Spray cooling device for long steel rail online quenching unit

A technology for cooling devices and rails, applied in quenching devices, furnaces, heat treatment equipment, etc., can solve problems such as small adjustment range, high noise, and inability to accurately control the cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

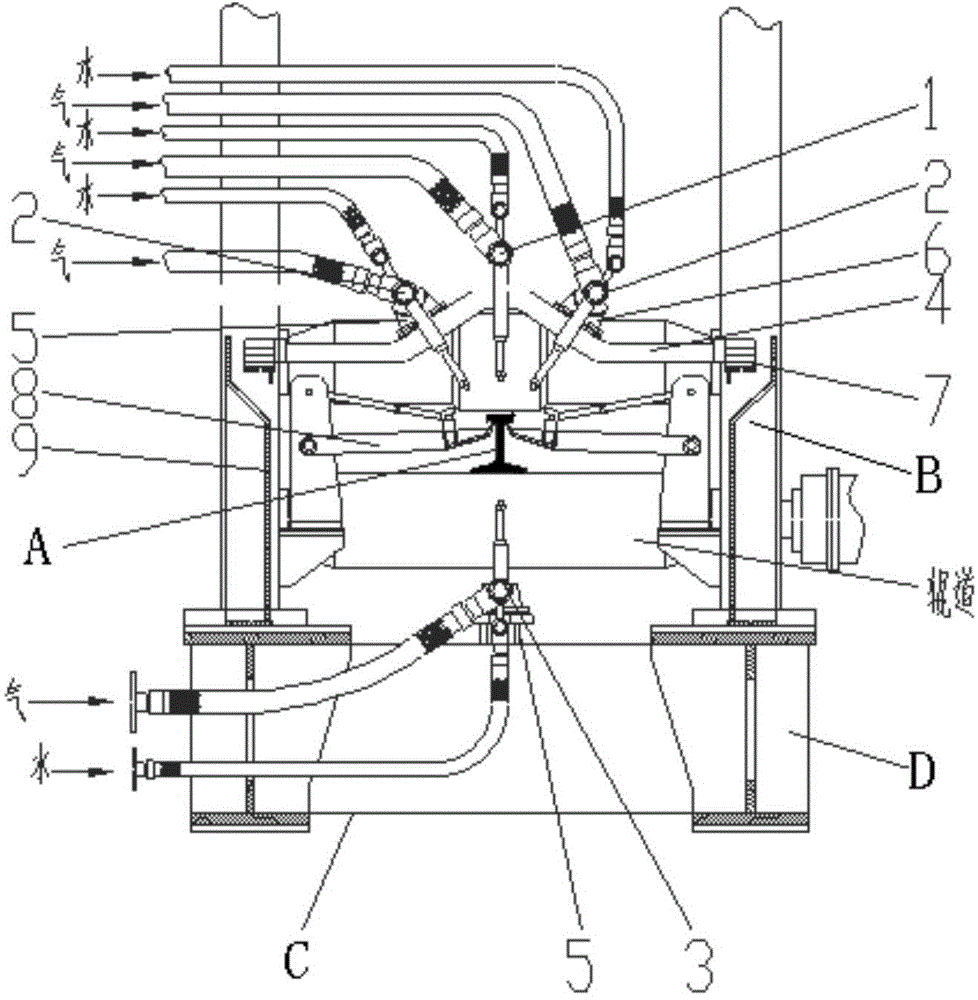

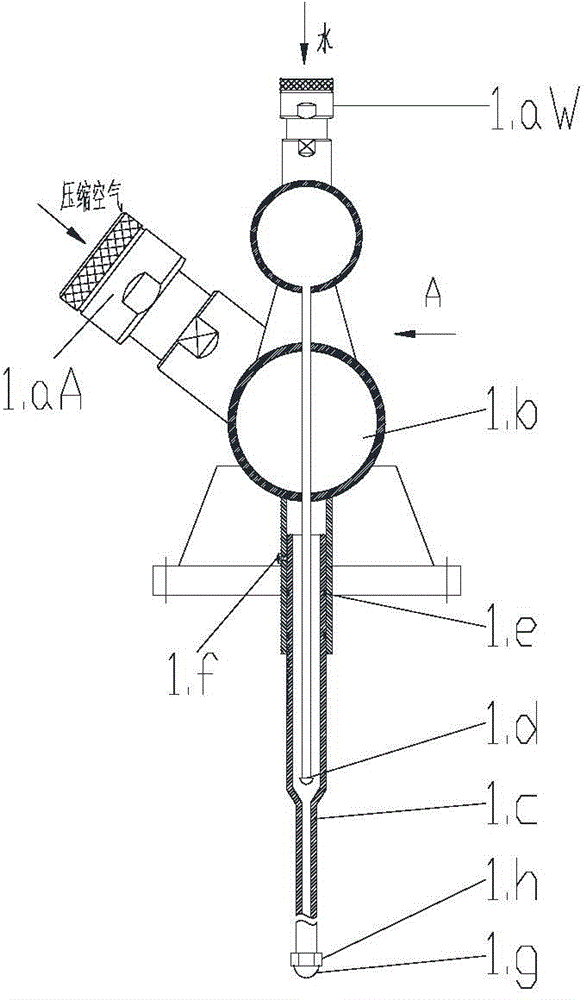

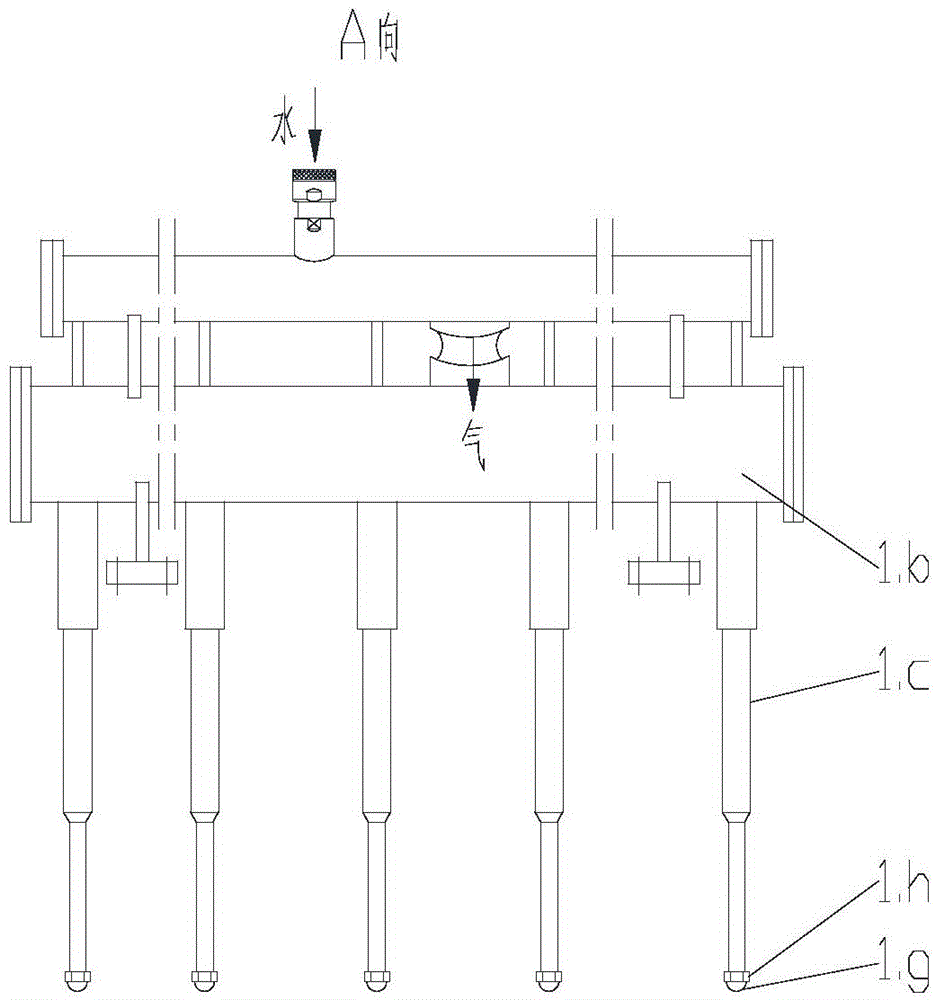

[0026] A spray cooling device for a long rail on-line quenching unit, including a strong cooling zone and a weak cooling zone arranged in sections from front to back in a 75-125m long quenching unit, and the front of the quenching unit is 1 / 3-1 / 2 long It is a strong cooling area, using spray (water mist) method; the rear 1 / 2~2 / 3 area is a weak cooling area, using the method of blowing air or blowing compressed air that has been pre-humidified in the ventilation duct main pipe or branch pipe , each cooling section is 1.2-4.5m long to match the distance between the roller table and the straightening traction roller, and each cooling section is composed of 4 cooling units; cooling and quenching the end surface and both sides of the rail head of rail A; Below the rail A, corresponding spray cooling is carried out on the bottom of the rail at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com