Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "No eddy current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

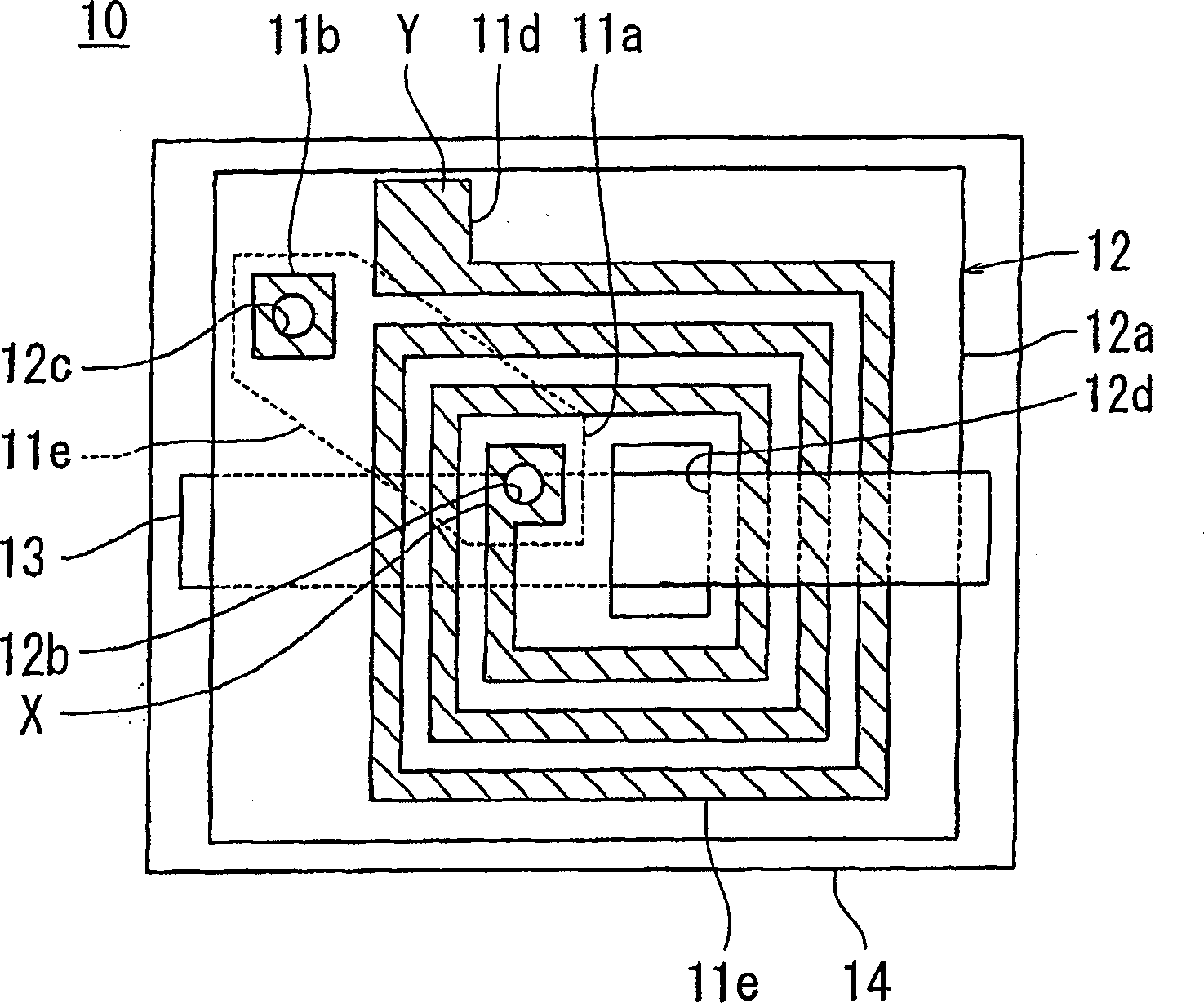

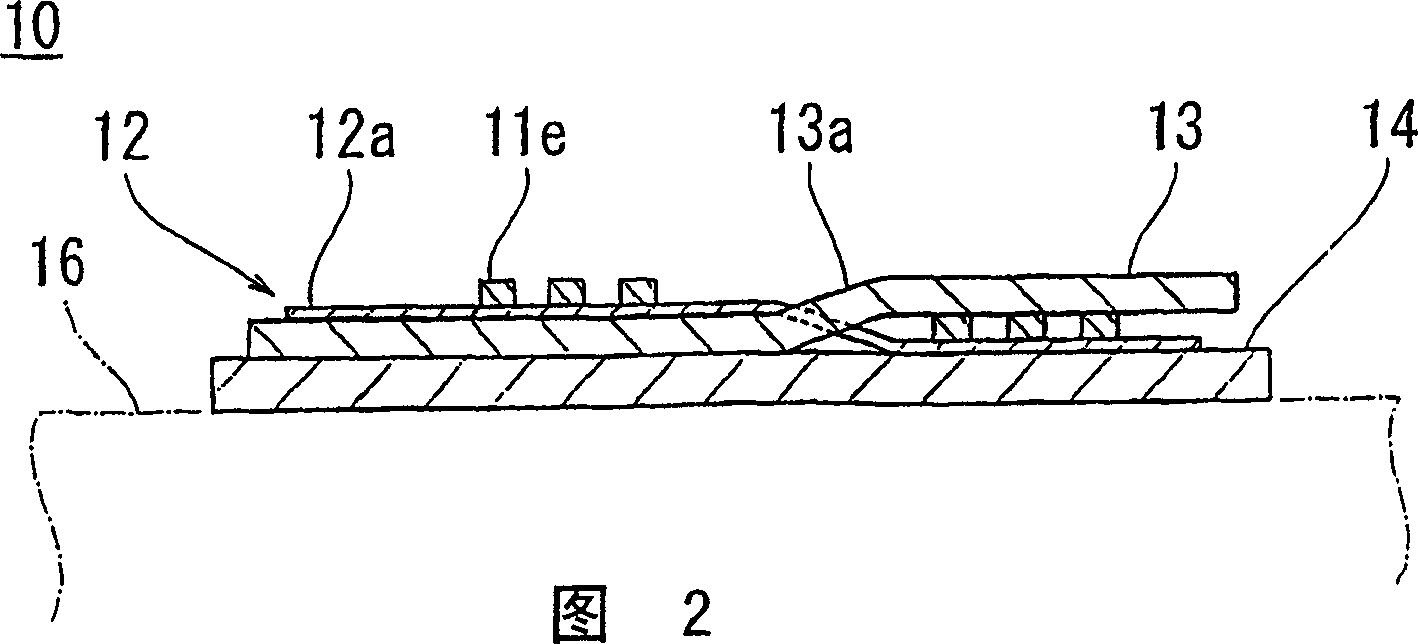

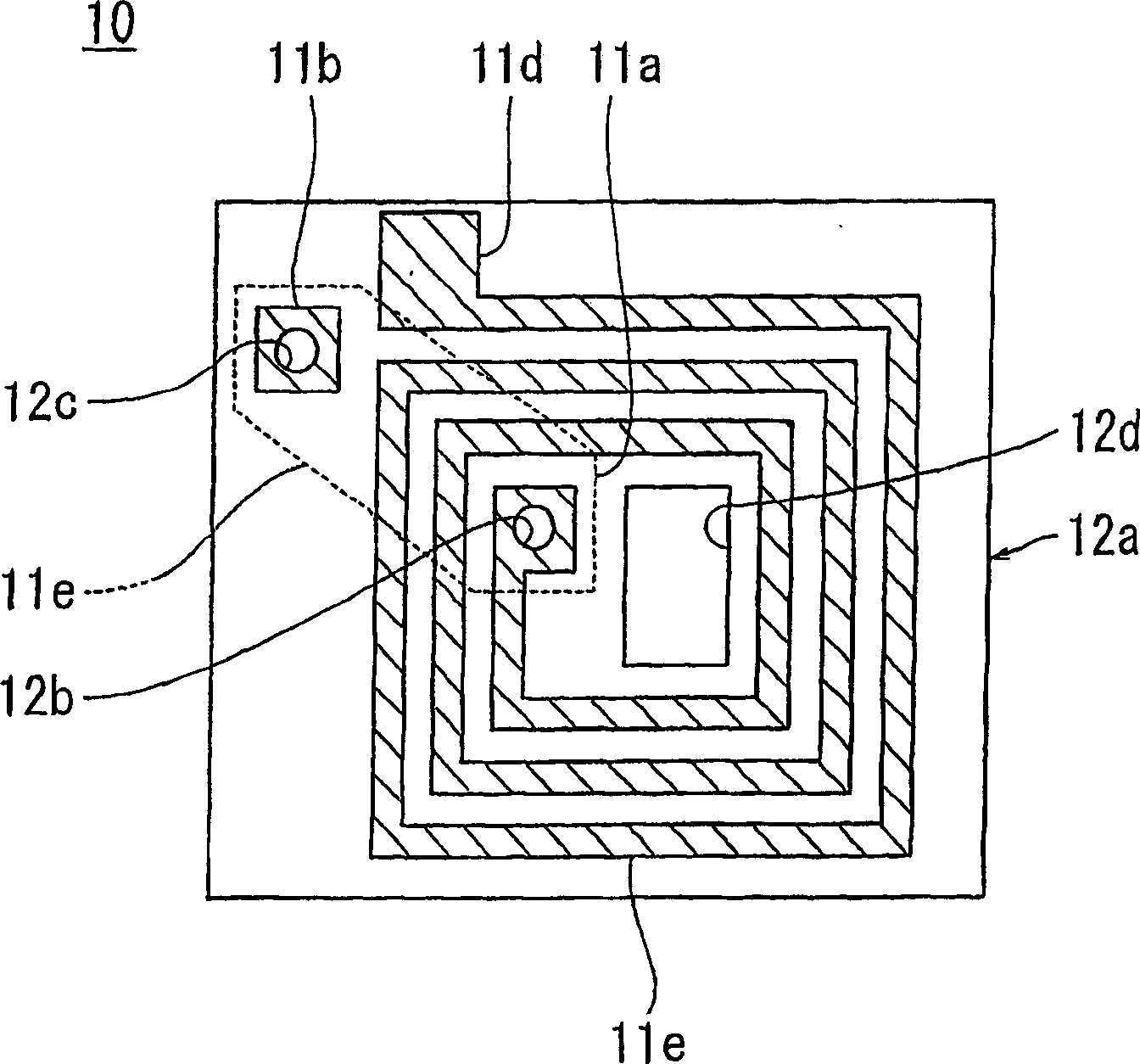

Antenna coil and RFID-use tag using it, transponder-use antenna

InactiveCN1871743AImprove rigidityEasy to useLoop antennas with ferromagnetic coreOther printing matterNon magneticRadio frequency

An antenna coil 10 comprises an air-core coil 12 which is wound helically in a plane and a plate magnetic core member 13 which is inserted in the air-core coil 12 so as to be approximately parallel with a plane of the air-core coil 12. The magnetic core member 13 is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member 13 is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member 13 is a magnetic coating which is formed by applying and drying the composite member. A non-magnetic conductive plate 14 which has a conductivity is layered on a surface of the air-core coil 12 through which the magnetic core member 13 is inserted. The conductive plate 14 is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. By doing this, it is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

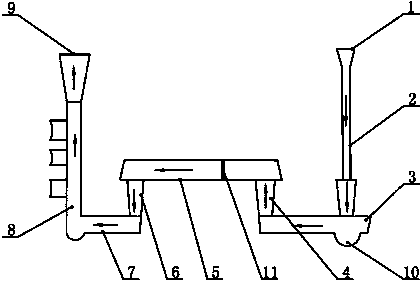

Garbage transfer station malodorous gas treatment technique and device

InactiveCN104492254AImprove purification efficiencyExtended stayDispersed particle separationCatalytic oxidationEnvironmental engineering

The invention relates to the technical field of waste gas purification, particularly a garbage transfer station malodorous gas treatment technique and device. The garbage transfer station malodorous gas treatment technique comprises a working mode and a disinfection mode, wherein the working mode adopts a low-temperature plasma cracking oxidation reactor and catalytic oxidation bed purification process; and the disinfection mode is implemented by the following steps: introducing air into the low-temperature plasma cracking oxidation reactor to generate ozone, hydroxy free radical and other active groups, and delivering to garbage, garbage leachate and other parts in need of disinfection treatment to perform disinfection. The garbage transfer station malodorous gas treatment device comprises a collecting system, a low-temperature plasma cracking oxidation reactor, a catalytic oxidation bed and a draught fan. The technique and device have high purification efficiency and favorable effect for malodorous peculiar smell, is slightly influenced by various environments and extrinsic conditions, and can effectively disinfect the parts in need of disinfection without influencing the biochemical properties of the garbage.

Owner:SHANDONG PALLET ENVIRONMENTAL ENG

Method for reducing difference of two sides of paper, and prepared paper

ActiveCN103966887AReduce double-sidednessUniform compositionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperGlass fiberPaper manufacturing

The invention provides a method for reducing difference of the two sides of paper. The paper is designed to be of a multilayer fiber layer structure; the pulp preparing and beating of each fiber layer are realized independently; a pulp material enters a paper machine with multiple independent flow channels, and is formed in forming areas through simultaneous stacking and paper manufacturing with pulp, wherein the content of fine fibers of which diameters are smaller than 1 micron in the pulp material I entering a flow channel closely adjacent to a forming net is higher than that of fine fibers of pulp material in other layers, and preferably, the content of the fine fibers in the pulp material I is 5-10% higher than that of the fine fibers of the pulp material in other layers. The invention further provides the paper which has low two-side difference, and is prepared by the method, in particular to a glass fiber paper with low two-side difference as well as a coalescent filter element comprising the glass fiber paper with low two-side difference. According to the glass fiber paper with low two-side difference, provided by the invention, the density of fibers in the paper thickness direction is uniform, so that the efficiency and a separation capability of the coalescent filter element can be remarkably improved.

Owner:SOUTH CHINA UNIV OF TECH

Novel cable bracket hoop and preparation method thereof

InactiveCN104419157AImprove flame retardant performanceNo eddy currentPipe supportsGlass fiberEngineering

The invention relates to the technical field of cable burying, and particularly provides a novel cable bracket hoop and a preparation method thereof. The novel cable bracket hoop is a molded part of an even SMC composite material; a reserved inserting hole is formed in the novel cable bracket hoop; the novel cable bracket hoop is connected with a cable bracket upright post through a bolt made of the SMC composite material; and the SMC composite material comprises the following components in percentage by mass: 18%-22% of unsaturated polyester resin, 8%-10% of a low-shrinkage additive, 45%-50% of a flame-retardant filler, 18%-20% of glass fiber and 3%-4% of other additives. The preparation method comprises the following steps: firstly preparing resin paste in preparation; and adding the glass fiber, stirring, heating, pressurizing and molding. The novel cable bracket hoop disclosed by the invention is energy-saving, environmentally-friendly, long in service life, good in flame retardant property, free of eddy, good in safety performance.

Owner:重庆杰友电气材料有限公司

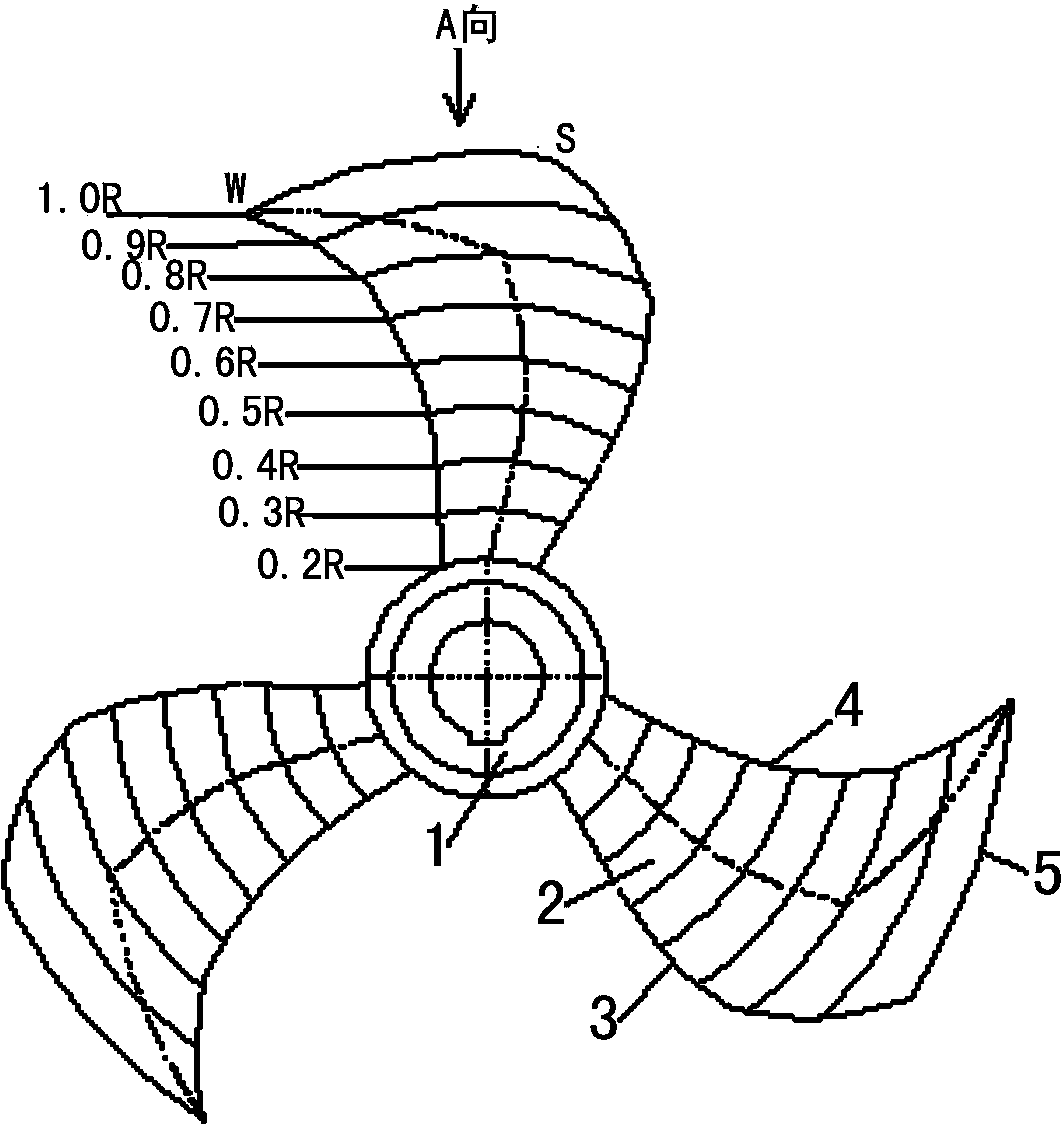

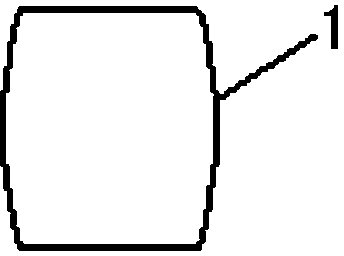

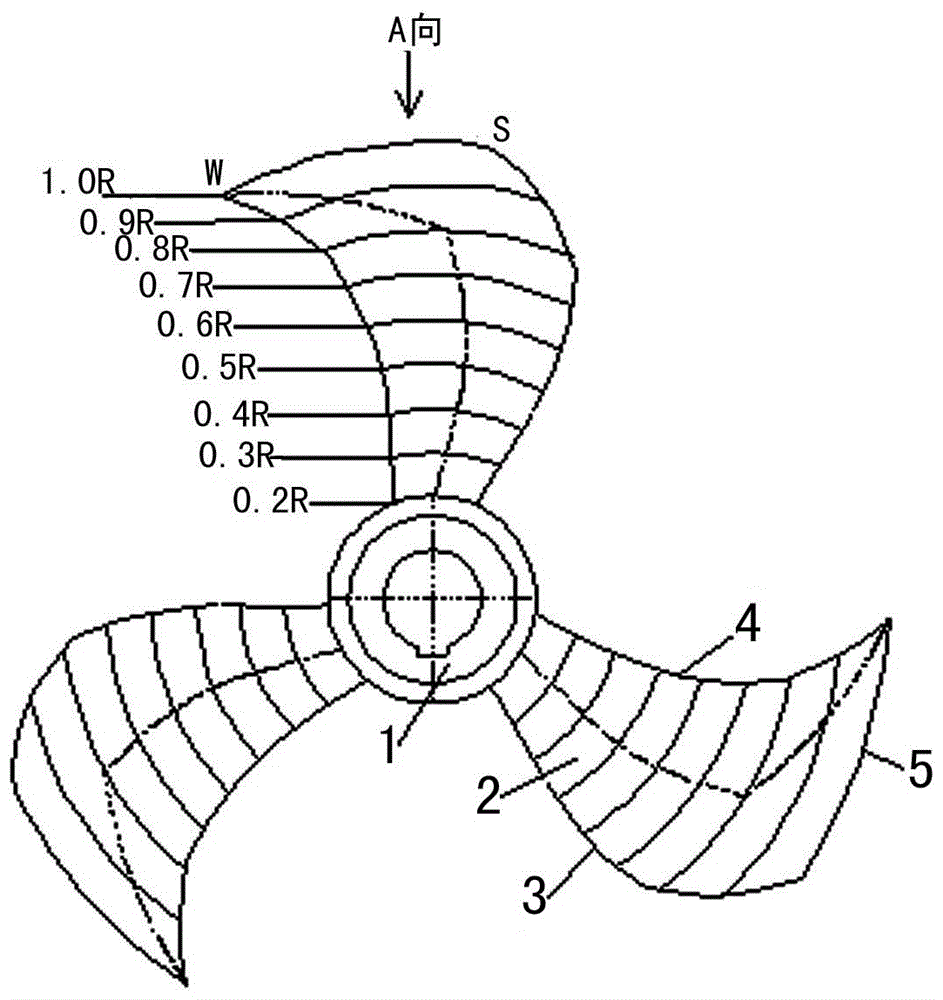

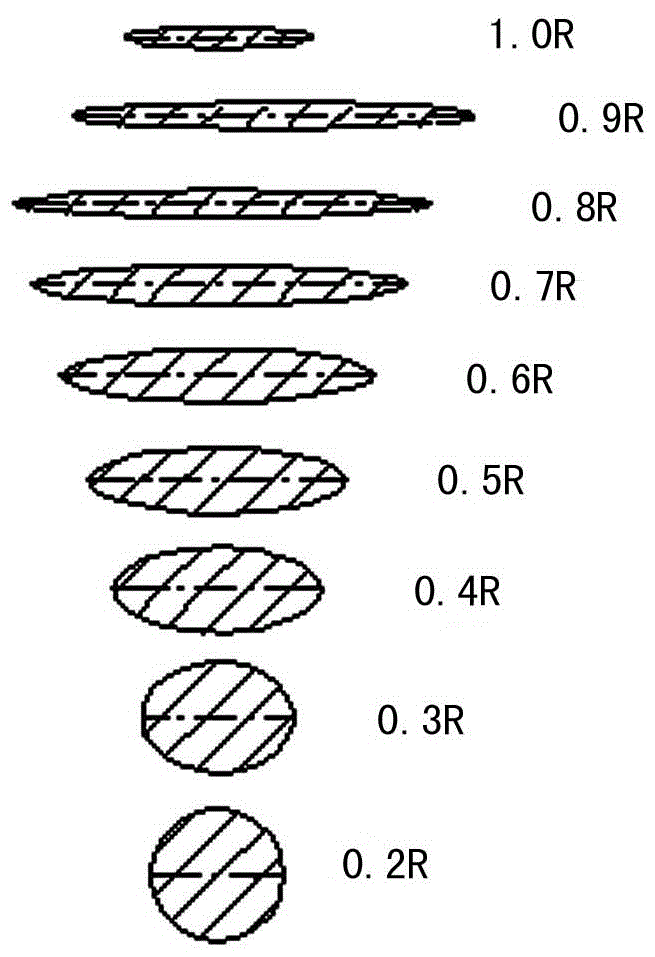

Marine propeller

A marine propeller comprises a propeller hub and blades evenly distributed on the circumference of the propeller hub. The propeller hub is shaped like a waist drum. The contour of the blade surface of each blade is formed by a hyperbola convex guiding edge, a hyperbola concave following edge and a circumferential arc edge in an enclosing mode. According to the blade surfaces of the blades, the arc chord length gradually increases from the position with the distance 0.2-0.8 times of the radius of the propeller, reaches the maximum value in the position with the distance 0.8 times of the radius of the propeller and slightly decreases from the position with the distance 0.8-1.0 times of the radius of the propeller; according to the shape of the cross section of each blade, the cross section, from the root of the blade to the position with the distance 0.2 times of the radius of the propeller, of the blade is round, and the cross section, from the position with the distance 0.2 times of the radius of the propeller to the position with the distance 1.0 times of the radius of the propeller, of the blade is an oval with the long axis gradually increasing and the short axis gradually decreasing ; the angle alpha of pitch of each blade ranges from 10 degrees to 25 degrees. The marine propeller is suitable for providing bidirectional power for moving forward and backward of a ship, can also make a double-propeller ship change a left propeller and a right propeller and has the advantage of being high in working efficiency.

Owner:周宗伟

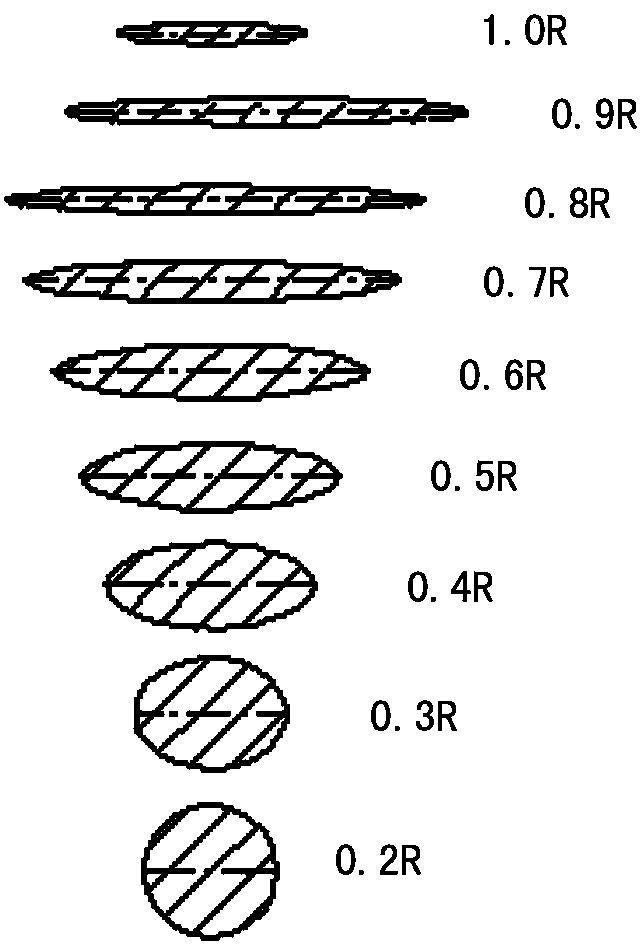

Cycling and precipitate recovering device for aluminum-air cells

PendingCN108365282AIncrease temperatureDissipate quicklyElectrolyte/reactants regenerationWaste accumulators reclaimingElectrolysisFilter system

The invention relates to a cycling and precipitate recovering device for aluminum-air cells. The device comprises an electrolyte tank, a cooling system, an aluminum-air battery pack, a precipitate filtering system and a pressure pump, wherein a bottom output end of the electrolyte tank is connected with a liquid inlet of the cooling system, a liquid outlet of the top end of the aluminum-air cell pack is connected with an input end of the precipitate filtering system through a one-way valve, and a bottom output end of the precipitate filtering system is connected with the pressure pump. According to the cycling and precipitate recovering device for the aluminum-air cells, an electrolyte can uniformly flow without generating vortex, and Al(OH)3 flocculent deposits produced from a reaction can be rapidly deposited and are filtered off, so that the service life of the electrolyte is prolonged, and the generating efficiency of the electrolyte is improved.

Owner:SHANGHAI JIAO TONG UNIV

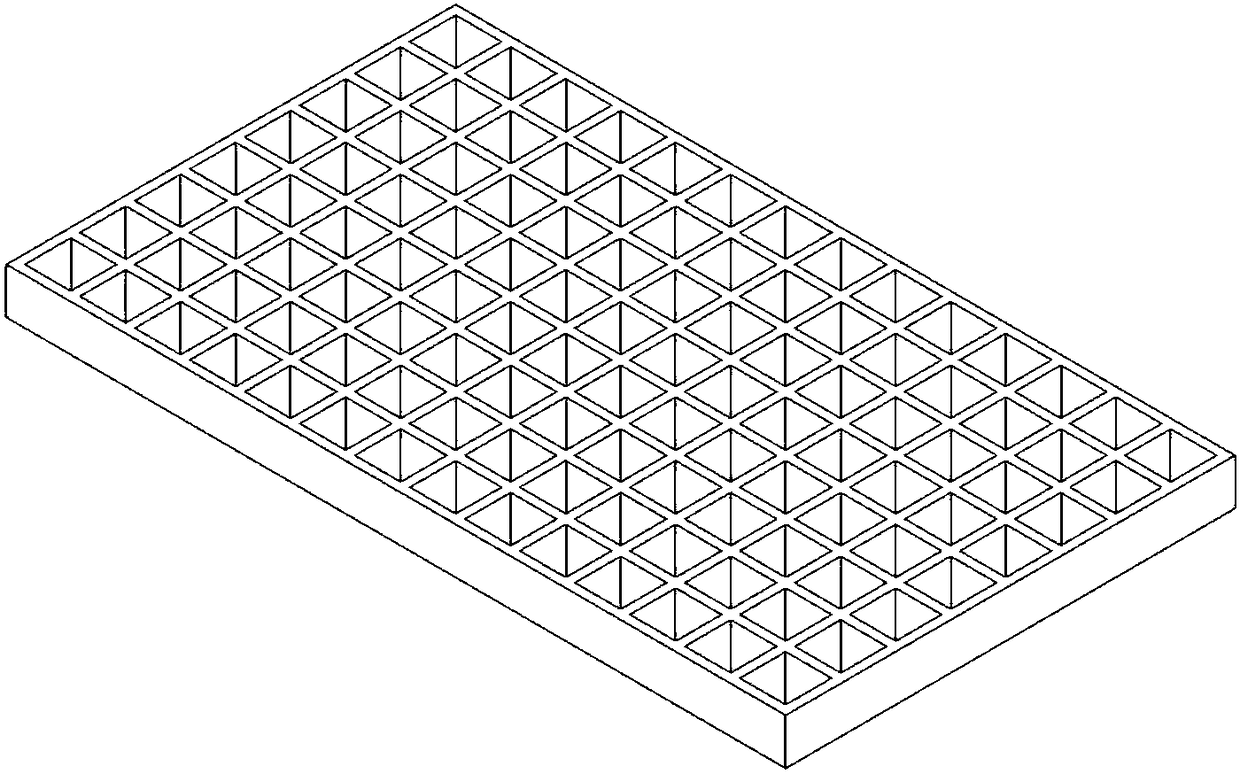

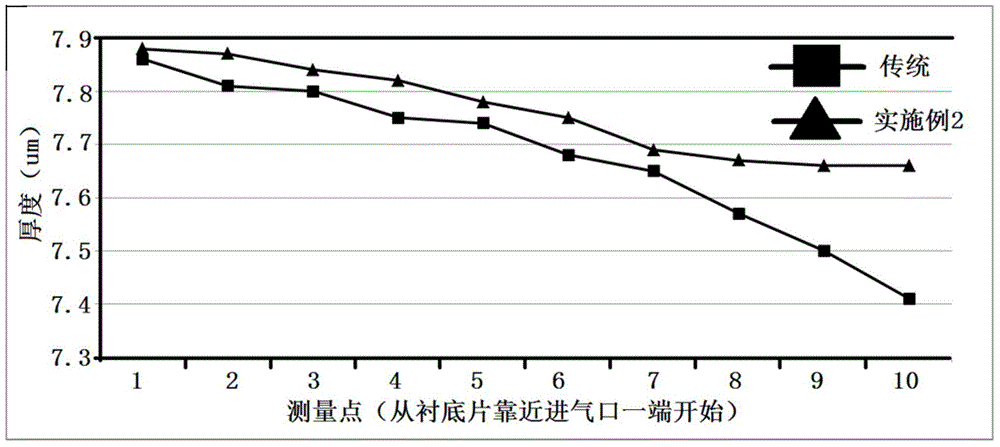

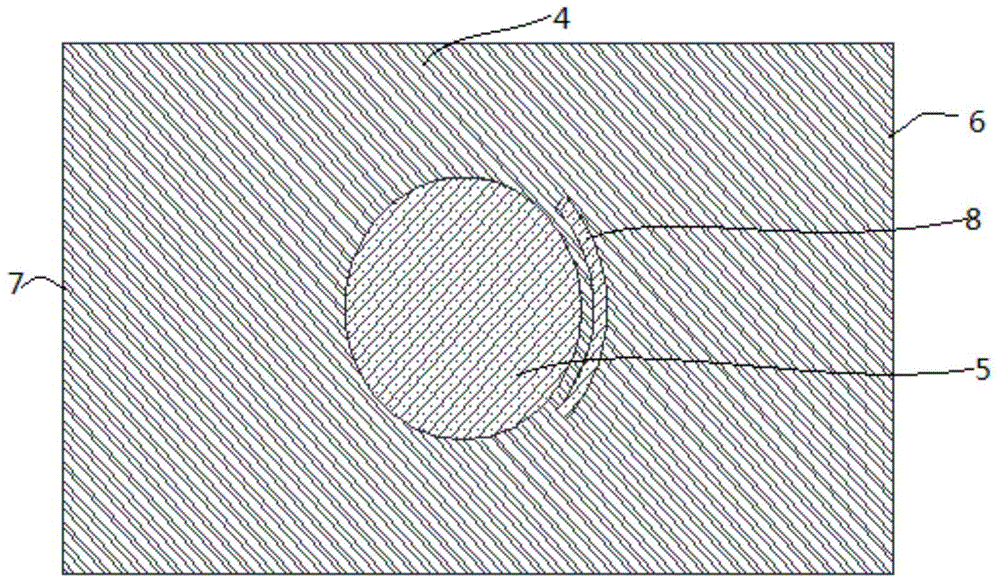

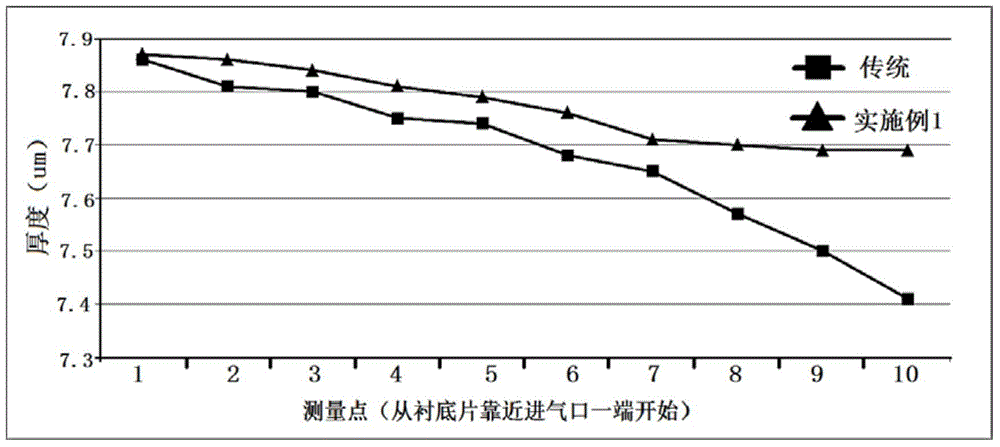

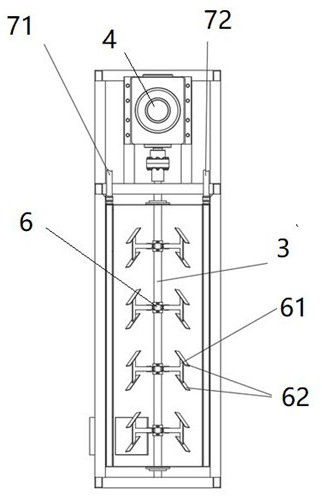

Chemical vapor deposition equipment used for producing silicon carbide epitaxial wafer

ActiveCN103603048AReduce the effect of epitaxial growthStable gas concentrationPolycrystalline material growthFrom chemically reactive gasesGas phaseChemical vapor deposition

The invention provides a method for improving the uniformity of silicon carbide epitaxial wafer, and the method can be used to produce silicon carbide epitaxial wafers with an even thickness. The method comprises the following steps: installing an air flow blocking ring under the air flow of a reaction cavity, then placing a silicon carbide substrate on a supporting platform, heating the reaction cavity to a temperature required by the epitaxy, and introducing reaction gas and carrier gas so as to finally form a silicon carbide epitaxial layer on the silicon carbide substrate. The silicon carbide epitaxial wafer obtained by the method has a more even thickness, besides the equipment is simple, so the method is a most practicable and cheapest method for improving conventional equipment, does not need much investment, and is benefit for the industrial production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

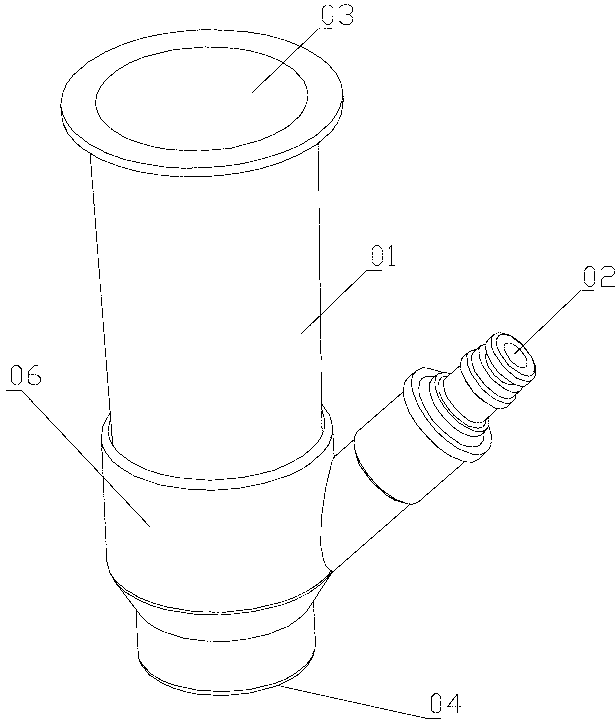

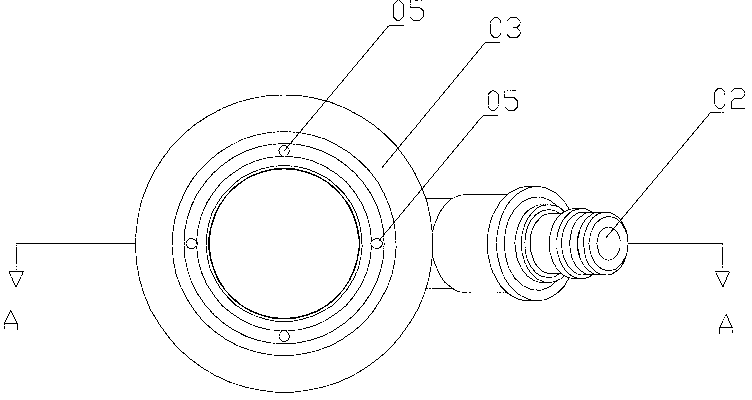

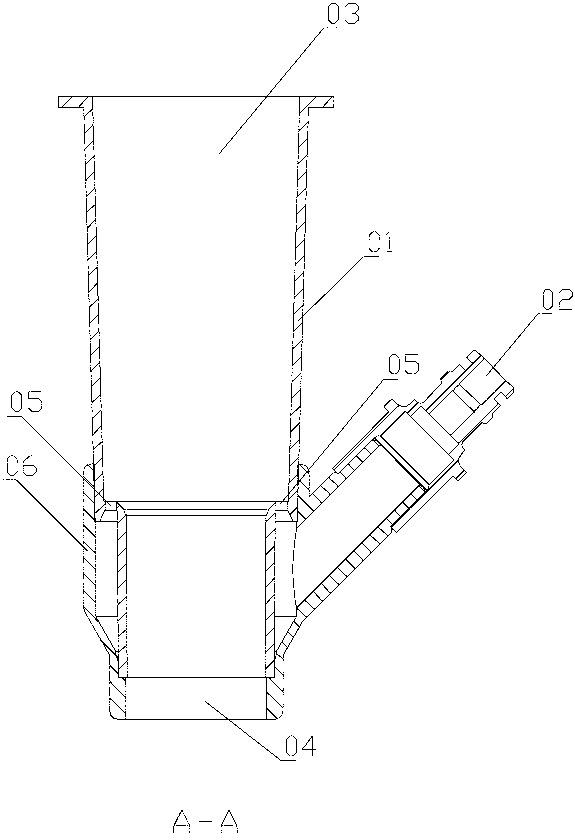

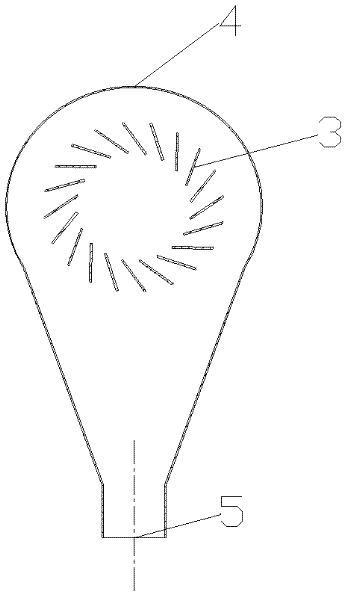

Siphon head used for cleaning swimming pool

ActiveCN103343631AImproved sewage discharge capacityReduce refluxGymnasiumSwimming poolsSiphonMarine engineering

The invention provides a siphon head used for cleaning a swimming pool. The siphon head comprises a barrel (1), a dirt outlet (3) is formed in the upper end of the barrel (1), a dirt suction opening (4) is formed in the lower end of the barrel (1), and a water inlet (2) is formed in the side wall of the barrel. The water inlet (2) is communicated with an inner cavity of the barrel (1) through a water outlet hole (5), and the water outlet direction of the water outlet hole (5) faces toward the dirt outlet (3). The siphon head used for cleaning the swimming pool is characterized in that the barrel (1) is of a closing-in structure which gradually becomes small from a water outlet of the water outlet hole (5) to the dirt outlet (3).

Owner:NINGBO DONGCHUAN SWIMMING POOL EQUIP

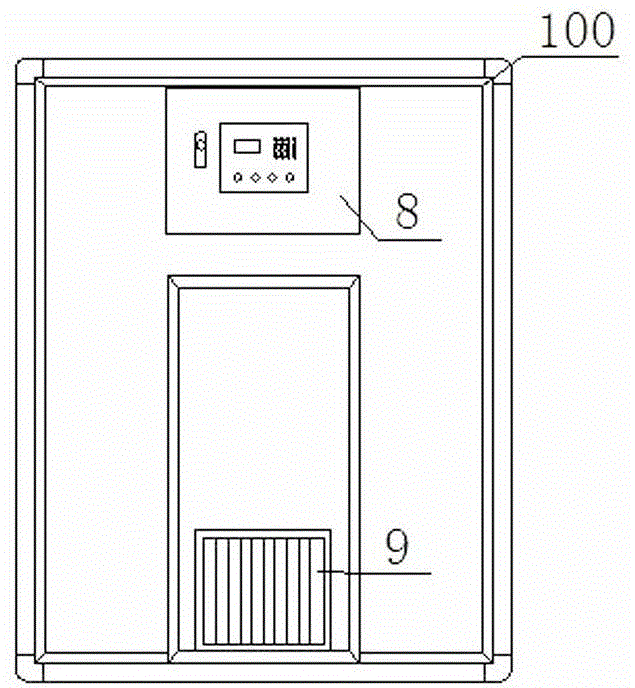

Substation indoor environment intelligent control device

InactiveCN104456832ANo excessive coolingSave energyMechanical apparatusSpace heating and ventilation safety systemsElectricityEngineering

The invention relates to a substation indoor environment intelligent control device which is characterized in that an indoor unit, an outdoor unit and a sensor set are included. The indoor unit comprises a box, an air inlet is formed in the upper portion of the box, an air outlet is formed in the lower portion of the box, the inside of the box is sequentially provided with an evaporator, a water collecting plate, a fan and a silencing pipeline from top to bottom, the evaporator corresponds to the air inlet in position, the water collecting plate is located under the evaporator, the upper end of the silencing pipeline is connected with the fan in a sealed mode, the lower end of the silencing pipeline is connected with the air outlet in a sealed mode, a controller is disposed in the box, a compressor is arranged in the outdoor unit, the sensor set comprises an outdoor temperature and humidity sensor and an indoor temperature and humidity sensor, and the evaporator, the fan, the compressor, the outdoor temperature and humidity sensor and the indoor temperature and humidity sensor are electrically connected with the controller. Environment control is performed on indoor space in a substation by means of the intelligent control device, potential safety hazards do not exist, energy can be saved, meanwhile, air outflow amount and air speed are easy to control, and eddies and turbulent flow can not be generated.

Owner:JIANGSU TAIPUDA TECH

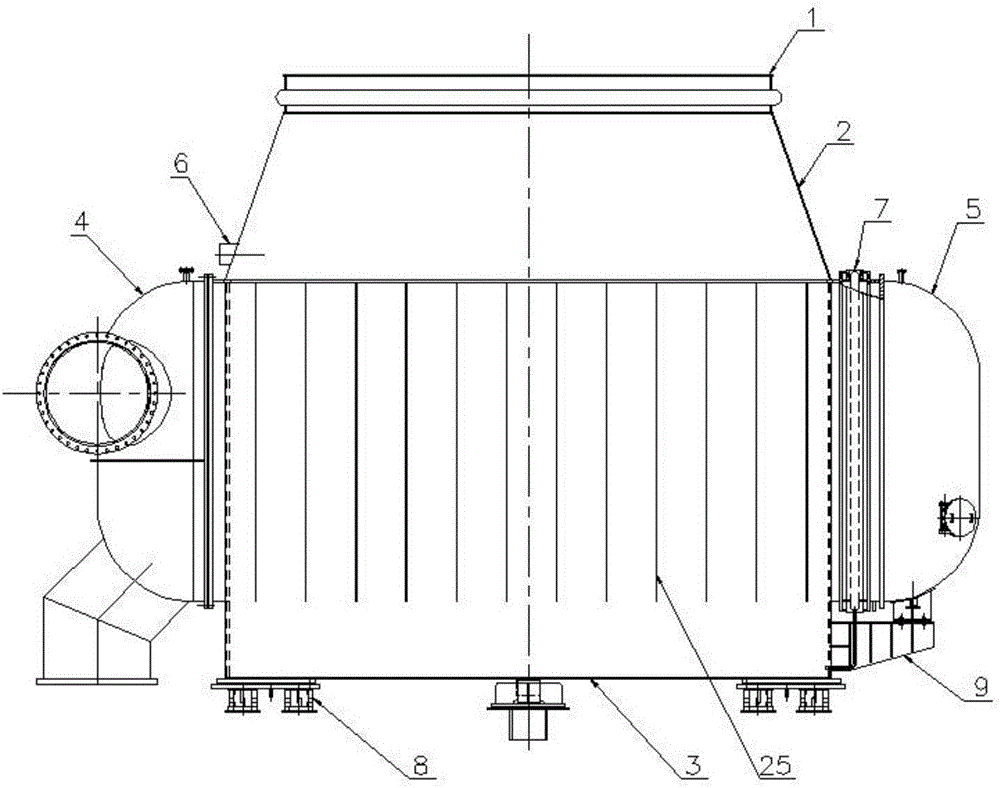

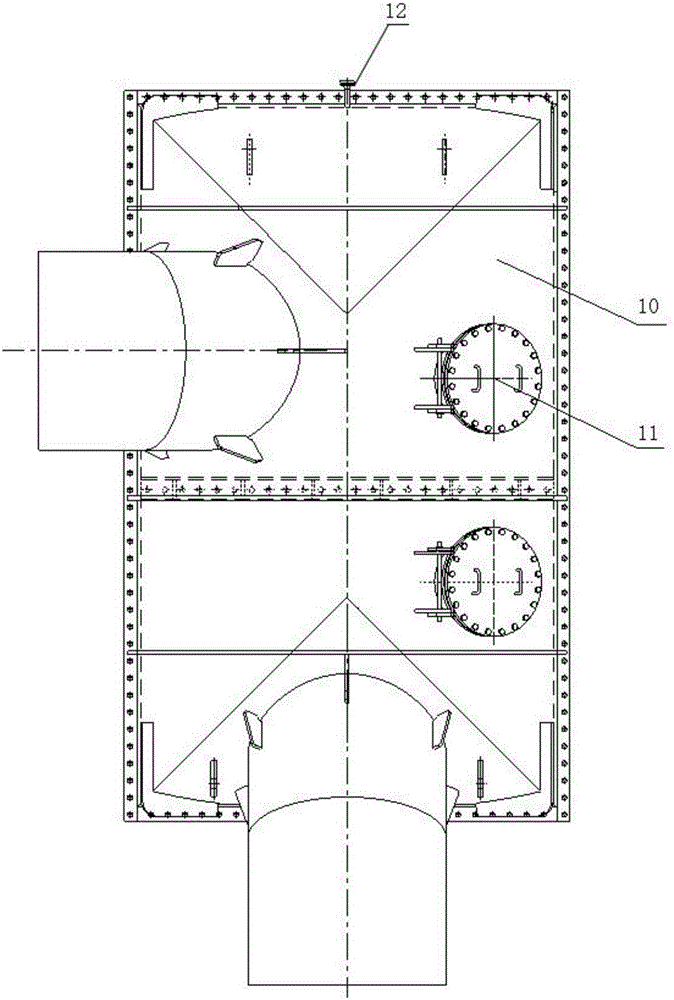

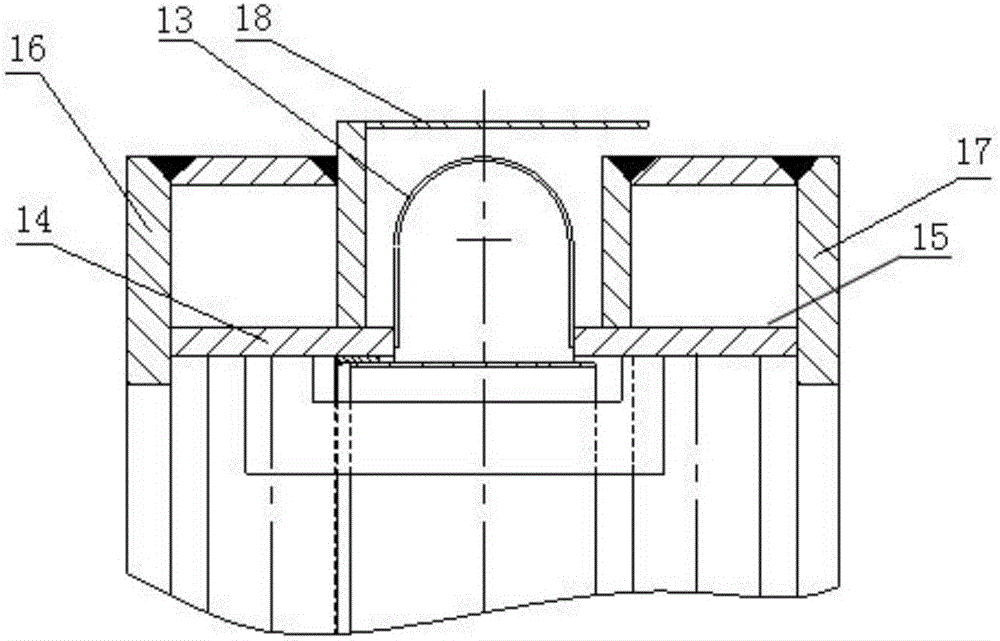

High-back-pressure condenser

ActiveCN106643200AImprove ball collection rateImprove heat transfer efficiencySteam/vapor condensersEddy currentEngineering

The invention relates to a high-back-pressure condenser. A throat expansion section and a shell expansion section of the condenser are both provided with reinforcing plate sets and protective covers, so that a corrugated pipe used in the condenser is not damaged by external force. A water chamber of the condenser adopts an all-arc water chamber, so that internal eddy current and eddy current dead areas in the water chamber are improved, and cooling water entering a cooling pipe of the condenser is uniform in flowing speed. Compared with a traditional water chamber, materials are largely saved, the machining difficulty is reduced, and the machining cost is reduced. A heat exchange pipe of the condenser adopts a novel pipe distributing mode on a middle pipe plate, so that a pipe speed airflow flowing speed is uniform without eddy currents, the shell side steam resistance is low, and the heat transfer coefficient of the condenser is high.

Owner:DEYANG DONGQI POWER STATION EQUIP

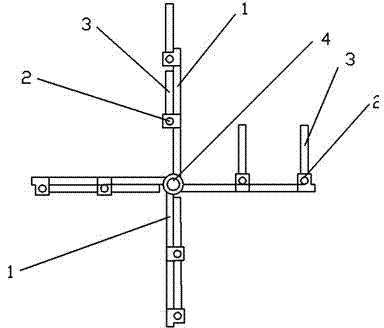

Composite cable clamping plate special for wind power generation tower barrel

InactiveCN105508151AHigh mechanical strengthStable mechanical strengthEngine fuctionsMachines/enginesFiberAlkali free

A composite cable clamping plate special for a wind power generation tower barrel comprises a clamping plate body (1), a clamping plate support (2) and tightening bolts (3). The clamping plate body is fixed to the clamping plate support through the tightening bolts, and the clamping plate body is made of resin, a low-shrinkage additive, an initiator, pigment paste, zinc stearate, magnesium oxide, styrene, alkali-free glass fibers and aluminum hydroxide. The composite cable clamping plate special for the wind power generation tower barrel has the advantages of being high in mechanical strength and bend resistance performance, free of distortion and brittle failures, resistant to acid-base, good in corrosion resistance, aging resistance, insulation performance and frame retardant property and the like. According to the composite, the high-strength alkali-free glass fibers serve as a reinforcing material, and the high-performance unsaturated polyester resin serves as a base material, so that the product has excellent physical and chemical performance, and the cable clamping plate is novel, can replace existing cable clamping plates made of various other materials, and has good application and popularization value.

Owner:宁夏顺和电工有限公司

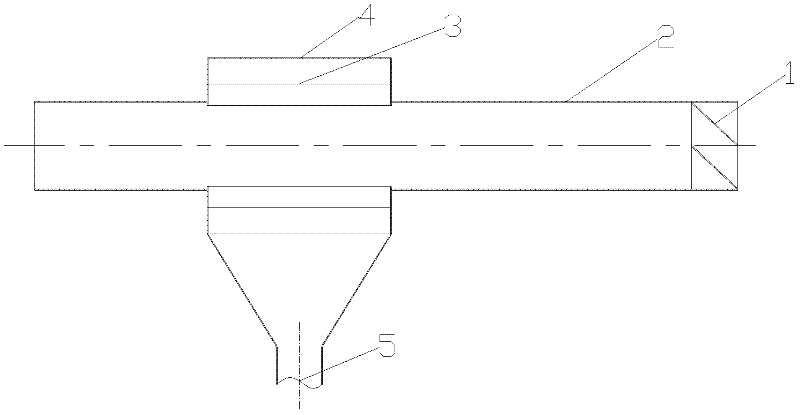

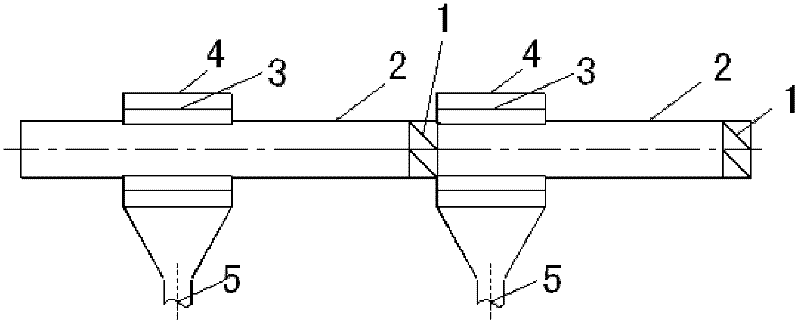

Dust removing device applied to pipeline

InactiveCN102343188ADoes not affect flowSimple structureDispersed particle separationParticulatesSolid particle

The invention discloses a dust removing device applied to a pipeline. A diversion component is connected with a conduit; a gas-solid separating fin is fixed on the side wall of a shell; the conduit is fixedly connected with the shell; both sides of the shell are provided with holes; a hole of the conduit is communicated with the holes of the shell; the gas-solid separating fin and the conduit are arranged concentrically; and the lower end of the shell is connected with a dust falling pipe. The dust removing device is used for removing entrained solid or liquid particles in the conveying process of various gases or liquids containing solid particles or liquid fog drops, so that influences on operation caused by dust or solid (liquid) particles in subsequent processes are reduced. In the invention, a fluid rotates while entering a pipeline through a pipeline embedded structural piece, so that the fluid moves forward spirally; and solid particles or liquid drops with large specific weights move towards a pipe wall side under the action of centrifugal force, move into an outer layer interlayer while passing through the blade gap of a dust removing component, and enter a recovering system under the action of gravity.

Owner:北京德天御投资管理有限责任公司

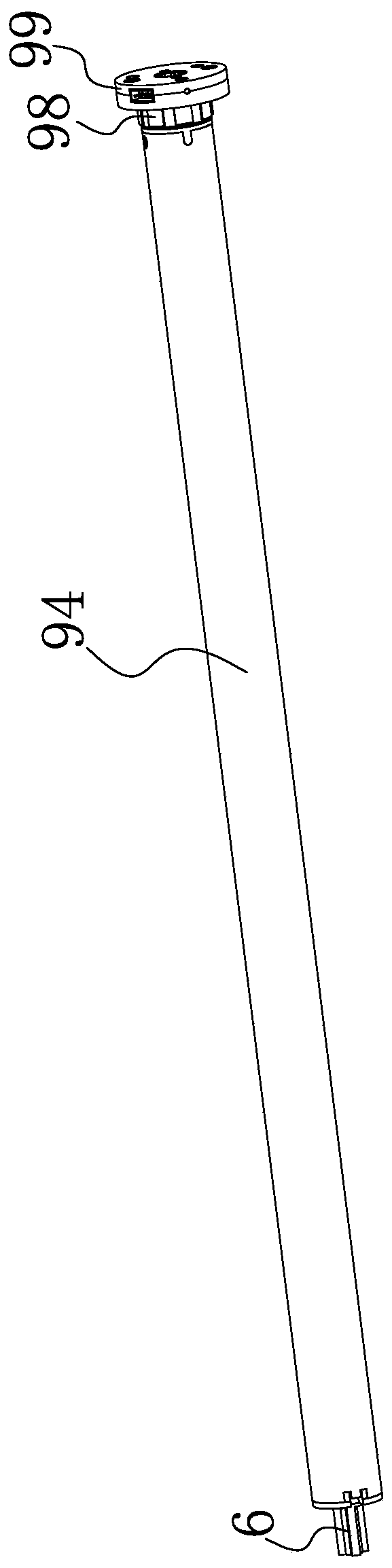

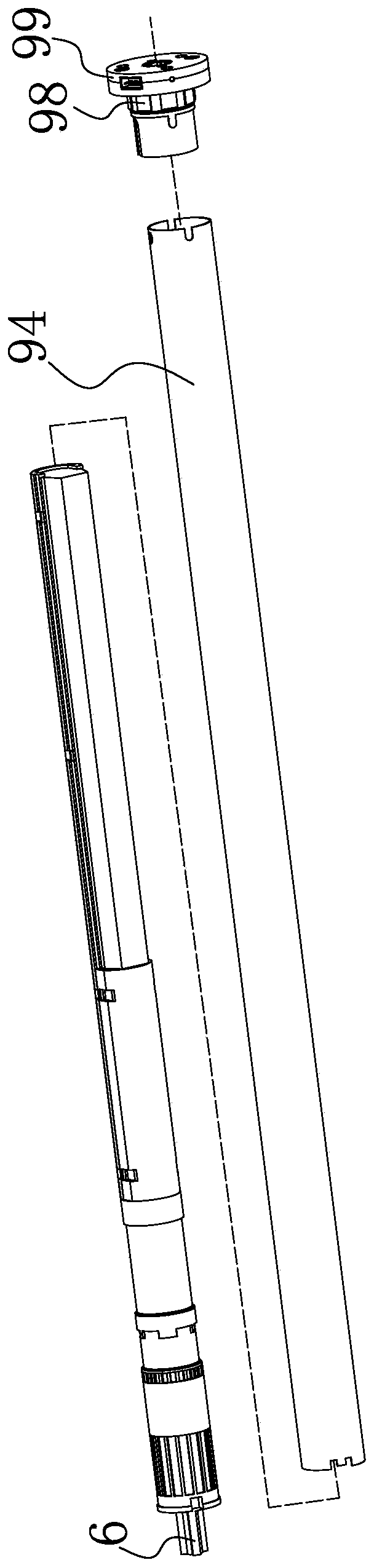

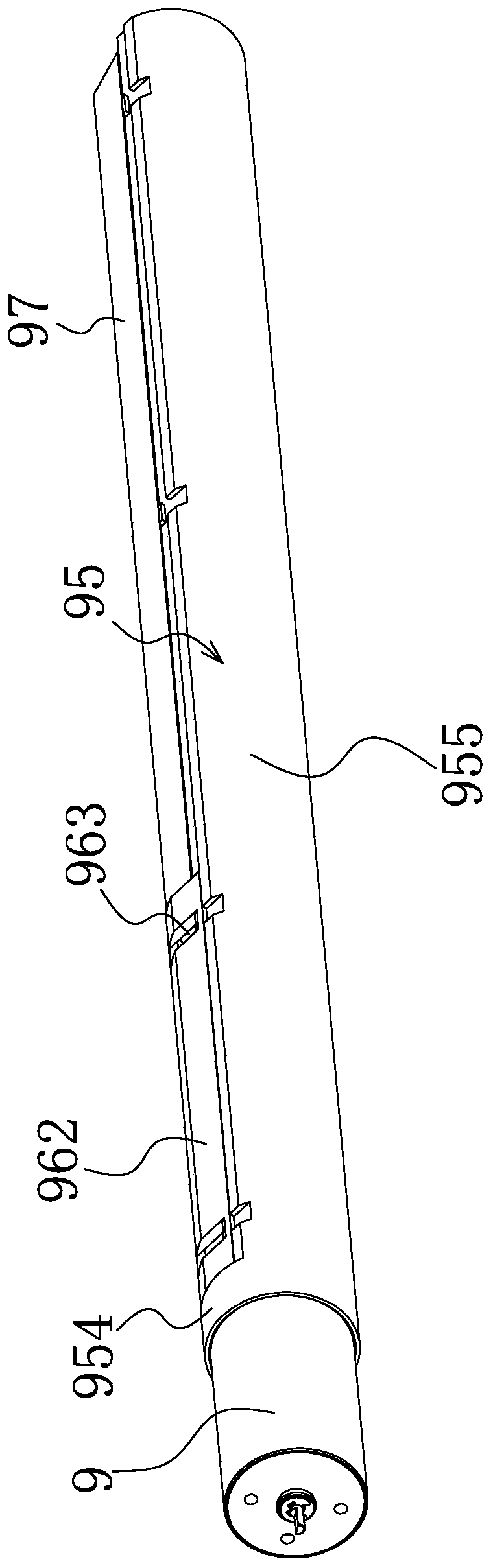

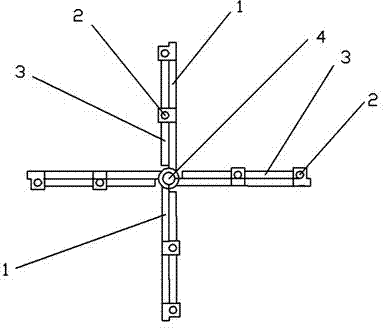

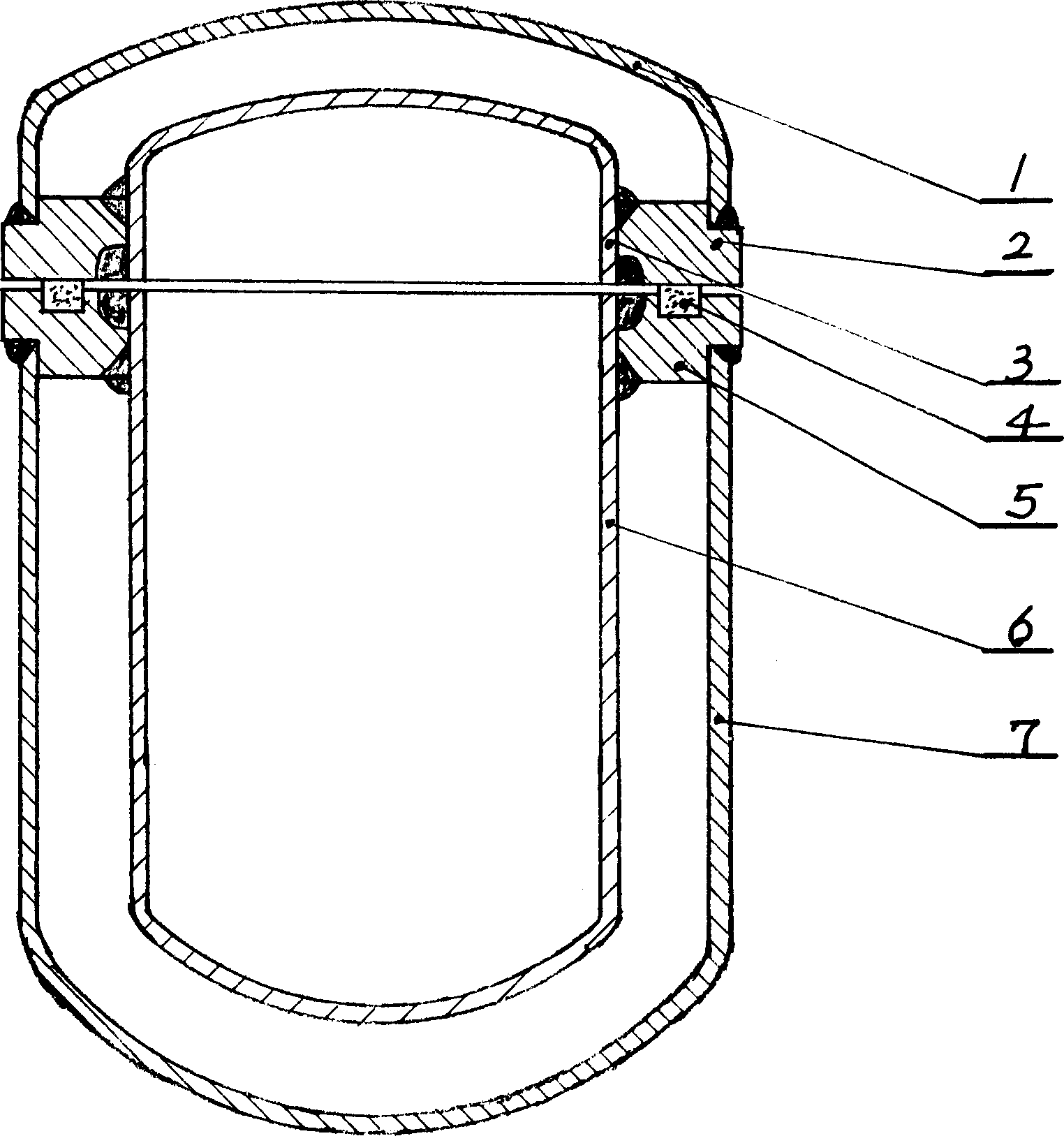

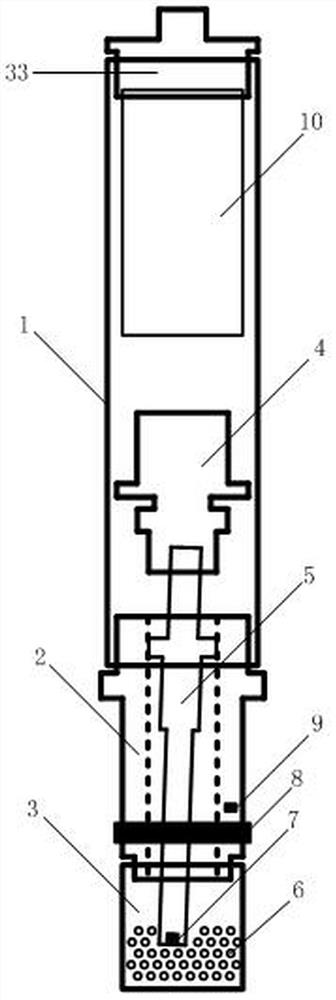

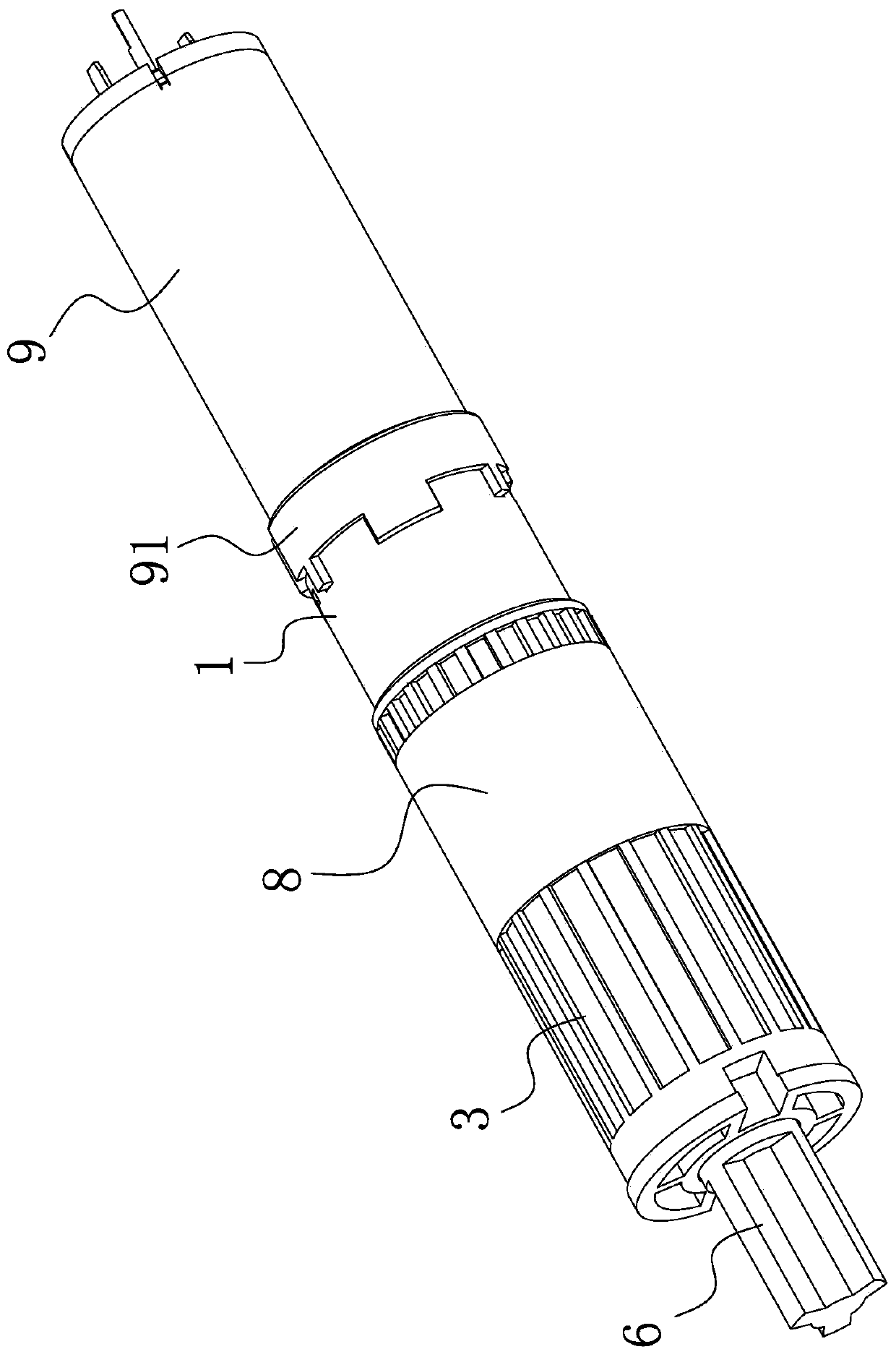

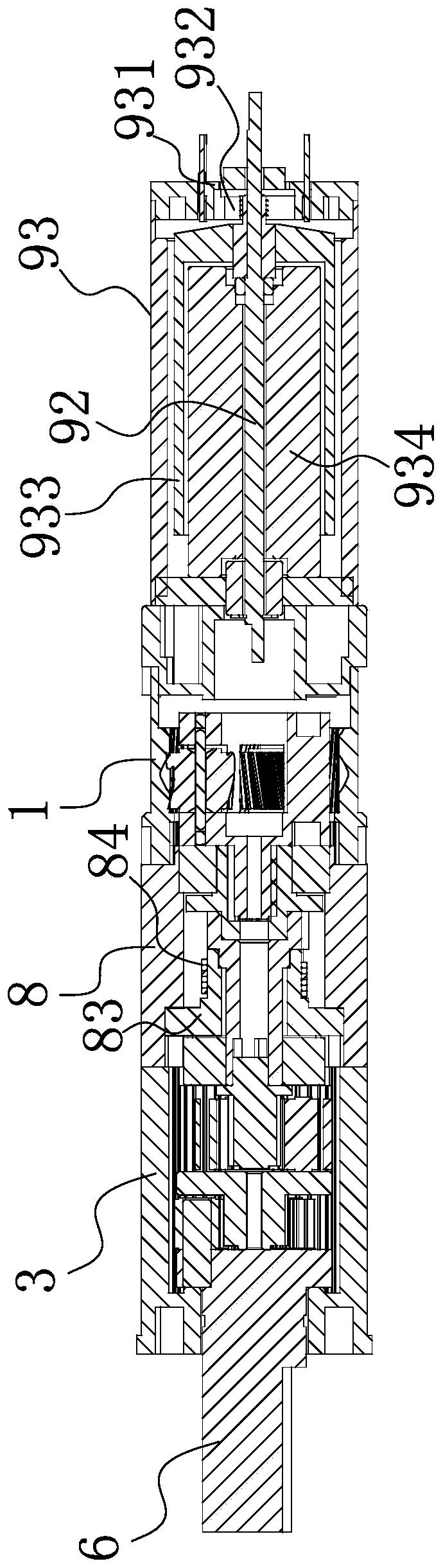

Tubular motor assembly with hollow cup motor structure

PendingCN110233546AReduce quality problemsQuick responseAssociation with control/drive circuitsMechanical energy handlingEddy currentEngineering

The invention relates to a tubular motor assembly with a hollow cup motor structure, and solves the problem that an existing tubular motor is insufficiently reasonable in design. The tubular motor assembly comprises a steel pipe body and a hollow cup motor; one end of a motor main body is inserted into a battery circuit board shell; a control circuit board and / or a power supply battery is arrangedin the battery circuit board shell; the other end of the motor main body is connected with a primary gear ring; a motor shaft of the motor main body is connected with a primary planetary gear assembly; the other end of the primary gear ring is connected with a secondary gear ring and a tertiary gear ring through a brake jacket; a primary planetary deceleration assembly is connected with a secondary planetary gear assembly through a brake structure; a tertiary planetary gear assembly is connected with an output shaft; and the other end, away from the output shaft, of the steel pipe body is connected with a cover body through a limiting ring. The tubular motor assembly has the advantages that a rotor iron core structure is cancelled; the hollow cup motor has no cogging effect; and no eddy current is generated, so that the response speed is greatly increased and the vibration is greatly weakened when a rotor is started and stopped, and the service life of the whole machine is prolonged.

Owner:HANGZHOU WISTAR MECHANICAL& ELECTRIC TECH CO LTD

Natural energy power multifunctional generation device

InactiveCN103696896ARaise the water levelImprove energy efficiencyHydro energy generationReaction enginesWater sourceStream flow

The invention discloses a natural energy power multifunctional generation device. Every blade is provided with an opening and a throttle door for opening and closing the opening, and the throttle door can rotate to open or close the opening within a range of 0-180 degree; by adjusting the pressure of the blades at various rotation positions, the pressure difference among the blade can be high, so that the energy source utilization rate is high, and vortexes can be avoided, further the natural energy power multifunctional generation device can rotate under high flow velocity as well as low flow velocity to generate electricity. The natural energy power multifunctional generation device can generate electricity through wind energy, river water energy and wave energy. The invention also discloses an overflow dam river basin power generation system. The overflow dam river basin power generation system is that a plurality of the natural energy power multifunctional generation device are horizontally arranged on a river way and achieves the water level raising function like as an overflow dam, the natural energy power multifunctional generation device can be arranged in a multi-stage mode in river basins to generate electricity through the water sources repeatedly and meanwhile play a role of raising the water level of rivers, and when river flow is small, parts of the natural energy power multifunctional generation device can be closed. Therefore, the overflow dam river basin power generation system can increase the water level of the river as well as generate electricity, thereby achieving the effects of water storage, electricity generation and landscape improvement.

Owner:张儒海

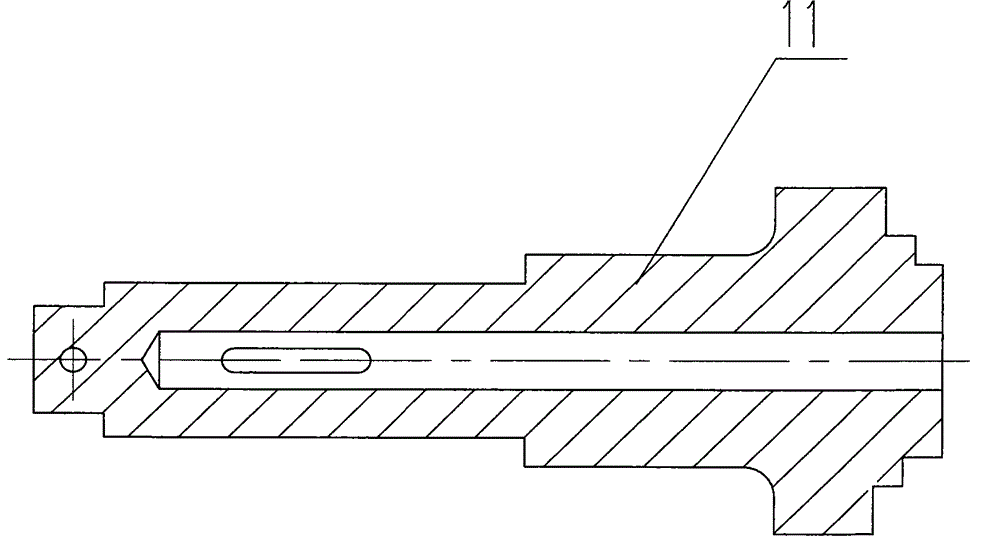

Sliding-flap free-float type

Provided is a sliding-flap free-float type. A left valve body and a right valve body are connected via a bolt. The left valve body, a filter screen and a choke plug are connected sequentially. The top of the left valve body is installed with an automatic emptying valve. A limiting device is fixed into a cavity of the left valve body. A floating ball, a shaft sleeve and a weighting block are fixedly connected and sleeve a valve shaft. The weighting block can be adjusted. A cotter pin, a plain washer, the valve shaft, a gland and the right valve body are sequentially connected. The side surface of the shaft sleeve is provided with a convex hole. The upper part is a waist-shaped hole and the lower part is a rectangular hole. A valve clack and a lower-part hole are in clearance fit. Two circular springs are utilized to press the valve clack on the external circumference of the shaft sleeve such that the valve clack and the valve shaft are closely attached. A shaft axis at the right end of the valve shaft is a blind hole. The side surface is provided with a waist-shaped hole. The axial shape and the size are the same as the upper part of the convex-shaped hole of the shaft sleeve. The shaft axis at the right end of the right valve body is provided with a blind hole. The connection between a left end surface and a central hole of the valve shaft is provided with an axial blind hole. The left end is covered by a radial through hole to the center. The outer side end is plugged and communicated with the axial blind hole and the central hole so that a Z-shaped conjugated passage is formed. In combination of condensation water buoyancy and the weighting block, the floating ball ascends or descends to rotate the shaft sleeve and control the passage to open and close. When condensation water flows out of the waist-shaped hole, no eddy occurs. Steam does not leak and energy is saved.

Owner:江苏江恒阀业有限公司

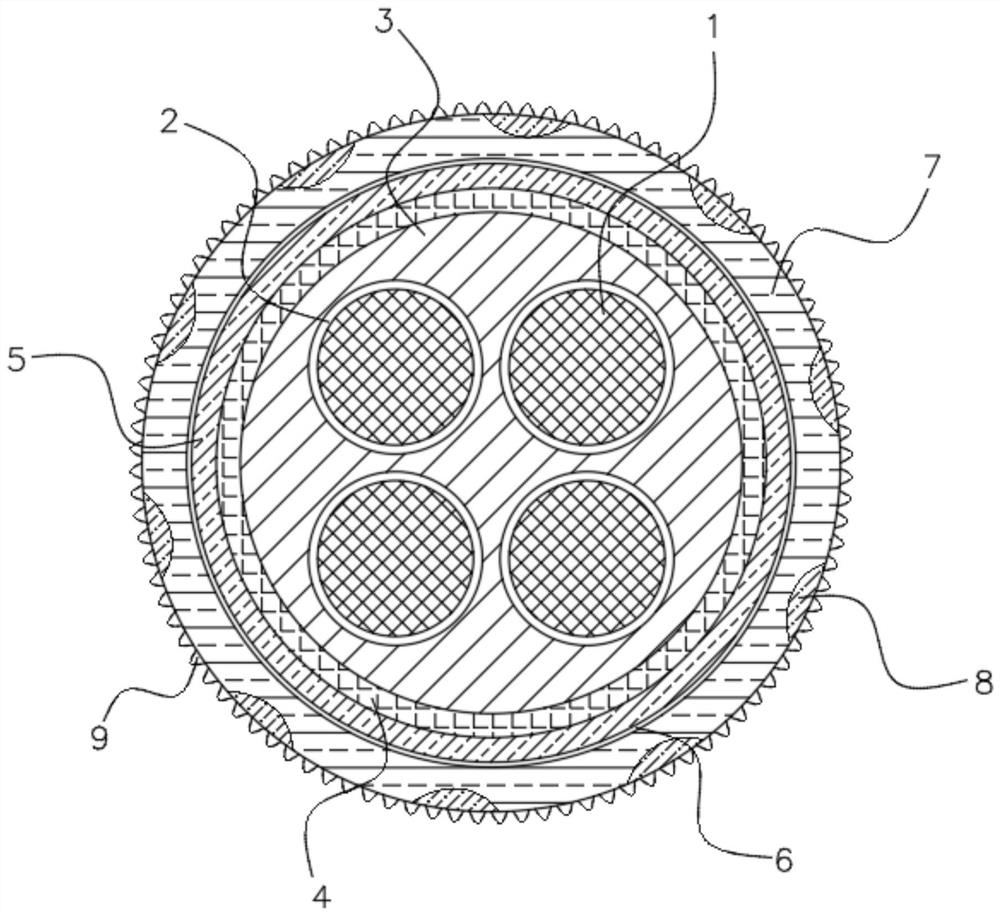

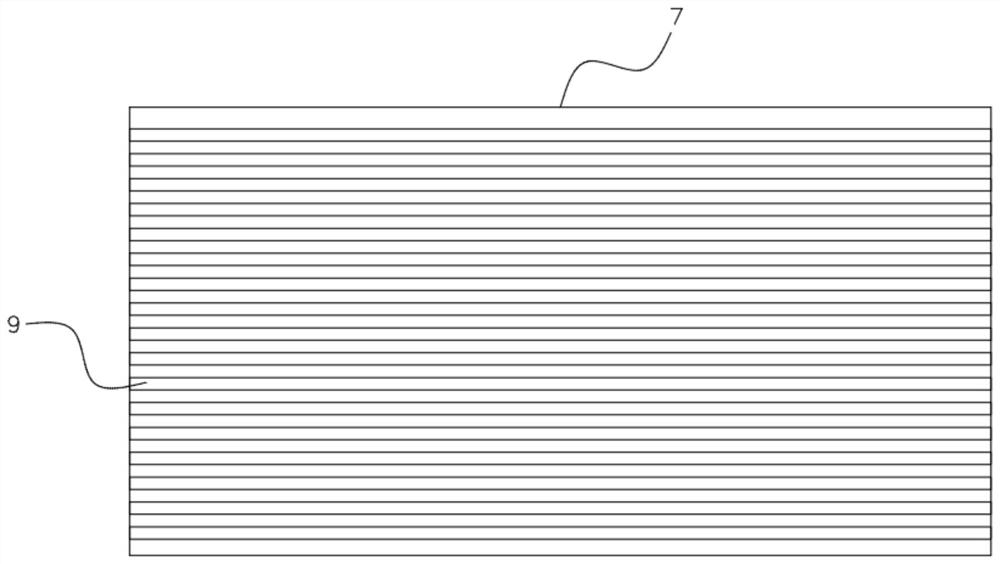

High-performance double-layer co-extrusion insulating flame-retardant fire-resistant computer cable

InactiveCN111799028AImprove heat resistanceImprove rigidityPlastic/resin/waxes insulatorsInsulated cablesPolypropyleneSteel belt

The invention relates to the technical field of power cables. The invention further discloses a high-performance double-layer co-extrusion insulating flame-retardant fire-resistant computer cable. Thecable comprises conductors, insulators, a wrapping tape, an inner sheath, an armor and an outer sheath. The insulators are arranged on the outer sides of the conductors and are made of polypropylenematerials, the plurality of conductors are embedded in the wrapping tape, fillers are embedded among the conductors in the wrapping tape, the inner sheath is arranged on the outer side of the wrappingtape, and the armor is arranged on the outer side of the inner sheath. According to the high-performance double-layer co-extrusion insulating flame-retardant fire-resistant computer cable, the insulators at the outer sides of the conductors are made of a polypropylene material; therefore, the heat resistance, rigidity and tensile strength of the cable are improved; and the armor is a linkage armor made of an aluminum alloy belt, and compared with a common double-steel-belt wrapping mode adopted by a common cable, the aluminum alloy belt and a non-magnetic material adopted by the linkage armordo not generate eddy currents, and the heat dissipation performance, the side pressure resistant performance and the anti-collision performance are good, , the inside is smooth and the insulator is not cut, and the safety coefficient is high.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

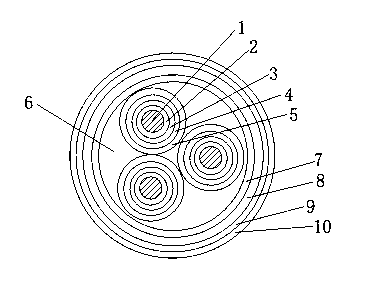

High-strength power cable

InactiveCN103106980AImprove conductivityImprove mechanical propertiesPower cables with screens/conductive layersMetal/alloy conductorsPower cableElectrical conductor

The invention discloses a high-strength power cable. The high-strength power cable comprises cable cores, and each cable core is formed by stranding of three insulated wire cores. Filler is arranged in gaps of the cable cores, a wrapping tape layer is wrapped outside the cable cores, an isolating layer and an armor layer are sequentially wrapped outside the wrapping tape layer in an extruded mode, and an outer protective jacket is wrapped on the outermost layer of the cable in an extruded mode. Each insulated wire core is composed of a conductor, an inner shielding layer, an insulating layer, an outer shielding layer and a metal shielding layer, wherein the inner shielding layer, the insulating layer, the outer shielding layer and the metal shielding layer are sequentially wrapped outside the conductor in an extruded mode. The high-strength power cable has the advantages of being good in conductivity, high in mechanical performance, creeping and aging resistant, high temperature resistant, good in corrosion resistant performance, long in service life, and the like, and is suitable for voltage classes of 0.6KV-35KV and dry or humid sites with temperature of 200 DEG C, 180 DEG C, 105 DEG C and 90 DEG C or below; and the high-strength power cable can be installed indoors or outdoors, also can be installed in a vertical mode or in a supported mode or in a laid mode along a wall, and even can be installed underground in a directly buried mode.

Owner:WUXI SHUGUANG CABLE

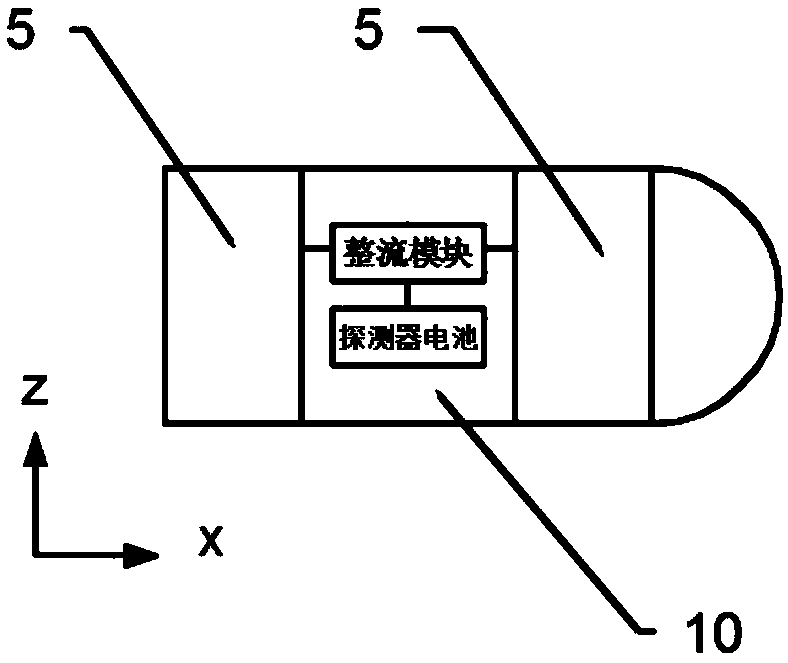

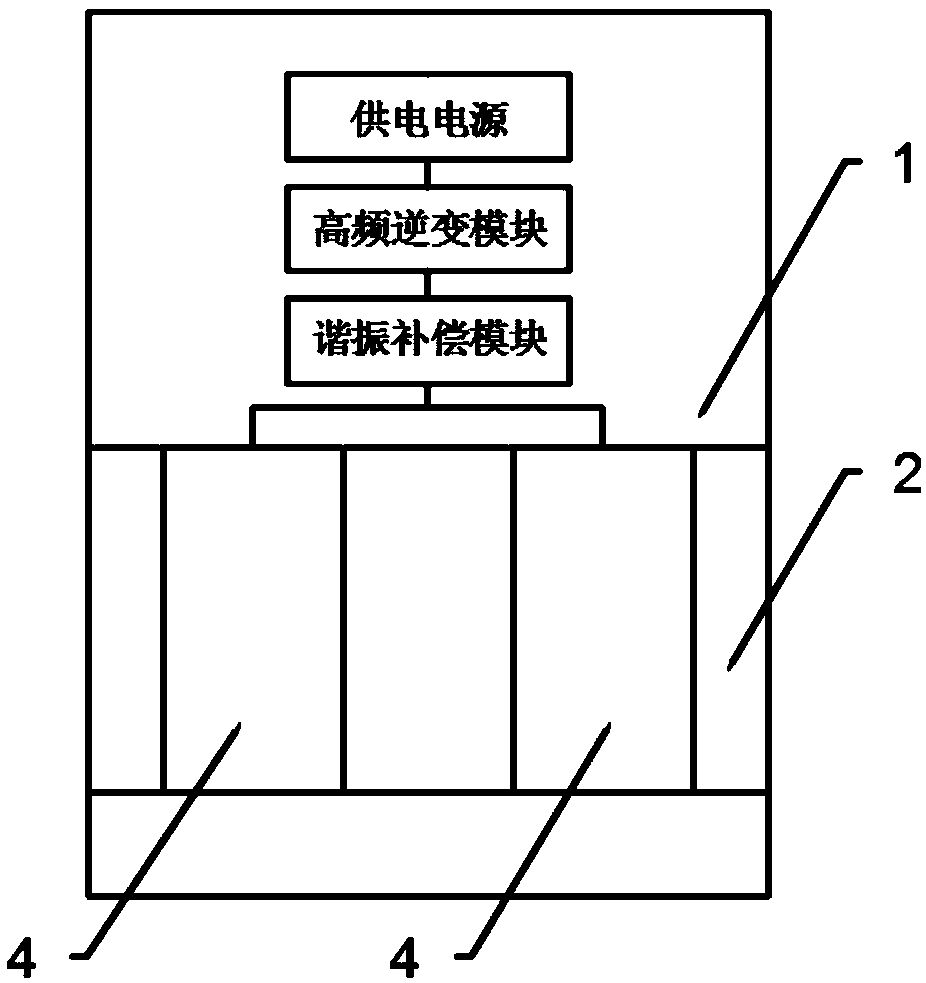

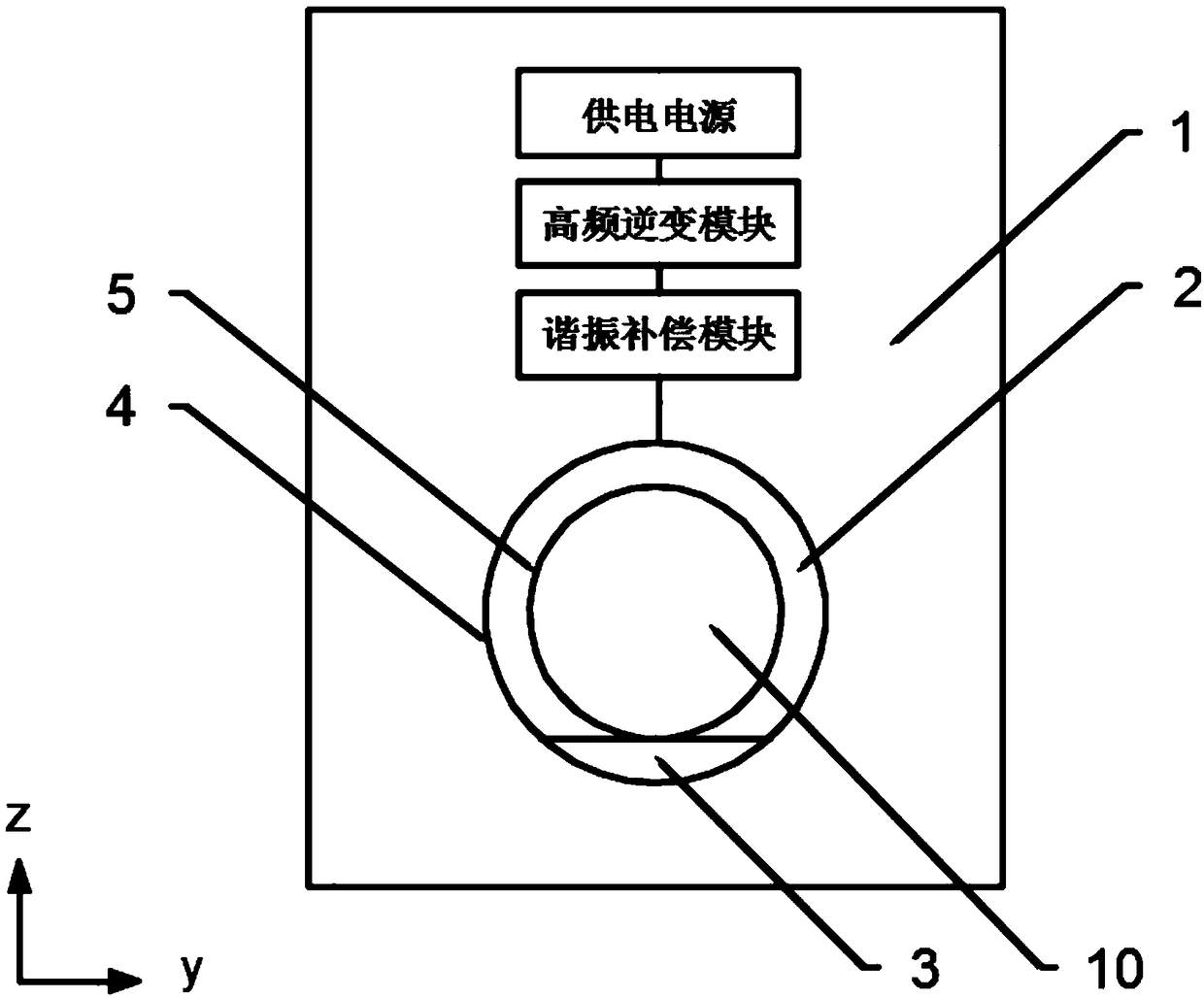

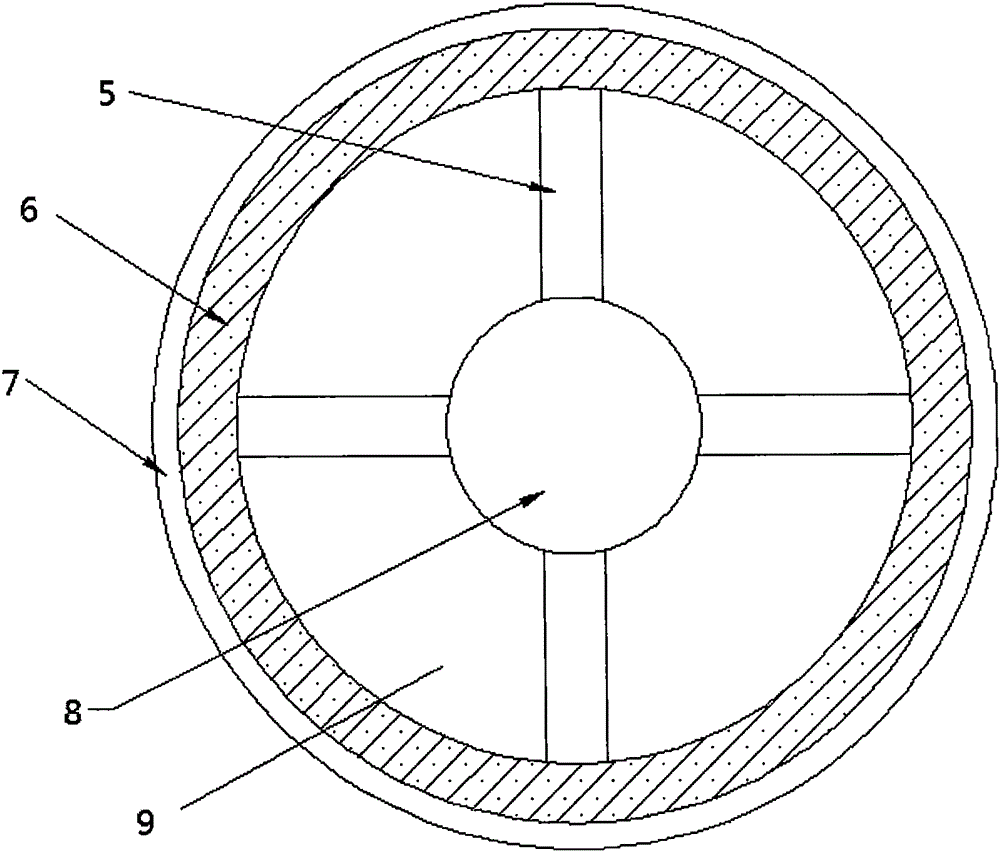

Cylindrical quadrupole plate structure underwater radio energy transmission device based on electric field coupling

PendingCN109088481AEasy to implementAvoid lossCircuit arrangementsCapacitanceElectromagnetic radiation

The invention belongs to the technical field of radio energy transmission, and relates to a cylindrical quadrupole plate structure underwater radio energy transmission device based on electric field coupling. The device comprises a transmitting part and a receiving part. The transmitting part is installed in the charging base station, and comprises a power supply, a high-frequency inverter module,a resonance compensation module and an electric energy transmitting terminal. The receiving part is installed in the underwater detector, and comprises an electric power receiving end, a rectifying module and a battery of the underwater detector. Two sets of electric energy transmitting and receiving terminals form a cylindrical quadrupole plate electric field coupling mechanism, which realizes the underwater radio energy transmission of cylindrical quadrupole plate structure based on electric field coupling. The invention directly supplies power to the detection equipment under water, whichcan shorten the charging time, improve the working efficiency and avoid unsafe factors such as electric leakage. In the underwater, especially in the seawater, the advantages are obvious, with no eddycurrent and low energy loss. The coupling electric field is basically confined between the capacitor plates, and the electromagnetic radiation is greatly reduced, which reduces the electromagnetic interference to the system.

Owner:DALIAN UNIV OF TECH

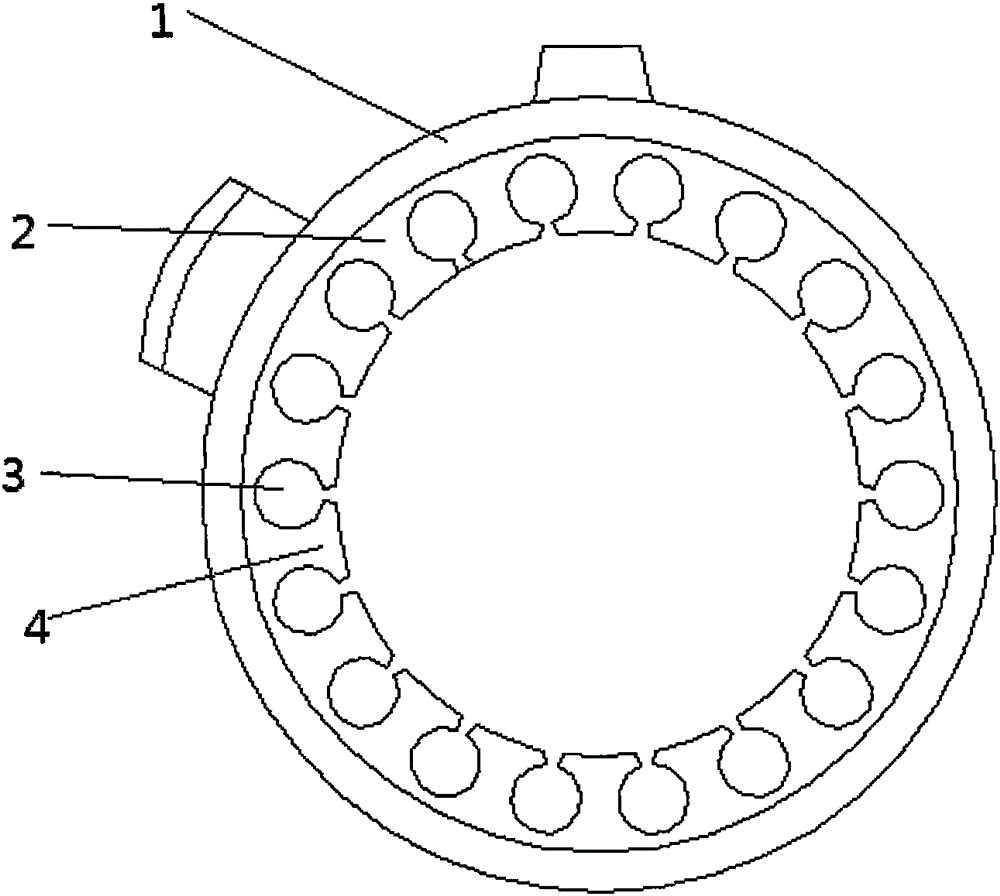

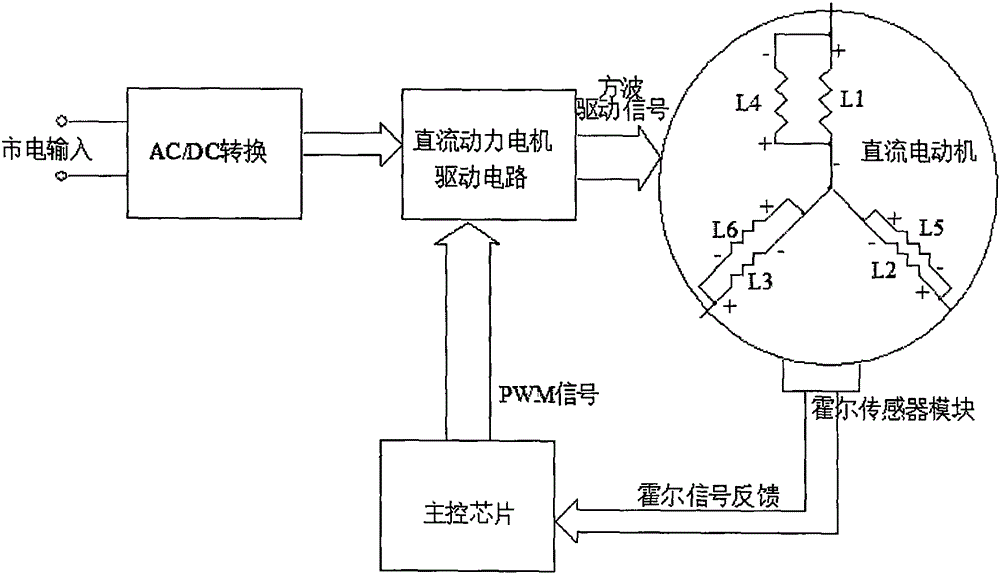

Motor capable of realizing high-efficiency DC power

InactiveCN105141059AReduce torque rippleReduce weightMagnetic circuit rotating partsMagnetic circuit stationary partsSine waveHigh torque

The invention provides a motor capable of realizing high-efficiency DC power, and belongs to the field of DC power motors. An adhesive Nd-Fe-B magnet is enabled to be magnetized into a standard sine wave magnetic pole by adopting an overall annular structure of a multilayer annular structure so that motor torque ripple is reduced, the DC power motor is enabled to generate stable high torque (high moment) under the condition of weak magnetism and low current. Besides, the structure of a rotor is enabled to be changed into a hollow structure so that the technical problem that the rotor structure cannot be changed into the hollow structure by the DC power motor can be solved, an effect of no generation of heat in operation of the motor can be achieved, and the motor can work under a high-power state without a cooling device.

Owner:孟繁志

Large flange for sealing induction furnace lid and furnace stack

InactiveCN1385668ALow priceReduce processing costsCrucible furnacesInduction furnaceMaterials science

The present invention relates to a kind of large flange for tight connecting furnace cover and furnace body of induction smelting furnace and induction sintering furnace. It includes furnace cover flange and furnace body flange, and is made up by using general steel, and is lined with stainless steel plate and made into large flange with composite type structure. It can protect sealing ring from burning, and can reduce production cost.

Owner:辽阳市粉末冶金有限公司

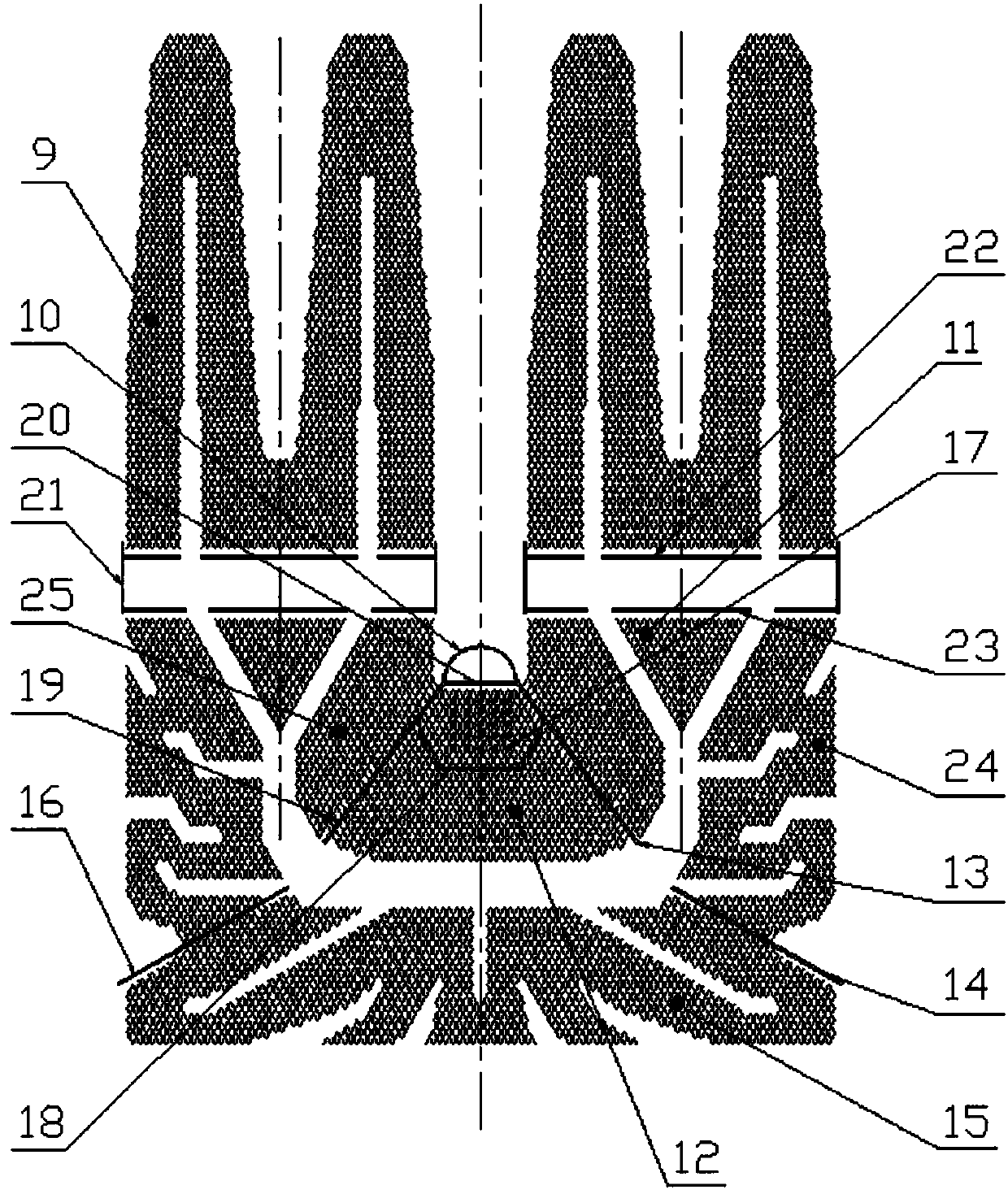

Magnesium alloy sand casting stepped slit type pouring system

InactiveCN107774911AReduce flow rateSpeed up the flowFoundry mouldsFoundry coresSand castingMaterials science

The invention relates to a magnesium alloy sand casting ladder gap gating system, which includes a gate, a sprue, a first runner, a second runner, a third runner and a ladder gap runner. The second runner is located above the first runner and the third runner. The bottom of the gate sprue is connected to one end of the first runner, and the other end of the first runner opens upward and passes through the second runner. The sprue is connected with one end of the second sprue, the other end of the second sprue opens downward and is connected with one end of the third sprue through the third sprue, and the other end of the third sprue is connected with the third sprue. The bottoms of the ladder slot runners are connected; the middle part of the second runner is provided with a filter screen for filtering the magnesium alloy liquid, and the cross-sectional area of the first runner, the second runner or the third runner is respectively larger than that of the runner. The cross-sectional area of the gate sprue, the second sprue or the third sprue. The gating system can make the molten magnesium flow smoothly without eddy current, splash and impact.

Owner:QINGDAO RUNCHENG VEHICLE FITTINGS CO LTD

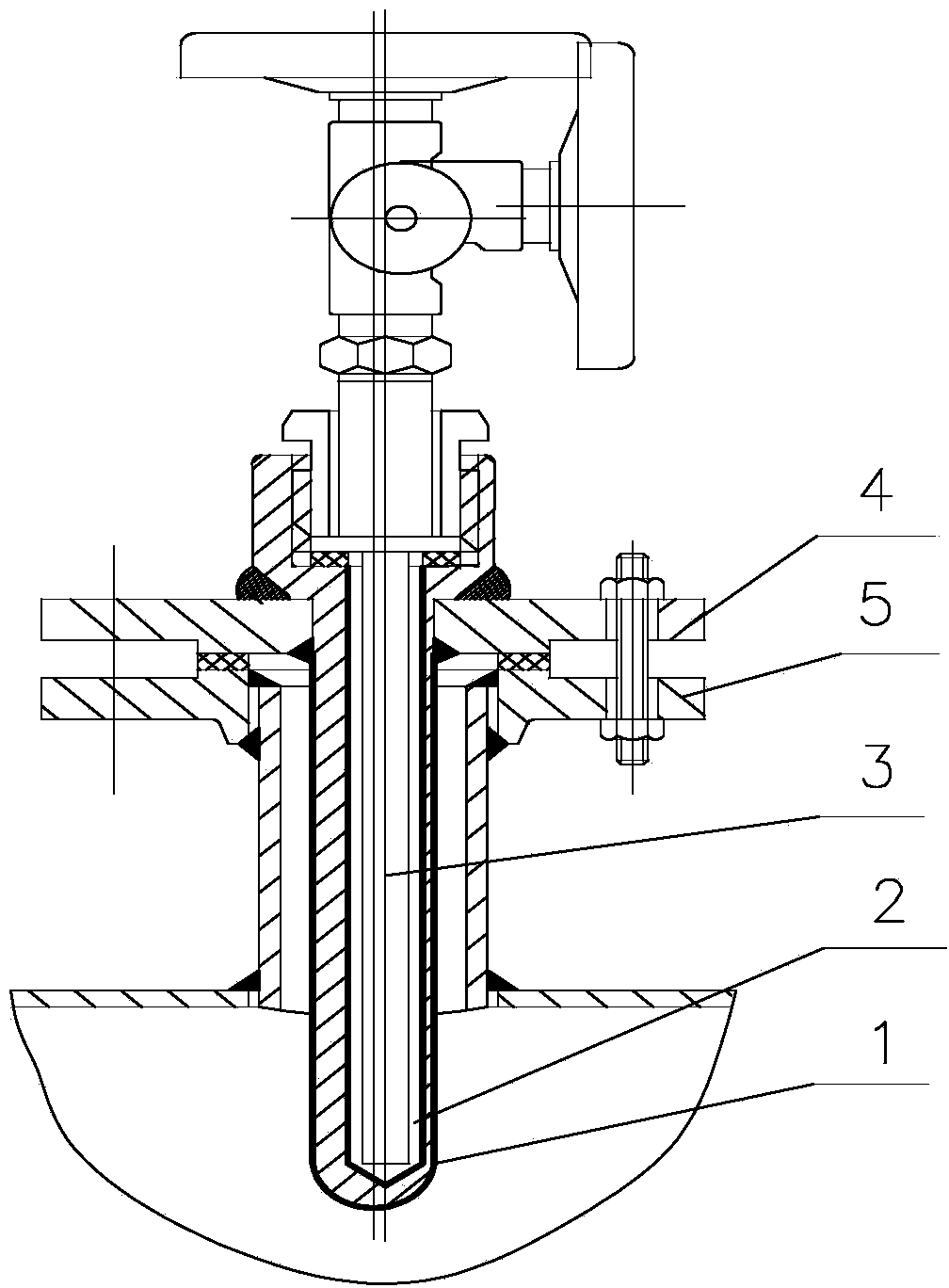

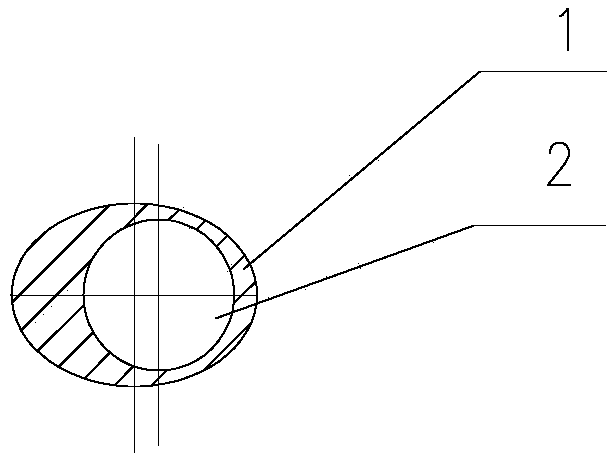

Thermowell

The invention discloses a thermowell. The thermowell comprises a tube body, wherein a thermometer installation hole is formed inside the tube body, the outer wall of the tube body is oval, the thermometer installation hole is round, the axis of the thermometer installation hole is parallel to the axis of the tube body, and the axis of the thermometer installation hole is deviated from the axis of the tube body. The thermowell has the advantages that when an oval long-axis portion of the tube body right faces the flowing direction of fluid, the change of a flow field is quite little after the fluid flows through the thermowell, and compared with a cylindrical thermowell, the thermowell generates no eddy; in addition, due to the fact that a temperature measurement component is arranged eccentrically, compared with a thermowell of a symmetrical structure, the thermowell of the eccentric structure has the advantages that the change of the inherent frequency of the thermowell is larger relative to the that the central position of the symmetrical thermowell, and the resonance caused by the identical frequency between the thermowell and the fluid is reduced to a great extent.

Owner:CHINA TIANCHEN ENG +1

boat propeller

Owner:周宗伟

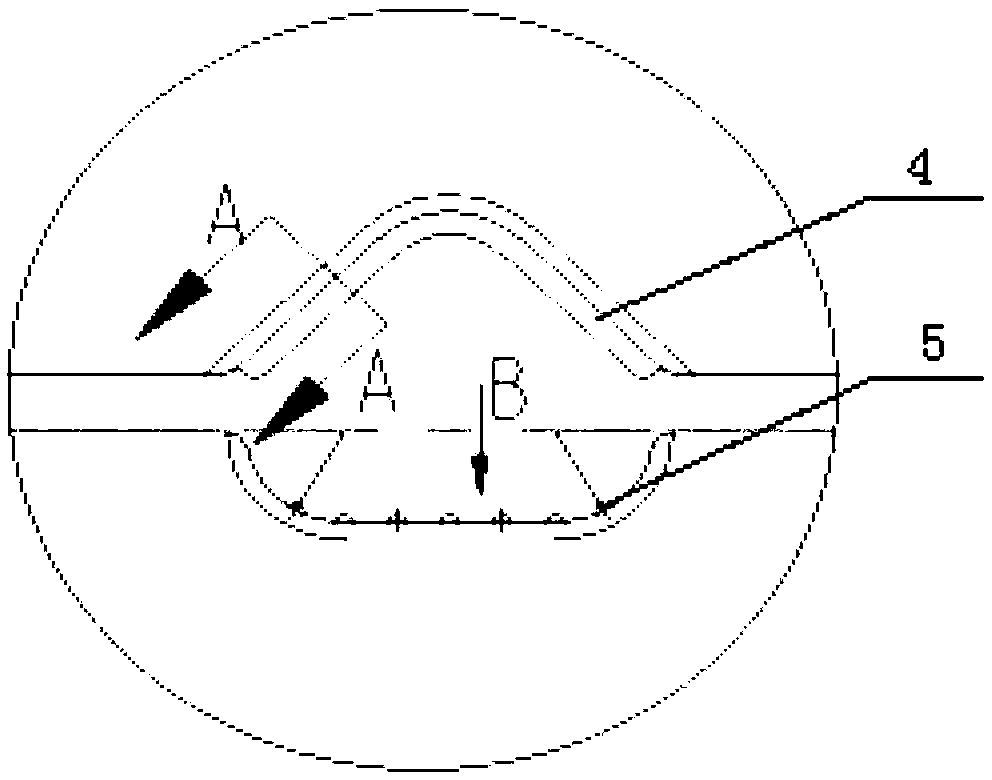

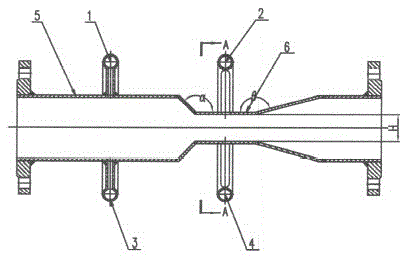

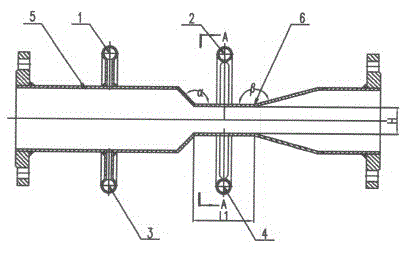

High-online diffusing pipe double rectangular flowmeter

InactiveCN105043466AGuaranteed accuracyGuaranteed stabilityVolume/mass flow by differential pressurePositive pressureEngineering

The invention relates to a flow measuring device, in particular to a high-online diffusing pipe double rectangular flowmeter which comprises a measuring pipeline. The high-online diffusing pipe double rectangular flowmeter is characterized in that two inverted-trapezoidal throttling elements are symmetrically distributed in the measuring pipeline about a central axis, a positive pressure sampling pipe is arranged on the measuring pipeline in a matched mode, and a negative pressure sampling pipe is arranged between the inverted-trapezoidal throttling elements in a matched mode. According to the high-online diffusing pipe double rectangular flowmeter, the structure is unique, the problems that the measuring precision is low and the measuring range is narrow are solved, and the problem of the measuring precision under the low reynolds number is solved.

Owner:银川融神威自动化仪表厂(有限公司)

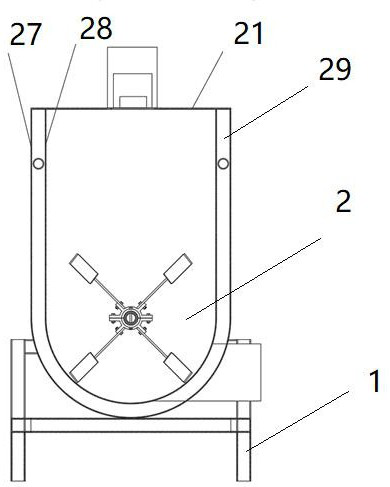

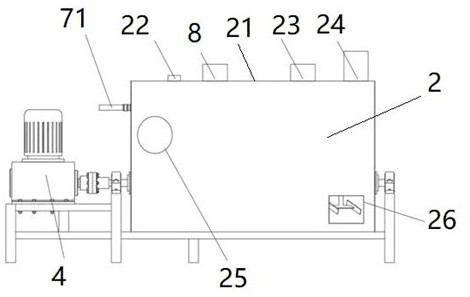

Novel kitchen waste fermentation bin

PendingCN111875420AEvenly distributedStir wellClimate change adaptationOrganic fertilisersProcess engineeringMechanical engineering

A novel kitchen waste fermentation bin comprises a base, wherein a fermentation bin body is placed on the base; a horizontal stirring shaft is arranged in the fermentation bin body; the stirring shaftis connected with a motor located on the base; an upper sealing cover, an air inlet, a zymophyte adding port and an air draft channel are arranged at the top of the fermentation bin body; a smashingdevice for pretreating kitchen waste is connected to a feeding port; four groups of stirring devices are arranged at the part, positioned in the fermentation bin, of the stirring shaft; each group ofstirring devices comprises two T-shaped brackets and stirring blades; the T-shaped brackets are vertically connected with the stirring shaft; the stirring blades are in non-vertical connection with two sides of the heads of the T-shaped brackets, i.e., two included angles alpha and beta between the heads of the T-shaped brackets and the stirring blades are obtuse angles; the stirring blades obliquely point to the top of the fermentation bin; a heating oil pump is arranged outside the fermentation bin; the fermentation bin comprises an outer layer and an inner layer, and an oil guide interlayeris arranged between the outer layer and the inner layer.

Owner:湖北应急产业技术研究院有限公司

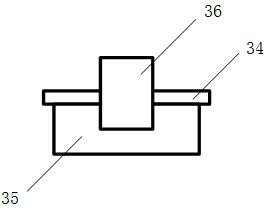

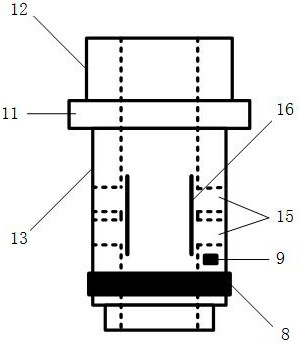

A swing type residual chlorine sensor

ActiveCN112525964BHigh measurement accuracySolve the problem of measuring the influence of residual chlorine valueMaterial electrochemical variablesEngineeringControl circuit

The invention discloses a swing-type residual chlorine sensor, which comprises a tube shell, a mounting base, an end cap, an eccentric rotating device, a swinging device, balls, a cathode, an anode, a temperature sensor and a control circuit board. There are mesh holes, the balls are arranged in the end cap, and the tube shell, the installation base and the end cap are fixedly connected sequentially from top to bottom; the eccentric rotating device and the control circuit board are fixed in the tube shell, and the The upper end of the oscillating device is fixedly connected with the eccentric rotating device, and the lower end passes through the installation base and enters the end cap; the cathode is fixed at the lower end of the oscillating device, and the eccentric rotating device controls the cathode to perform circular motion through the oscillating device; the anode and temperature The sensors are all fixed on the installation base, and the control circuit board is respectively connected with the cathode, the anode, the temperature sensor and the eccentric rotation device. The invention solves the technical problems that the existing residual chlorine sensor cannot accurately measure the residual chlorine value of the solution and is inconvenient to clean the cathode.

Owner:重庆昕晟环保科技有限公司

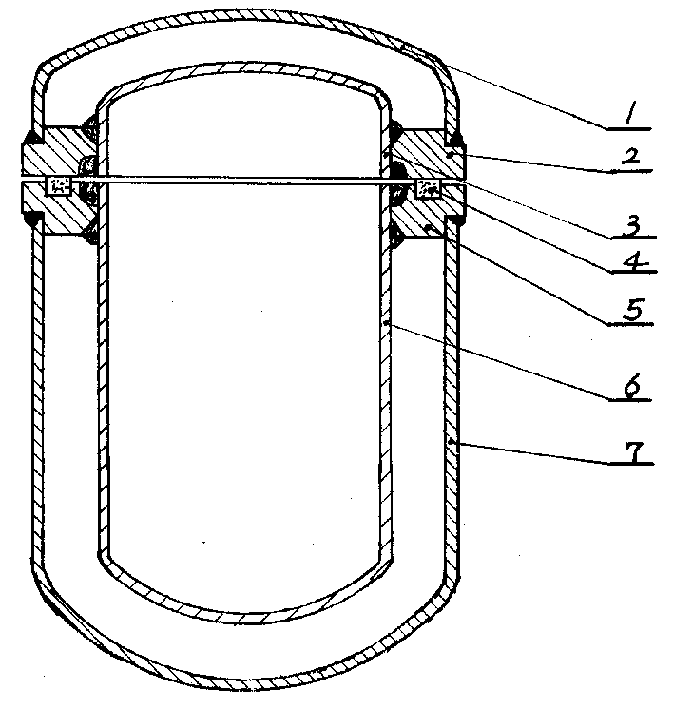

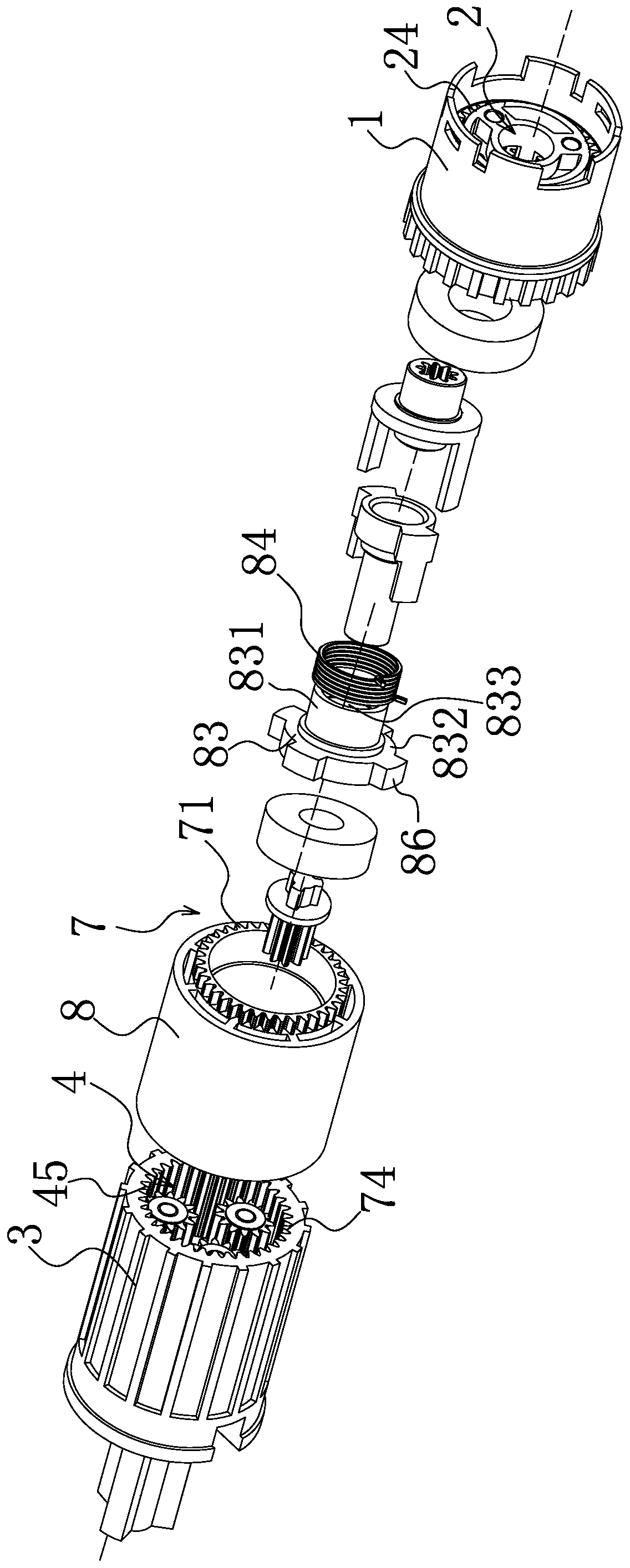

Transmission structure of hollow cup tubular motor

PendingCN110266145AReduce quality problemsQuick responseSelf acting brakesToothed gearingsEngineeringAutomotive engineering

The invention relates to a transmission structure of a hollow cup tubular motor, and solves the problem that an existing transmission structure of the tubular motor is insufficiently reasonable in design. The transmission structure comprises a motor main body, a motor connecting seat, a primary gear ring, a primary planetary gear assembly, a brake outer sleeve, a secondary planetary gear assembly, a ternary planetary gear assembly and a secondary and ternary gear ring, wherein the motor main body is a hollow cup motor; a brake driving part and a brake driven part which are coaxially arranged are arranged in the brake outer sleeve in a penetrating mode; the brake driving part is connected with the output end of the primary planetary gear assembly; the brake driven part is connected with the input end of the secondary planetary gear assembly; the brake driving part is in transmission connection with the brake driven part; and a brake assembly connected with the brake driving part and the brake driven part is arranged on the inner side of the periphery of the brake outer sleeve. The transmission structure has the advantages that the transmission stability is high, the component layout is reasonable, the structure is compact, and the brake effect is good.

Owner:HANGZHOU WISTAR MECHANICAL& ELECTRIC TECH CO LTD

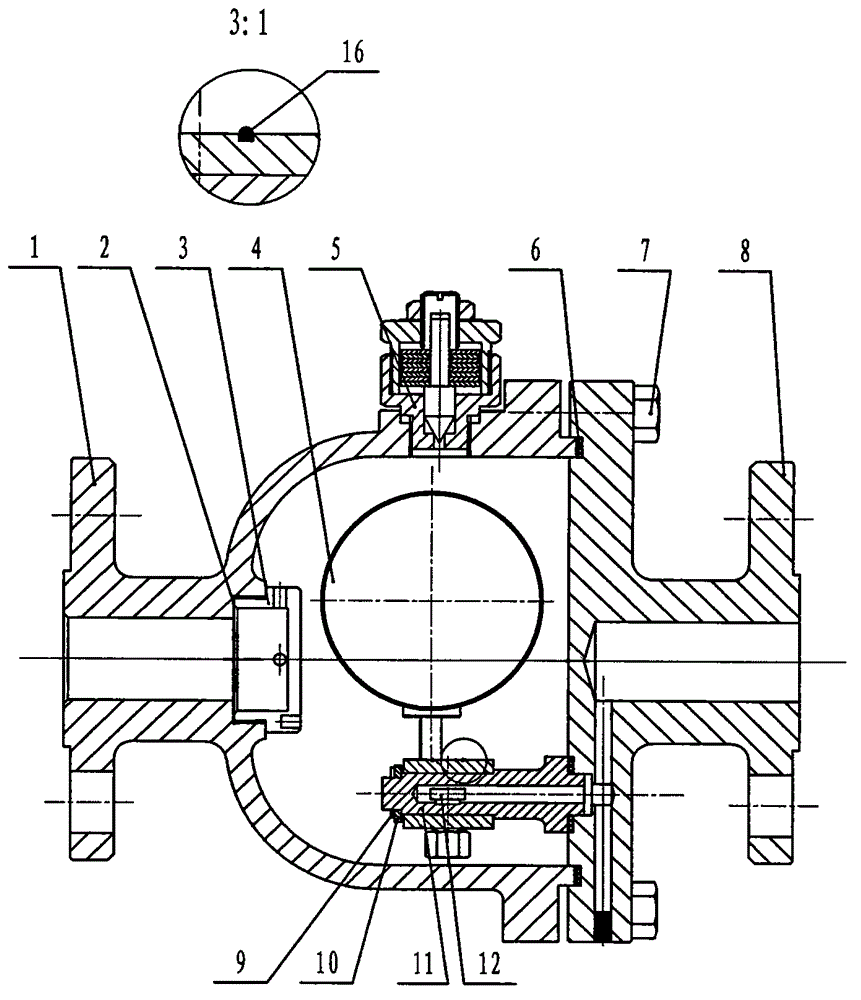

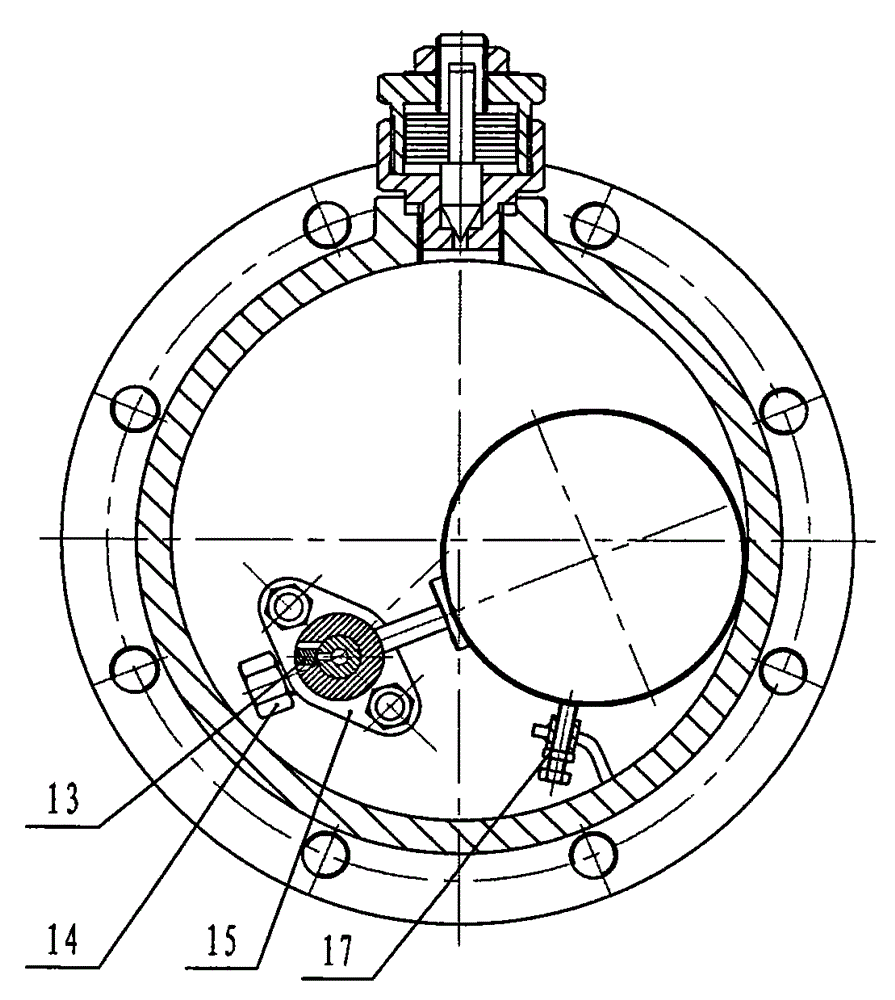

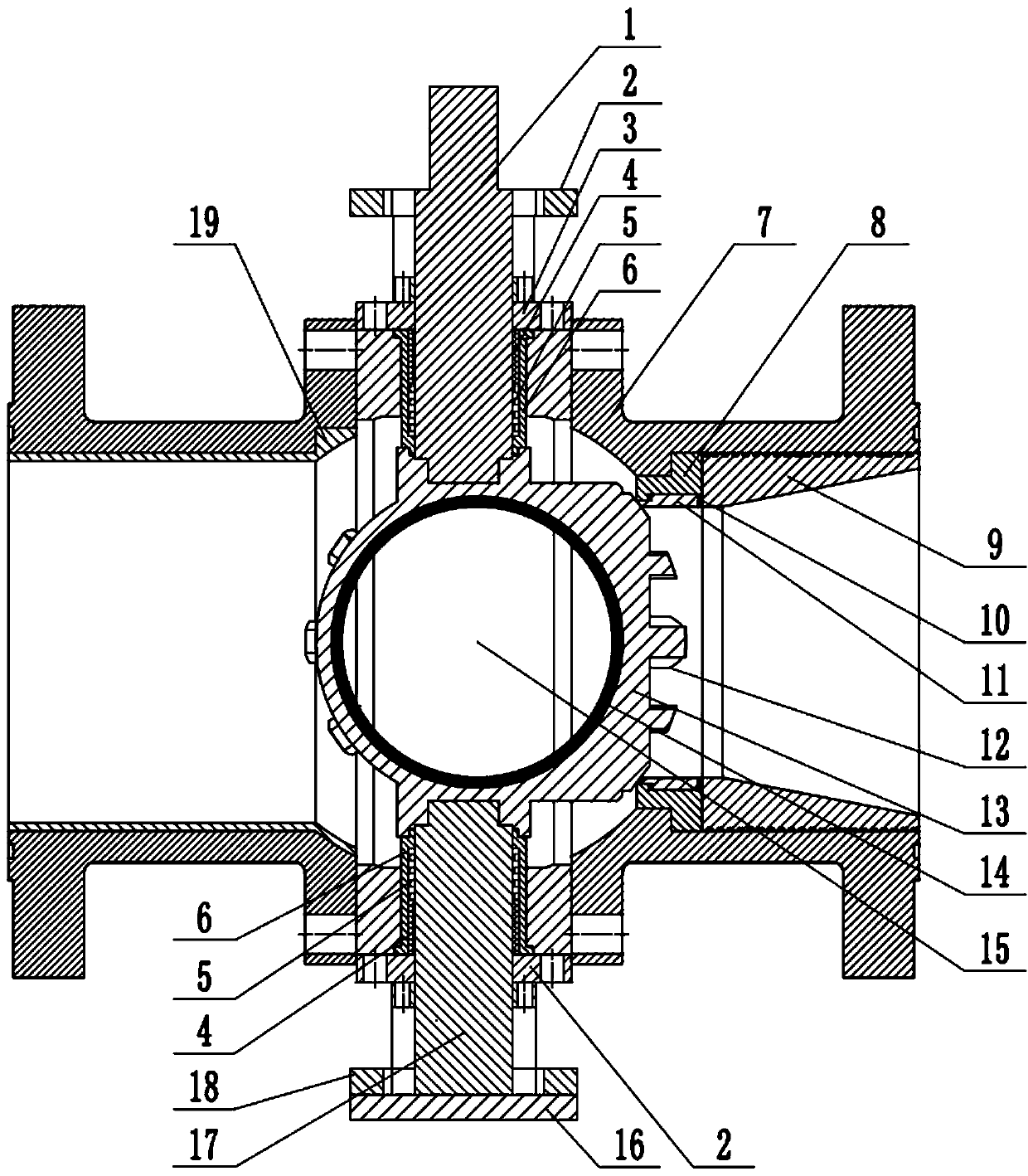

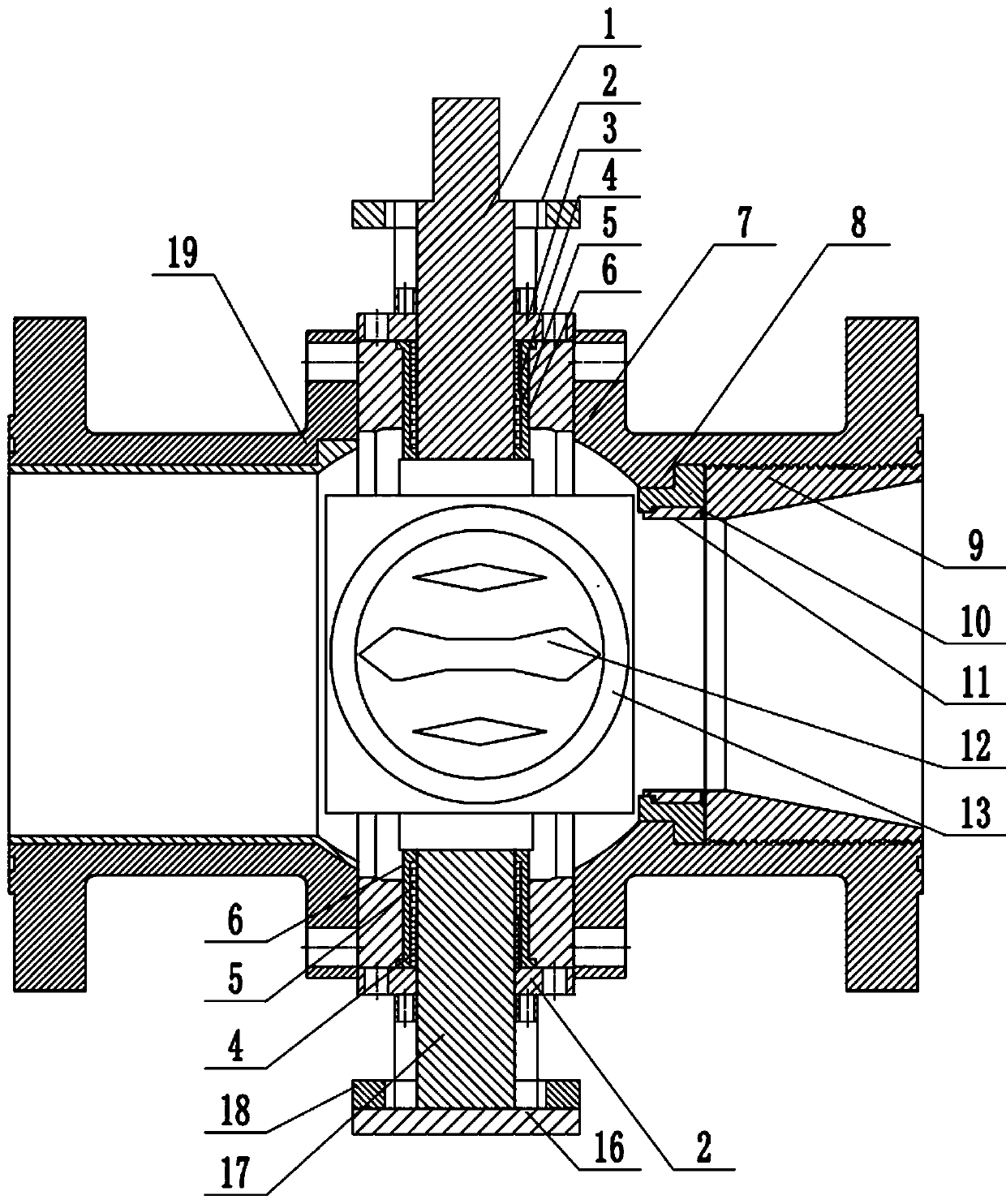

Scouring-resistant slurry valve

PendingCN109869499AHigh hardnessImprove heat resistancePlug valvesValve members for absorbing fluid energySlurryAlloy

Provided is a scouring-resistant slurry valve. The scouring-resistant slurry valve comprises an upper valve shaft, large pressing covers, a valve body, a valve plate and a lower valve shaft. A flow inlet and a flow outlet are formed in the side face of the valve body; mounting holes for the large pressing covers are formed in the top face and the bottom face of the valve body correspondingly, thelarge pressing covers are mounted in the mounting holes, the valve plate is supported and fixed in the valve body through the large pressing covers, and the upper valve shaft and the lower valve shaftpenetrate through the large pressing covers and then are connected with the valve plate; packing and a bearing sleeve are mounted between each large pressing cover and the corresponding valve shaft,and the packing and the bearing sleeves supporting the valve shafts to rotate are pressed in the large pressing covers through glands; an upper support is mounted on the top face of the valve body; alower support is mounted at the bottom of the valve body; a bottom cover for limiting the lower valve shaft is mounted on the lower support; the valve plate is provided with a circular-hole valve plate channel for passing of slurry; a valve seat is arranged on the flow inlet of the side face of the valve body, and the valve seat is fixed and limited in the flow inlet through a nut; the diameter ofthe valve plate channel is smaller than that of an alloy sleeve and larger than the diameter of the valve seat. The slurry valve is good in airtightness, resistant to high-pressure scouring and longin service life.

Owner:GUANGXI KEDE VALVE CO LTD

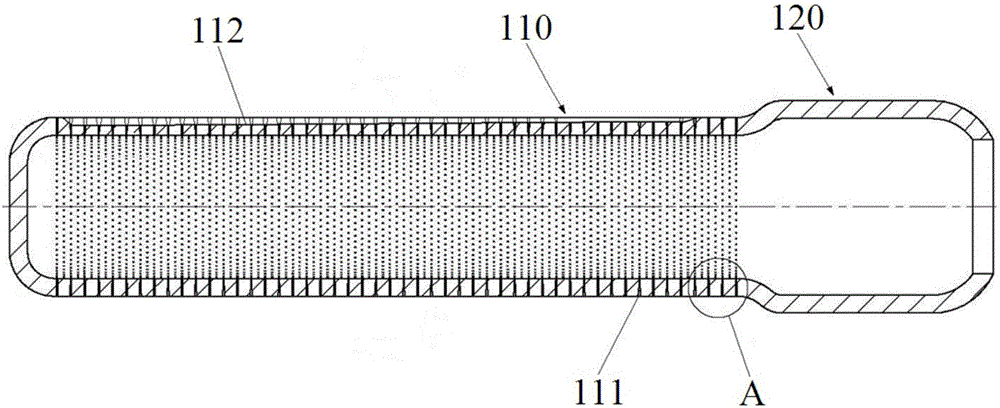

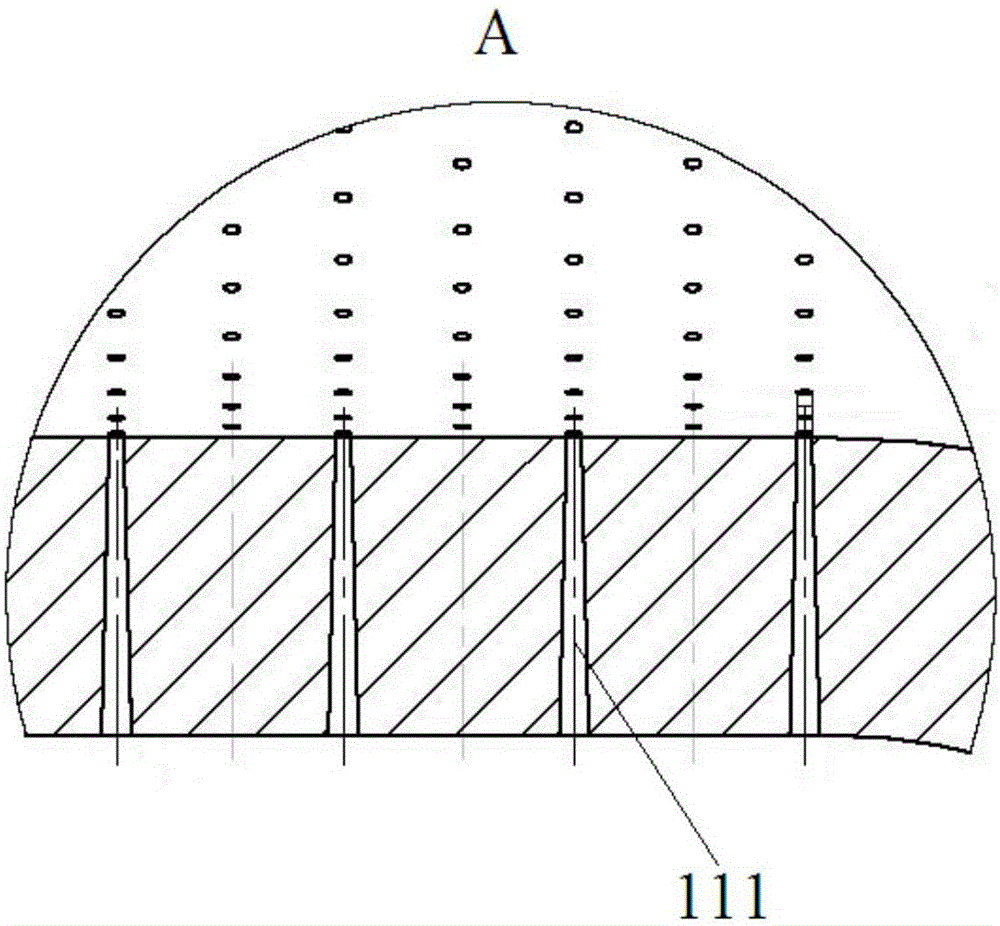

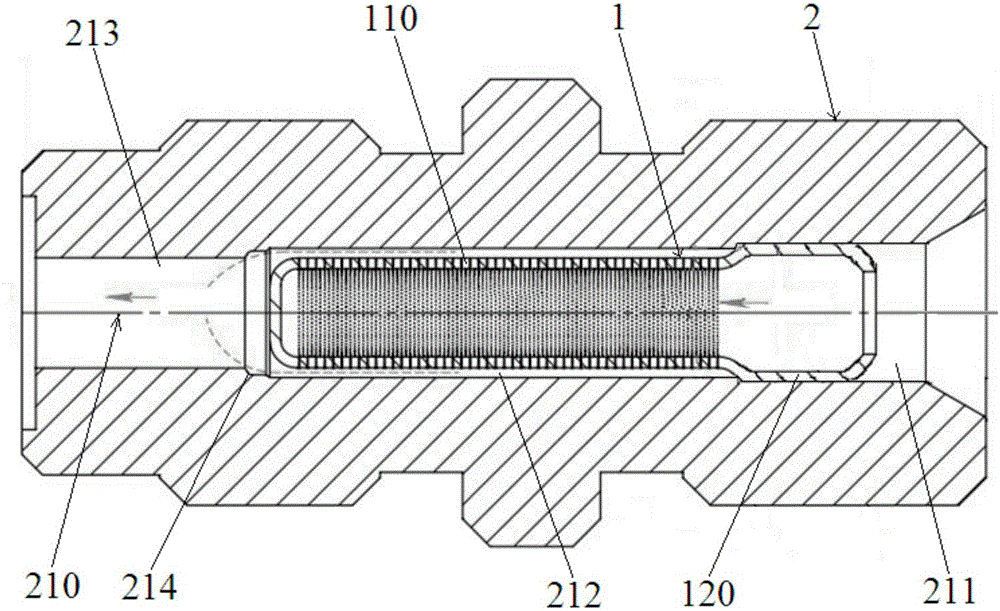

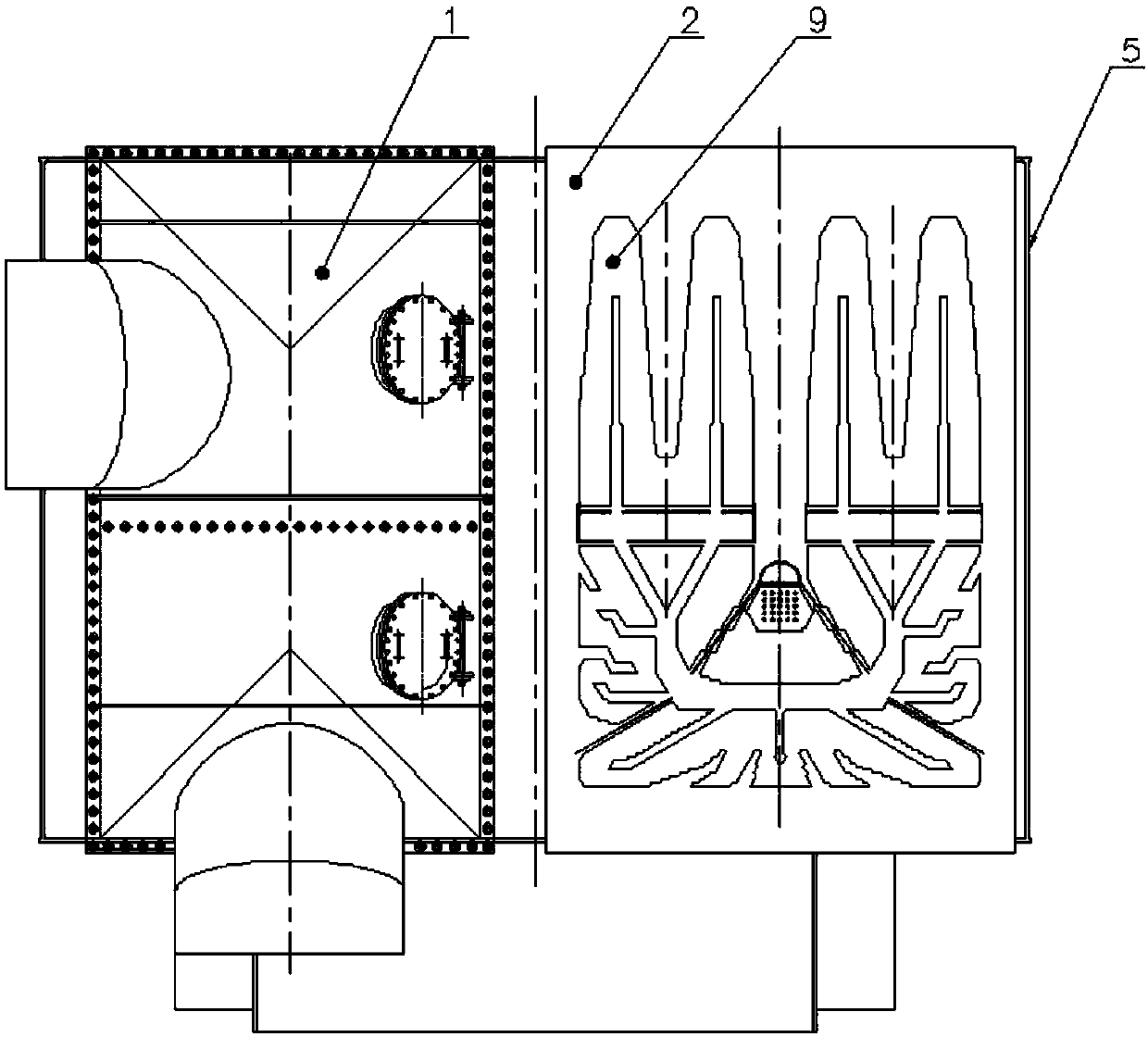

Fuel oil pre-atomization device, fuel oil atomization joint and manufacturing method of fuel oil pre-atomization device

ActiveCN106000677AImprove combustion efficiencyAvoid erosionInternal combustion piston enginesSpray nozzlesInjection pressureMicrometer

The invention discloses a fuel oil pre-atomization device, a fuel oil atomization joint and a manufacturing method of the fuel oil pre-atomization device. The fuel oil pre-atomization device comprises a cup-shaped body of which one end is a blind end and the other end is an open end. The side wall of the cup-shaped body is provided with an atomization portion adjacent to the blind end and a mounting portion located at the open end of the cup-shaped body. The side wall of the atomization portion is provided with multiple atomization holes with the pore diameter ranging from 10 micrometers to 60 micrometers. The fuel oil atomization joint comprises a straight-through connecting joint in which a step hole is formed. The fuel oil pre-atomization device is assembled in the step hole. The manufacturing method of the fuel oil pre-atomization device comprises the following steps that the cup-shaped body with the mounting portion and the atomization portion is stamped through a die; the atomization holes are machined in the atomization portion of the cup-shaped body through lasers; diversion trenches are cut in the atomization portion of the cup-shaped body; and polishing treatment is conducted on the cup-shaped body. By the adoption of the fuel oil pre-atomization device, pre-atomization can be conducted on fuel oil, the pre-atomized fuel oil can be prevented from forming an eddy in a spray head, and the injection pressure and the atomization effect of the fuel oil are guaranteed.

Owner:陕西华远动力科技有限公司

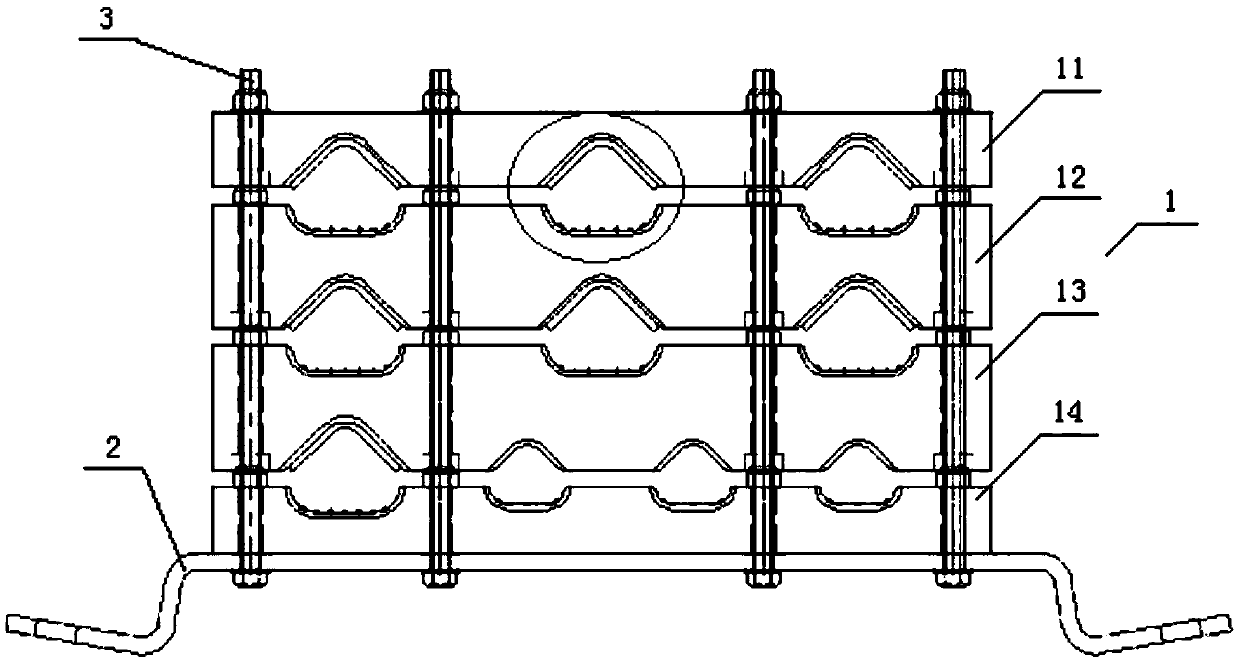

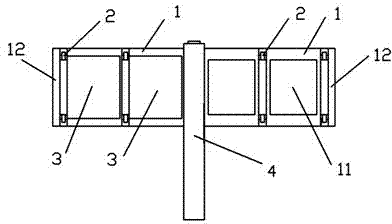

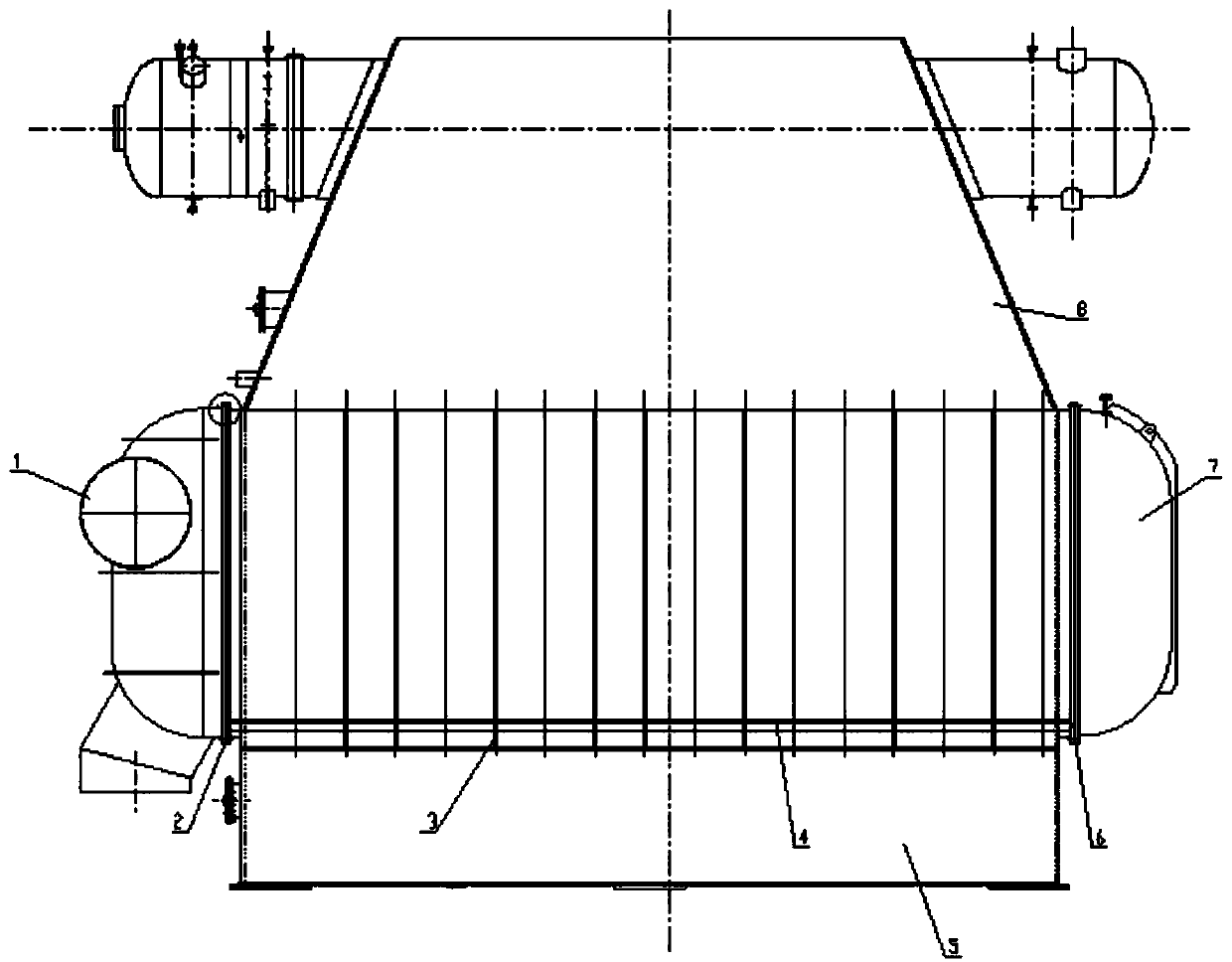

A new type of pipe layout condenser

ActiveCN106288845BNo eddy currentImprove heat transfer performanceSteam/vapor condensersIce removalHeat transfer coefficientSupercooling

The invention relates to a condenser with a novel tube arrangement manner. The upper parts of tube bundle areas in the condenser are divided into two symmetrical sides by using the center line of a tube plate surface, and each side is composed of connected M-shaped tube bundle areas. Tube bundle areas at the lower part of the tube plate surface in the condenser are symmetrical about the center line of the tube plate surface, and are unfolded and arranged towards the periphery by using an air cooling area as a center. Three steam baffle plates in the air cooling tube bundle area are gradually decreased so that a gradually decreased area is formed by the air cooling tube bundle area. Through the tube arrangement manner, the tube bundle steam flow field is uniform and free of vortex flow, the shell-side steam resistance is small, the heat load distribution is uniform, the condensed water supercooling degree is small, and the heat transfer coefficient and operation vacuum degree of the condenser are relatively high.

Owner:DEYANG DONGQI POWER STATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com