Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

386results about How to "Improve heat treatment effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

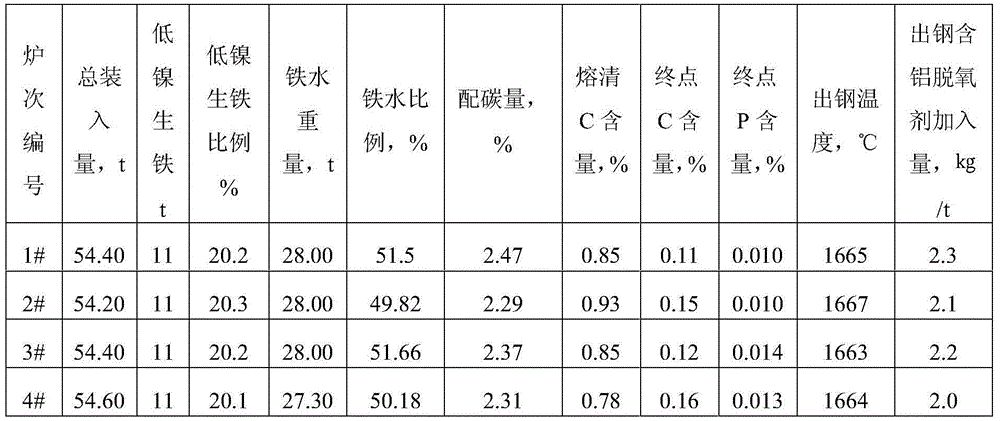

CrNiMo high-strength pinion steel and preparation method thereof

ActiveCN104372258AImprove heat treatment effectGuaranteed mechanical propertiesProcess efficiency improvementPinionUltimate tensile strength

The invention relates to a CrNiMo high-strength pinion steel and a preparation method thereof. The pinion steel comprises the following chemical components in percentage by mass: 0.19%-0.25% of C, 0.17%-0.37% of Si, 0.70%-1.00% of Mn, at most 0.030% of P, at most 0.030% of S, 0.85%-1.25% of Cr, 0.40%-0.70% of Ni, 0.30%-0.40% of Mo, 0.015%-0.050% of Al, at most 2.5*10<-4>% of H, 30*10<-4>%-80*10<-4>% of N, at most 15*10<-4>% of T.O, and the balance of Fe and inevitable impurities. The invention also provides a preparation method of the pinion steel. The nickel molybdenum alloy is added to improve the heat treatability of the material, thereby ensuring the mechanical properties of the material. The hardenability of the material is enhanced, and the material satisfies the performance requirements for large module pinions.

Owner:SHANDONG IRON & STEEL CO LTD

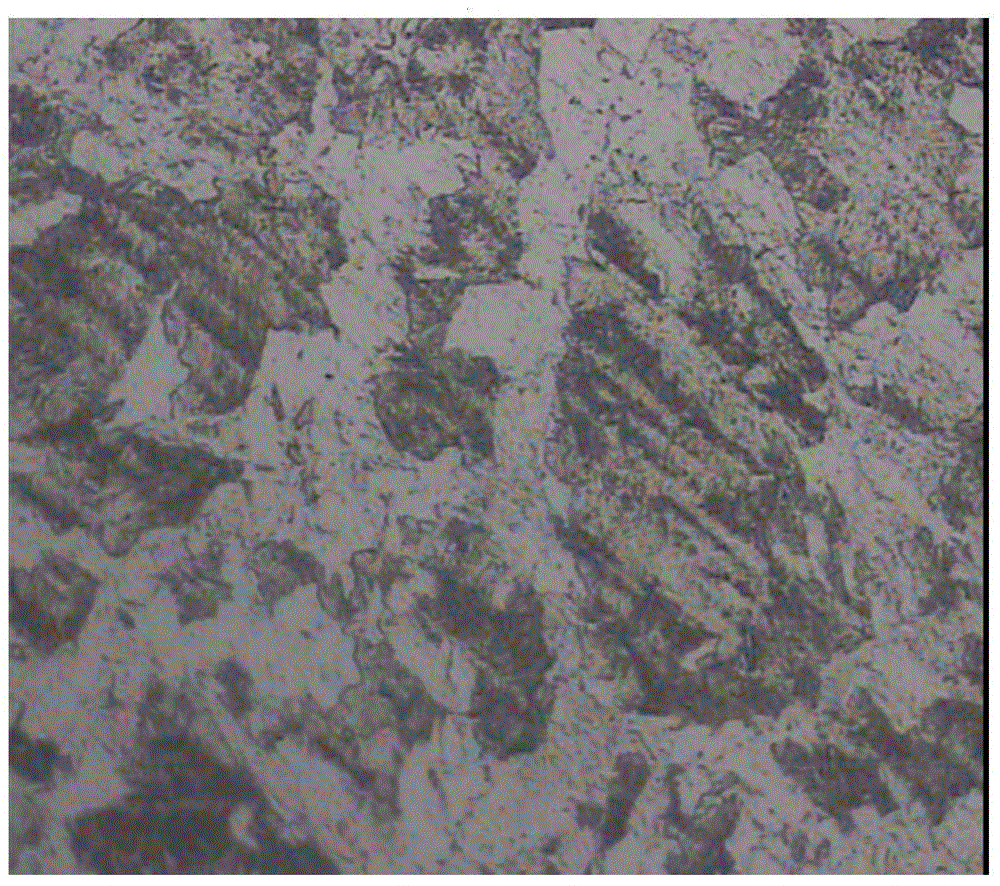

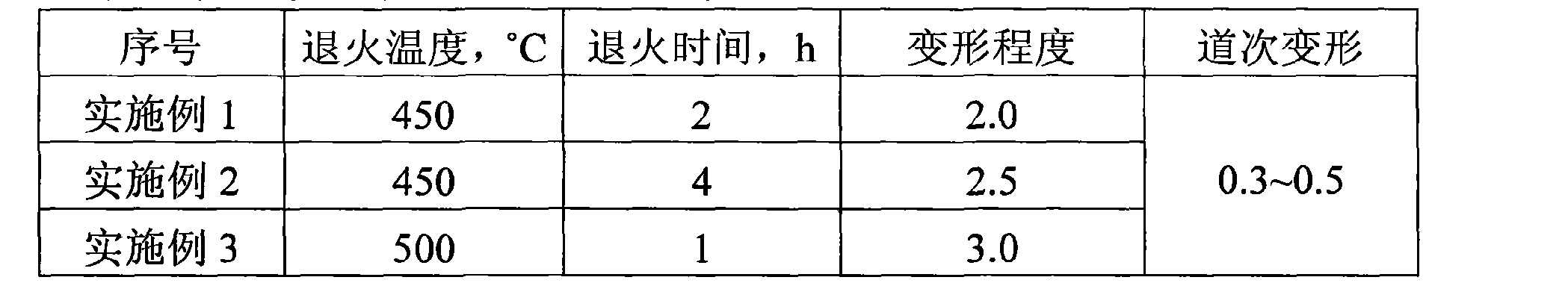

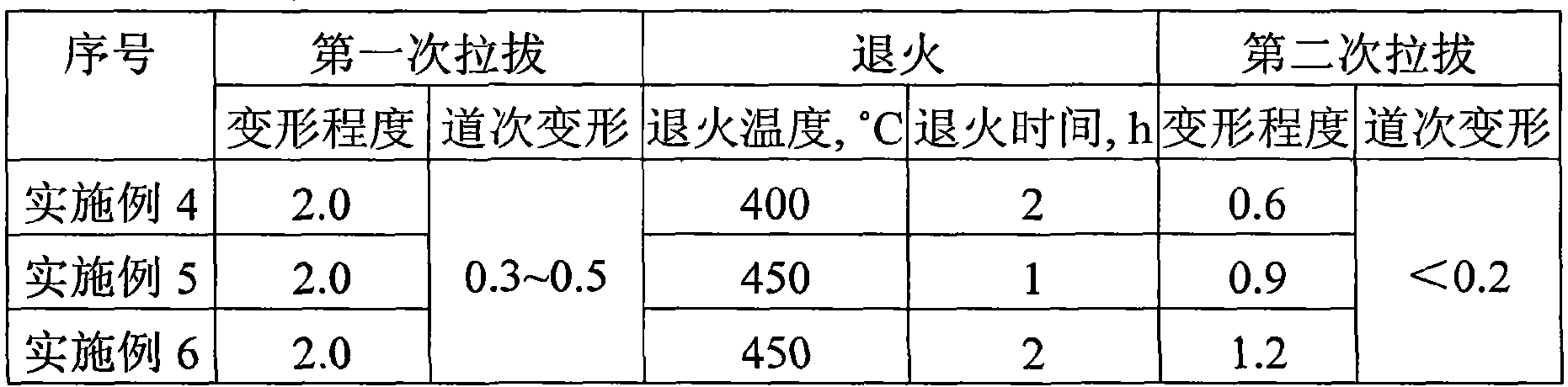

Cu-Cr-Zr alloy preparation technology for contact wire

The invention discloses a process for preparing Cu-Cr-Zr alloys applicable to contact lines. The process comprises the following steps that alloys comprising 0.30 to 0.50 percent of Cu, 0.10 to 0.15 percent of Cr, 0.01 to 0.02 percent of Zr and Si are melt in a vacuum induction furnace, wherein alloy elements, namely Cr, Zr and Si, are added by master alloys; fine casting-state crystal grains and oversaturated matrix tissues having secondary dendritic crystal spaces are obtained by controlling solidification velocity and cooling velocity; rolling in fit, drawing deformation and annealing thermal treatment to the fine casting-state crystal grains and oversaturated matrix tissues are carried out so as to control deformation degrees and parameters for the thermal treatment; and the strain-hardening effect and the precipitation strengthening effect are organically combined. Therefore, the alloys have the advantages of excellent tensile strength, electrical conductivity and high-temperature resistant softening capacity and lower cost under the conditions of simplified process and the simpler apparatus and components, and are applicable to industrial production.

Owner:邢台鑫晖铜业特种线材有限公司 +3

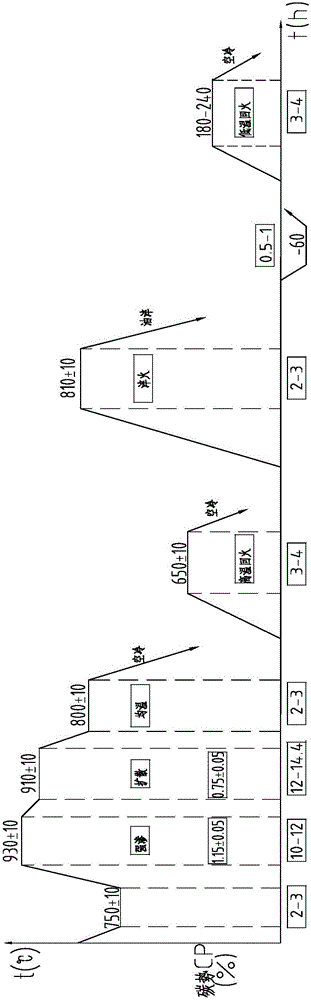

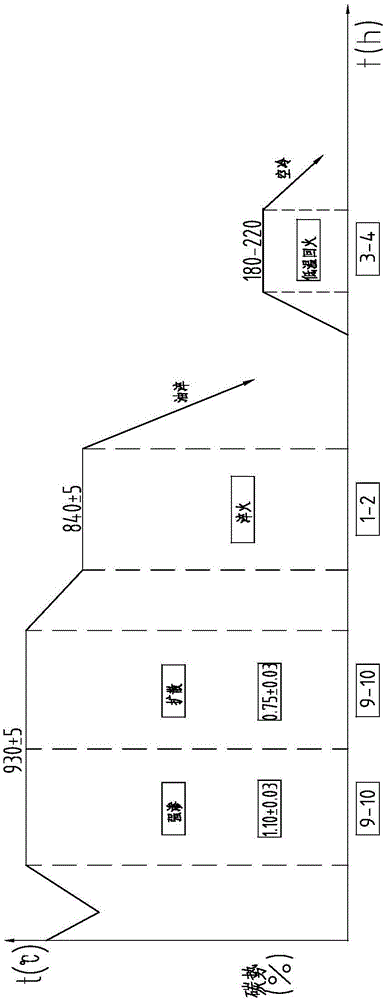

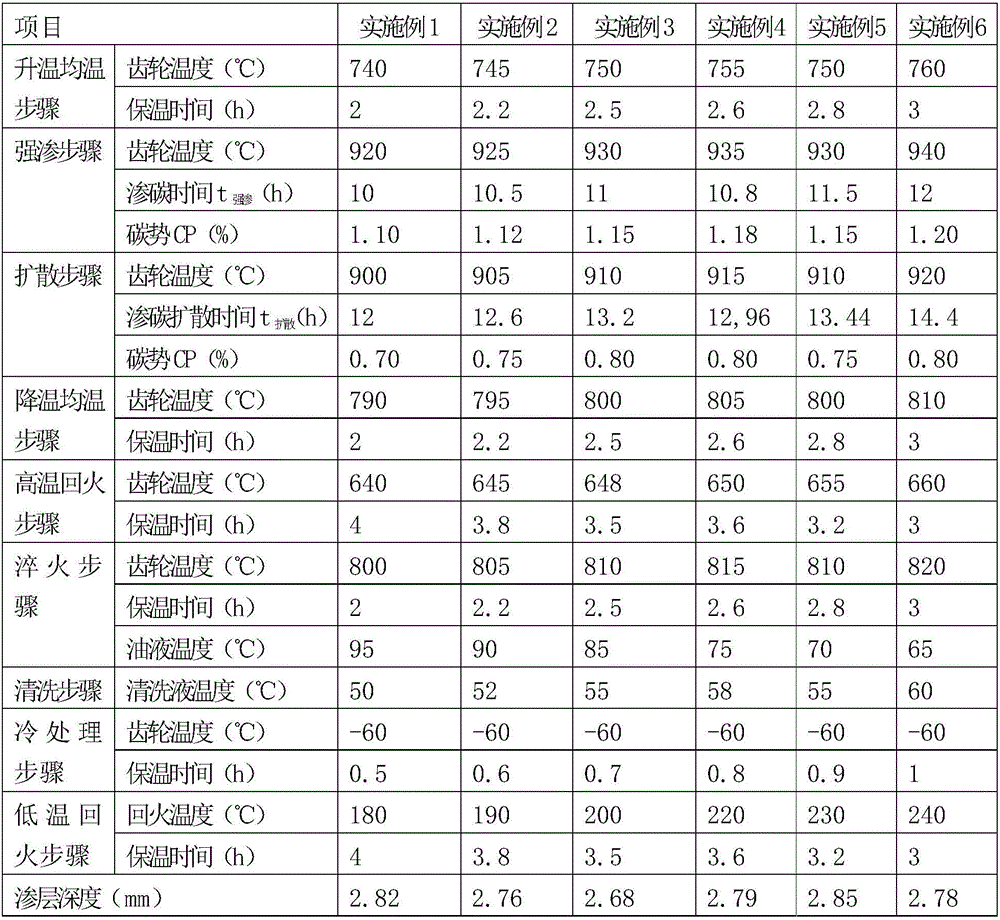

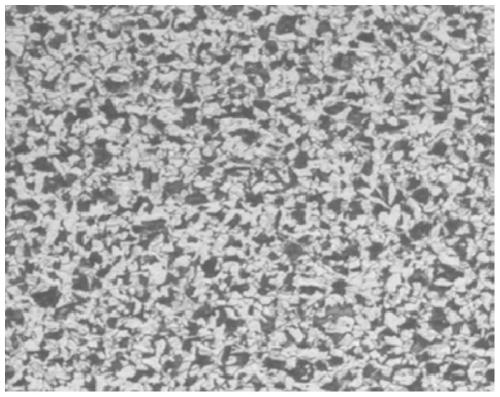

Carburizing and quenching method of low-speed heavy-duty gear

ActiveCN106756753AReduce carbon contentReduce carburizing potentialSolid state diffusion coatingFurnace typesCold treatmentLow speed

The invention relates to a carburizing and quenching method of a low-speed heavy-duty gear. The carburizing and quenching method comprises the steps of (1) temperature increase and temperature uniformization; (2) strong carburizing; (3) diffusion; (4) temperature decrease; (5) high-temperature tempering; (6) quenching; (7) cold treatment; and (8) low temperature tempering. According to the carburizing and quenching method of the low-speed heavy-duty gear, harmful carbide of a gear carburized layer can be effectively removed, dispersively distributed fine granular carbide can be obtained, the content of retained austenite on the surface is greatly decreased, a metallographic structure of the gear surface is improved, the surface hardness and abrasion resistance of the gear are improved, and the heat treatment property of a product is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

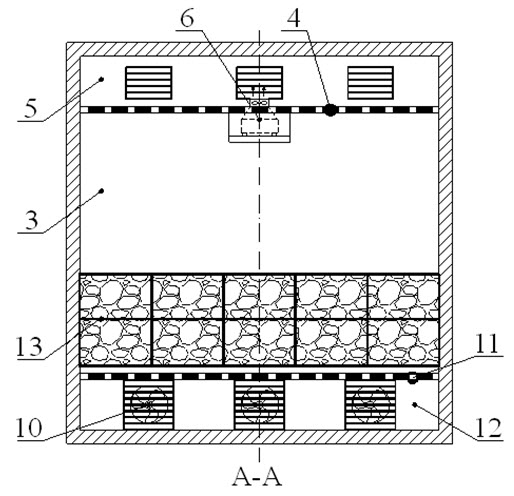

Heat pump type pressure gradient fruit vegetable heat treatment library

ActiveCN101919436AReduce heat treatment energy consumptionShorten the timeFood processingFruits/vegetable preservation by heatingThermodynamicsAir treatment

The invention discloses a heat pump type pressure gradient fruit vegetable heat treatment library. The library is composed of a library entry, a heat pump system, a circulation air system and a humidifying system, the library entry is divided into four parts of air treatment, air supply plenum, fruit vegetable heat treatment and return air plenum. The upper end and the lower end of the clapboard are respectively provided with three centrifugal fans and three pressure gradient fans, an air supply homogenizing plate and a return air floor plate are respectively arranged at the upper part and the lower part in the library, and a fruit vegetable heat treatment chamber is formed between the two plates. An air supply plenum chamber is formed between the air supply homogenizing plate and the upper top wall of the library entry, and a return air plenum chamber is formed between the return air floor plate and the lower bottom of the library entry. The condenser of the heat pump system is arranged in an air treatment chamber, a centrifugal humidifier is arranged above the right side of the clapboard, and the return air floor plate is placed with a fruit vegetable box. Pressure gradient air supply is adopted, so that treatment time can be reduced. The invention adopts heat pump heat source, the heat pump can supply 3-5 units of heat into the library while a compressor consumes every 1 unit electricity; compared with the electric heating method, fruit vegetable heat treatment energy consumption can be obviously reduced, and energy conservation effect of the system is obvious.

Owner:TIANJIN UNIV

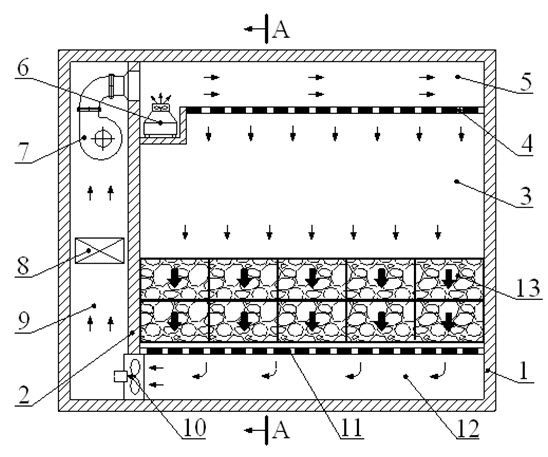

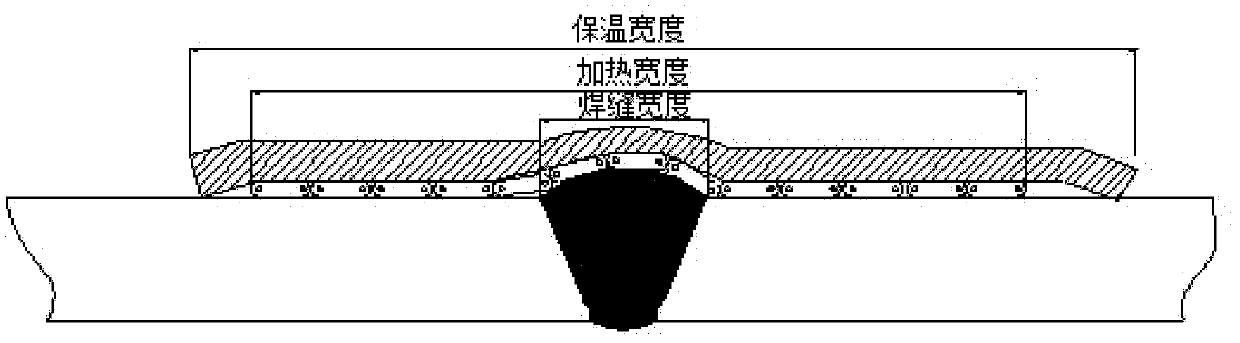

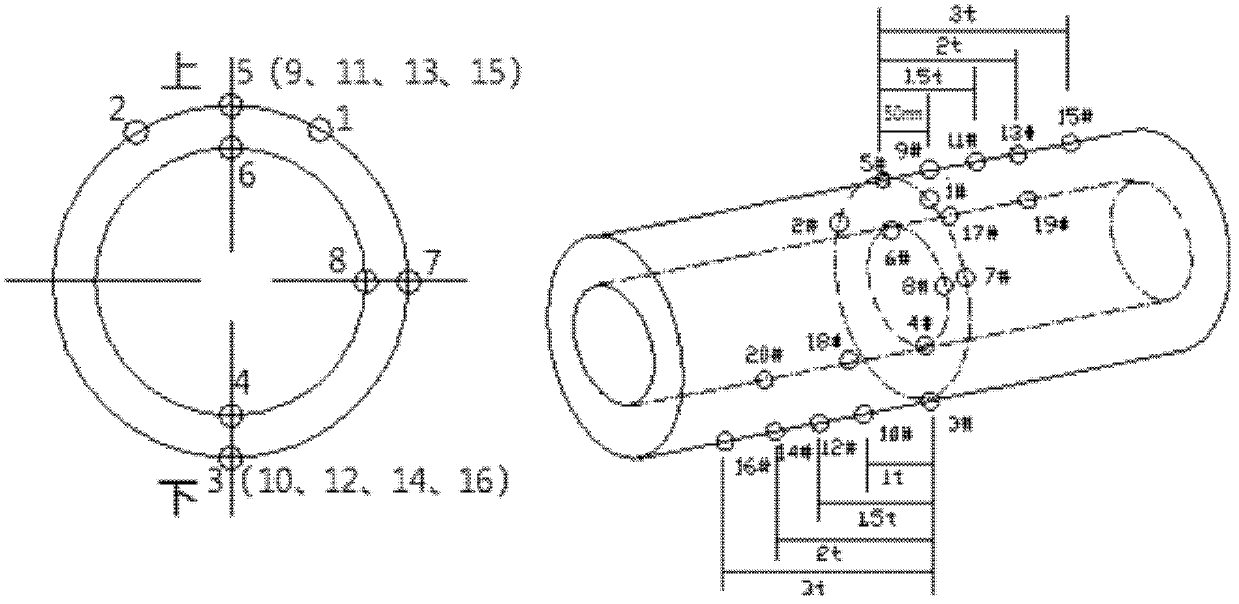

Local heat treatment method of thick-wall P92 pipeline in field condition

ActiveCN102605158AEasy to useImprove heat treatment effectFurnace typesPipeline systemsElectrical resistance and conductanceData simulation

The invention discloses a local heat treatment process of a thick-wall P92 pipeline in field condition. The method comprises the following steps: calculating by adopting the experiment and the data simulation according to the internal diameter and the wall thickness to obtain the corresponding heating width and the corresponding heat-preserving width; locally heating the pipeline by using a flexible ceramic resistance heater; energizing the pipeline when the temperature reaches 80-100 DEG C, heating, and keeping the temperature constant for 2h; heating the pipeline to 300 DEG C at the speed of 150 DEG C per hour; heating the pipeline to 765 DEG C at the speed of 80 DEG C per hour when the temperature reaches 300 DEG C, and preserving the heat for at least 4h at the rate of 5min for the wall thickness of every 1mm; decreasing the temperature of the pipeline to 300 DEG C at the speed of 100 DEG C per hour; deenergizing the pipeline; and cooling the pipeline slowly to room temperature. Due to the adoption of the technical scheme, the temperature difference (less than 25 DEG C) between the inner wall and the outer wall of the P92 pipeline can be reduced effectively during the heat treatment at constant temperature after welding, the residual stress at the welded joints of the pipeline subjected to heat treatment can be reduced effectively, and the use performance of the material can be guaranteed.

Owner:TIANJIN UNIV

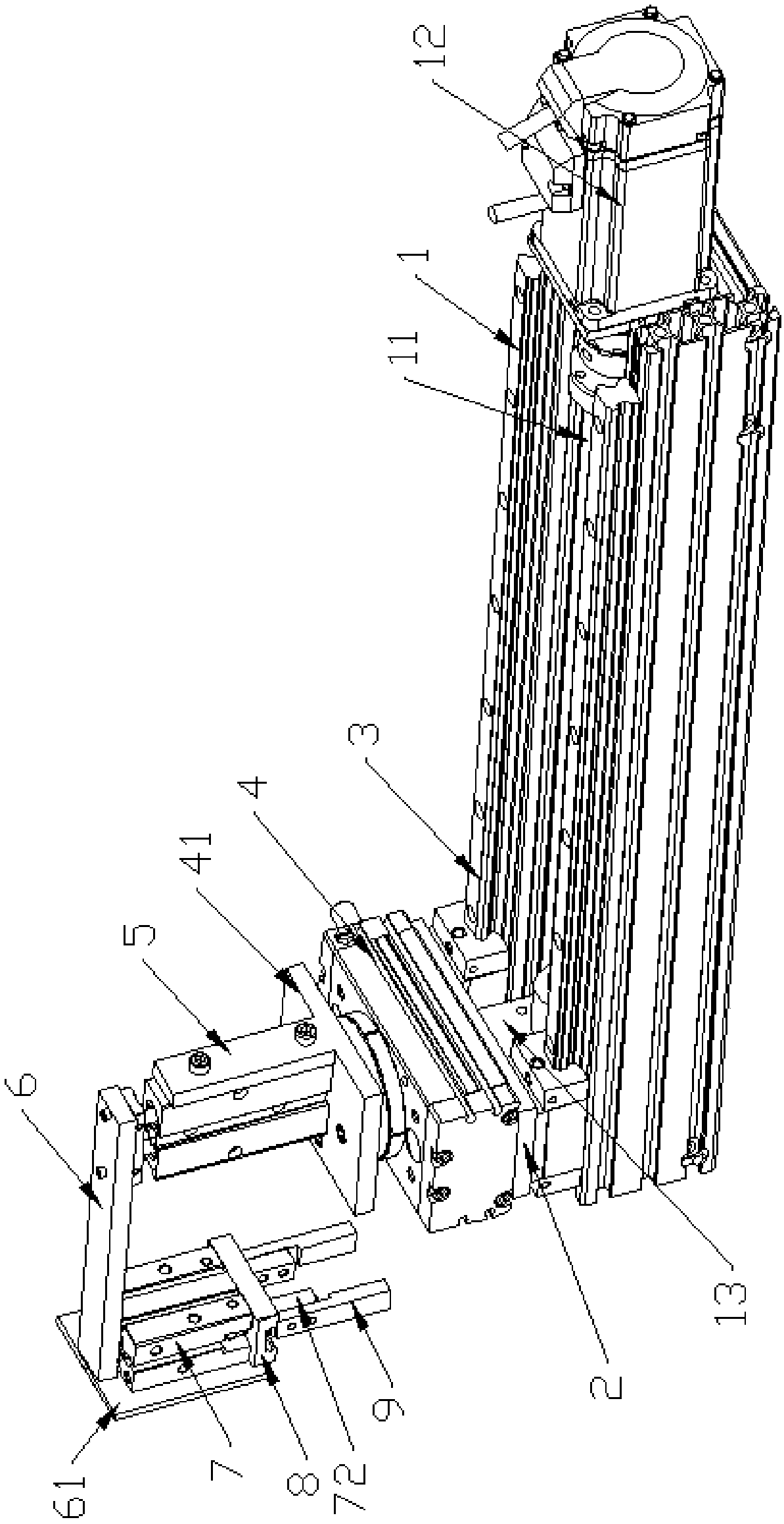

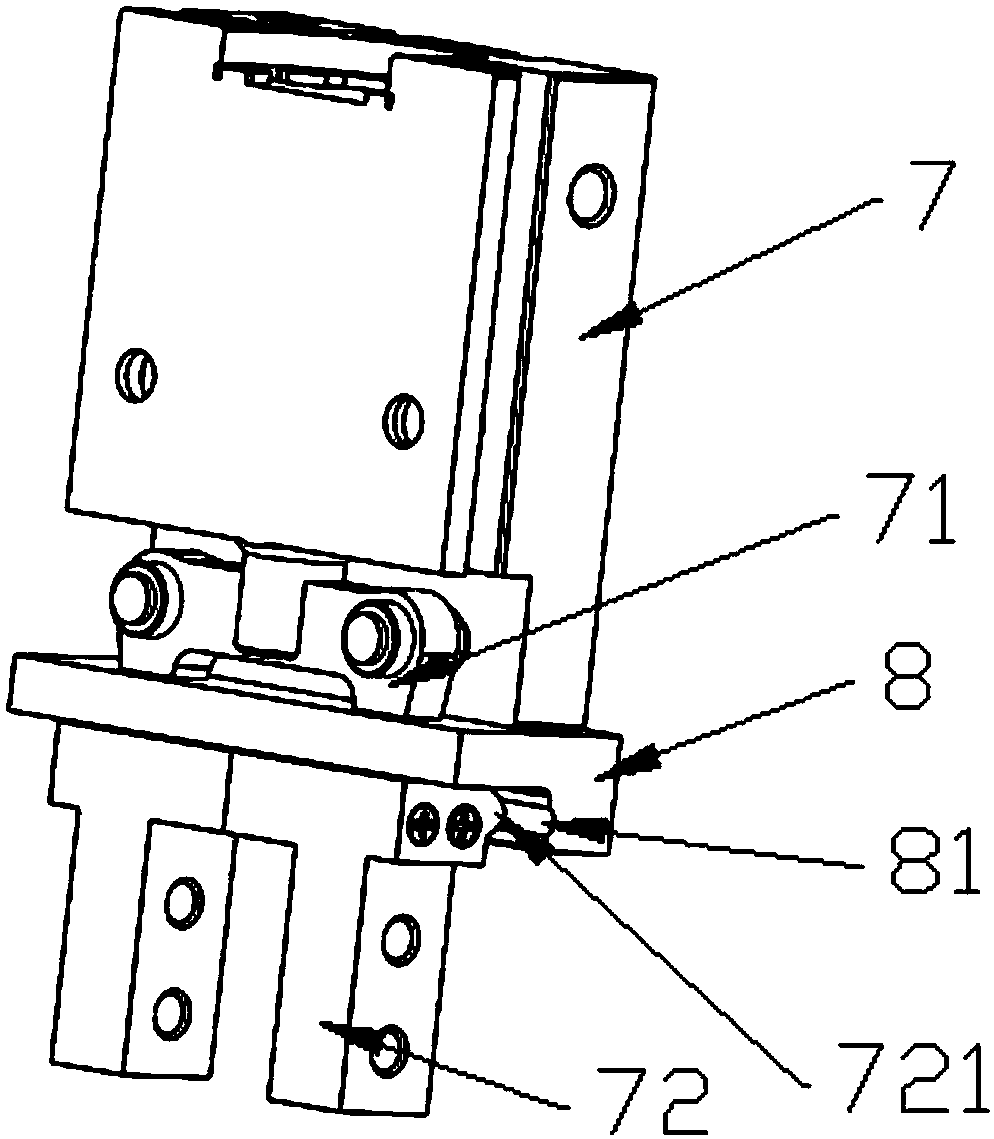

Quenching equipment for completing quenching, isothermal treatment or tempering in same slot by transferring through hanging basket

ActiveCN103924047ASimple transmission structureImprove reliabilityQuenching devicesThermal energySaline water

The invention relates to thermal treatment equipment and specifically relates to quenching equipment for completing quenching, isothermal treatment or tempering in the same slot by transferring through a hanging basket. The quenching equipment comprises a heating furnace, a discharging table, a quenching slot, an isothermal slot, an air-cooling slot, a saline water cleaning slot, a clear water cleaning slot and an unloading table, wherein the quenching slot, the isothermal slot, the air-cooling slot, the saline water cleaning slot and the clear water cleaning slot are arranged between the discharging table and the unloading table in sequence; the quenching slot and the isothermal slot are formed by dividing a liquid-connected large slot through an adjustable baffle plate; a transfer mechanical hand is arranged above the discharging table and the unloading table; a material taking hook of the transfer mechanical hand is equipped with the hanging basket for hanging and transferring workpieces. The quenching equipment disclosed by the invention can sufficiently utilize heat energy and lower thermal treatment process cost; by adopting a mode that liquid transfers heat for workpieces, tempering and isothermal temperatures of workpieces are more uniform, and better thermal treatment effect is obtained; the mechanical hand can realize automatic transfer of workpieces in different working media, and can realize various quenching processes.

Owner:TANGSHAN YAJIE MACHINERY

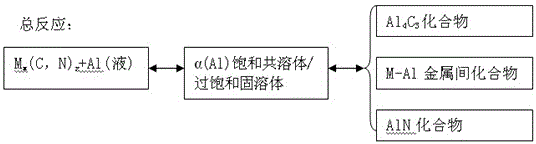

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

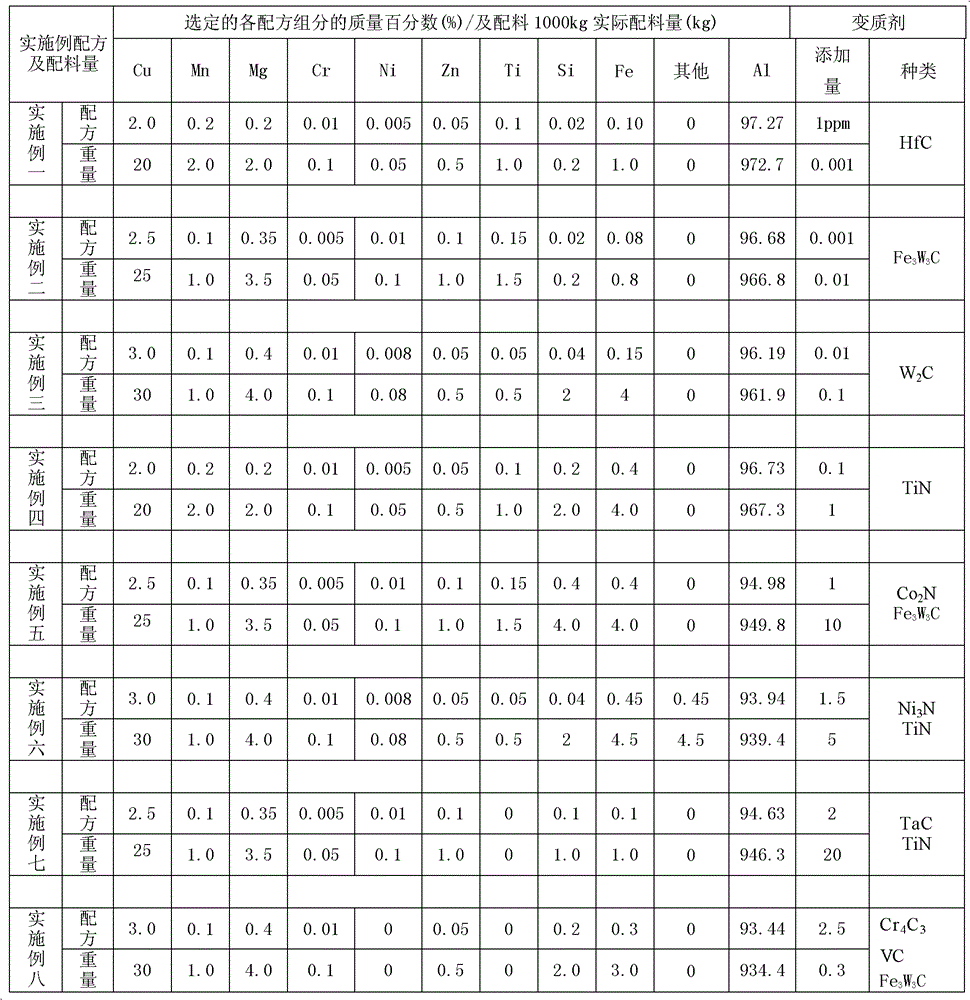

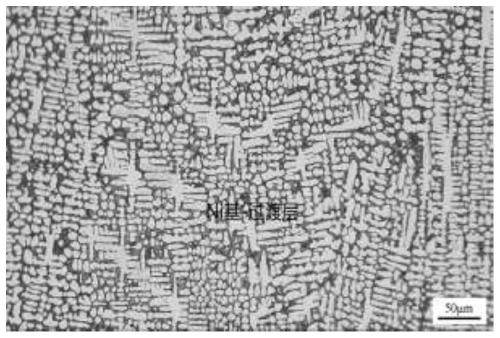

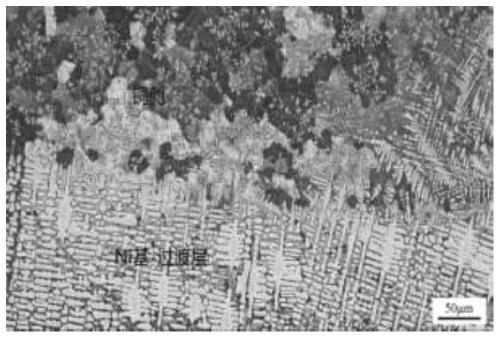

Ni based-flux-cored wire and method for preparing copper-steel base gradient composite

ActiveCN111558793AAvoid Welding DefectsImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsCopperWelding defect

The invention discloses a Ni based-flux-cored wire. The Ni based-flux-cored wire comprises a flux core and a welding scale, wherein the flux core is prepared from the following components in percentage by mass: 86%-90% of Ni powder, 3%-5% of Mn powder, 6%-7% of Si powder, the balance of Cu powder, and the sum of the mass percentage of the components is 100%. The Ni based-flux-cored wire is used asa transition layer to avoid welding defects caused by thermophysical parameter difference of two types of materials during direction connection of copper-steel. The invention further provides a method for preparing copper-steel base gradient composite based on the Ni based-flux-cored wire used as the transition layer. The problem of the welding defects caused by direct connection in existing copper / steel composite is solved, parts can be combined from the steel side to the copper side to reach a gradient mode, so that the combining capacity of a heterogeneous material interface is enhanced, and the mechanical properties of composite members are improved.

Owner:XIAN UNIV OF TECH

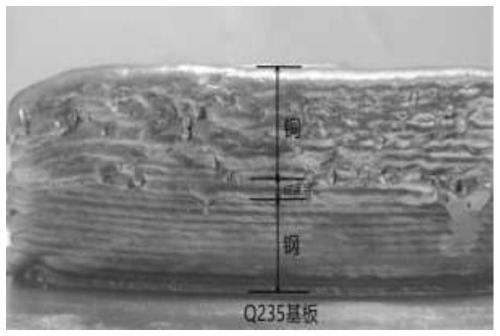

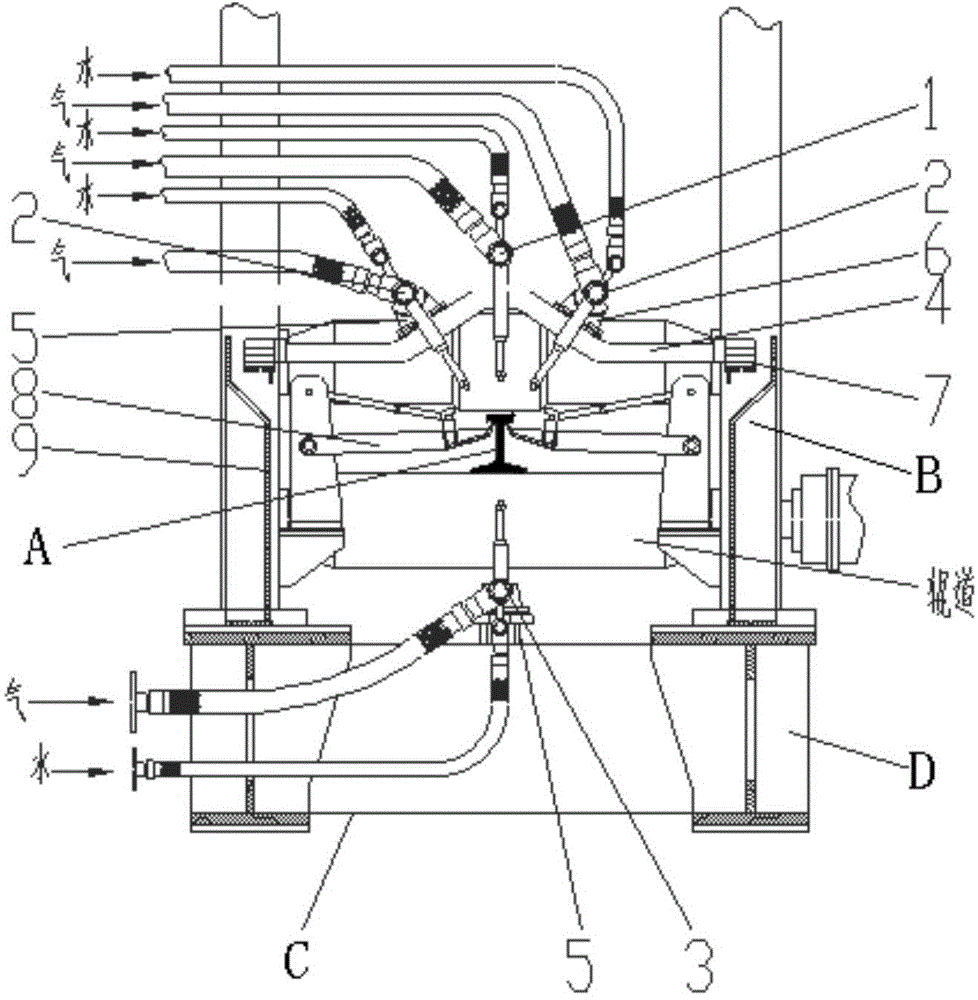

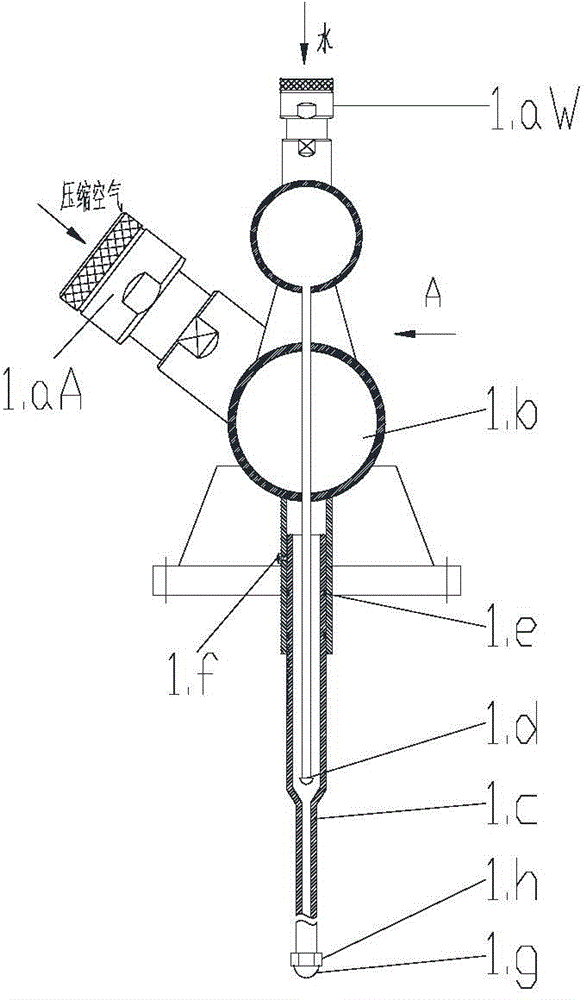

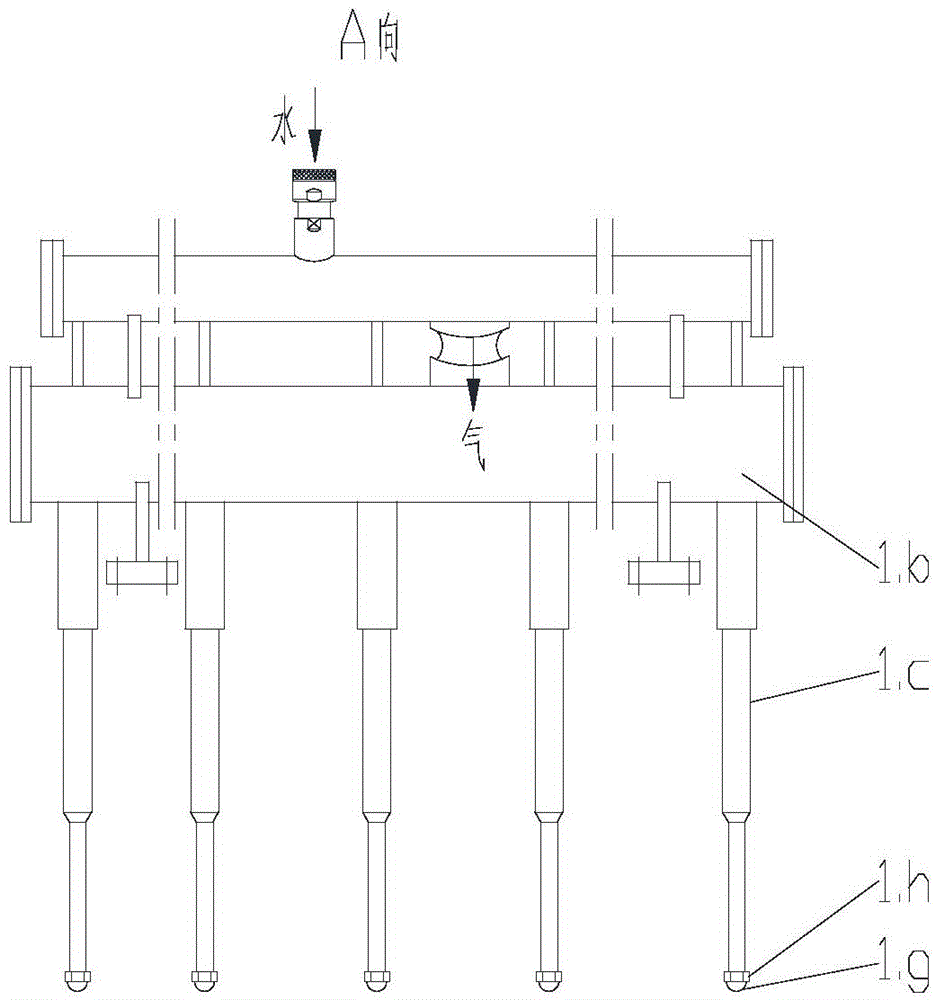

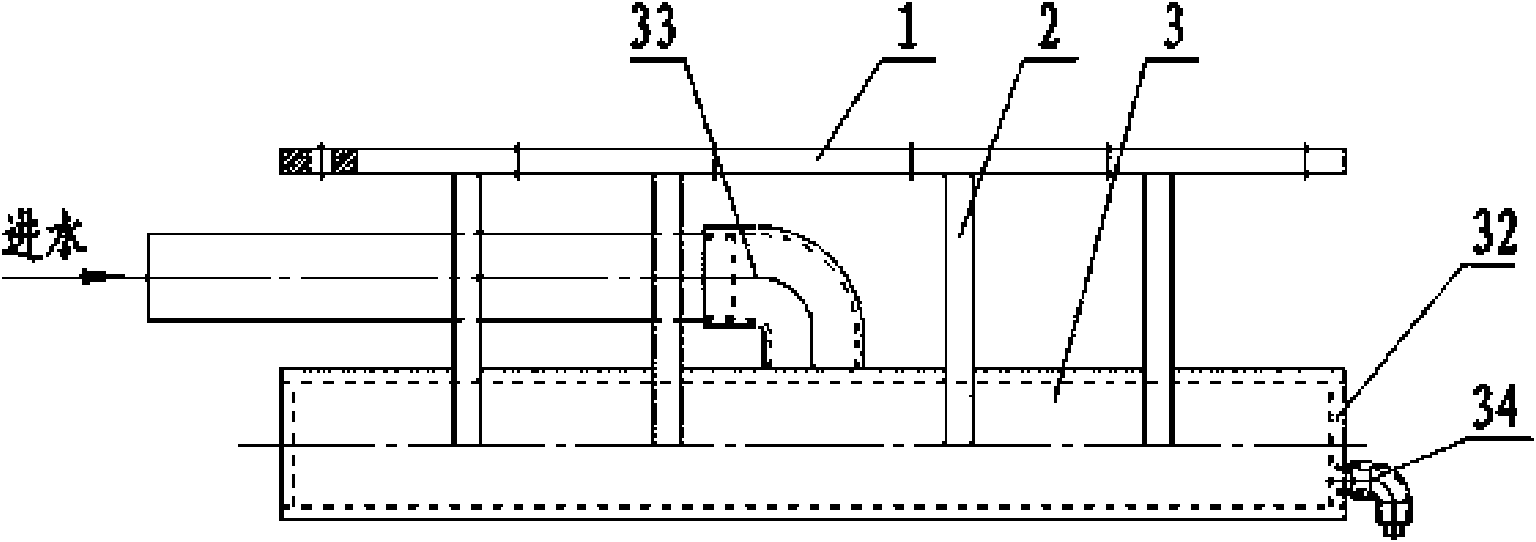

Spray cooling device for long steel rail online quenching unit

ActiveCN104017975AControl performanceFlexible and diverse cooling control methodsFurnace typesHeat treatment furnacesTreatment effectSpray cooling

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Blank-making rolling method for synchronous sliding sleeve of automotive transmission

The invention discloses a blank-making rolling method for a synchronous sliding sleeve of an automotive transmission using circular steel as a blank material. The method comprises the steps of cutting, heating, upsetting, punching a blind hole and pre-forming, punching a wad and pressing an end face, performing ring rolling forming, shaping, normalizing, performing impeller blasting and the like, wherein the key point is that a rolling wheel used in the step of the ring rolling forming is provided with an annular groove corresponding to a blank of the synchronous sliding sleeve of the automotive transmission. By applying ring rolling process to the blank of the synchronous sliding sleeve of the transmission, the subsequent machining amount is reduced to the greatest extent, the material consumption is reduced and the service life of the finished product is prolonged.

Owner:重庆市平岗机械有限公司

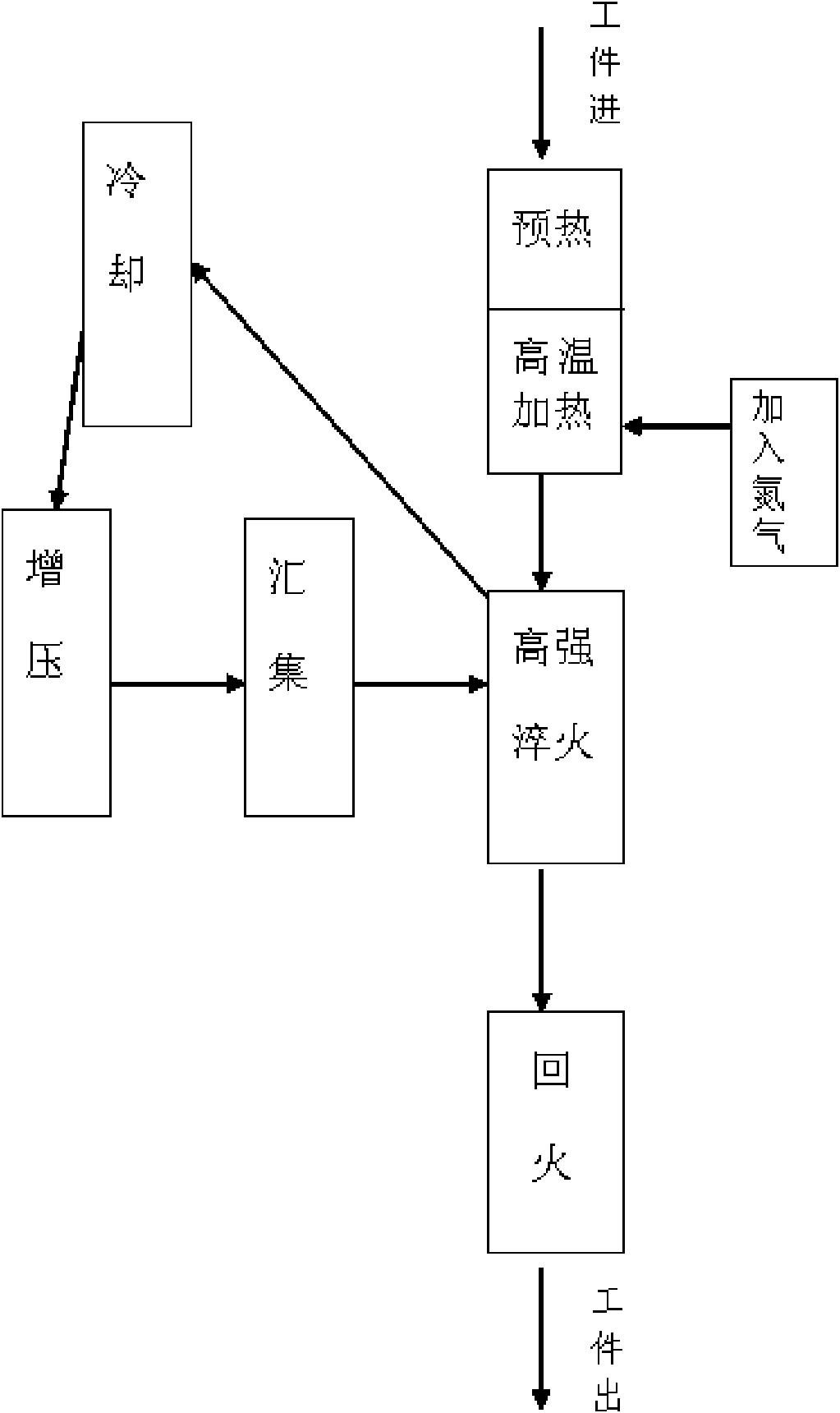

Heating processing technology for wear-resistant cutting board

ActiveCN101570819AHigh strengthIncrease productivityFurnace typesQuenching agentsQuenchingWear resistant

The invention relates to a heating processing technology of a wear-resistant cutting board, in which a shaped wear-resistant cutting board workpiece is preheated, heated under high temperature, and then is subjected to high-strength quenching and tempering. The technology comprises the following steps: A. preheating: the preheating temperature is 450-550 DEG C, and the preheating time is 0.5-1.125min / mm; B. high temperature heating: the temperature is 870-890 DEG C, and the holding time is 0.5-1.125min / mm; C. high-strength quenching: whole spray water time of high-strength quenching is 70-700 seconds, and time in intensified spray is 15-20 seconds; D. tempering: low temperature tempering is carried out, followed by air cooling to room temperature; high pressure cooling water used in the invention is recyclable. The invention has the advantages of making full use of reasonable heating processing technology under the premise of ensuring fine property of the wear-resistant cutting board, improving production efficiency and saving energy consumption, thus lowering production cost of the wear-resistant cutting board.

Owner:LIUZHOU JINMAO MACHINERY

Corrosion resistant metal coating for gear box inner surface

ActiveCN106498291AStable austenite phaseImprove hardenabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCorrosion resistantMetal coating

The invention discloses a corrosion resistant metal coating for a gear box inner surface. The corrosion resistant metal coating comprises the following components by mass percentage: 0.03-0.05% of C, 0.45-0.48% of Mn, 12.76-12.79% of Cr, 6.12-6.15% of Ni, 0.16-0.18% of Mg, 0.22-0.25% of Mo, 0.27-0.29% of Co, 0.26-0.28% of V, 0.22-0.24% of Ti, 0.21-0.23% of Na, 0.12-0.15% of Ga, 0.32-0.35% of Eu, 0.12-0.14% of Lu, 0.62-0.68% of La, and the balance Fe.

Owner:南京创贝高速传动机械有限公司

Steel for bucket teeth and preparation method thereof

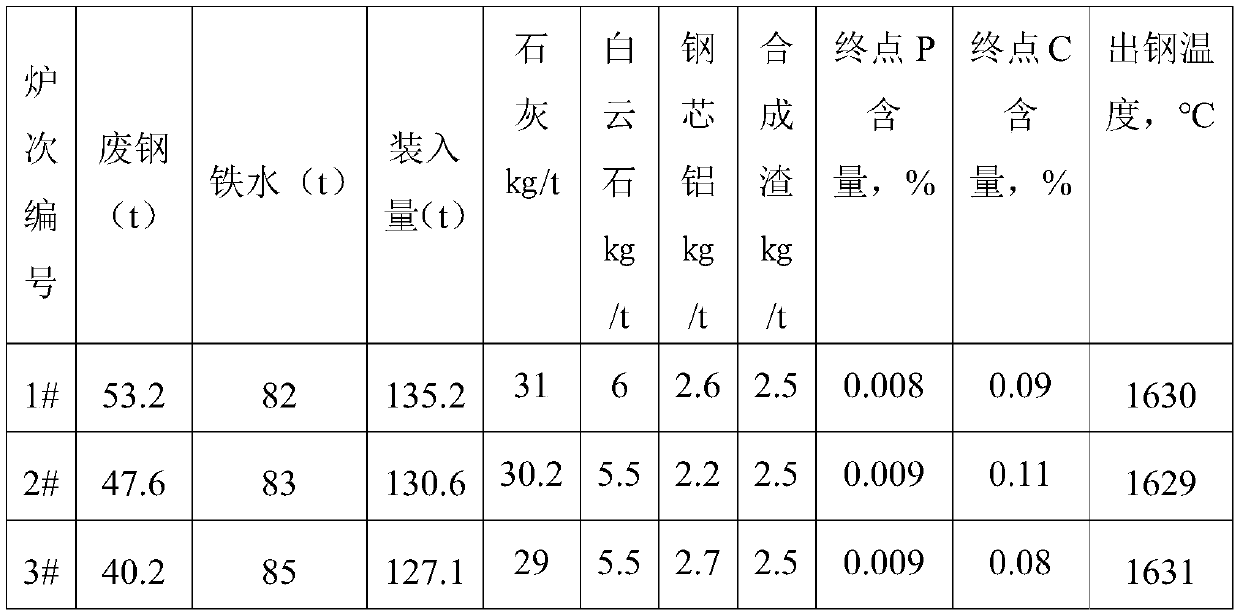

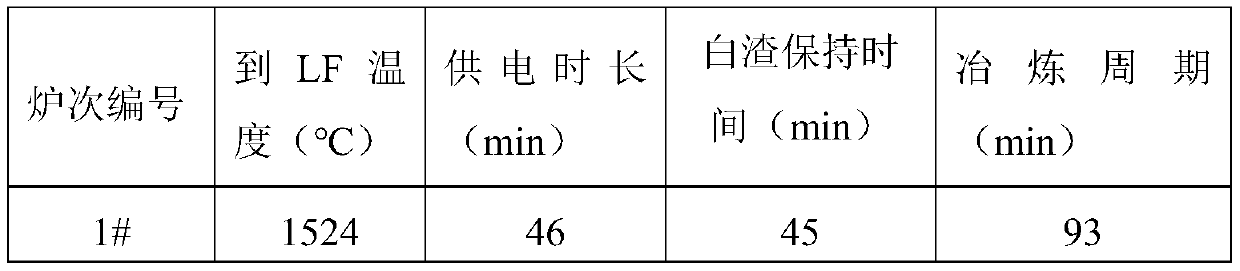

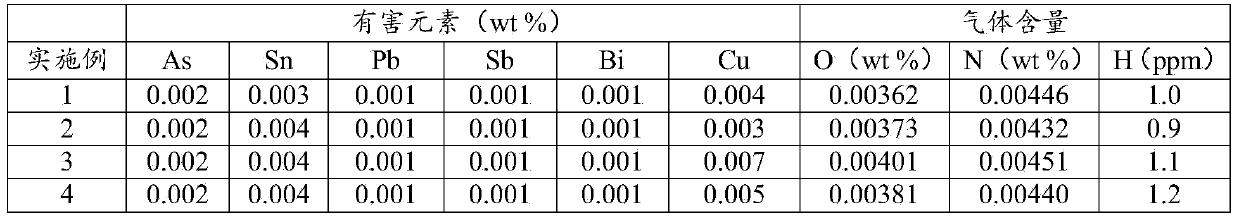

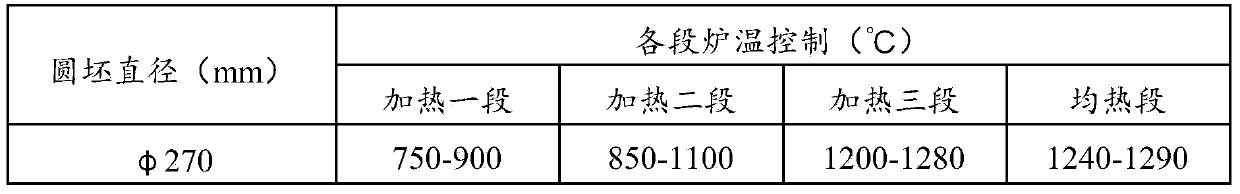

PendingCN110343973AImprove heat treatment effectGuaranteed mechanical propertiesChemical compositionThermal treatment

The invention relates to the technical field of metallurgy, in particular to steel for bucket teeth and a preparation method thereof. The steel comprises the following chemical components in percentage by mass: 0.30-0.34% of C, 1.30-1.50% of Si, 0.80-1.10% of Mn, equal to or less than 0.025% of P, equal to or less than 0.025% of S, 1.50-1.70% of Cr, 0.06-0.08% of Ti, 0.10-0.18% of Mo, 0.020-0.050%of Al, equal to or less than 1.5*10% of H, equal to or less than 80*10% of N, equal to or less than 1.5*10% of T.O and the balance of Fe and unavoidable impurities. The preparation method comprises the following steps: 1, electric furnace smelting; 2, refining furnace smelting; 3, VD furnace vacuum smelting; 4, continuous casting; and 5, rolling. The steel is excellent in macrostructure, high inpurity, low in gas content, fine and small in crystal particle, compact in texture, low in banded structure grade, and high in mechanical property and improves the technological processability and thermal treatment of a material.

Owner:SHANDONG IRON & STEEL CO LTD

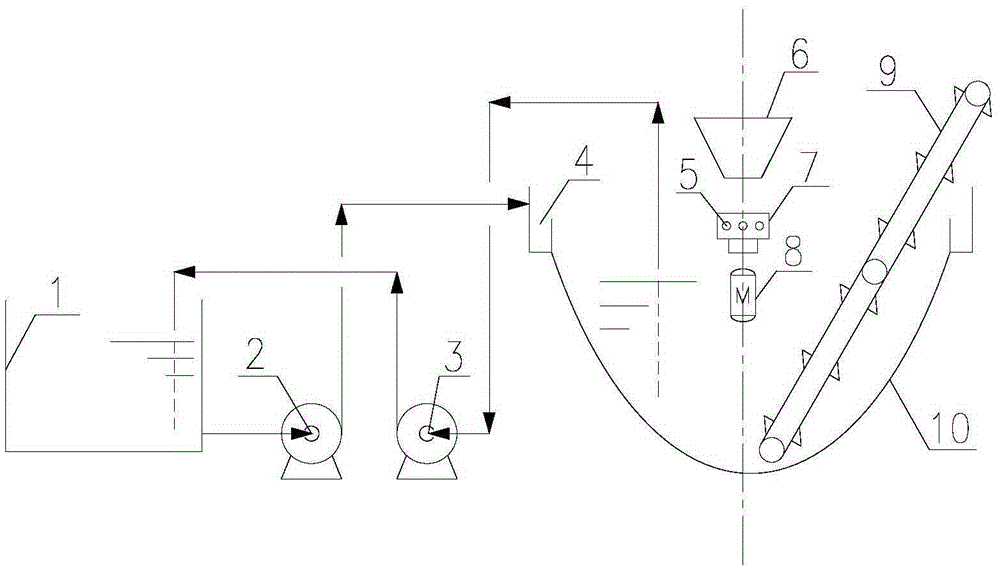

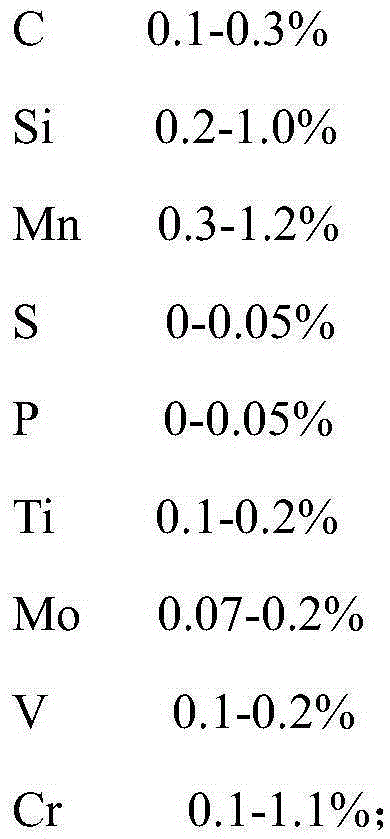

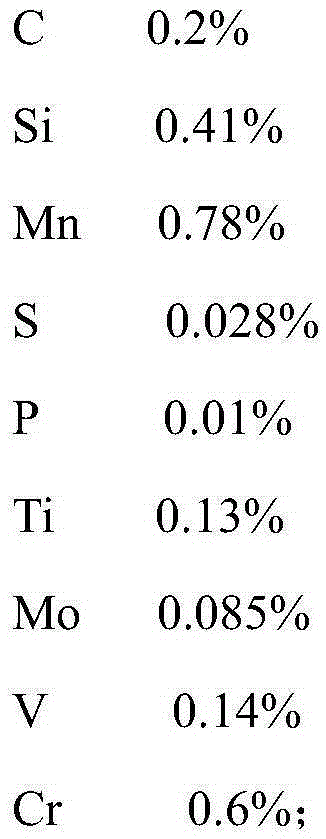

Wear-resisting low-carbon steel shot, preparation method thereof and centrifugal atomizing device

ActiveCN105385961AMeet diverse needsImprove roundnessFurnace typesHeat treatment furnacesWater storage tankThermal treatment

The invention relates to a wear-resisting low-carbon steel shot, a preparation method thereof and a centrifugal atomizing device, and belongs to the technical field of metal abrasives. The wear-resisting low-carbon steel shot consists of the following chemical components in percentage by mass: 0.1-0.3% of C, 0.2-1.0% of Si, 0.3-1.2% of Mn, 0-0.05% of S, 0-0.05% of P, 0.1-0.2% of Ti, 0.07-0.2% of Mo, 0.1-0.2% of V, 0.1-1.1% of Cr and the balance of Fe. The preparation method comprises the following steps: smelting, centrifugal atomizing and forming, drying, coarse screening, quenching and tempering. The centrifugal atomizing device comprises a water storage tank, a centrifugal rotary plate and a centrifugal atomizing tank, wherein the centrifugal atomizing tank sequentially passes through a water outlet pump, the water storage tank and a water inlet pump to form a circulating loop; the upper part of the centrifugal atomizing tank is provided with a centrifugal rotary plate; and the top of the centrifugal atomizing tank is provided with ring-shaped water slots which are distributed along the circumference. The wear-resisting low-carbon steel shot has the characteristics of impact resistance, high cleaning efficiency and fatigue resistance, and has wear-resisting times up to 3500-3600 times; the preparation method is simple and good in thermal treatment effect; and the used centrifugal atomizing device is simple in structure, low in cost and easy to realize.

Owner:ZIBO LUBAO METAL PROD CO LTD

Sheet carbonizing method

ActiveCN102990752AImprove efficiencyGood heat treatment effectWood charring/burningThermal treatmentEngineering

The invention discloses a sheet carbonizing method, comprising the following steps of: a) a sheet drying process; b) a first rapid heating stage; c) a first heat preservation stage; d) a humidification and heat preservation stage; e) a second rapid heating stage; f) a second heat preservation stage; and g) a rapid cooling stage; reducing the temperature inside a carbonizing kiln to 130-140 DEG C, then naturally cooling to 40 DEG C or less, and drawing. The sheet carbonizing method disclosed by the invention is high in production efficiency, good in thermal treatment effect, excellent in stability, and even in wood color; the loss of the mechanical property of the sheet in the carbonizing process can be reduced to the minimal degree; and the sheet does not easily crack or deform.

Owner:ZHEJIANG SHIYOU TIMBER

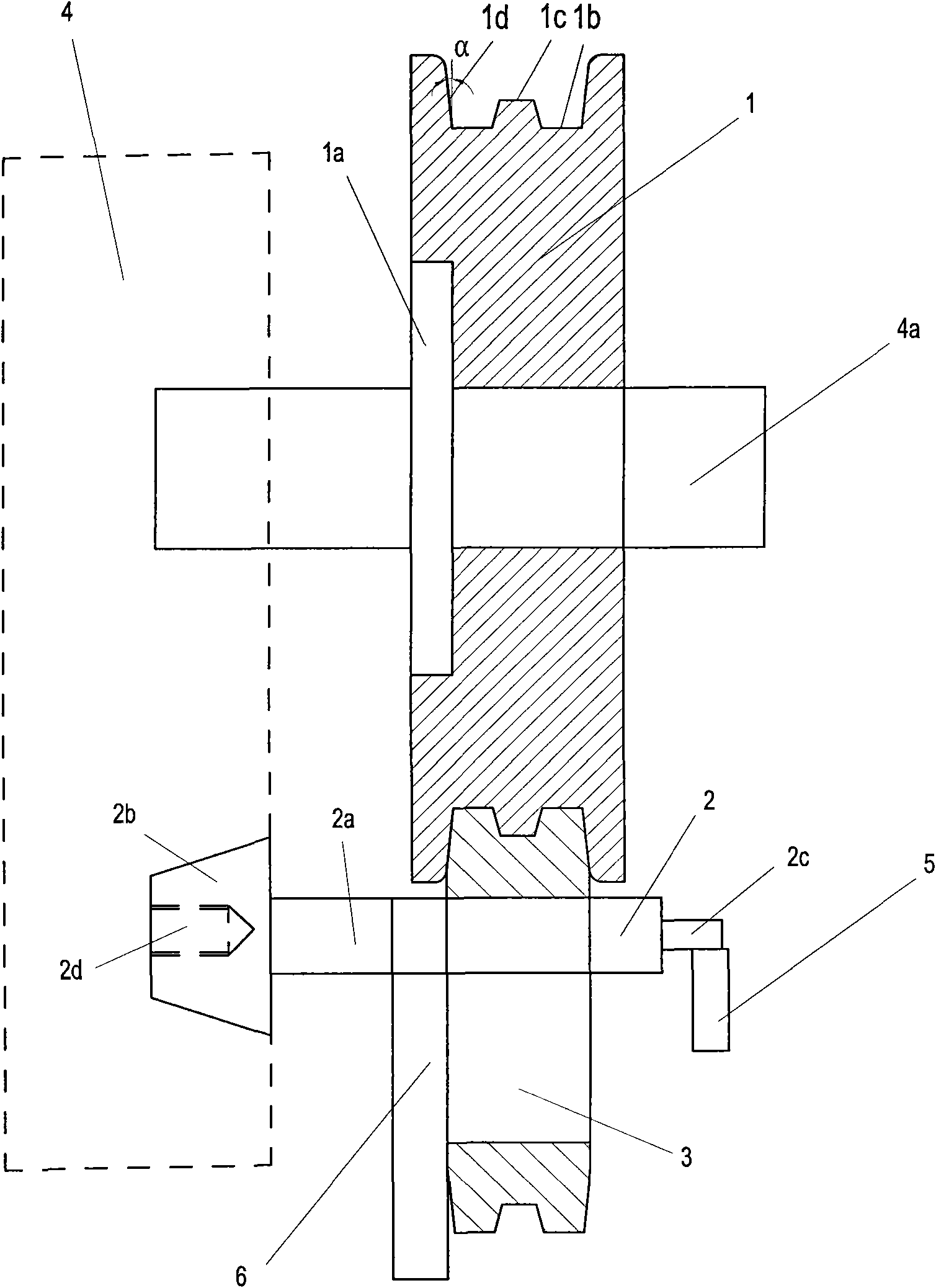

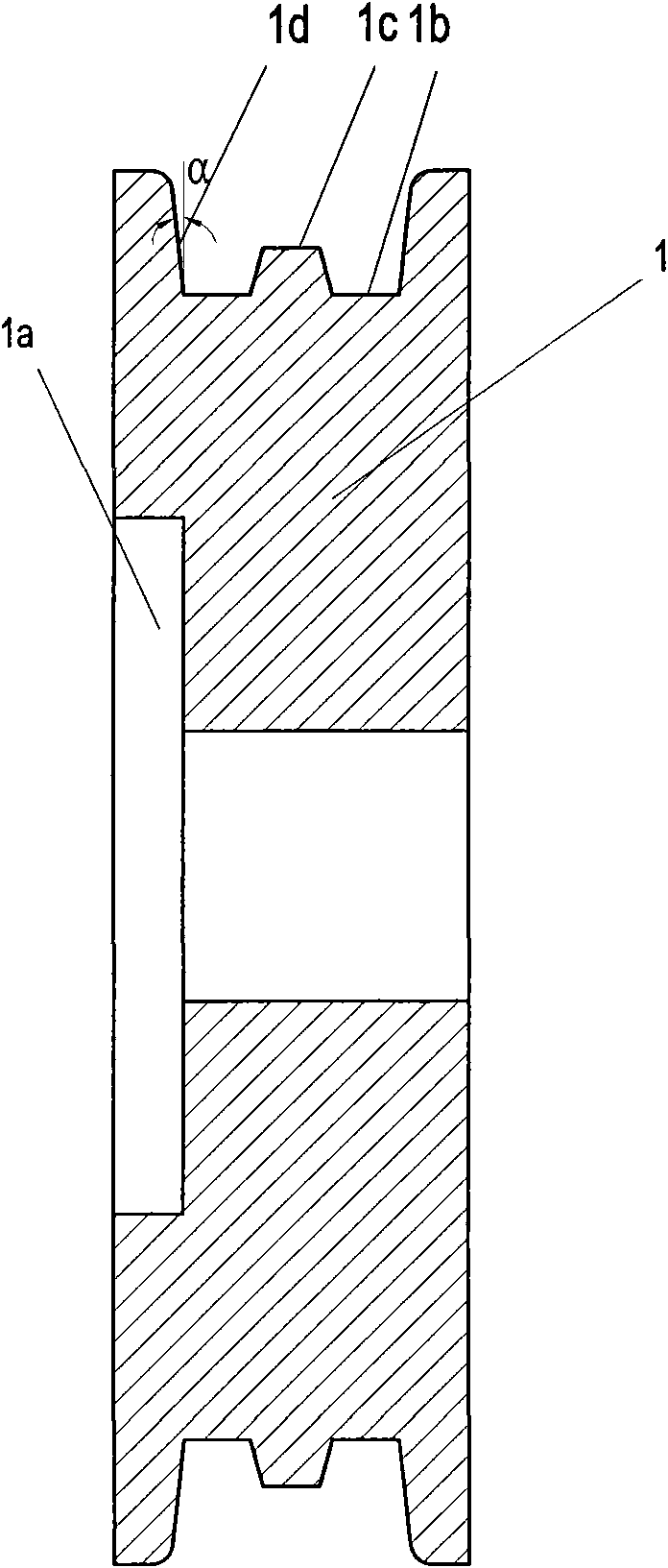

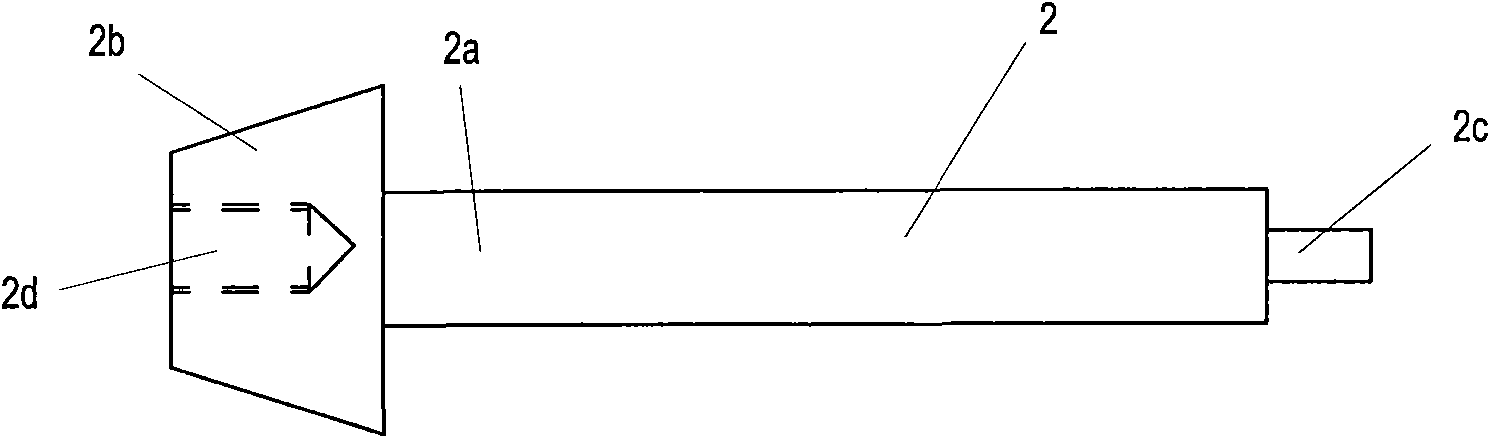

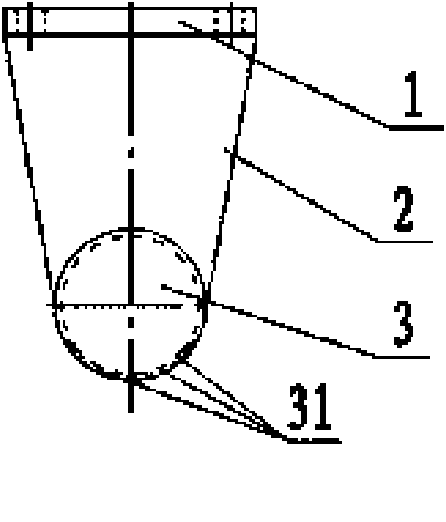

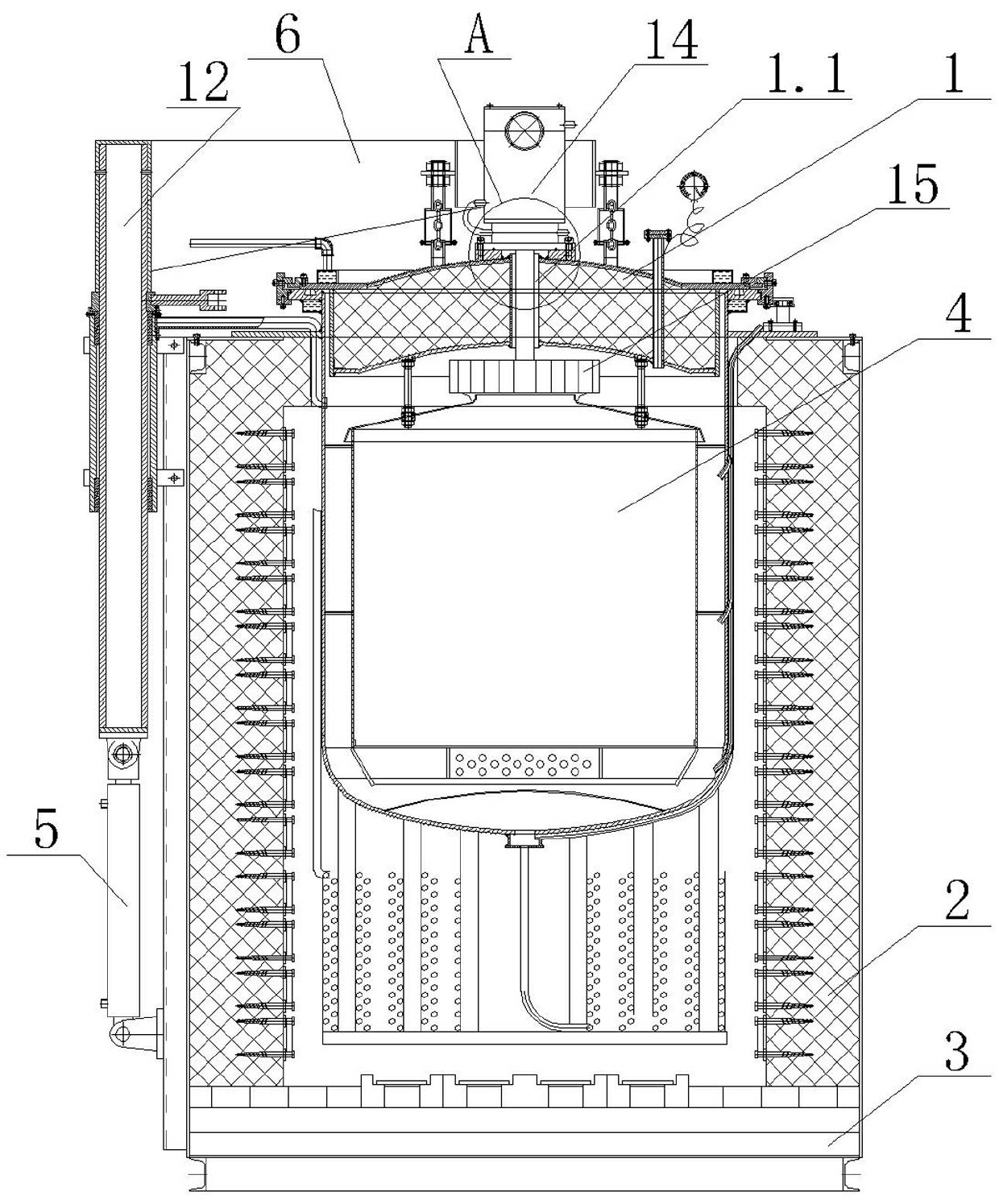

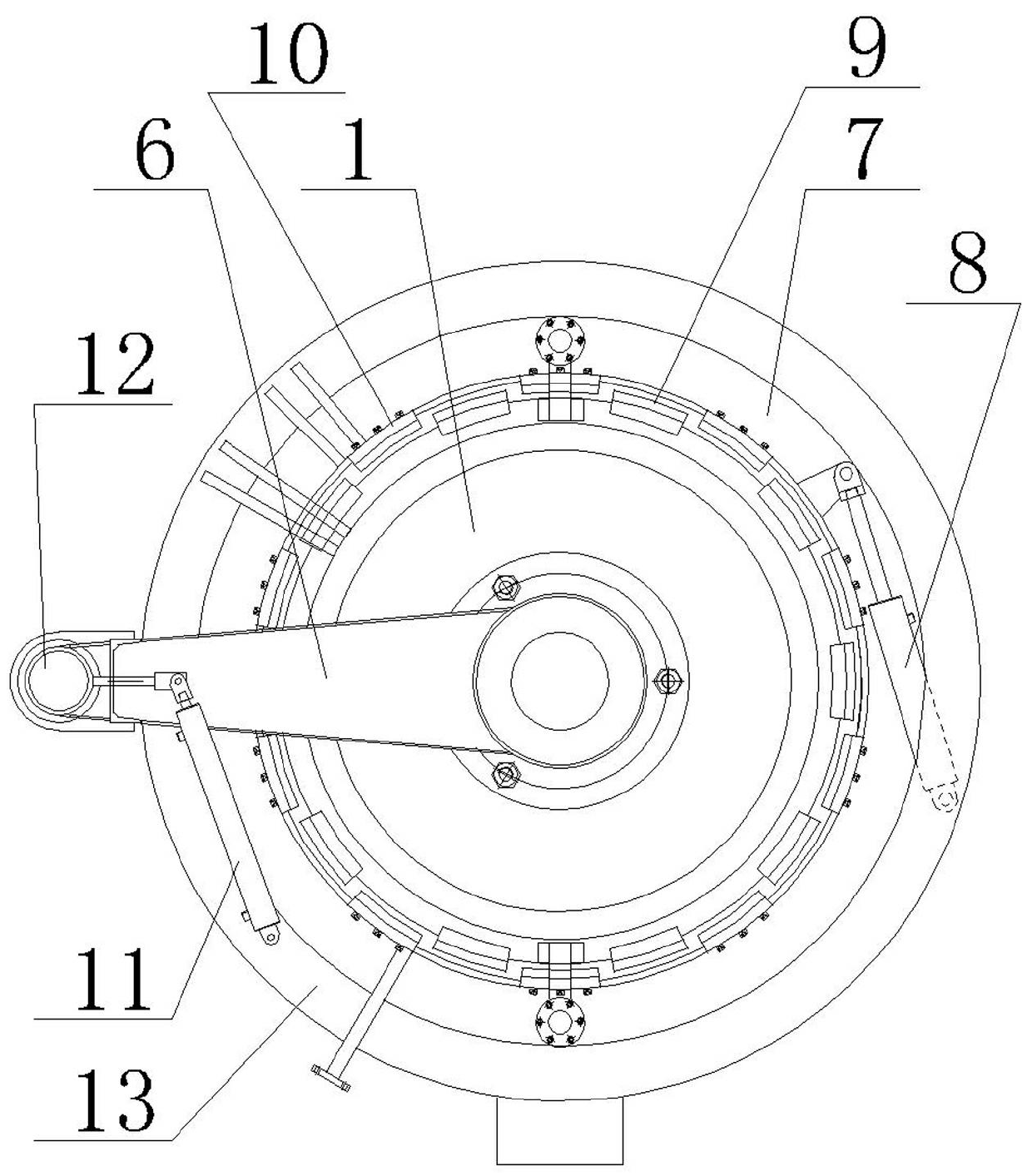

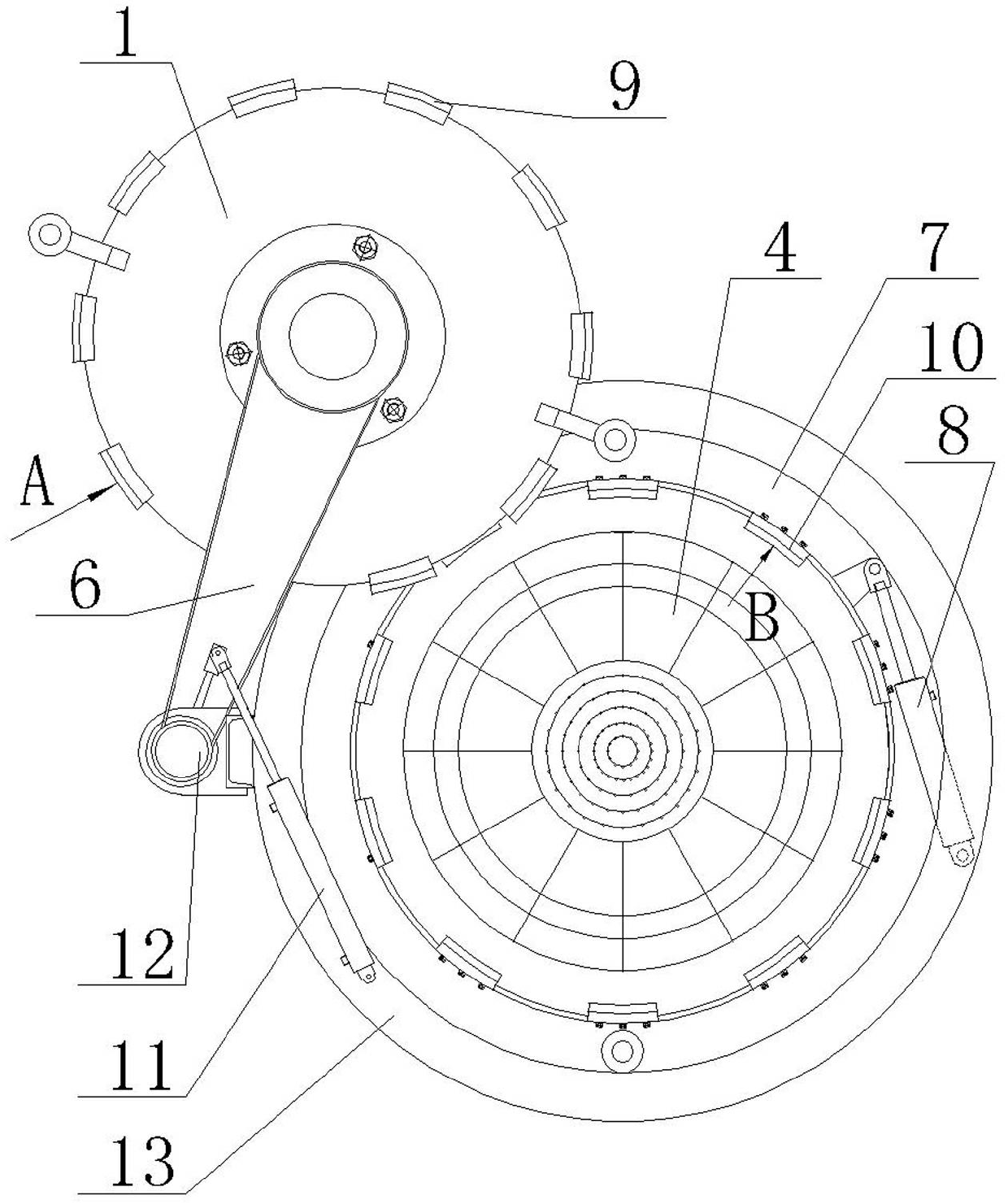

Blackening furnace

InactiveCN102605314AEasy to openImprove sealingMuffle furnacesSolid state diffusion coatingSelf lockingEngineering

The invention discloses a blackening furnace. The blackening furnace comprises a furnace cover (1), a furnace wall (2), a base (3), a lifting cylinder (5) and a rocker arm (6), wherein the furnace cover (1), the furnace wall (2) and the base (3) enclose to form a furnace chamber (4); the piston rod of the lifting cylinder (5) is connected with the outer end of the rocker arm (6); the inner end of the rocker arm (6) is fixed with the furnace cover (1); the cylinder wall of the lifting cylinder (5) is fixed with the furnace wall (2); a horizontal annular groove is formed in the inner wall of the furnace wall (2); a self-locking ring which can rotate along the circumferential direction of the annular groove is arranged in the annular groove; a second cylinder used for rotating the self-locking ring is arranged on the self-locking ring; a radially outwards-convex bump is arranged on the outer circumferential surface of the furnace cover (1); and a radially inwards-concave locking block used for rotationally locking the bump is arranged on the inner circumferential surface of the self-locking ring. The blackening furnace can be opened or locked conveniently and rapidly; and moreover, the air pressure in a furnace chamber can be improved.

Owner:宁波东方加热设备有限公司

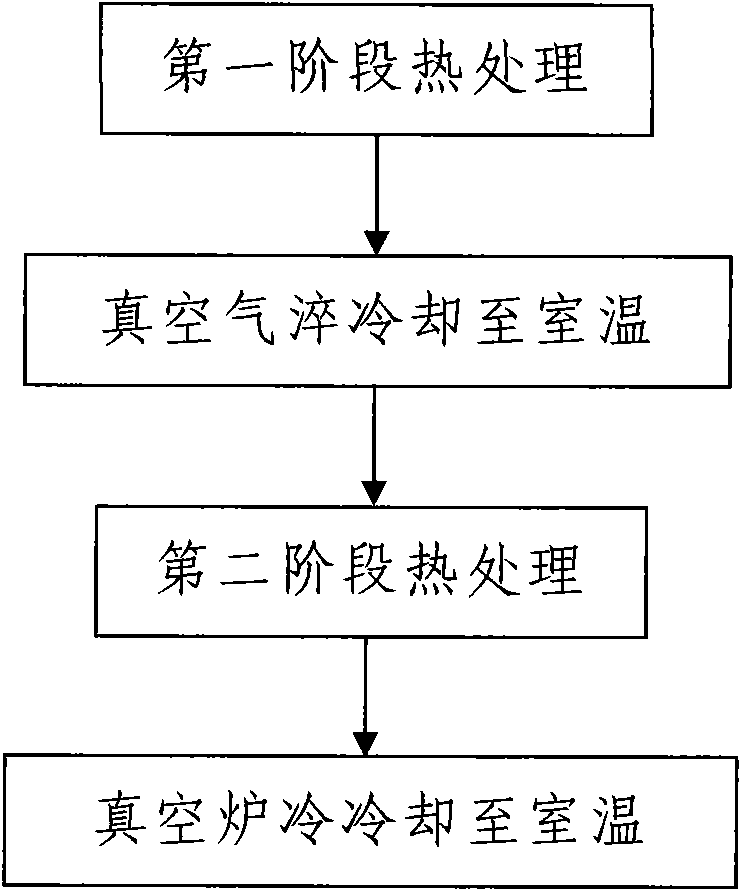

Thermal treatment method for improving mechanical property of titanium alloy strip

The invention discloses a thermal treatment method for improving mechanical property of a titanium alloy strip, which comprises the following steps of: 1, a first stage of thermal treatment: performing the first stage of thermal treatment on the treated titanium alloy strip by adopting a vacuum thermal treatment furnace, wherein the heating temperature is 780 to 820 DEG C, the heat preservation time is 10 to 20 minutes and the cooling mode is vacuum gas quenching; and a second stage of thermal treatment: performing the second stage of thermal treatment on the treated titanium alloy strip after the first stage of thermal treatment by adopting the vacuum thermal treatment furnace, wherein the heating temperature is 460 to 540 DEG C, the heat preservation time is 6 to 10 hours and the cooling mode is vacuum furnace cooling. The method has the advantages of reasonable design, simple thermal treatment, simple and convenient operation and good thermal treatment effect; the mechanical property of the treated titanium alloy strip is greatly improved; and the method fully meets the technical requirements of the TB2 titanium alloy strip for aviation and spaceflight for high strength, high toughness, high modulus and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

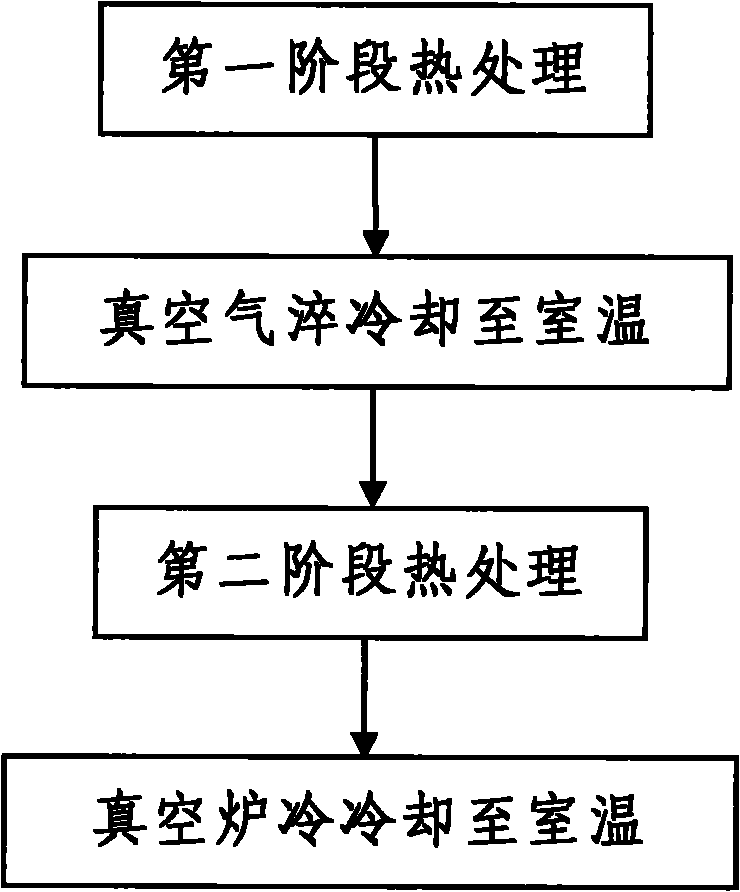

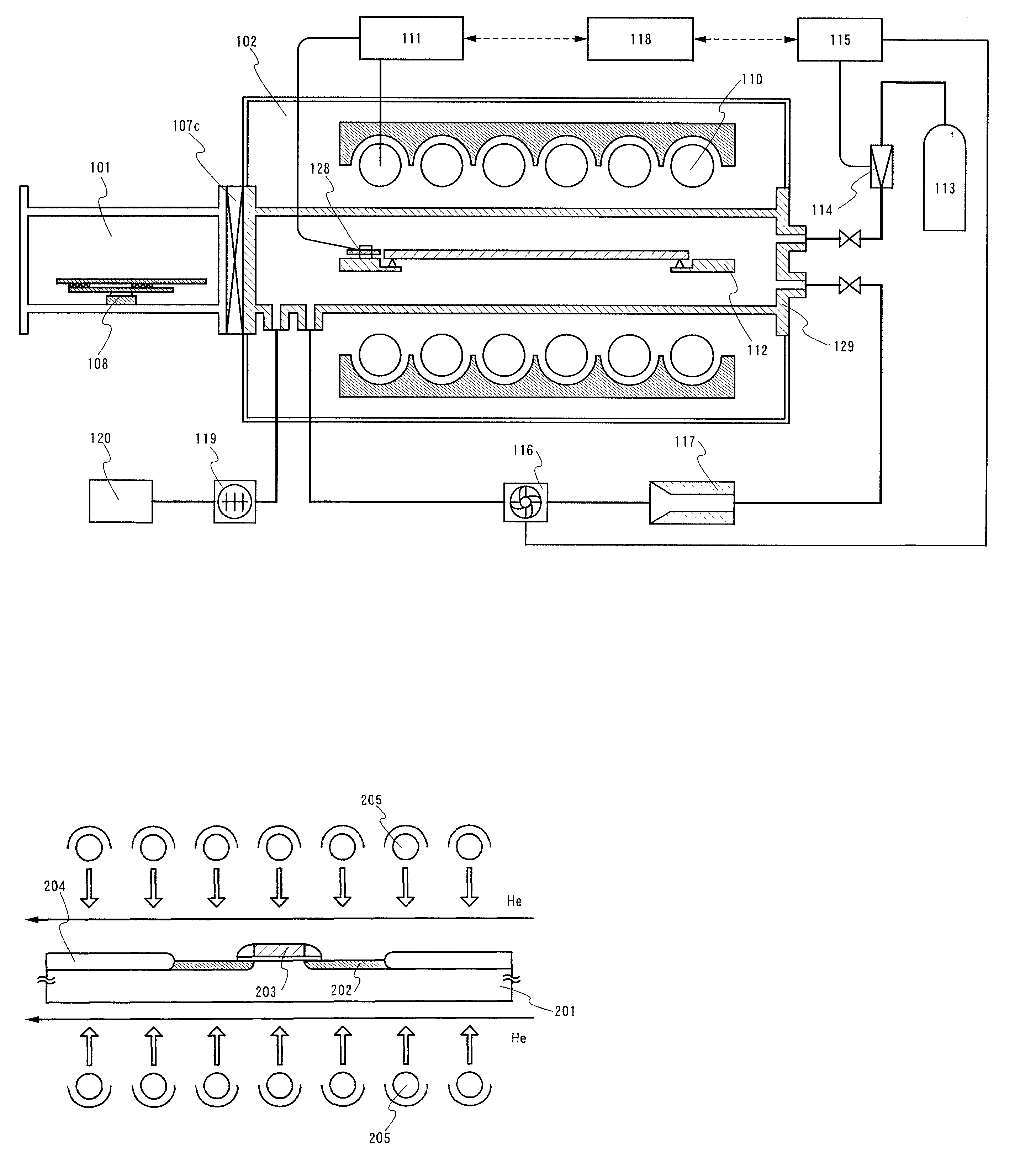

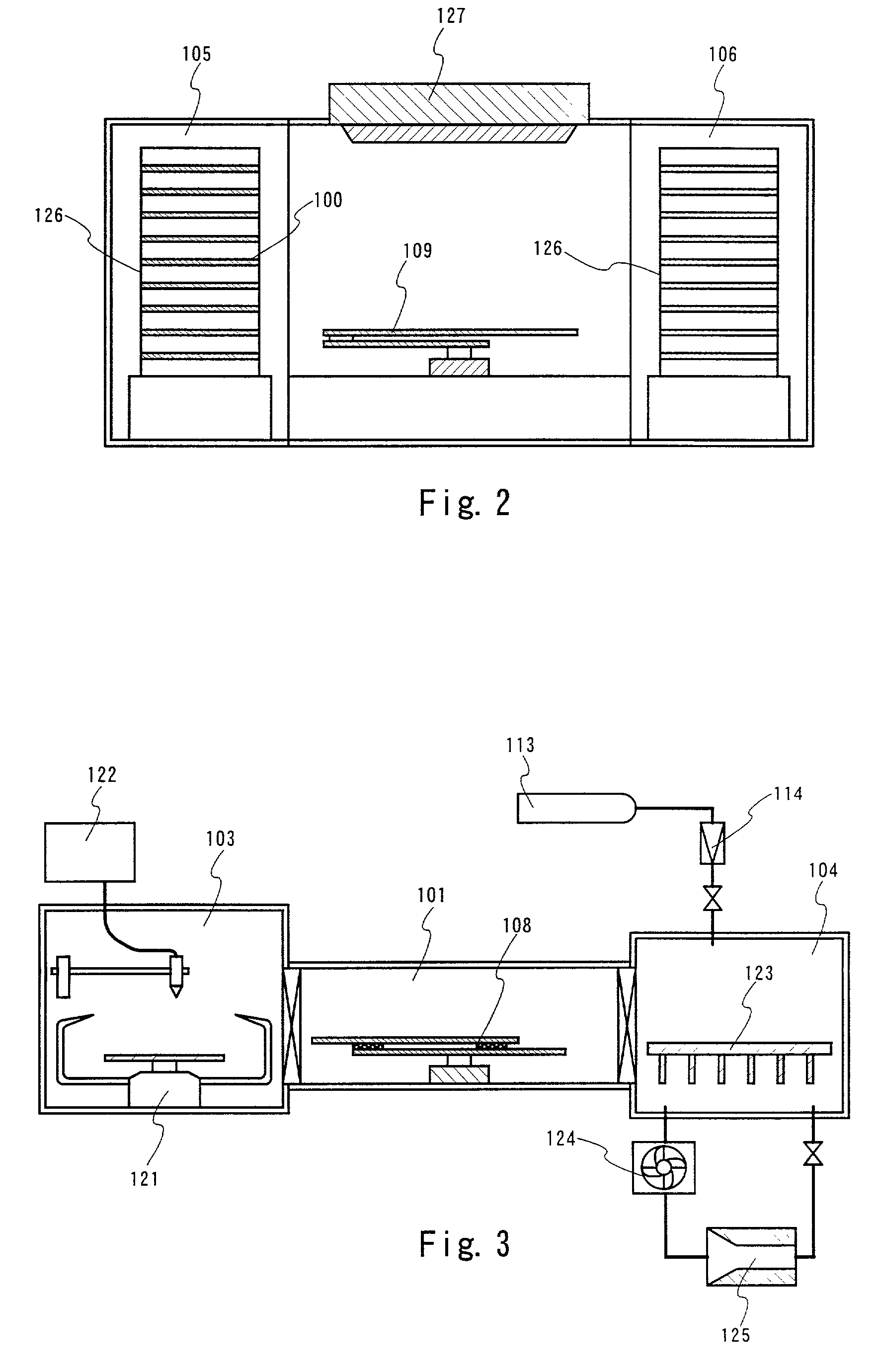

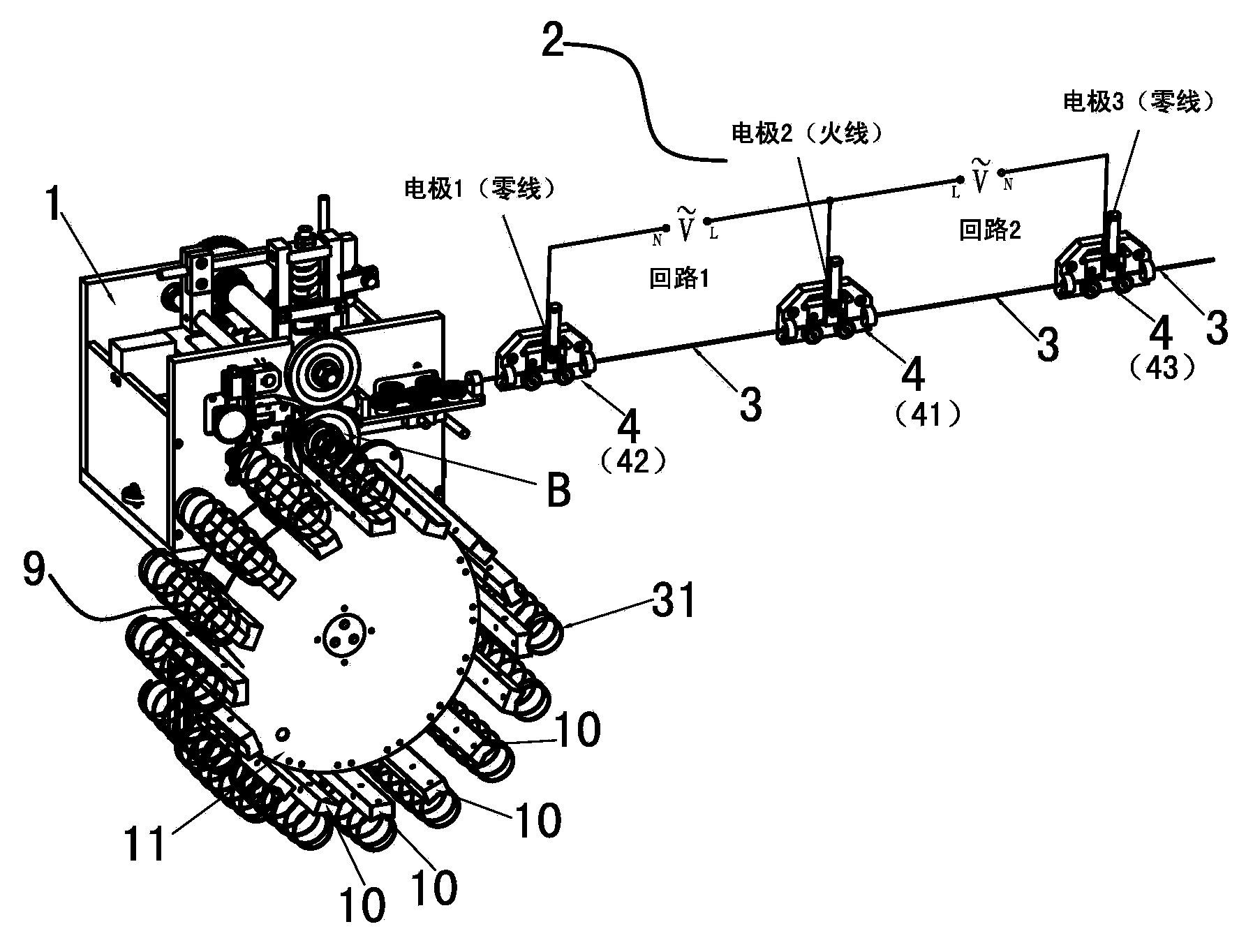

Heat treatment apparatus and method of manufacturing a semiconductor device

InactiveUS7179729B2Good reproducibilityShort timeTransistorSemiconductor/solid-state device detailsPulse shapingEngineering

A heat treatment apparatus which enables a heating process for a short time with high reproducibility in a manufacturing process of a MOS transistor manufactured using a semiconductor substrate, and a method of manufacturing a semiconductor device using the heat treatment apparatus are provided. The heat treatment apparatus of the present invention which enables the above heat treatment method is characterized by comprising: a light source; a power supply for turning the light source on and off in a pulse shape; a processing chamber in which the substrate can be irradiated with light from the light source; and a unit for supplying a coolant to the processing chamber and also increasing and decreasing the supply amount.

Owner:SEMICON ENERGY LAB CO LTD

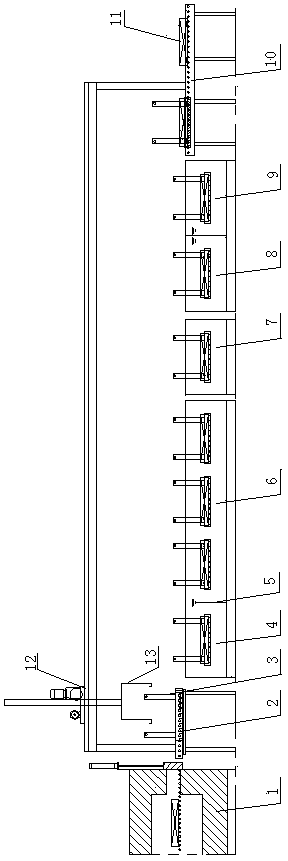

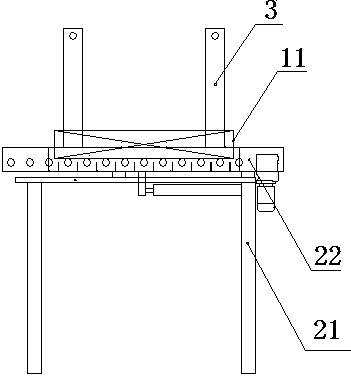

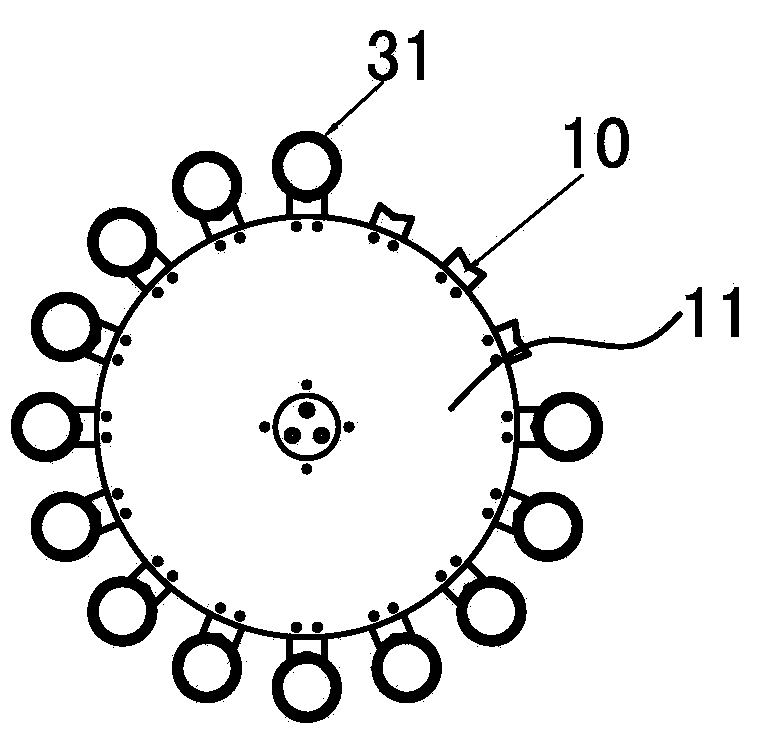

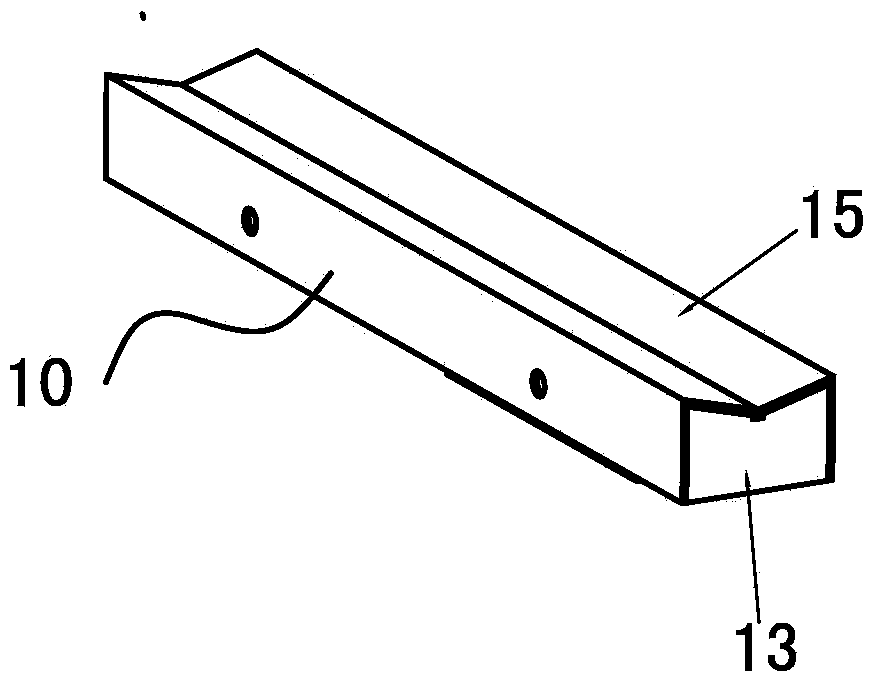

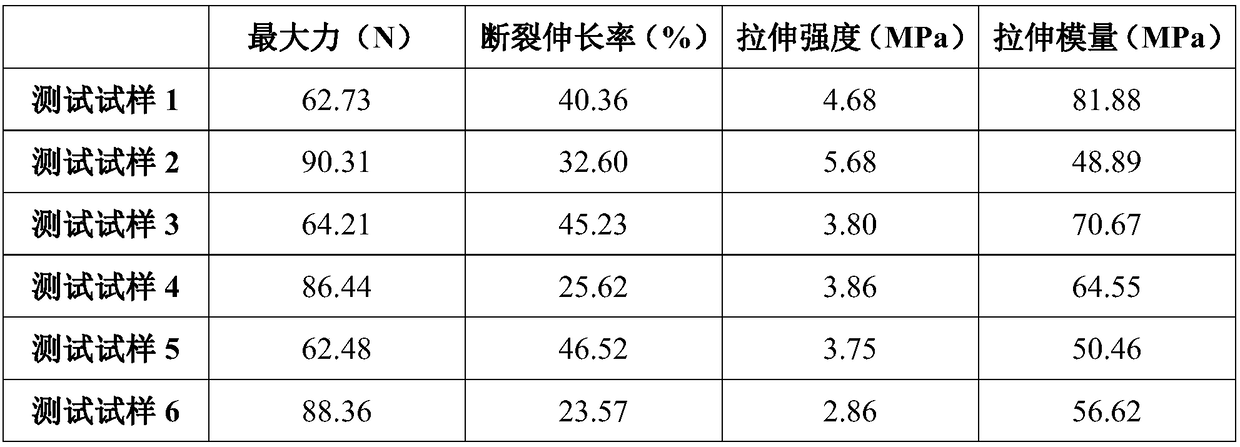

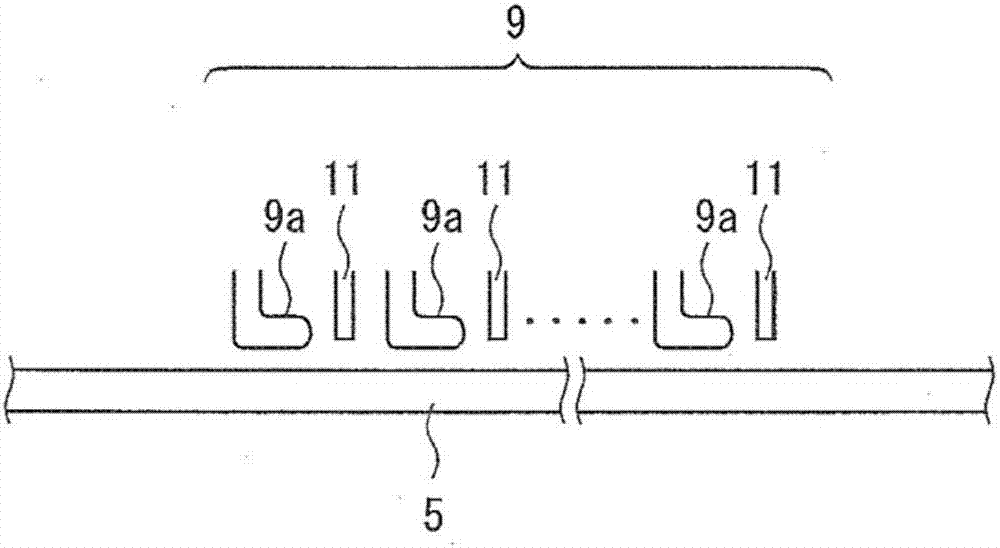

Spring steel wire heating, winding and cooling conveying device

InactiveCN103894522AImprove efficiencyAvoid safety hazardsFurnace typesWire springsSpring steelWinding machine

The invention discloses a spring steel wire heating, winding and cooling conveying device, relates to equipment used for manufacturing springs, in particular to equipment used for manufacturing springs by heating, conveying and winding steel wires and then conveying the springs. The spring steel wire heating, winding and cooling conveying device comprises a spring winding machine (1), a heating mechanism (2) and a spring cooling conveying mechanism (9), and is characterized in that the spring cooling conveying mechanism (9) comprises an annular conveying mechanism (11), wherein a plurality of magnetic attracting blocks (10) are installed on the annular conveying mechanism (11). The spring steel wire heating, winding and cooling conveying device can automatically convey and cool the springs, does not need manual operation, not only is high in efficiency, but also avoids safety risks.

Owner:GUANGZHOU LIANROU MACHINERY & EQUIP

Corrosion-resistant metal coating used for outer surface of gear box

ActiveCN106498290AImprove corrosion resistanceImprove antistatic performanceNon-macromolecular adhesive additivesFilm/foil adhesivesMetal coatingCorrosion resistant

The invention discloses a corrosion-resistant metal coating used for the outer surface of a gear box. The corrosion-resistant metal coating comprises, by mass, 0.06%-0.08% of C, 0.15%-0.18% of Mn, 10.76%-10.79% of Cr, 2.12%-2.15% of Ni, 0.13%-0.15% of Mg, 0.21%-0.23% of Mo, 0.25%-0.27% of Co, 0.06%-0.08% of V, 0.42%-0.44% of Ti, 0.22%-0.25% of Na, 0.17%-0.19% of Ga, 0.22%-0.25% of Ce, 0.16%-0.18% of Nd, 0.32%-0.38% of La and the balance Fe.

Owner:南京创贝高速传动机械有限公司

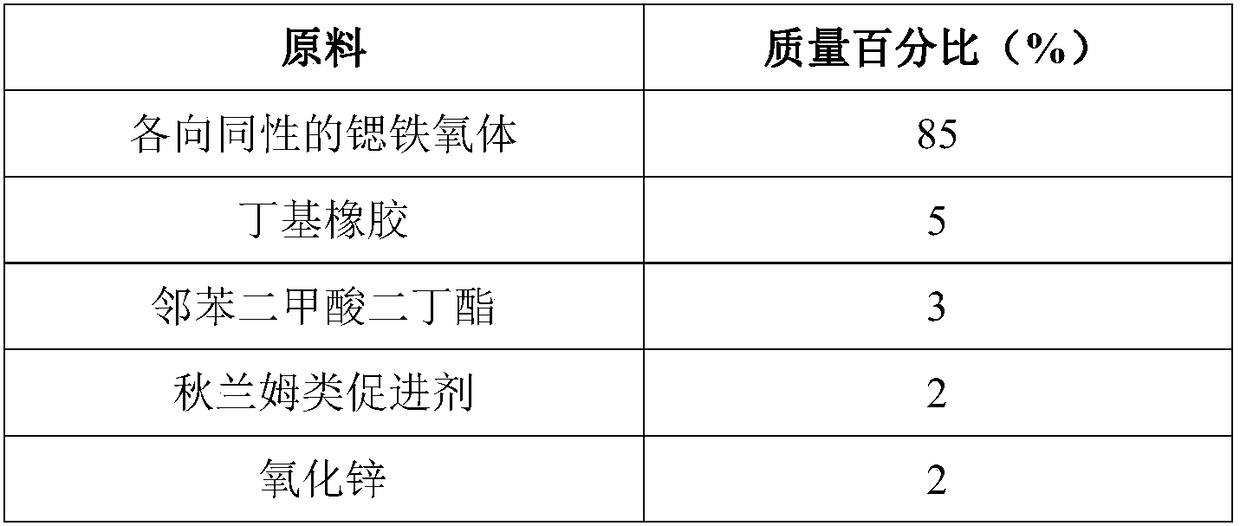

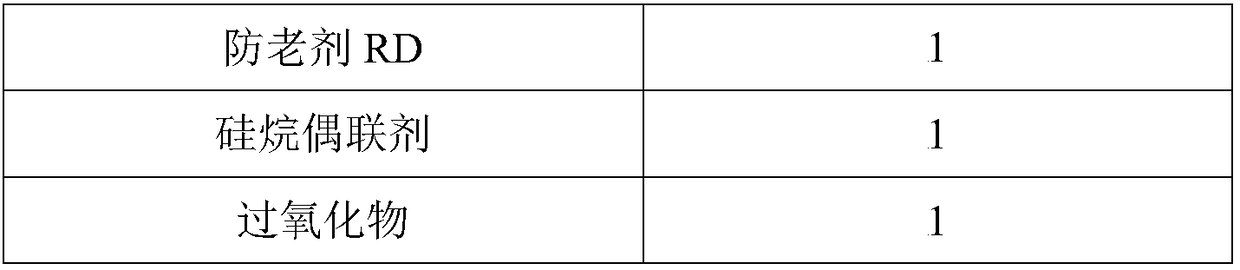

Rubber magnetic stripe and preparation method thereof

The invention discloses a rubber magnetic stripe and a preparation method thereof. The rubber magnetic stripe is prepared from the following ingredients in mass percent content: 75% to 85% of permanent-magnet ferrite magnetic powder, 5% to 15% of rubber, 1% to 5% of plasticizer, 1% to 3% of accelerant, 1% to 3% of activating agent, 0.5% to 2% of anti-ageing agent, 1% to 3% of coupling agent and 0.5% to 3% of vulcanizing agent. The preparation method comprises the following steps: 1) modifying the permanent-magnet ferrite magnetic powder to obtain modified magnetic powder; 2) mixing and smelting the modified magnetic powder, the rubber, the plasticizer, the accelerant, the activating agent, the anti-ageing agent and the vulcanizing agent to obtain a blank; 3) mixing and breaking the blank and rolling the blank into pieces to obtain semi-finished product pieces; 4) cutting and vulcanizing the semi-finished product pieces to obtain vulcanized pieces; 5) performing microwave treatment on the vulcanized pieces and cooling and cutting the vulcanized pieces. The rubber magnetic stripe disclosed by the invention has the advantages of large magnetism, high mechanical strength, good dimensional stability, evenness in internal and external vulcanization, long service life, simple preparation technology and low energy consumption.

Owner:GUANGZHOU GOLDEN SOUTH MAGNETIC MATERIAL

Medium-carbon alloy cast steel shots and manufacturing method thereof

The invention relates to medium-carbon alloy cast steel shots and a manufacturing method thereof. Each medium-carbon alloy cast steel shot comprises the following chemical components in percentage by mass: 0.35 to 0.45 percent of carbon, 0 to 0.2 silicon, 0.45 to 0.5 percent of manganese, 0.8 to 1.2 percent of chrome, 0 to 0.015 percent of sulfur, 0 to 0.020 percent of phosphor and the balance of iron and inevitable impurities. The manufacturing process comprises the following steps of: mixing and smelting, namely, smelting the raw material composition mixed proportionally into liquid steel, pouring the liquid steel into a tundish and performing deoxygenation by adopting an deoxidant; preparing shots by a centrifugally forming method, namely, pouring deoxygenized liquid steel into a centrifugal disc which rotates at a high speed, throwing out the liquid steel under the action of a centrifugal force to make the liquid steel fall into a cooling water pool, and taking the liquid steel out and drying the cooled steel to obtain formed cast steel shots; and performing heat treatment, namely, heating the formed cast steel shots until the temperature reaches 860 to 880 DEG C, performing cold quenching after keeping the temperature for 20 to 40 minutes, tempering for 40 to 80 minutes at the temperature of between 350 and 500 DEG C, and after tempering, cooling rapidly by a steel plate vibrating screen water cooling method to produce the medium-carbon alloy cast steel shots. The medium-carbon alloy cast steel shots and the manufacturing method thereof have the advantages of guaranteeing the high rigidity of the steel shots, avoiding crack generated in the centrifugally forming process and the heating tempering process, improving the toughness and the like.

Owner:淄博大亚金属科技股份有限公司

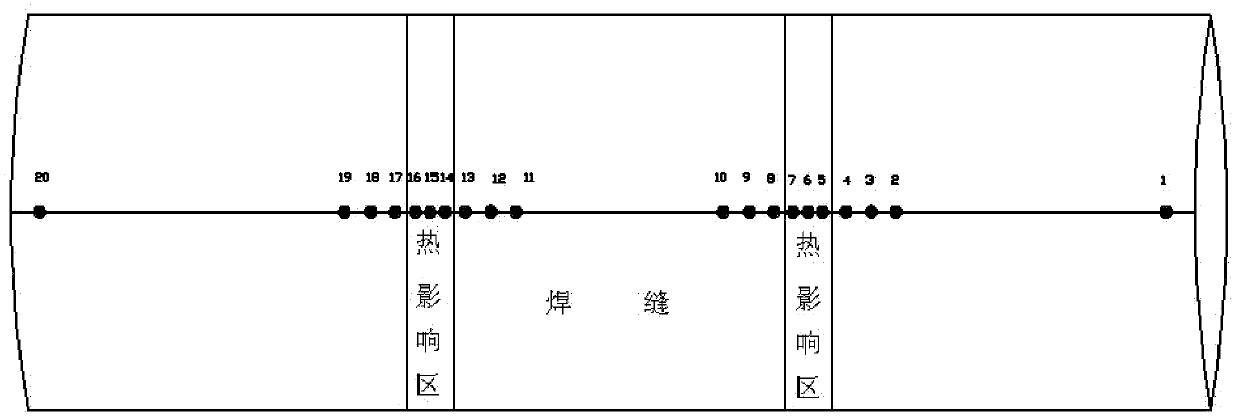

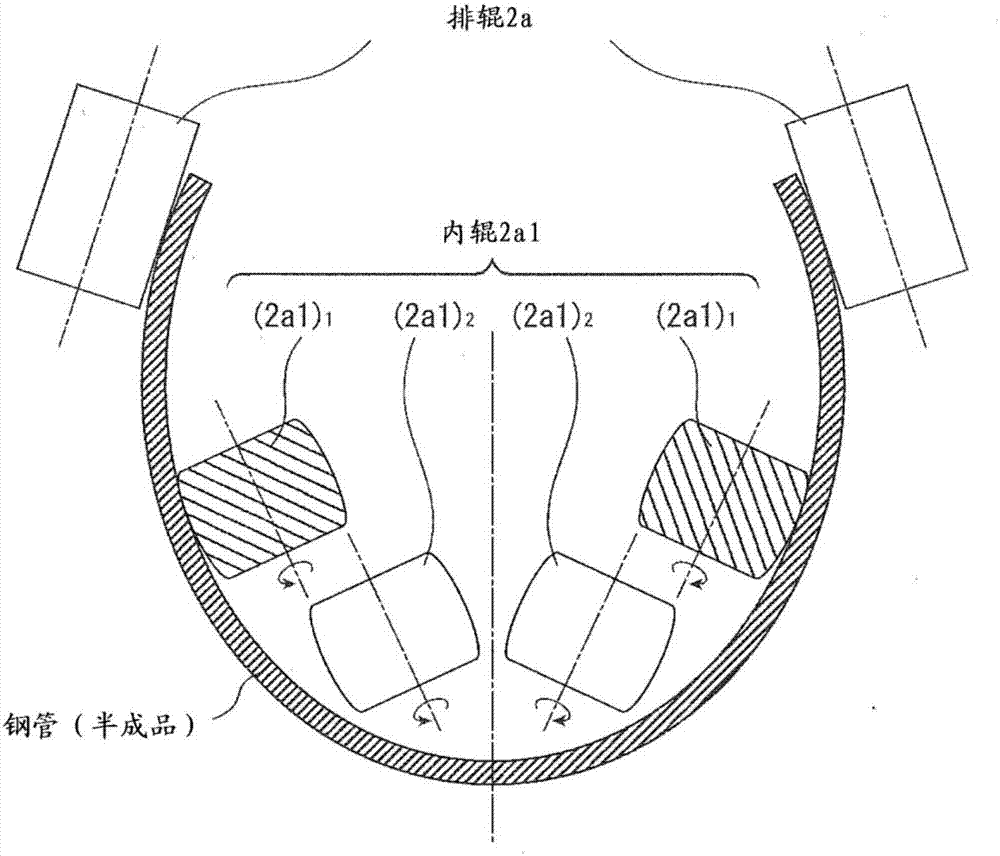

High-strength thick-walled electric resistance welded steel pipe for conductor casing for deep well, production method therefor, and high-strength thick-walled conductor casing for deep well

ActiveCN107109568AHigh strengthImprove toughnessFurnace typesRigid pipesElectrical conductorThick wall

Provided is an electric resistance welded steel pipe that has high strength, high toughness, and excellent post-welding heat treatment resistance. A hot-rolled steel sheet comprising the following is used as a starting material: a composition containing 0.01-0.12% of C, 0.05-0.50% of Si, 1.0-2.2% of Mn, 0.03% or less of P, 0.005% or less of S, 0.001-0.10% of Al, 0.006% or less of N, 0.010-0.100% of Nb, and 0.001-0.050% of Ti; and a structure that comprises 90% or more by volume of a main phase that is a bainitic ferrite phase and 10% or less (including 0%) by volume of a second phase, in which the average particle size of the bainitic ferrite phase is 10(mu)m or less and extremely fine Nb deposits having a particle size of less than 20 nm are dispersed at a rate that, when calculated in terms of Nb, surpasses 75% by ratio (%) of the total amount of Nb. The starting material is formed to have a substantially circular cross section by roll forming and subsequently subjected to electric resistance welding in order to obtain an electric resistance welded pipe, the electric resistance welded section of the electric resistance welded pipe is subjected to inline heat treatment, and the result is subjected to diameter reduction rolling so that the deviation from roundness of a steel pipe end section is 0.6% or less.

Owner:JFE STEEL CORP

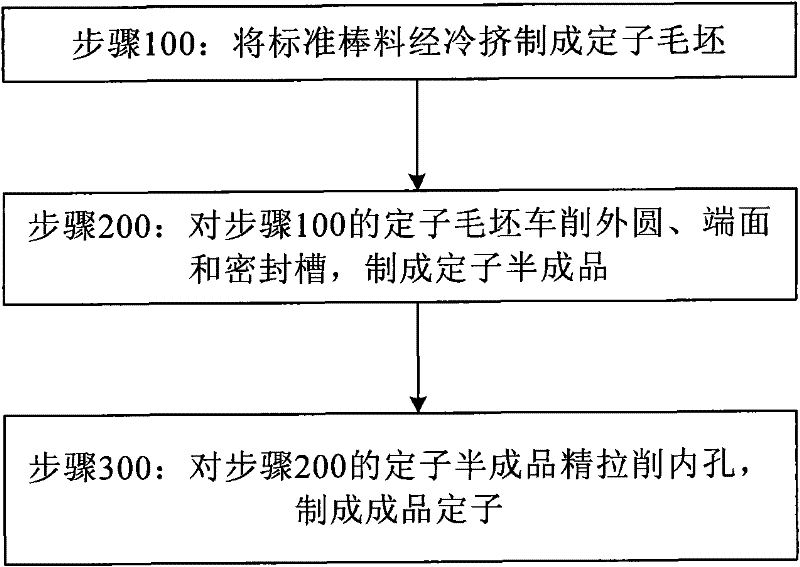

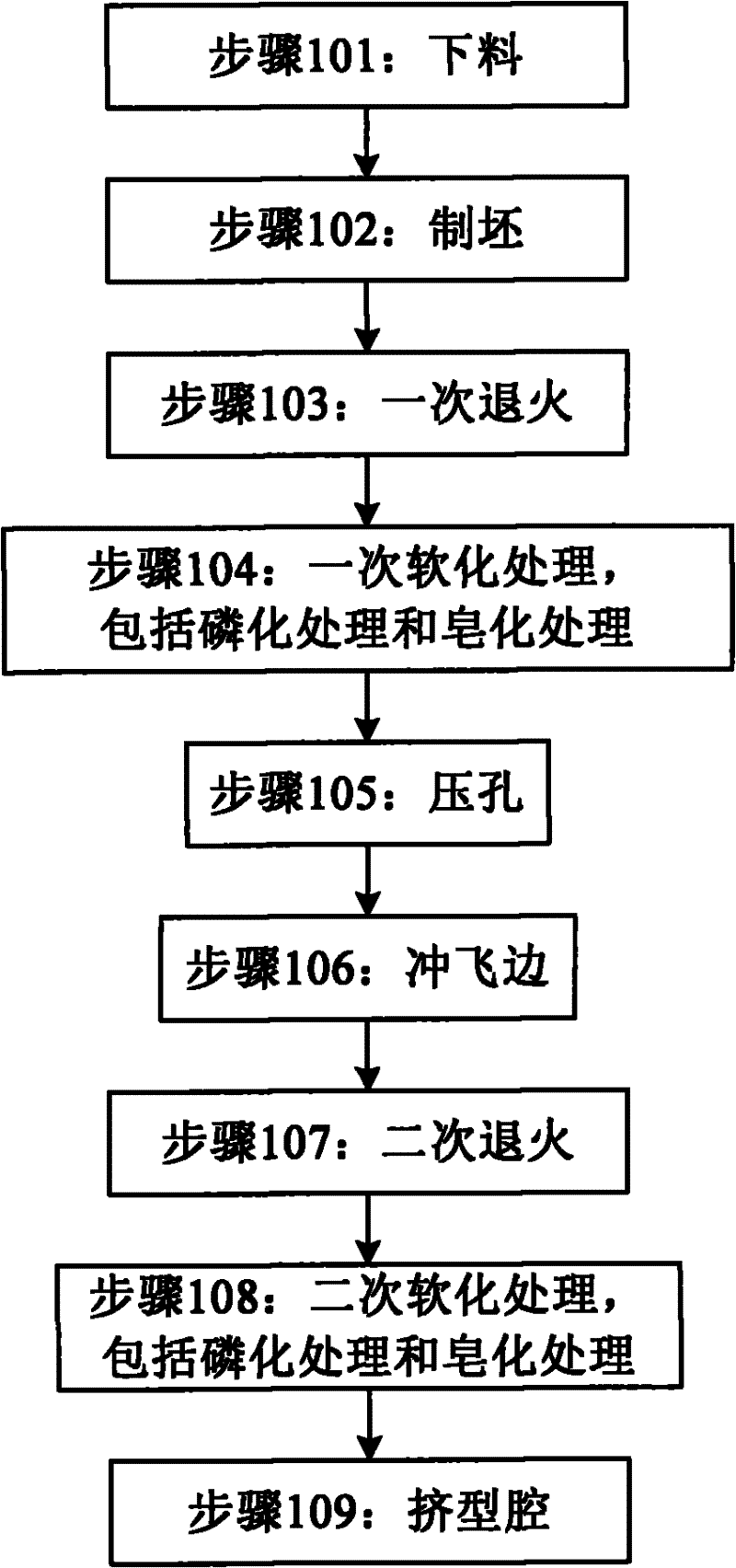

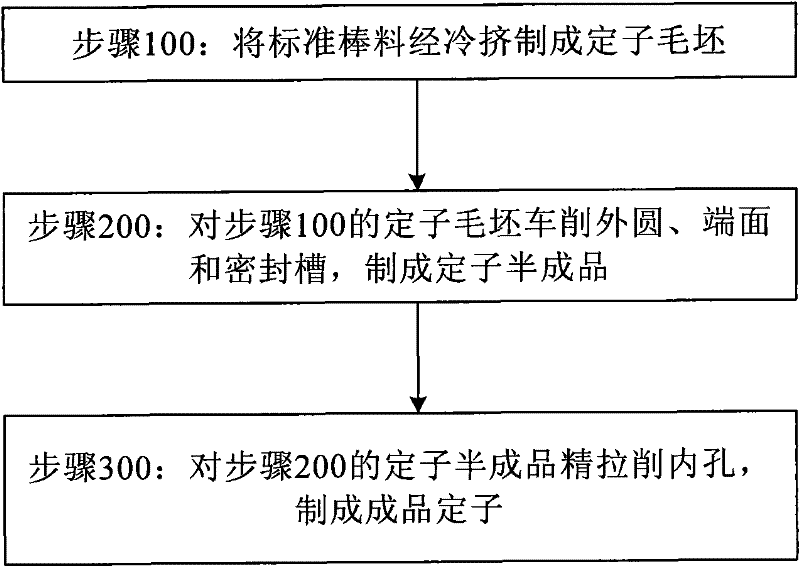

The processing method of the stator

ActiveCN102280976AImprove heat treatment effectImprove fatigue resistanceManufacturing stator/rotor bodiesEngineeringBar stock

The invention relates to a technological method for processing a stator, and the method comprises the following steps of: step 100, performing cold extrusion on a standard bar stock to manufacture a stator blank; step 200, turning an excircle, an end face and a sealing groove on the stator blank obtained in the step 100 to manufacture a stator semi-finished product; and step 300, forming an innerhole on the stator semi-finished product obtained in the step 200 through burnish broaching to manufacture the finished product of the stator. By using the technological method, the chipping allowance of the blank is small; the manufacturing of a broaching tool is simple, and the grinding cost is low; the inner hole is not needed to be turned, the heat treatment performance of parts is good, and the anti-fatigue capacity of materials is improved; and a cold extrusion process is adopted, the flow property of a material is improved, and a multi-time spheroidizing annealing process is mixed intothe cold extrusion process so that organization particles of the material is further thinned, the coarse crystal phenomenon is reduced in the subsequent carburizing and quenching process, and the fatigue resistance of the material is greatly improved.

Owner:DANFOSS POWER SOLUTIONS (JIANGSU) CO LTD

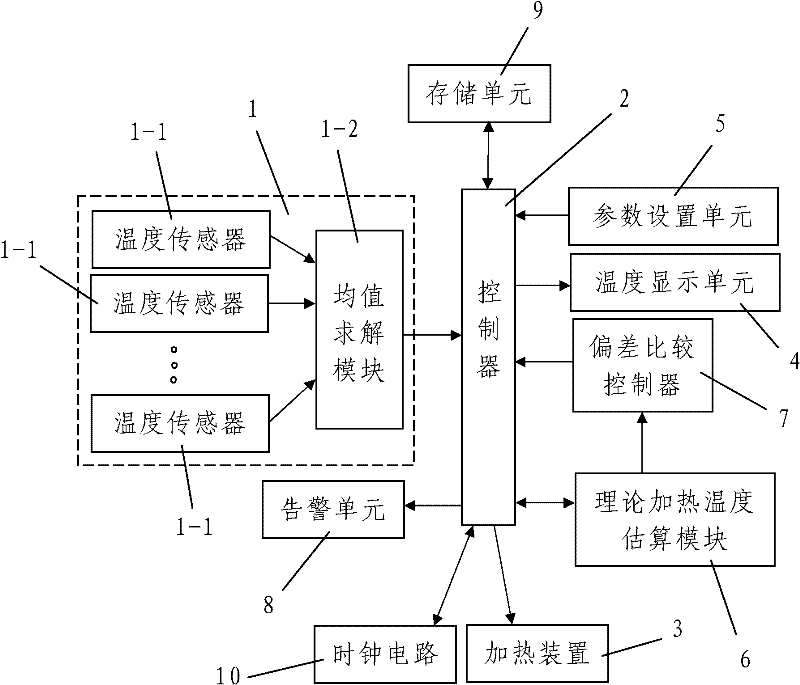

Automatic temperature regulating system for constant temperature furnace

InactiveCN102455134AReasonable designLow costControl devices for furnacesSocial benefitsComputer module

The invention discloses an automatic temperature regulating system for a constant temperature furnace. The automatic temperature regulating system comprises a temperature detection unit, a controller, a temperature display unit, a parameter setting unit, a theoretic heating temperature estimating module, a deviation comparing controller and a warning unit, wherein the controller is used for controlling a heating device of the constant temperature furnace according to the temperature information detected by the temperature detection unit; the deviation comprising controller is used for comparing and analyzing the temperature which is detected by the temperature detection unit in real time with the actual heating temperature calculated by the theoretic heating temperature estimating module; the warning unit is controlled by the controller; the temperature detection unit comprises a plurality of temperature sensors and mean solving modules, wherein the temperature sensors are arranged in the center and a plurality of positions on the inner side of the circumferential wall in the constant temperature furnace; and the mean solving modules are respectively connected with the temperature sensors. The automatic temperature regulating system has the advantages of reasonable design, good use effect and high intelligent degree and is easy and convenient to operate; the detected temperature can accurately reflect the actual temperature in the heating furnace in the current state; the heat treatment effect of processed workpieces can be effectively ensured; and the automatic temperature regulating system has remarkable economic and social benefits.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

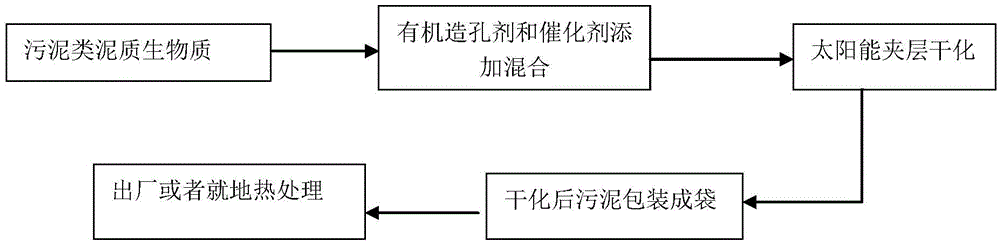

Method for realizing anti-shrinkage recarburization sludge drying

ActiveCN105481221AHigh carbon contentGood yieldSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSludgePolyvinyl alcohol

A method for realizing anti-shrinkage recarburization sludge drying is characterized in that an organic pore-forming agent and a catalyst are added into a sludge dry basis subjected to centrifugal dewatering to be uniformly mixed, distributing is carried out in a solar power interlayer drying system, and through the organic combination of the synergistic effect of framework construction and the pore-forming agent and solar power drying, a low-shrinkage recarburization function on the basis of realizing quick sludge drying is realized, wherein the organic pore-forming agent comprises 50-80% of a pore-forming agent and 20-50% of an aggregate according to the mass ratio; the pore-forming agent is prepared by mixing one or more of natural fibers such as starch, saw dust, sawdust and crop stalks according to an arbitrary ratio; the aggregate is prepared by mixing one or more of high-molecular polymers such as polyvinyl chloride, polystyrene, polyvinyl alcohol and resin according to an arbitrary ratio; the catalyst is the KOH solution with the concentration of greater than or equal to 0.4 mol / L, and the mass ratio of the catalyst to the organic pore-forming agent is 1:1, and the adding amount of the organic pore-forming agent is 5-30% of that of the sludge dry basis. According to the method, the dried sludge size is reduced, and when the sludge moisture content is less than 20%, the dried sludge size is reduced to 16.4-52.2% of the original size of sludge; after pyrolysis, the carbon recovery rate is increased by 20-30%, and BET is increased by 40-120%.

Owner:SHANGHAI JIAO TONG UNIV

Component transfer tool

PendingCN108032279ARealize automatic transferImprove positionProgramme-controlled manipulatorGripping headsDrive motorForce output

The invention provides a component transfer tool, and belongs to the field of component processing equipment. The component transfer tool comprises a base, a movable seat, a rotary cylinder and a lifting cylinder. A mounting groove is formed in the middle of the base, a lead screw is erected in the mounting groove, the axis of the lead screw is parallel to the longitudinal center line of the base,a driving motor is arranged at an end of the base, a force output shaft of the driving motor is fixedly connected with an end of the lead screw, and a nut is fittingly arranged on the lead screw andis fixedly connected with the movable seat by a connecting plate which is vertically arranged. The component transfer tool has the advantages that components at different locations can be quickly transferred by the component transfer tool, and the component transfer tool is high in precision and efficiency.

Owner:TIANJIN KAIDA HEAVY HYDROPOWER EQUIP MFG

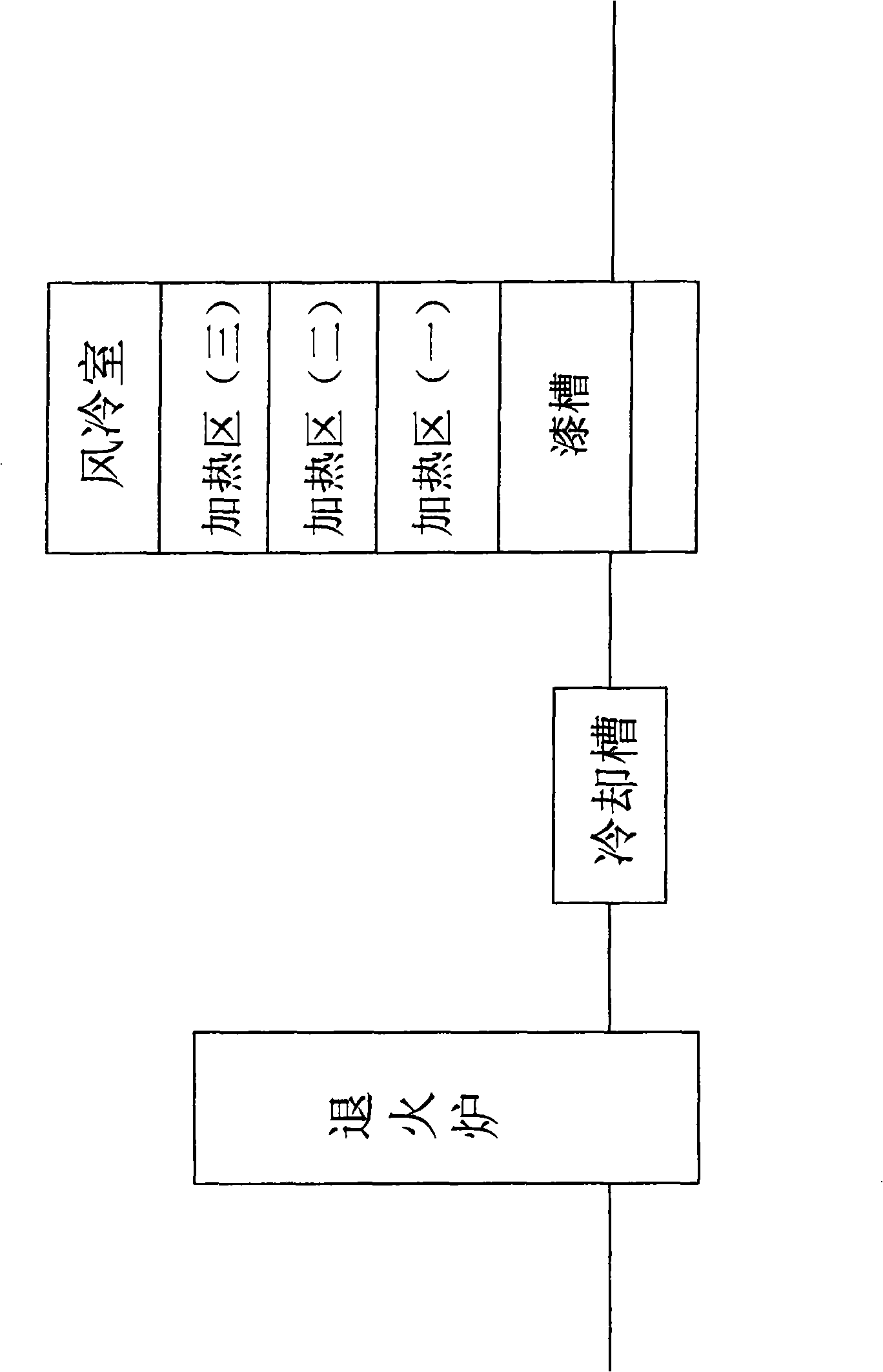

Enamelling copper flat wire paint-dipping process

The invention discloses a lacquer dipping technique of a lacquer-covering copper strap wire, relates to the lacquer dipping techniques of the lacquer-covering copper strap wire, and comprises following steps: a copper strap wire is transmitted into an annealing furnace at the speed of 6 to 8 meters per minute, the temperature of the annealing furnace is controlled between 480 and 520 DEG C, and heating stroke lasts for 8 to 10 meters; then the copper strap wire is cooled to the temperature of 20 to 40 DEG C; the lacquer dipping of the copper strap wire is implemented at the speed of 6 to 8 meters per minute; then the copper strap wire is heated, a heating device with three levels of heaters is provided, the temperature of the three levels of heaters are respectively controlled at 160 to 200 DEG C, 230 to 270 DEG C and 300 to 350 DEG C, and the copper strap wire orderly passes through the three temperature regions and then through a cooling device that is arranged at an upper part of the heating furnace; finally the copper strap wire is cooled naturally and then stored. The lacquer dipping steps are repeated for 6 to 10 times. The heating furnace of the invention has three levels of heaters and the temperature gradually is raised, the copper strap wire orderly passes the three heating regions and then is cooled, consequently, the copper strap wire that is thermally processed by the lacquer dipping technique has good quality effect.

Owner:WUXI XIZHOU MAGNET WIRES

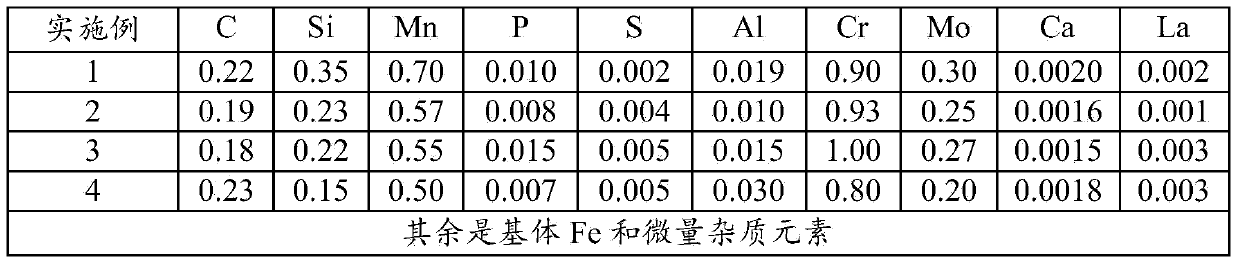

Low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material and production method thereof

InactiveCN103436787AStrong enoughImprove resistance to H

<sub>2</sub>

S corrosion performanceChemical compositionRare earth

The invention discloses a low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material. The low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material comprises the following chemical components in percentage by mass: 0.18-0.23% of C, 0.15-0.23% of Si, 0.50-0.70% of Mn, less than or equal to 0.015% of P, less than or equal to 0.05% of S, 0.010-0.030% of Al, 0.80-1.00% of Cr, 0.20-0.30% of Mn, 0.0015-0.0020% of Ca, less than or equal to 0.03% of La and the balance of matrix Fe and impurity elements. The invention also discloses a production method of the low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material. The low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material has the advantages of relatively low cost, good plasticity, low crack sensitivity, low residual stress, good hardenability, stable performance and relatively high percentage of elongation.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Manufacturing method of high-strength aluminum alloy rivet wire for spaceflight

ActiveCN106756333AImprove performanceGuaranteed heat treatment performanceSolution treatmentHigh intensity

The invention discloses a manufacturing method of a high-strength aluminum alloy rivet wire for spaceflight, and relates to a manufacturing method of a novel aluminum alloy rivet wire. The imperious demands of China space industry for high-strength riveting materials, particularly light aluminum alloy rivet materials are met, the material strength is ensured, and meanwhile rivets are required to have certain plasticity. The manufacturing method comprises the first step of alloy solution preparation, the second step of molten aluminum refining treatment, the third step of casting of an alloy cast bar, the fourth step of homogenizing annealing, the fifth step of cast bar sawing, the sixth step of hot extrusion forming, the seventh step of intermediate annealing, the eighth step of cold drawing, the ninth step of solution treatment and the tenth step of aging treatment. According to the aluminum alloy rivet wire manufactured through the manufacturing method, the tensile strength is not smaller than 580 Mpa, the stipulated non-proportional extension strength is not smaller than 500 Mpa, the percentage elongation after fracture is not smaller than 6%, the shear strength is not smaller than 320 Mpa, and application requirements of spaceflight products are met. The manufacturing method can be used for machining and manufacturing spaceflight aluminum alloy rivets.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com