Automatic temperature regulating system for constant temperature furnace

An automatic adjustment, constant temperature furnace technology, applied in the direction of furnaces, furnace components, furnace control devices, etc., can solve the problems of uneven heating temperature distribution, affecting the heat treatment effect of processed products, etc., to achieve high practical value, intuitive display effect, easy installation The effect of convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

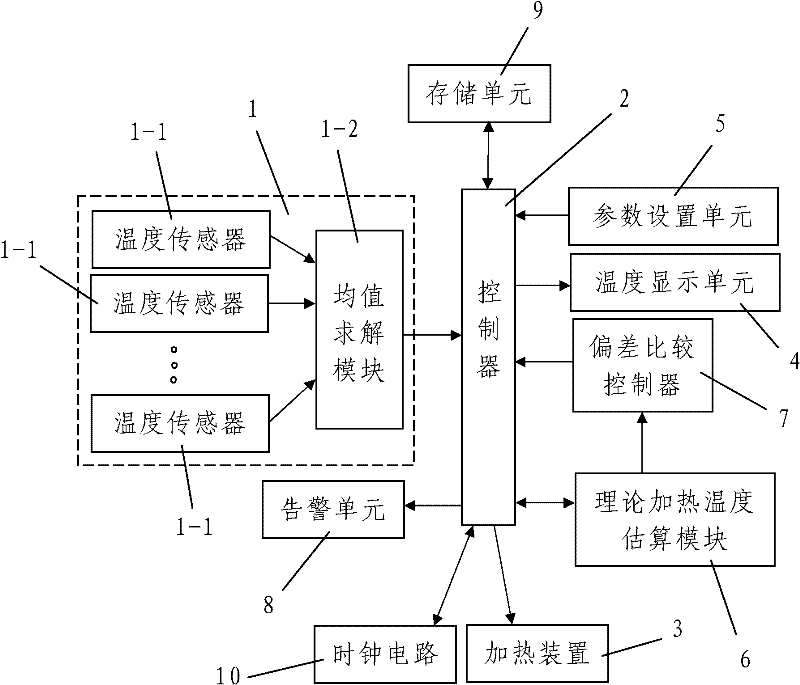

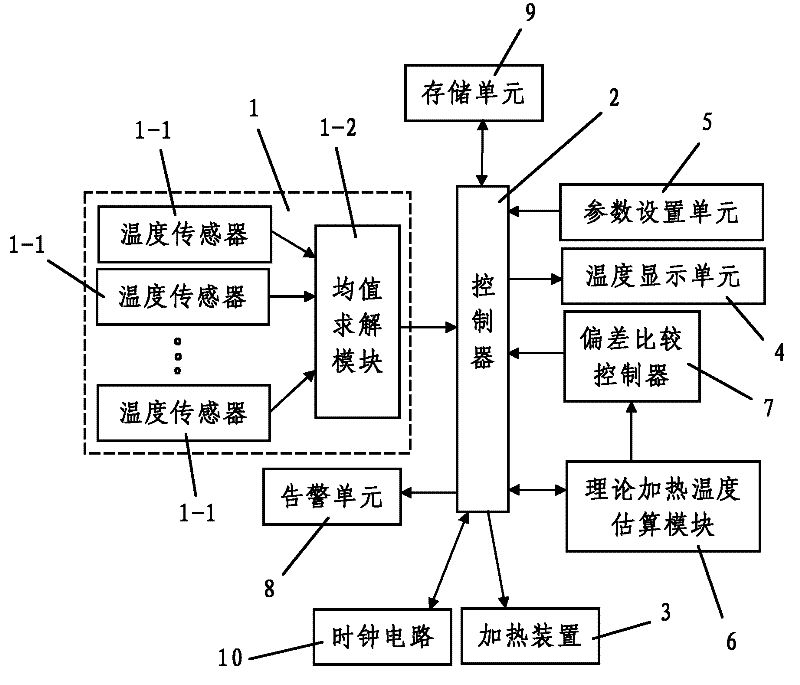

[0023] Such as figure 1 As shown, the present invention includes a temperature detection unit 1 that detects the heating temperature in the constant temperature furnace in real time, a controller 2 that controls the heating device 3 of the constant temperature furnace according to the temperature information detected by the temperature detection unit 1, and controls the The temperature display unit 4 and the parameter setting unit 5 connected to the device 2, the temperature detection unit 1 is connected to the controller 2, and the controller 2 is connected to the heating device 3. At the same time, the present invention also includes heating according to the heating device 3 The theoretical heating temperature estimation module 6 that synchronously estimates the theoretical heating temperature in the constant temperature furnace according to the efficiency, and the actual heating under the current state calculated by the real-time detected temperature of the temperature detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com