Energy-saving stainless steel wire hydrogen retreat furnace

A stainless steel wire, energy-saving technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of reduced cooling effect, no heat recovery in the cooling section, and easy formation of scale, so as to reduce heat treatment energy consumption and save electric heating load , The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

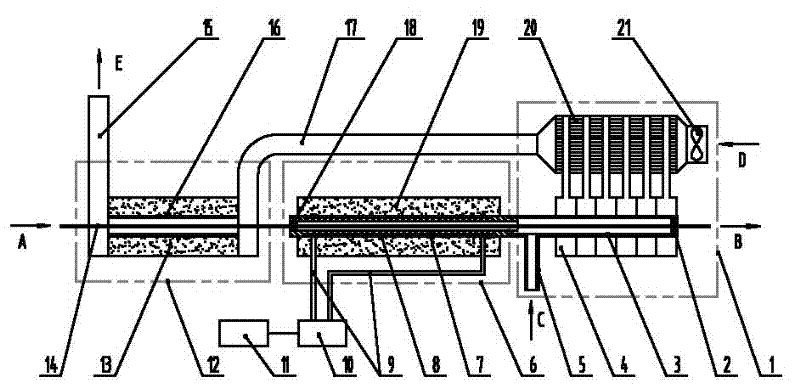

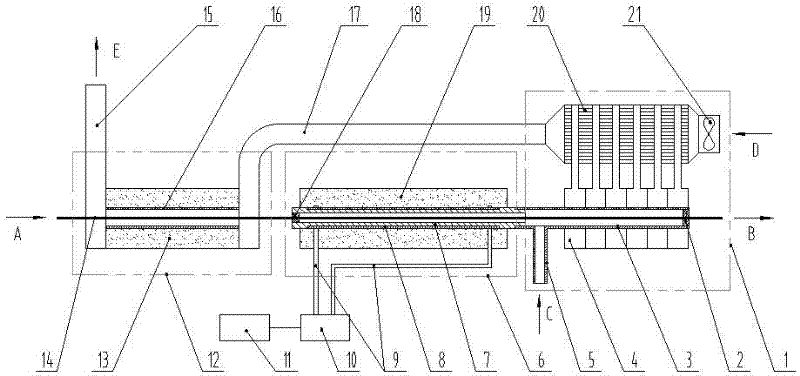

[0015] An energy-saving stainless steel wire hydrogen annealing furnace of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, in an energy-saving stainless steel wire hydrogen annealing furnace of the present invention, the stainless steel wire 14 passes through the blowing preheating section 12, the heating section 6 and the cooling section 1 horizontally from left to right in sequence, wherein the blowing preheating The left end of the section 12 is connected to the exhaust pipe 15, the right end is connected to the high-temperature air pipe 17, and a preheating section steel pipe 16 is placed horizontally in the middle; A high-temperature ceramic tube 7 with a high-temperature stainless steel tube 8, wherein the two ends of the high-temperature stainless steel tube 8 are respectively connected to electrodes 9 of a power supply cabinet 10 controlled by a control cabinet 11; the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com