Antenna coil and RFID-use tag using it, transponder-use antenna

A technology of antenna coils and transponders, which can be used in the direction of electrical alarms, record carriers used by machines, and mid-position feeds between antenna terminals, which can solve problems such as large intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

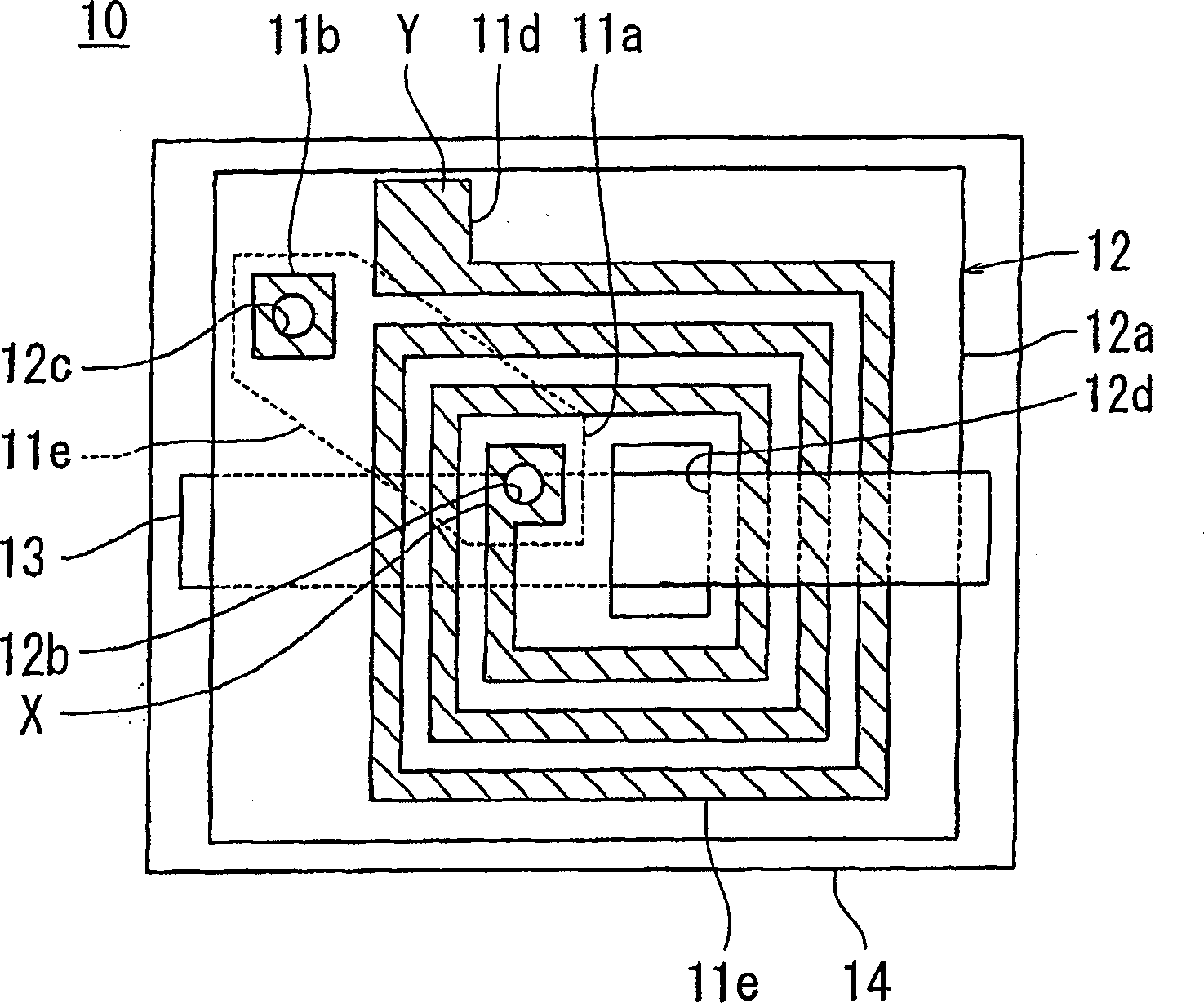

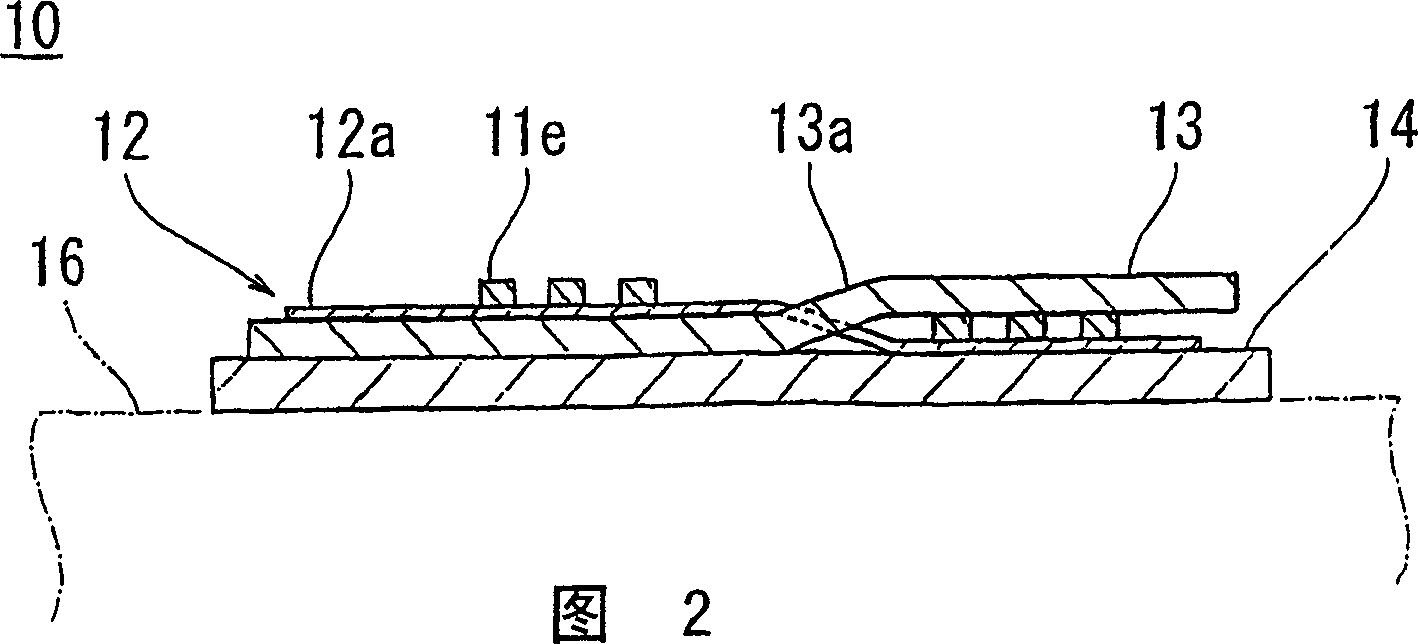

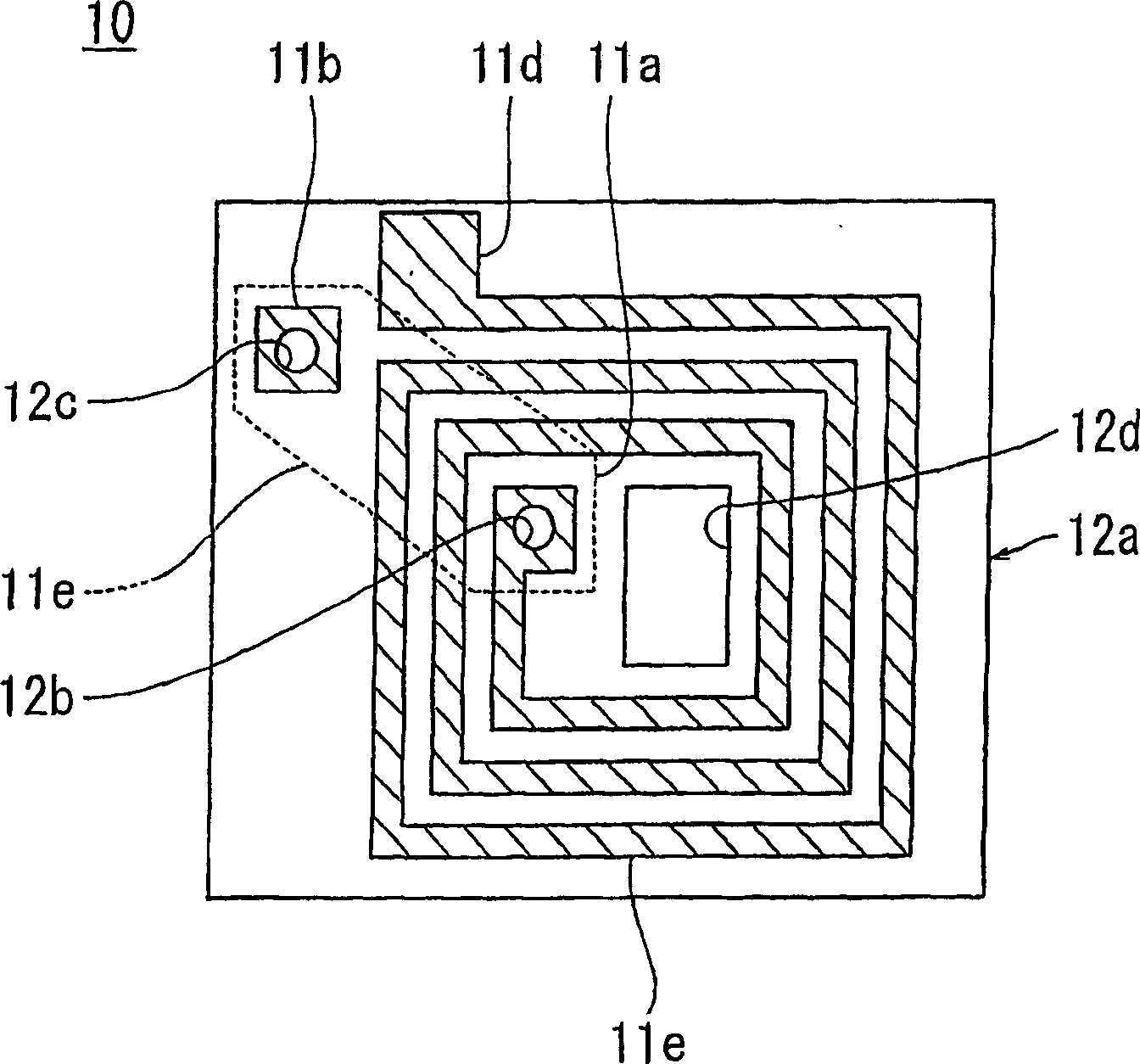

[0122]First, an air-core coil is formed on one main surface of an electrical insulating film. As the electrical insulating film, a polyimide film having a thickness of 50 μm and a length and width of 50 mm was used. Copper foils with a thickness of 35 μm are stacked on one main surface of the polyimide film, and these copper foils are etched to form a rectangular spiral wound four times on the other main surface of the polyimide film. hollow coil. The conductor constituting this air-core coil was formed with a width of 0.8 mm. The outer shape of the air-core coil formed from this conductor is 18 mm x 47 mm.

[0123] Secondly, by injection molding the mixture obtained after mixing 92% by weight of carboxyl iron powder and nylon resin, a magnetic core part 13 composed of a composite material with a thickness of 0.87 mm and an outer shape of 35 mm × 52 mm is obtained. A hole of 35 mm x 1 mm was opened in the electrical insulating film, and the magnetic core member 13 was inser...

experiment example 2

[0125] On the same electrical insulating film as in Experimental Example 1, the same air-core coil having the same conductor configuration as in Experimental Example was formed by the same steps as in Experimental Example 1. Separately, another paint obtained by mixing amorphous flakes, acrylic resin, and ethyl acetate as a solvent in a weight ratio of 70:10:20 was prepared. This paint was applied and dried to the entire surface of one main surface of a polyethylene terephthalate film having a thickness of 0.1 mm to obtain a magnetic coating film having a thickness of 0.1 mm. The film with the magnetic coating film formed on the main surface was cut into a size of 35 mm x 60 mm together with the magnetic coating film to obtain a magnetic core member 13 composed of a magnetic film coated with a composite material and dried. Next, a hole of 35 mm x 1 mm was opened in the electrical insulating film at the center of the air-core coil, and the magnetic core member 13 was inserted i...

experiment example 3

[0156] exist Figure 4 and Figure 5 An electrical conductor 112 is formed on the surface of an insulating member 111 composed of an electrical insulating film as shown. As the electrical insulating film, a polyimide film having a thickness of 50 μm and a length and width of 65 mm×55 mm was used. Copper foils with a thickness of 35 μm are laminated and bonded to one main surface of the polyimide film, and these copper foils are etched to meander on the other main surface of the polyimide film, and three pieces are alternately formed. The forward path portion 112 a and the return path portion 112 b each having a length of 40 mm are formed at a gap of 10 mm, thereby forming a series of conductors 112 . The conductor 112 is formed with a width of 0.8 mm.

[0157] Thereafter, the first magnetic core member 113 having a thickness of 1 mm and a length and width of 40 mm×20 mm was bonded to the back surface of the electrical insulating film 112 provided with the conductor 112 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com