High-performance double-layer co-extrusion insulating flame-retardant fire-resistant computer cable

A computer cable, double-layer co-extrusion technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve problems such as poor heat dissipation, cable heat resistance, weak rigidity and tensile strength, and no resistance to lateral pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

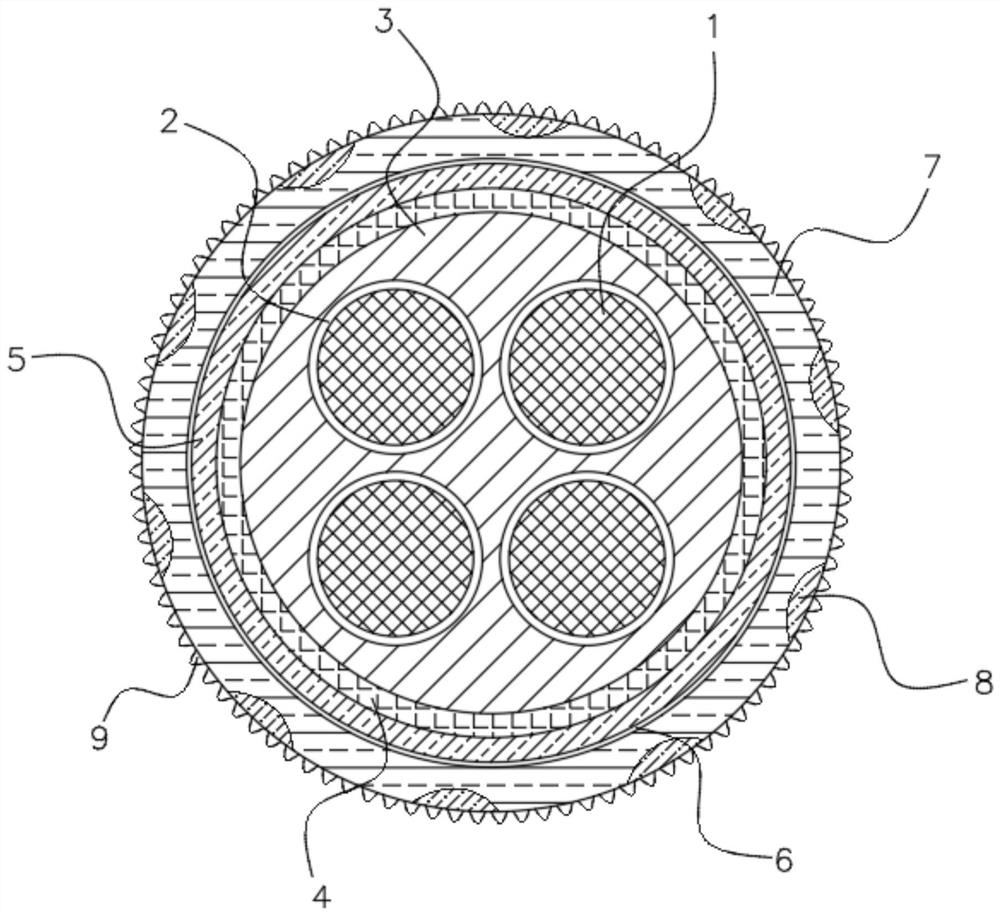

[0026] see Figure 1-2 , a high-performance double-layer co-extruded insulation flame-retardant fire-resistant computer cable, including a conductor 1, insulation 2, tape 4, inner sheath 5, armor 6 and outer sheath 7, the insulation 2 is arranged on the outside of the conductor 1, And insulation 2 is made of polypropylene material, the heat resistance of polypropylene is higher than that of polyethylene, under normal circumstances, the melting temperature of polypropylene is about 40%-50% higher than that of polyethylene, about 160-170°C, In addition, from the perspective of rigidity and tensile strength, polypropylene has low density, better mechanical properties than polyethylene, and outstanding rigidity. Multiple conductors 1 are embedded in the tape 4, and the conductors in the tape 4 1 is embedded with a filling 3, the filling 3 is a mineral insulating mica tape, the inner sheath 5 is set on the outside of the tape 4, the inner sheath 5 is made of radiation cross-linked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com