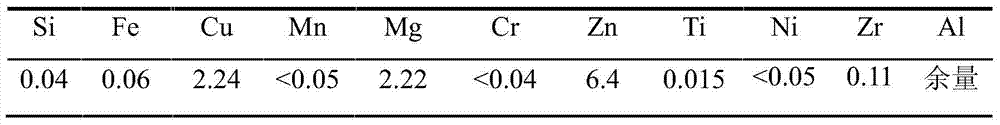

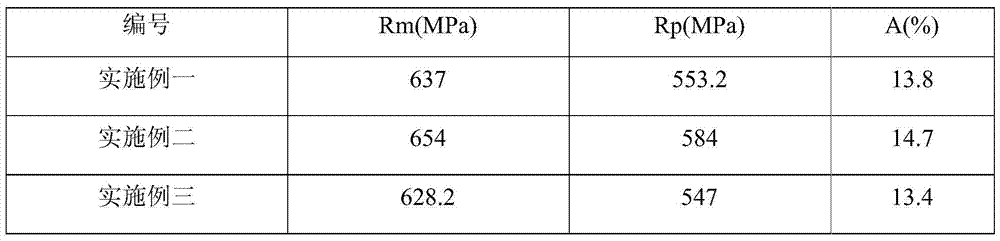

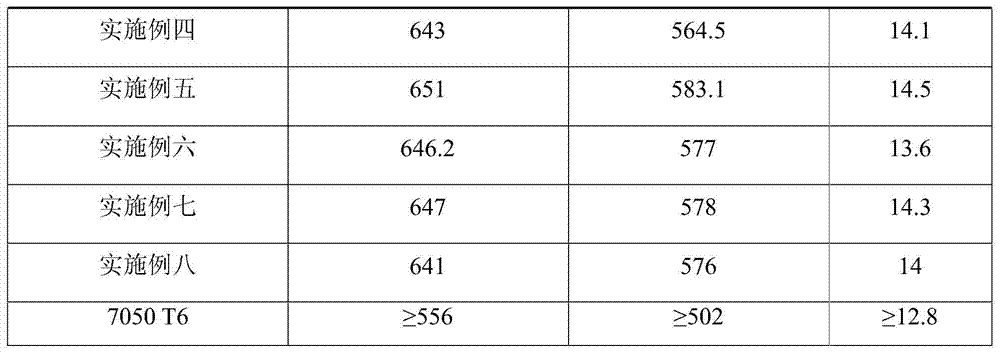

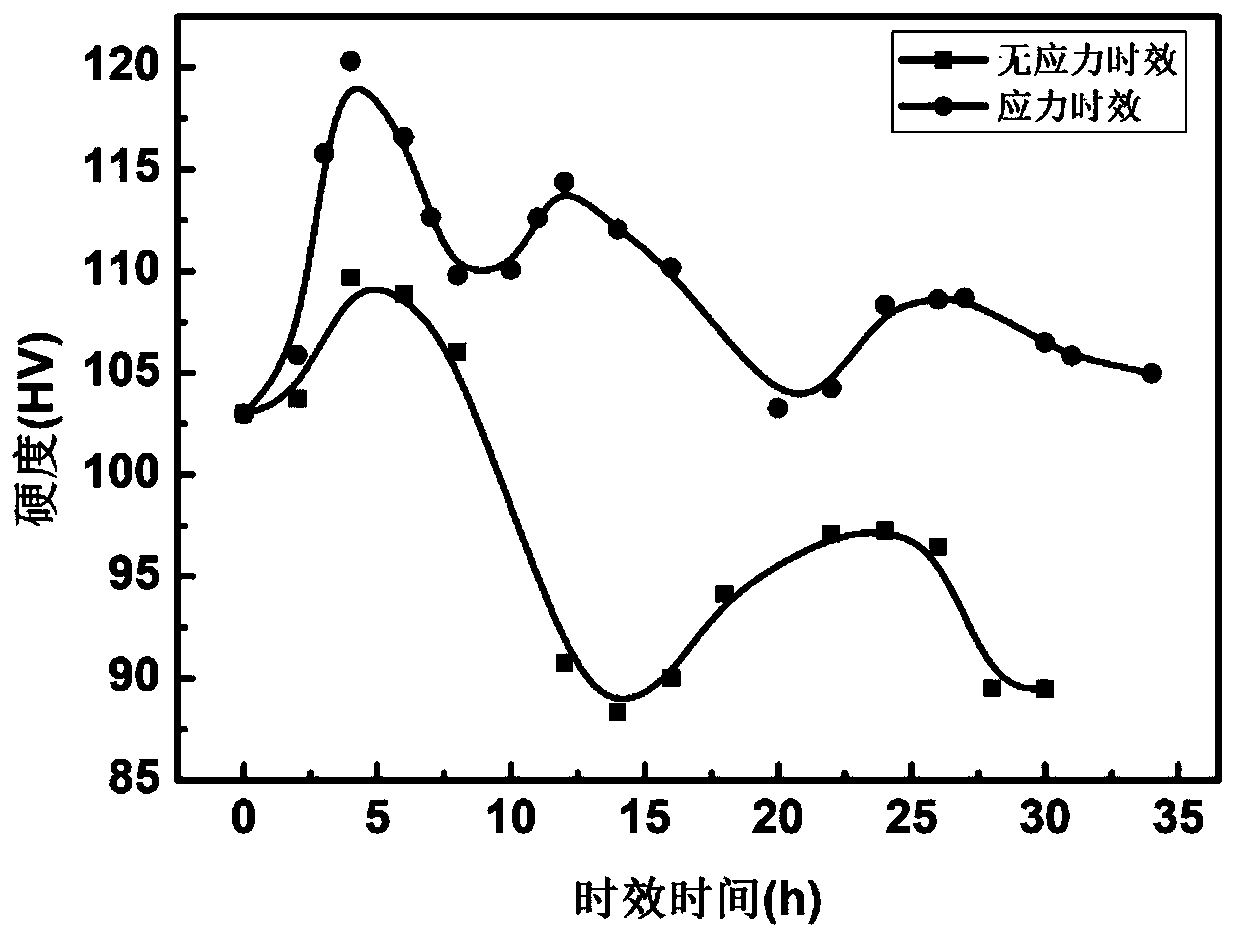

A kind of process method of current solution aging heat treatment of 7050 aluminum alloy

ActiveCN105543743BImprove mechanical propertiesReduce heat treatment energy consumptionMetallic materialsAlternating current

A current solid solution aging heat treatment process method for 7050 aluminum alloy, which belongs to the technical field of metal material heat treatment and specifically includes: (1) Homogenization treatment: while passing direct current into the 7050 aluminum alloy ingot, homogenization treatment is performed, and air cooling is carried out to Room temperature; (2) Hot extrusion: (3) Solution treatment: While the billet is supplied with alternating current, solution treatment is performed, and water cooling is performed at room temperature; (4) Aging treatment: While the billet is supplied with alternating current, it is processed Time processing. The process method of the present invention reasonably controls the heating temperature and holding time of current intensity, homogenization, solid solution treatment and aging treatment, and obtains significant solid solution strengthening effect on the premise of significantly reducing heat treatment energy consumption, and finally obtains excellent mechanical properties. Workpieces used in industrial production.

Owner:NORTHEASTERN UNIV LIAONING

Induction heating tempering treatment method

InactiveCN112813235AEasy to operateAvoid sequence requirements before and after heat treatmentFurnace typesIncreasing energy efficiencyTemperingEngineering

The invention relates to an induction heating tempering treatment method, and belongs to the technical field of roller manufacturing. A roller to be subjected to tempering treatment is locally heated by an electromagnetic induction coil to be subjected to tempering treatment. The induction heating tempering treatment method comprises the following steps that A, the quenched roller rotates at a certain speed; B, the electromagnetic induction coil is operated to conduct multi-stage induction heating tempering on local parts of the roller, wherein the operation speed of the electromagnetic induction coil is 50-100 mm / min, and the final target heating temperature is 200-600 DEG C; and C, air cooling is conducted, and then the roller subjected to tempering treatment is machined into a finished product. According to the induction heating tempering treatment method, the multiple local parts, having different technical indexes, of the roller are subjected to tempering treatment through the induction heating tempering heat treatment method, the heat treatment state and form and location tolerance of other parts are not affected, and operability is higher. Compared with an overall heating tempering treatment mode, the heat treatment energy consumption is greatly reduced, the heat treatment energy consumption is saved by 50% or above, and the production cost of the roller is remarkably reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Bucket tooth shell mold casting method

ActiveCN111408689BReduce usageReduce heat treatment energy consumptionFoundry mouldsFoundry coresInsulation layerThermal insulation

The invention discloses a casting method for a bucket tooth shell mold applied in the casting field. The method includes sand box molding and vibratory pouring. The sand box molding includes steps such as upper and lower box molding, box closing, and covering insulation layer; a shell mold and a sealing shell with a thickness not greater than 3mm are made in a horizontal metal mold, and the upper metal mold is removed. , replace it with a box body, check the shell shape, and repair the local unformed parts with coated sand to ensure that the sand box is vacuumed and air-tight. Add steel shots to the box, cover it with agricultural film, vacuumize it, and demould it from the lower metal mold to complete the shape of the upper and lower box; lower the core to close the box, and cover the top surface and surroundings of the sand box with quartz sand or insulation cotton insulation layer. The sand box is in a vacuum state during pouring, vibrates immediately after pouring, and stops vibrating before the vacuum is withdrawn. By adopting the casting method of the method, the amount of coated sand used is greatly reduced, the as-cast crystal grains of the wear-resistant parts are refined, the generation of cracks is avoided, and the energy consumption of heat treatment is reduced.

Owner:HANDAN HUIQIAO COMPOSITE MATERIAL TECH CO LTD

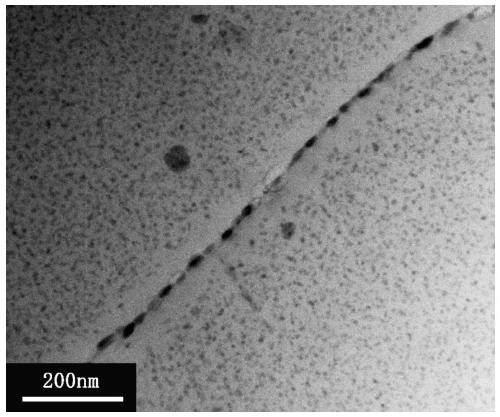

An Aging Process for Improving the Microstructure and Properties of 7n01 Aluminum Alloy

ActiveCN109423586BSimple heat treatment processReduce heat treatment energy consumptionSolution treatmentManganese

The invention relates to the field of production of aluminum alloys, in particular to an aging process for improving the 7N01 aluminum alloy structure and performance. Firstly, a 7N01 aluminum alloy which is in an extrusion state or in a rolled state and is subjected to solution treatment is subjected to natural aging treatment, then the 7N01 aluminum alloy is subjected to heat preservation at a certain temperature, and tensile stress is applied while heat preservation. Through the process, the aging separation process of the 7N01 aluminum alloy is improved. The applicable 7N01 aluminum alloycomponents comprise, by mass, 4.0-5.0% of zinc, 1.0-2.0% of magnesium, smaller than or equal to 0.20% of copper, 0.20-0.70% of manganese, smaller than or equal to 0.30% of chromium, smaller than or equal to 0.25% of zirconium, smaller than or equal to 0.20% of titanium, smaller than or equal to 0.10% of vanadium, and the balance aluminum and inevitable impurities. The tensile stress is added in the aging process, and by improving the matrix precipitate and grain boundary precipitate morphologies of the 7N01 aluminum alloy, the performance of the 7N01 aluminum alloy is remarkably improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Energy-saving stainless steel wire hydrogen retreat furnace

InactiveCN101988148BSmall hearthReduce heat transferFurnace typesHeat treatment furnacesHydrogenMetallurgy

The invention discloses an energy-saving stainless steel wire hydrogen retreat furnace, which comprises a blow-drying pre-heating section, a heating section and a cooling section in turn from left to right. The left end of the blow-drying pre-heating section is connected with an exhaust pipe, the right end is connected with a high-temperature air pipe, and the middle is horizontally provided witha pre-heating section steel pipe; a high-temperature ceramic pipe of which the outer circle is sleeved with a high-temperature stainless steel pipe is horizontally arranged on the cooling section at a part coaxial with the pre-heating section steel pipe; a cooling section steel pipe of which the outer circle is sleeved with multiple heat pipe heat exchanger evaporation sections is horizontally arranged on the cooling section at a part coaxial with the high-temperature ceramic pipe; and the upper part of the cooling section is provided with a heat pipe heat exchanger condensation section of which the left end is connected with the high-temperature air pipe and the right end is connected with a fan. As the high-temperature stainless steel pipe is used as an electric heating element and the heat pipe heat exchanger recycles the waste heat of the cooling section, the heat efficiency is improved; and as the heating pipe is externally covered by high-temperature resistant insulating material, the service life of the high-temperature pipe is greatly prolonged.

Owner:江西华立金属制品有限公司

High temperature resistant oil well pipe for thermal recovery well and its manufacturing method

ActiveCN107287499BLow costSolve the technical problem of strength heat loss failureChemical compositionRoom temperature

The invention discloses a high-temperature-resistant oil well pipe used for a thermal recovery well and a manufacturing method for the oil well pipe. Chemical composition in steel comprises, by weight, 0.36%-0.60% of C, 0.46%-0.70% of Si, 1.60%-1.80% of Mn, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 1.6%-1.8% of Cr, 0.01%-0.03% of Nb, 0.01%-0.03% of Ti, and the balance Fe and unavoidable impurities. The heating temperature for a round billet is 1240-1300 DEG C, the pipe manufacturing temperature is 1050-1150 DEG C, isothermal quenching heat treatment is conducted on a molded steel pipe, the molded steel pipe is subjected to heat preservation for 4-15 s at the temperature of 980-1000 DEG C and quickly cooled with the cooling speed being greater than 130 DEG C per second, the temperature is maintained for 20-40 min after the molded steel pipe is cooled to the temperature of 200-300 DEG C, and then the steel pipe is cooled to the room temperature. The manufactured high-temperature-resistant oil well pipe used for the thermal recovery well has excellent high temperature creep resistant and intensity attenuation resistant properties.

Owner:ANGANG STEEL CO LTD

A kind of high-speed steel roll and preparation method thereof

The invention discloses a high-speed steel roll and a preparation method thereof, belonging to the technical field of steel rolling. Particularly, the high-speed steel roll comprises the following chemical compositions in percentage by mass: 2.00-3.20% of tungsten, 2.00-3.00% of chromium, 1.00-1.20% of carbon, 0.60-1.00% of silicon, 0.50-0.80% of molybdenum, 0.20-0.60% of vanadium, 0.20-0.60% of boron, 0.20-0.60% of silver, 0.05-0.10% of nitrogen, 0.20-0.60% of copper, 0.08-0.16% of rare earth, 0.04-0.10% of magnesium, 0.04-0.10% of titanium, 0.10-0.20% of potassium, 0.08-0.16% of sodium, 0.02-0.04% of tellurium, 0.02-0.04% of bismuth, and the balance of iron and inevitable trace impurities of which the content is less than 0.01%. According to the high-speed steel roll material disclosed by the invention, the macro-hardness of the roll surface has a qualitative leap; compared with the prior art, the high-speed steel roll material has the advantage that the tensile strength and impact toughness are greatly increased and improved.

Owner:山东格新精工有限公司

A method of heat treatment of wood under high pressure and humidity

ActiveCN105563581BImprove uniformityGood colorPressure impregnationWood impregnation detailsPulp and paper industryHigh pressure

Disclosed is a hot and humid high-pressure wood heat treatment method. Wood is treated through a pressure tank, and the pressure tank is put in hot oil, so that the airtight effect of a heat treatment process is guaranteed, and spontaneous ignition cannot occur even though the heat treatment temperature reaches 220 DEG C; a hot oil pool is adopted so that the effect that the temperature is kept consistent all the time in the heat treatment process can be guaranteed, and accordingly the uniformity of wood heat treatment is improved; the moisture content of the wood before treatment is adjusted to saturated water content and always kept in the state of the saturated water content and the wood is always kept in the environment of saturated steam before drying treatment in the step (5); under the action of water molecules, the heat treatment time can be effectively shortened, and the energy consumption of heat treatment is reduced; nutrient substances in the wood are more thoroughly degraded; and the color and luster of the treated wood are more uniform, the wood can be prevented from being cracked in the heat treatment process, and the quality of the heat-treated wood is effectively improved.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com