Composite cable clamping plate special for wind power generation tower barrel

A technology of composite materials and cable splints, which is applied in wind power generation, wind turbines, engines, etc., can solve the problem of low mechanical properties of plastic cable splints and nylon cable splints, low flame retardant coefficients of plastic and nylon cable splints, and the impact on wind power generation towers. Use and other issues to achieve the effect of avoiding power loss and damage to cables, improving the value of promotion and application, and reducing transmission costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

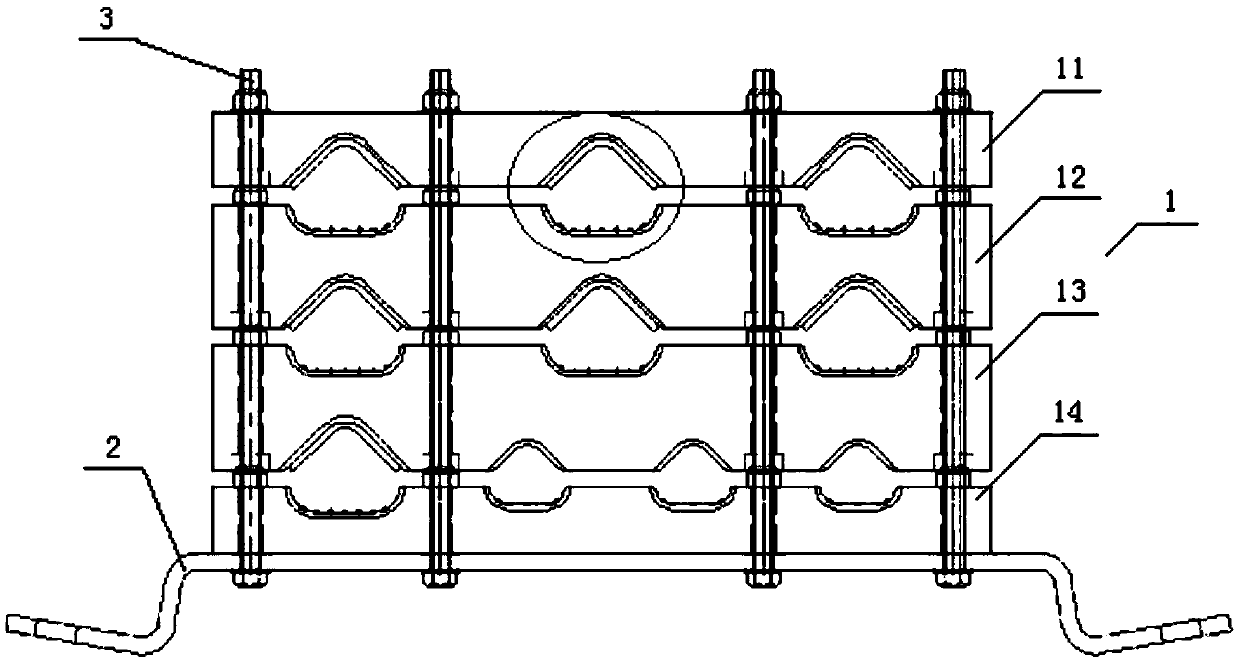

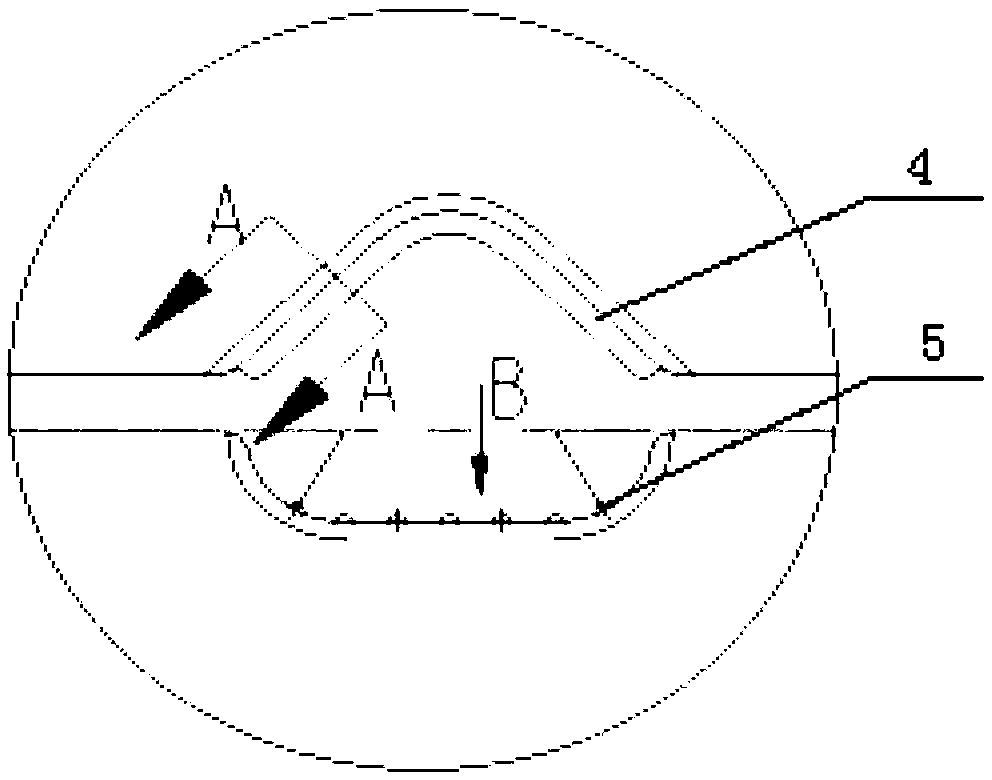

[0020] Such as figure 1 and Figures 3 to 5 Shown is the power cable splint structure, including splint 1, splint support 2 and tightening bolt 3, the splint 1 is fixed on the splint support 2 through the tightening bolt 3, the splint 1 includes the upper splint 11, upper middle Plywood 12, middle and lower plywood 13 and lower plywood 14, the inner surface of plywood 1 is designed with anti-skid groove 4 and designed with anti-skid friction surface 5; the raw material components selected by said plywood 1 are calculated by mass parts: 17 parts of p171-903 resin , 8 parts of low shrinkage additive PS, 490 parts of initiator TBPB, 1 part of pigment paste, 1 part of zinc stearate, 300 parts of magnesium oxide, 2 parts of styrene, 26 parts of alkali-free glass fiber, 12 parts of 1250 mesh aluminum hydroxide, and The plywood 1 is pressed and formed through a fully automatic compression molding process, and the number of layers of the plywood 1 and the size of the plywood 1 can be...

Embodiment 2

[0022] Such as figure 2 Shown is the lighting cable splint structure, including splint 1, splint support 2 and tightening bolt 3, the splint 1 is fixed on the splint support 2 through the tightening bolt 3, the splint 1 includes the upper splint 11, the middle Upper clamping plate 12, middle and lower clamping plate 13 and lower clamping plate 14, the inner surface of clamping plate 1 is designed with anti-slip groove 4 and is designed with anti-slip friction surface 5; the raw material components selected by described clamping plate 1 are calculated by mass parts: 17 parts of resin, low 8 parts of shrinkage additive, 490 parts of initiator, 1 part of pigment paste, 1.2 parts of zinc stearate, 330 parts of magnesium oxide, 2 parts of styrene, 26 parts of alkali-free glass fiber, 12 parts of aluminum hydroxide, and through automatic molding The molding process is press molding, and the number of layers of the plywood 1 and the size of the plywood 1 can be manufactured accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com