Low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material and production method thereof

A technology of oil casing and production method, which is applied in the field of low-cost rare earth-containing H2S corrosion-resistant oil casing materials, which can solve the problems of drilling rig ecological environment damage, hydrogen sulfide overflow, scrapping, etc., to ensure H2S corrosion resistance and residual stress The effect of low and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

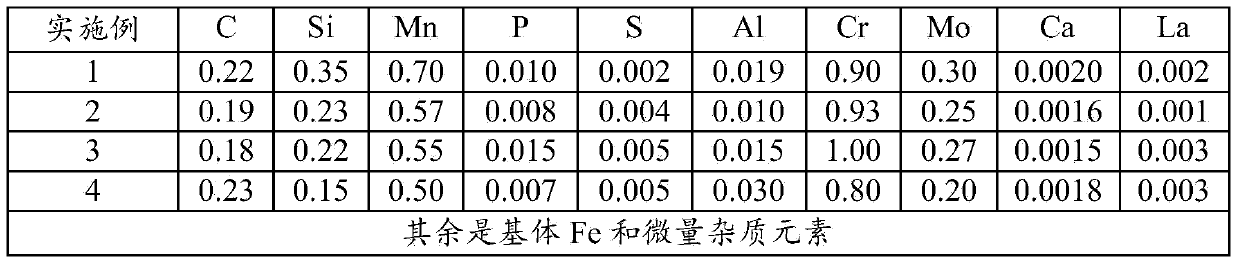

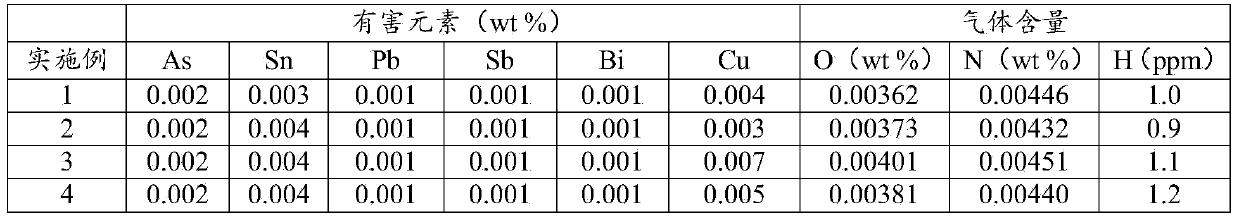

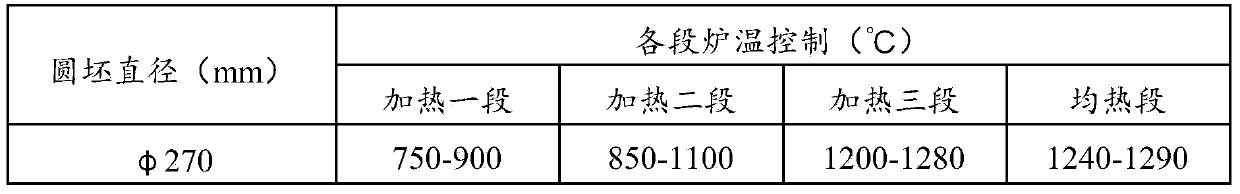

[0024] Low-cost rare earth-containing anti-H of the present invention 2 The production method of S corroded petroleum casing includes steelmaking production, casing rolling and heat treatment of rolled casing. The production process is briefly described as: converter smelting → LF furnace refining → VD furnace vacuum treatment → round billet continuous casting → round Billet heating→perforation→continuous rolling pipe→diameter reduction→cooling bed cooling→saw cutting→heat treatment→straightening→flaw detection→threading. The specific process is as follows:

[0025] Steelmaking production includes: molten iron pretreatment → top-bottom combined blowing converter smelting → LF furnace refining → VD furnace vacuum treatment → round billet continuous casting. Transport the blast furnace molten iron to the steelmaking desulfurization station for desulfurization pretreatment by spraying magnesium powder. The amount of magnesium powder injected per ton of blast furnace molten iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com