Chemical vapor deposition equipment used for producing silicon carbide epitaxial wafer

A technology of chemical vapor deposition and epitaxial wafers, which is applied in the direction of chemically reactive gases, chemical instruments and methods, and single crystal growth, which can solve problems such as uniformity and surface defects, thick silicon carbide epitaxial layers, and increased manufacturing costs. Achieve the effects of simple cost input, reduced thickness difference, and small uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

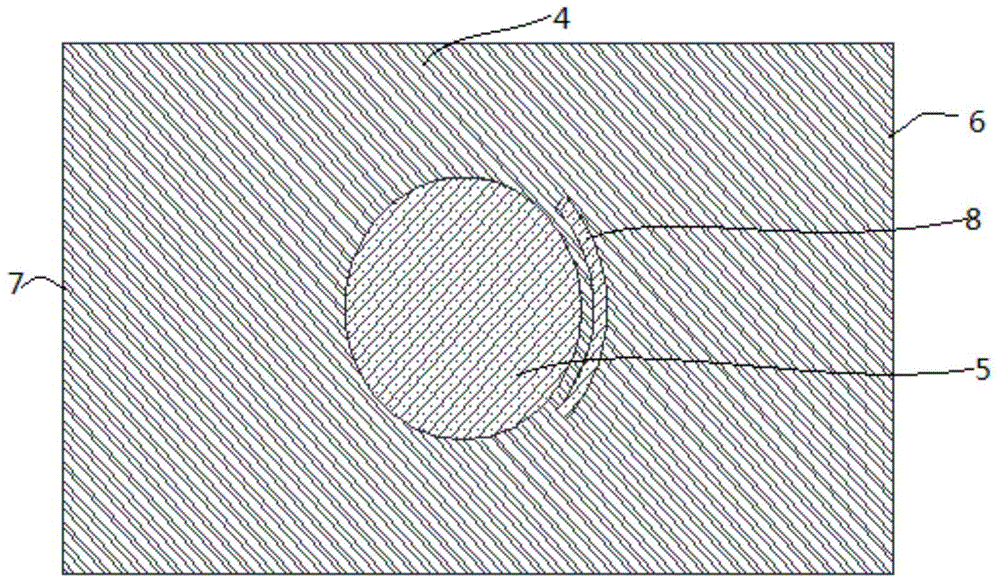

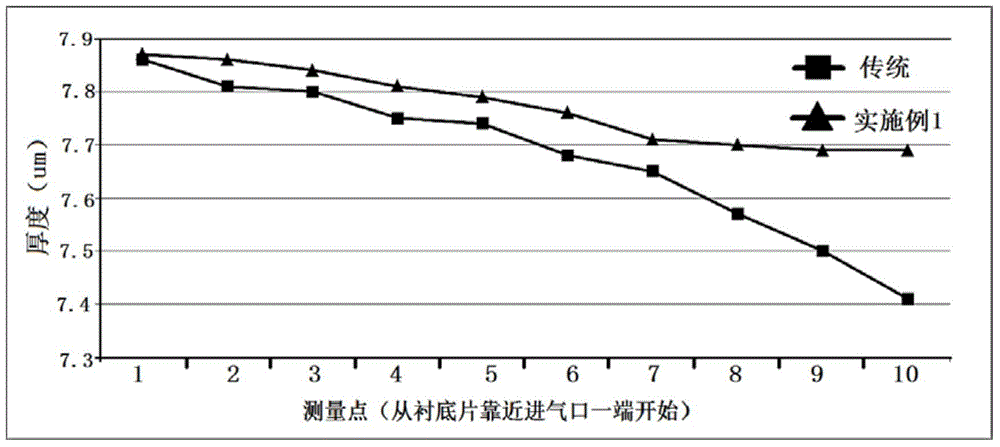

[0028] Such as image 3 As shown, the arc of the barrier ring is 180 degrees, the width is 0.9 cm, and the setting height is 0.4 cm. Through the above process, the growth of the epitaxial wafer is completed. In the direction of the corresponding airflow of the silicon carbide substrate, 10 points are measured at intervals, point 1 corresponds to the upper part of the airflow, and point 10 corresponds to the lower part of the airflow. The measurement results are as follows: Figure 5 As shown, the thickness of the silicon carbide epitaxial wafer obtained in Example 1 is reduced from 2.13% to 0.97%.

Embodiment 2

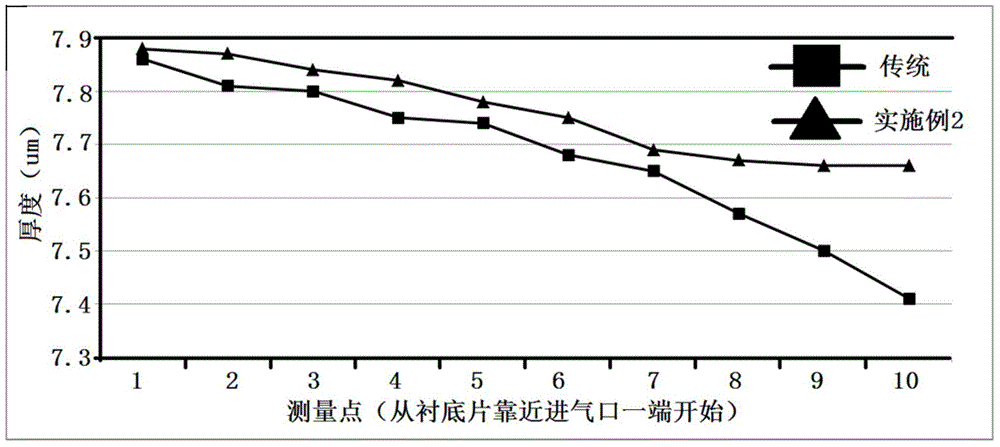

[0030] Such as Figure 4 As shown, when the arc of the barrier ring is 90 degrees, the width is 1.0 cm, and the height is set to 0.5 cm, the growth of the epitaxial wafer is completed through the above process flow. In the direction of the corresponding airflow of the silicon carbide substrate, 10 points are measured at intervals, point 1 corresponds to the upper part of the airflow, and point 10 corresponds to the lower part of the airflow. The measurement results are as follows: Image 6 As shown, the thickness uniformity of the silicon carbide epitaxial wafer obtained in Example 2 is reduced from 2.13% to 1.19%.

Embodiment 3

[0032] The width of the graphite barrier ring is 0.8cm, the height is 0.3cm, the radius is 1cm larger than the width of the substrate wafer, and the thickness uniformity of the epitaxial wafer prepared when the radian is 100 degrees is reduced from 2.16% to 1.21%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com