Water-cooling premixed combustion method and device

A premixed combustion and water cooling technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of large furnace size and large NOx emissions, and achieve the effects of small furnace, reduced NOx emissions, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a water-cooled premixed combustion method, comprising the following steps:

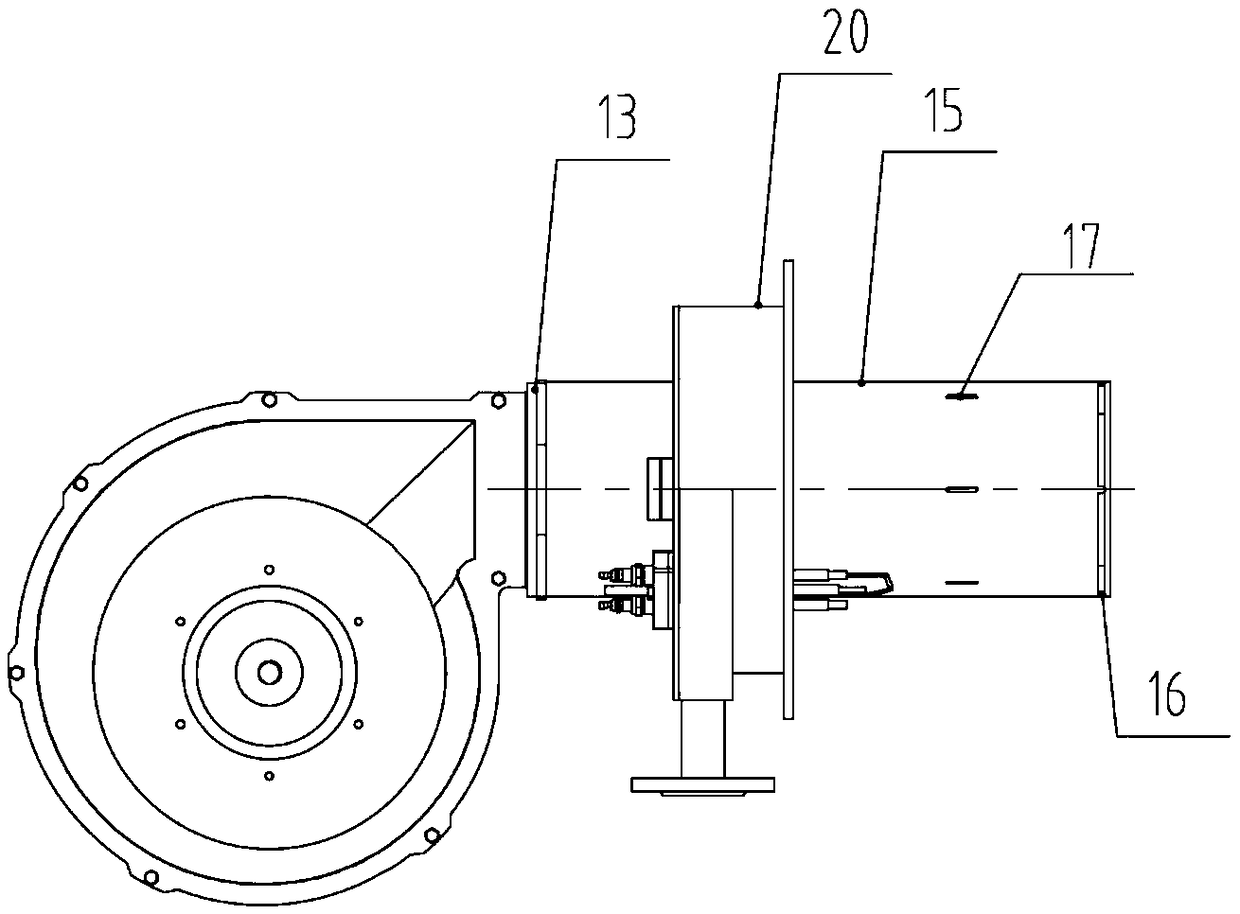

[0033] S1, the burner 13 extends into the interior of the furnace 14 to form an annular combustion tube 15, and the gas and air are premixed in the annular combustion tube 15 to form a mixed gas;

[0034] S2, the mixed gas is ejected through the end outer wall of the annular combustion tube 15, and the air velocity is greater than the combustion velocity;

[0035] S3, the mixed gas burns close to the water wall 9 to form a main flame.

[0036] Different from the traditional water-cooled premixed combustion method, in this embodiment, the mixed gas in the burner 13 is sprayed from the end outer wall of the annular combustion cylinder 15, and the speed of the jetted air flow is greater than the combustion speed, and the mixed gas is close to the water-cooled wall 9 burn to form the main flame. Not only can the combustion flame be stabilized through the water wall 9, so ...

Embodiment 2

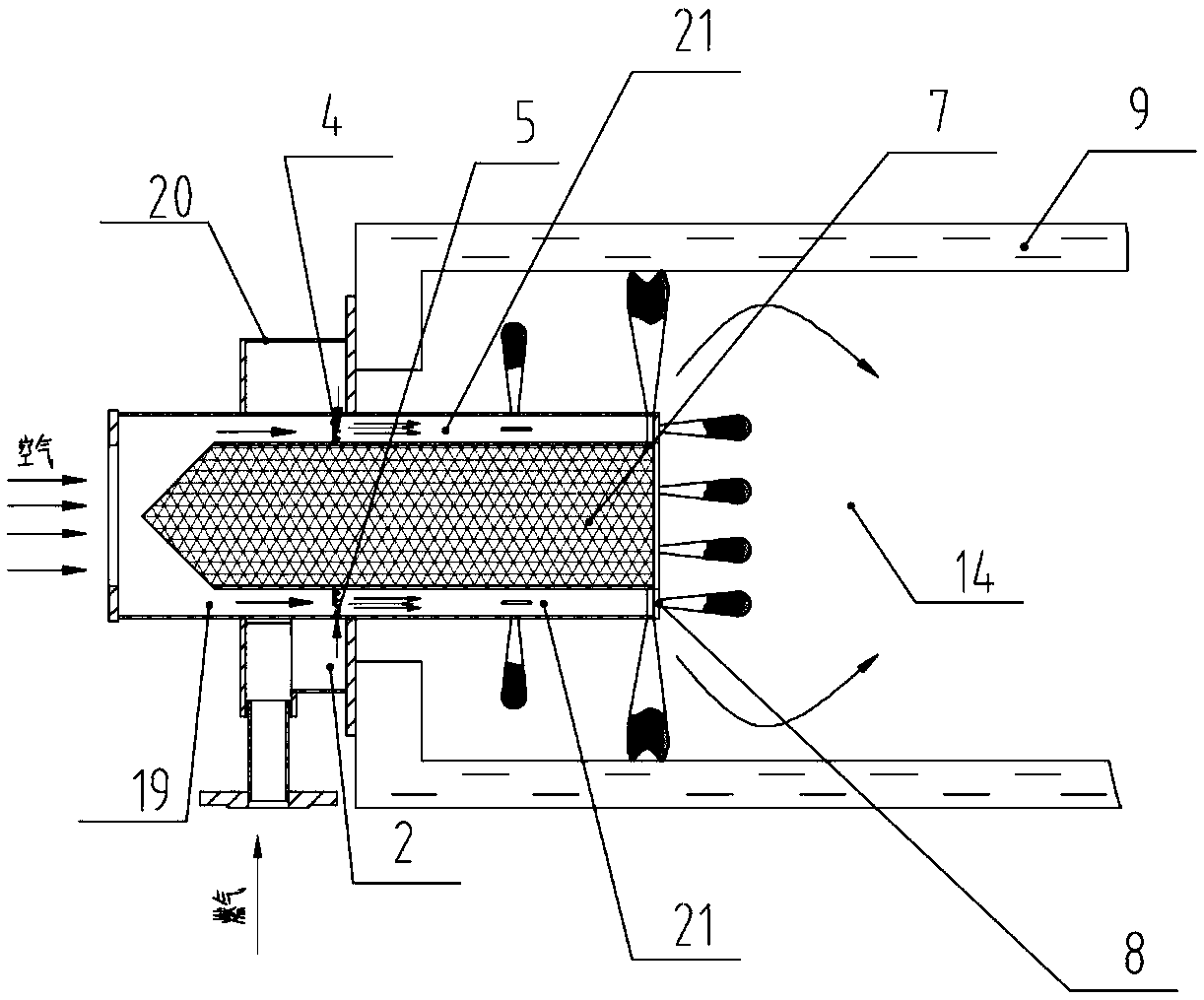

[0040] Such as Figure 1-3 As shown, this embodiment provides a water-cooled premixed combustion device, including a burner 13 and a furnace 14 , and the burner 13 extends into the furnace 14 to form an annular combustion tube 15 . The front end of annular combustion tube 15 is provided with air inlet and gas inlet, and air and combustion gas form mixed gas in annular combustion tube 15, and the end outer wall of annular combustion tube 15 is provided with the outlet hole 16 of mixed gas. The mixed gas is sprayed out from the outlet hole one 16 to form a main flame, and the main flame is perpendicular to the annular combustion tube 15 . The inner wall of the furnace 14 is a water-cooled wall 9, and the mixed gas burns close to the water-cooled wall 9 to form a main flame. The opening shape of air outlet one 16 can be annular seam, circular hole, square hole etc.

[0041] When the mixed gas is ejected from the outlet hole one 16, the air velocity of the mixed gas is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com