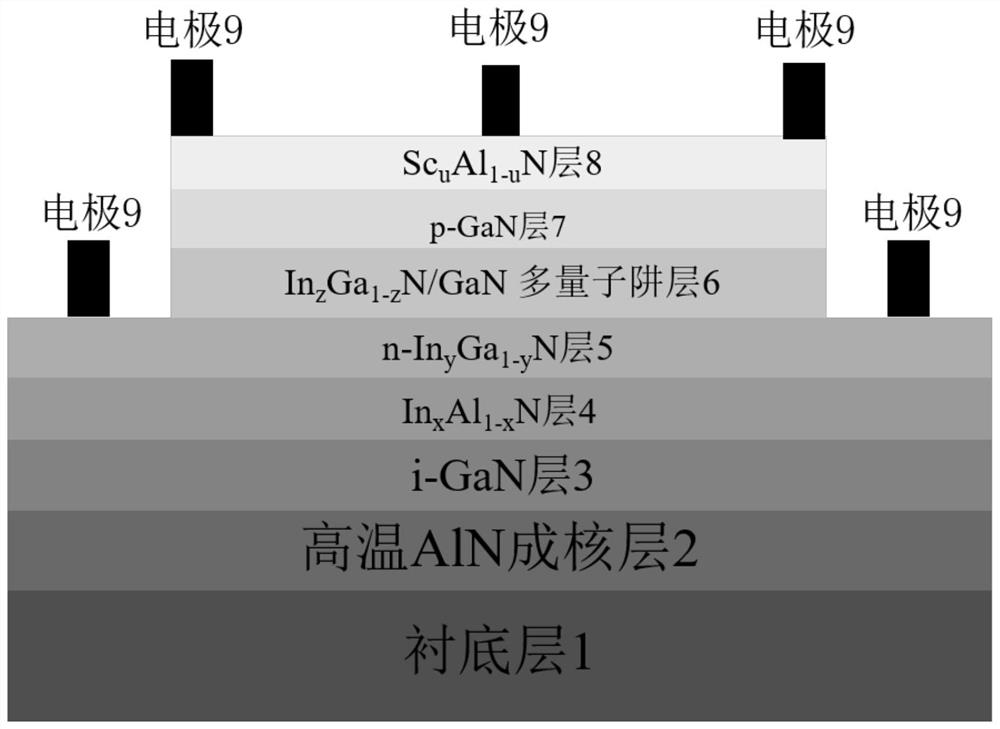

N-polarity InGaN-based solar cell based on ScAlN and InAlN polarization insertion layer enhanced electric field

A solar cell and intercalation layer technology, applied in the field of microelectronics, can solve the problems of InGaN material epitaxy is difficult and the difference in spontaneous polarization is not large, so as to reduce the impact of epitaxial growth, enhance drift ability, and ensure crystal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

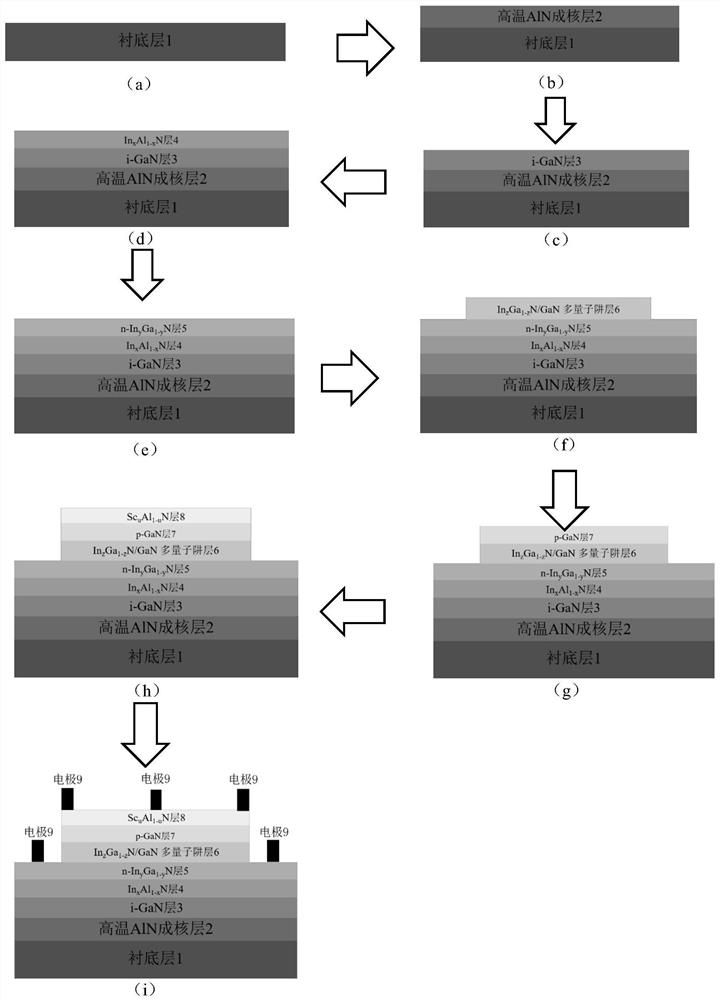

[0039] Example 1, preparing In on a SiC substrate with a thickness of 10nm 0.21 al 0.79 N-polarization enhancement layer and Sc with a thickness of 10nm 0.3 al 0.7 N-polarized enhancement layer, 30 cycles of In 0.15 Ga 0.85 N / GaN multiple quantum wells, N-polar InGaN-based solar cells that can absorb 420nm light wavelength.

[0040] In step one, the substrate is pretreated.

[0041] 1a) After cleaning the SiC substrate, place it in the metal organic chemical vapor deposition MOCVD reaction chamber, and reduce the vacuum degree of the reaction chamber to 2×10 -2 Torr: Introduce hydrogen gas into the reaction chamber, and under the condition that the pressure of the MOCVD reaction chamber reaches 50 Torr, heat the substrate to a temperature of 900°C and keep it for 5 minutes to complete the heat treatment of the substrate;

[0042] 2a) The heat-treated substrate is placed in a reaction chamber at a temperature of 1050° C., and ammonia gas with a flow rate of 3000 sccm is p...

Embodiment 2

[0062] Example 2, preparing In on a GaN substrate with a thickness of 15nm 0.22 al 0.77 N layer and Sc with a thickness of 15nm 0.35 al 0.7 N-polarized enhancement layer, 20 periods of In 0.22 Ga 0.78 N / GaN multiple quantum wells, N-polar InGaN-based solar cells with an absorption wavelength of 510nm.

[0063] Step 1, pretreating the substrate.

[0064] 1.1) After the GaN substrate was cleaned, it was placed in a metal-organic chemical vapor deposition MOCVD reaction chamber, and the vacuum degree of the reaction chamber was reduced to 1.5×10 -2Torr: Introduce hydrogen into the reaction chamber, and under the condition that the pressure of the MOCVD reaction chamber reaches 750 Torr, heat the substrate to a temperature of 1100°C and keep it for 3 minutes to complete the heat treatment of the substrate;

[0065] 1.2) The heat-treated substrate is placed in a reaction chamber at a temperature of 1150° C., and ammonia gas with a flow rate of 4000 sccm is introduced for 5 mi...

Embodiment 3

[0092] Embodiment 3, prepare the In that thickness is 20nm on sapphire substrate 0.23 Al 0.78 N layer and Sc with a thickness of 20nm 0.4 Al 0.6 N-polarized enhancement layer, 10 periods of In 0.3 Ga 0.7 N / GaN multiple quantum wells, N-polar InGaN-based solar cells with an absorption wavelength of 550nm.

[0093] Step A, pretreating the substrate.

[0094] After the sapphire substrate is cleaned, it is first placed in a metal organic chemical vapor deposition MOCVD reaction chamber, and the vacuum degree of the reaction chamber is reduced to 1.7×10 -2 Torr: Introduce hydrogen gas into the reaction chamber, and under the condition that the pressure of the MOCVD reaction chamber reaches 500 Torr, heat the substrate to a temperature of 1300°C and keep it for 10 minutes to complete the heat treatment of the substrate; then heat-treated the substrate Place it in a reaction chamber with a temperature of 1300°C, pass through ammonia gas with a flow rate of 5000 sccm, and carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com