Heat pump type pressure gradient fruit vegetable heat treatment library

A differential pressure, fruit and vegetable technology, applied in heating preservation of fruits/vegetables, food processing, etc., can solve the problem of lack of commercial application of professional heat treatment equipment, achieve significant system energy saving, improve heat treatment quality, and reduce water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

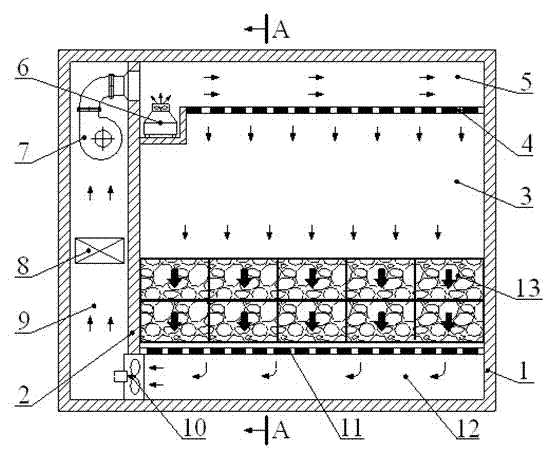

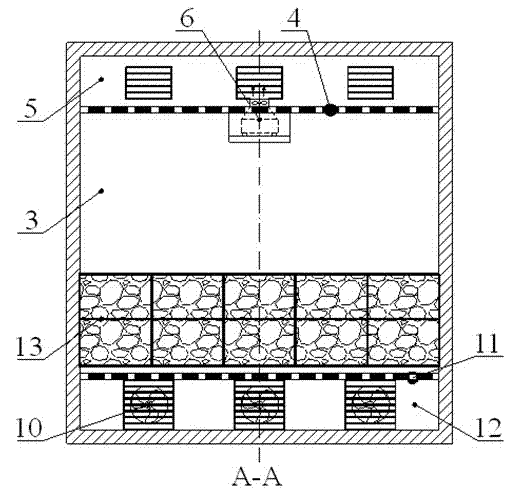

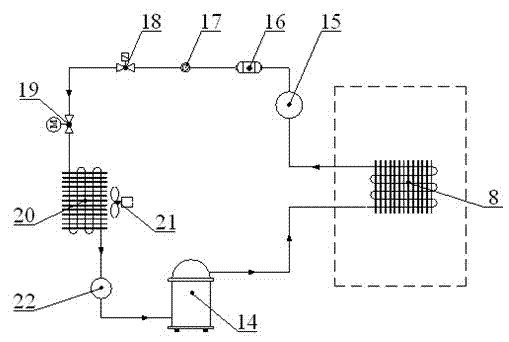

[0015] The working principle and system structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The heat pump type differential pressure fruit and vegetable heat treatment storage is composed of storage body, heat pump, circulating air, humidification and other systems. The storage body is divided into four parts: air treatment chamber, air supply static pressure chamber, fruit and vegetable heat treatment chamber and return air static pressure chamber. The storage body 1 is divided into two parts by a partition 2, and three centrifugal fans 7 and three differential pressure fans 10 are respectively installed on the upper and lower ends of the partition to form a circulating air system. The upper part of the storage body 1 is provided with an air supply equalizer 4, and the lower part is provided with a return air floor 11, and the fruit and vegetable heat treatment chamber 3 is formed between the air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com