Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Protrusion suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

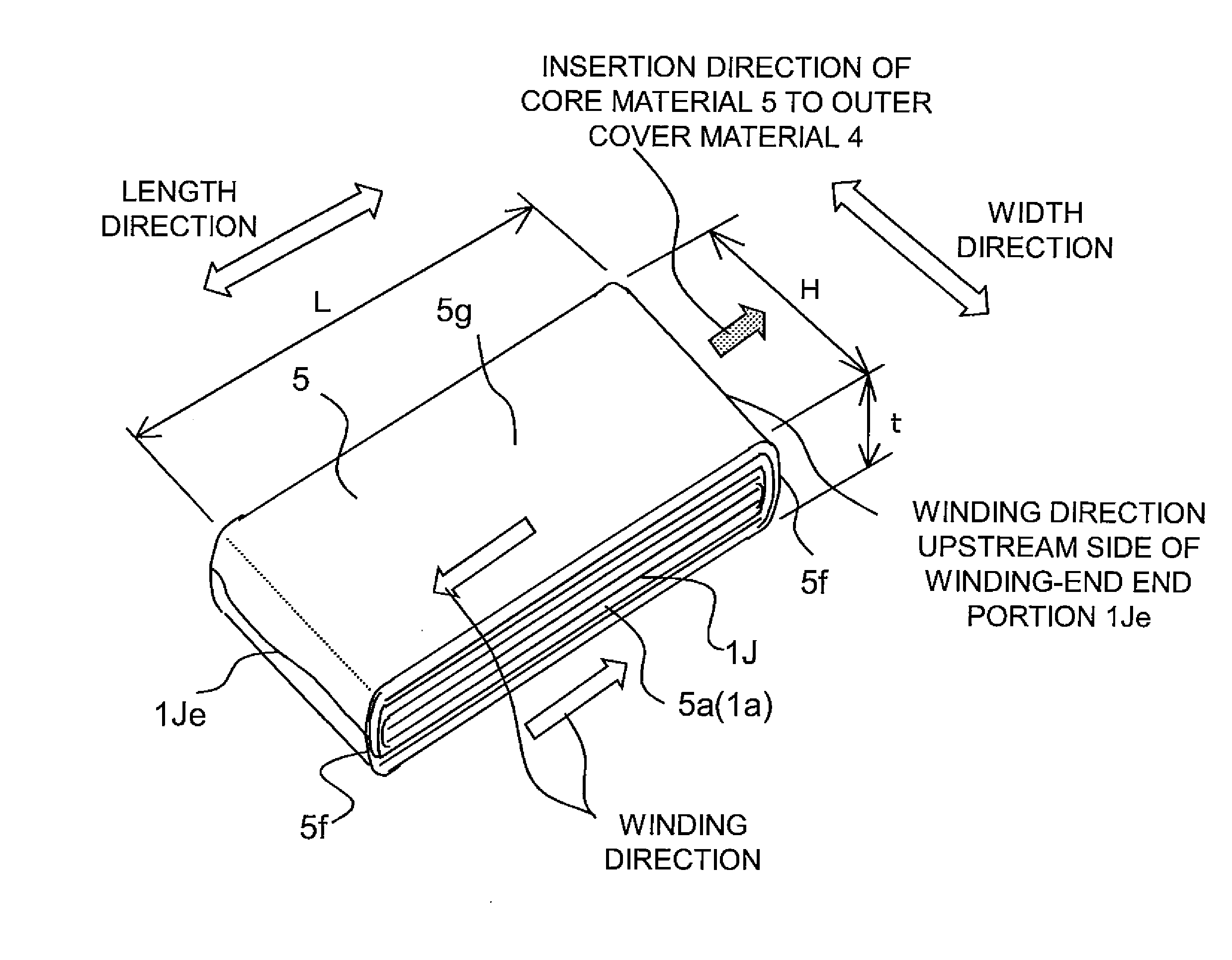

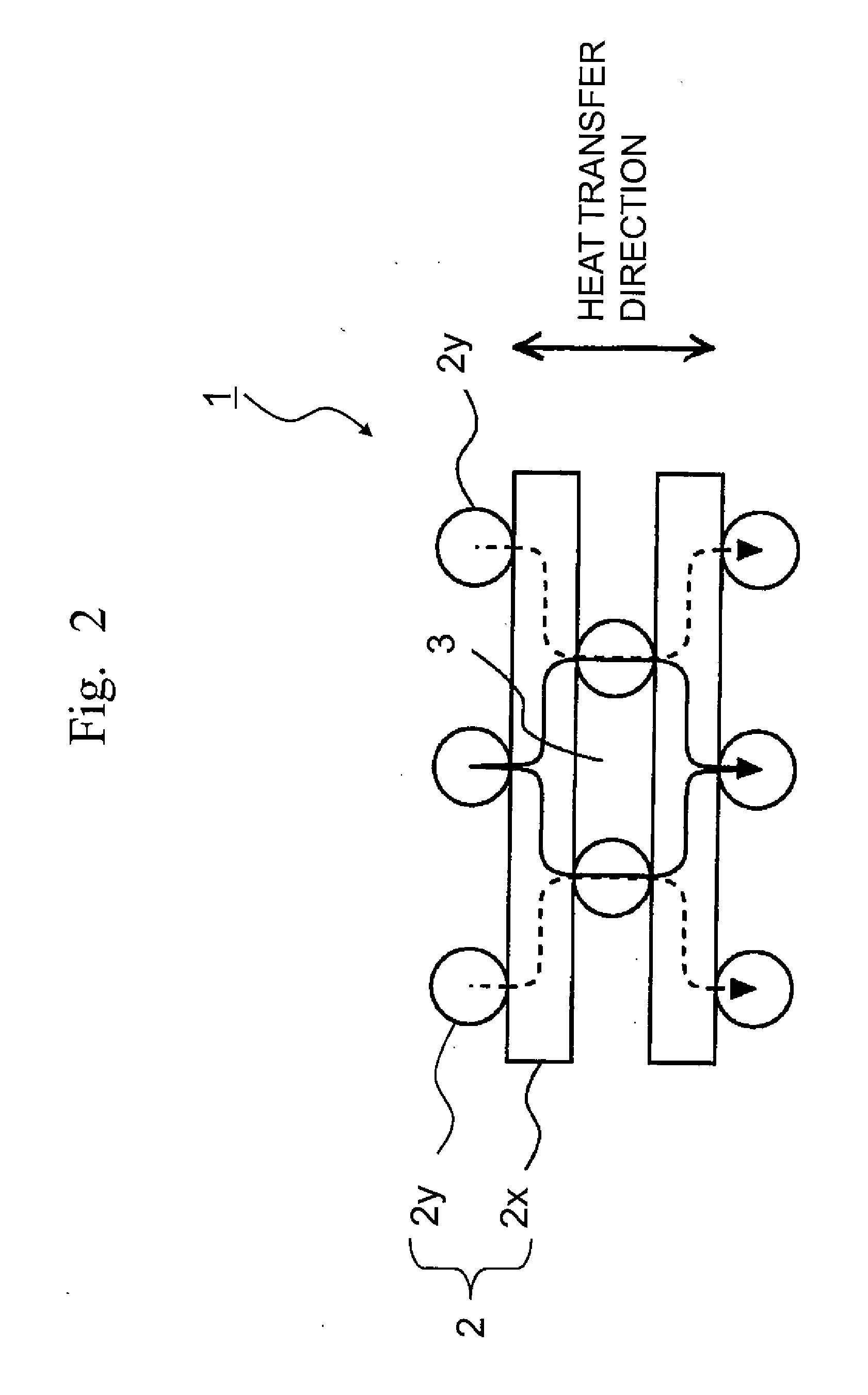

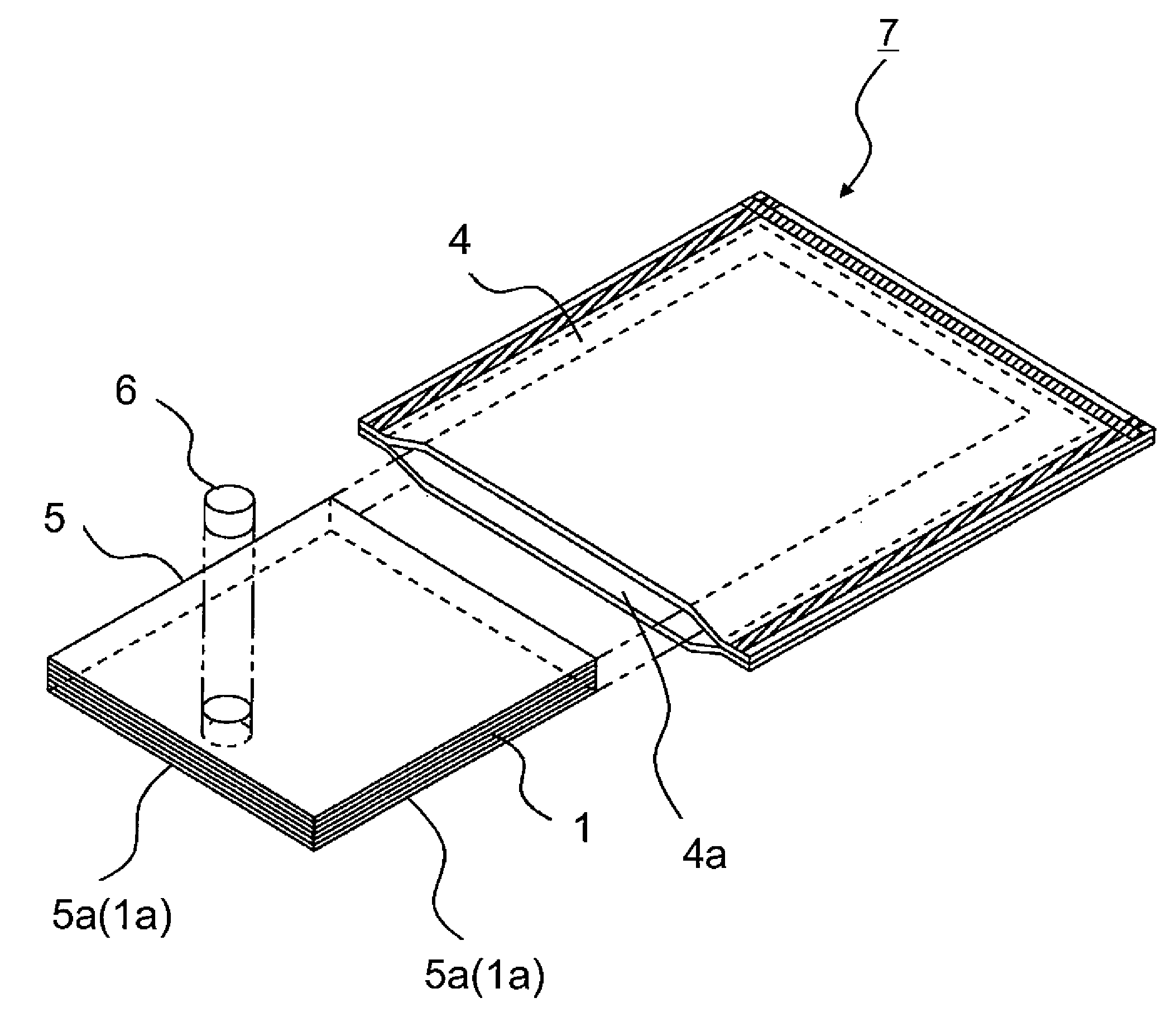

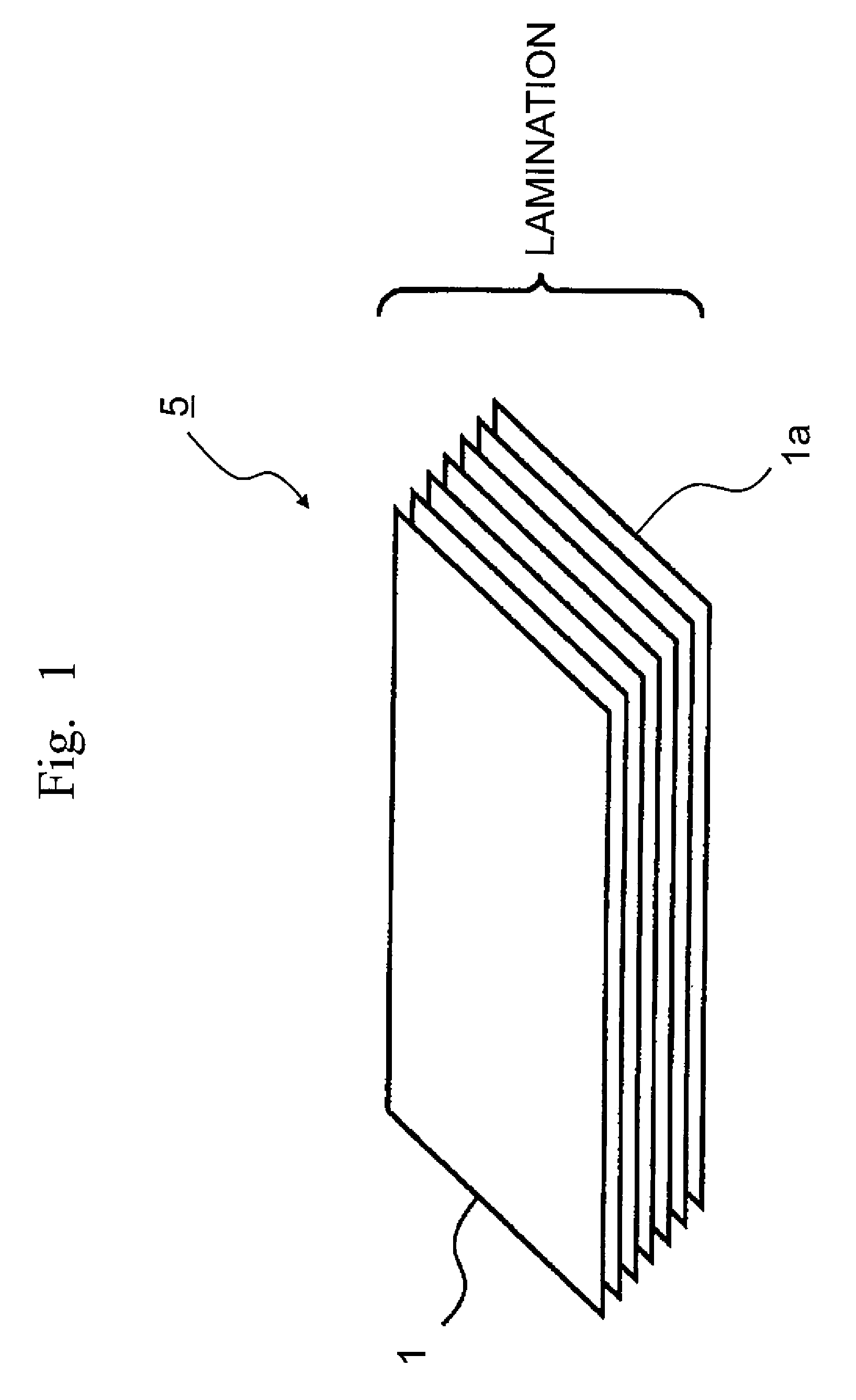

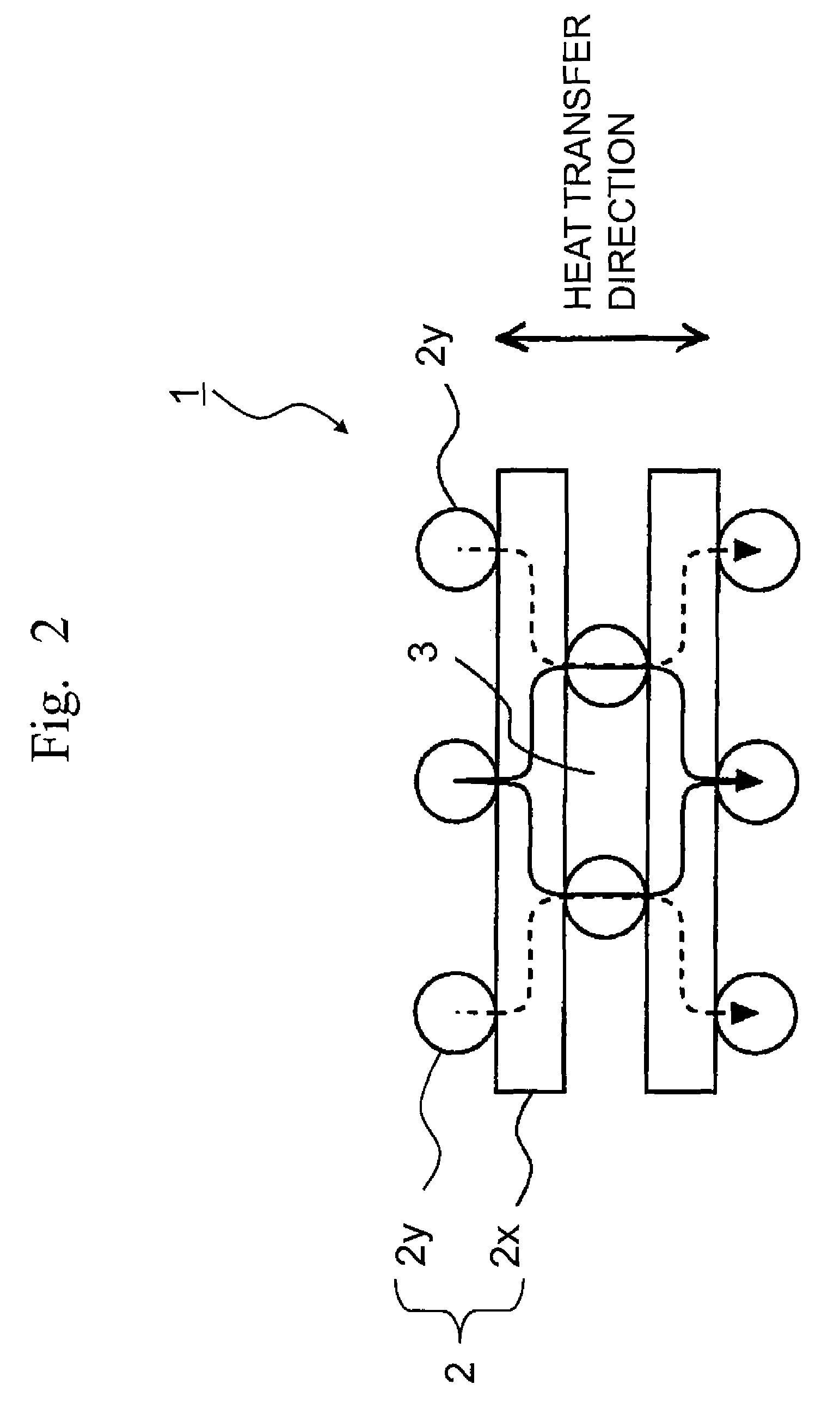

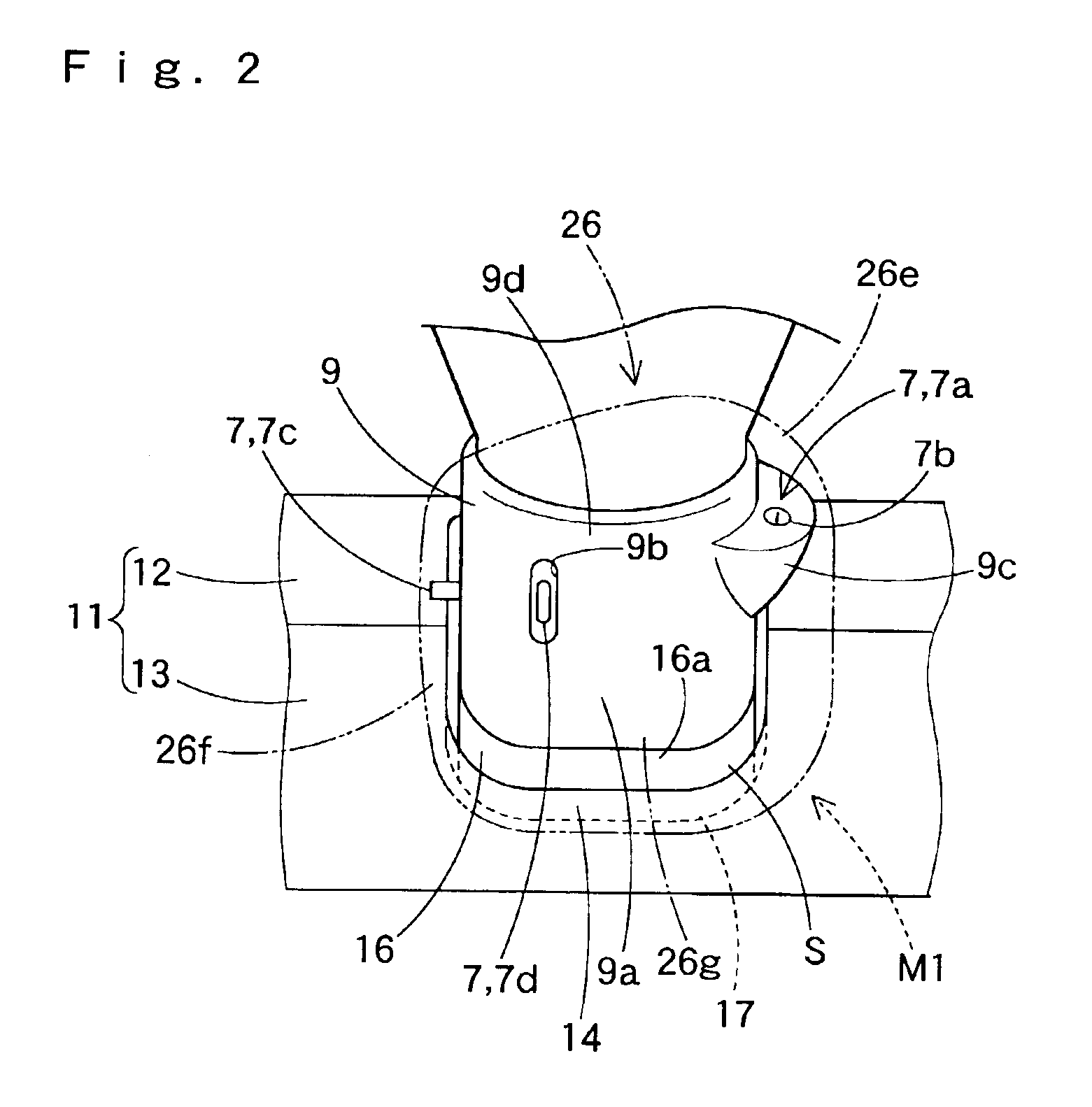

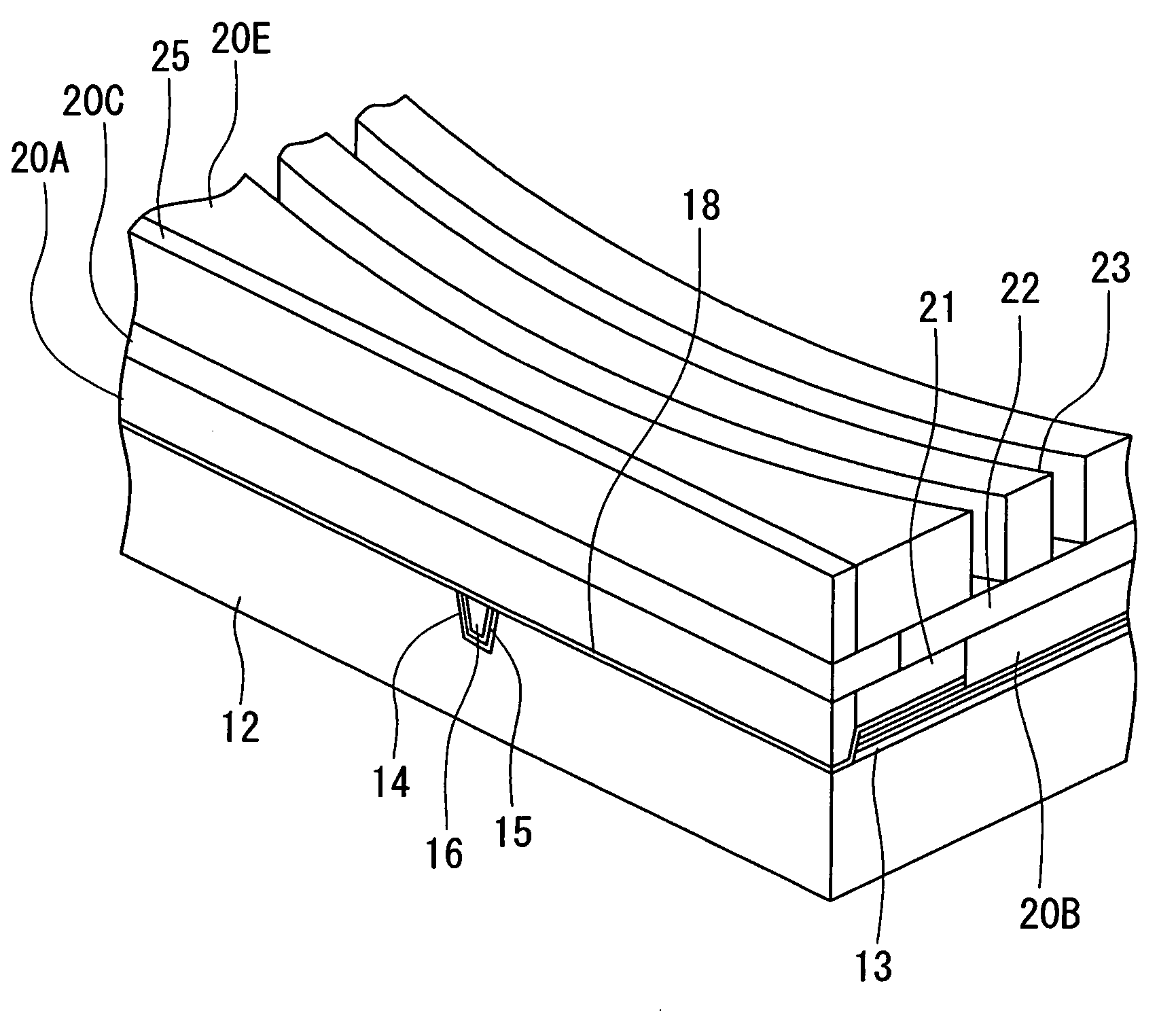

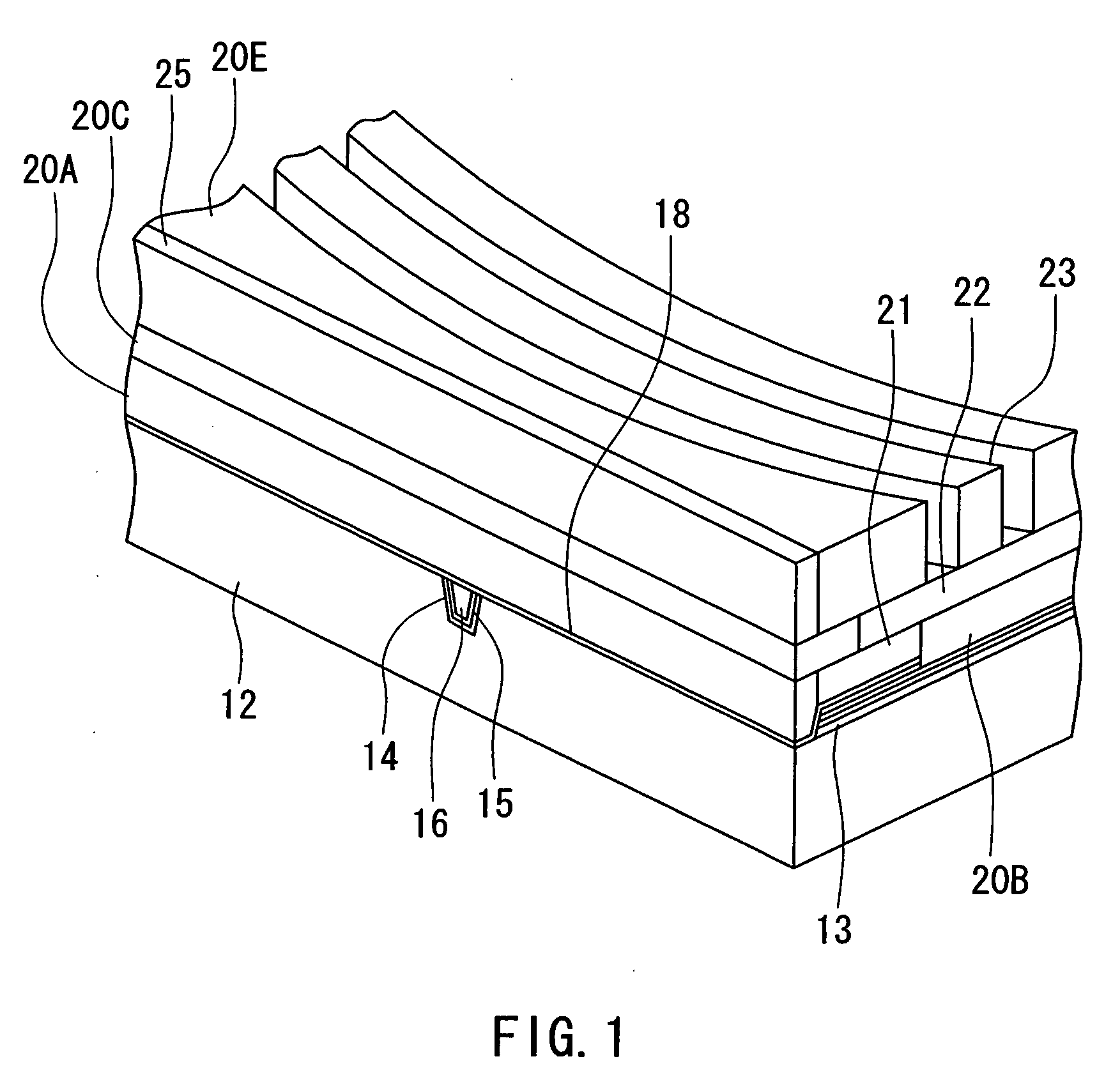

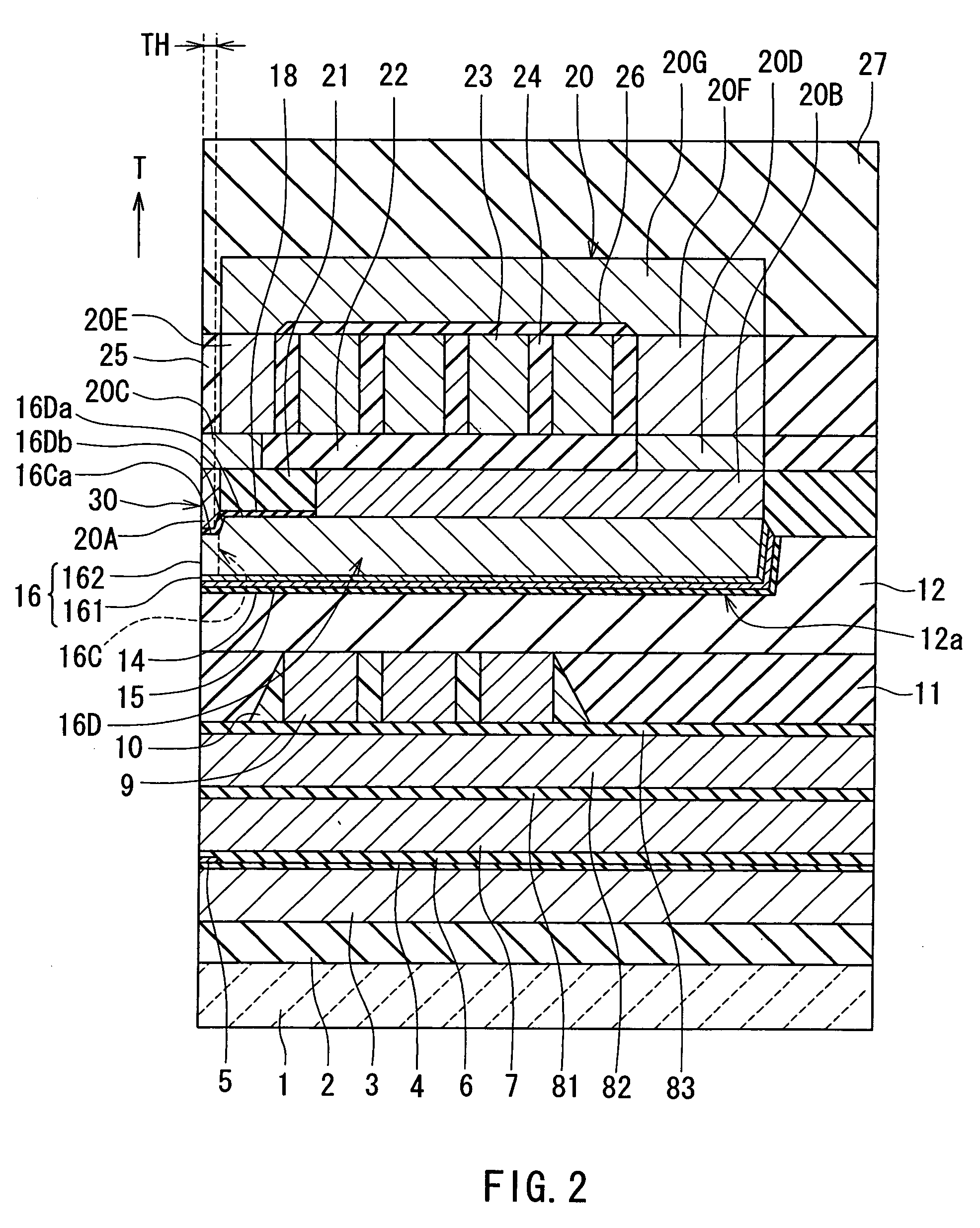

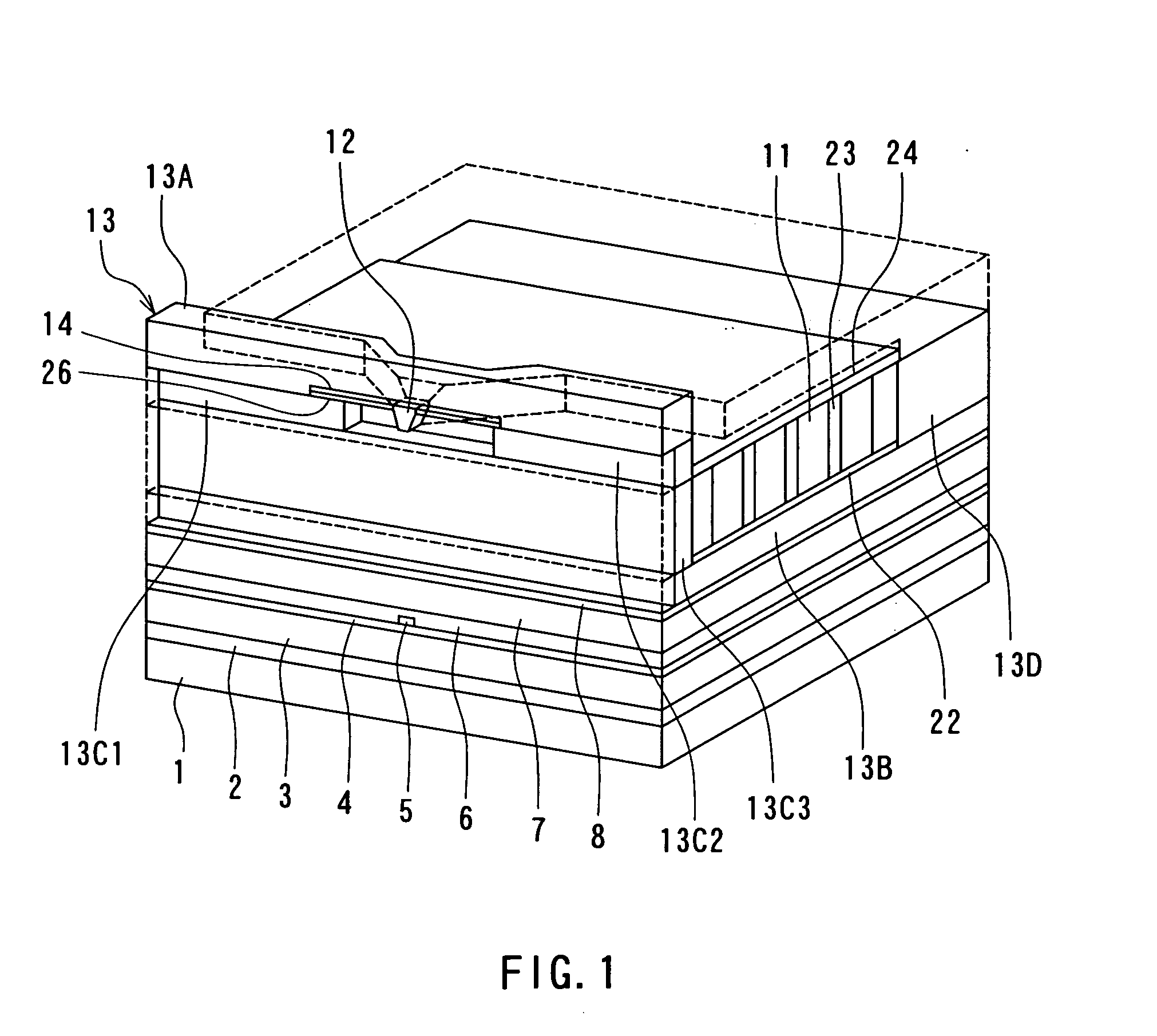

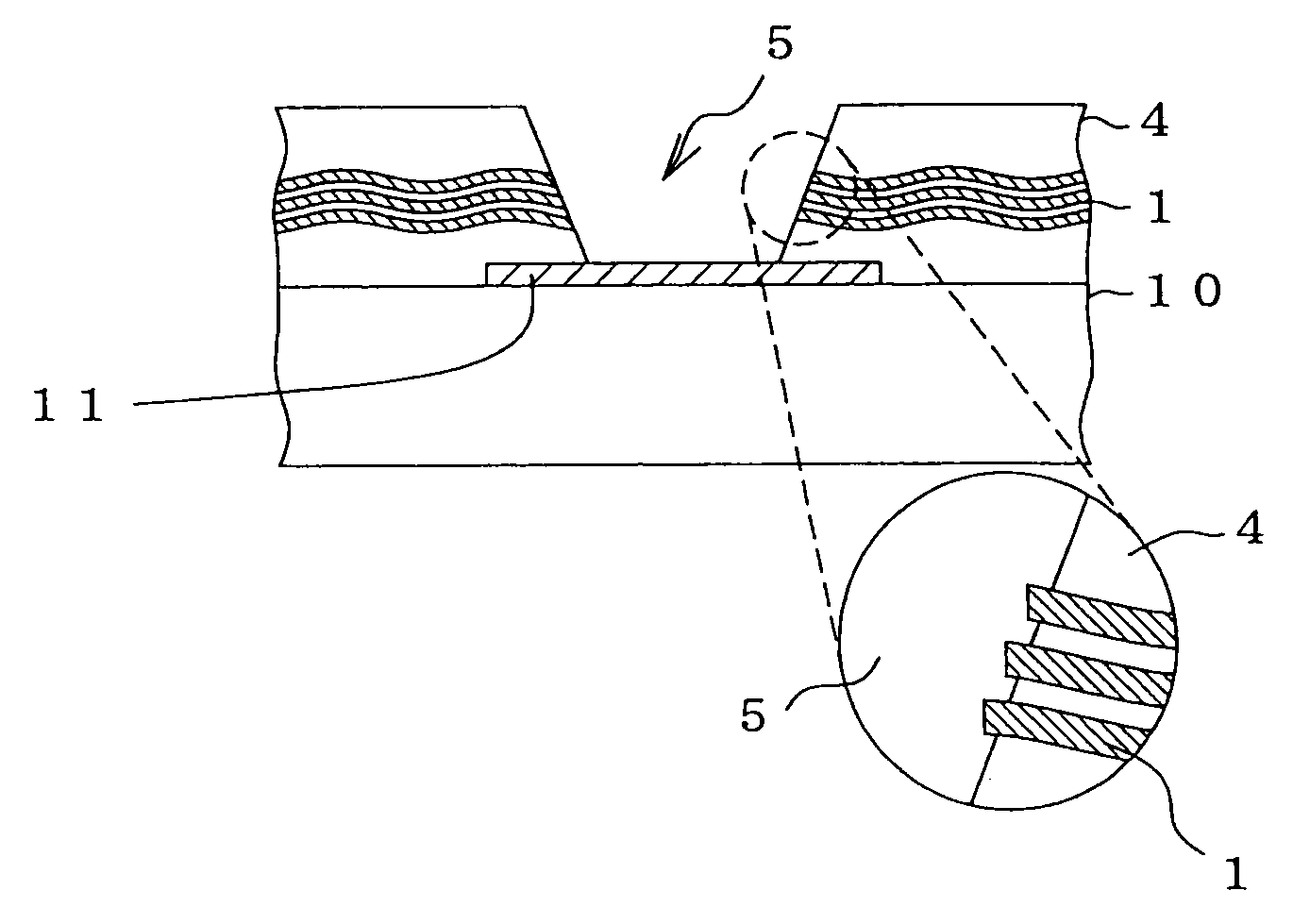

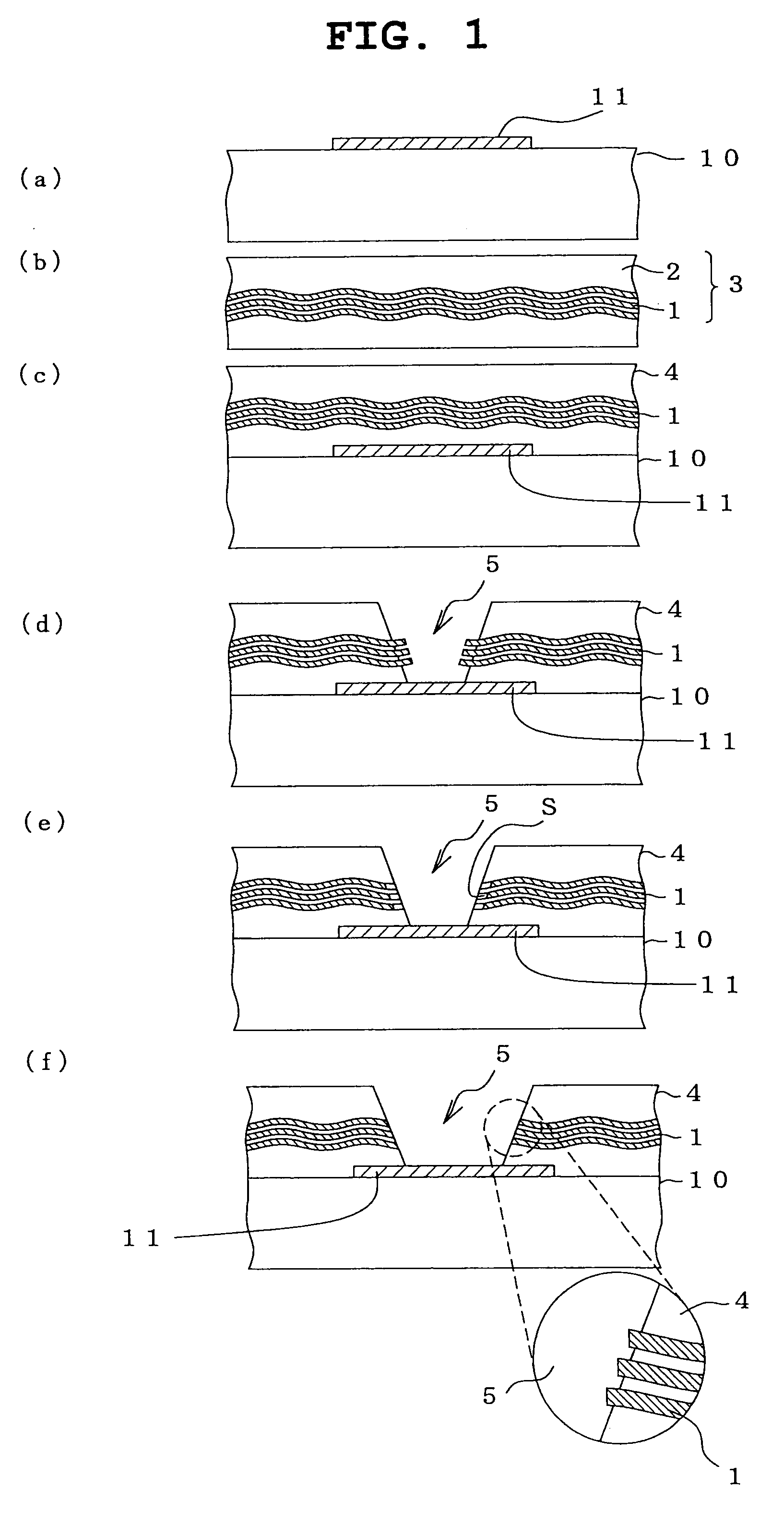

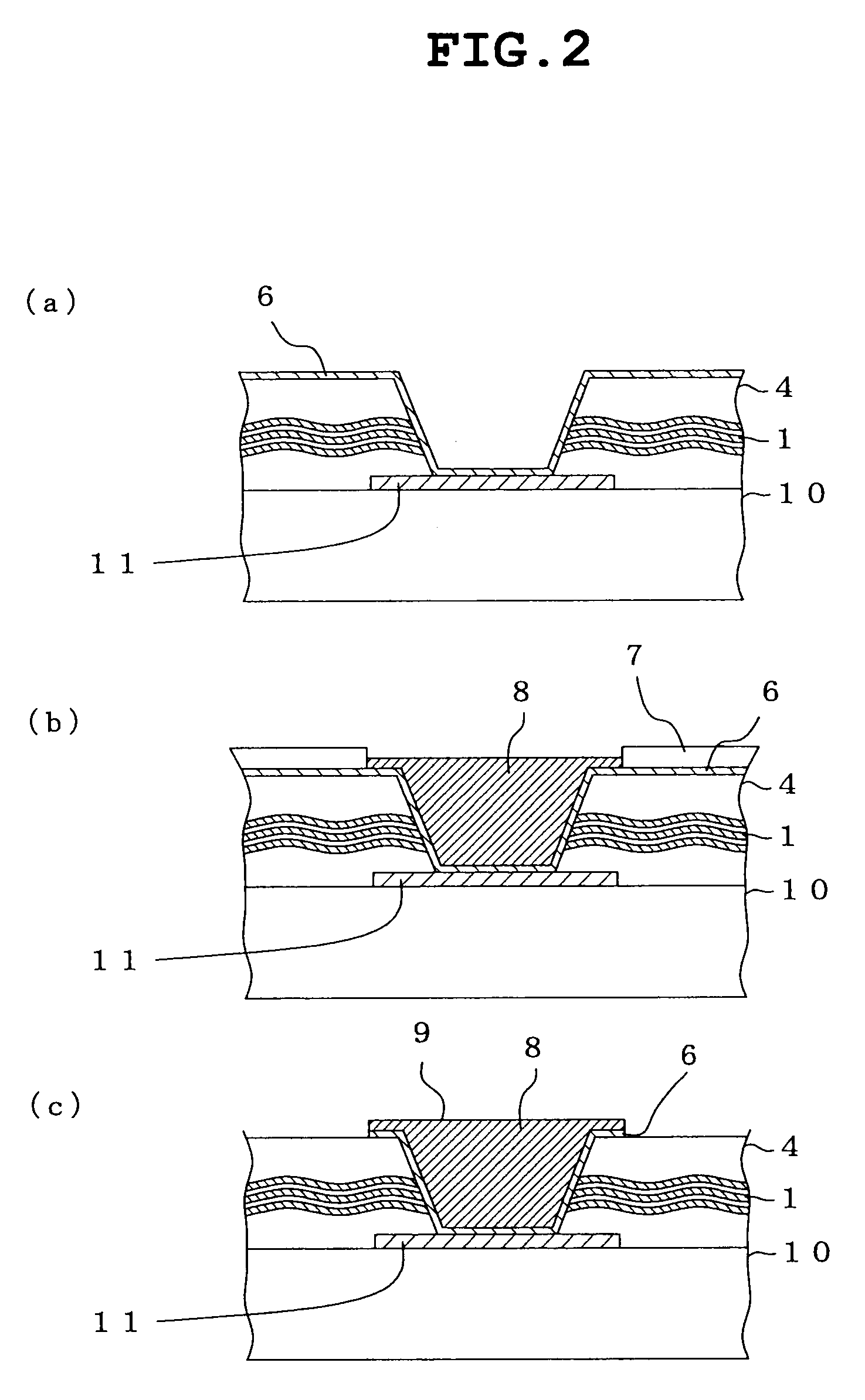

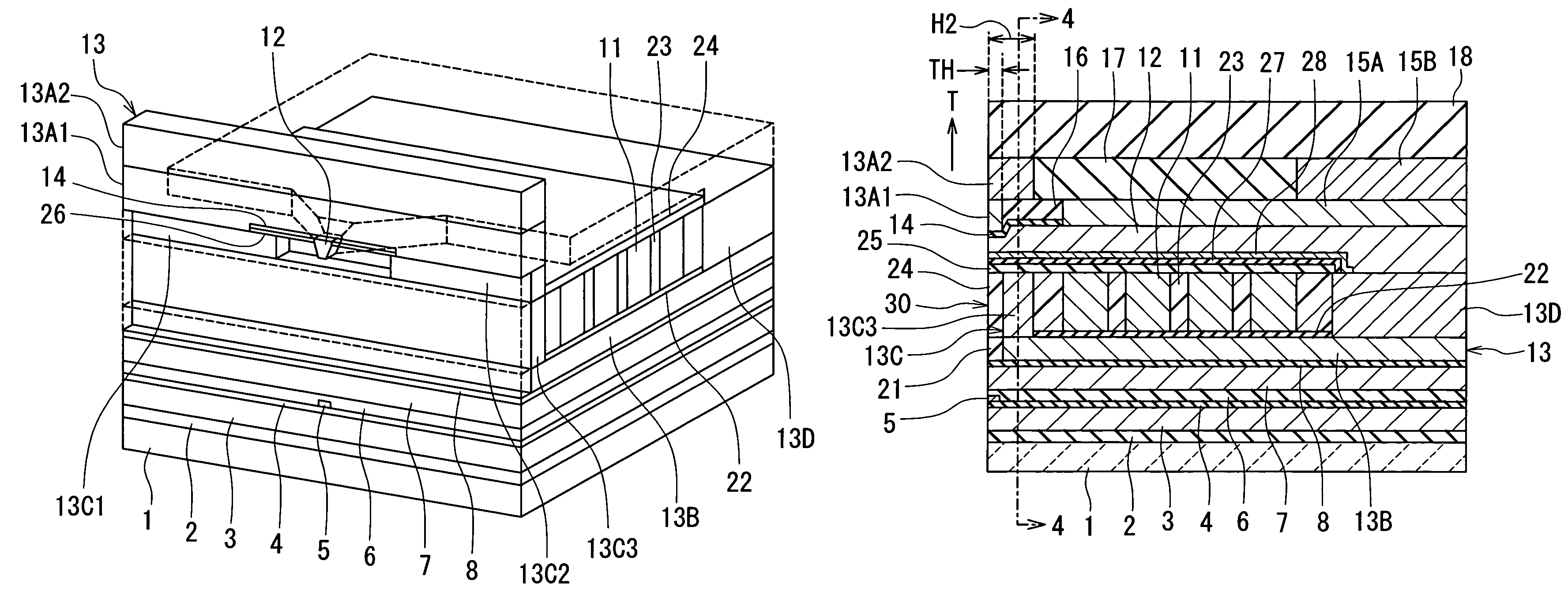

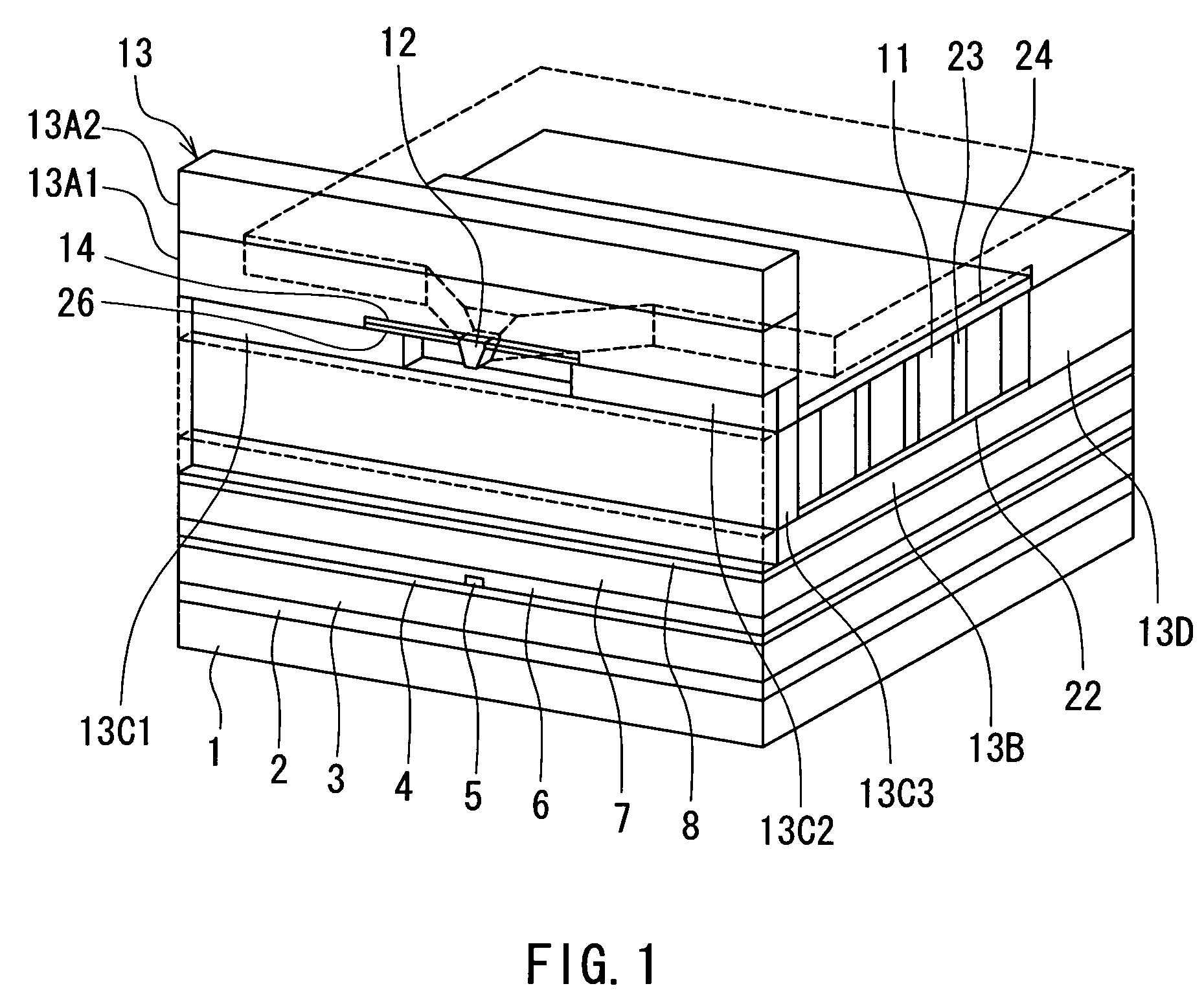

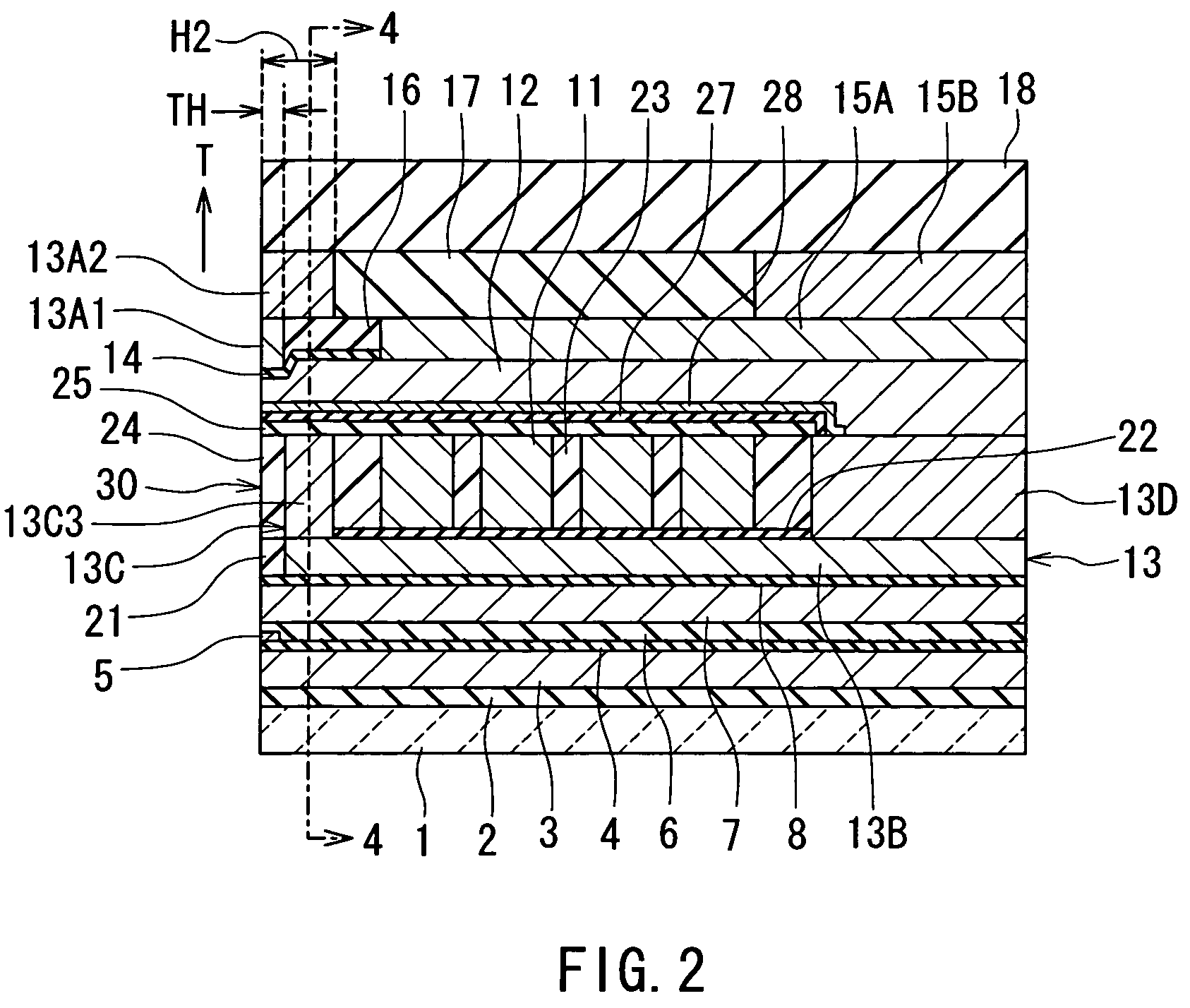

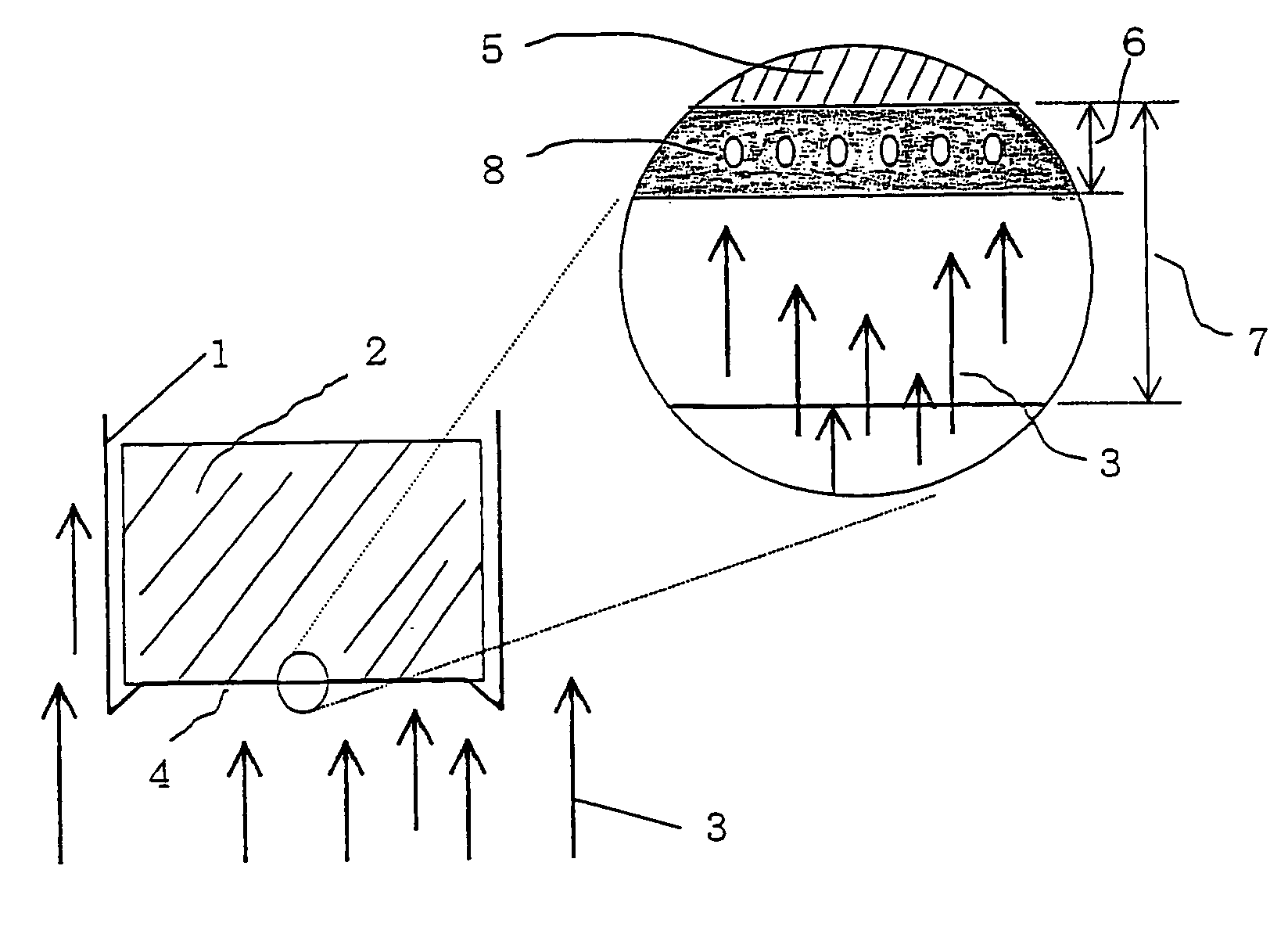

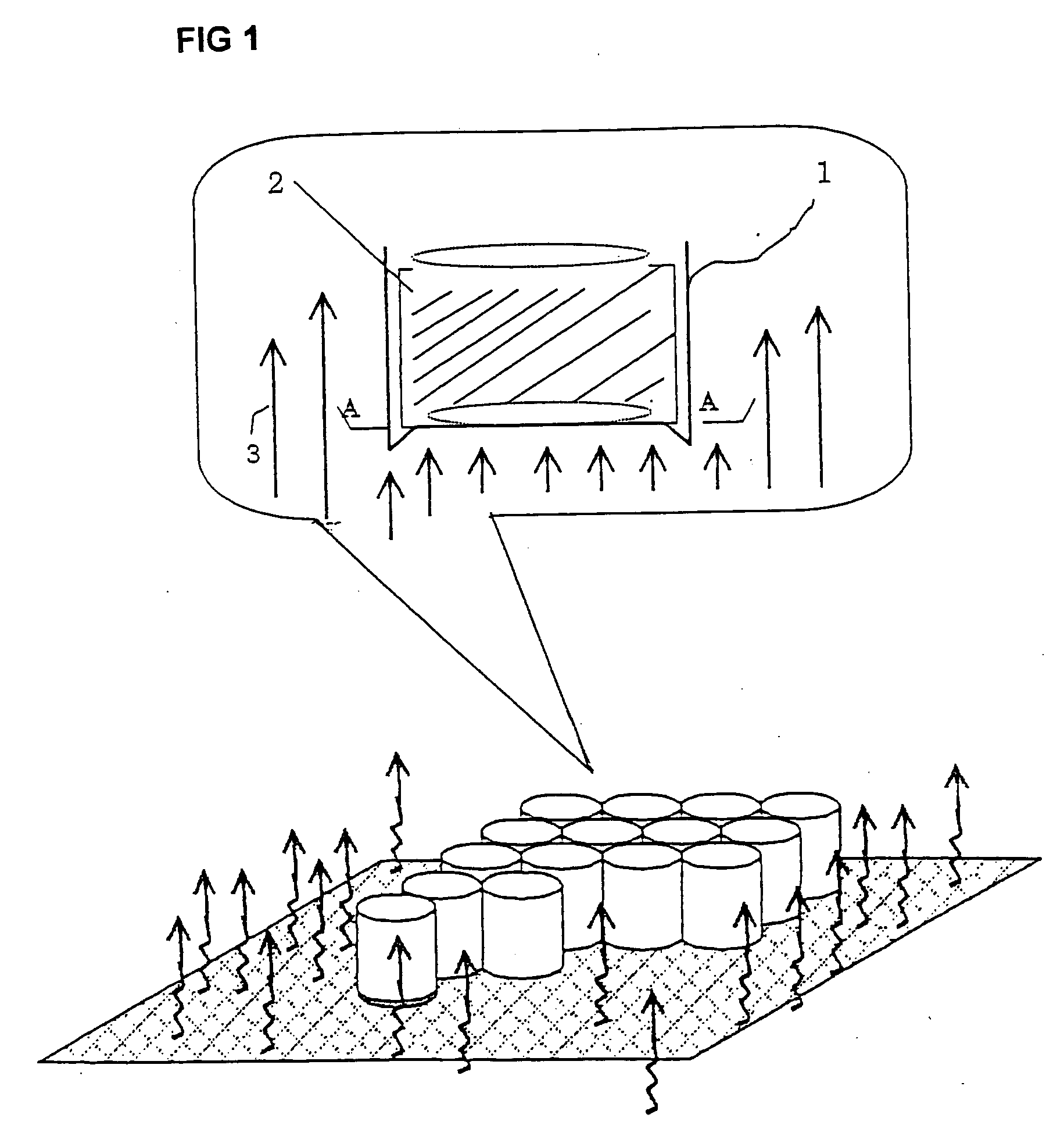

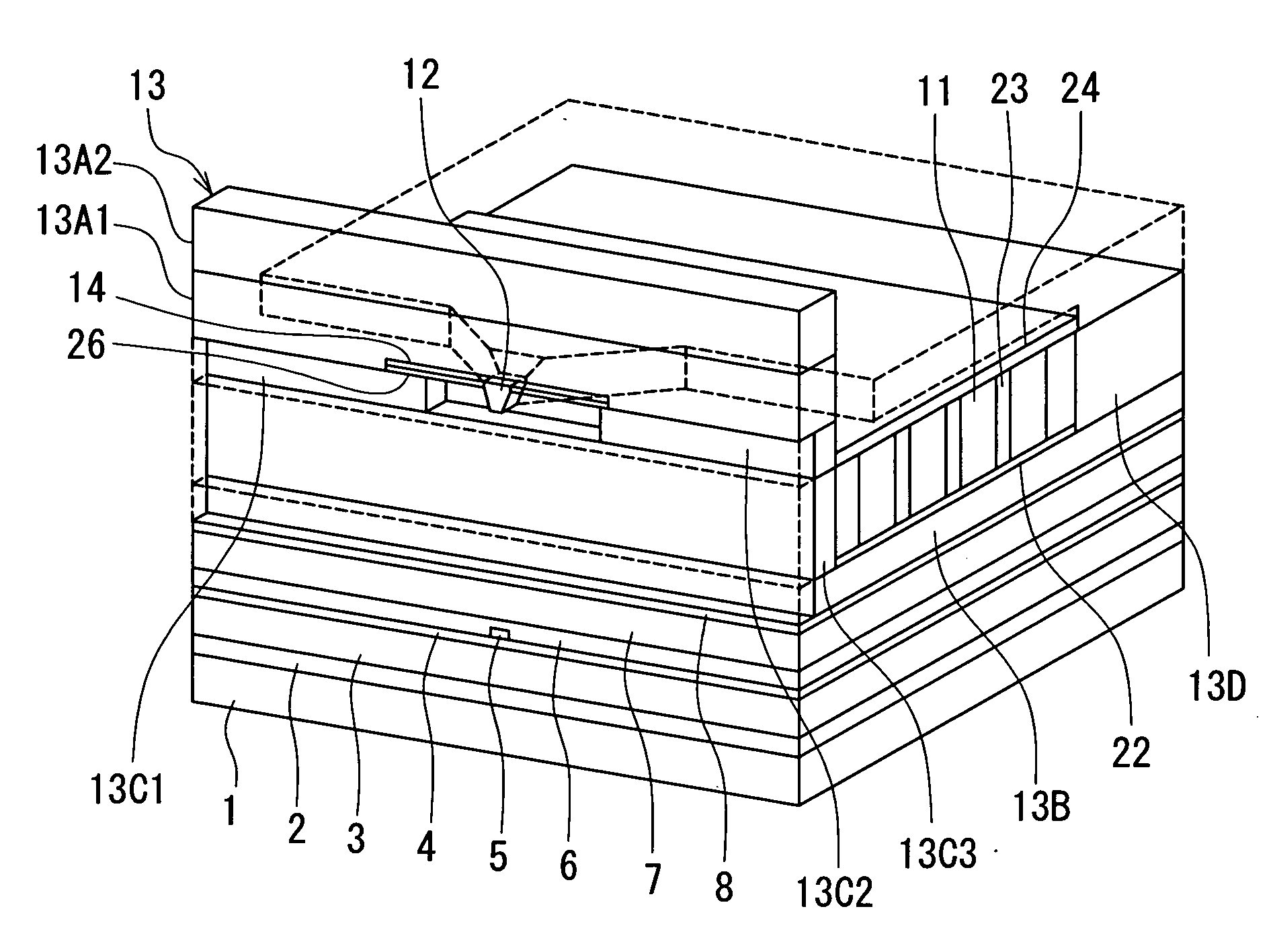

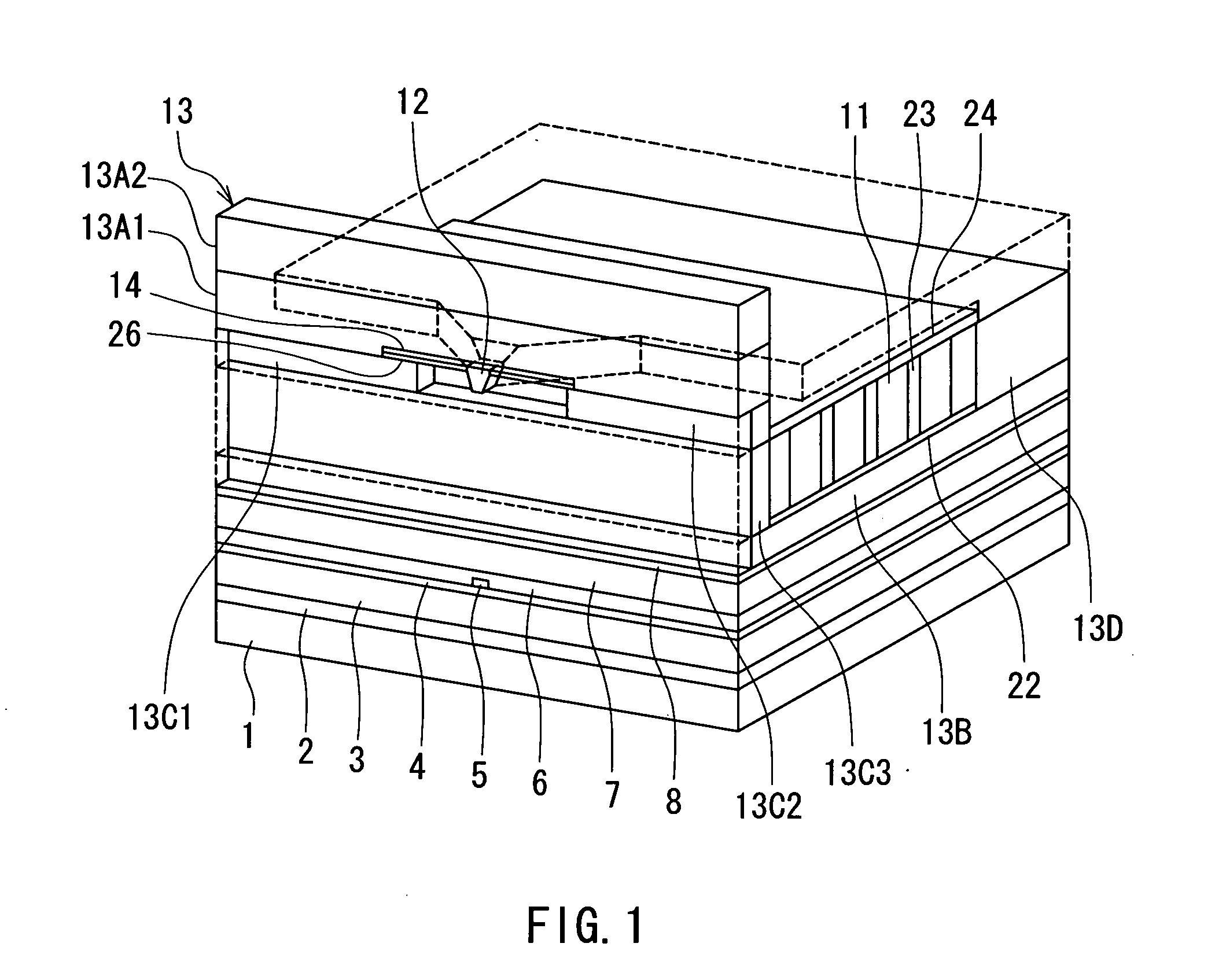

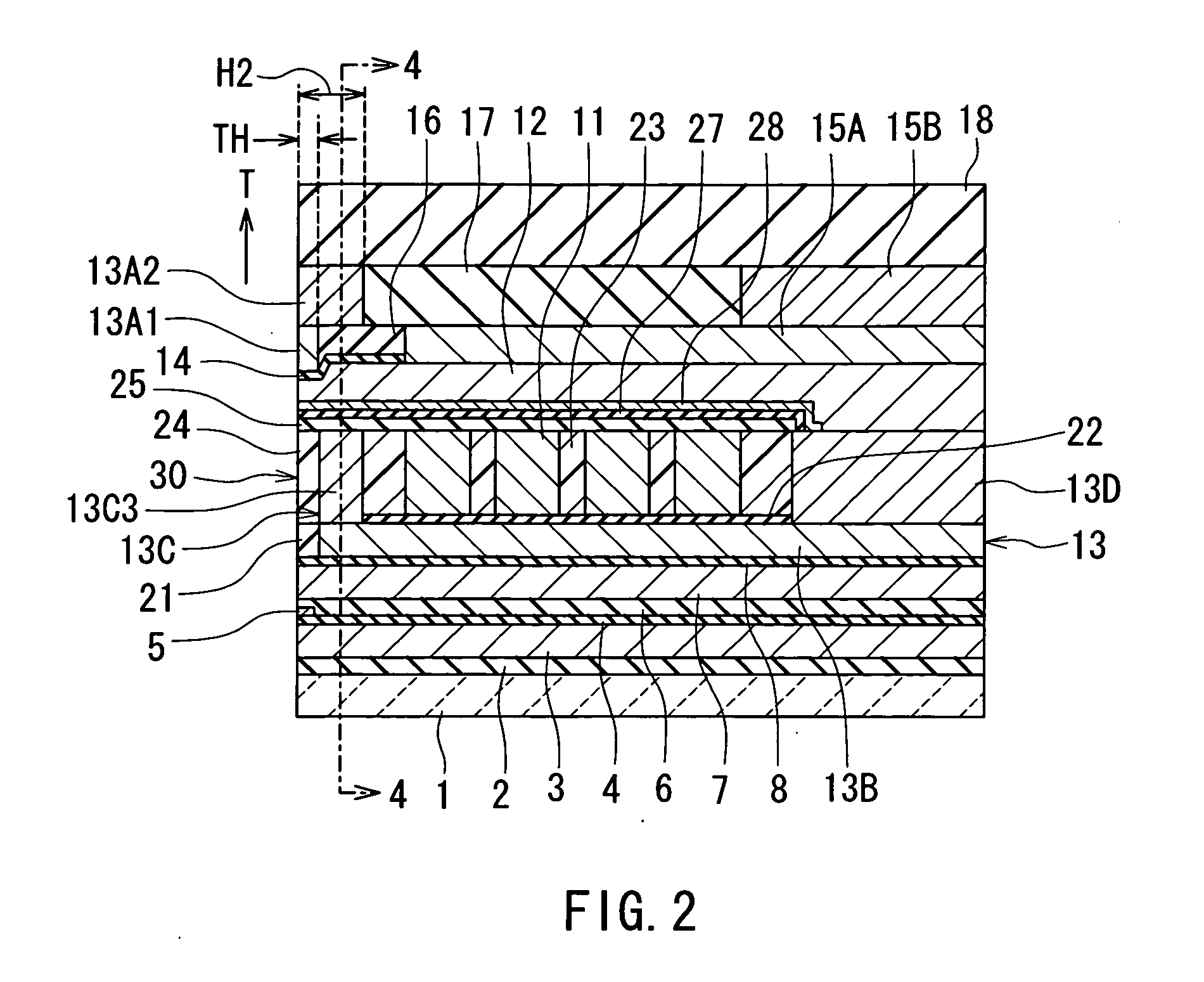

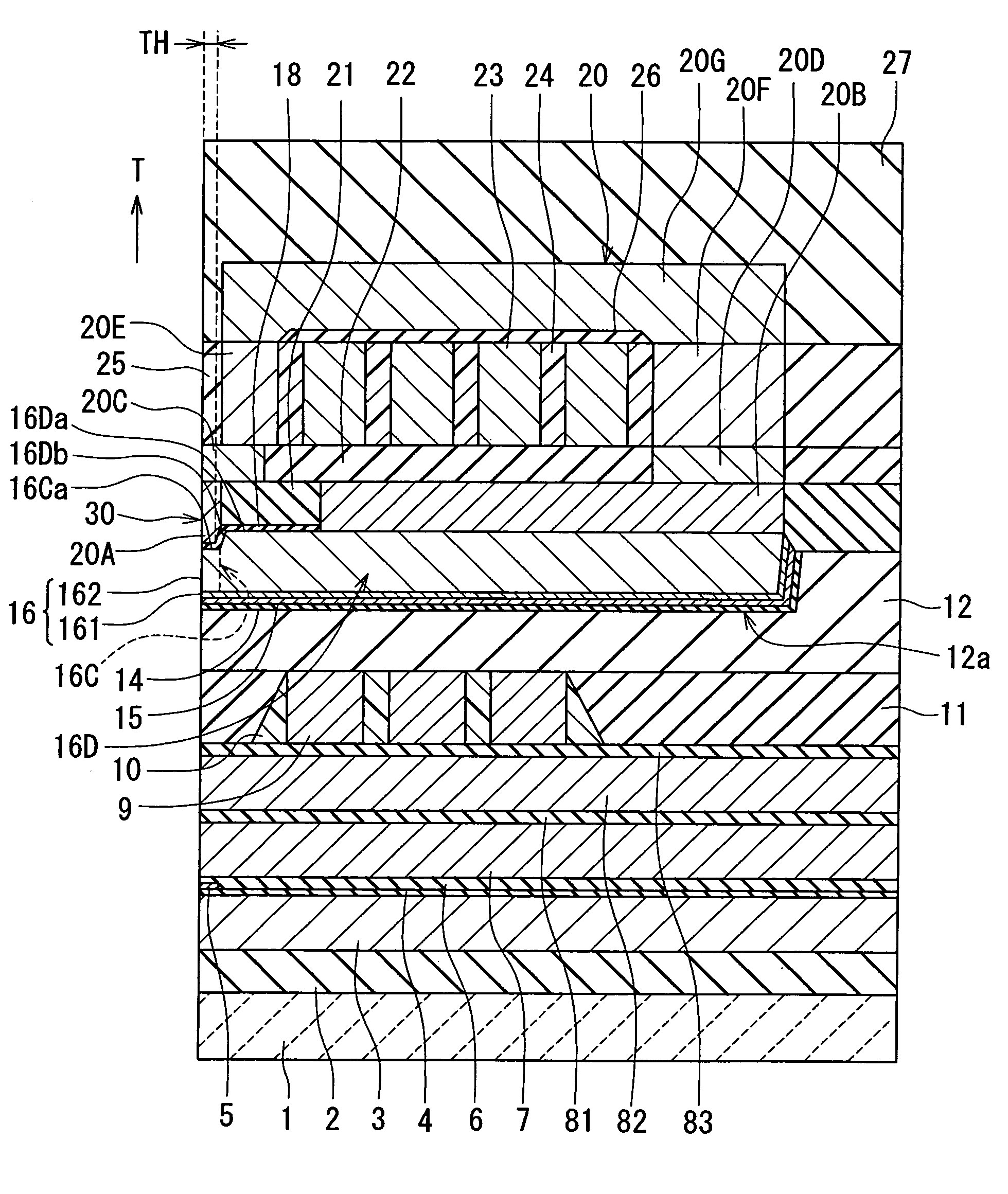

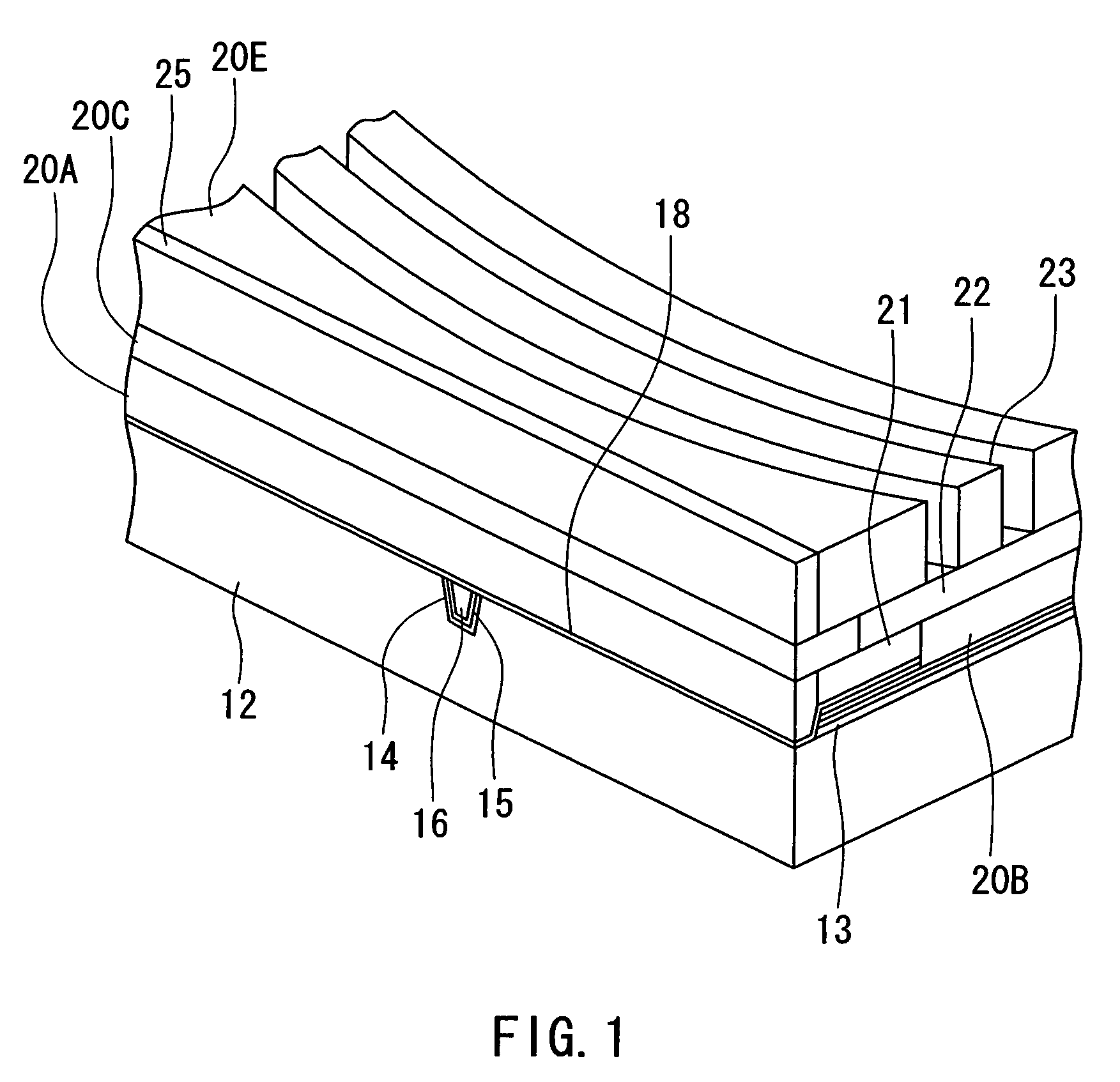

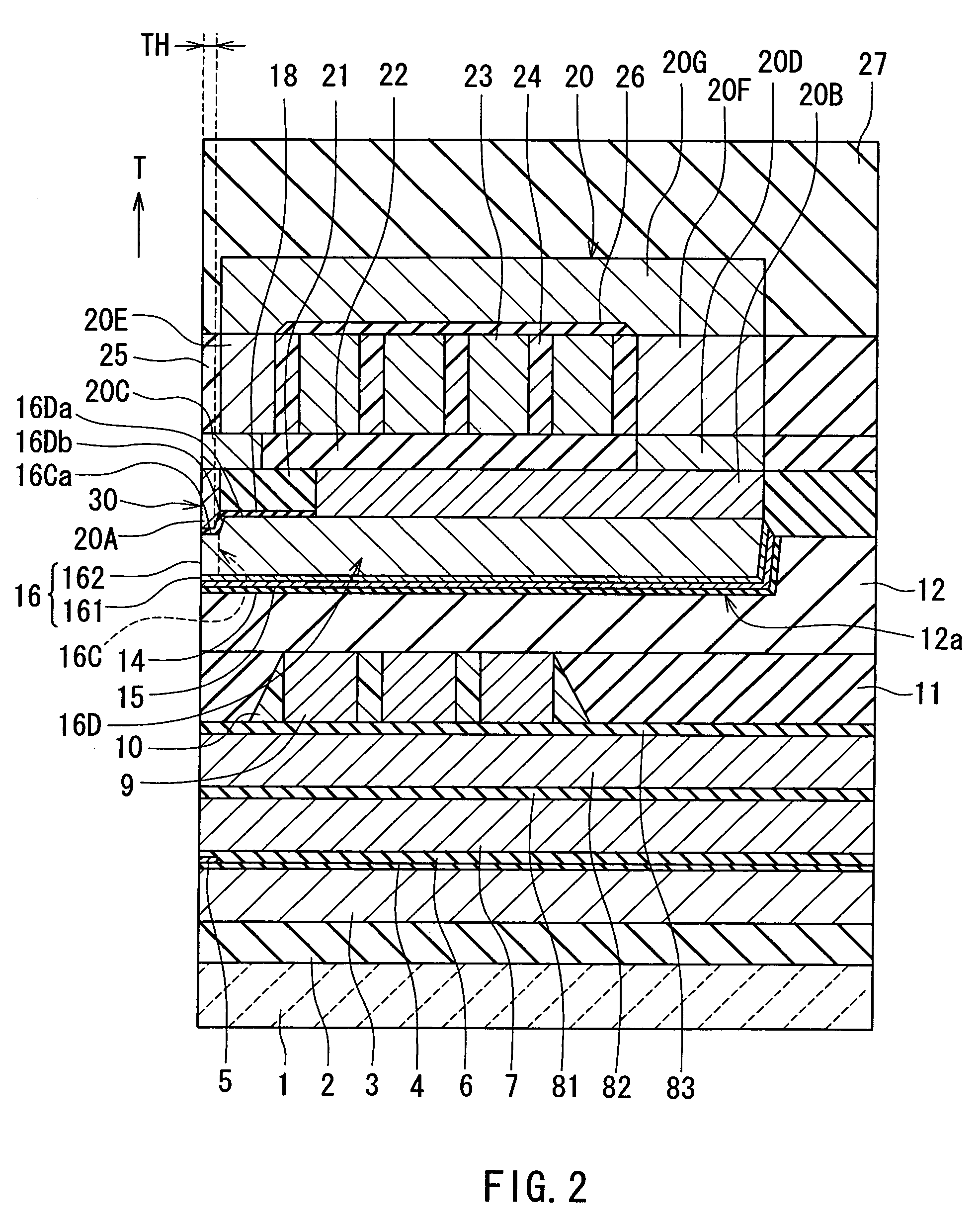

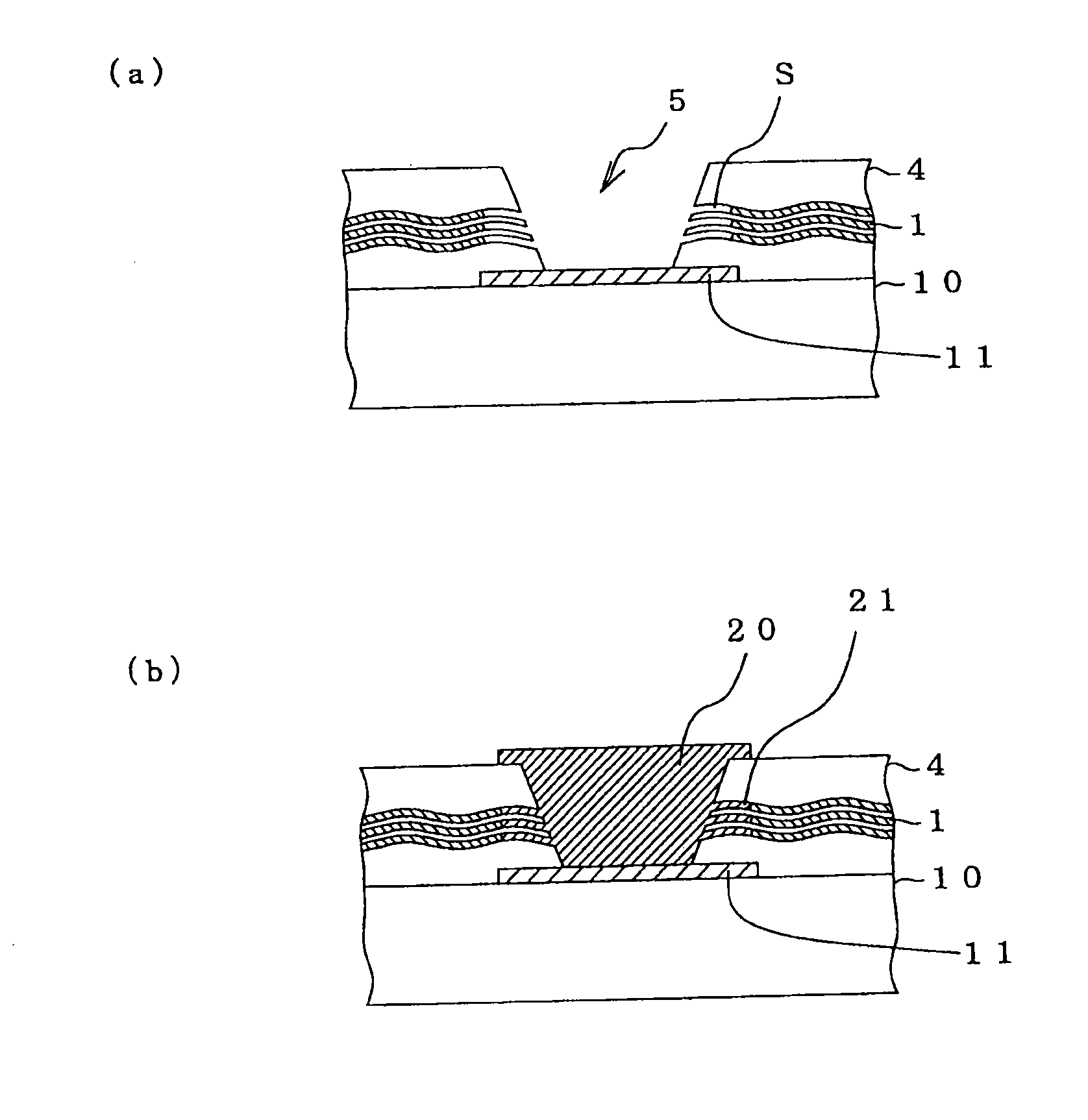

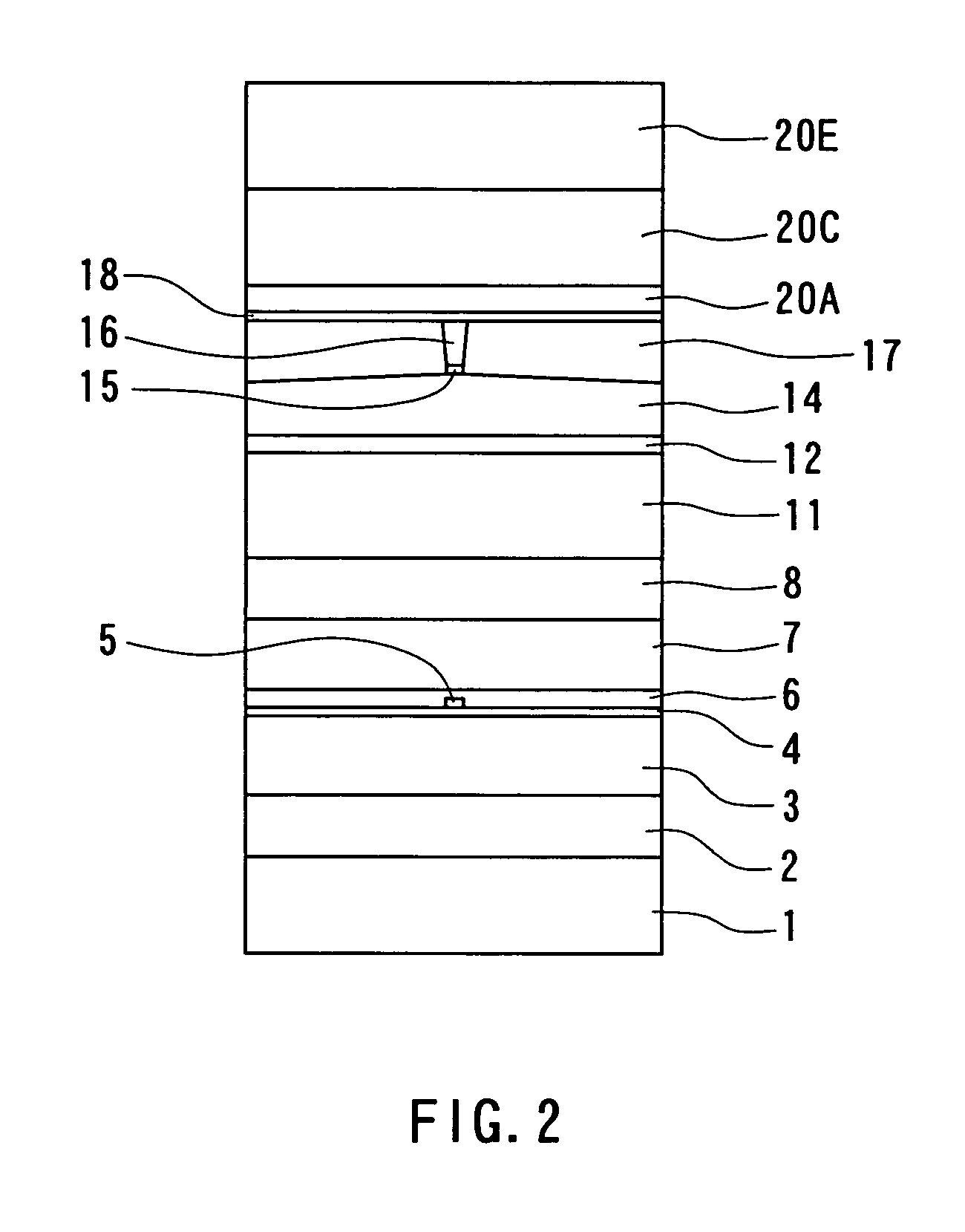

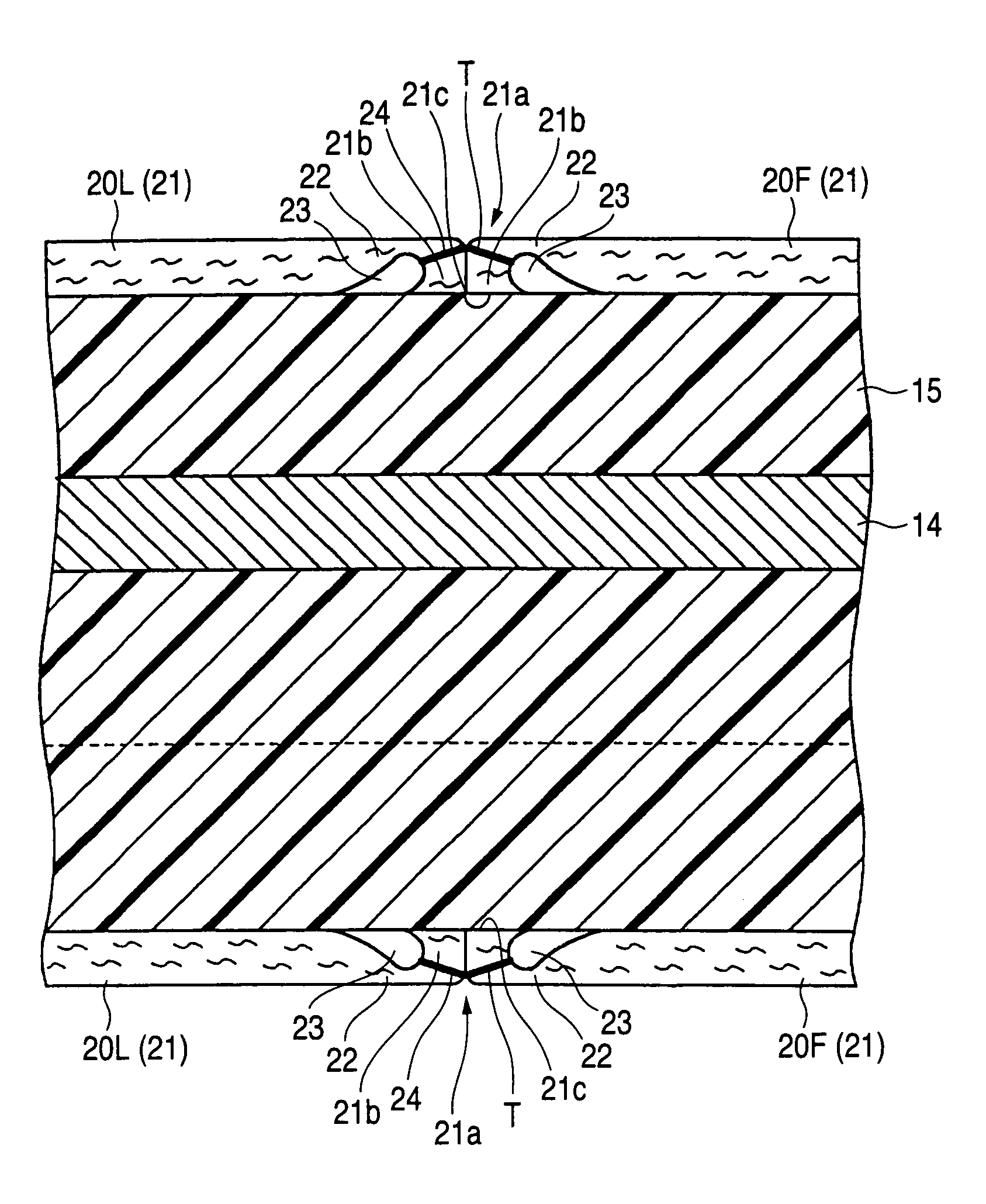

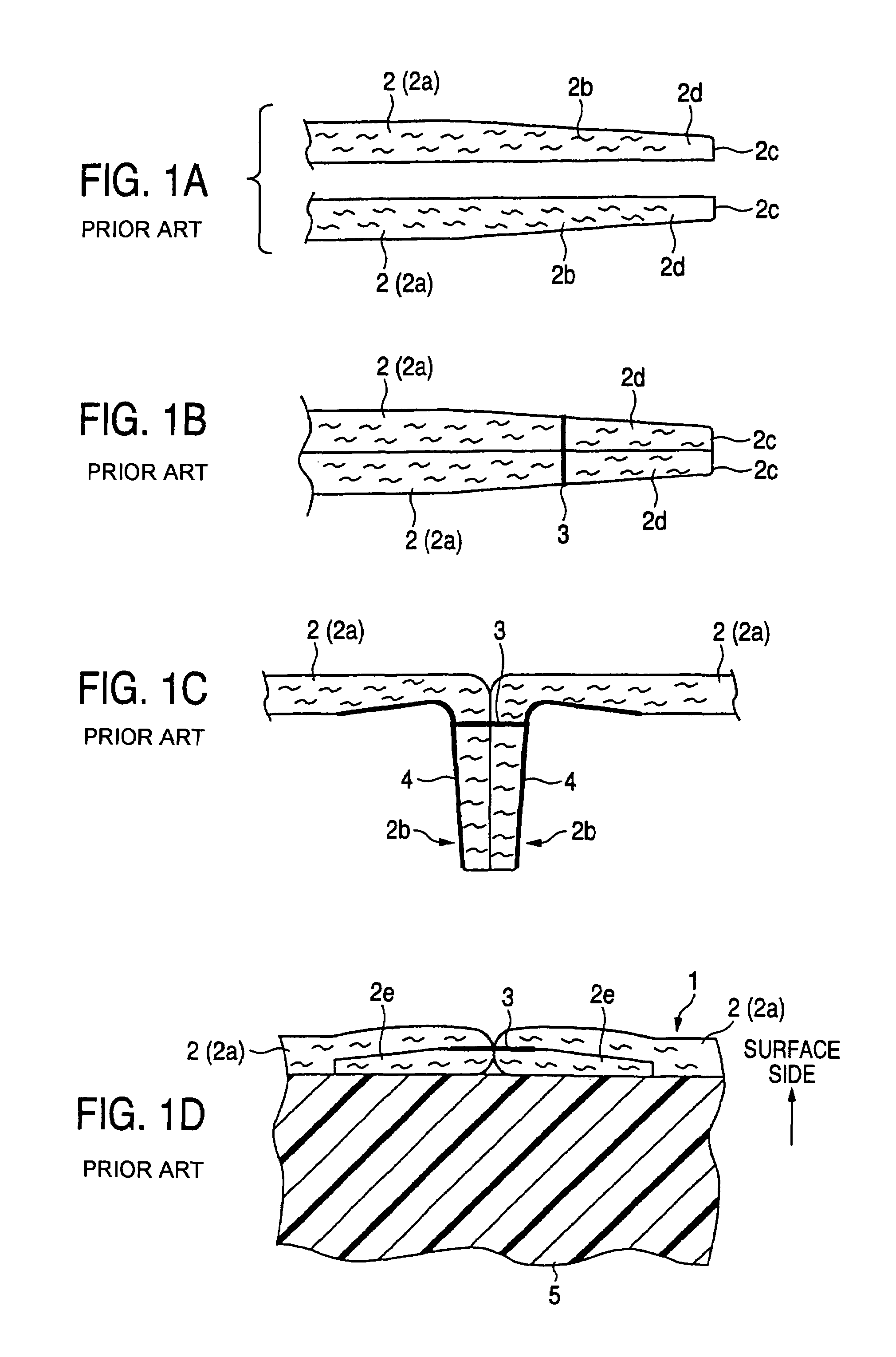

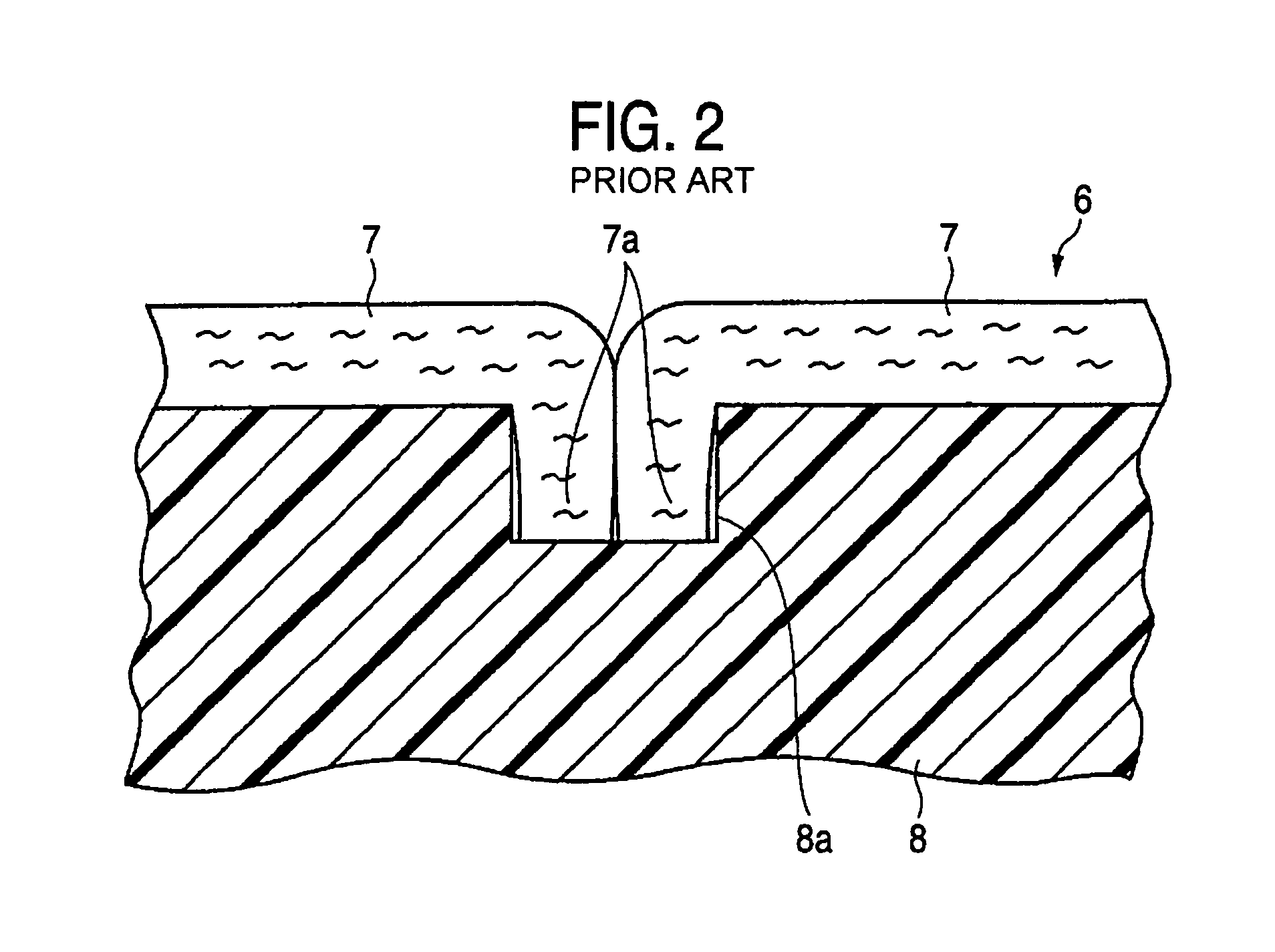

Vacuum heat insulating material, heat insulating box, refrigerator, refrigerating/air-conditioning apparatus, water heater, appliance, and manufacturing method of vacuum heat insulating material

InactiveUS20120196059A1Protrusion suppressionEasy to processEnvelopes/bags making machineryThermal insulationFiberAir conditioning

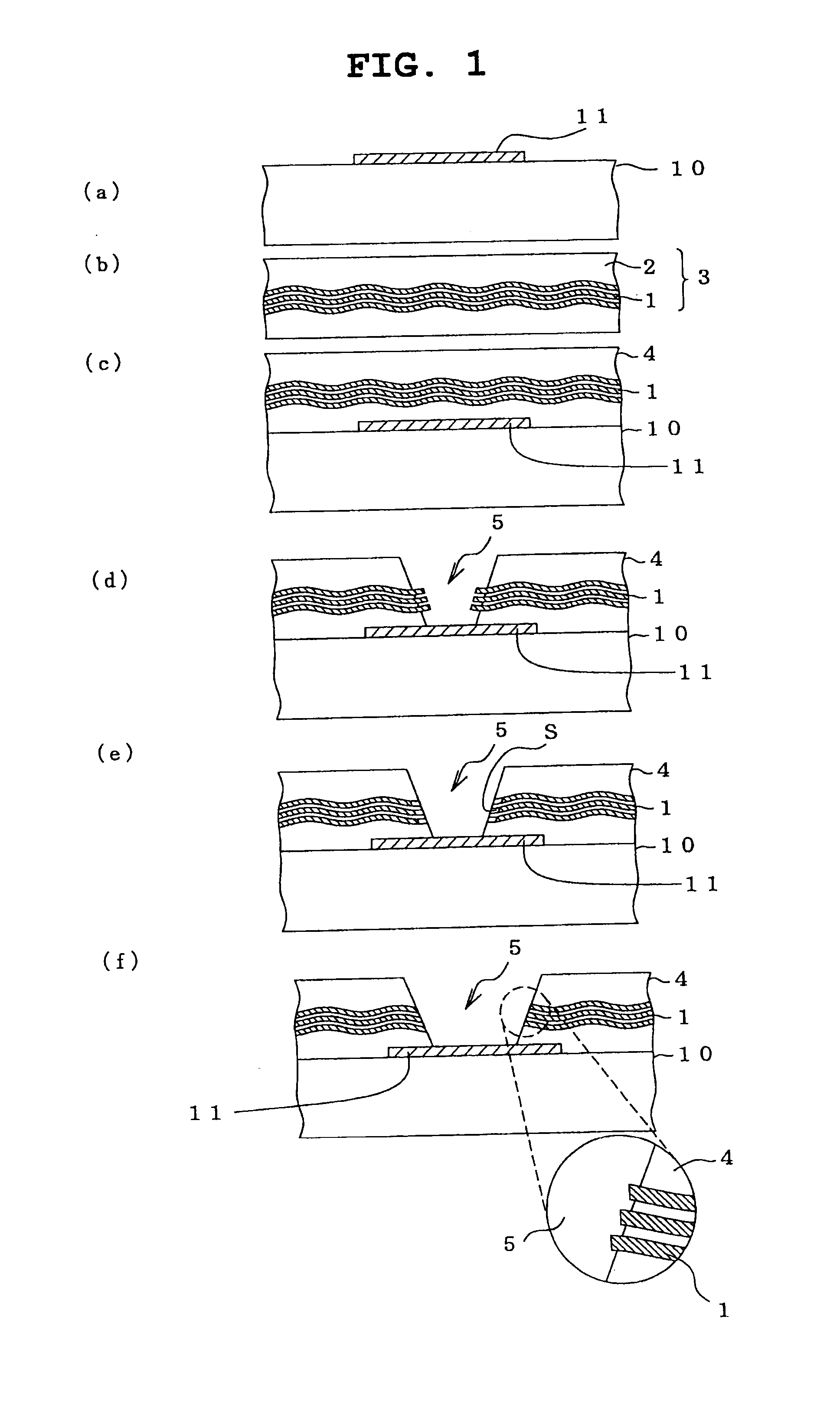

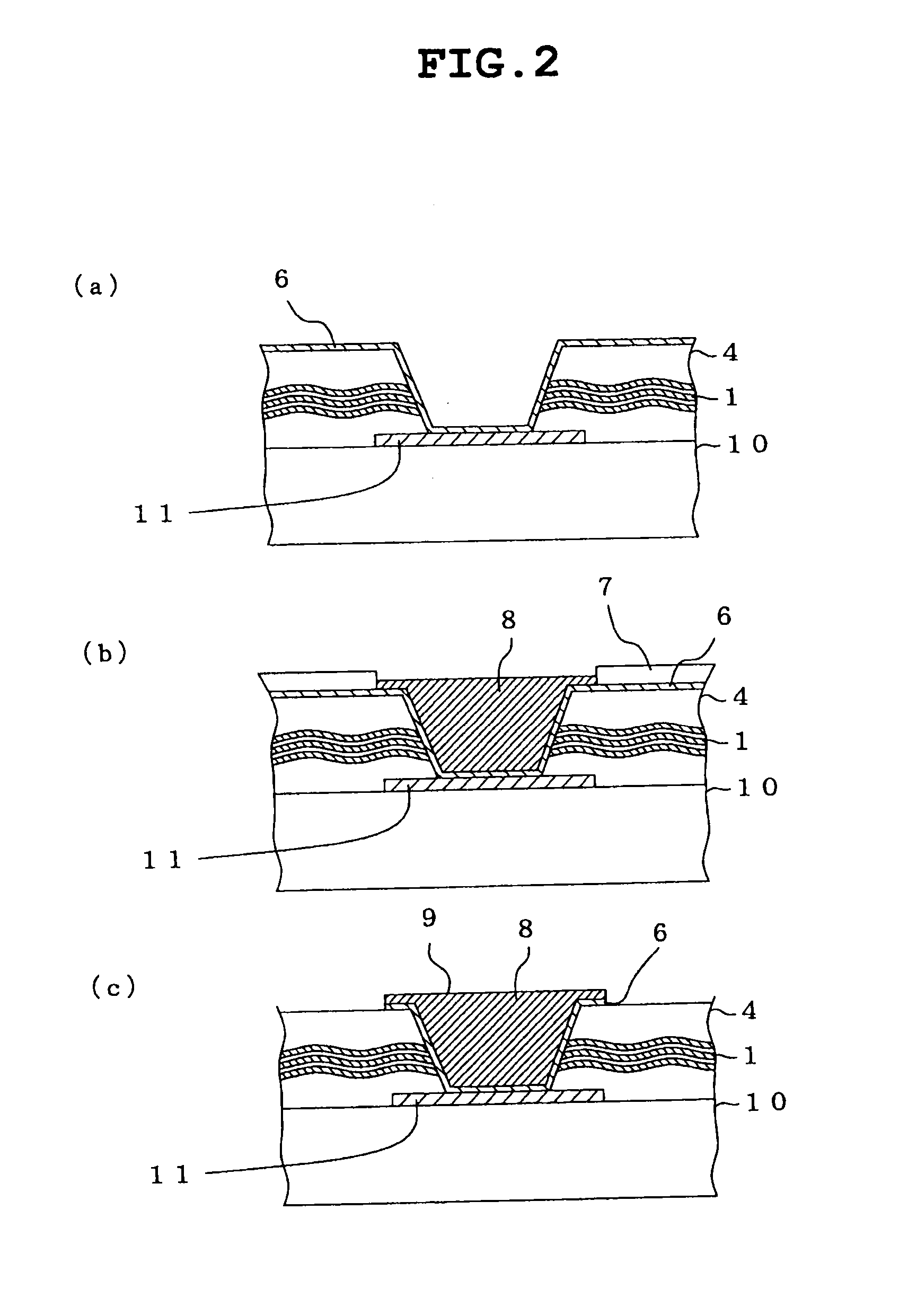

A highly reliable vacuum heat insulating material having excellent processability, handleability and heat insulating performance, and a heat insulating box using the vacuum heat insulating material are provided. In the vacuum heat insulating material with the inside in an approximately vacuum state by sealing a core material 5 having a structure wherein plural pieces of fiber assembly 1 are laminated by a gas-barrier outer cover material 4, by using long fiber for the core material, fiber dust or remaining fiber by cutting is prevented from protruding into a sealing portion of the outer cover material from a cut surface of a sheet or an opening portion, and sealing failure is reduced. Further, since the core material is structured so as to be wound continuously from an inner side toward an outer side, the vacuum heat insulating material is easily manufactured, and excellent in handleability.

Owner:MITSUBISHI ELECTRIC CORP

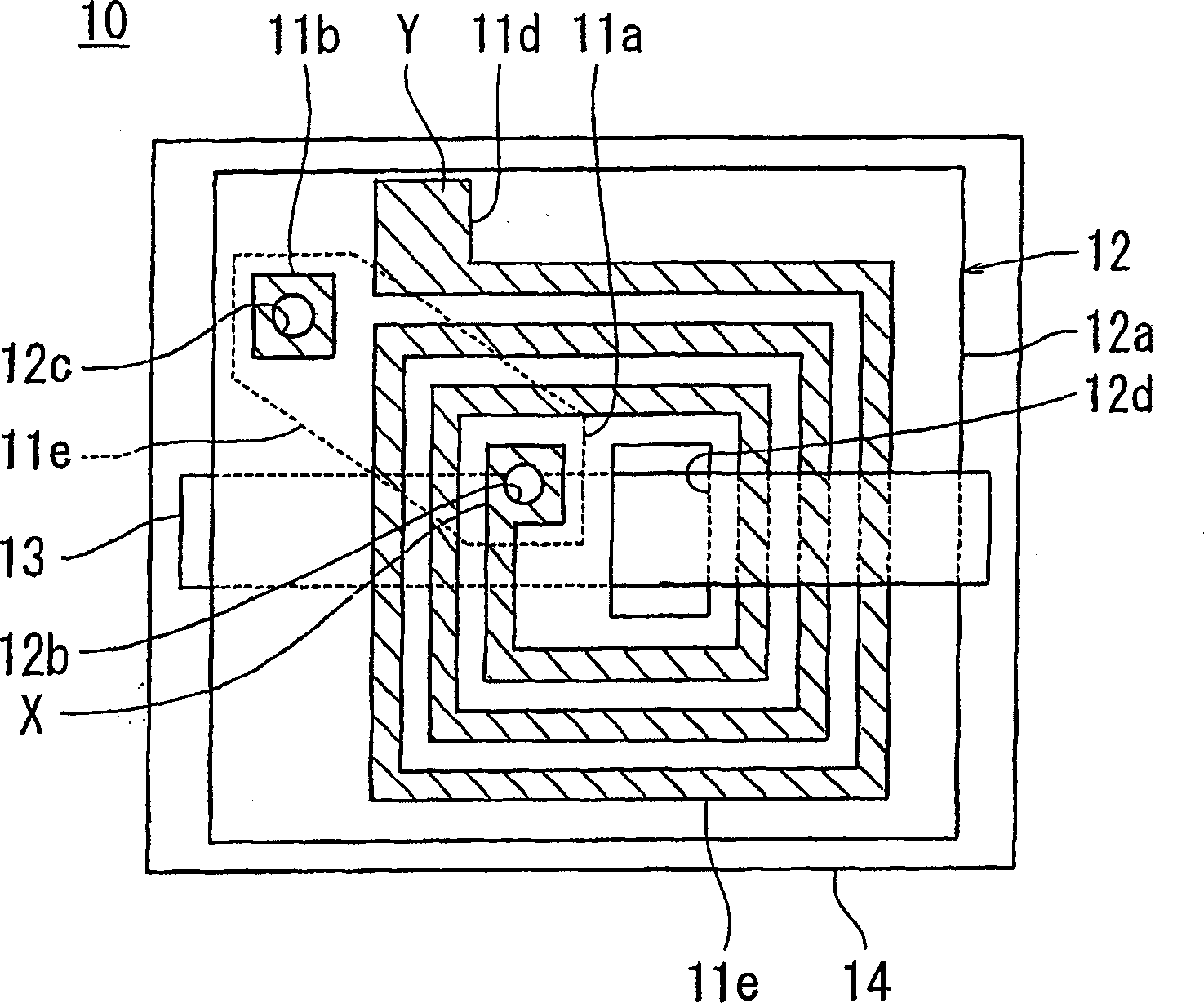

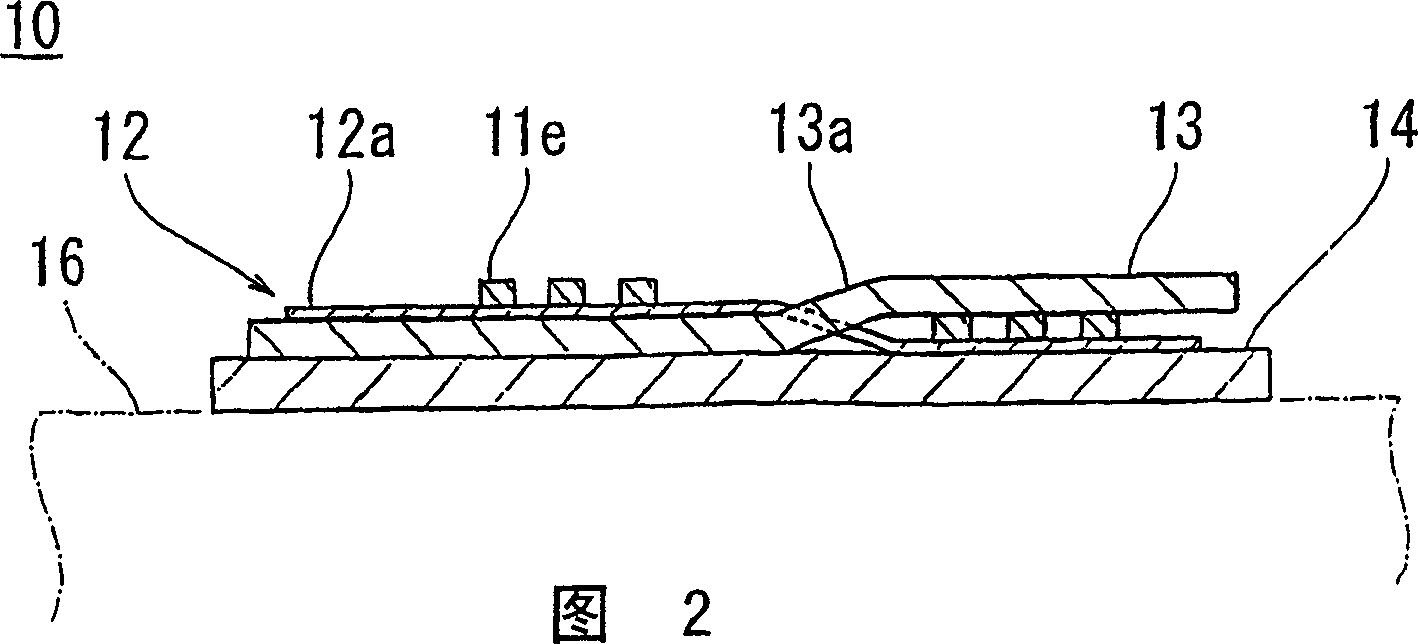

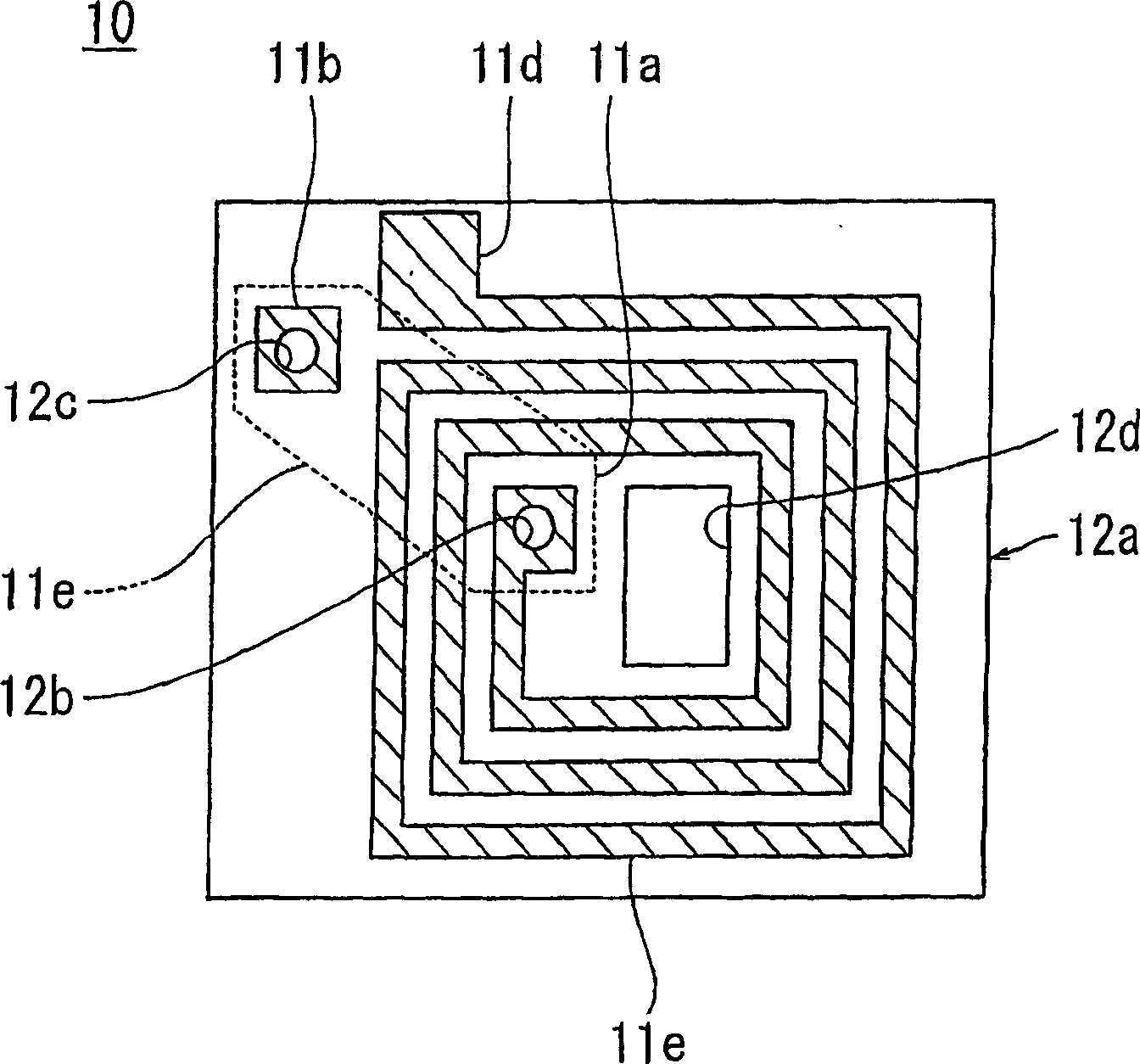

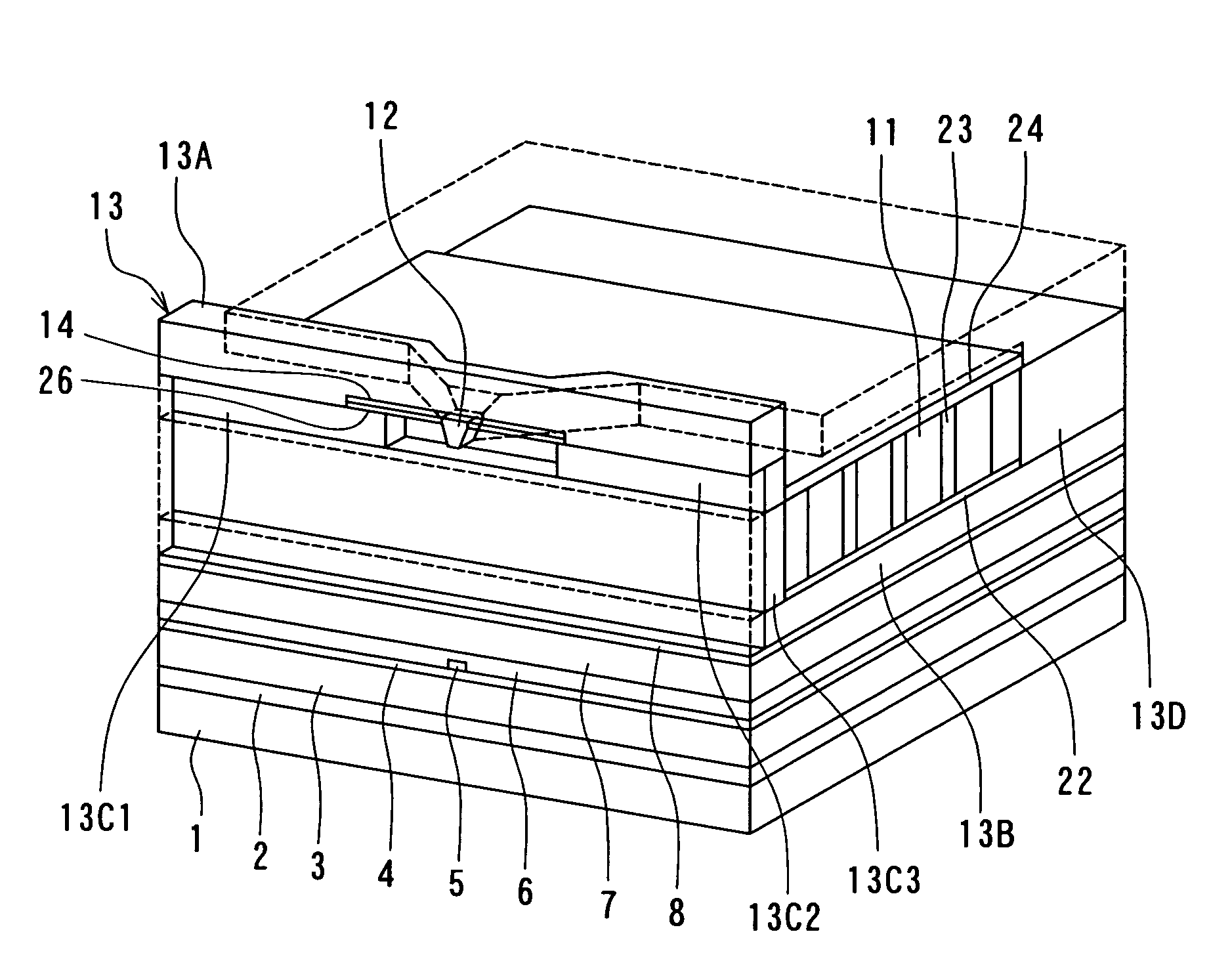

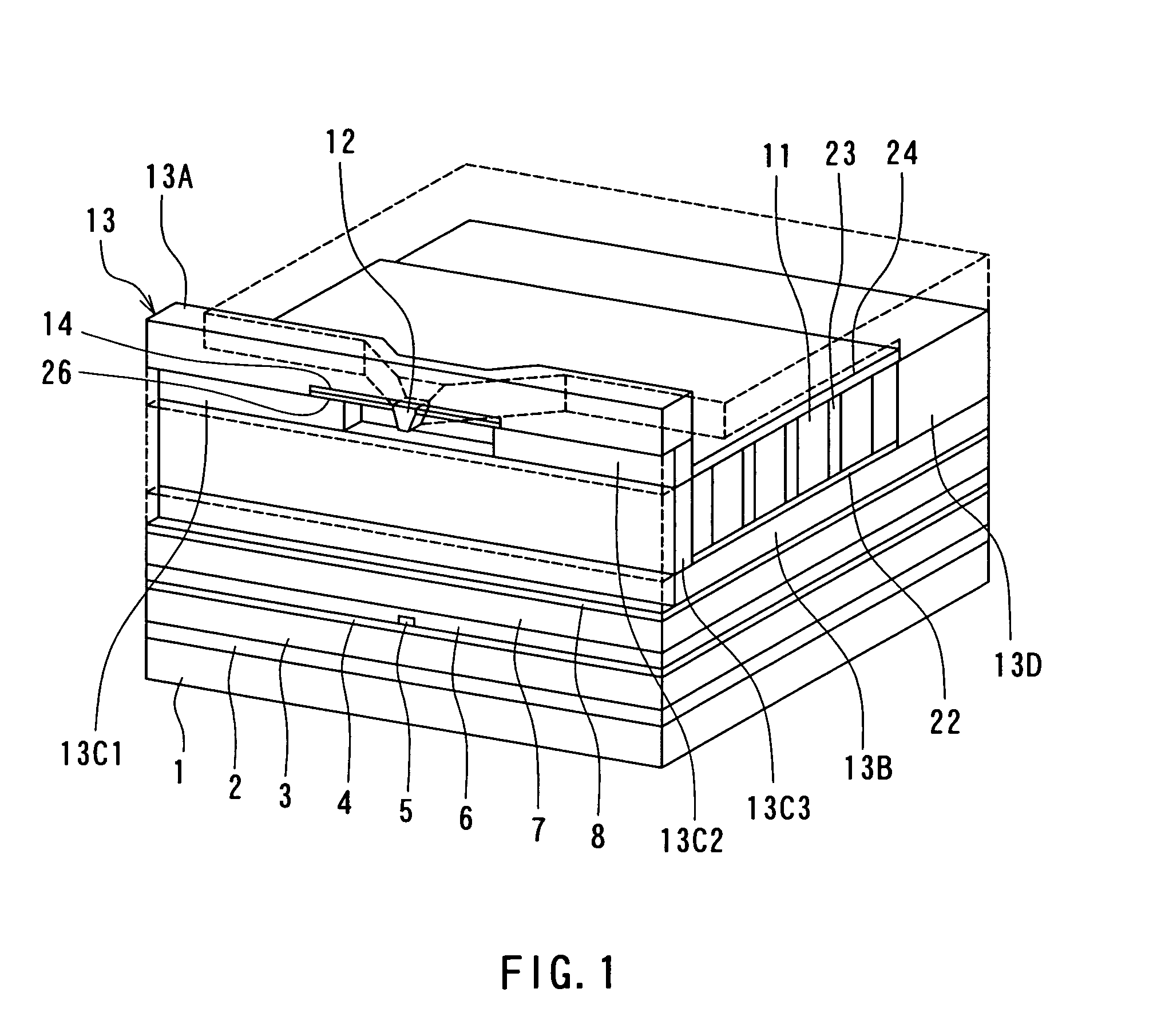

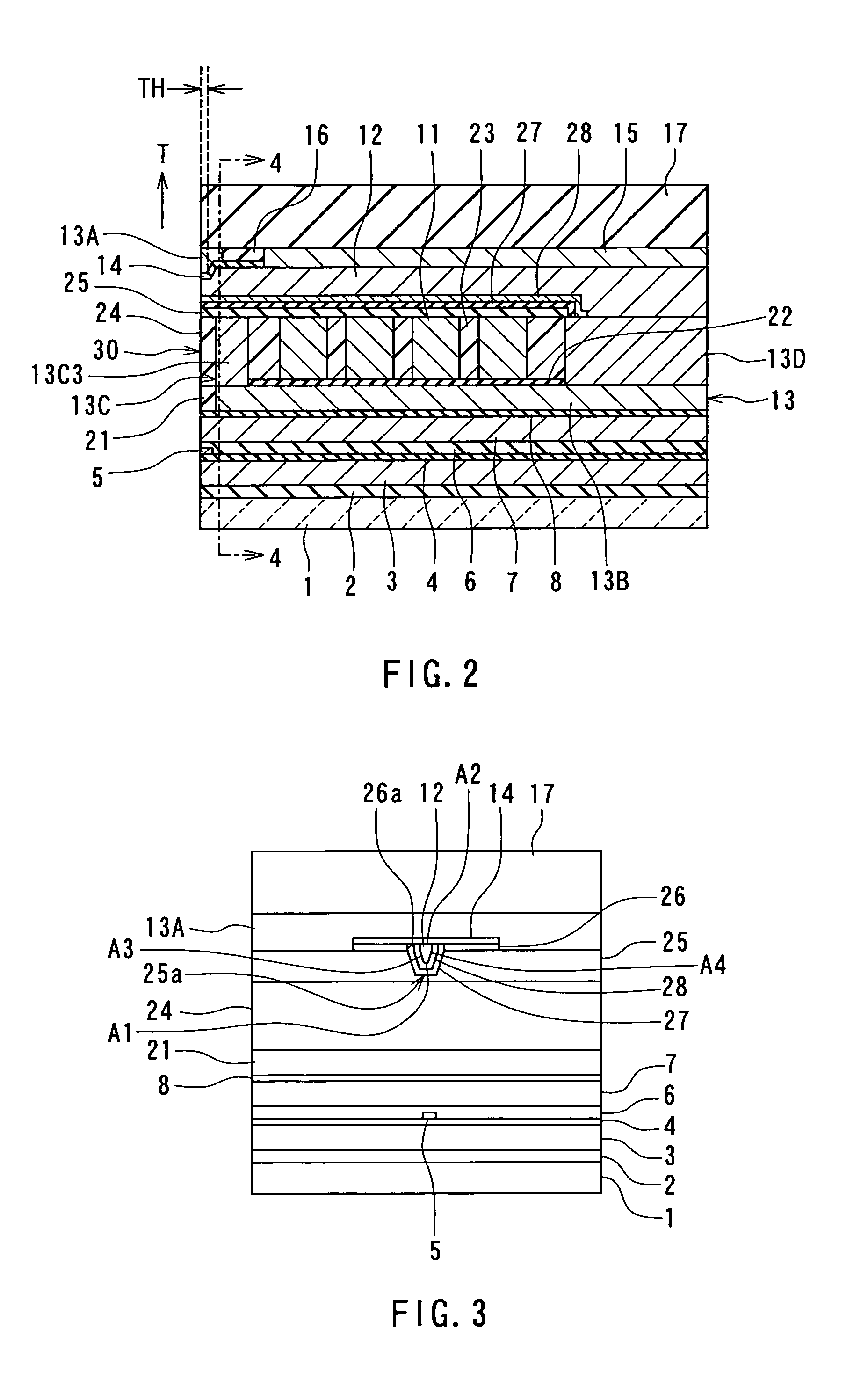

Antenna coil and RFID-use tag using it, transponder-use antenna

InactiveCN1871743AImprove rigidityEasy to useLoop antennas with ferromagnetic coreOther printing matterNon magneticRadio frequency

An antenna coil 10 comprises an air-core coil 12 which is wound helically in a plane and a plate magnetic core member 13 which is inserted in the air-core coil 12 so as to be approximately parallel with a plane of the air-core coil 12. The magnetic core member 13 is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member 13 is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member 13 is a magnetic coating which is formed by applying and drying the composite member. A non-magnetic conductive plate 14 which has a conductivity is layered on a surface of the air-core coil 12 through which the magnetic core member 13 is inserted. The conductive plate 14 is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. By doing this, it is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

Vacuum heat insulating material, heat insulating box, refrigerator, refrigerating/air-conditioning apparatus, water heater, appliance, and manufacturing method of vacuum heat insulating material

InactiveUS9103482B2Protrusion suppressionEasy to processThermal insulationLayered productsFiberAir conditioning

Owner:MITSUBISHI ELECTRIC CORP

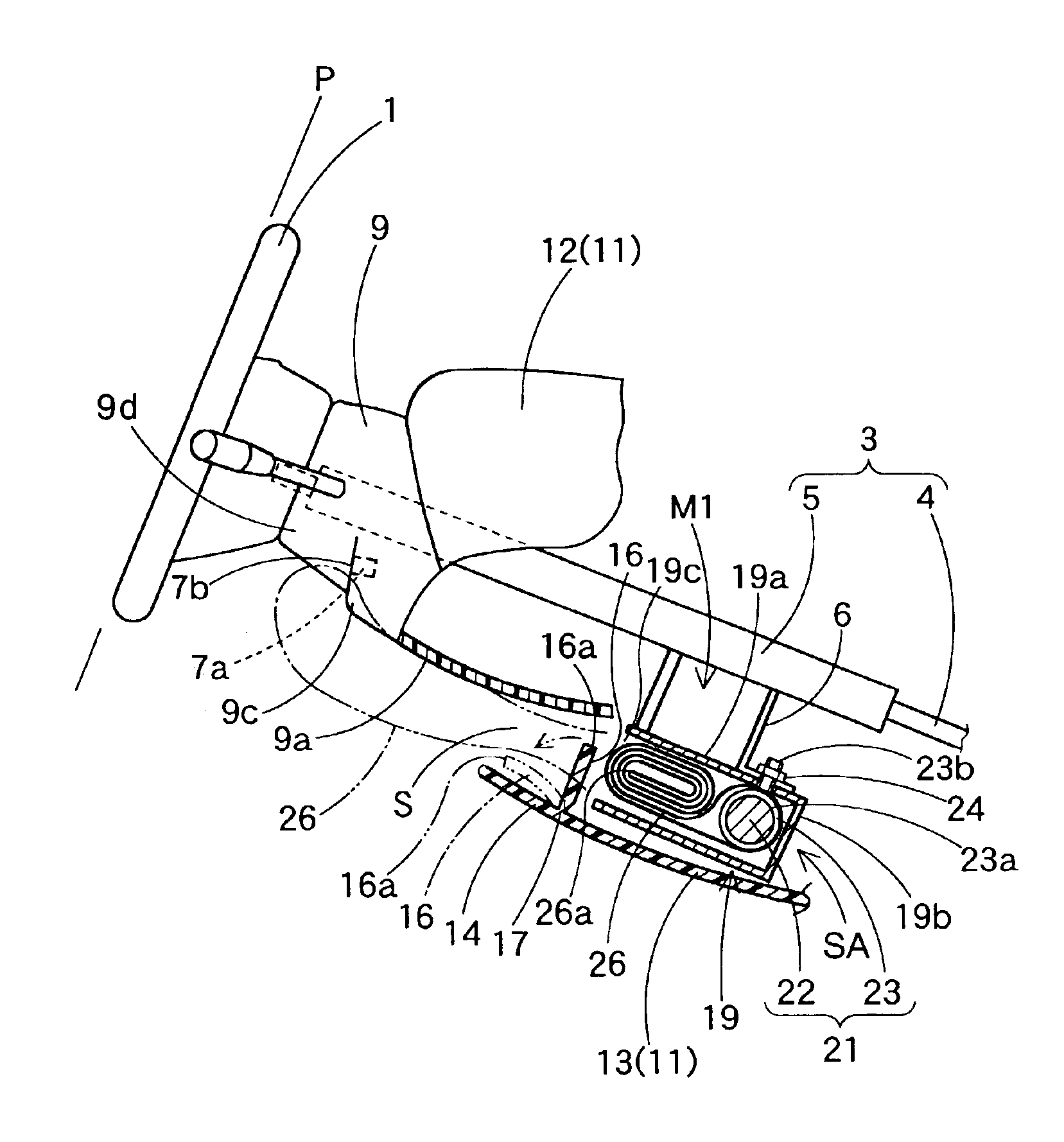

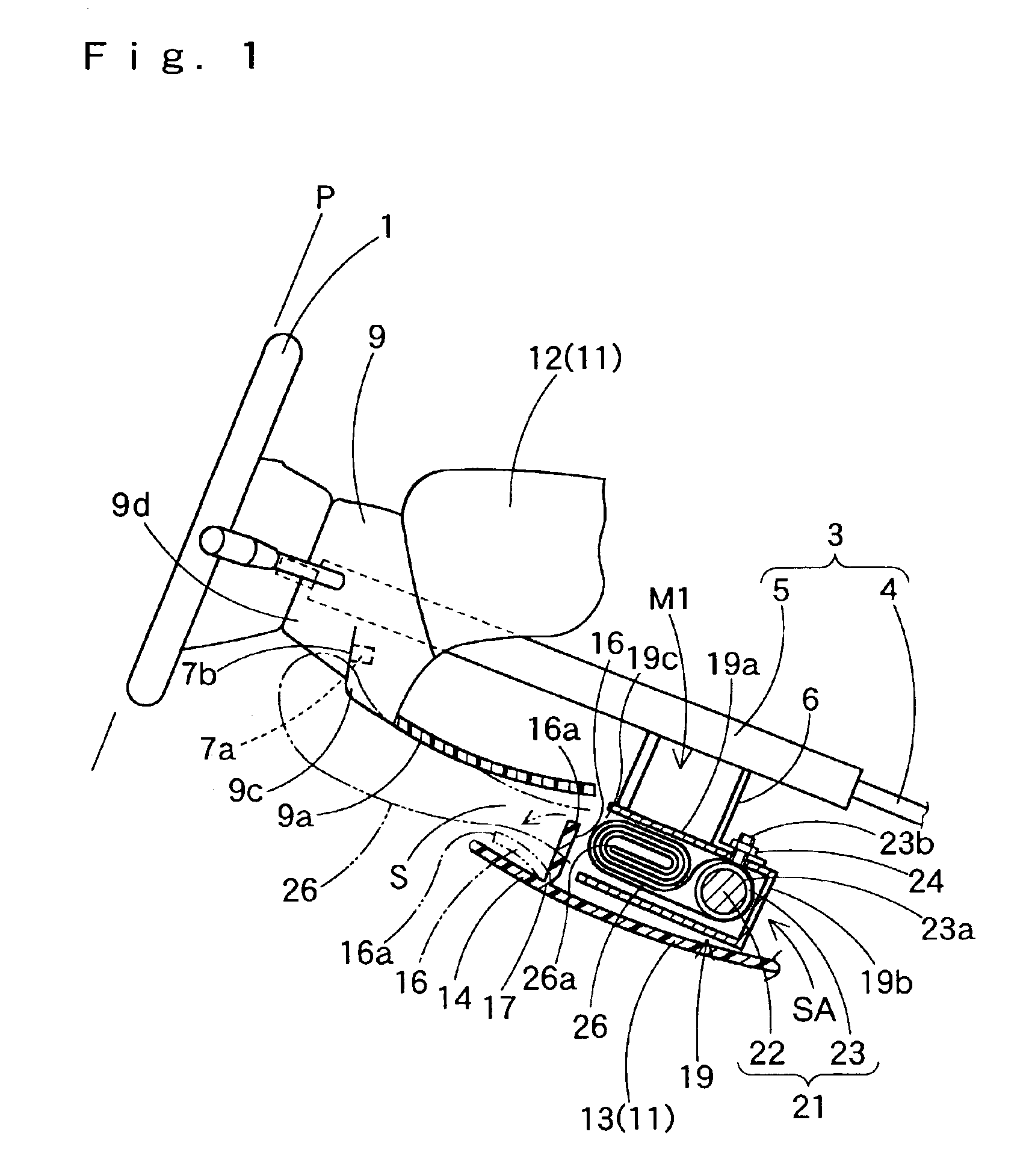

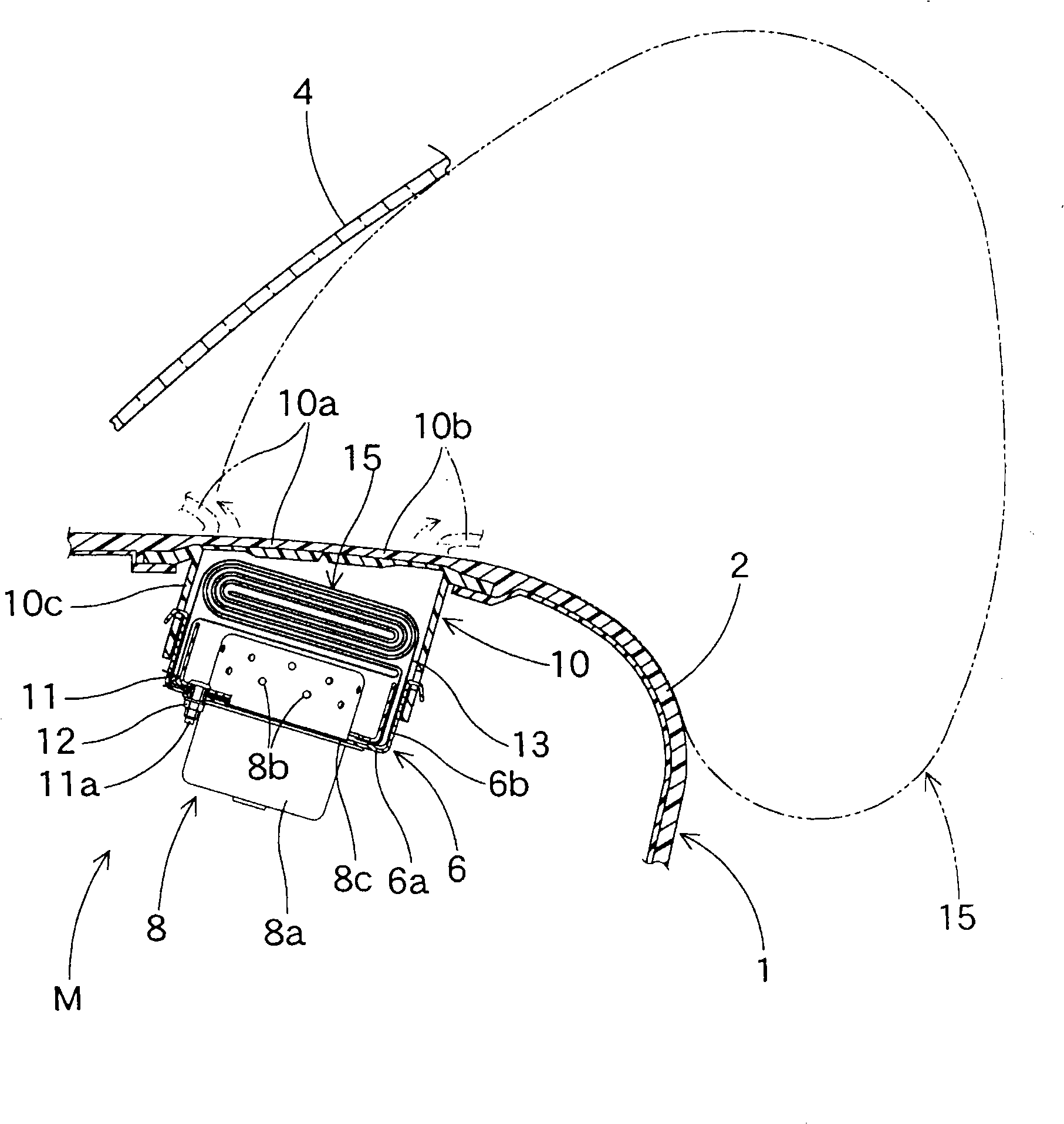

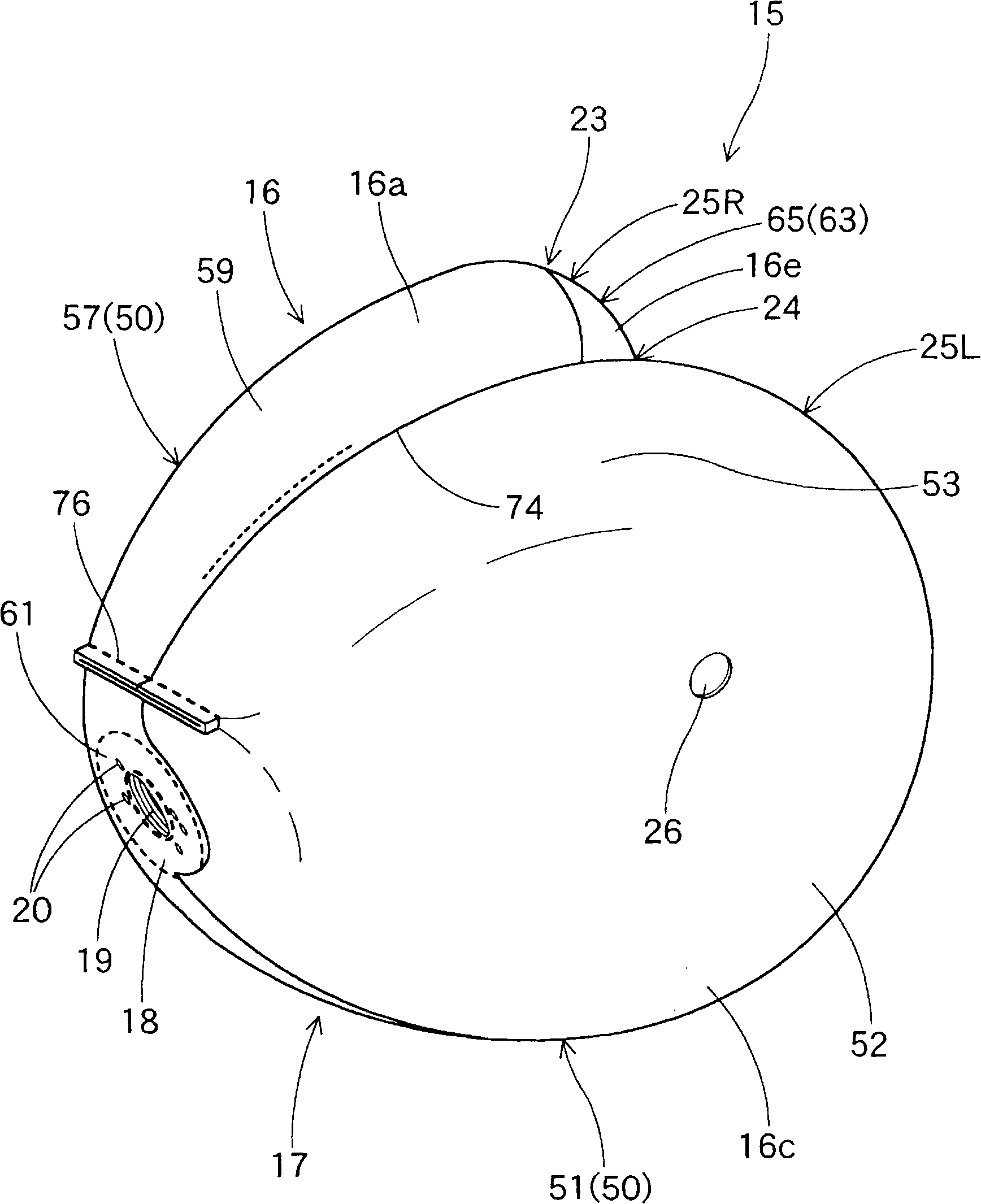

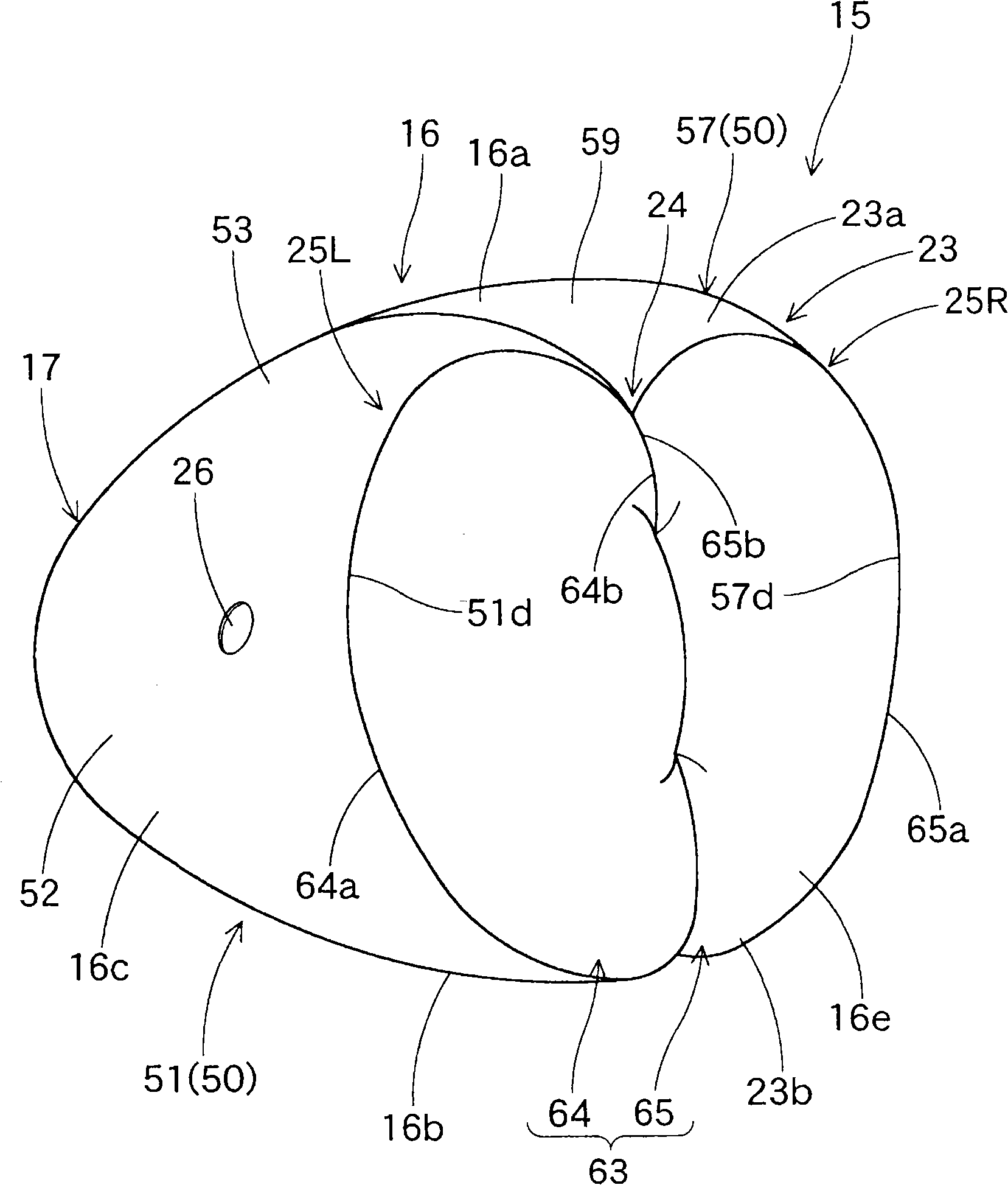

Air bag device for knee protection

InactiveUS6942245B2Shorten the time periodSuppresses to pressurePedestrian/occupant safety arrangementEngineeringAirbag

A knee protecting airbag device (M1), wherein an airbag (26) covers the substantial lower surface (9a) of a column cover (9) protruded to a driver side. Therefore, the airbag is minimized in the capacity without deteriorating the protection of the knee of the driver. As a result, it is possible to shorten the time period required for the airbag to complete the expansion and inflation. The airbag has a generally plate shape capable of covering at least the lower surface of the column cover when it completes the inflation. Even if the knee of the driver comes close to the column cover when the driver depresses a brake pedal or the like, the airbag being expanded and inflated is smoothly arranged in a narrow space between the knee of the driver and the column cover lower surface without interfering with the knee of the driver. With the knee protecting airbag device according to the present invention, therefore, the airbag is rapidly expanded and inflated in the narrow space between the column cover and the knee of the driver thereby to protect the knee of the driver properly.

Owner:TOYODA GOSEI CO LTD

Magnetic head for perpendicular magnetic recording and method of manufacturing same

ActiveUS20080013209A1Protrusion suppressionSuppress saturationRecord information storageHeads for perpendicular magnetisationsEngineeringElectrical and Electronics engineering

A magnetic head comprises a pole layer, a shield layer, a gap layer disposed between the pole layer and the shield layer, and a coil. The shield layer incorporates a first layer, a second layer, a third layer and a fourth layer that are disposed on the gap layer one by one. The first layer has an end face located in a medium facing surface. The second layer has: a first surface located in the medium facing surface; a second surface touching the first layer; and a third surface opposite to the second surface. The third layer touches the third surface of the second layer. An end face of each of the third and fourth layers closer to the medium facing surface is located at a distance from the medium facing surface.

Owner:HEADWAY TECH INC +1

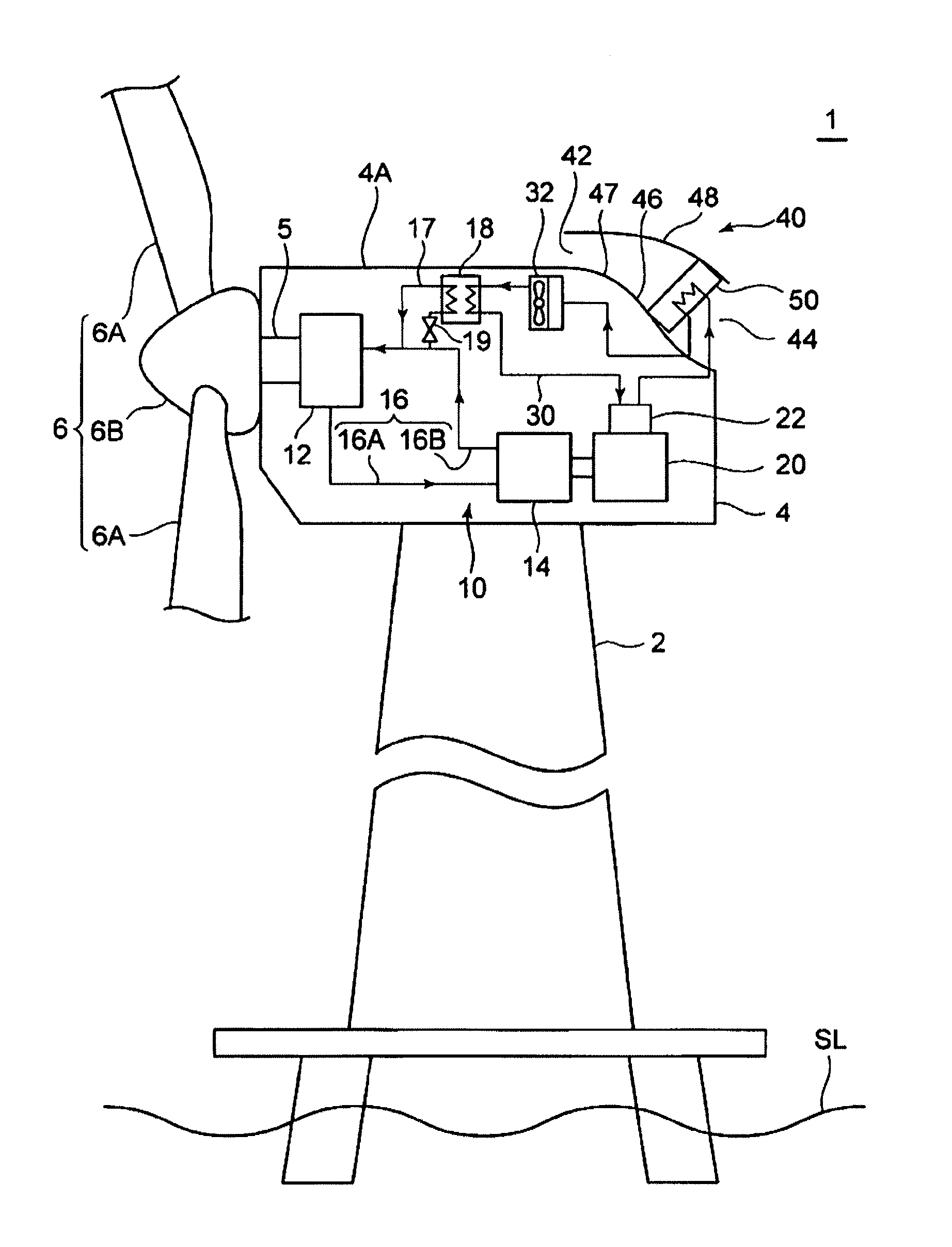

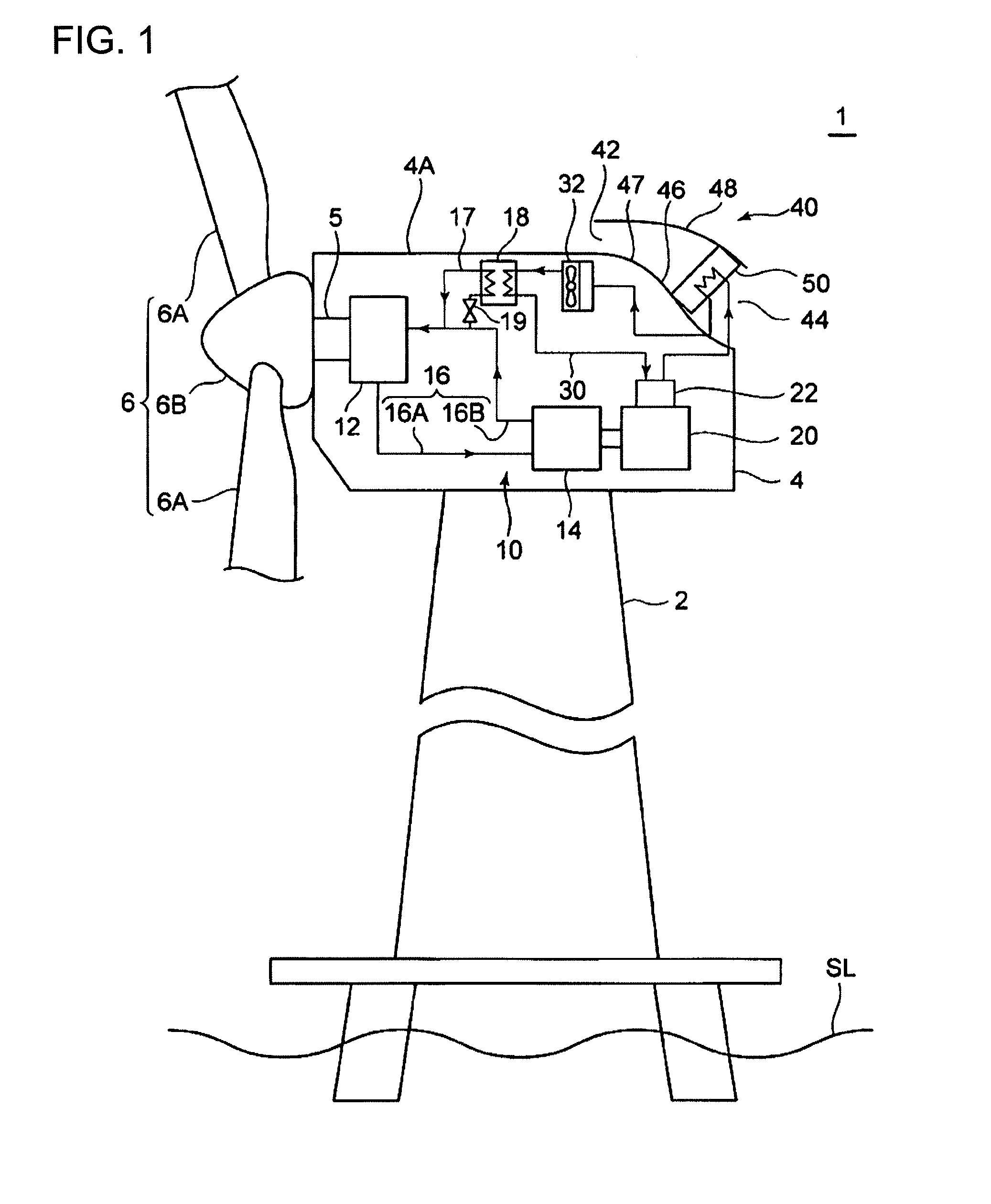

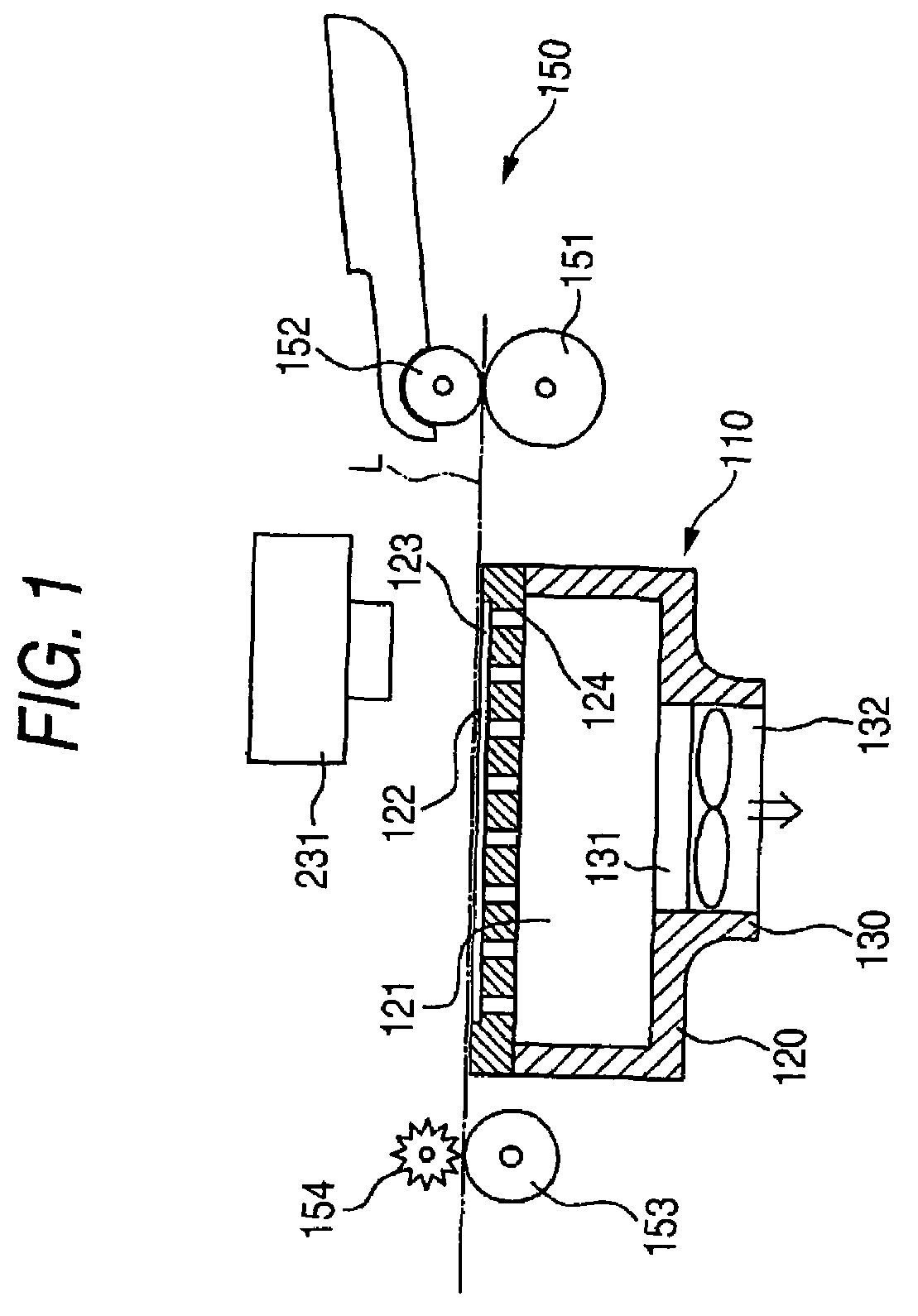

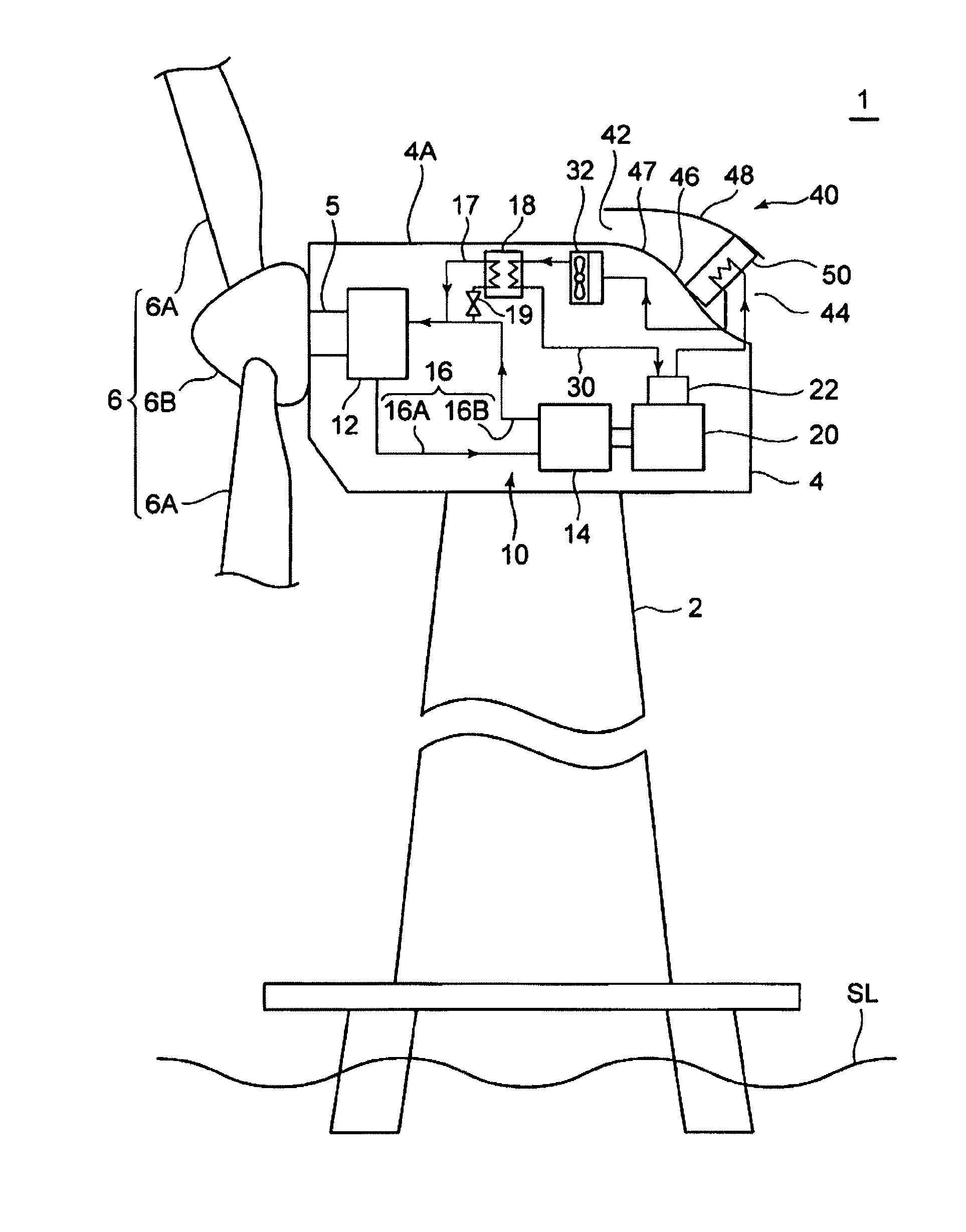

Wind turbine generator

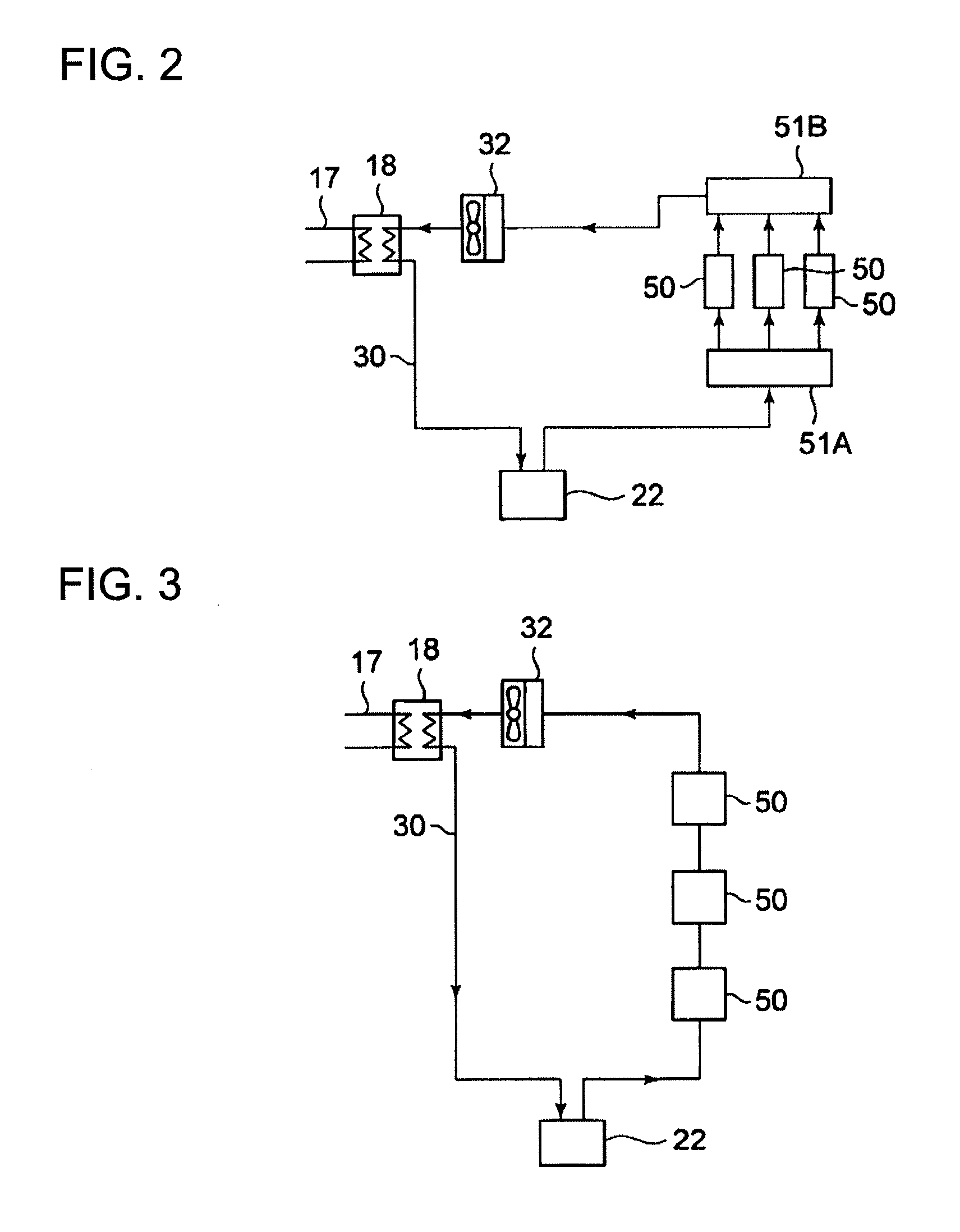

InactiveUS20120148407A1Simplify the hardening processIncrease the cross-sectional areaPropellersRotary propellersDouble wallTower

A wind turbine generator includes a tower, at least one blade, a hub supporting the blade, a nacelle supported by the tower and having a duct part with an intake port and an exhaust port, and a heat exchanger provided in the duct part and cooling a cooling medium for a heat-producing component inside the tower or nacelle. The wall of the nacelle has a double wall structure constituted of an inner wall and an outer wall in an area where the duct part is provided. The inner wall forms a bottom surface of the duct part and has a curved portion which curves inward toward a center line of the nacelle with increasing distance from the hub. The duct part increases in cross-section from a side of the intake port to a side of the exhaust port at least in an area where the curved portion is formed.

Owner:MITSUBISHI HEAVY IND LTD

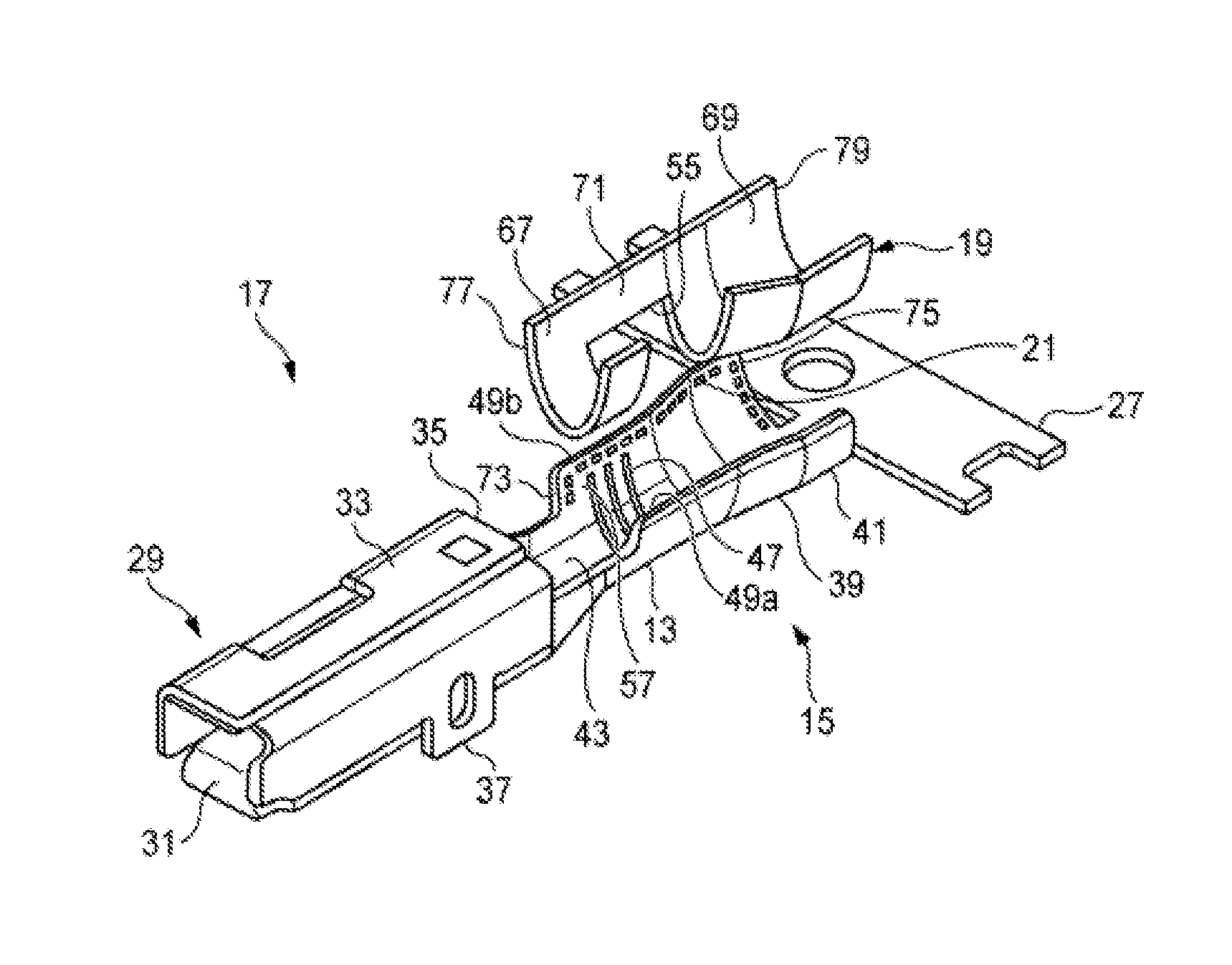

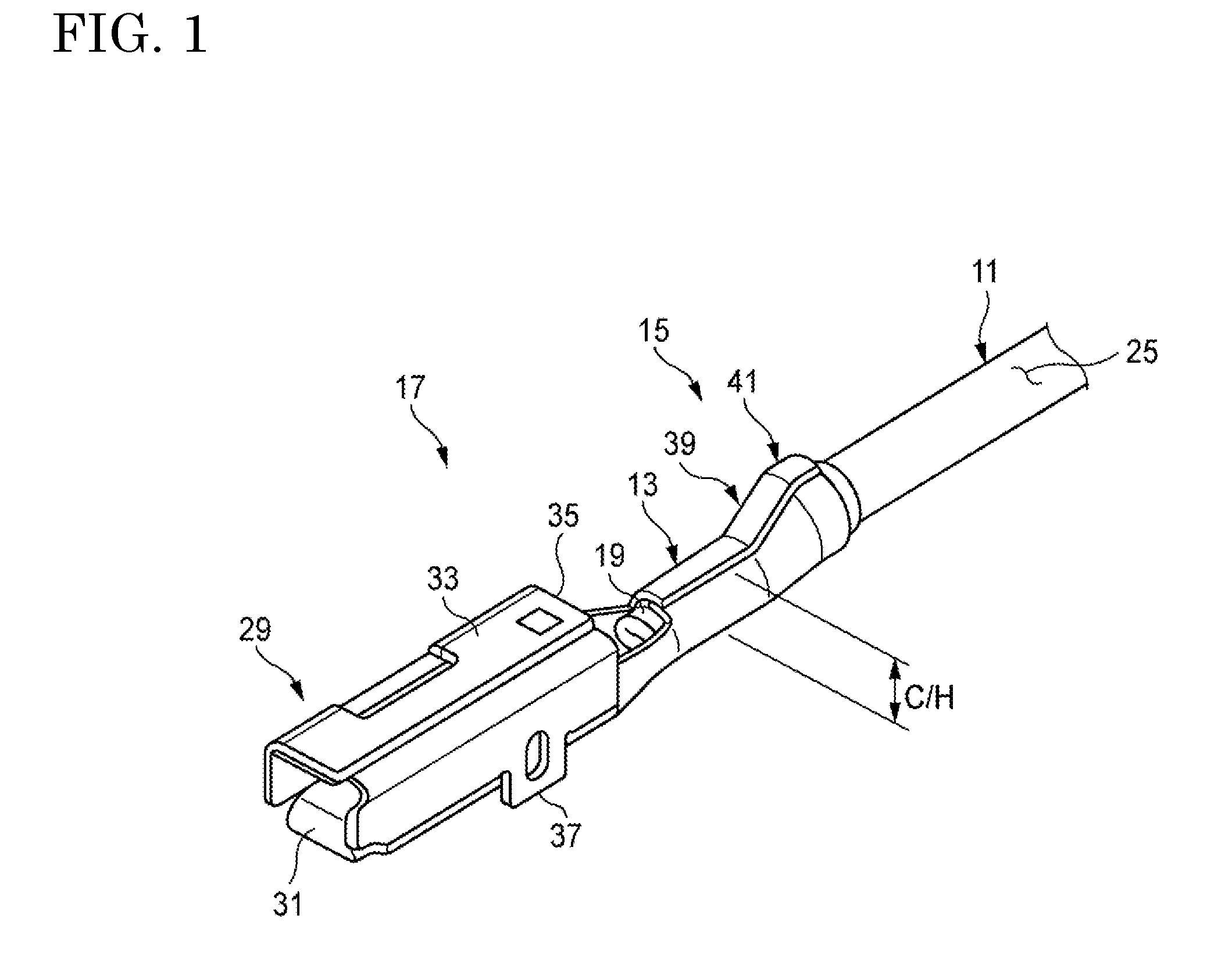

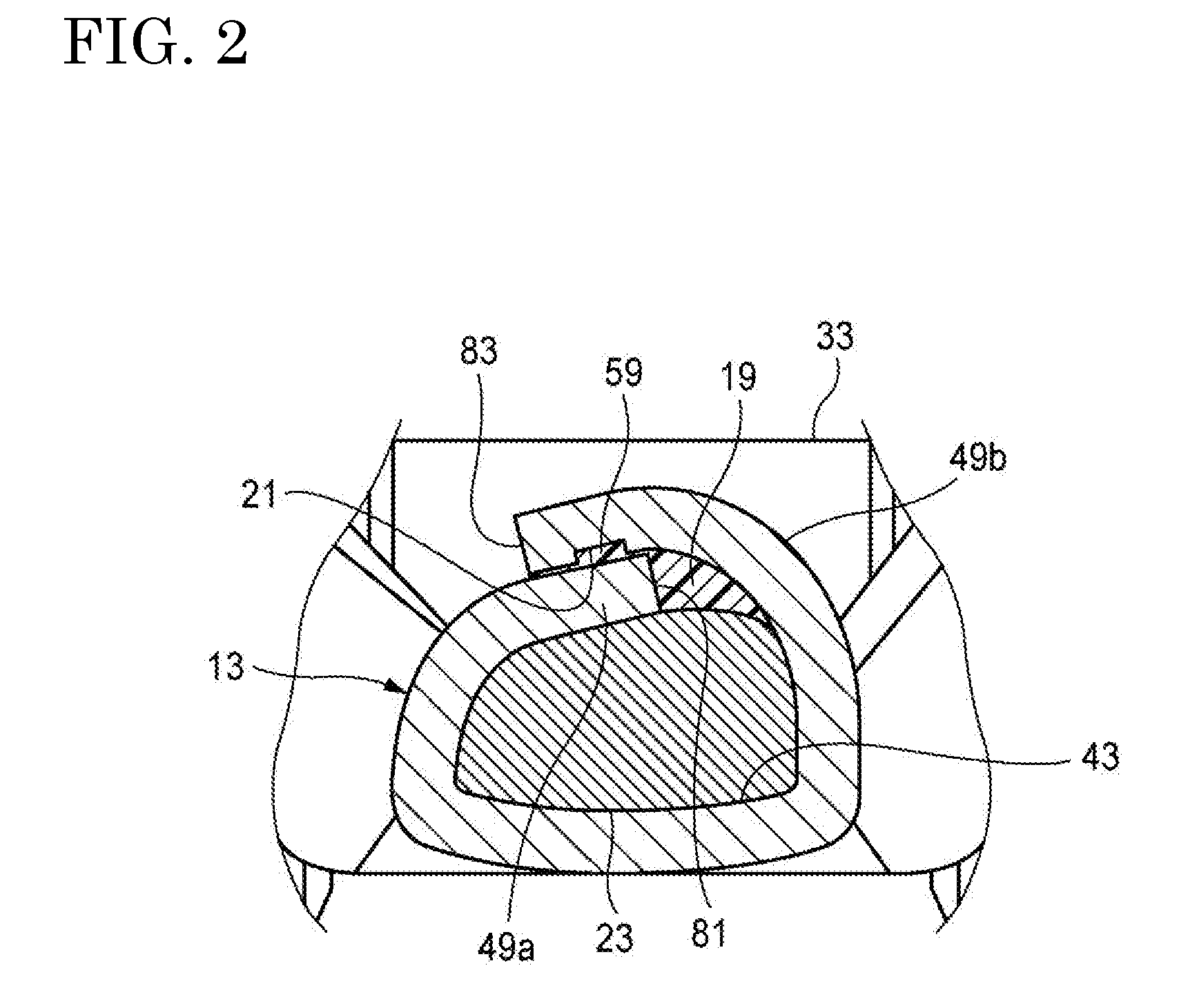

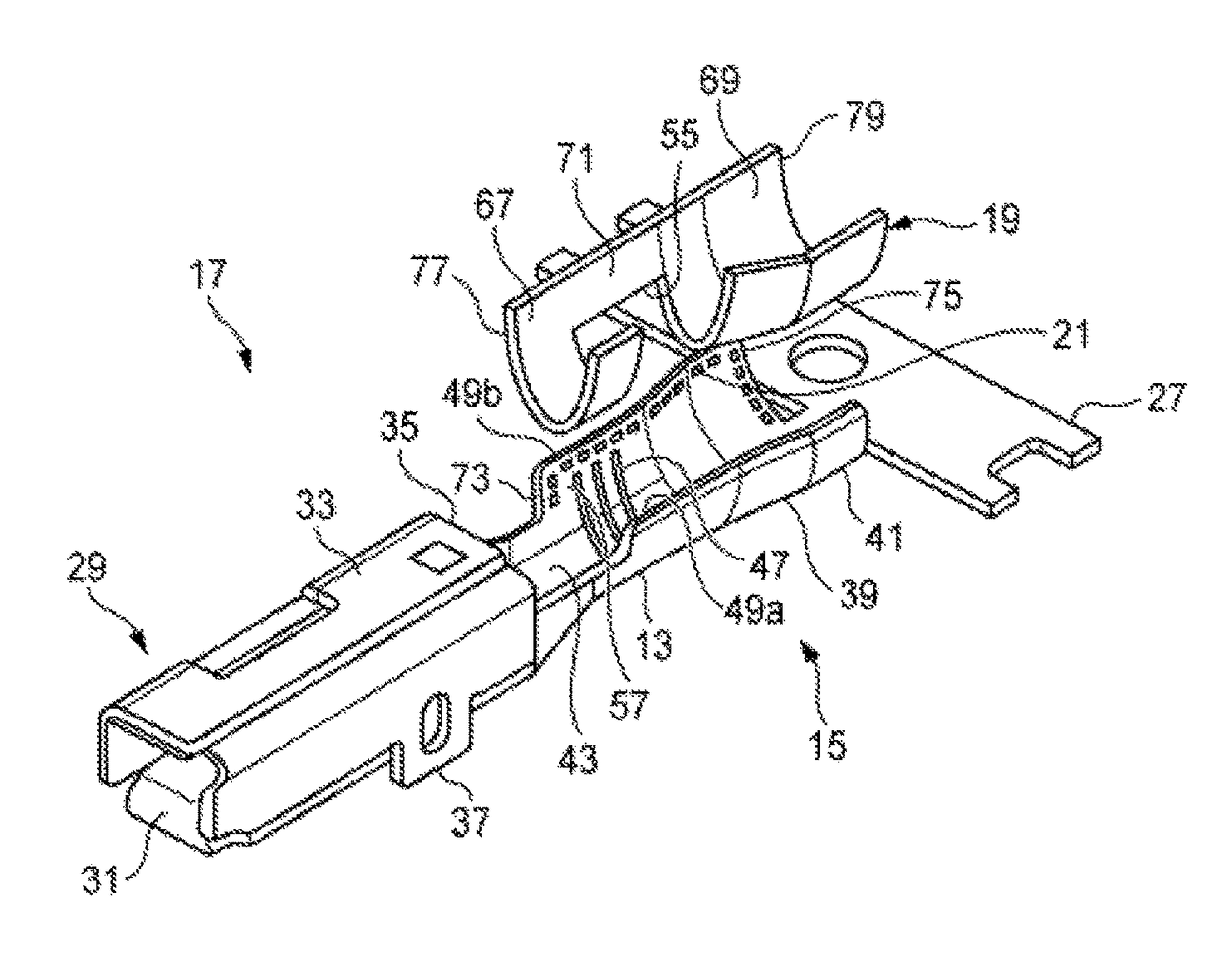

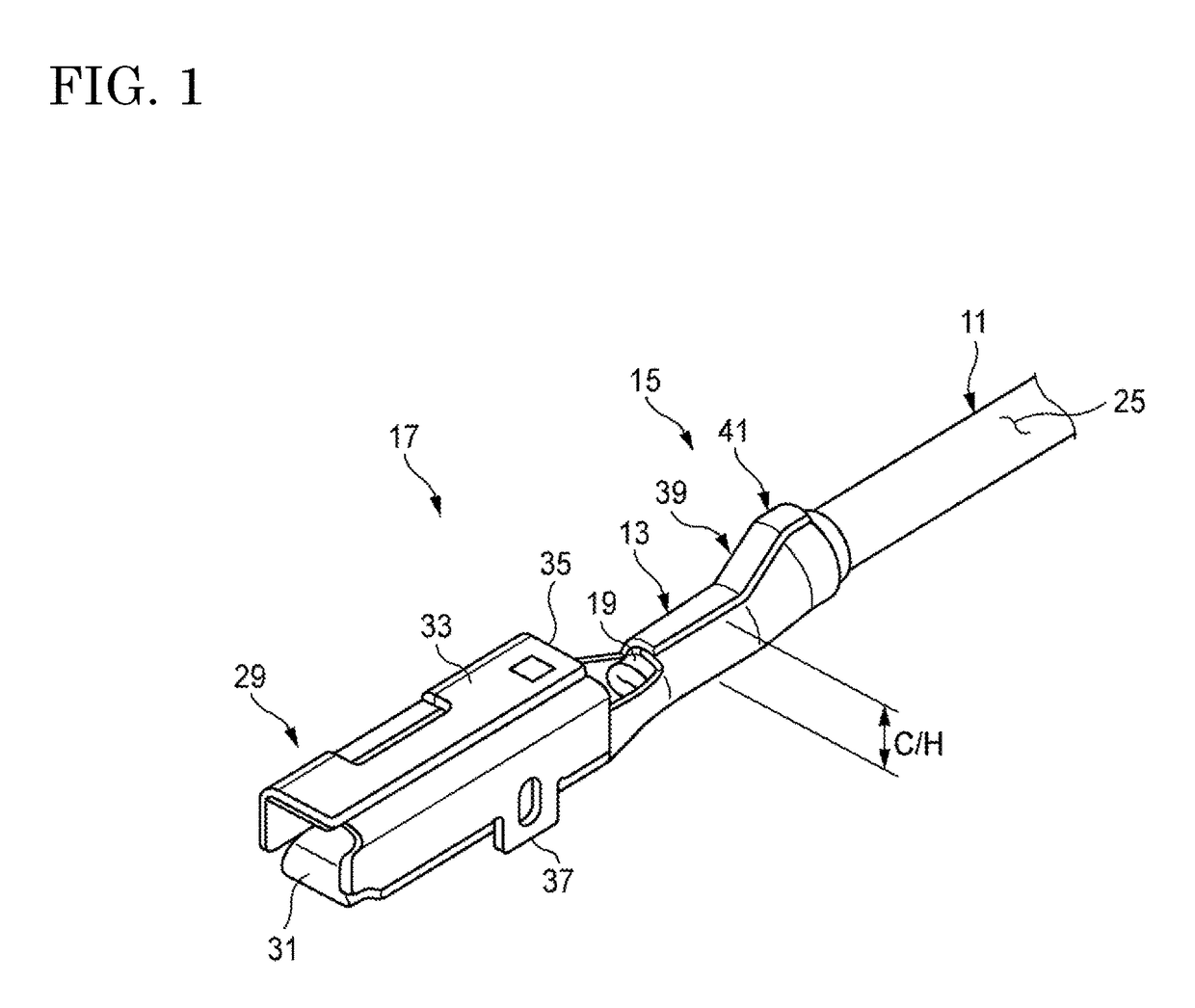

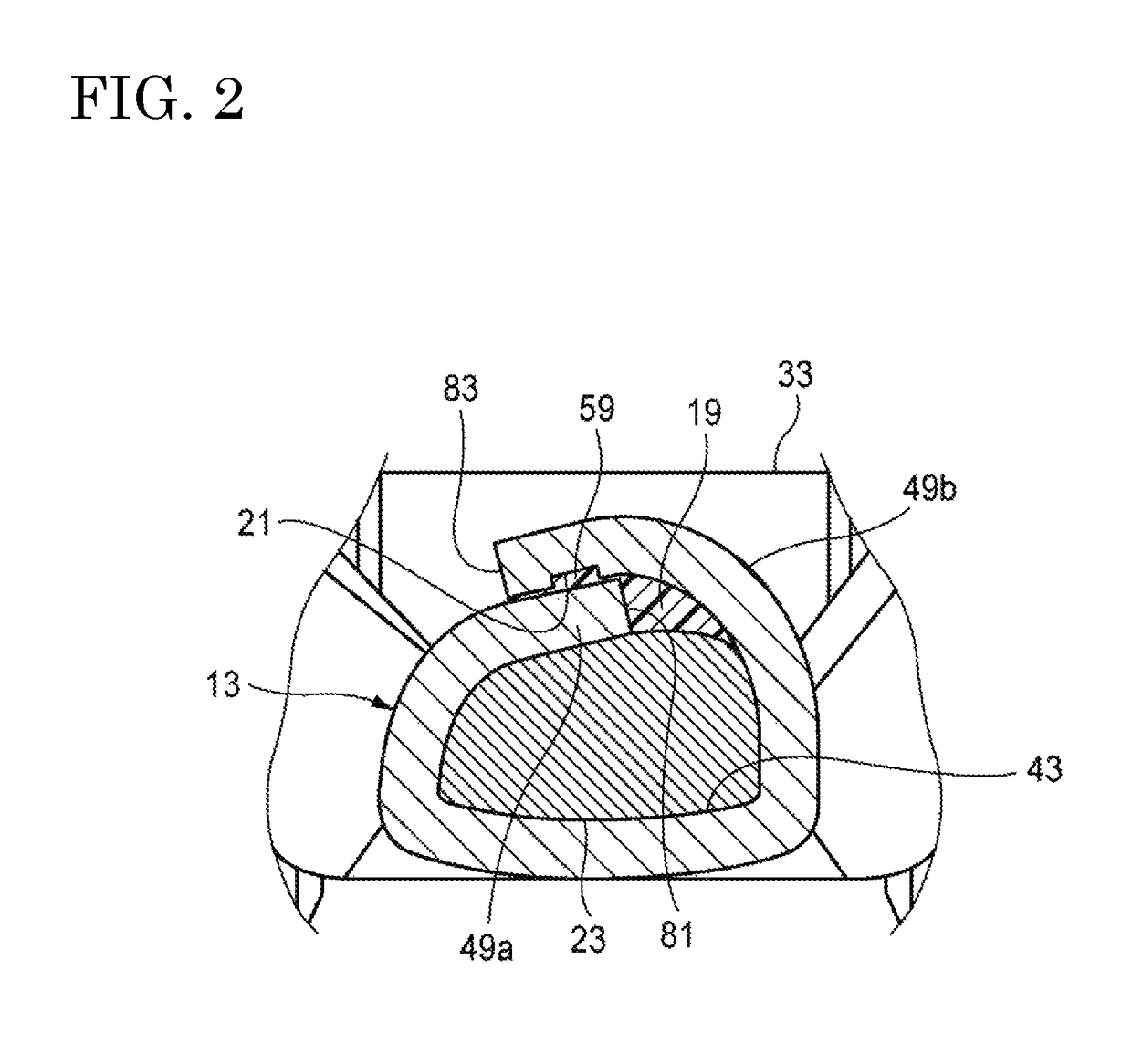

Structure for connecting crimping terminal and electric wire

InactiveUS20170005417A1Protrusion suppressionHigh densityCouplings bases/casesConnections effected by permanent deformationElectrical conductorEngineering

A structure for connecting a crimping terminal and an electric wire, includes: the crimping terminal that is provided with an electric wire connection section to be crimped to the electric wire, the electric wire connection section including a conductor crimping section and a sheath crimping section which are successively disposed to each other; a waterproof material that includes an opening for allowing the conductor and the conductor crimping section to make contact with each other, has a size to surround the conductor and the sheath which are to be crimped, and is installed between the electric wire connection section and the electric wire; and a recess that is formed on at least one of the electric wire connection section and the sheath, and a bulged and deformed section of the waterproof material deformed by the electric wire connection section which is caulked and crimped enters.

Owner:YAZAKI CORP

Magnetic head for perpendicular magnetic recording and method of manufacturing same

ActiveUS20070211377A1Protrusion suppressionSuppress the wide-range adjacent track eraseRecord information storageHeads for perpendicular magnetisationsCouplingPerpendicular magnetic field

A pole layer has an end face located in a medium facing surface, allows a magnetic flux corresponding to a magnetic field generated by a coil to pass therethrough, and generates a write magnetic field for writing data on a recording medium by means of a perpendicular magnetic recording system. A shield incorporates: a first layer having an end face located in a region of the medium facing surface forward of the end face of the pole layer along the direction of travel of the recording medium; a second layer disposed in a region sandwiching the pole layer with the first layer; a first coupling portion coupling the first layer to the second layer without touching the pole layer; and a second coupling portion coupling the pole layer to the second layer and located farther from the medium facing surface than the first coupling portion.

Owner:HEADWAY TECH INC

Production method of multilayer printed wiring board and multilayer printed wiring board

ActiveUS20090133910A1Shorten the protruding lengthImprove reliabilityDecorative surface effectsInsulating layers/substrates workingEngineeringIrradiation

Multilayer printed wiring boards may be prepared by forming a via hole by laser irradiation in insulating layer formed by a prepreg, comprised of a glass cloth impregnated with a thermosetting resin composition, and subjecting the via hole to a glass etching treatment with a glass etching solution and then to a desmear treatment with an oxidizing agent solution. By such a process, etch back phenomenon and excessive protrusion of glass cloth from the wall surface of a via hole can be sufficiently suppressed, and a highly reliable via can be formed. Particularly, a highly reliable via can be formed in a small via hole having a top diameter of 75 μm or below.

Owner:AJINOMOTO CO INC +1

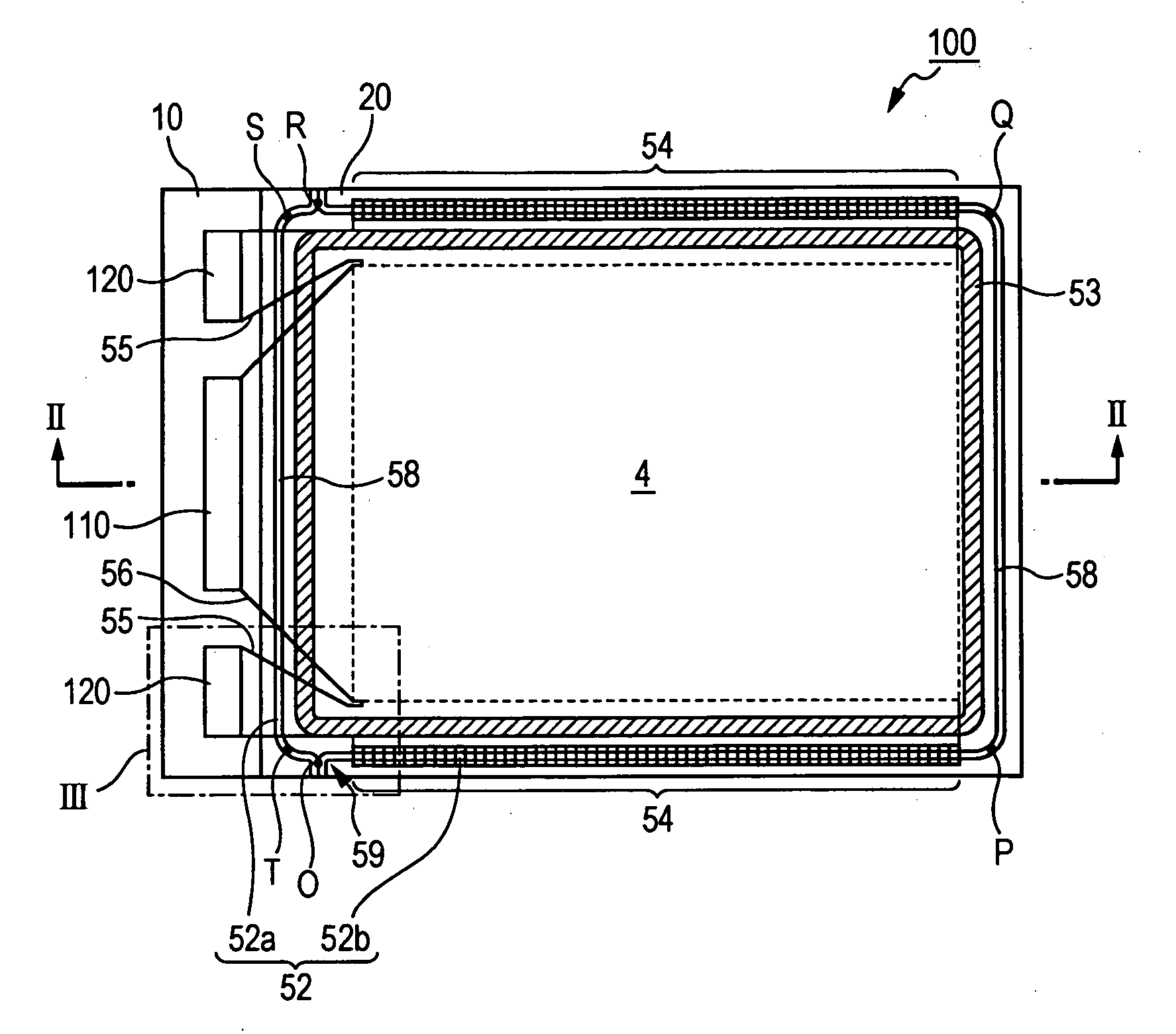

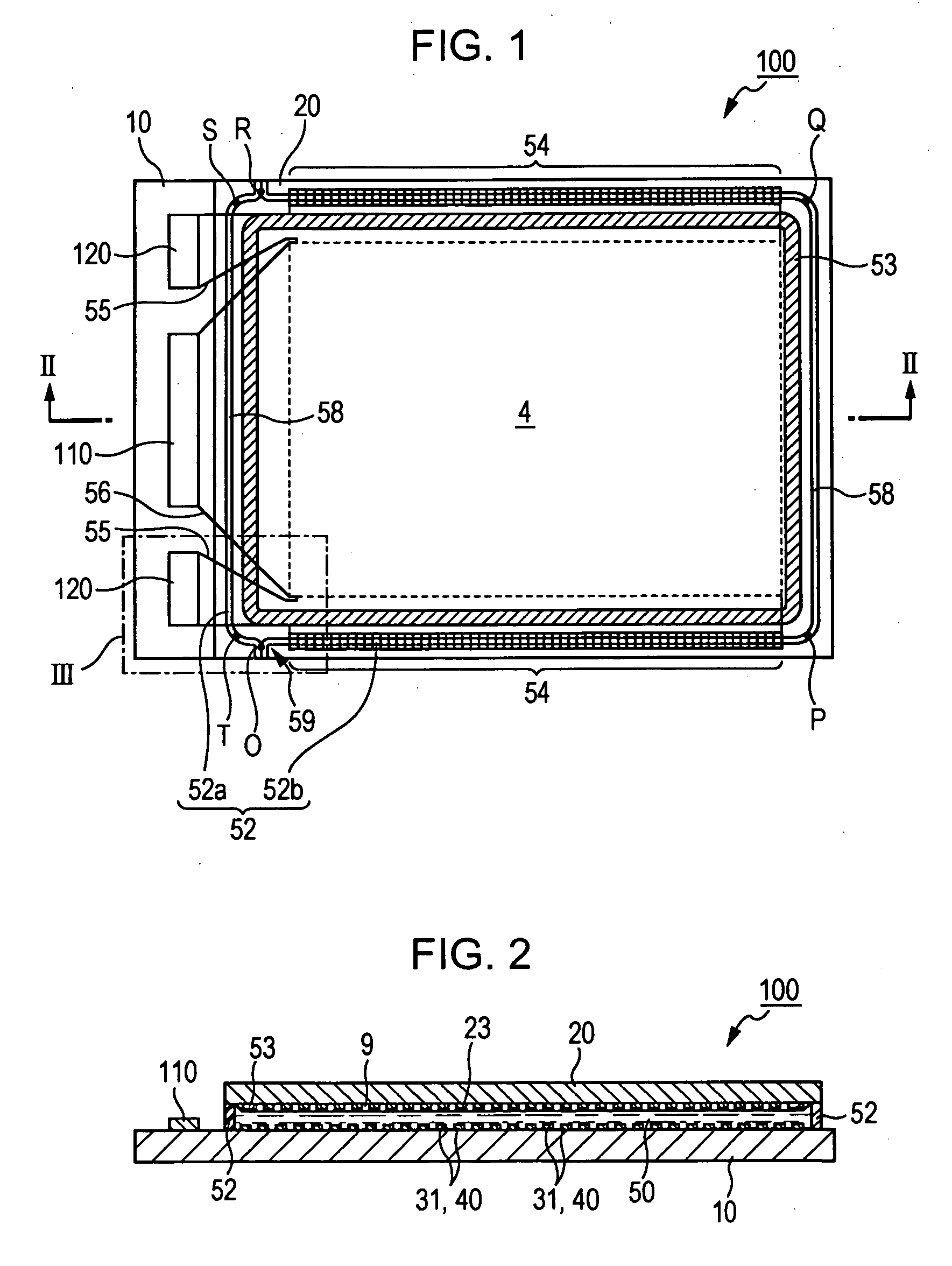

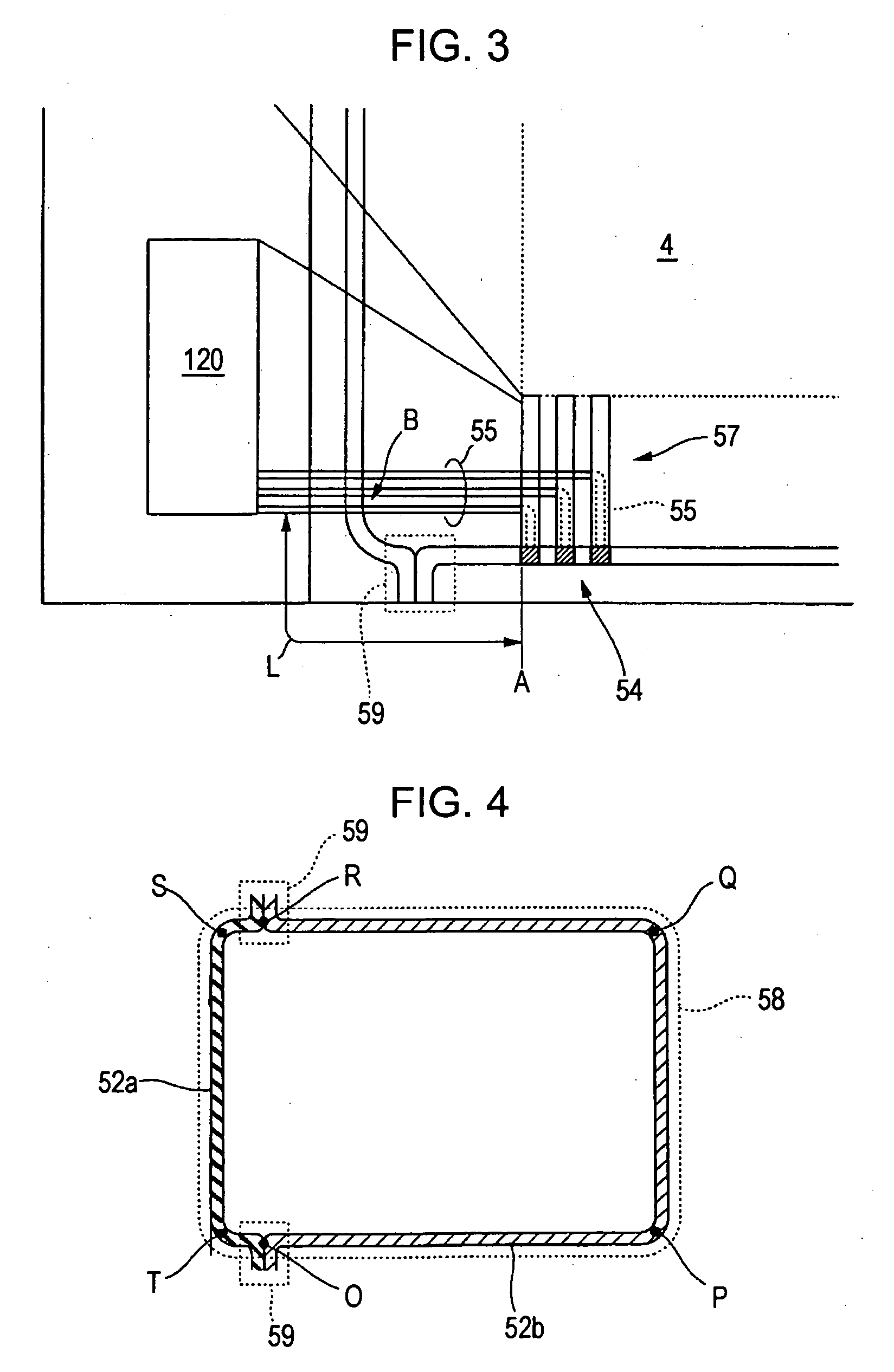

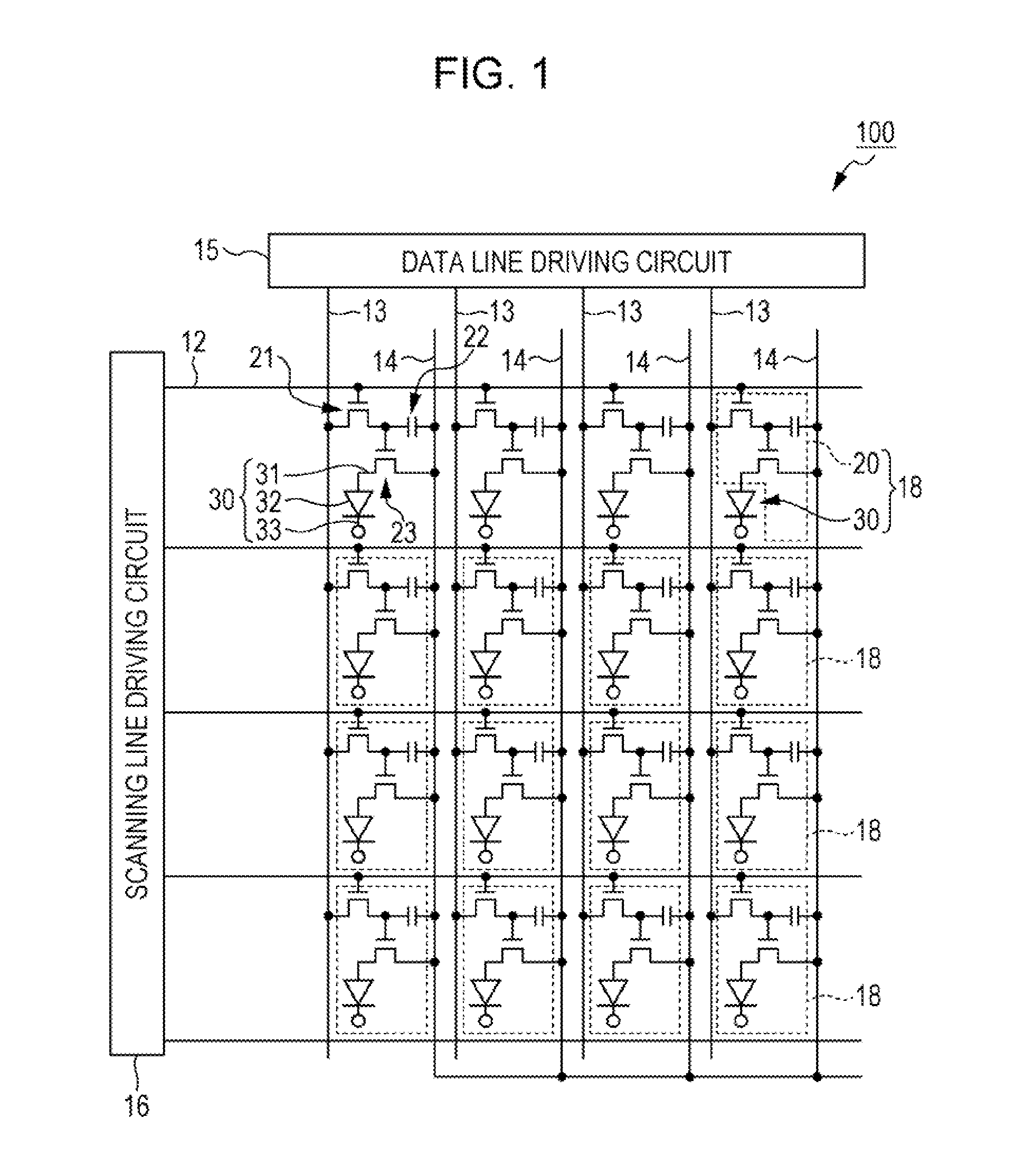

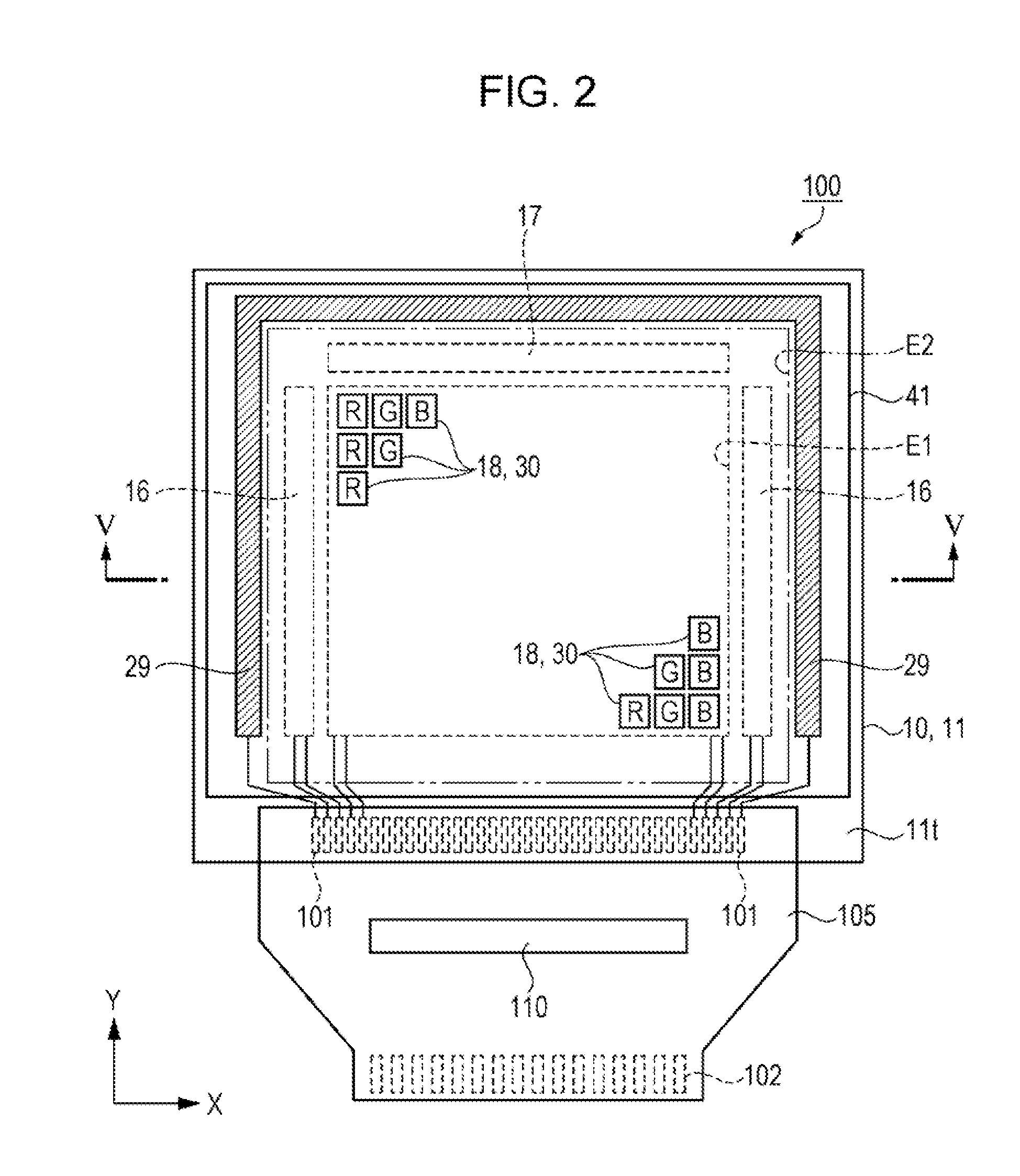

Method of manufacturing liquid crystal device, liquid crystal device, and electronic apparatus

ActiveUS20060139563A1Excellent reliabilityEasily influencedNon-linear opticsLiquid crystal devicesElectrical and Electronics engineering

A method of manufacturing a liquid crystal device having a first substrate and a second substrate facing each other with a liquid crystal layer interposed therebetween, and a sealing member formed in a peripheral portion of at least one of the substrates. The method includes forming the sealing member, disposing the liquid crystal layer inside the sealing member, and bonding the first substrate to the second substrate. In forming the sealing member, a ring-shaped portion that seals the liquid crystal layer inside the sealing member, a first sealing layer and a second sealing layer that face each other to be separated from each other are formed. In the bonding of the first substrate to the second substrate, a junction portion is formed in which the first and second sealing layers are pressed and joined outside the sealing member so as to form the ring-shaped portion.

Owner:138 EAST LCD ADVANCEMENTS LTD

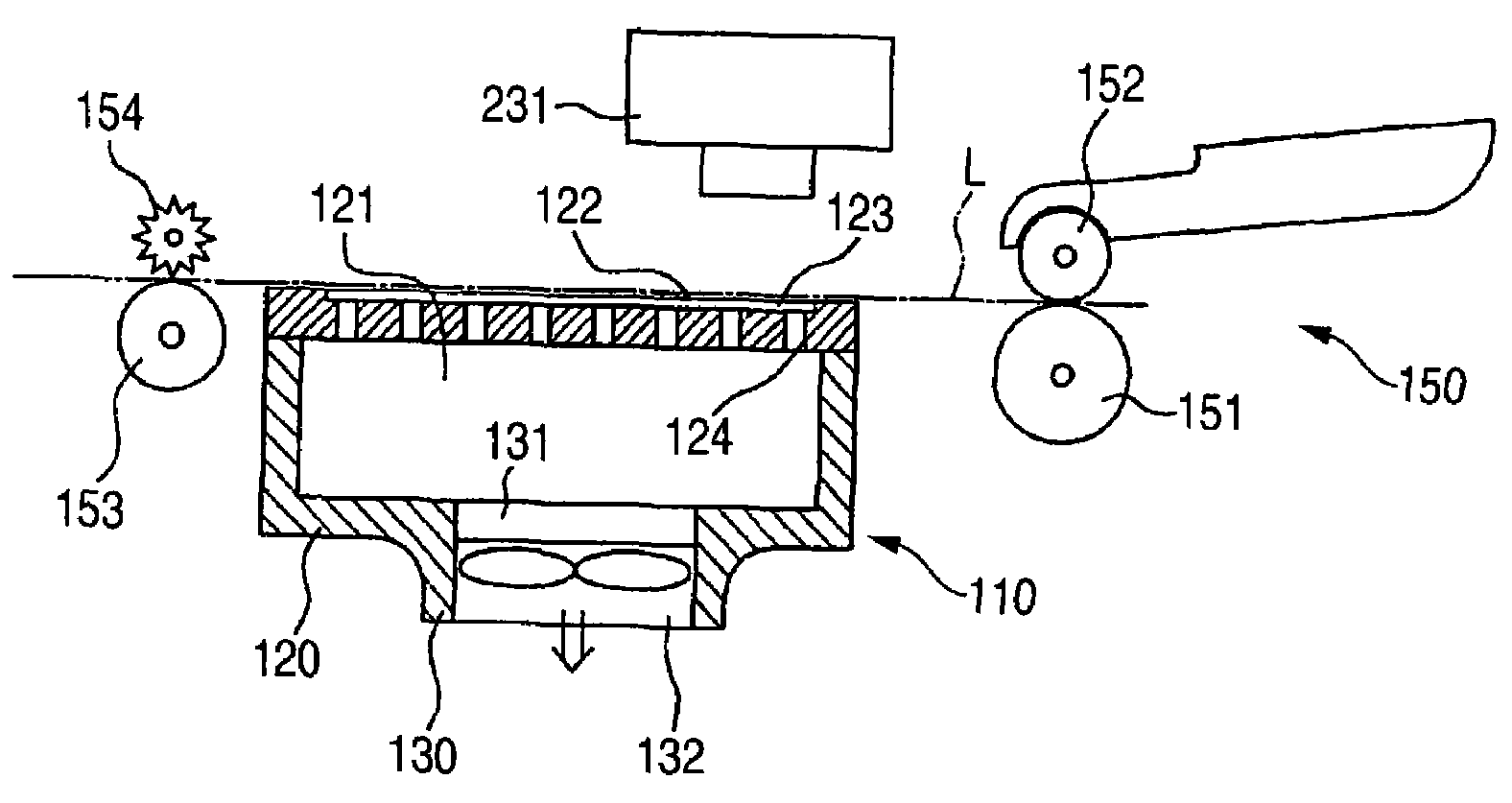

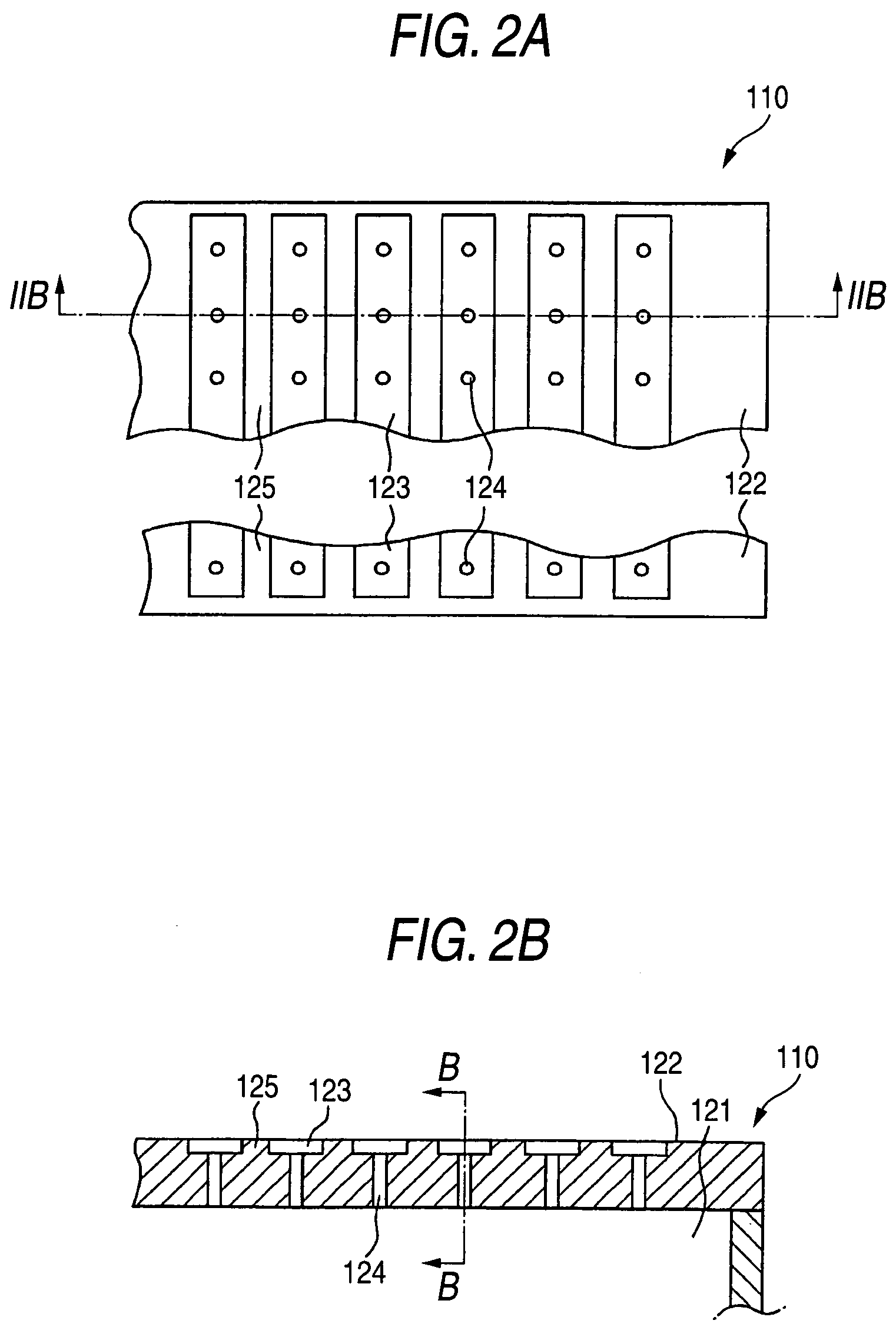

Medium transporting device and recording apparatus

ActiveUS7390085B2Avoid curlInhibition effectRigid pipesOther printing apparatusEngineeringMechanical engineering

On a medium transporting surface, a dimple extending continuously from a transportation upstream end of a medium to a transportation downstream end are formed. Hereby, a leading end of the medium, after pulled into the dimples once, is transported in the pulled state. Therefore, it is prevented that the leading end of the medium is curled up by a conventional partition wall provided in the direction perpendicular to the medium transporting direction, so that it is possible to prevent a stain on the medium caused by contact with a recording head.

Owner:SEIKO EPSON CORP

Magnetic head for perpendicular magnetic recording and method of manufacturing same

ActiveUS7633714B2Protrusion suppressionSuppress the wide-range adjacent track eraseRecord information storageShielding headsCouplingEngineering

A shield incorporates: a first layer, a second layer, a third layer, a first coupling portion, and a second coupling portion. The first layer has: a first surface located in a region of a medium facing surface forward of an end face of a pole layer along the direction of travel of a recording medium; a second surface opposed to the pole layer; and a third surface opposite to the second surface. The second layer touches the third surface. The third layer is disposed in a region sandwiching the pole layer with the first layer. The first coupling portion couples the first layer to the third layer without touching the pole layer. The second coupling portion is located farther from the medium facing surface than the first coupling portion and couples the pole layer to the third layer.

Owner:HEADWAY TECH INC +1

Laminated metal sheet for can lid excelling in appearance after retorting

InactiveUS20070031688A1Good lookingInduce and turbiditySynthetic resin layered productsCans/barrels/drumsWater vaporMetal sheet

The laminated metal sheet for can end is formed by laminating polyester film on both sides thereof, thus providing excellent appearance after retorting. The polyester film laminated to a side to become outer face of the formed can end has (1) half-time of crystallization of the resin of amorphous polyester layer formed near the interface between the polyester film and the metal sheet of 40 seconds or smaller at 130° C., (2) thickness of the amorphous polyester layer from 0.5 to 8 μm, (3) water vapor transmissivity of the polyester film of 100 g / m2 / 24 hr or smaller. The amorphous polyester layer resin is preferably a polyester composition prepared by formulating a polyester (I) (30 to 60% by weight) composed mainly of ethylene terephthalate as the main repeating unit, and a polyester (II) (40 to 70% by weight) composed mainly of butylene terephthalate as the main repeating unit.

Owner:JFE STEEL CORP

Magnetic head for perpendicular magnetic recording and method of manufacturing same

ActiveUS20080024911A1Protrusion suppressionSuppress the wide-range adjacent track eraseRecord information storageShielding headsCouplingEngineering

A shield incorporates: a first layer, a second layer, a third layer, a first coupling portion, and a second coupling portion. The first layer has: a first surface located in a region of a medium facing surface forward of an end face of a pole layer along the direction of travel of a recording medium; a second surface opposed to the pole layer; and a third surface opposite to the second surface. The second layer touches the third surface. The third layer is disposed in a region sandwiching the pole layer with the first layer. The first coupling portion couples the first layer to the third layer without touching the pole layer. The second coupling portion is located farther from the medium facing surface than the first coupling portion and couples the pole layer to the third layer.

Owner:HEADWAY TECH INC +1

Airbag for deputy driver's seat

ActiveCN101279601AProtrusion suppressionPrevent movementPedestrian/occupant safety arrangementEngineeringAirbag

Owner:TOYODA GOSEI CO LTD

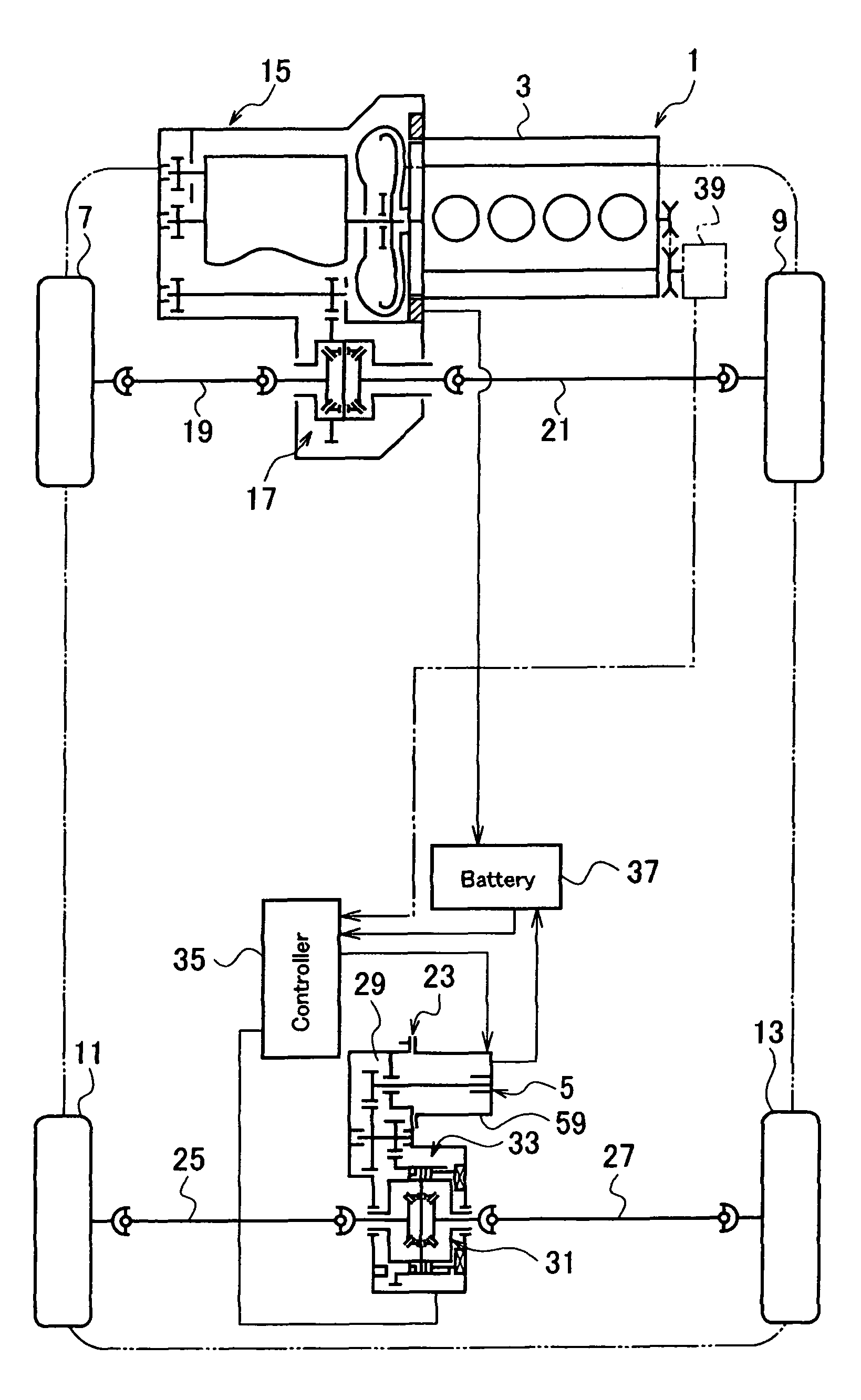

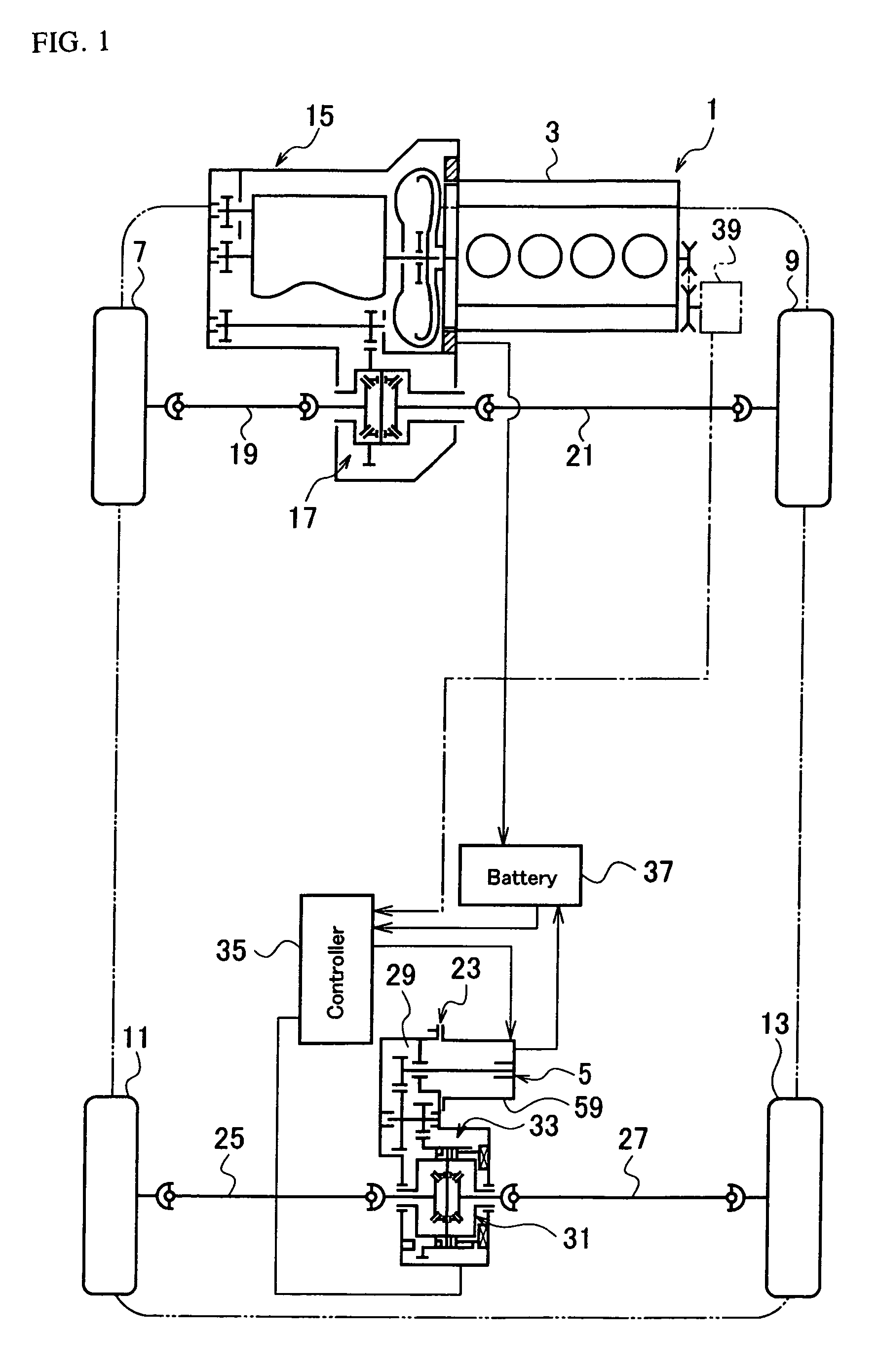

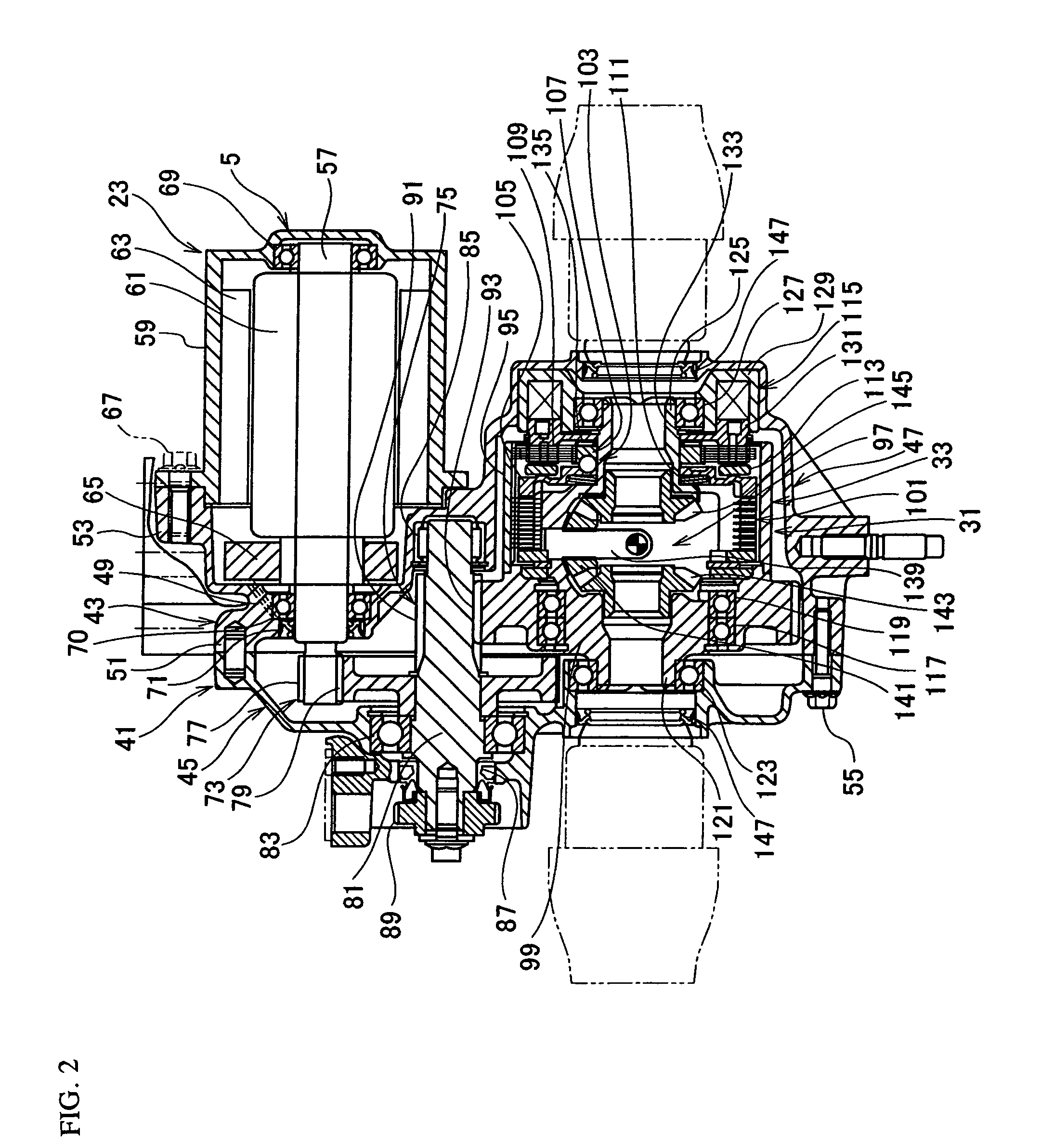

Reduction drive device

ActiveUS7990004B2Small sizeImprove controllabilitySpeed controllerDynamo-electric brakes/clutchesReduction driveEngineering

A reduction drive device is compact, hardly causes an electric motor thereof to vibrate, and has improved noise / vibration controllability. The reduction drive device includes the electric motor attached to a casing and capable of outputting torque, first and second reduction mechanisms supported by the casing, to reduce and transmit the rotational output of the electric motor, and a rear differential supported by the casing, to distribute the rotational output reduced by the first and second reduction mechanisms to a pair of axle shafts. Rotor, stator, and brush of the electric motor partly overlap the rear differential when seen in a rotation radius direction.

Owner:GKN DRIVELINE TORQUE TECHNOLOGY KK

Magnetic head for perpendicular magnetic recording having a multilayer shield structure and method of manufacturing same

ActiveUS7551394B2Protrusion suppressionSuppress saturationManufacture head surfaceRecord information storageEngineeringElectrical and Electronics engineering

A magnetic head comprises a pole layer, a shield layer, a gap layer disposed between the pole layer and the shield layer, and a coil. The shield layer incorporates a first layer, a second layer, a third layer and a fourth layer that are disposed on the gap layer one by one. The first layer has an end face located in a medium facing surface. The second layer has: a first surface located in the medium facing surface; a second surface touching the first layer; and a third surface opposite to the second surface. The third layer touches the third surface of the second layer. An end face of each of the third and fourth layers closer to the medium facing surface is located at a distance from the medium facing surface.

Owner:HEADWAY TECH INC +1

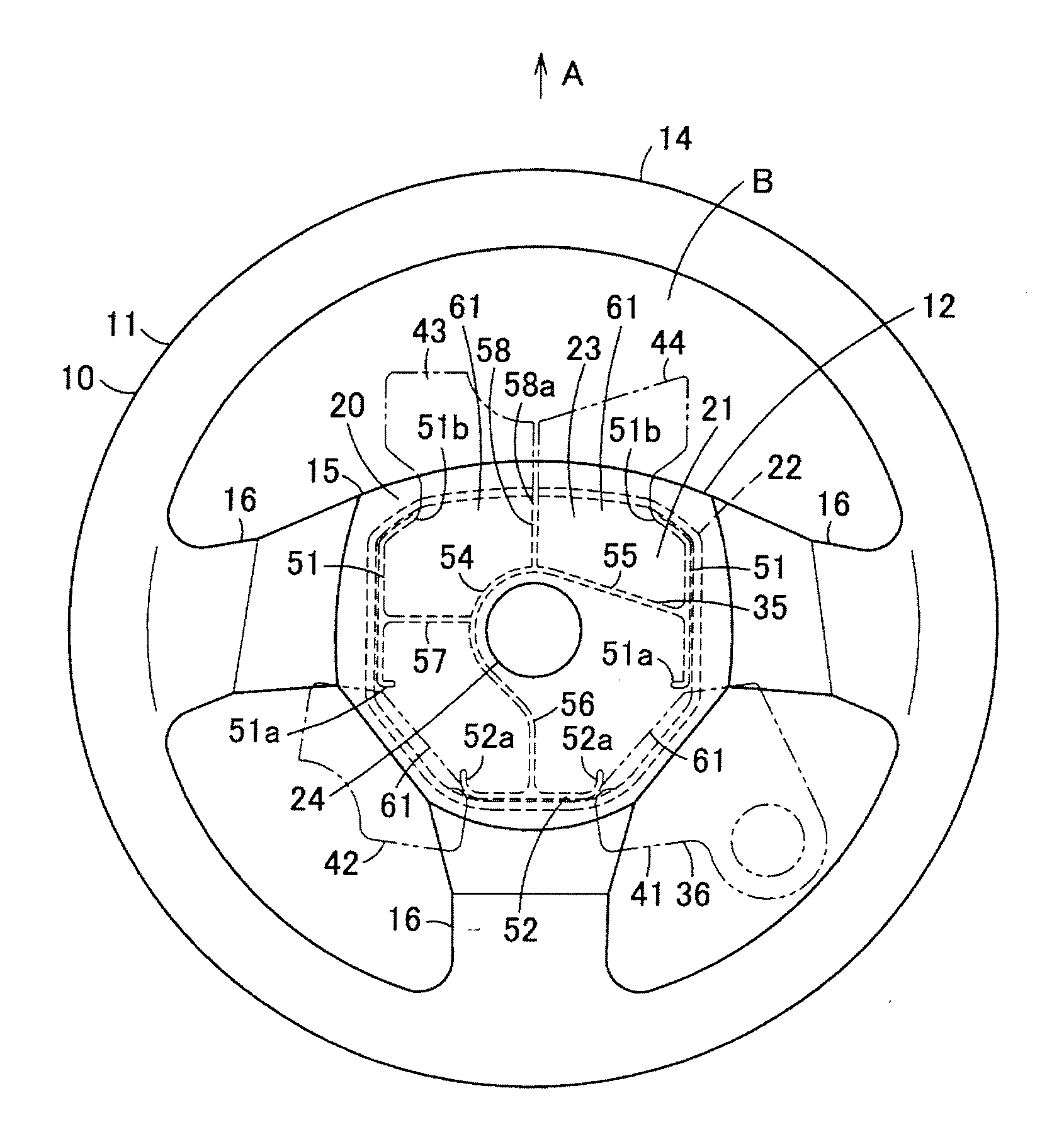

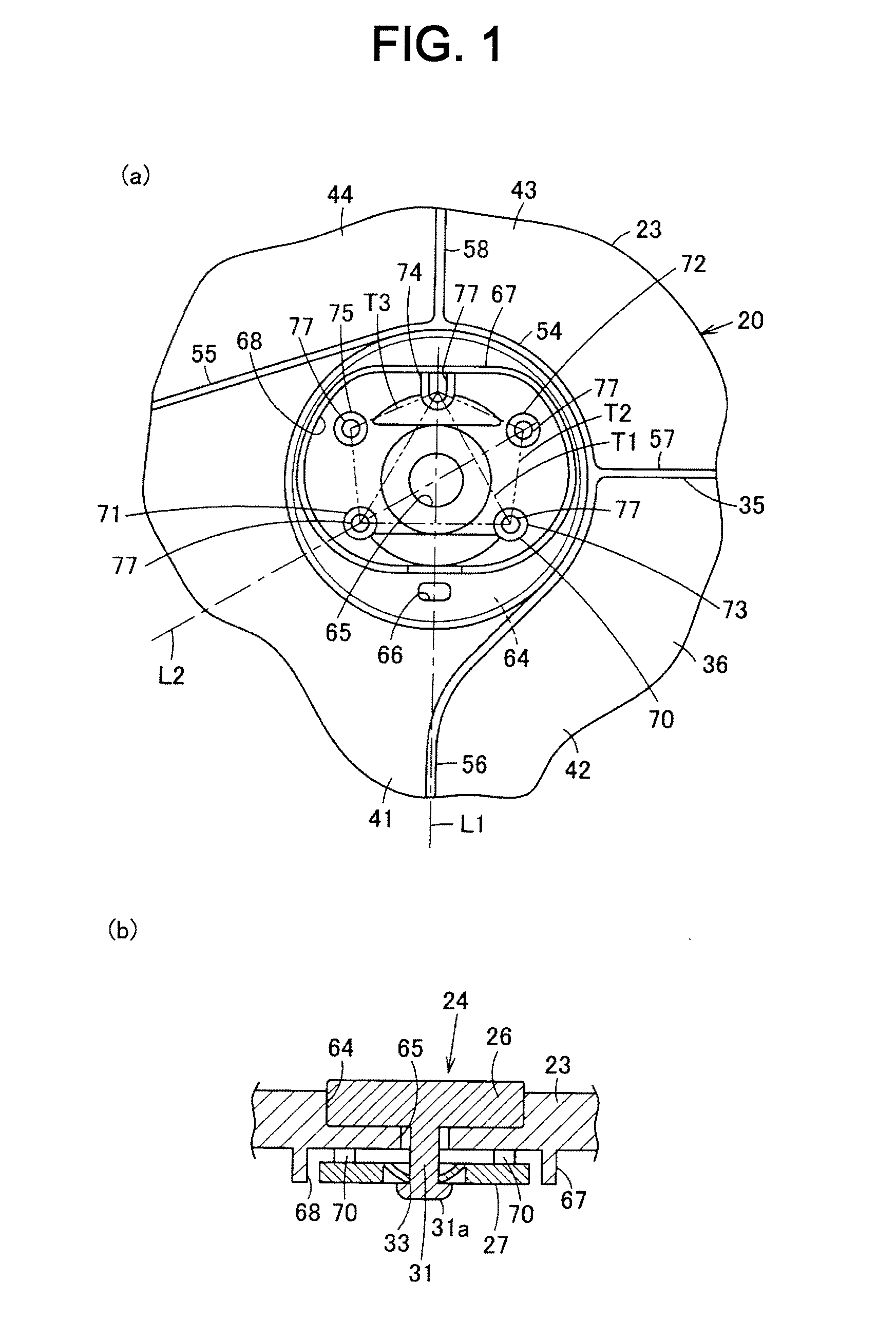

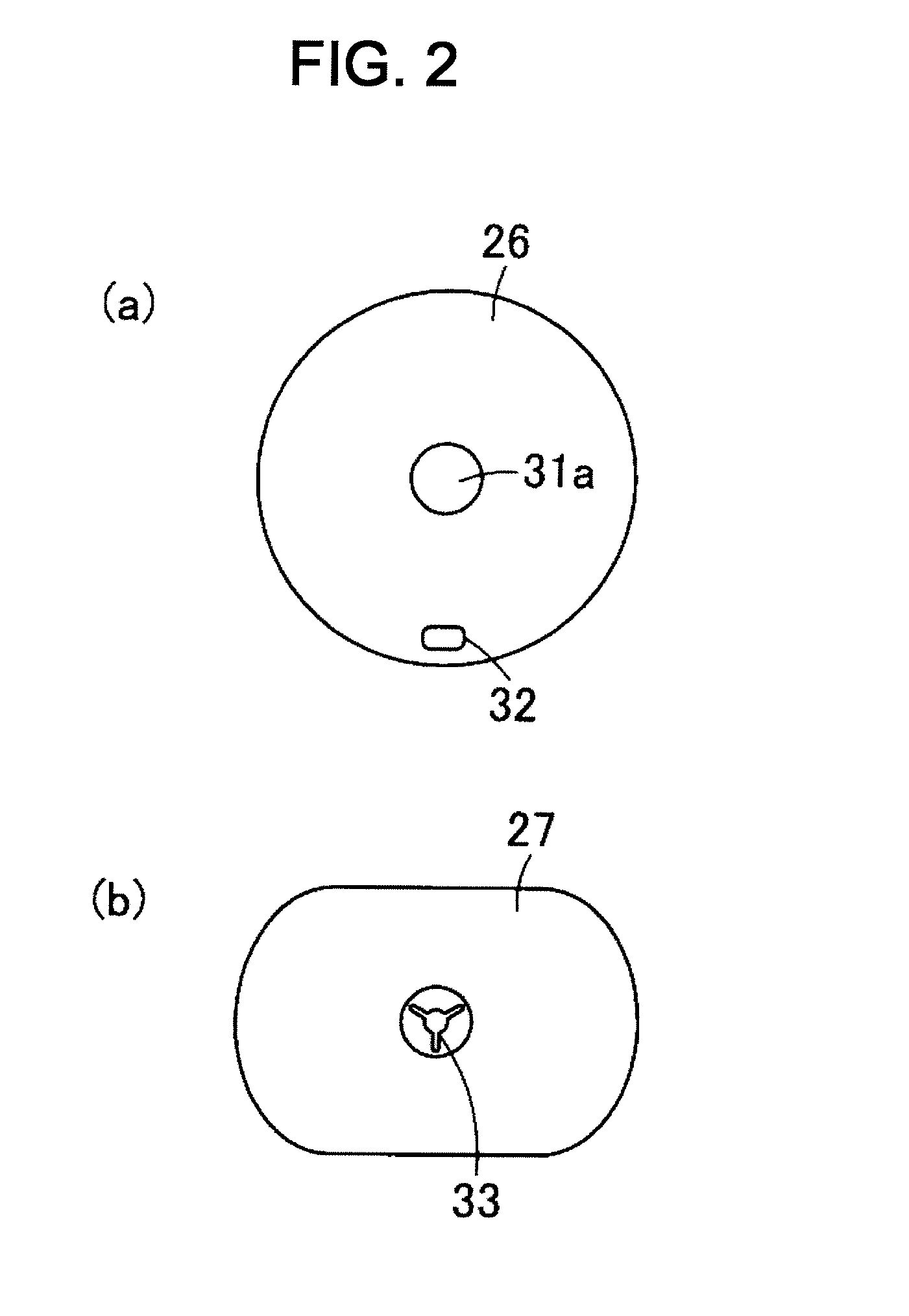

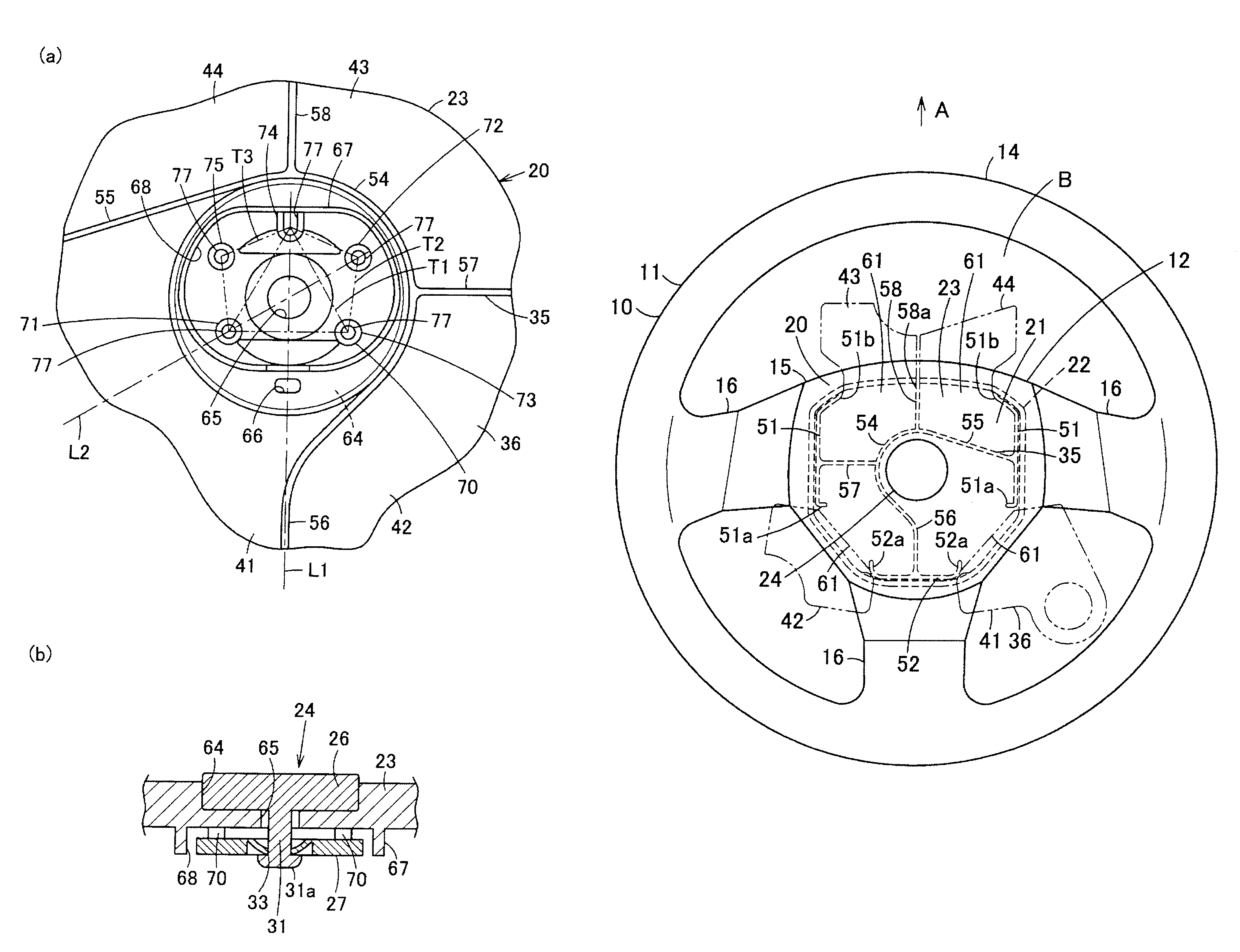

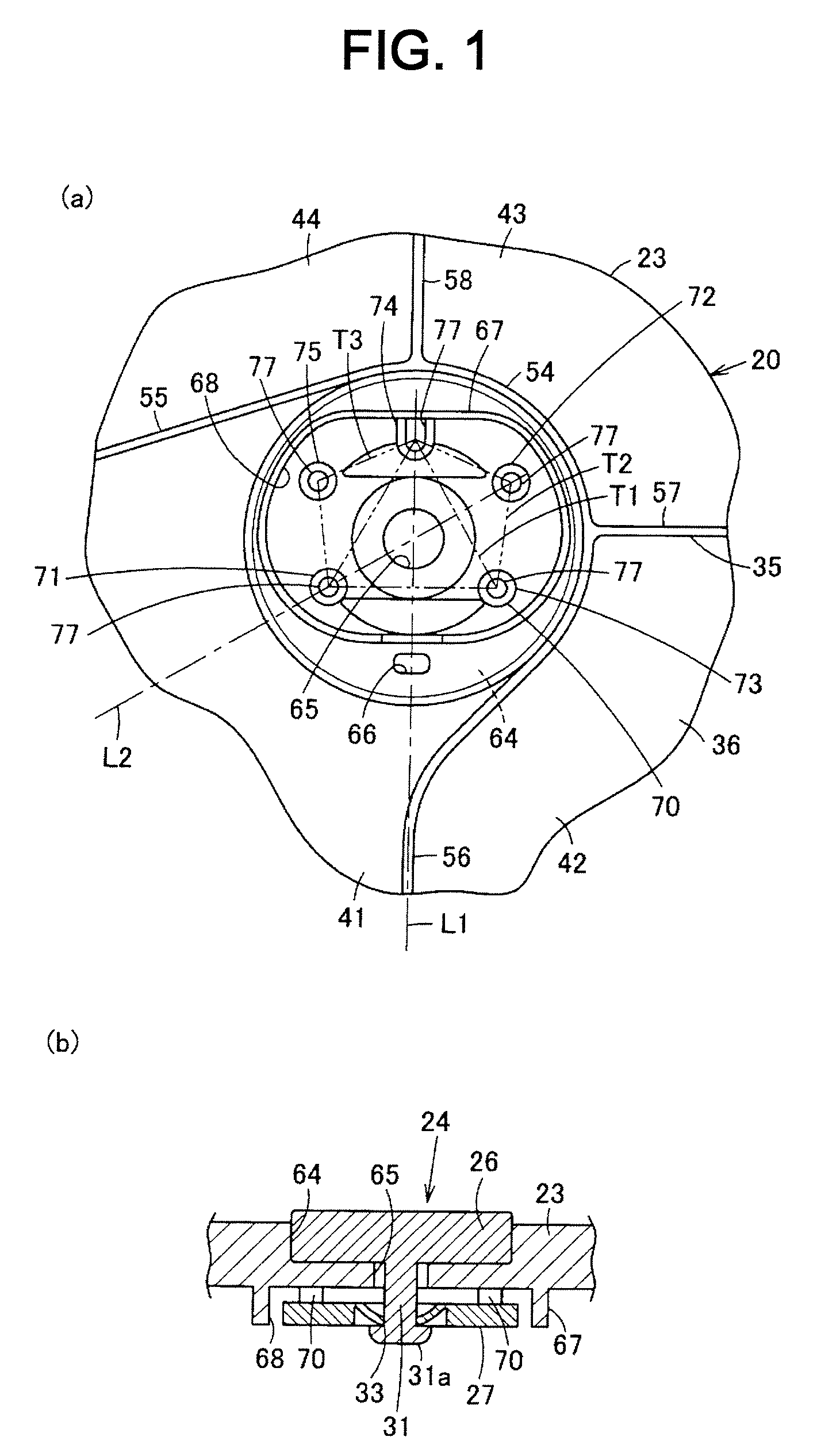

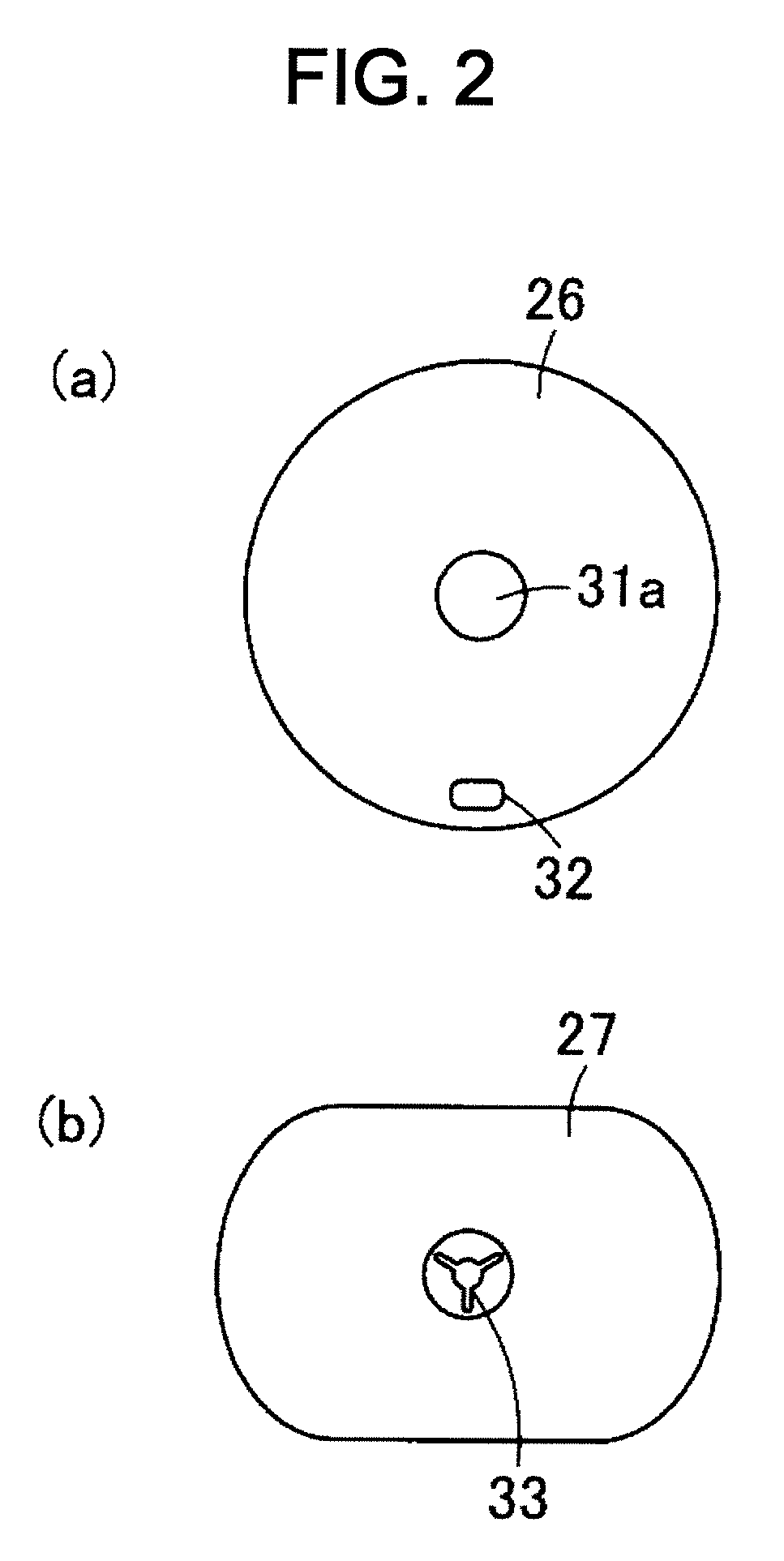

Cover member of airbag device

InactiveUS20130285355A1Improve balanceImprove workabilityPedestrian/occupant safety arrangementEngineeringCentrifugal force

First support portions 71 and 72 positioned on a predetermined straight line L2 approximately perpendicular to a broken line of a hinge portion is set in a support portion 70 that supports a back plate 27 with respect to a back face side of a door portion 36. Second and third support portions 73 and 74 positioned in line symmetry with respect to the straight line L2, are set in the support portion 70. It is possible to receive the centrifugal force, which is applied to the back plate 27 due to the expansion of the door portion 36, with good balance by the first to third support portions 71, 72, 73, and 74. An emblem 24 can be reliably fixed to the door portion 36 with preventing a fixing pin 31 from being excessively locked into a through hole 33 more than necessary.

Owner:NIHON PLAST CO LTD

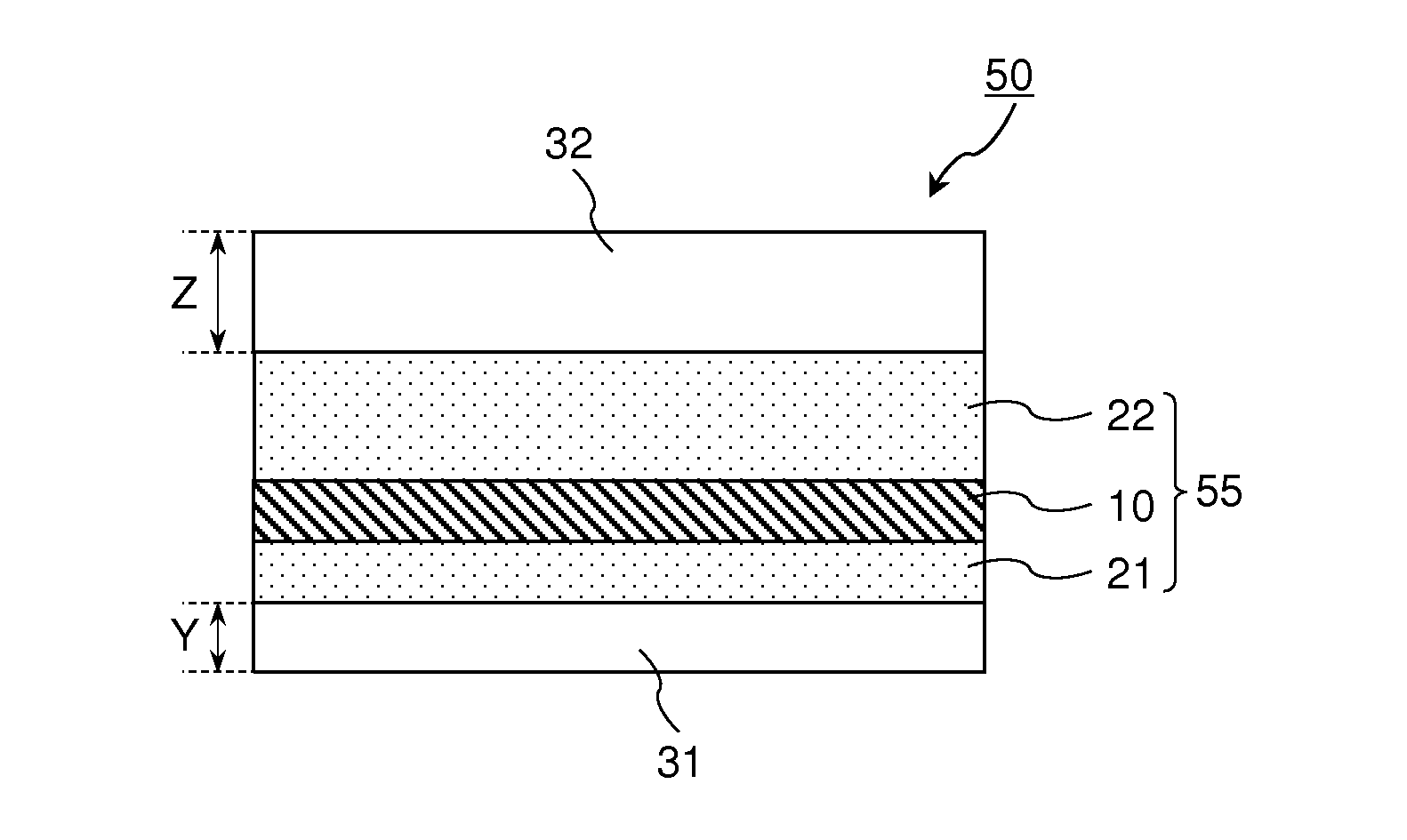

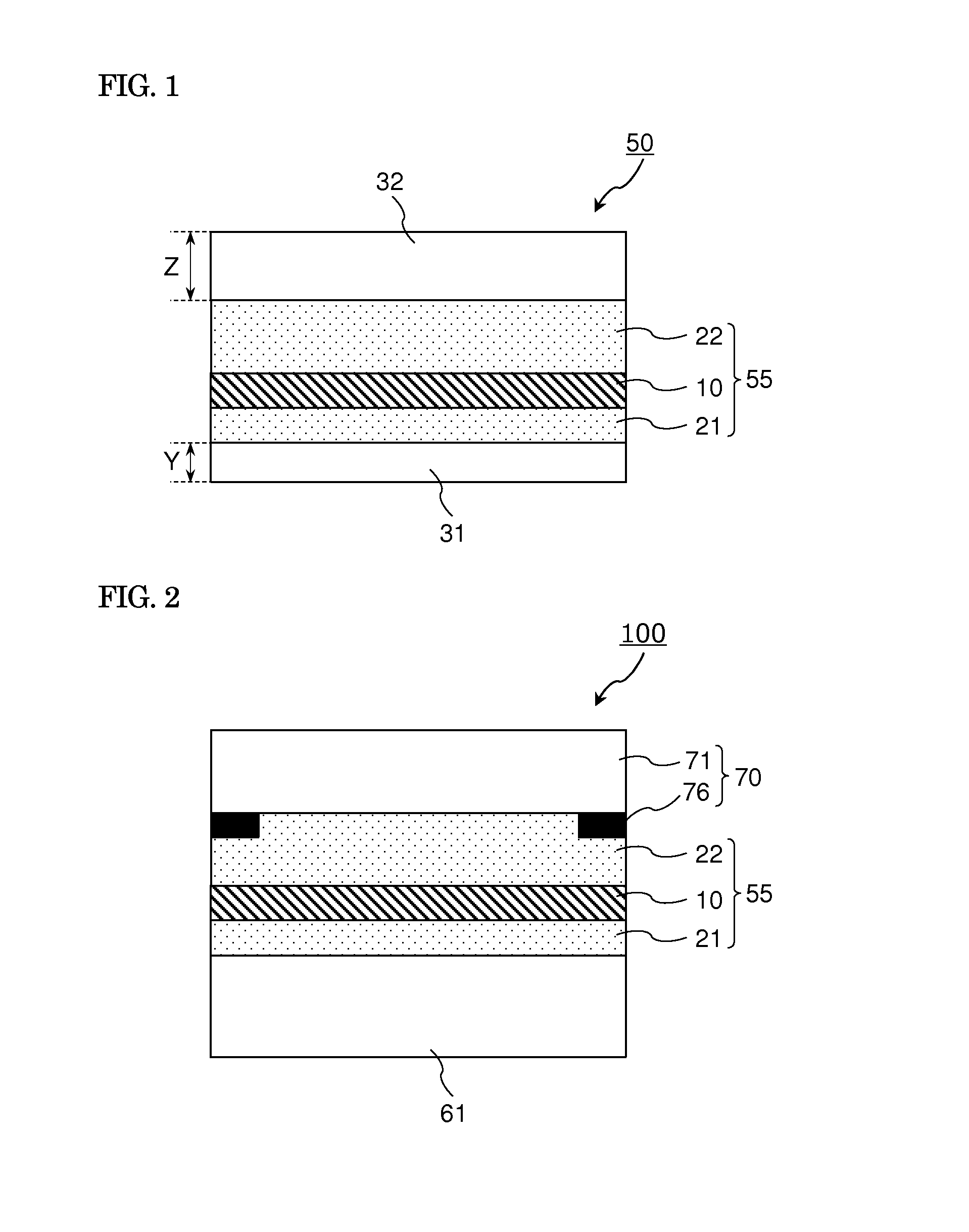

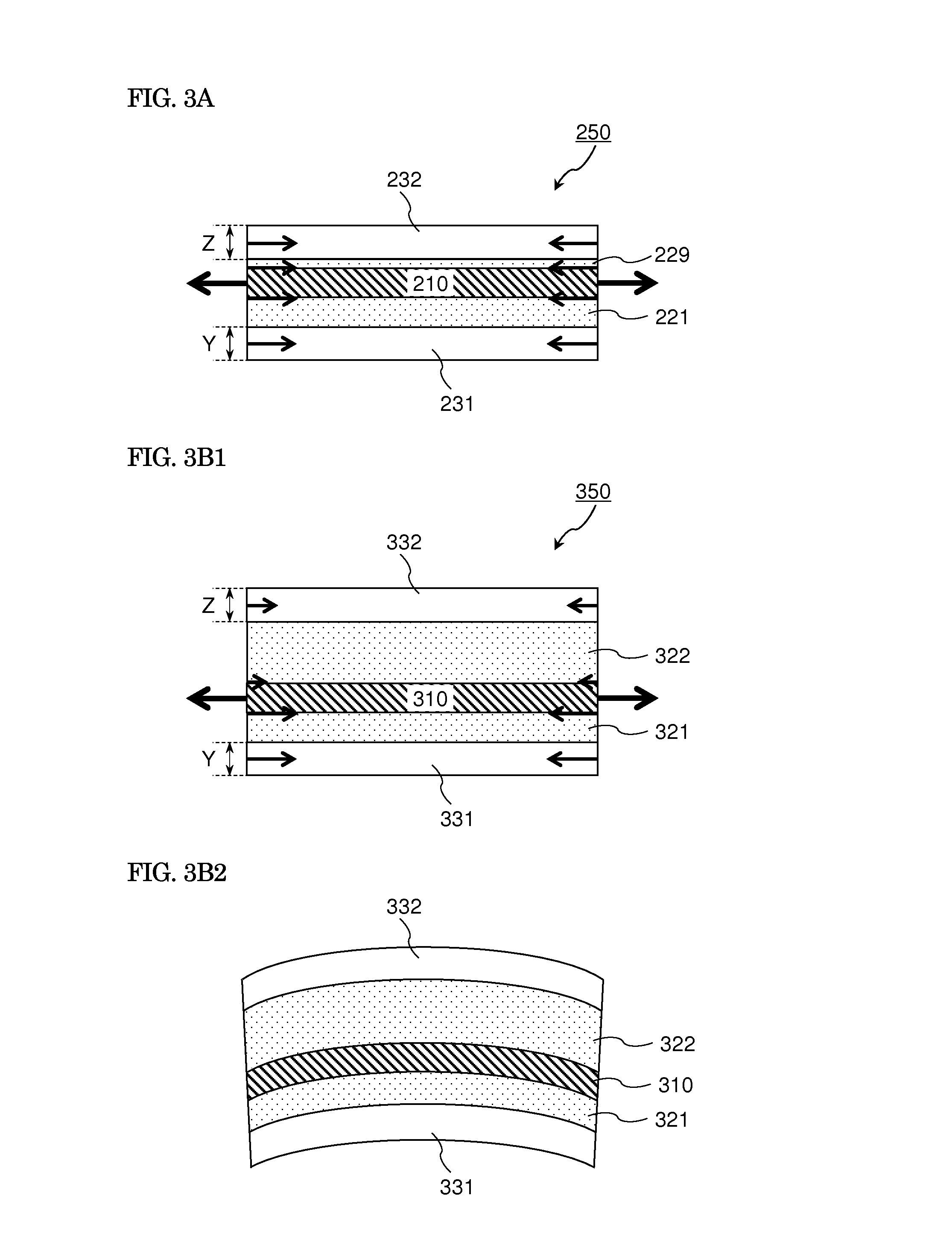

Optical film with pressure sensitive adhesive on both sides and method for producing image display device using thereof, and method for suppressing curl of optical film with pressure sensitive adhesive on both sides

ActiveUS20160109631A1Simple processImprove workabilityLamination ancillary operationsLaminationDisplay deviceEngineering

The optical film with a pressure sensitive adhesive on both sides includes a first pressure sensitive adhesive layer having a thickness of 3 μm to 30 μm on first main surface of an optical film, and a second pressure sensitive adhesive layer having a thickness of 50 μm or more on second main surface of the optical film. A first protective sheet and a second protective sheet are releasably attached on the first pressure sensitive adhesive layer and the second pressure sensitive adhesive layer, respectively. The residual stress of the second pressure sensitive adhesive layer S2 (N / cm2), the thickness of the first protective sheet Y (μm); and the thickness of the second protective sheet Z (μm) satisfy the following relationship: 20≦Y≦80; 45≦Z; and Y+0.17 Z+10.6 S2≧63.

Owner:NITTO DENKO CORP

Wind turbine generator

InactiveUS8632303B2Simplify the hardening processIncrease the cross-sectional areaPropellersPump componentsNacelleDouble wall

A wind turbine generator includes a tower, at least one blade, a hub supporting the blade, a nacelle supported by the tower and having a duct part with an intake port and an exhaust port, and a heat exchanger provided in the duct part and cooling a cooling medium for a heat-producing component inside the tower or nacelle. The wall of the nacelle has a double wall structure constituted of an inner wall and an outer wall in an area where the duct part is provided. The inner wall forms a bottom surface of the duct part and has a curved portion which curves inward toward a center line of the nacelle with increasing distance from the hub. The duct part increases in cross-section from a side of the intake port to a side of the exhaust port at least in an area where the curved portion is formed.

Owner:MITSUBISHI HEAVY IND LTD

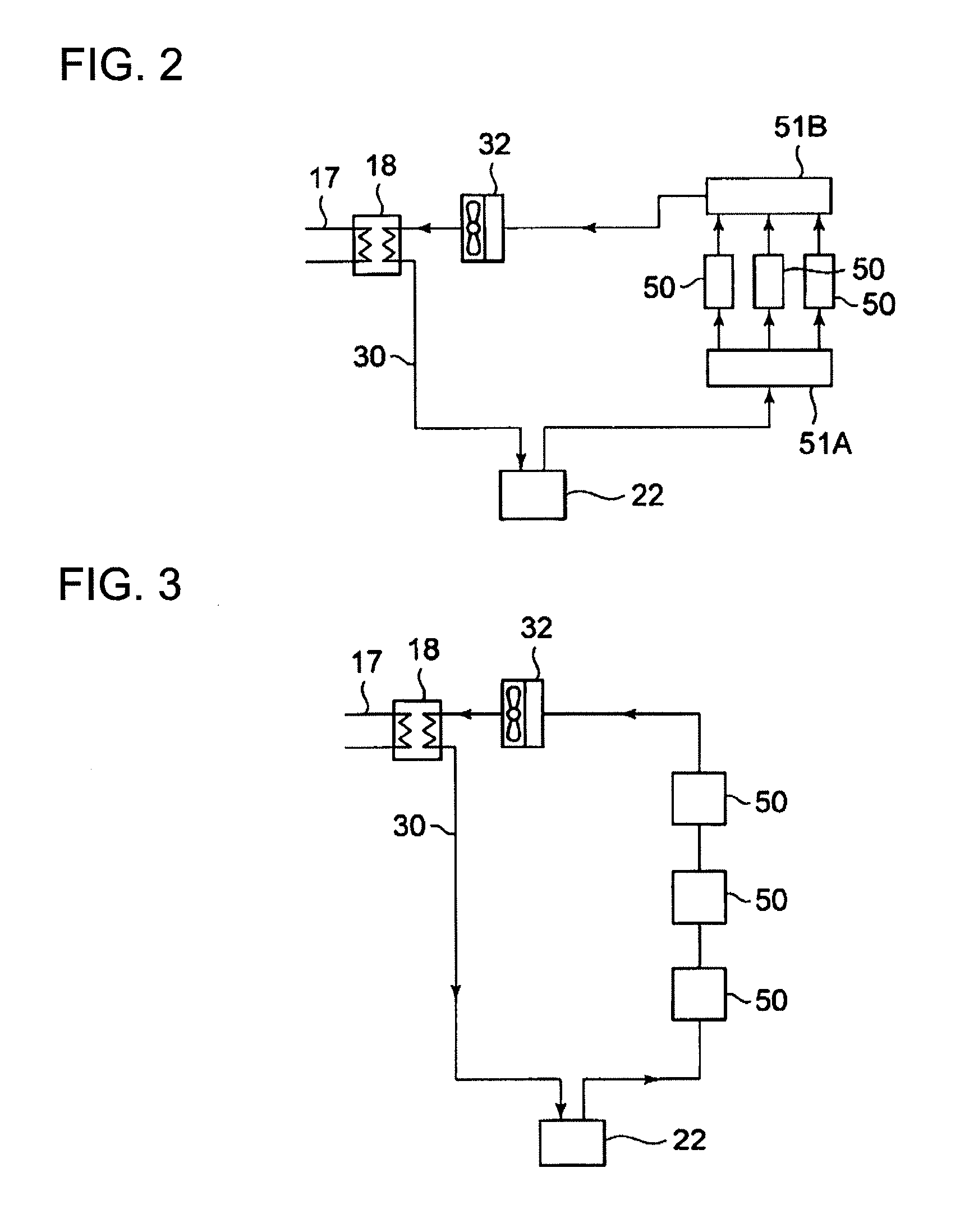

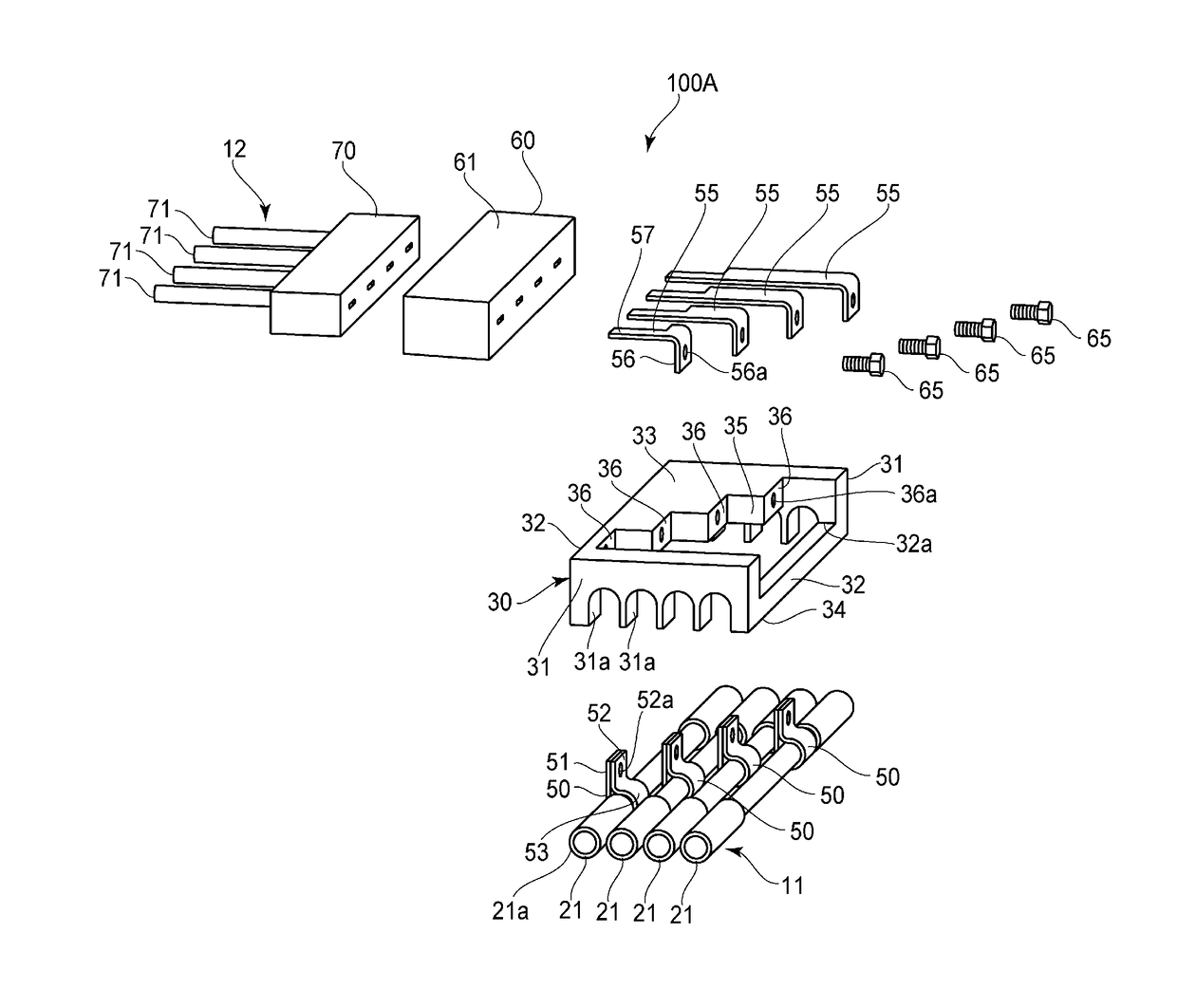

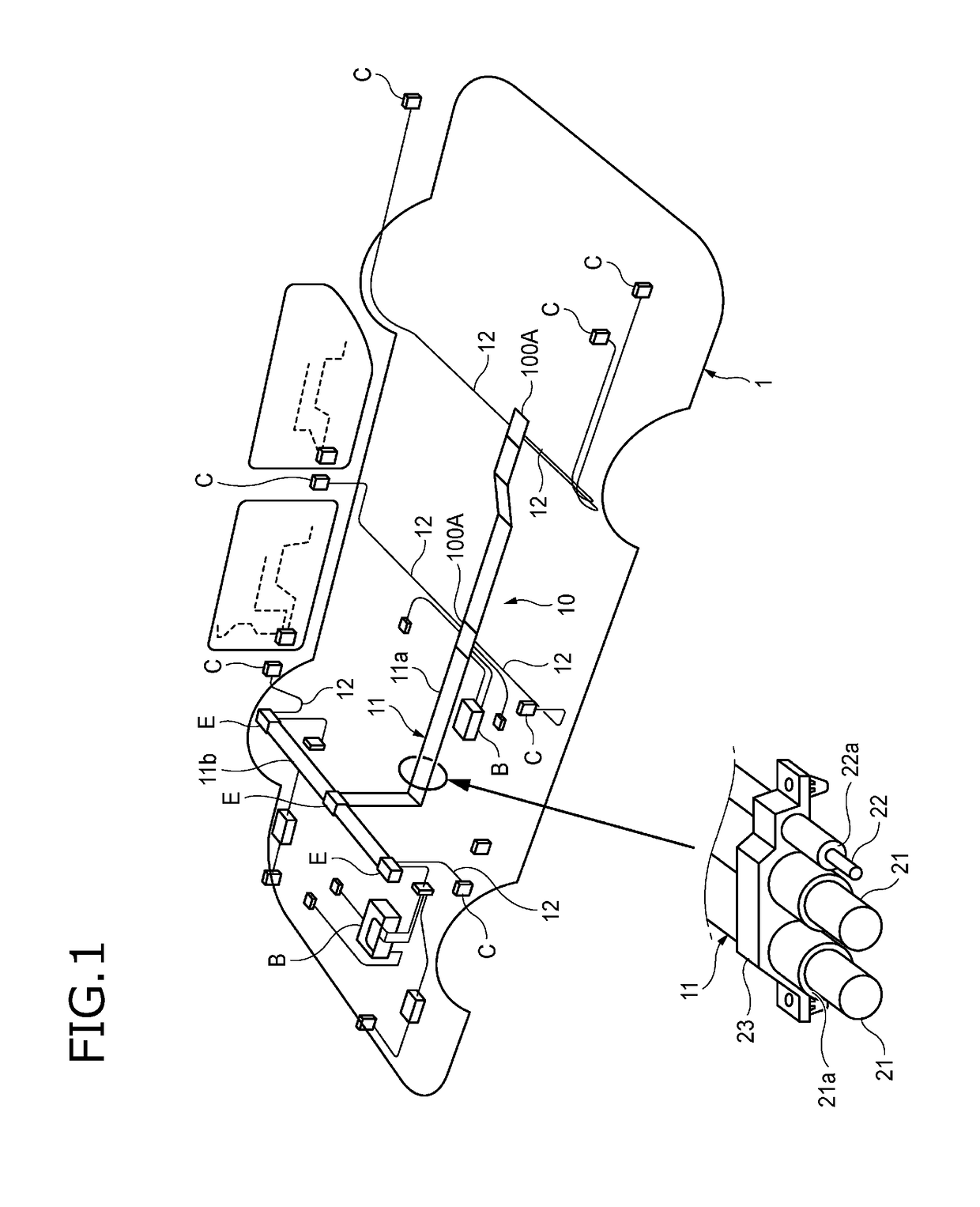

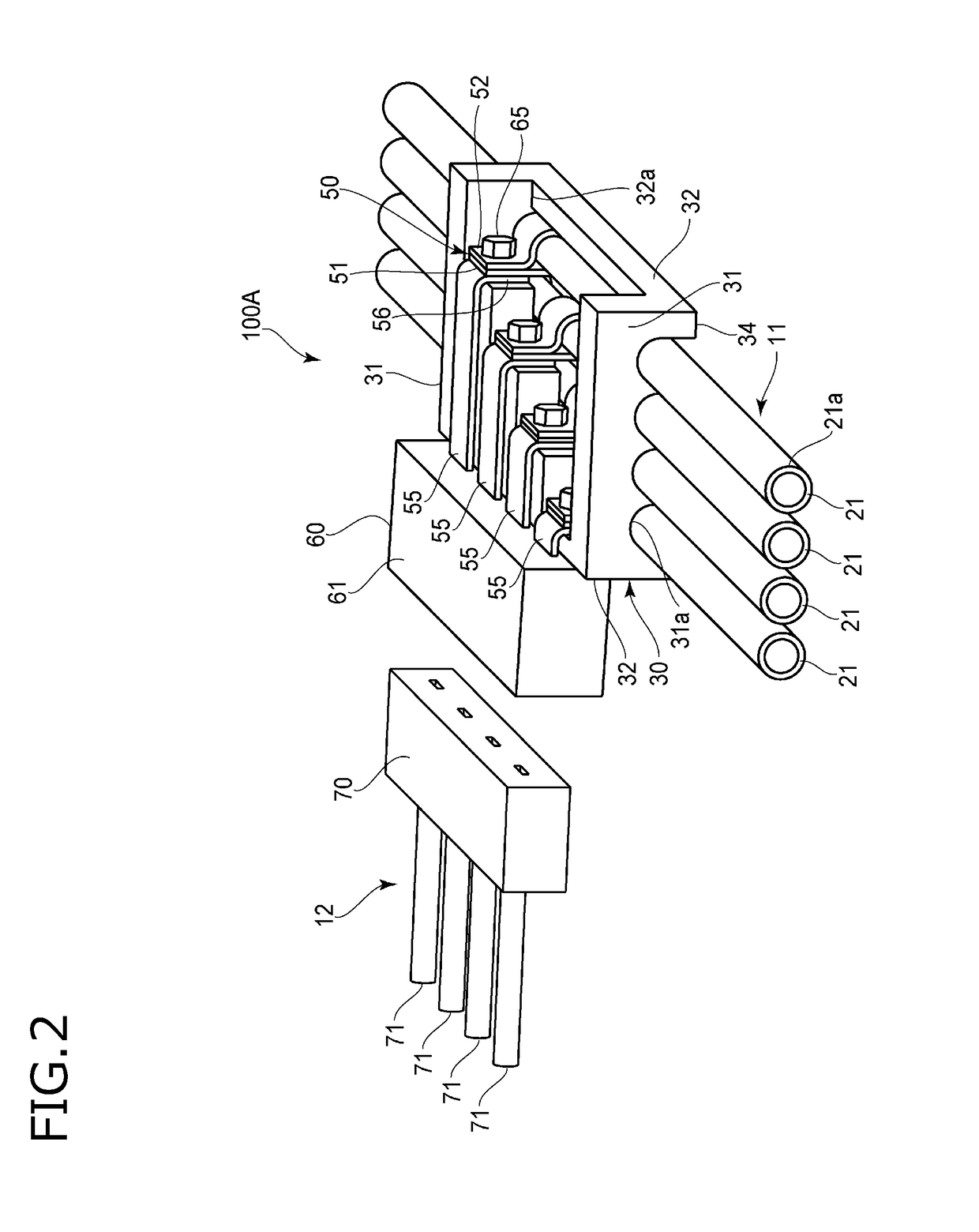

Branching structure and wire harness

ActiveUS20180118138A1Improve connection reliabilitySave spaceVehicle connectorsCoupling device detailsElectrical conductorElectrical connection

A branching structure for connecting a branch harness to a main line harness, includes connection terminals configured to electrically connect branch lines of the branch harness to main lines of the main line harness respectively, a terminal block on which the connection terminals are supported, and fasteners that respectively fasten the connection terminals onto the terminal block. Each of the connection terminals has a belt-shaped wound portion to be wound around a corresponding one of the main lines. The wound portion is fastened by a corresponding one of the fasteners so that both ends of the wound portion come closer to each other and a center portion of the wound portion tightens around the main line so as to be brought into surface contact with a bar conductor of the main line.

Owner:YAZAKI CORP

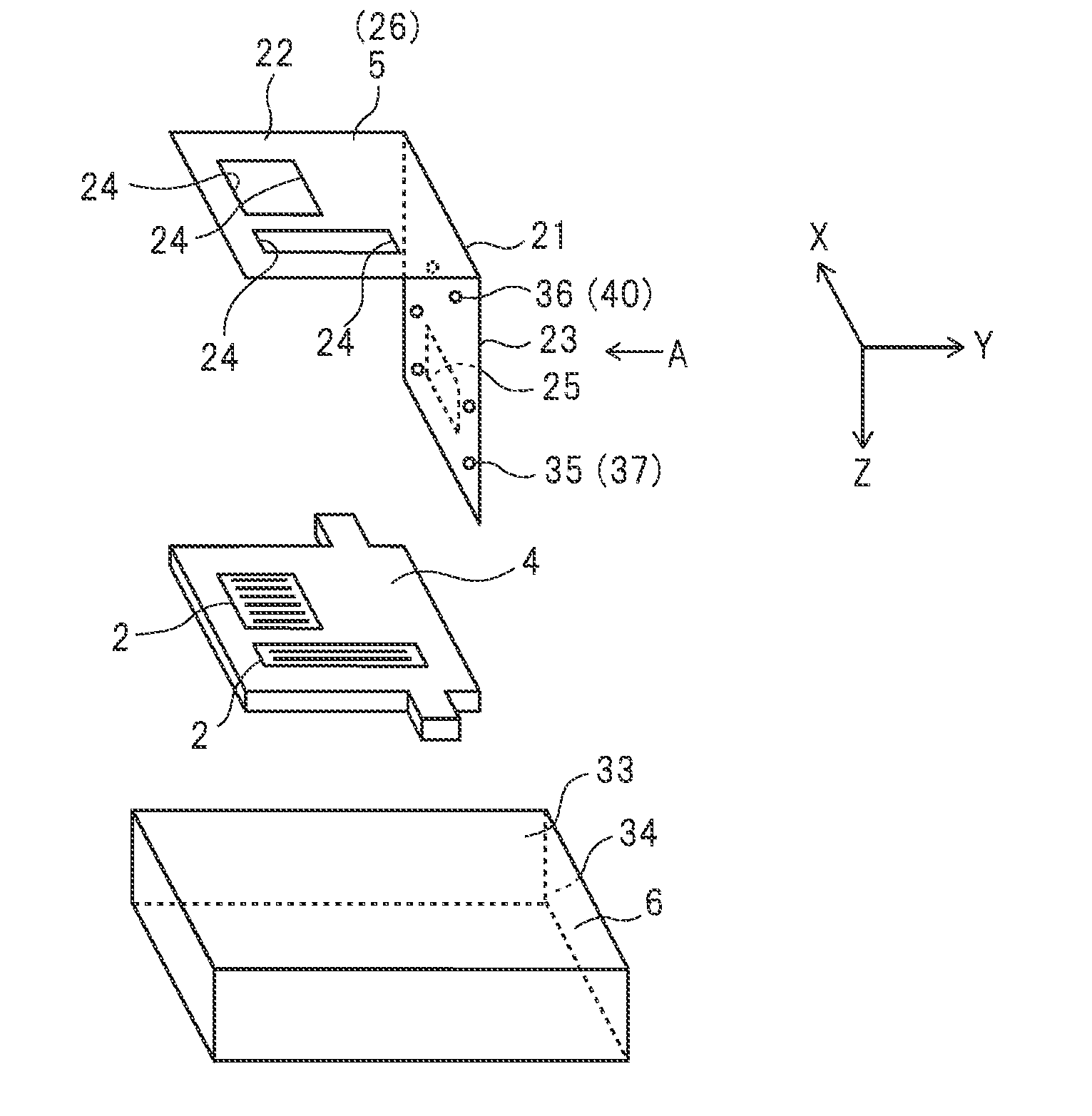

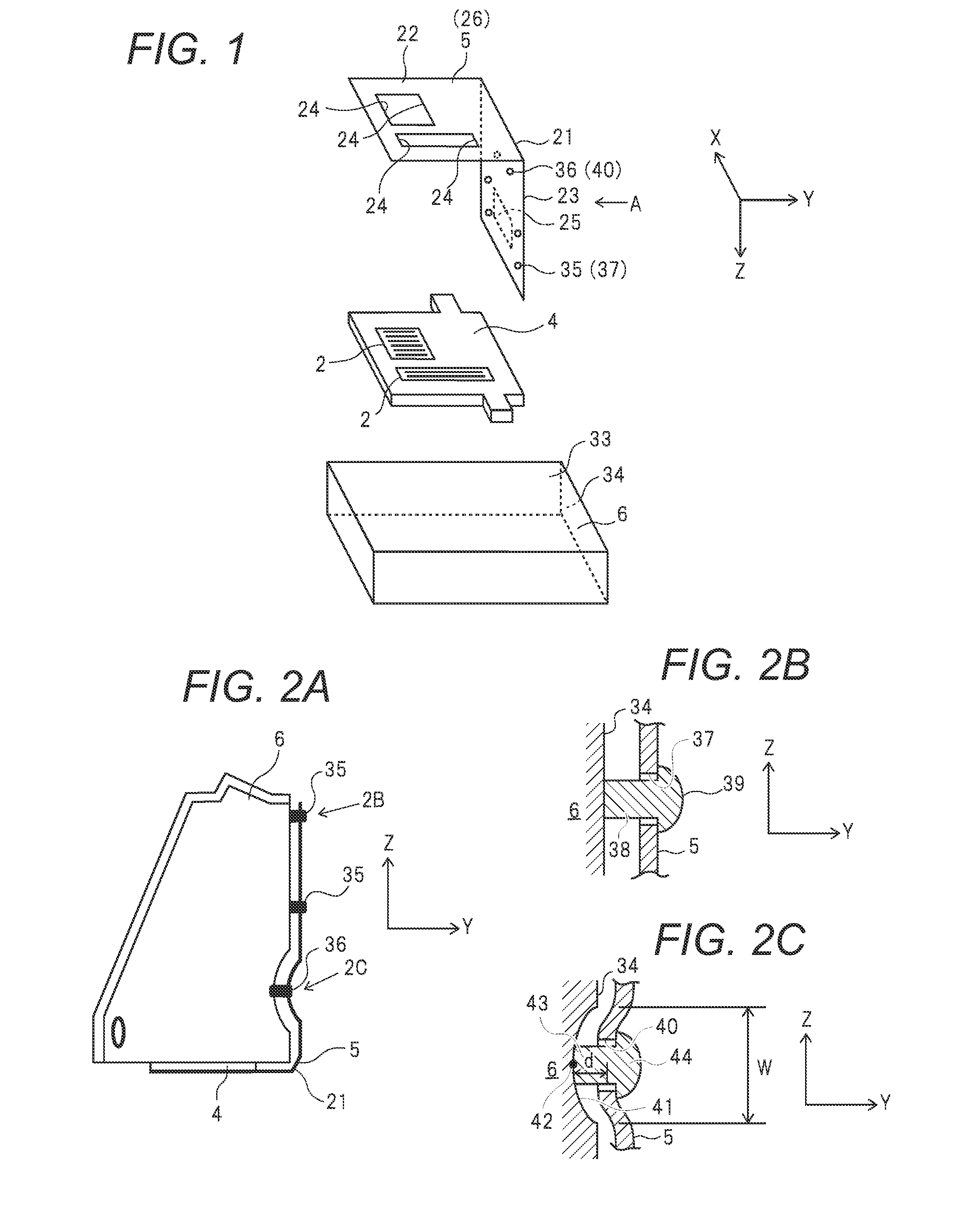

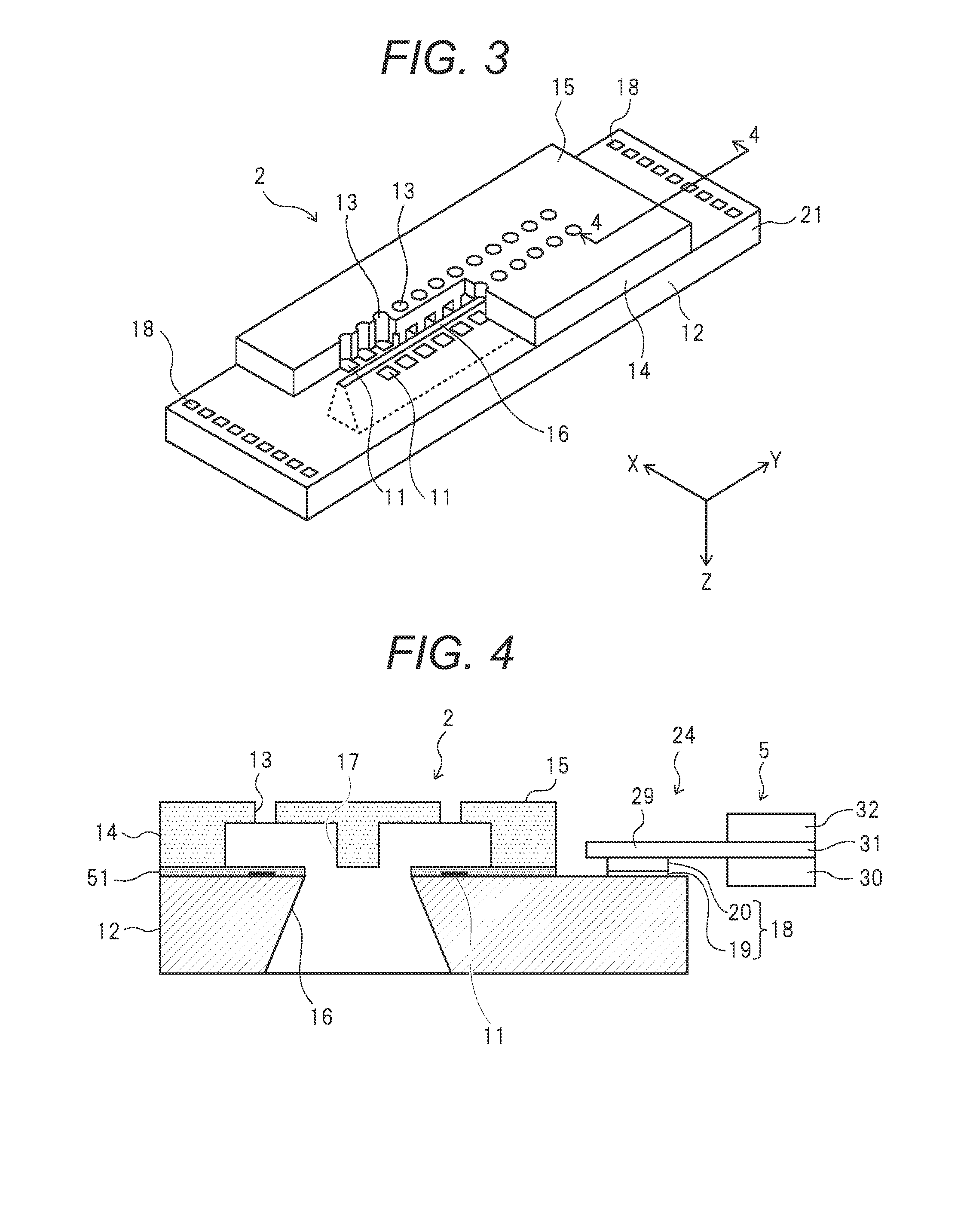

Liquid ejection head and method of producing the same

ActiveUS20150130873A1Protrusion suppressionPrinted circuit assemblingOther printing apparatusEngineeringRecord element

A liquid ejection head, including a recording element substrate for ejecting liquid in response to an externally supplied electrical signal; an electrical wiring board having a first and second part mutually joined via a bent portion, the first part having an electrical joint portion for supplying the signal to the substrate, the second part having an electrical signal input portion into which the signal is input and to which the joint portion is connected; and a housing having a first and second surface mutually adjoining, the first and second surfaces respectively supporting the first and second parts. The second part is fixed to the second surface at plural first fixing positions around the input portion. The second surface has a depressed portion formed closer to the bent portion than the first fixing positions. The second part is fixed to the housing at a second fixing position inside the depressed portion.

Owner:CANON KK

Production method of multilayer printed wiring board and multilayer printed wiring board

ActiveUS20130319749A1Improve reliabilityProtrusion suppressionInsulating layers/substrates workingElectrical connection printed elementsEngineeringIrradiation

Multilayer printed wiring boards may be prepared by forming a via hole by laser irradiation in insulating layer formed by a prepreg, comprised of a glass cloth impregnated with a thermosetting resin composition, and subjecting the via hole to a glass etching treatment with a glass etching solution and then to a desmear treatment with an oxidizing agent solution. By such a process, etch back phenomenon and excessive protrusion of glass cloth from the wall surface of a via hole can be sufficiently suppressed, and a highly reliable via can be formed. Particularly, a highly reliable via can be formed in a small via hole having a top diameter of 75 μm or below.

Owner:AJINOMOTO CO INC +1

Magnetic head for perpendicular magnetic recording and method of manufacturing same

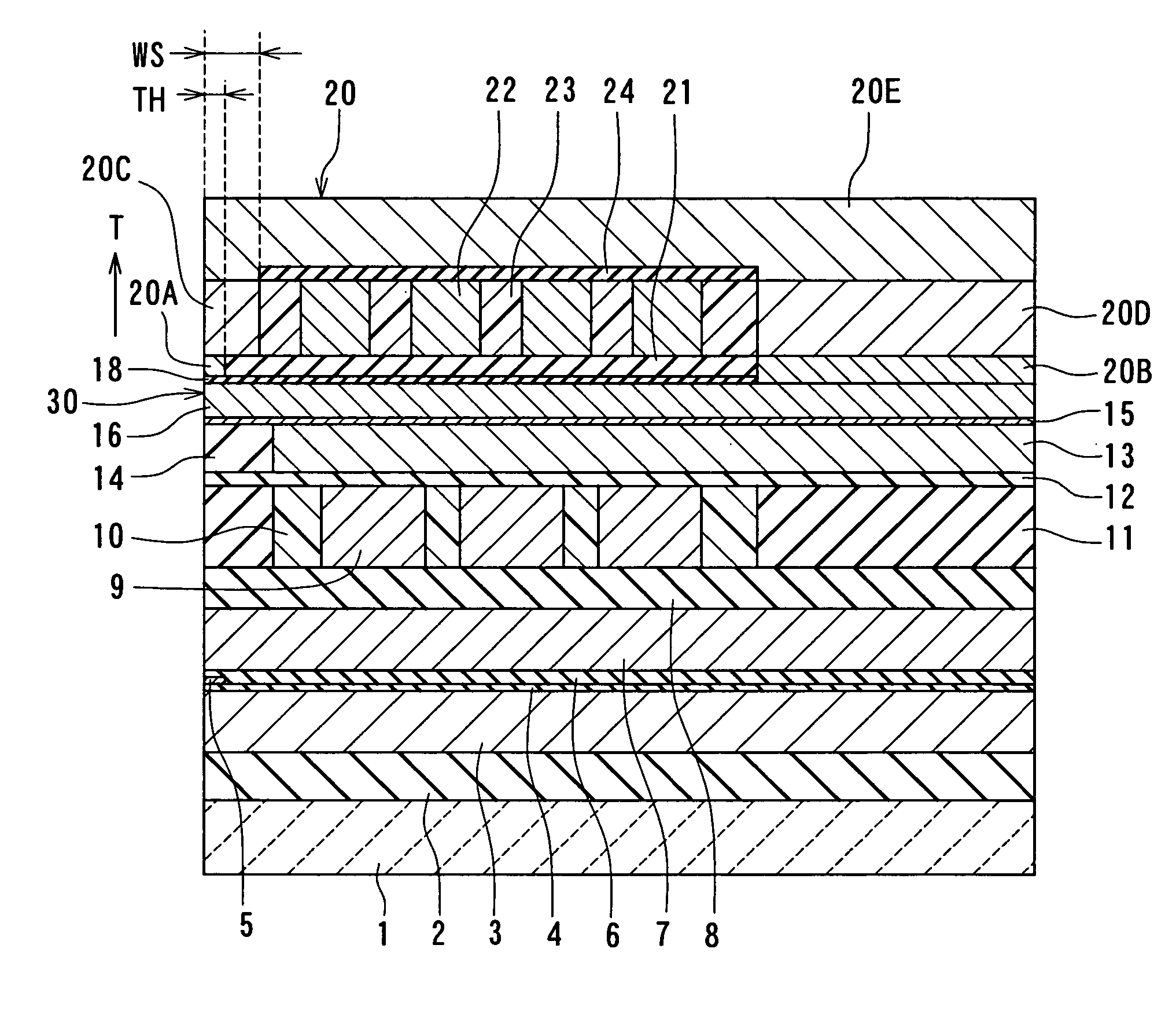

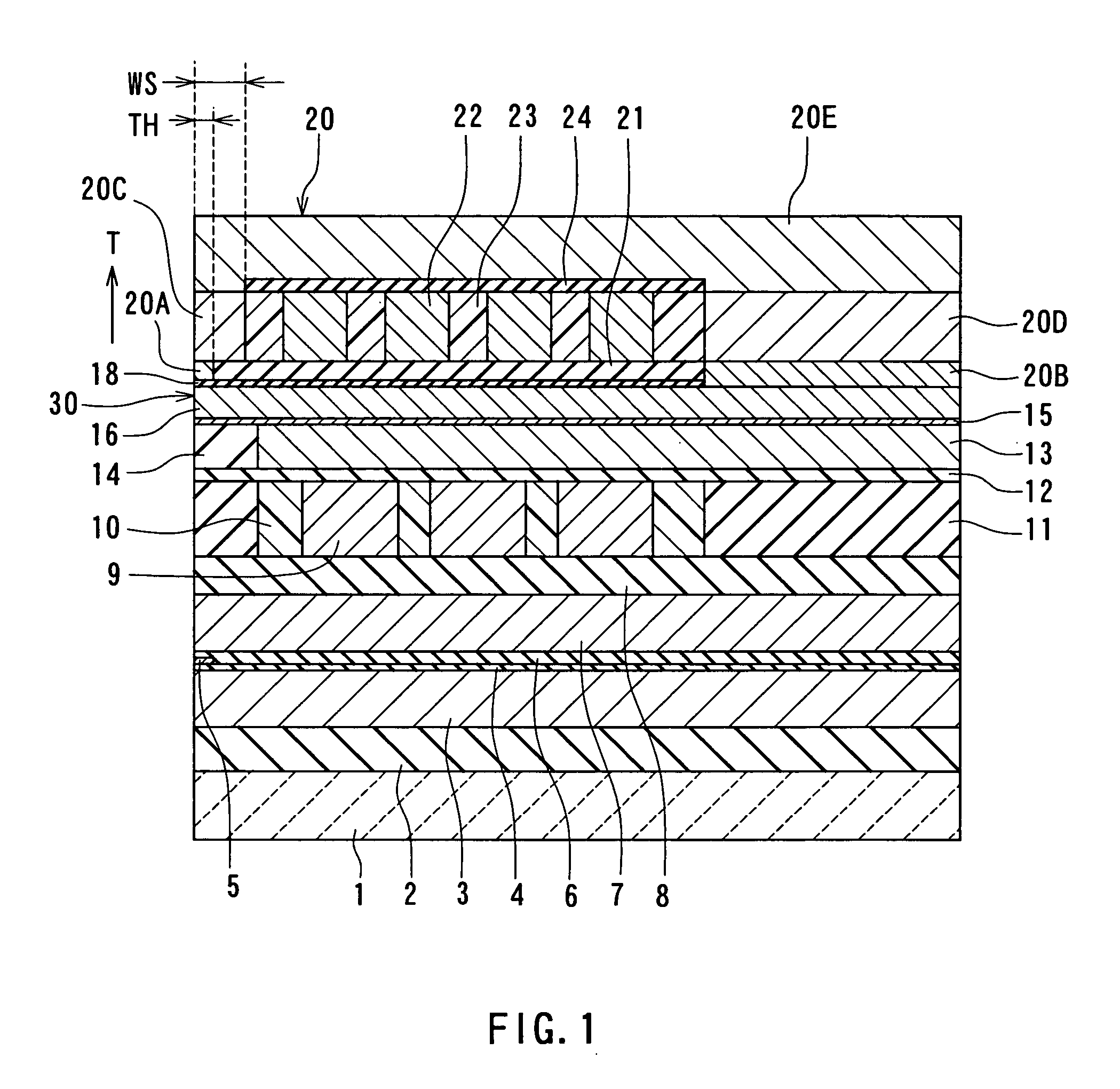

ActiveUS20050280937A1Protrusion suppressionDefine the throat height with accuracyConstruction of head windingsManufacture head surfaceCouplingEngineering

A magnetic head comprises a pole layer, a gap layer, a shield layer, a nonmagnetic layer, and a coil. The shield layer incorporates: a first layer disposed on the gap layer; a second layer disposed on the first layer; a two layered coupling layer disposed on a region of the pole layer where an opening of the gap layer is formed; and a third layer disposed to couple the second layer to the coupling layer. The first layer defines throat height TH. The nonmagnetic layer is disposed on a side of the first layer. The coil is disposed on the nonmagnetic layer on a side of the second layer.

Owner:HEADWAY TECH INC

Leathered steering wheel

InactiveUS7210372B2High tensile strengthEasy to seeControlling membersMechanical apparatusSteering wheelAbutment

In a leathered steering wheel, a leather layer is so arranged as to cover a covered layer of a ring part, and the leather layer is formed by stitching, along the circumferential direction of the ring part, a plurality of leather materials to one another, and the end portions of the leather material are structured with thin portions formed by thinning the back sides of the end portions such that thickness around stitching portions is lowered, wherein a length L1 from the stitching portion to the end face of each leather material is set to be substantially equal to or slightly smaller than a thickness t1 of a main portion of the leather material, and the end face is brought into abutment to the covered layer.

Owner:TOYODA GOSEI CO LTD +1

Magnetic head for perpendicular magnetic recording and method of manufacturing same

ActiveUS7609479B2Protrusion suppressionSuppress the wide-range adjacent track eraseRecord information storageHeads for perpendicular magnetisationsCouplingMagnetic flux

A pole layer has an end face located in a medium facing surface, allows a magnetic flux corresponding to a magnetic field generated by a coil to pass therethrough, and generates a write magnetic field for writing data on a recording medium by using a perpendicular magnetic recording system. A shield incorporates: a first layer having an end face located in a region of the medium facing surface forward of the end face of the pole layer along the direction of travel of the recording medium; a second layer disposed in a region sandwiching the pole layer with the first layer; a first coupling portion coupling the first layer to the second layer without touching the pole layer; and a second coupling portion coupling the pole layer to the second layer and located farther from the medium facing surface than the first coupling portion.

Owner:HEADWAY TECH INC

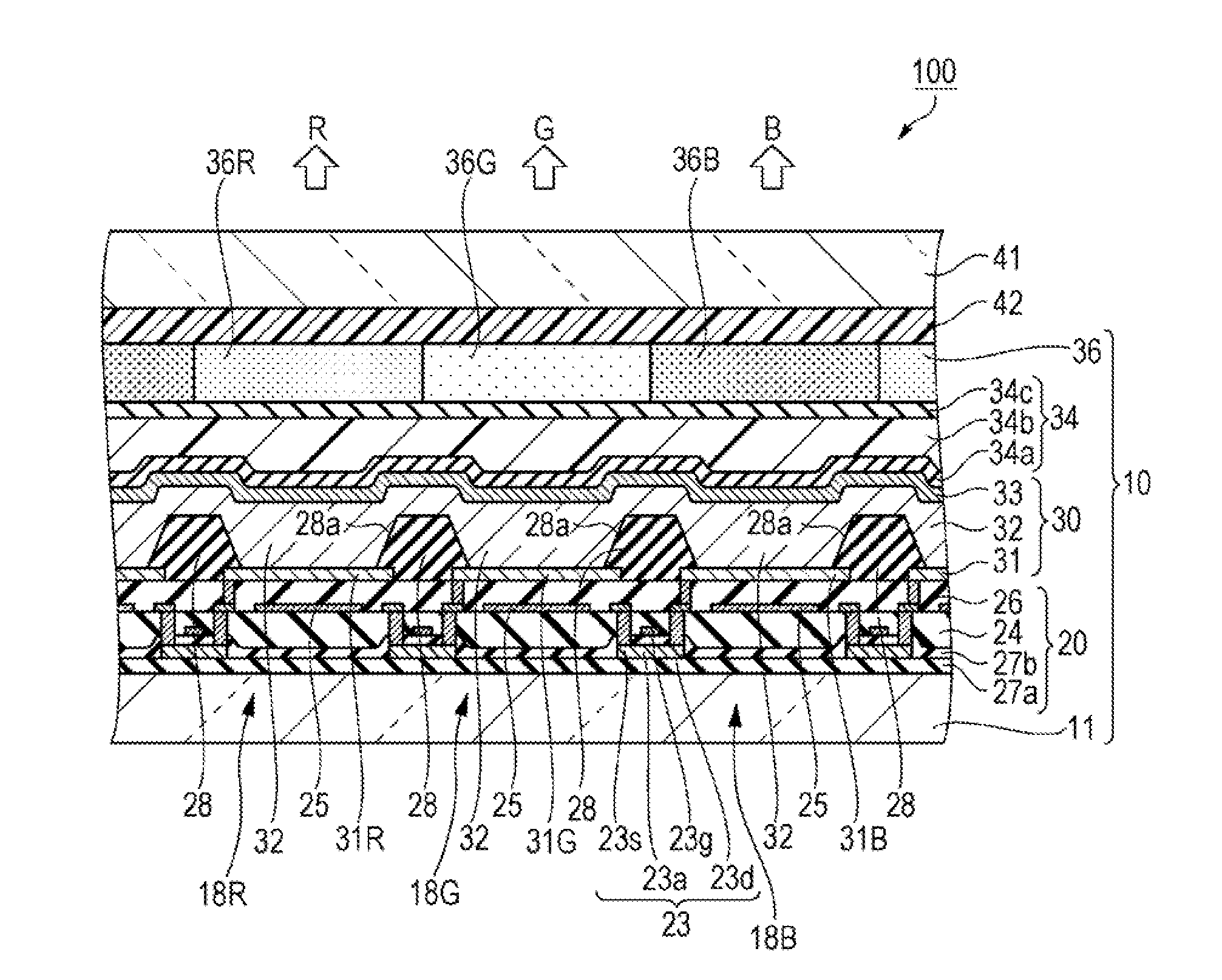

Organic el device and electronic apparatus

ActiveUS20160226018A1Avoid breakingInfiltration can be suppressedSolid-state devicesSemiconductor/solid-state device manufacturingOrganic devicesEngineering physics

Owner:SEIKO EPSON CORP

Cover member of airbag device

InactiveUS9027955B2Improve manufacturabilityIncrease productivityStampsPedestrian/occupant safety arrangementAirbagCentrifugal force

First support portions 71 and 72 positioned on a predetermined straight line L2 approximately perpendicular to a broken line of a hinge portion is set in a support portion 70 that supports a back plate 27 with respect to a back face side of a door portion 36. Second and third support portions 73 and 74 positioned in line symmetry with respect to the straight line L2, are set in the support portion 70. It is possible to receive the centrifugal force, which is applied to the back plate 27 due to the expansion of the door portion 36, with good balance by the first to third support portions 71, 72, 73, and 74. An emblem 24 can be reliably fixed to the door portion 36 with preventing a fixing pin 31 from being excessively locked into a through hole 33 more than necessary.

Owner:NIHON PLAST CO LTD

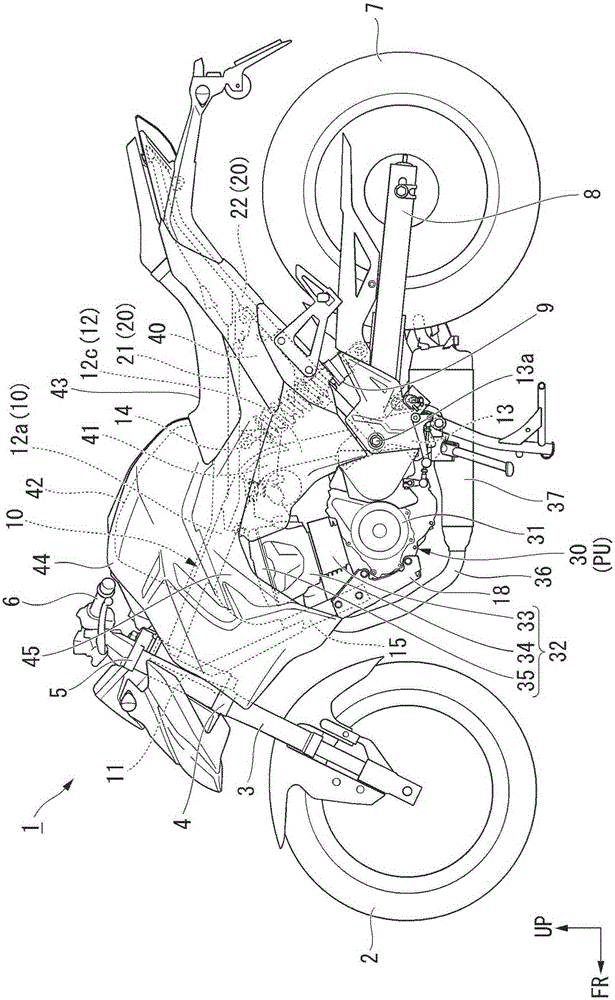

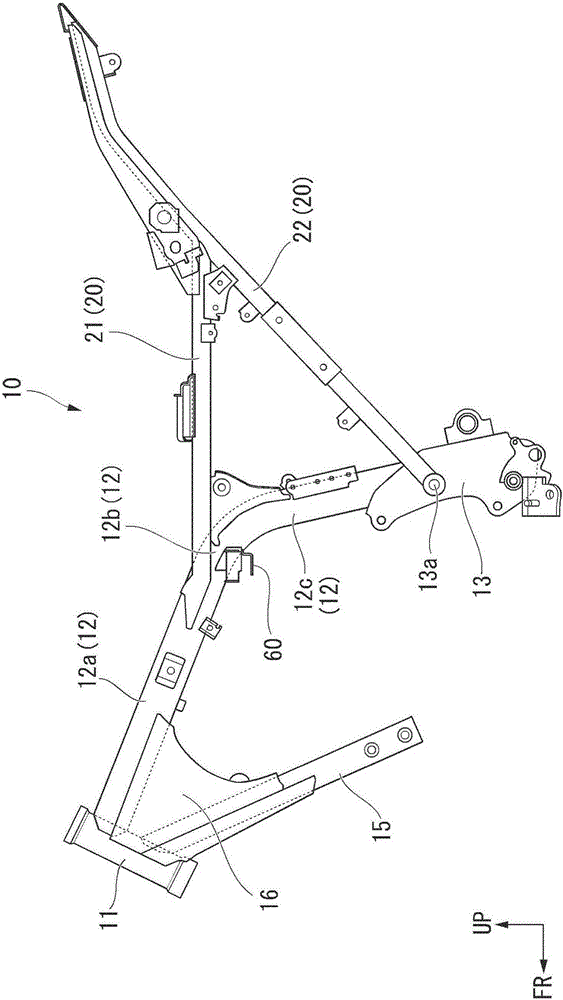

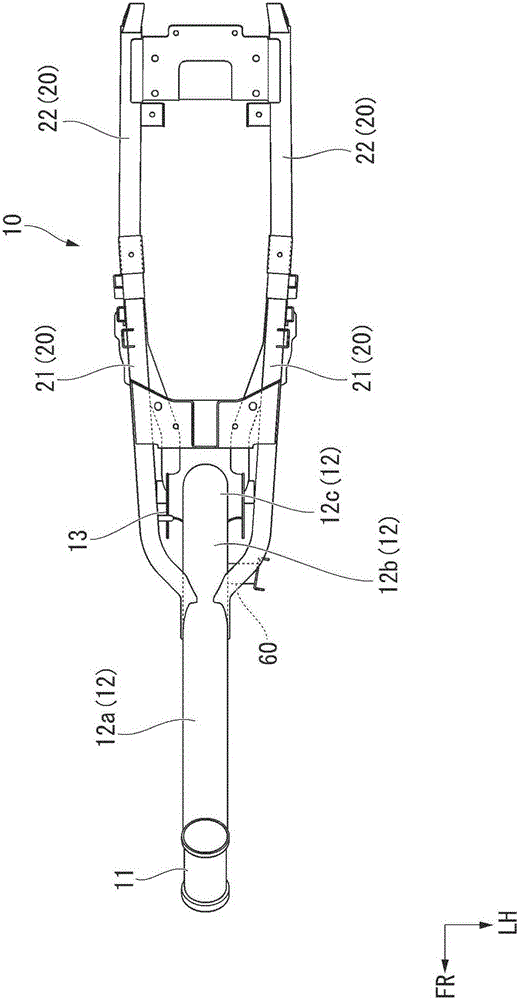

Bestriding vehicle

ActiveCN106379453AEasy to handleSmall footprintFuel tanksMotorcyclesAir filterMechanical engineering

The invention provides a bestriding vehicle. A main framework (12) comprises a backward extending part (12a) backwardly extending from a head pipe (1), and a downward extending part (12c) downwardly extending from the back end part of the backward extending part (12a). An engine (30) is configured under the backward extending part (12a) and in front of the downward extending part (12c); at least one part of an air filter (40) is configured behind the downward extending part (12c) of the main framework (12); the air filter (40) and an air absorbing channel (41) connected with an air absorbing part of the engine (30) are arranged outside one side of left and right sides of a vehicle width direction of the downward extending part surrounding the main framework (12); an absorbing tank (52) when side-looked is overlapped with at least one part of the absorbing channel (41) and configured in front of the downward extending part (12c) of the main framework (12) in a non-overlapping way; and a cleaning pipe (56) is configured under the backward extending part (12a) of the main framework (12).

Owner:HONDA MOTOR CO LTD

Structure for connecting crimping terminal and electric wire

InactiveUS9774099B2Protrusion suppressionHigh densityCouplings bases/casesConnections effected by permanent deformationElectrical conductorElectric wire

A structure for connecting a crimping terminal and an electric wire, includes: the crimping terminal that is provided with an electric wire connection section to be crimped to the electric wire, the electric wire connection section including a conductor crimping section and a sheath crimping section which are successively disposed to each other; a waterproof material that includes an opening for allowing the conductor and the conductor crimping section to make contact with each other, has a size to surround the conductor and the sheath which are to be crimped, and is installed between the electric wire connection section and the electric wire; and a recess that is formed on at least one of the electric wire connection section and the sheath, and a bulged and deformed section of the waterproof material deformed by the electric wire connection section which is caulked and crimped enters.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com