A new type of pipe layout condenser

A condenser and pipe layout technology, which is applied in steam/steam condensers, tubular elements, heat exchange equipment, etc., can solve the problems of eddy current dead zone, uneven steam resistance, large subcooling degree, etc., and achieve heat transfer The coefficient and the effect of high operating vacuum, uniform steam flow field without eddy current, and uniform heat load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

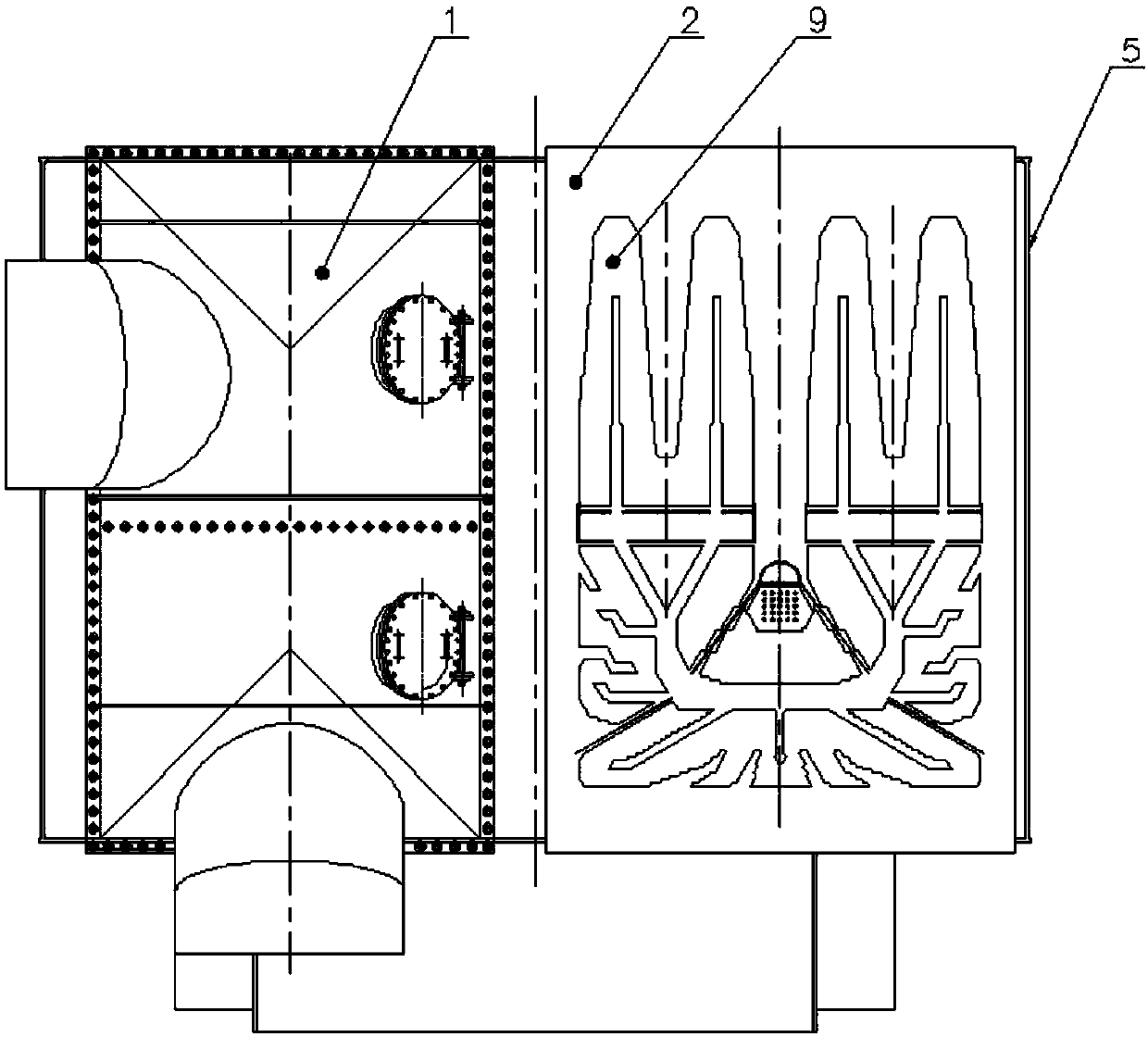

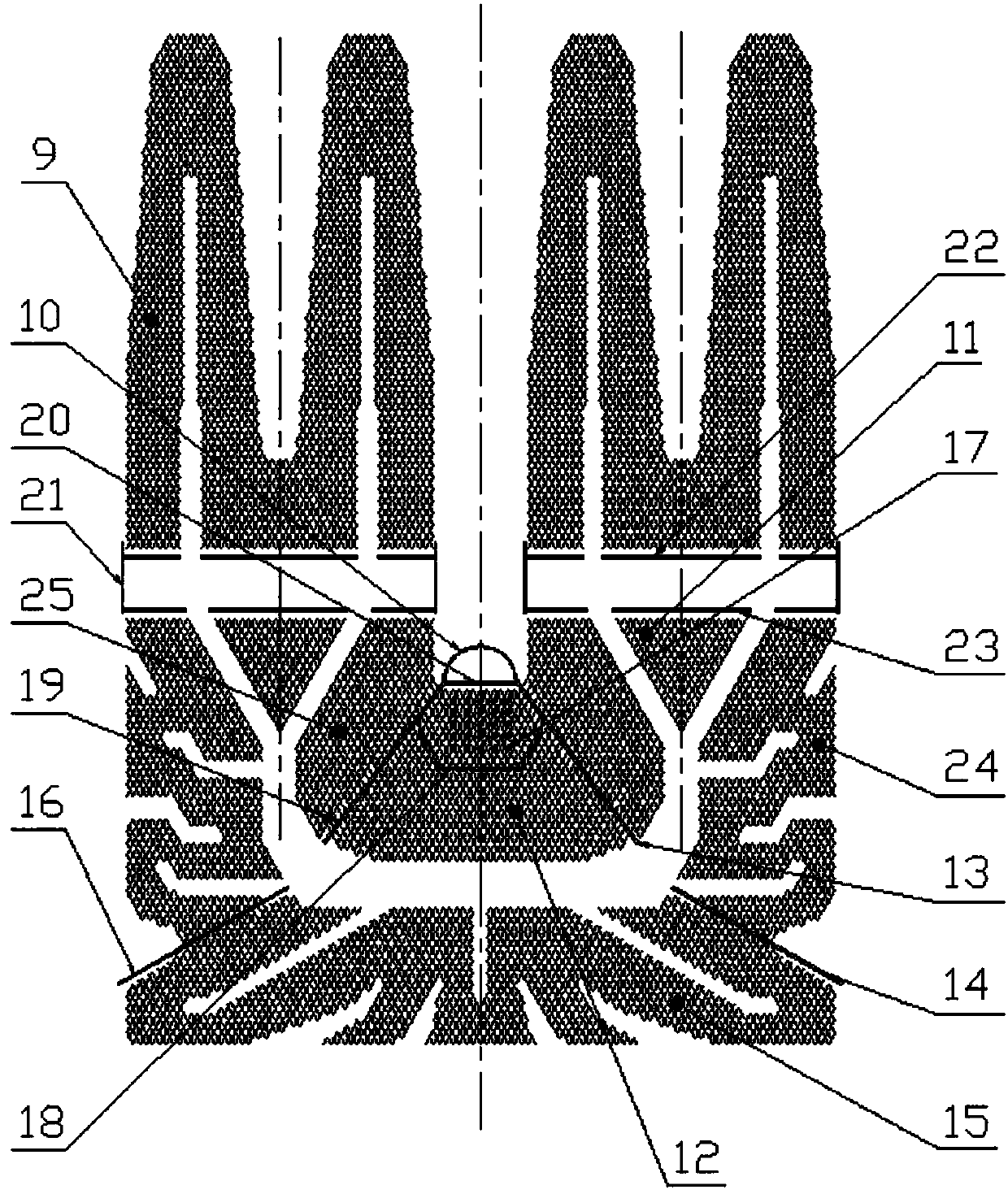

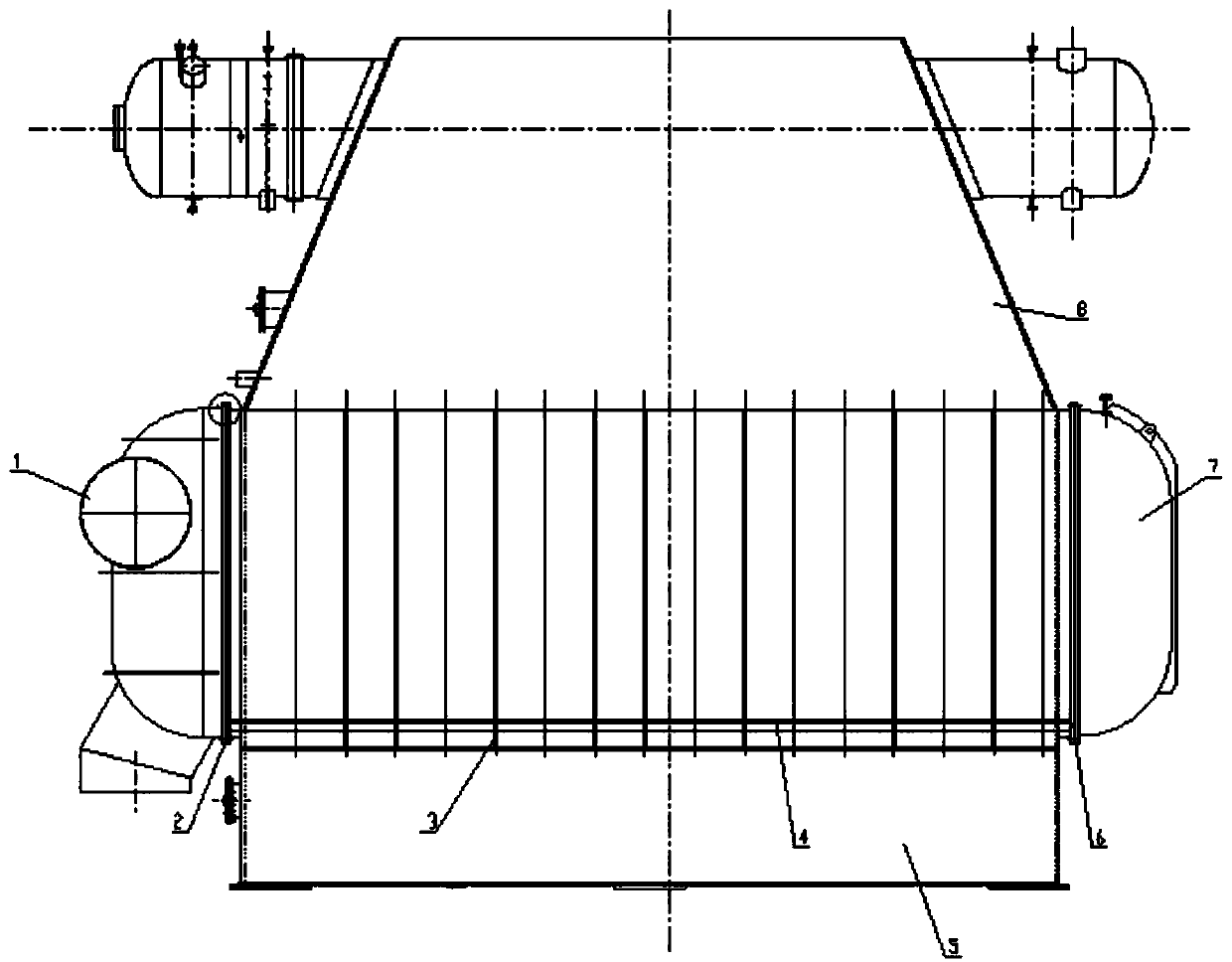

Embodiment 1

[0026] like figure 1 , figure 2The condenser of a new type of pipe layout shown is composed of a front water chamber 1, a front tube plate 2 of the condenser, a middle tube plate 3 of the condenser, a heat exchange tube 4, and a condenser shell assembly 5, Condenser rear end tube plate 6, condenser rear water chamber 7, rear neck 8, M-shaped tube bundle area 9, air extraction tube 10, inverted triangular tube bundle area 11, air cooling area 12, air cooling area steam baffle A13, set Water plate A14, meandering tube bundle area 15 at the lower part of the tube sheet surface, water collecting plate B16, air-cooling flow hole 17, stainless steel corrugated steam baffle 18, air-cooling zone steam baffle B19, air-cooling zone steam baffle C20, split-range steam baffle 21. It is composed of the upper porous water spray plate 22, the lower porous water spray plate 23, the outer curved pipe area 24 on the lower side of the official office, and the tube bundle areas 25 on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com