Motor capable of realizing high-efficiency DC power

A power motor and power technology, applied in the field of DC power motors, can solve the problems of high-speed performance of magnet demagnetization, limited constant power range, poor safety and stability, etc., and achieve the effect of eliminating harmonics, light weight, and no iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

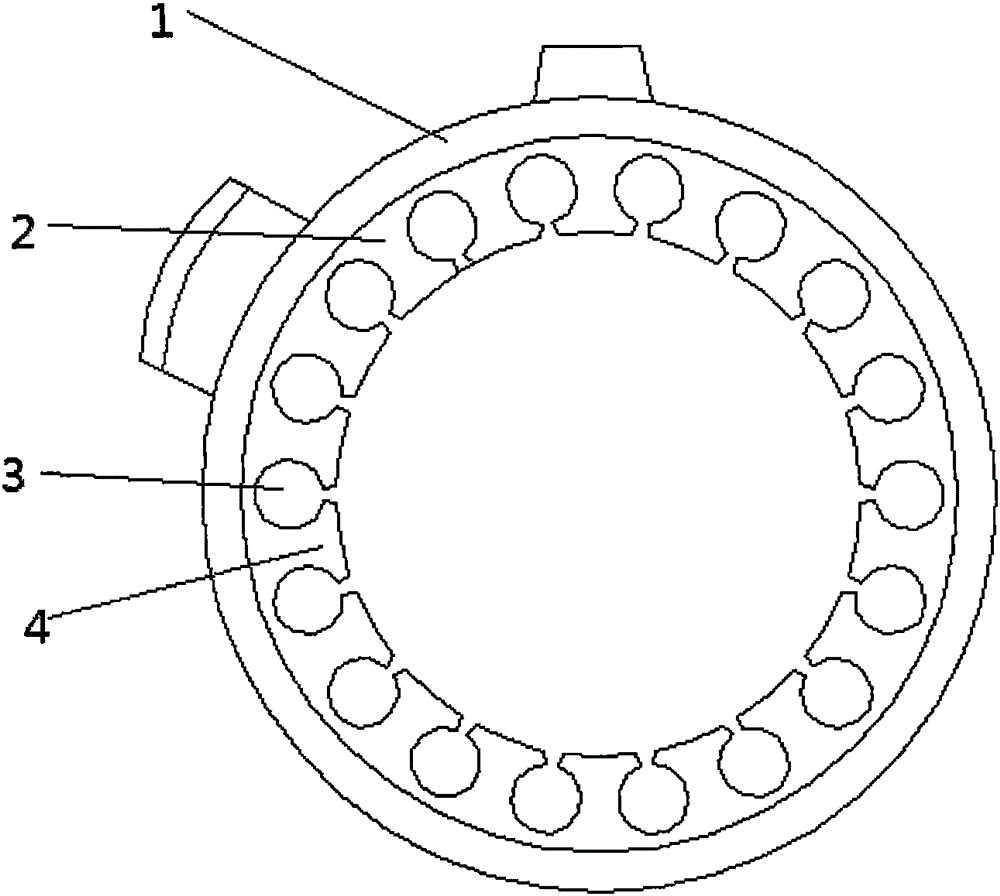

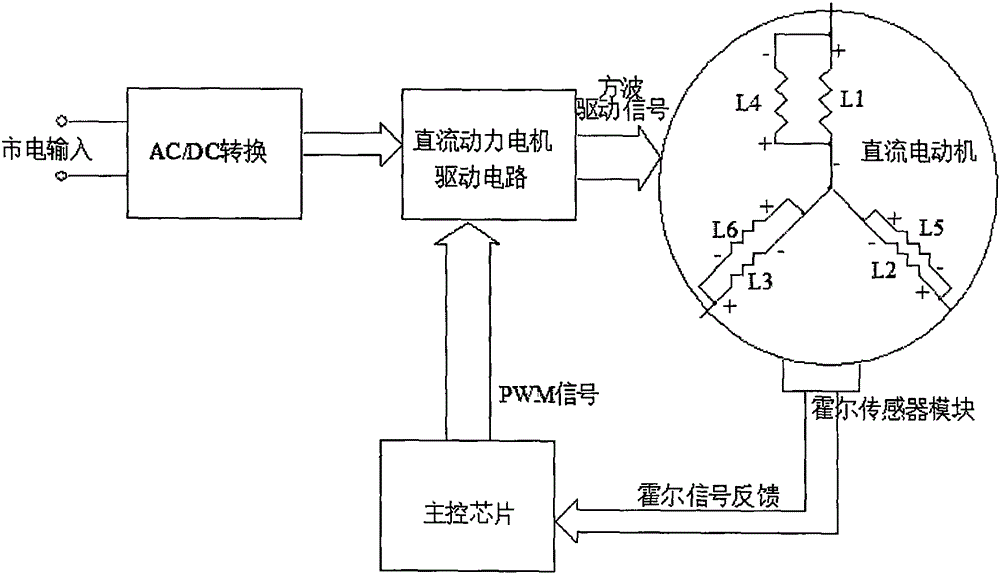

[0019] A motor capable of realizing high-efficiency DC power according to the present invention includes a rotor, a DC power motor drive circuit and a stator.

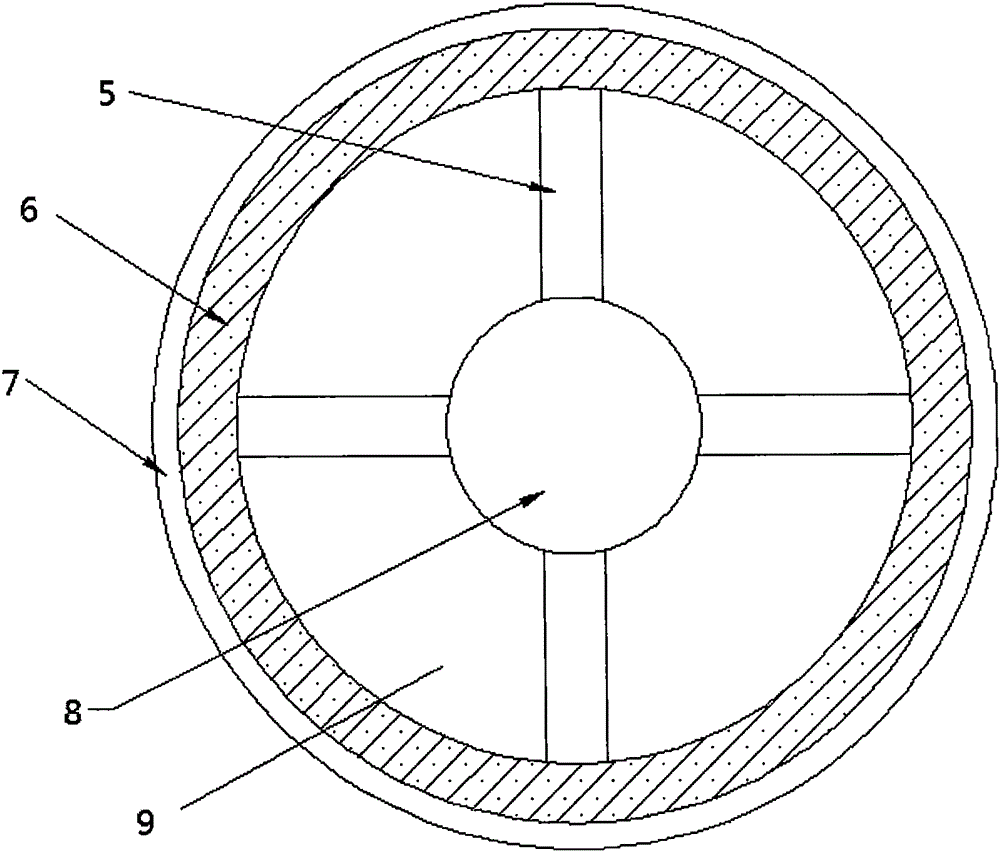

[0020] Such as figure 1 As shown: the rotor includes a rotor shaft 8, a rotor magnet bracket 5, a rotor magnet 6 and a reinforcement lining 7 that are sheathed in sequence from the inside to the outside, and the rotor magnet 6 is an integral structure composed of a tubular magnet. The material of the rotor magnet is bonded neodymium iron stilt, and the rotor magnet 6 is fixedly sleeved on the outer ring of the rotor magnet support 5. In terms of processing technology, the bonded magnetic material is easy to process and shape, compared with the rotor of the traditional DC power motor , the overall ring structure or multi-layer ring structure adopted by the present invention can magnetize the bonded NdFeS magnet into a standard sine wave magnetic pole, which reduces the torque ripple of the motor and makes the DC power m...

Embodiment 2

[0028] The difference between embodiment 2 and embodiment 1 lies in that the rotor magnet is a multi-layer structure composed of multi-layer tubular magnets arranged inside and outside in sequence. Of course, the material of the tubular magnet 15 is also bonded neodymium iron stilbium.

Embodiment 3

[0030] The difference between embodiment 3 and embodiment 1 is that the rotor magnet is an integrally cast integral structure rotor, which hardly generates heat when the motor is working, and can maintain the high-power working state of the motor without a cooling device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com