Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Won't cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

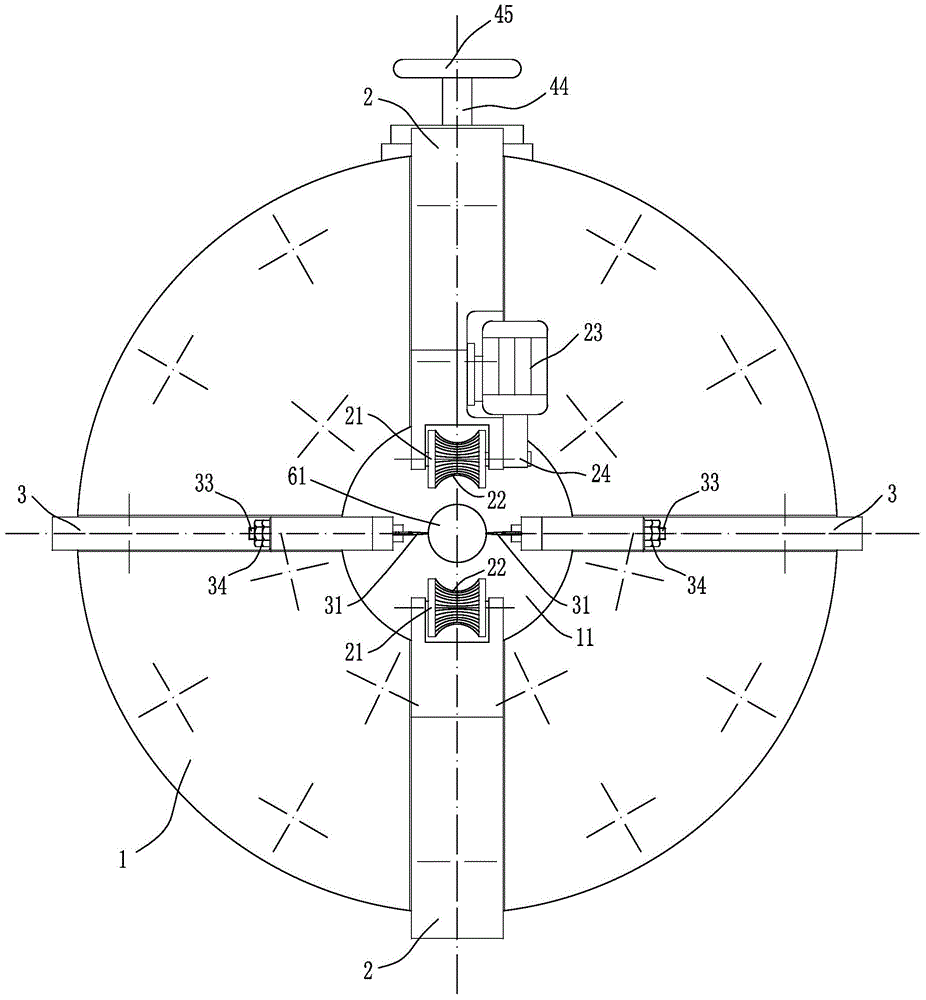

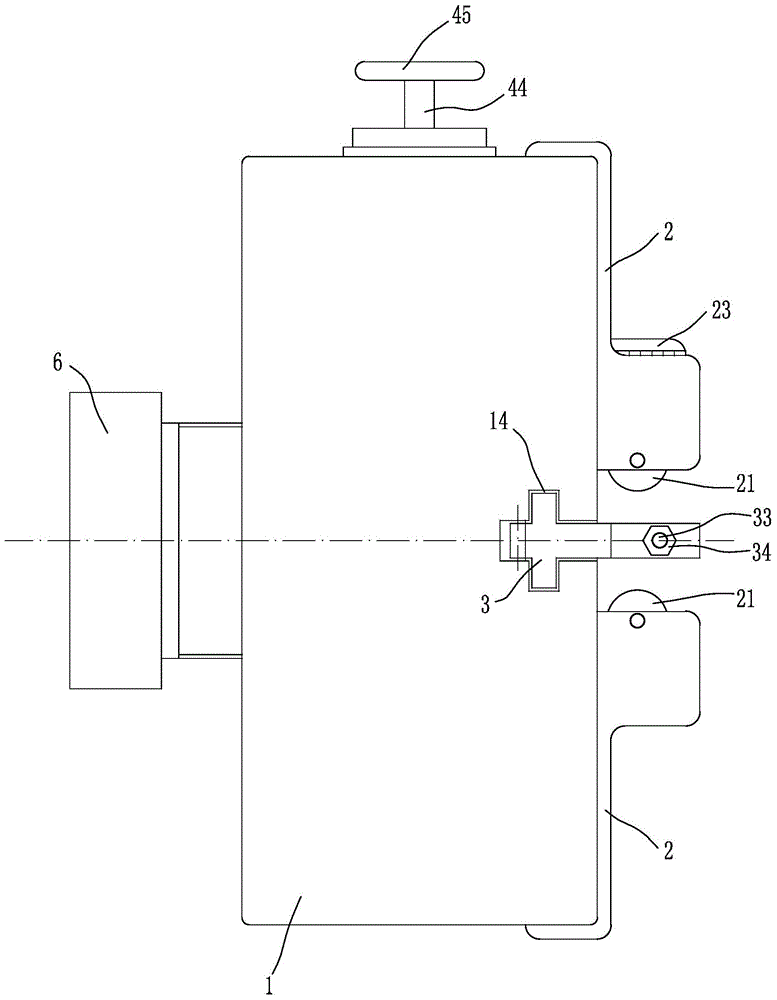

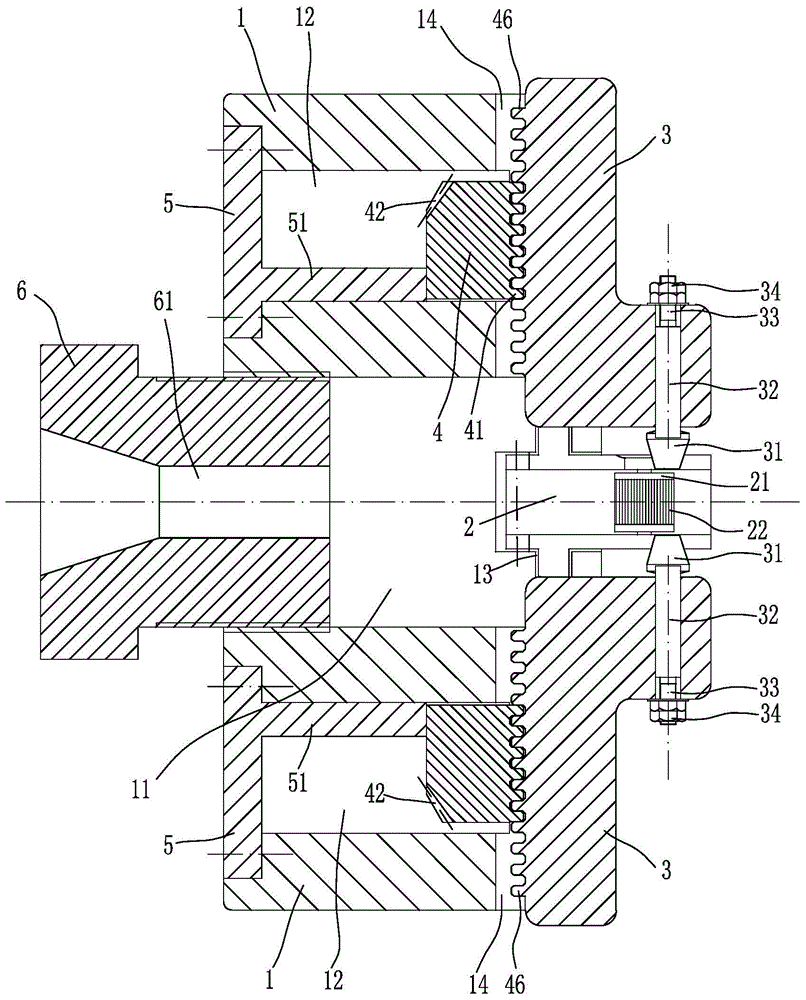

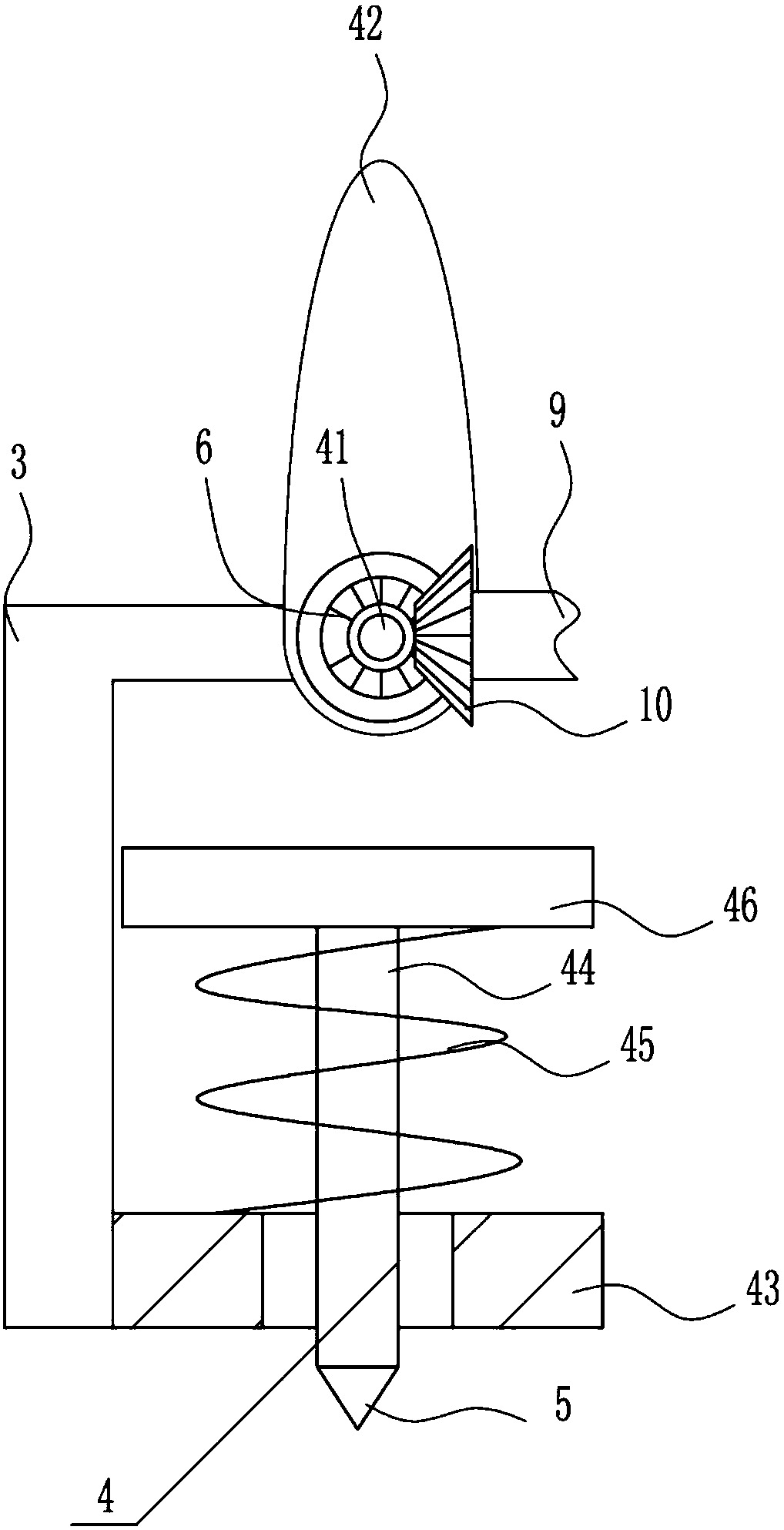

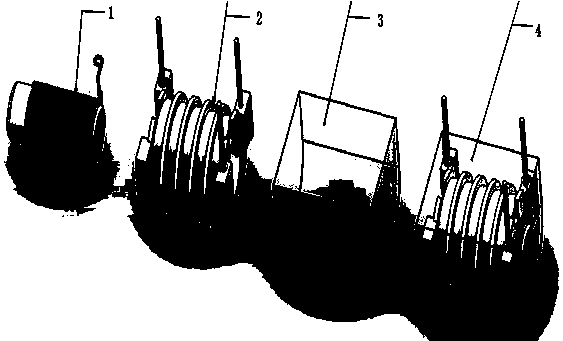

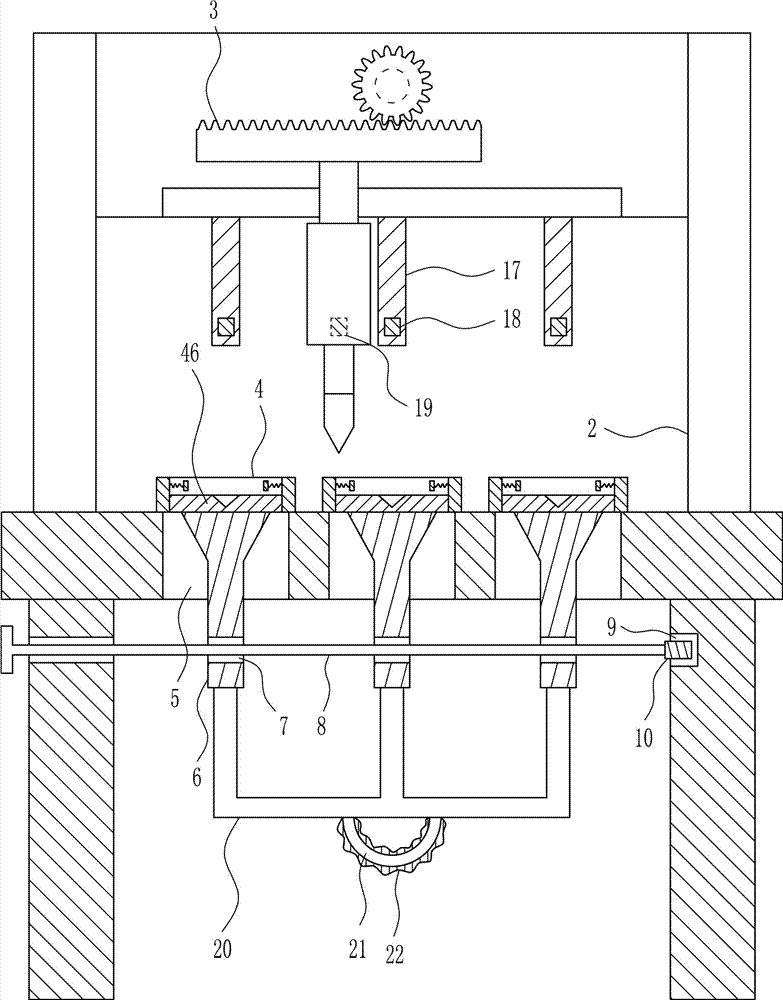

Automatic stripper for scrap cable

InactiveCN104821521AOperational securityQuick StripBasic electric elementsApparatus for removing/armouring cablesScrapEngineering

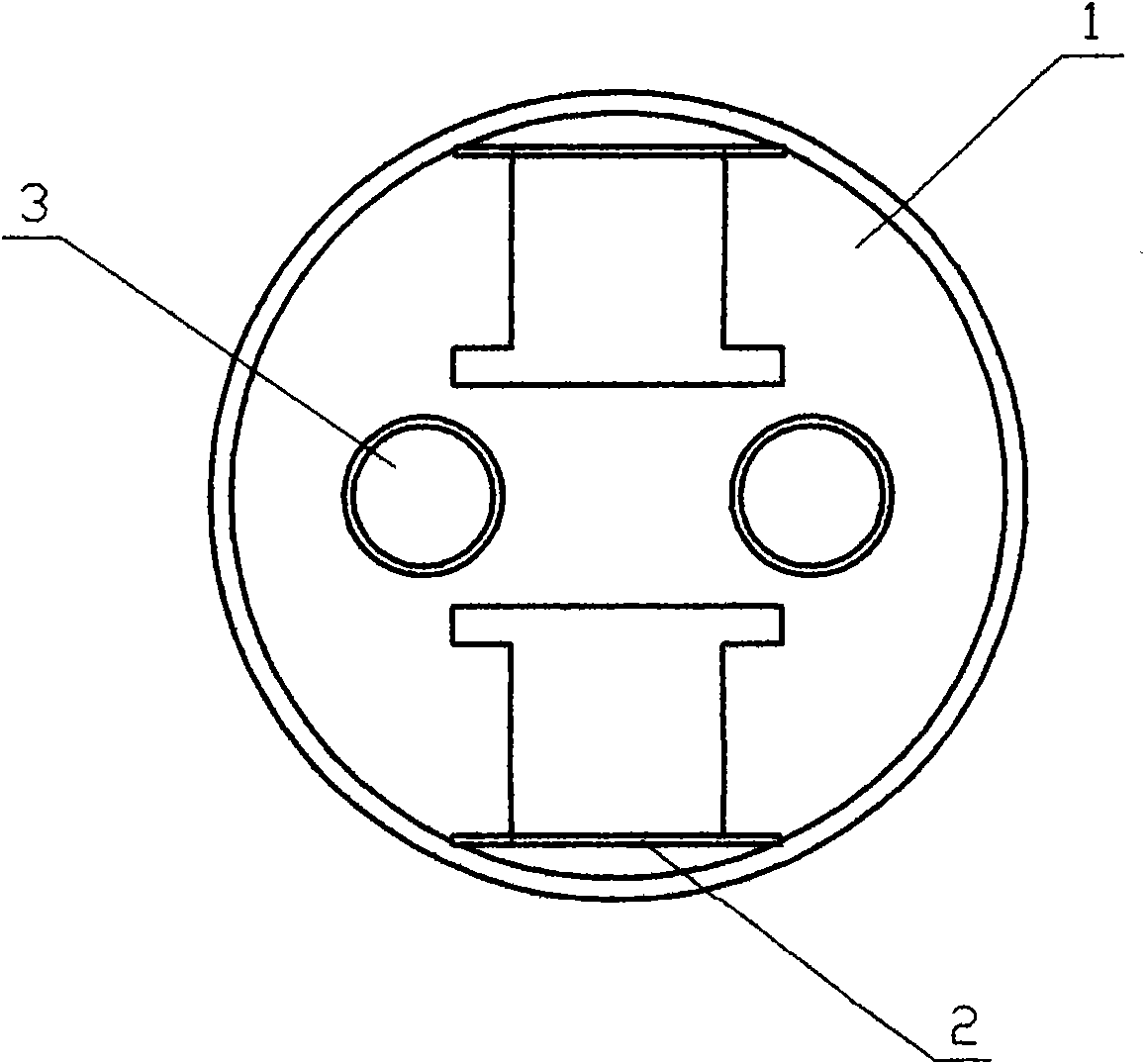

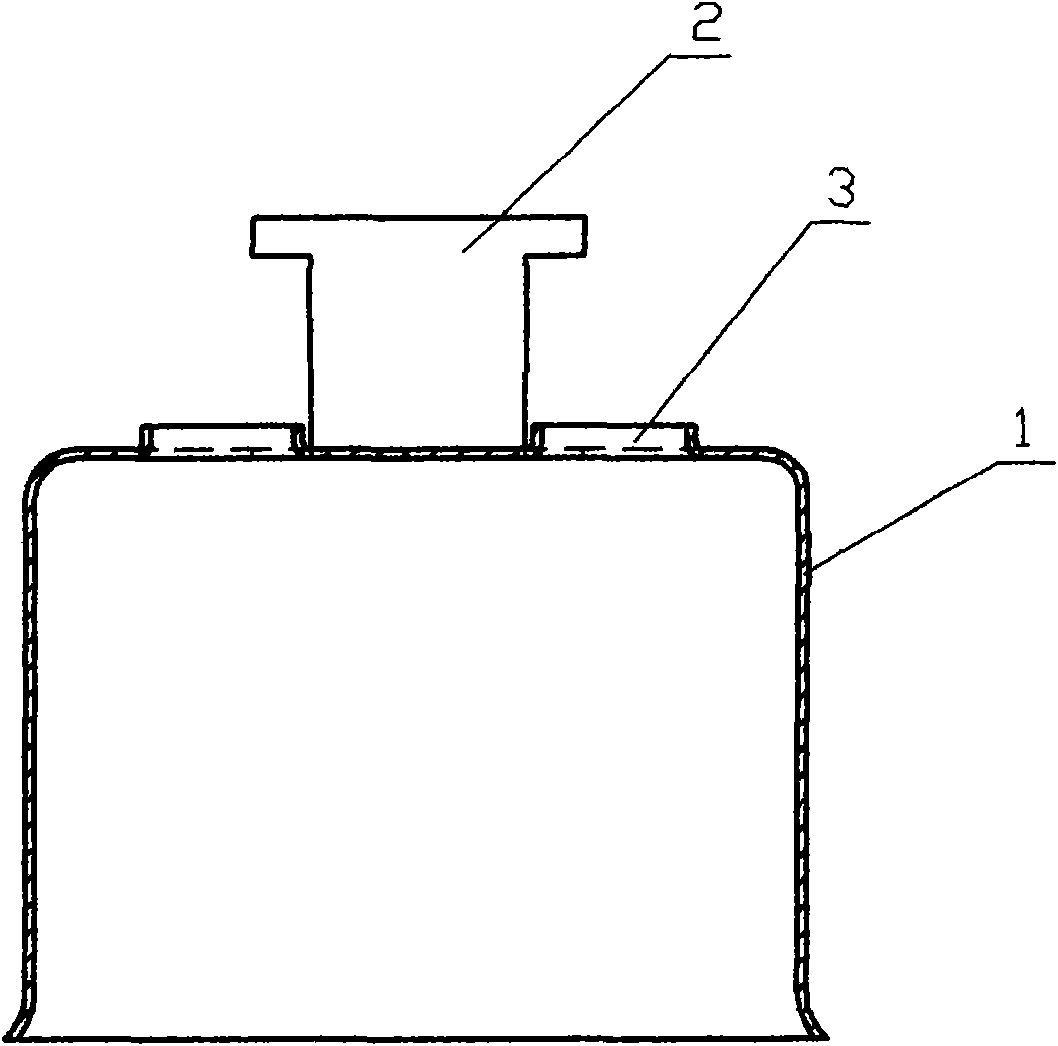

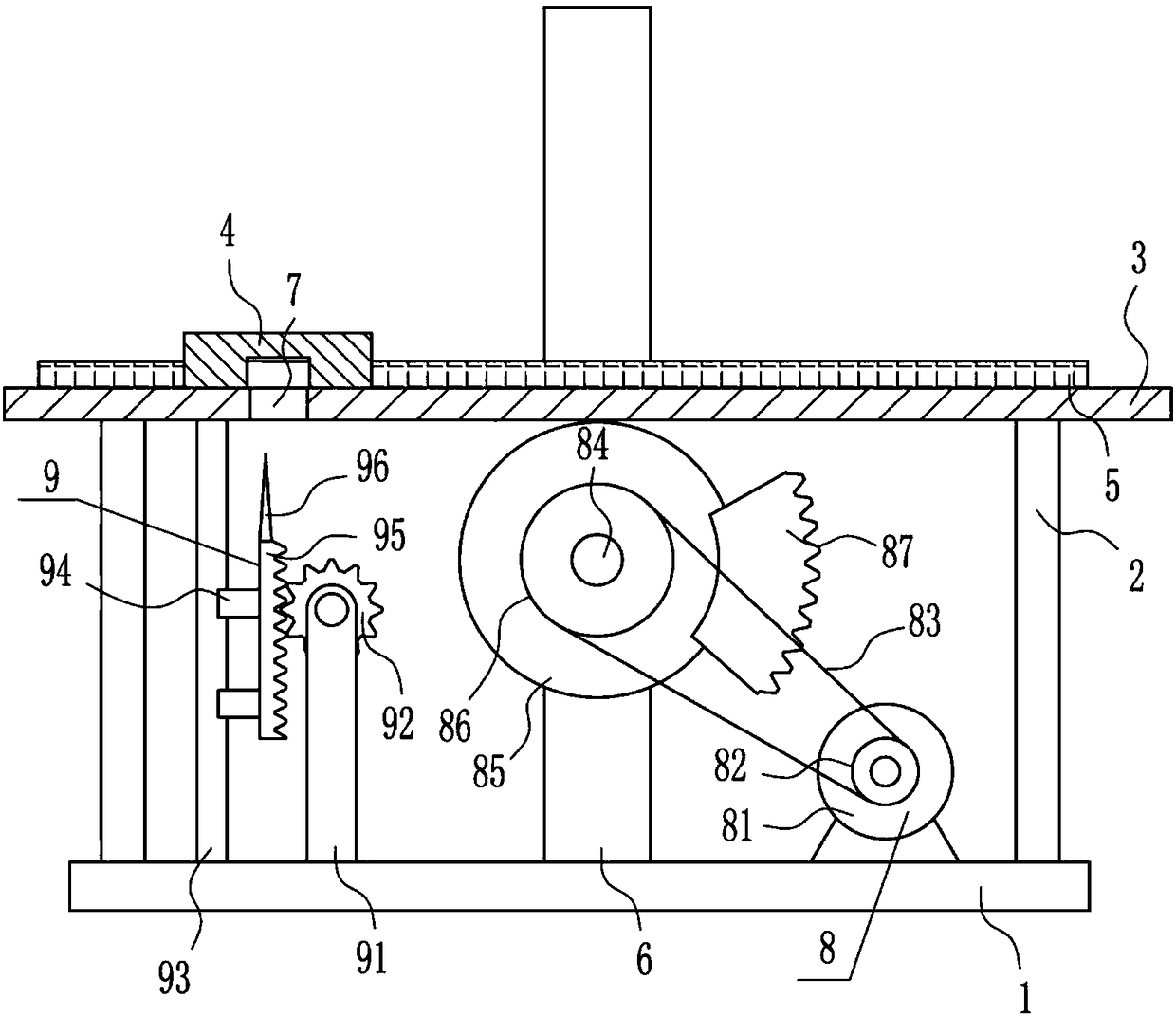

The invention discloses an automatic stripper for a scrap cable, which comprises a round disc seat. The central position of the disc seat is provided with a cable through hole; two clamping sliding blocks sliding along the radial direction are symmetrically arranged on the disc surface at the front side of the disc seat; two cutting sliding blocks are also symmetrically arranged on the disc surface at the front side of the disc seat; the clamping sliding blocks and the cutting sliding blocks are arranged in a mutual staggered mode; the inner end of the clamping sliding block is provided with a clamping wheel in a rotating mode; the outer peripheral surface of the clamping wheel is provided with a clamping groove sunk inwardly; the clamping wheel is in rotary connection with a clamping driving device; the inner end of the cutting sliding block is fixedly provided with a cutting knife; and the disc seat is provided with a synchronous driving device for driving the clamping sliding blocks and the cutting sliding blocks to slide synchronously. The outer skin of the scrap cable can be safely, conveniently and quickly stripped, the cable core is not cut damaged, and the cable core can be prevented from being damaged.

Owner:STATE GRID CORP OF CHINA +1

Radish slicing device

InactiveCN107775682AAffect sliceConsistent thicknessMetal working apparatusEngineeringMechanical engineering

The invention relates to a slicing device, in particular to a radish slicing device. The technical problem to be solved by the present invention is to provide a radish slicing device with fast slicing speed, uniform thickness of cut radish slices, no manual slicing, and no hand injury by blades. In order to solve the above-mentioned technical problems, the present invention provides such a radish slicing device, which includes a leg, a U-shaped frame, a 7-shaped plate, a lifting device, a blade, a first bevel gear, a vertical plate, a first bearing seat, a first Rotating shaft, second bevel gear, horizontal plate, etc.; symmetrical mounting legs on the left and right sides of the outer bottom of the u-shaped frame, a push plate is arranged in the u-shaped frame, the push plate is vertically arranged, and the push plate slides with the u-shaped frame Cooperate. Through the cleaning device, the present invention can not only remove the radish slices sticking to the blade, but also clean the blade, so that the slicing speed is fast, the thickness of the cut radish slices is uniform, no manual slicing is required, and the radish slices will not be damaged by the blade. The effect of cutting hands.

Owner:卢勇军

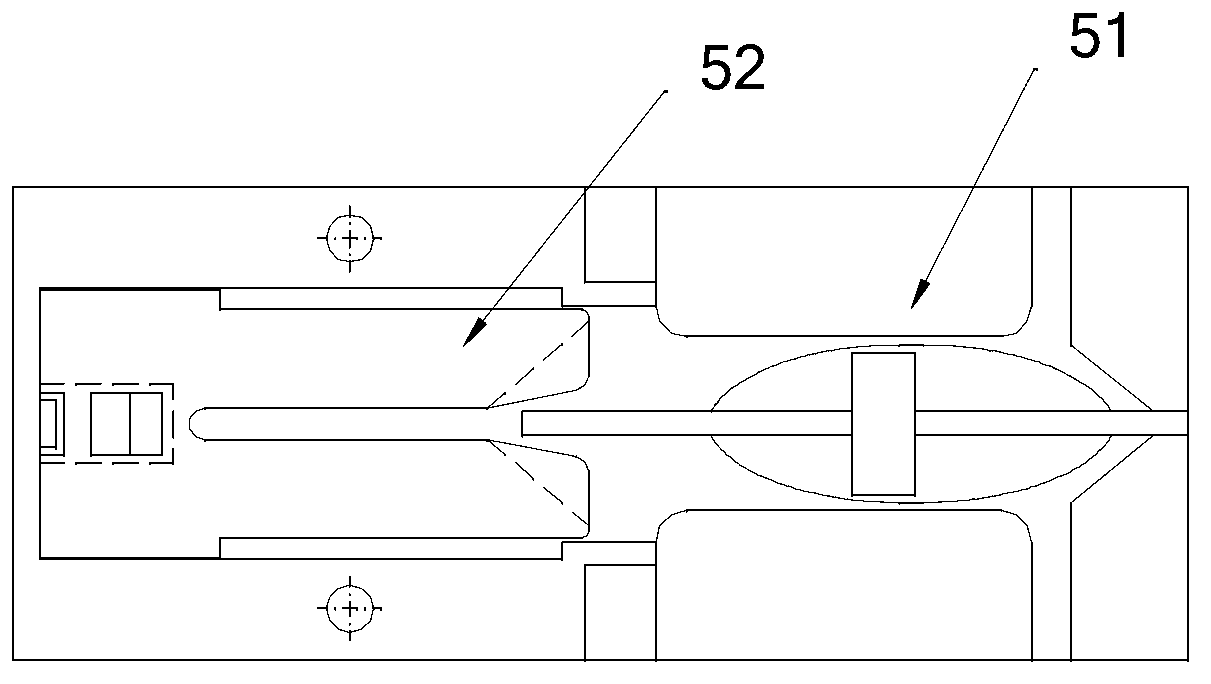

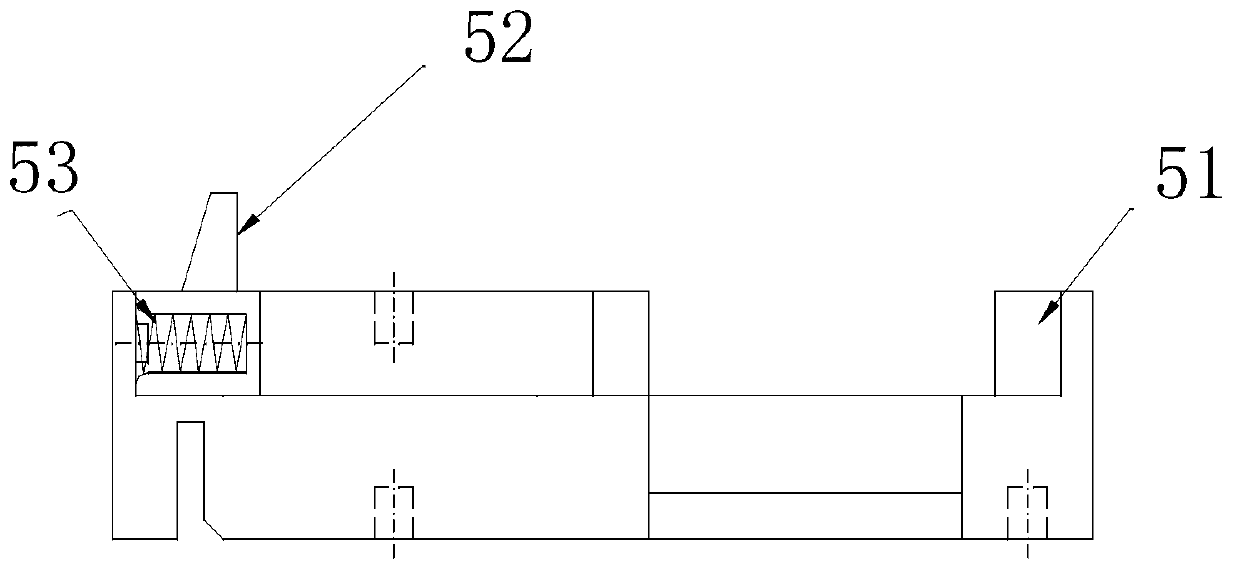

Areca nut cutter

InactiveCN103009413AWon't cutIncrease productivityMetal working apparatusStructural engineeringMechanical engineering

The invention provides an areca nut cutter. A corresponding areca nut gripper is disposed on a gripper base plate which is disposed on a chain. A base comprises a movable block arranging part and an areca nut arranging part. The movable block arranging part is a square groove. A lengthened retainer is on the inner wall of each two sides of the right end of the square groove. The areca nut arranging part is a semi-ellipsoidal groove, a cutter groove which transversely penetrates the semi-ellipsoidal groove is reserved on the semi-ellipsoidal groove, and a vertical through hole is reserved at the center of the semi-ellipsoidal groove. A movable block is disposed on the movable block arranging part of the base, and a spring is disposed in a left side middle hole of the movable block. Areca nuts can be placed at different angles without loosening according to different shaping requirements of different areca nut products and cut into different shapes, the shaping requirements of various products are completely satisfied, high production efficiency is achieved, cut of fingers can be avoided, and the cut areca nut is uniform, attractive and high in shaping rate.

Owner:杨支钢

Power transmission line foreign matter cleaning device

The invention provides a power transmission line foreign matter cleaning device comprising a hand-held part, a foreign matter collecting part (20) which is connected on the hand-held part, and a cutting part which is fixedly arranged on the foreign matter collecting part (20) and used for cutting a foreign matter wound on the foreign matter collecting part (20). Height of the cutting part is less than that of the foreign matter collecting part (20). The foreign matter hung on a power transmission line is picked up by the foreign matter collecting part and wound on the foreign matter collecting part, then the foreign matter is cut after being contacted with the cutting part and then falls off from the power transmission line. According to the power transmission line foreign matter cleaning device, the foreign matter hung on the power transmission line can be high-efficiently cleaned, and operation safety of the power transmission line can also be ensured.

Owner:STATE GRID CORP OF CHINA +1

Multi-project wafer cutting method for improving finished product rate of chips

InactiveCN101834160AReduce areaReduce the numberSemiconductor/solid-state device manufacturingLayout planningAgricultural engineering

The invention discloses a multi-project wafer cutting method for improving finished product rate of chips, and provides a method for cutting multi-project wafers based on an optimal layout planning acquired by quick optimal solution of a simulated annealing algorithm according to the yield demand and the cutting demand of different chips in the practical production. The method can ensure that all chips with complete functions and the same priority in the same cutting group can be simultaneously cut on the same mask plate, effectively realize the priority that the high-priority chips are not cut, furthest reduce the loss of the finished product rate of the chips caused by wafer cutting factors, meanwhile reduce the number of the wafers required for production, and reduce the production cost.

Owner:ZHEJIANG UNIV

Low-loss oriented cutting method of large-size sapphire crystal blanks

InactiveCN102152420AImprove processing efficiencyReduce processing stepsFine working devicesSheet steelCrystal orientation

The invention provides a low-loss directional cutting method of large-size sapphire crystal blanks. The large sapphire crystal blanks are fed in a rotation manner in the method, and the processing efficiency of the method is improved by one time than that of a traditional band-saw cutting method. Before cutting, the end faces of the large-size sapphire crystal blanks are oriented, steel plates in corresponding angles are selected according to the crystal orientation deviation of the end faces for bonding, thereby the accurate orientation is finished in a cutting procedure. The method is greatly improved on the basis of the traditional band-saw cutting method, has the advantages of higher cutting efficiency, better cutting surface quality, high surface flatness, shorter follow-up processing time, lower unit production cost and the like, and can be used for correcting the crystal orientation of the end faces of the large sapphire crystal blanks.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

Mounting method for temperature transmitter thermosensors of electric cooker

InactiveCN101536868APrecise positioningImprove versatilityThermometer detailsCooking vesselsTemperature controlHeat sensitive

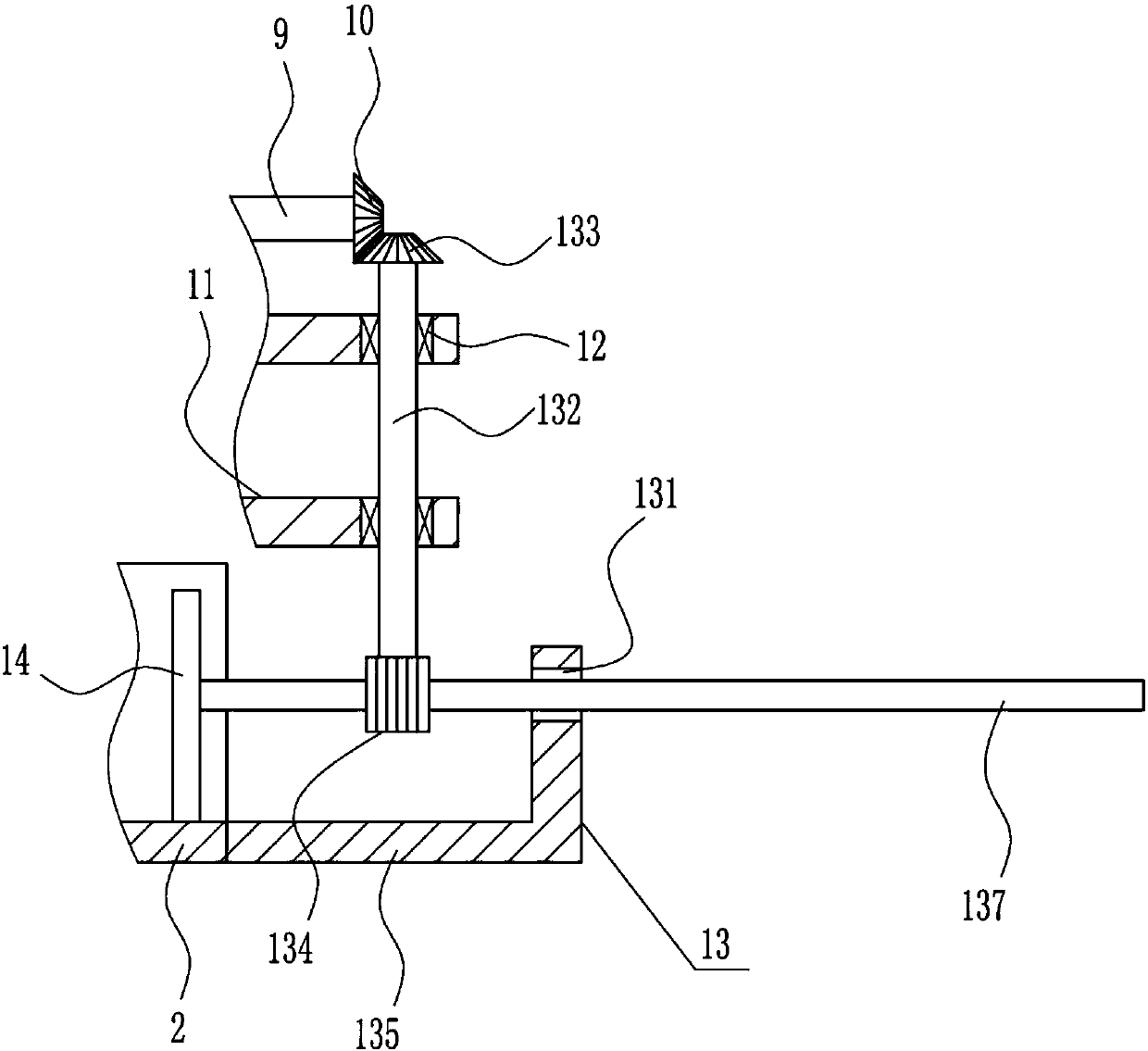

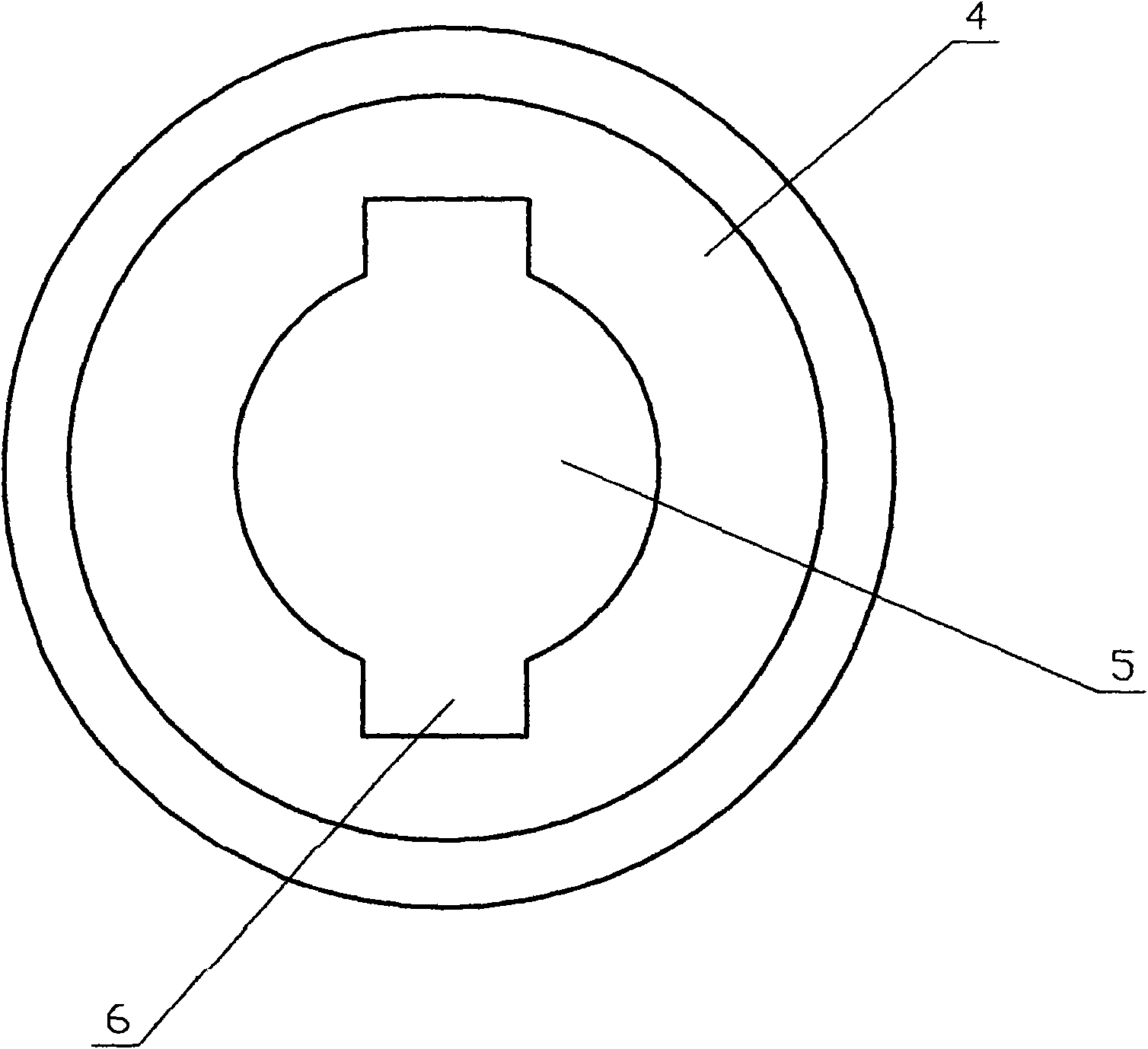

The invention relates to a mounting method for temperature sensor thermosensors of an electric cooker. The mounting method comprises the following steps: providing an inner shell (1) with a bottom punched with two T-shaped guide feet and a turnup hole for positioning and fixing extracted leads (11); providing an outer shell (4) with a bottom punched with a round hole and two guide grooves in the round hole; mounting a temperature control element (10) in a groove of tablettings (7), penetrating the leads (11) wrapped by a sleeve out of the turnup holes at the bottom of the inner shell (1) to be tightly matched with and fixed on the turnup holes; arranging the tablettings (7) between the inner shell (1) and an aluminum cover (13) to be riveted and compacted and using the tablettings (7) to compact temperature control element (10); supporting the inner shell (1) in the outer shell (4) by springs (12), penetrating the leads (11) wrapped by the sleeve out of the round hole of the outer shell (4), and penetrating the T-shaped guide feet of the inner shell (1) out of the round hole of the outer shell (4) to be bent in the guide grooves of the outer shell (4). The mounting method for the temperature sensor thermosensors of the electric cooker can reduce materials, decrease the cost, improve the qualified rate and ensure the product to be more reliable in the working process.

Owner:信宜市福尔电子有限公司

Uniform plastic rod cutting equipment

The invention relates to cutting equipment, in particular to uniform plastic rod cutting equipment. The uniform plastic rod cutting equipment has the advantages that the time-saving and labor-saving effects are achieved, manual cutting is not needed, cuts are avoided, and cut plastic rods are uniform in length. The uniform plastic rod cutting device comprises a base plate and the like; supportingrods are symmetrically arranged on the left side and the right side of the top of the base plate; a placing plate is arranged between the top ends of the supporting rods on the left side and the rightside; a through hole is formed in the left side of the placing plate; an N-shaped frame is arranged on the left side of the top of the placing plate and is located right above the through hole; and avertical plate is arranged in the middle of the top of the base plate and is located on the rear side of the placing plate. According to the uniform plastic rod cutting equipment, by means of a fixing device, the plastic rods can be fixed in the cutting process, the phenomenon that the cutting effect is affected due to the fact that the plastic rods move can be avoided, and therefore the effectsthat time and labor are saved, manual cutting is not needed, the cuts are avoided, and the cut plastic rods are uniform in length can be achieved.

Owner:泗县东方塑料有限责任公司

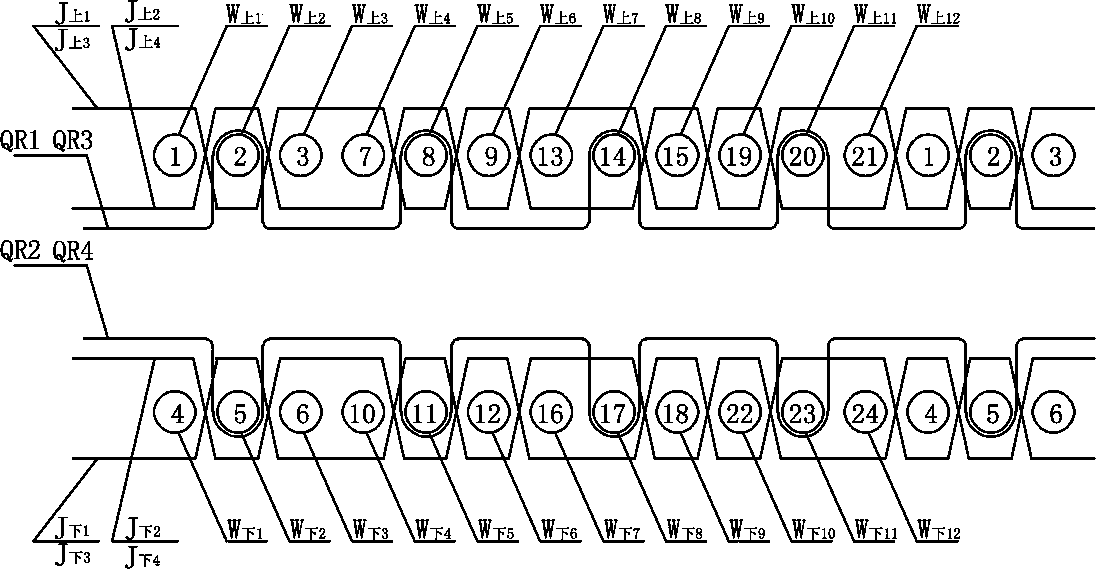

Loop pile fabric and weaving method thereof

The invention discloses a loop pile fabric and a weaving method thereof. The loop pile fabric comprises a piece of base cloth, a looped pile and velvets, wherein the looped pile and the velvets are weaved on the base cloth; the loop pile fabric is made of double-layer base cloth fabrics in a divided mode, wherein the double-layer base cloth fabric is composed of loop pile warps, upper base cloth layer and a lower base cloth layer in an interweaving mode; the loop pile warps are capable of converting continuously when interweaving with the upper base cloth layer and the lower base cloth layer; the looped pile is formed through weaving the loop pile warps at the lower side of the upper base cloth layer and the upper side of the lower base cloth layer in a long beating-up mode and a short beating-up mode; the velvet is divided to form velvets after reciprocally linking the loop pile warps between the upper base cloth layer and the lower base cloth layer; the looped pile and the velvets of the loop pile fabric are combined and transformed to form figured patterns. The loop pile fabric has both the bold feature of the looped pile and the elegant feature of the velvet; the method can produce the single-surface jacquard loop pile fabric with the looped pile and the base cloth, the weaving method is easy to perform, the weaving cost is low, and the produced loop pile fabric is high in quality.

Owner:LIAONING CAIYI WILD SILK PROD

Push device for processing bread

InactiveCN102528845AAvoid wastingEnsure hygiene and safetyMetal working apparatusEngineeringMechanical engineering

The invention discloses a push device for processing bread. The device comprises two parallel longitudinal beams, a push plate component and a cylinder, wherein the two parallel longitudinal beams are located on the two sides of the push device respectively; the push plate component crosses between the two longitudinal beams and can slide along the length direction of the two longitudinal beams; a free end of the cylinder is fixedly connected to the push plate component; and the cylinder body part is fixed on the two longitudinal beams. Compared with the prior art, the push device disclosed by the invention can completely avoid manual operation so as to guarantee the food health and safety and improve the bread slicing efficiency; and meanwhile, as the cylinder applies thrust to the bread, the cutting of a cutter is convenient, and the shape of the bread slices can be guaranteed without crushing, thereby avoiding material waste.

Owner:邱万来

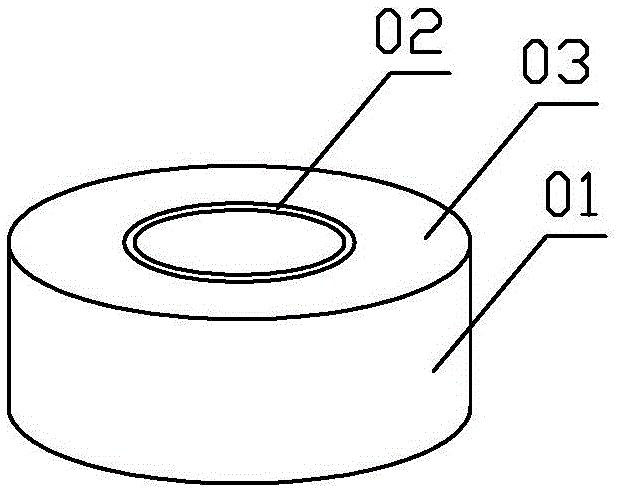

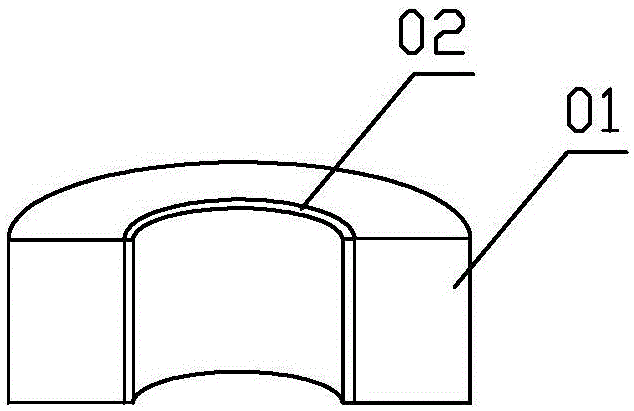

Valve suitable for being mounted on airbag product

ActiveCN103148249AAvoid lossNot easy to hangOperating means/releasing devices for valvesCheck valvesEngineeringAirbag

The invention relates to a valve suitable for being mounted on an airbag product, which comprises a valve casing, wherein an upwards extended threaded connection part is arranged in the middle of the upper surface of the valve casing, and, at the circumference, is in threaded connection with glands used for fixing the valve onto the airbag product. The valve is characterized in that the glands are two, namely the first gland and the second gland below the former; the inner layer of the airbag product is pressed between the second gland and the upper end surface of the valve casing, and the outer layer thereof is pressed between the first gland and the second gland; against the two-layer structure of the used airbag, two fixing positions are arranged on the valve; and the second gland and the upper end surface of the valve casing form one fixing position for the inner layer film of the air bag, and the first and the second glands form one fixing position for the outer layer film of the air bag, that is, the valve can fix the two layers of films of the air bag respectively. Therefore, the valve is suitable for being mounted on the airbag product.

Owner:NINGBO BRAVO MFG OF INFLATORS & ACCESSORIES

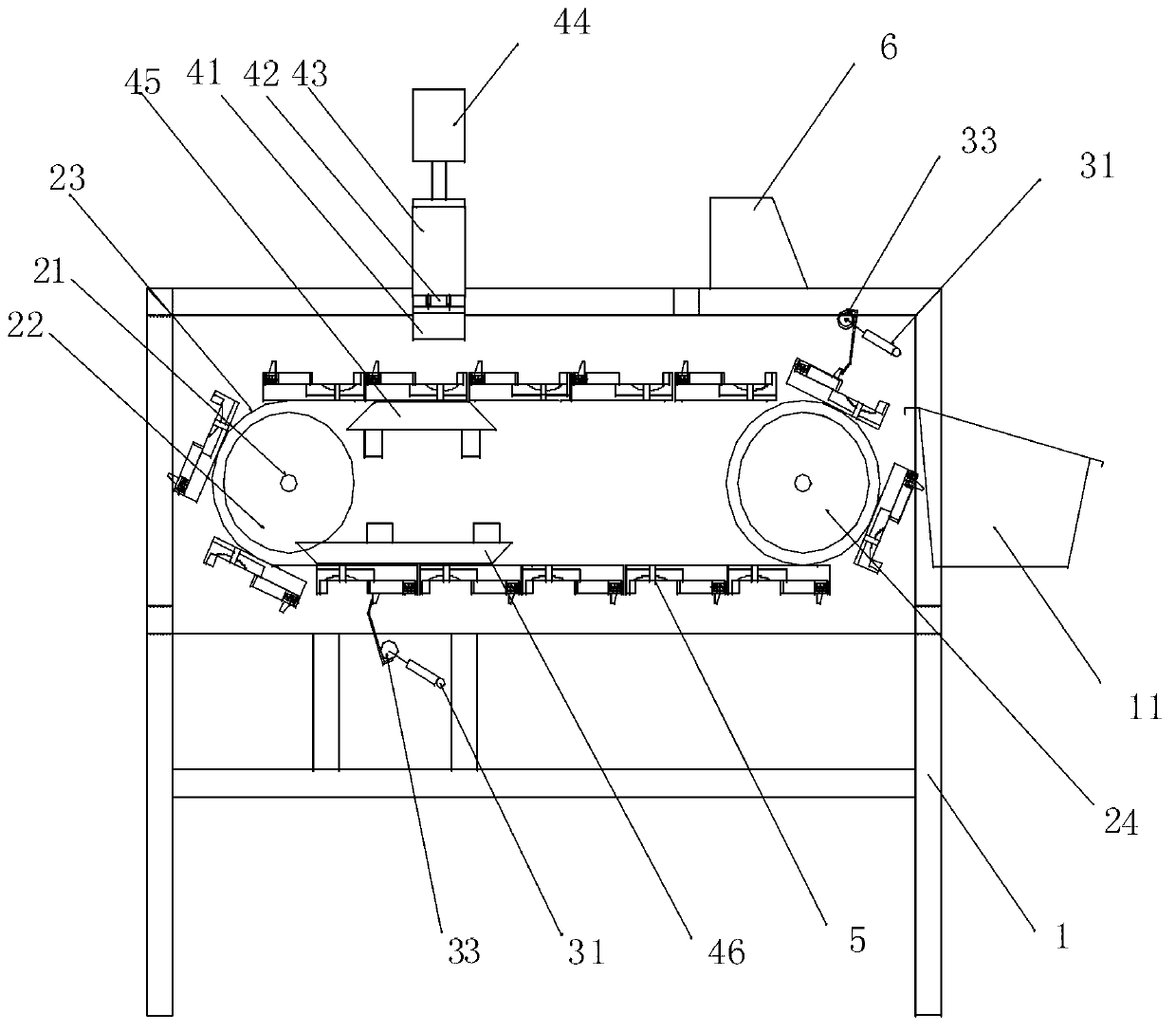

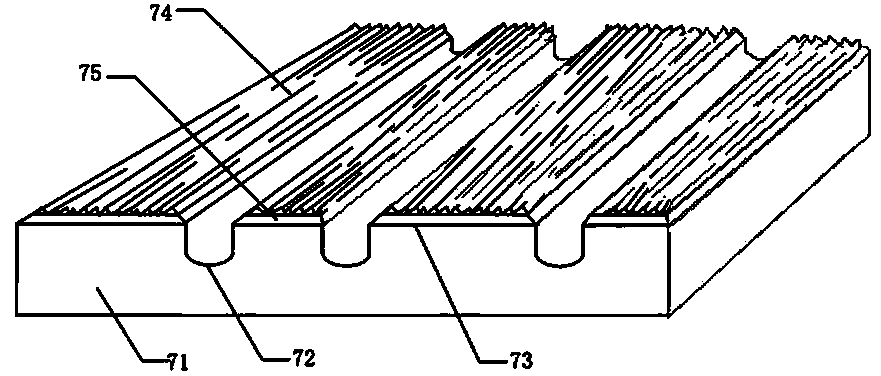

Discharging mechanism for fully-automatic paper pipe cutting machine and discharging method of discharging mechanism

ActiveCN105034071AIncrease productivityReduce labor intensityMetal working apparatusDischarge efficiencyElectric control

The invention relates to a discharging mechanism for a fully-automatic paper pipe cutting machine. The discharging mechanism comprises a rack, a discharging box, an electric control box, a first drive device, a second drive device, a rotary discharging device, a receiving device and a pushing device. The discharging box is arranged on the upper portion of the rack. The electric control box is arranged on one side of the rack. Both the first drive device and the second drive device are arranged in the electric control box. A discharging groove is formed in the bottom of the discharging box. The rotary discharging device is arranged in the discharging groove. The two ends of the rotary discharging device are connected with the discharging box. The first drive device is connected with the rotary discharging device in a drive manner. The receiving device is arranged on the lower portion of the rotary discharging device. A pushing groove is formed in the bottom of the receiving device. The pushing device is arranged in the pushing groove. The second drive device is connected with the pushing device in a drive manner. The discharging mechanism can achieve fully-automatic discharging and is high in discharging efficiency and free of cutting hands, and economic benefits are increased; and by means of the discharging mechanism, hundreds of paper pipes can be put into the discharging box at a time, the feeding frequency of the paper pipes is decreased, and continuous production of the paper pipe cutting machine is achieved.

Owner:东莞市大道精密智能装备有限公司

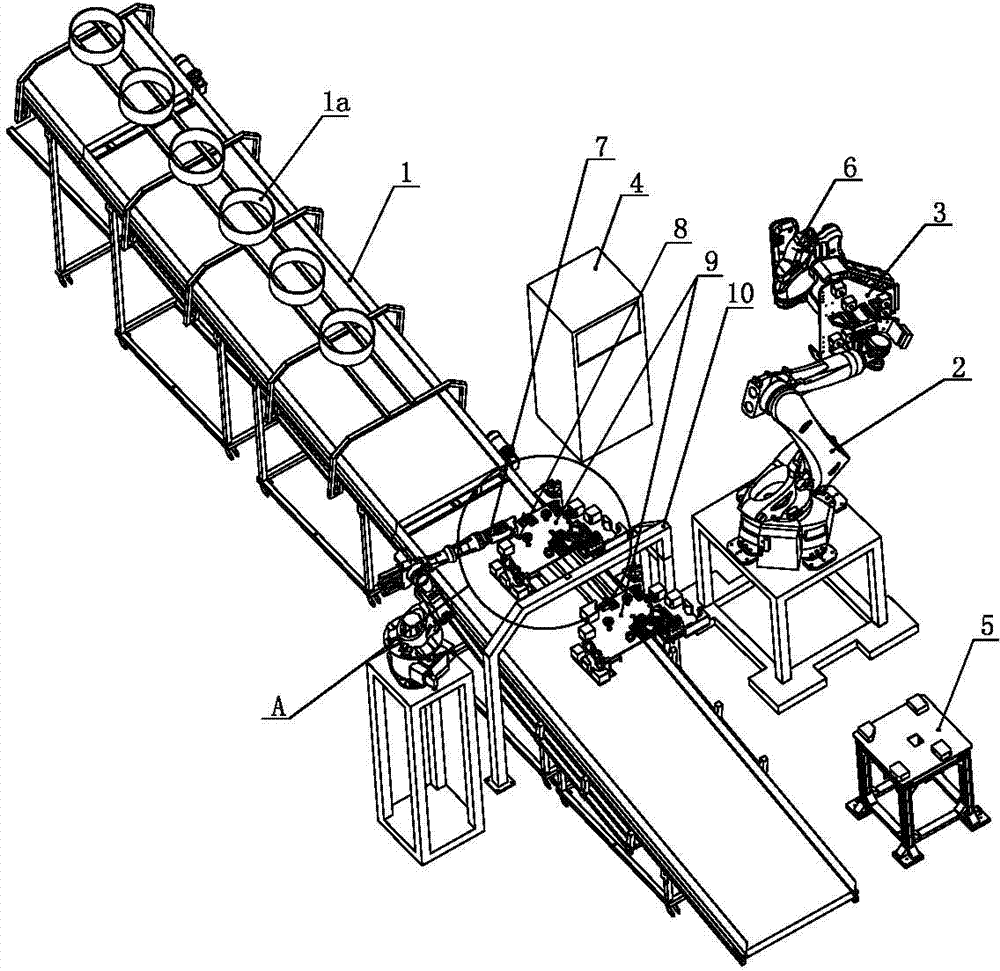

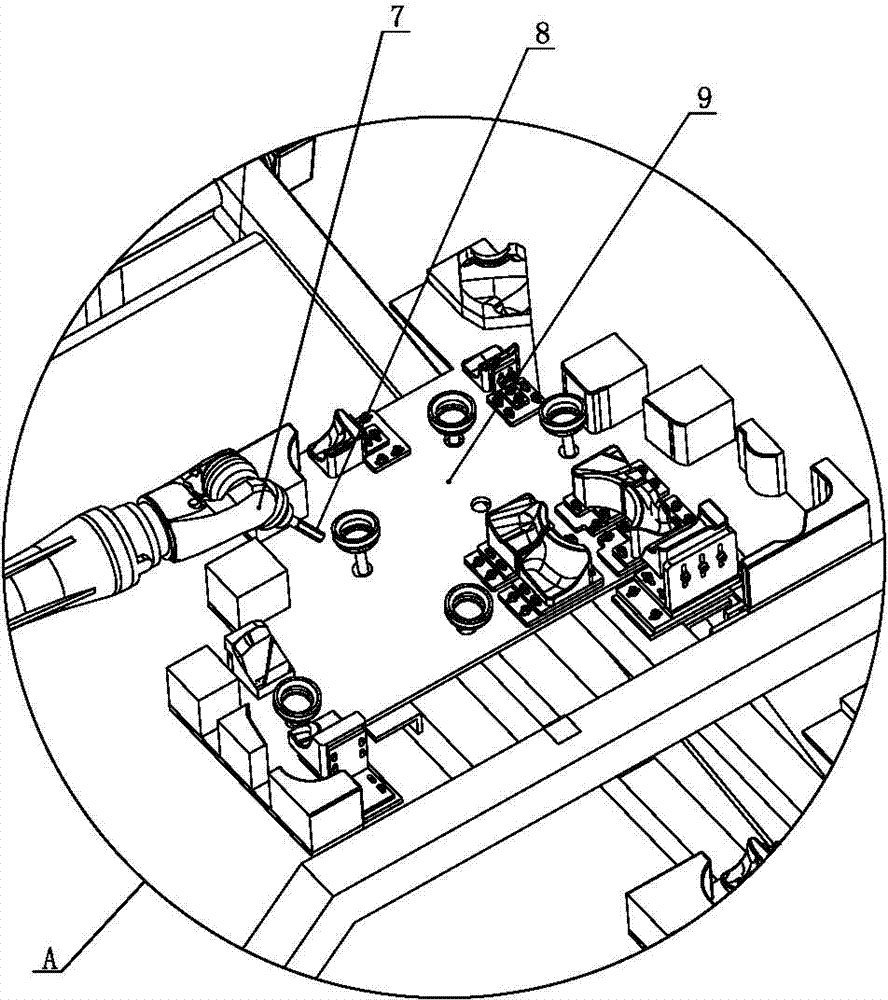

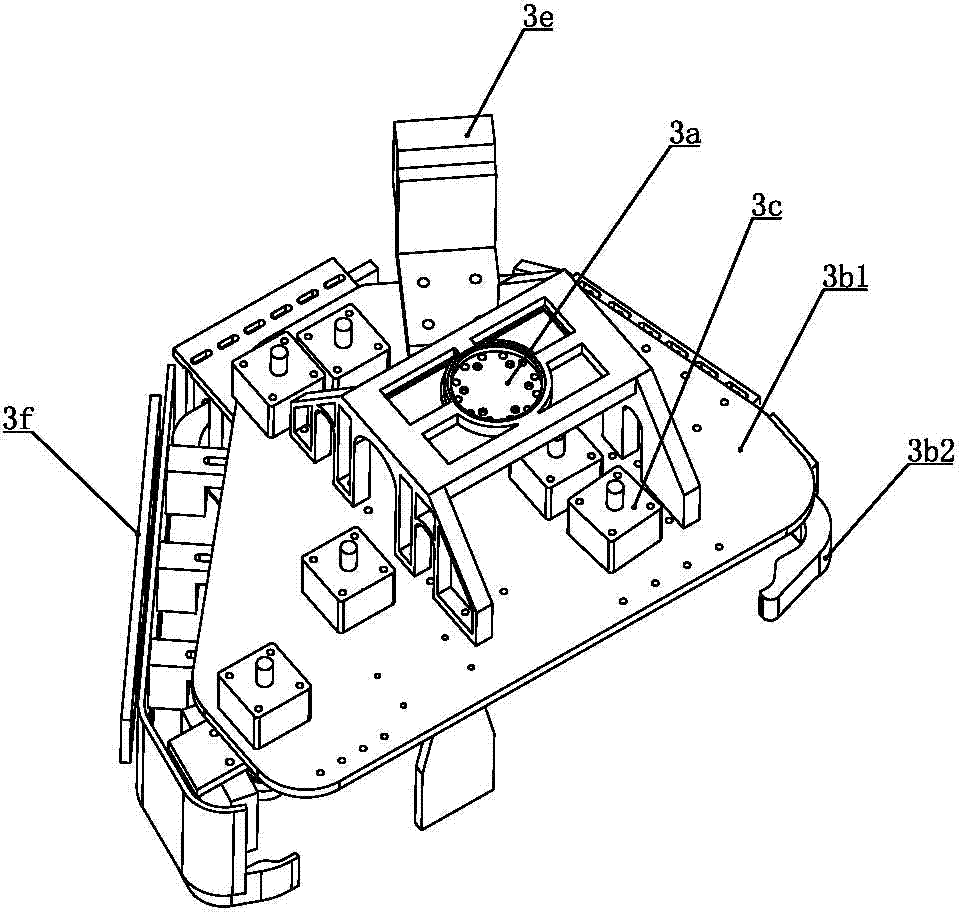

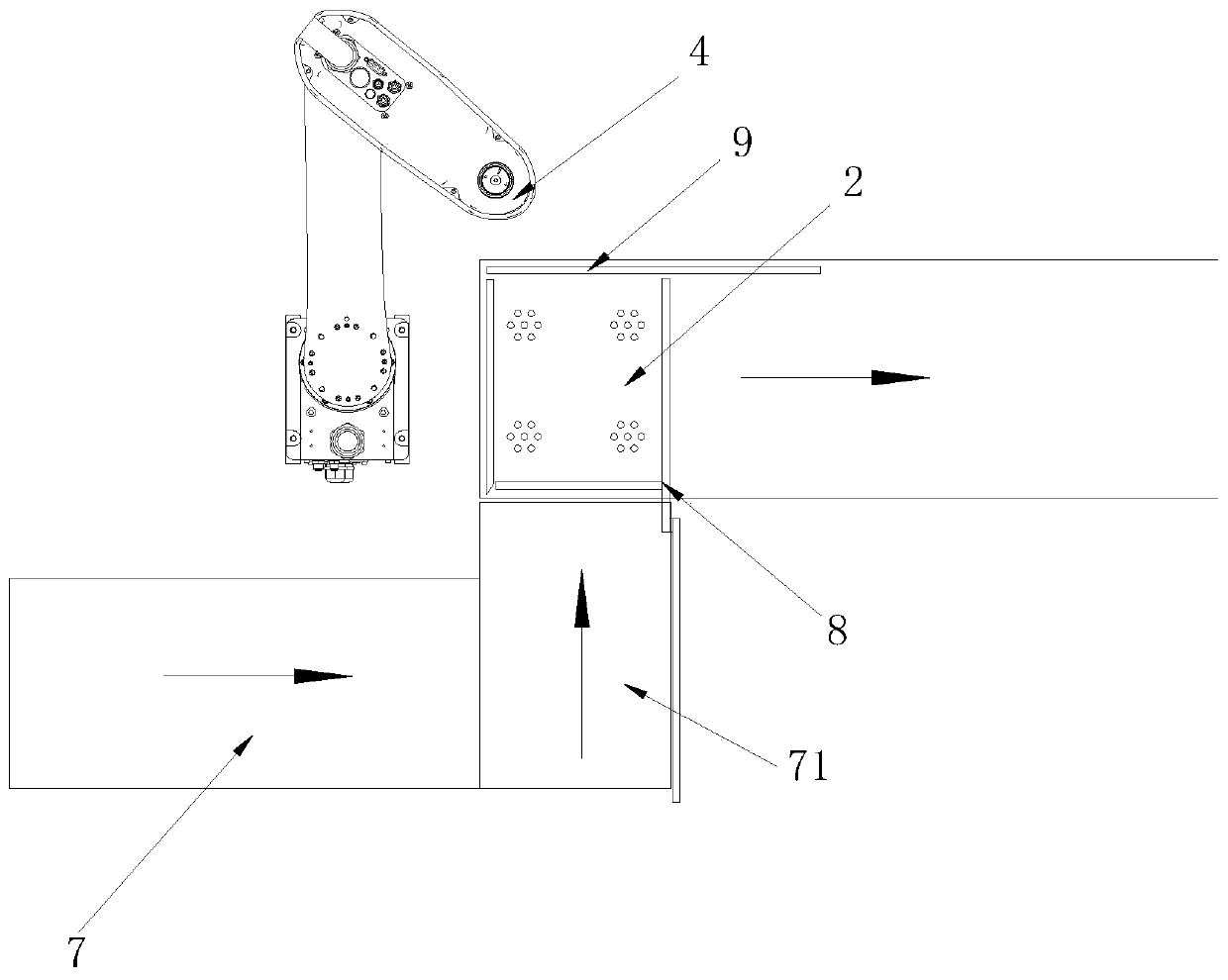

Trimming mechanism of plastic oil tank and method of trimming oil tank

The invention relates to a trimming mechanism of a plastic oil tank and a method of trimming the oil tank. The trimming mechanism comprises a big robot, a barcode printer, a weighing table and a trimming conveying line, wherein the big robot, the barcode printer and the weighing table are all located at the right side of the trimming conveying line, an oil tank grasping mechanism capable of grasping the plastic oil tank is arranged on the end of a mechanical arm of the big robot, the barcode printer and the weighing table are respectively arranged in a working travel range of the mechanical arm of the big robot, a small robot is arranged on a position, which is opposite to the big robot, at the left side of the trimming conveying line, a trimming knife capable of cutting trimmings of joint lines of the plastic oil tank is arranged on the end of a mechanical arm of the small robot, two trimming tables with the consistent shape and size are arranged between the big robot and the small robot in parallel, and the two trimming table are both fixed above the trimming conveying line. When one plastic oil tank is trimmed by the small robot, waiting, grasping, barcode pasting and weighing of another plastic oil tank can be completed by the big robot, and the trimming speed is quick, so that the production period is shortened, and the production efficiency is improved.

Owner:YAPP AUTOMOTIVE PARTS

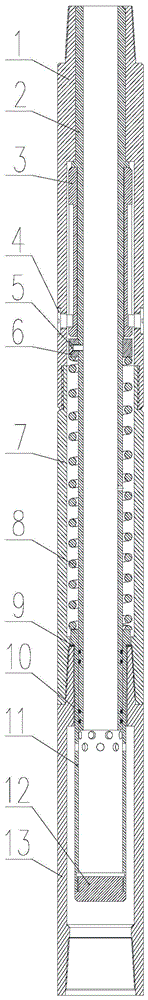

Switching type tubing pump blanking plug

ActiveCN104594847AImprove reliabilityEasy to manufactureSealing/packingElectrical and Electronics engineeringScrew thread

The invention discloses a switching type tubing pump blanking plug. The switching type tubing pump blanking plug comprises an upper connector, a connecting body, a lower connector and a central tube. The upper end of the central tube is arranged inside the upper connector in sleeving mode. The inner wall of the upper connector is two-step-typed. A snap ring is fixed on the central tube, and a track sleeve is arranged between the snap ring and a lug boss arranged on the two-step position of the inner wall of the upper connector. The upper connector is provided with a track pin matched with a track of the track sleeve. The outside of the lower end of the central tube is provided with a switch sleeve in a sleeving mode. Multiple oil inlet holes are formed in the switch sleeve. A spring is arranged between the switch sleeve and the snap ring in a sleeving mode. The connecting body is arranged outside the spring, and one end of the connecting body is connected with the upper connector in a threaded mode. The lower connector is connected with the connecting body is a threaded mode, and is connected with the switch sleeve in a matched mode. The switching type tubing pump blanking plug is installed between a pump cylinder coupling and a fixing valve, and opening and closing of the switching type tubing pump blanking plug is controlled by lowering a sucker rod, so that occurrence of the well kick and blowout accident is prevented during well workover treatment, and the non-well-killing well workover treatment is achieved.

Owner:XI'AN PETROLEUM UNIVERSITY

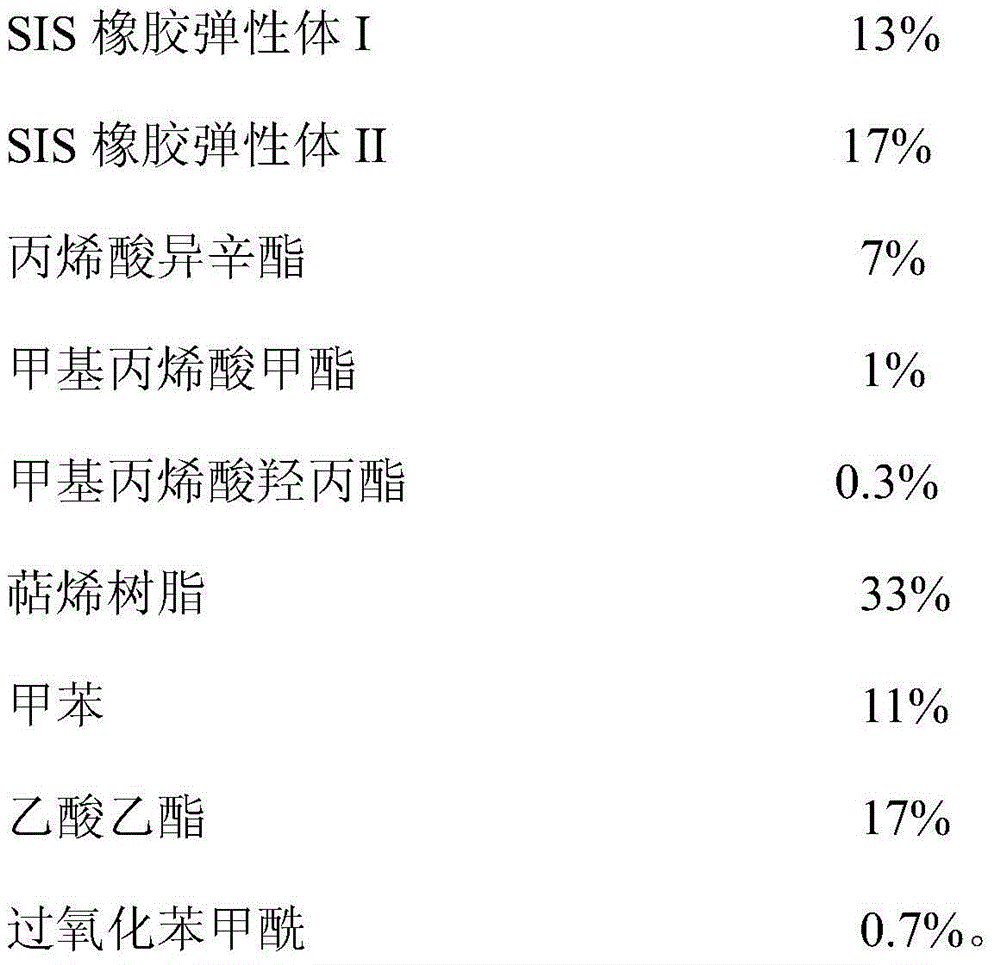

Bearing adhesive tape and preparation method thereof

ActiveCN104559824AHigh tensile strengthLow elongationFilm/foil adhesivesOrganic non-macromolecular adhesiveAdhesion forcePolymer science

The invention relates to a bearing adhesive tape which comprises an acrylic acid modified hot-melt pressure-sensitive adhesive layer and an unilateral stretching film layer, which are fixedly connected with each other; the bearing adhesive tape is high in tensile strength, and low in elongation, can bear a heaviest weight of 10 kg / cm<2>, is high in bearing performance, and low in hardness, cannot cut operators, is low in requirements on used ambient temperature, can be used at the temperature of -20-40 DEG C, and is convenient to use; the acrylic acid modified hot-melt pressure-sensitive adhesive layer is high in cohesion, adhesion force, ageing resistance, and adhesive force on a substrate, has an excellent adhesion stress on polar materials and non-polar materials, is wide in application range, contains no solvent, has no pollution to an environment, does not need to be used with a tackifying primer, is convenient to use, and reduces the use cost. A preparation method of the bearing adhesive tape is simple in process, easy to operate, high in production efficiency, high in coating precision, and high in qualified rate, and can be used for producing adhesive tapes with any widths and any lengths.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Loop pile fabric and weaving method thereof

The invention discloses a loop pile fabric and a weaving method thereof. The loop pile fabric comprises a piece of base cloth, a looped pile and velvets, wherein the looped pile and the velvets are weaved on the base cloth; the loop pile fabric is made of double-layer base cloth fabrics in a divided mode, wherein the double-layer base cloth fabric is composed of loop pile warps, upper base cloth layer and a lower base cloth layer in an interweaving mode; the loop pile warps are capable of converting continuously when interweaving with the upper base cloth layer and the lower base cloth layer; the looped pile is formed through weaving the loop pile warps at the lower side of the upper base cloth layer and the upper side of the lower base cloth layer in a long beating-up mode and a short beating-up mode; the velvet is divided to form velvets after reciprocally linking the loop pile warps between the upper base cloth layer and the lower base cloth layer; the looped pile and the velvets of the loop pile fabric are combined and transformed to form figured patterns. The loop pile fabric has both the bold feature of the looped pile and the elegant feature of the velvet; the method can produce the single-surface jacquard loop pile fabric with the looped pile and the base cloth, the weaving method is easy to perform, the weaving cost is low, and the produced loop pile fabric is high in quality.

Owner:LIAONING CAIYI WILD SILK PROD

Radial edge drill bit with protection sleeve

ActiveCN104249178ANovel structureEasy to operateProtection and storage accessoriesTransportation and packagingWire loopDrill bit

The invention provides a radial edge drill bit with a protection sleeve. The radial edge drill bit comprises a drill edge and a drill handle, wherein a round support frame is arranged on the drill handle in a sheathing manner, a plurality of baffle plates are hung on the round support frame, a wire winding ring is arranged at one end, near the drill edge, of the outer side of each baffle plate, the top end of the drill handle is provided with a pull wire fixing device, each baffle plate respectively passes through wire regulating positions arranged on the wire winding ring and the pull wire fixing device, each baffle plate is in a rectangular shape, one end of each baffle plate is in a circular arc shape, and the radian of the circular arc shape is identical to the radian of the round support frame. The radial edge drill bit has the advantages that the structure is novel, and the operation is simple and convenient, so the protection sleeve realizes the multifunction, and the cost is reduced.

Owner:江苏天工精密工具有限公司

Adhesive tape cutting device

InactiveCN104495489AImprove efficiencyImprove practicalityArticle deliveryEngineeringMechanical engineering

The invention discloses an adhesive tape cutting device. The adhesive tape cutting device comprises a shell, a movable cavity and elastic filler, wherein the movable cavity is formed in the shell and is matched with the tip of the forefinger of a human body; a T-shaped groove is formed in one side of the shell; a T-shaped block is arranged at the bottom of the T-shaped groove; the tail end of a vertical part of the T-shaped block is provided with a blade; the two ends of the horizontal part of the T-shaped block are also provided with a plurality of rubber blocks, and the rubber blocks are in contact with the inner wall of the shell; the elastic filler is arranged in a gap between the movable cavity and the shell; a joint at the junction of a first section of the finger and a second section of the finger projects outwards through bending of the first section of the foreigner to squeeze the elastic filler in the shell, the elastic filler deforms to push the T-shaped block in the T-shaped groove to displace, and finally the blade protrudes out of a notch of the T-shaped groove, so an electrician can conveniently cut an adhesive tape after wrapping the adhesive tape, and the wire end insulation treatment efficiency is increased.

Owner:宜宾市净源电子科技有限公司

Wire clip for photovoltaic tracking device and cable collection anchoring device with wire clip

InactiveCN105743030AAnchored tightlySave materialPhotovoltaicsPhotovoltaic energy generationElectrical and Electronics engineeringPhotovoltaic solar energy

Owner:SUZHOU JINSHAN SOLAR TECH

Processing method for packing tape

ActiveCN105017981AWill not affect normal useNo extra weightFilm/foil adhesivesEngineeringPlastic film

The invention provides a processing method for a packing tape with better user experience. No right-angled corners are available at the upper and lower ends of a produced tape, so that a user is not cut, and meanwhile, the end face of a tape coil is not sticky, so that the tape is more convenient to take and use. The processing method comprises the following main steps: adding a tape raw material acrylic acid into an emulsification tank for emulsification; then putting the emulsified raw material into a reaction pot to be heated to prepare glue; then adding the glue into a coating machine; mounting a plastic thin film coil on the coating machine and smearing the glue to a plastic thin film through the coating machine to prepare a mother coil; pipe-cutting the mother coil through a pipe cutter; stripping the successfully pipe-cut tape through a stripping machine to obtain coils of tapes; polishing the upper and lower inner corners of a paper element of the stripped tape by using a polishing machine; polishing the right-angled corners with the inner corners to bevels or arc-shaped faces; and uniformly adhering paper element powder left when the right-angled corners are polished to the end face of the tape coil of the tape to prepare a finished product packing tape.

Owner:广东宝兰山新材料科技有限公司

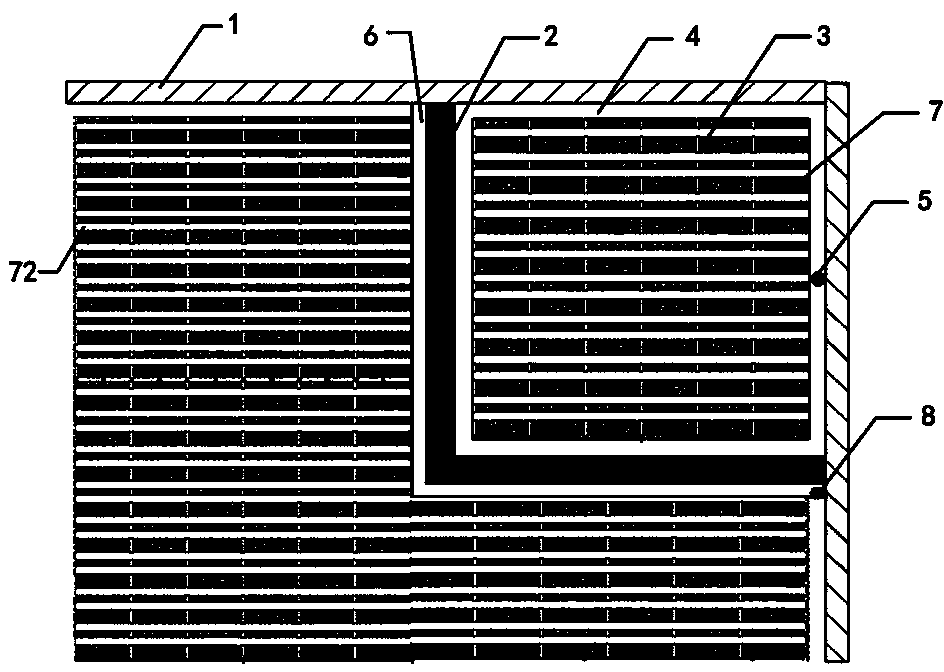

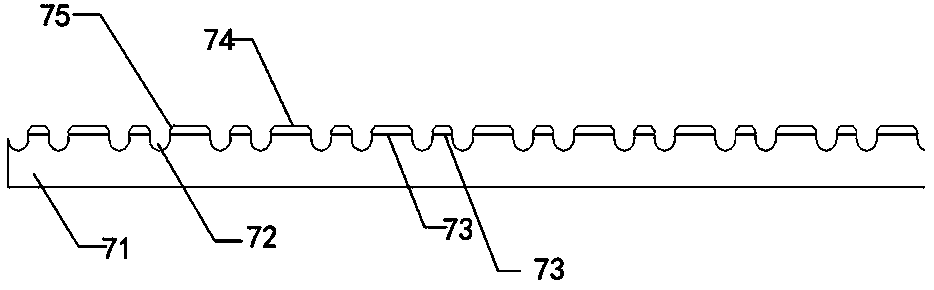

Shower room floor drainage skid resistance structure

ActiveCN104196198APrevent spillageImprove skid resistanceSewerage structuresFlooringMechanical engineeringShower

The invention discloses a shower room floor drainage skid resistance structure which comprises a wall body (1) and a partition (2). A shower room is separated out in a rest room through the partition (2), a shower floor (3) is arranged in the shower room, and annular drainage ditches (4) are arranged between the shower floor (3) and the wall body (1) and between the shower floor (3) and the partition (2). The annular drainage ditches (4) are internally provided with floor drains, and a water blocking ditch (6) is further formed outside the partition (2). The water blocking ditch (6) is also internally provided with a standby floor drain (8), and skid resistance floor tiles (7) are laid on the shower floor (3) and floors, outside the shower room, of the rest room. The laying direction of the skid resistance floor tiles (7) is that drainage grooves (72) face the floor drain (5) in a unified mode. The shower room floor drainage skid resistance structure has the high water accumulation preventing capability, can effectively drain and resist skid and is safe to use and convenient to clean.

Owner:QINGDAO HOUKE INFORMATION ENG

Conducting wire protection mechanism

This invention relates to one line protection structure, which comprises the following parts: one back board to set at least one light source on back board with one exit end on one side of back board; one fix element to fix lamp source; one light source wire to fix element exit through exit end; one buffer pad set in exit end to isolate lamp source wire and back board; the wire protection structure aphototropism module by use of one buffer pad to isolate lamp source wire and back board to avoid lamp source wire cut for dead light.

Owner:CHUNGHWA PICTURE TUBES LTD

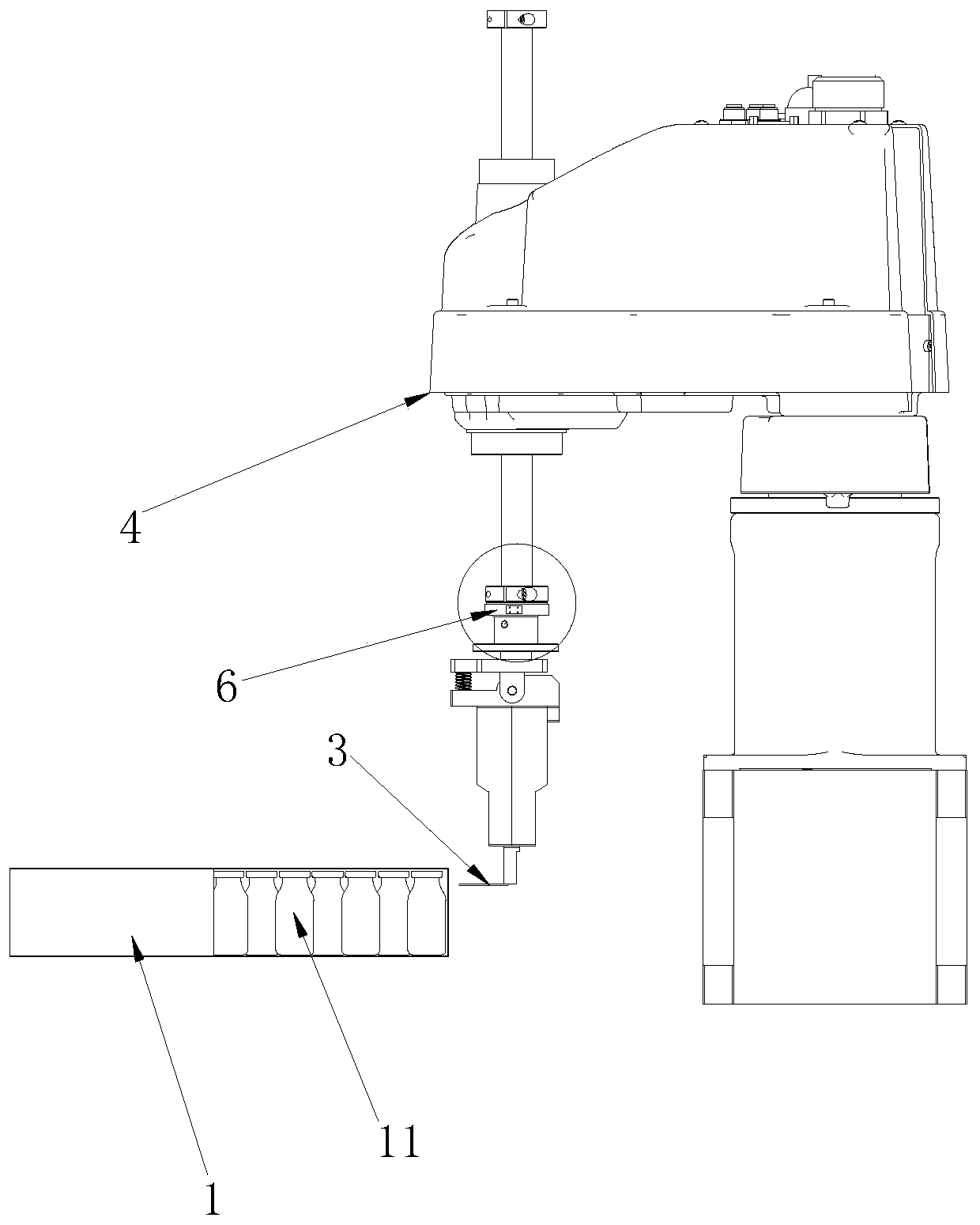

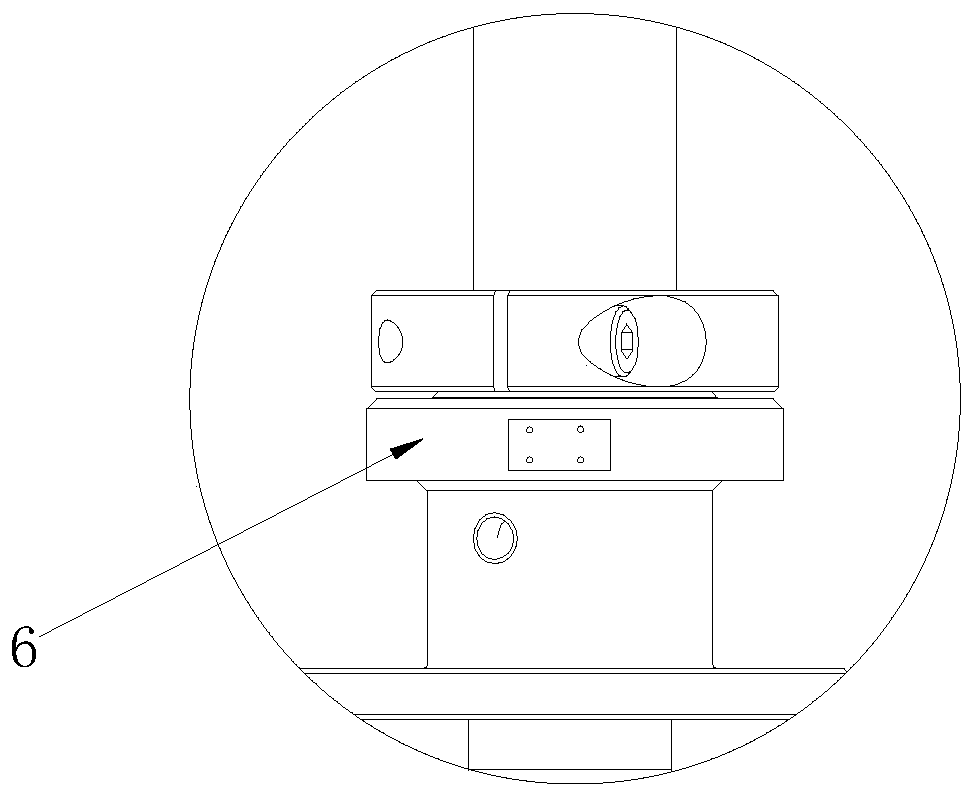

Robot film cutting device and flexible film cutting method

InactiveCN109850293AConstant cutting depthGuaranteed cutting effectArticle unpackingTorque sensorThermocouple

The invention discloses a robot film cutting device. The robot film cutting device comprises a robot, wherein the robot is provided with a torque sensor, the torque sensor is provided with a cutter, and the cutter is provided with a thermocouple and a heating device. According to the robot film cutting device, the torque sensor is arranged on the robot, according to a feedback torque value of thecutter sensed by the torque sensor during film cutting, a deviation value is obtained by subtracting the feedback torque value from a set torque value, and the robot obtains the deviation value and then a feed amount is obtained through PD operation; the robot adjusts the cutter according to the feed amount based on a film cutting path, so that the deviation between the feedback torque value and the set torque value is within a certain range when the cutter cuts a film, and the film cutting depth is ensured to be constant when the cutter cuts the film; and the effect of film cutting is ensuredand a bottle body cannot be damaged. The robot film cutting device is applied to the field of bottle packaging material unpacking.

Owner:TRUKING TECH LTD

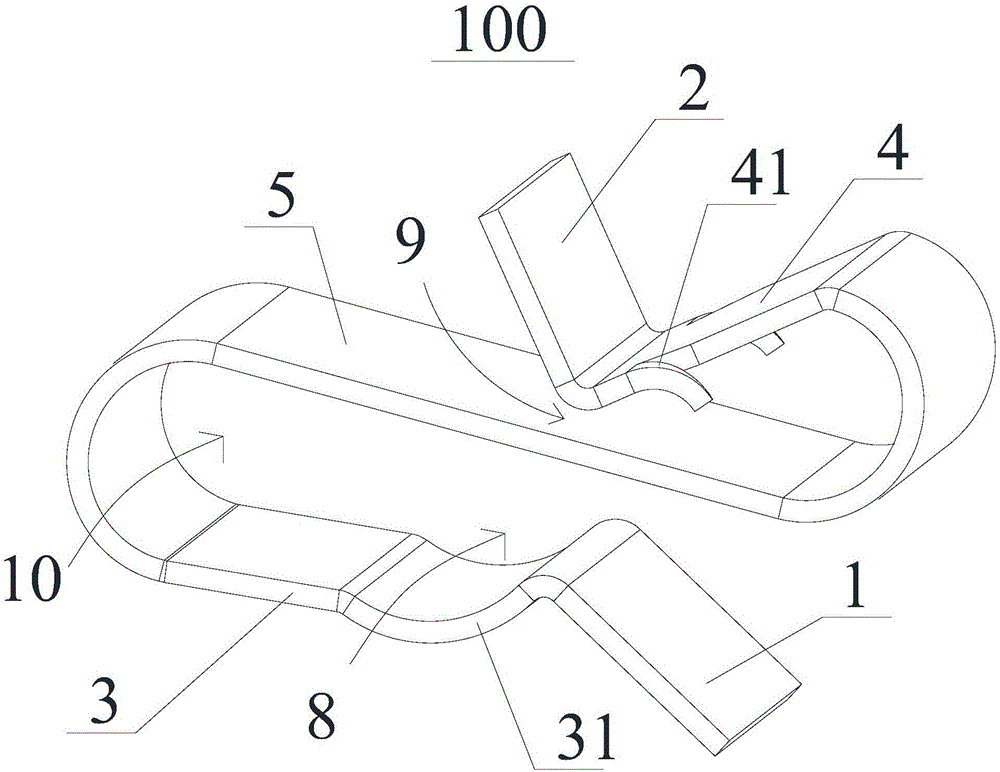

Handheld cable sheath cutter

PendingCN113381346AFlexible structureReduce volumeApparatus for removing/armouring cablesHand heldStructural engineering

The invention relates to the technical field of cable processing auxiliary equipment, in particular to a handheld cable sheath cutter. According to the technical scheme, the handheld cable sheath cutter comprises an upper hinge and a lower hinge which are vertically and oppositely arranged, the left side of the upper hinge and the left side of the lower hinge are hinged through a cylindrical pin, a locking adjusting mechanism is arranged on the right side of the upper hinge and the right side of the lower hinge, a cutting mechanism is installed on the front side of the upper hinge, and auxiliary guide mechanisms are arranged on the rear side of the upper hinge and the front side and the rear side of the lower hinge. The handheld cable sheath cutter is easy to operate, small in size, capable of conveniently and rapidly cutting a cable sheath, capable of saving labor, low in cost and good in cutting consistency, cable insulation cannot be cut, and the scrapping risk does not exist.

Owner:南京科唯信智慧科技有限公司

Cutting equipment for petroleum pipeline

The invention relates to cutting equipment, in particular to cutting equipment for a petroleum pipeline. According to the cutting equipment for the petroleum pipeline, the time and labor are saved, manual cutting is not needed, and cutting injuries are avoided in the cutting process. The cutting equipment for the petroleum pipeline comprises a base and the like; supporting seats are symmetricallymounted on the left and right sides of the top of the base; a sliding groove is formed in the middle of the top of the base and internally provided with a first sliding block, and the first sliding block and the interior of the sliding groove are in slide fit; a hollow cylinder is mounted on the top of the first sliding block; storing holes are formed in the circle center of the left side face andthe circle center of the right side face of the hollow cylinder correspondingly; and a travelling device is arranged on the left side face in the hollow cylinder. A saw disc can be driven by the travelling device to rotate around the petroleum pipeline for comprehensive cutting, and the effects that the time and the labor are saved, manual cutting is not needed, and the cutting injuries are avoided in the cutting process are achieved.

Owner:新昌县益旭龙机械科技有限公司

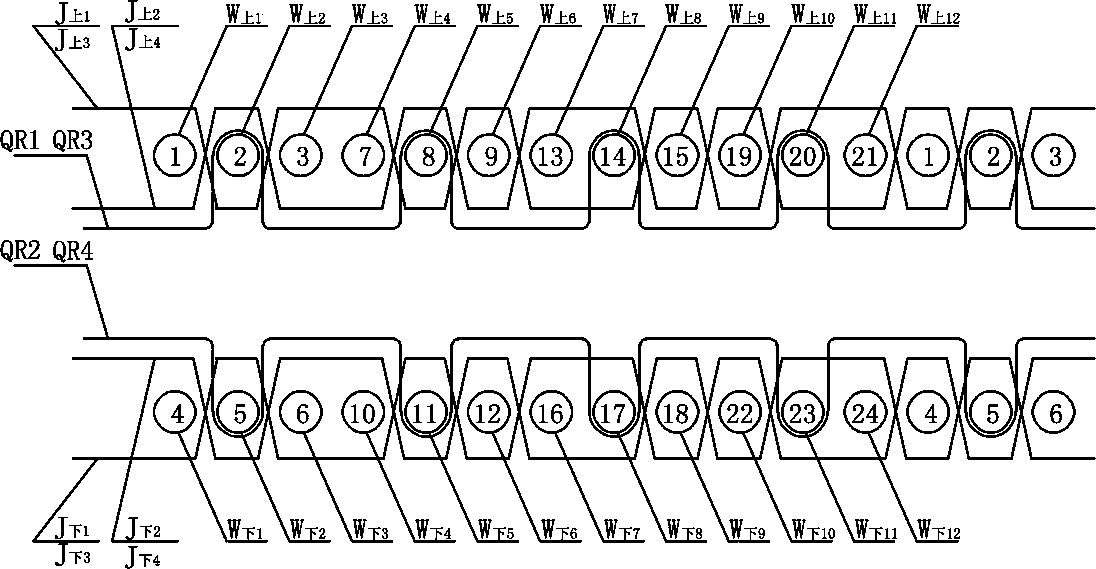

Manufacturing method of flyback transformer

InactiveCN103779057BImprove the ability to withstand pressure agingIncrease productivityTransformersInductancesKnot tyingCopper wire

The invention discloses a manufacturing method of a flyback transformer. The manufacturing method comprises steps as follows: (1), the winding number of coils is set; (2), a to-be-wound primary magnetic bar is fixed on a jig; (3), a wire head with required length by a product is reserved; (4), the wire head winds tightly along the edge of the jig for one circle counterclockwise, and a wire tail presses the wire head which winds for one circle in a 1 / 2 position of a reverse side of the magnetic bar, is parallelly attached to the first circle of copper wire which finishes winding, and is fixed; (5), the wire head is perpendicularly guided out to the tail end of the magnetic bar along the surface of the magnetic bar and is fixed, and equipment is started for winding; (6), the wire tail is tightly attached to the tail end of a winding, a knot is tied in a cross manner, and the wire tail is cut off according to the required length after winding to form a semi-finished product for standby application; (7), during later process production, the knot tied on the primary magnetic bar is untied in the direction opposite to the tying direction, and the wire head or the wire tail is connected to the corresponding position according to requirements of a product; and (8), potting is performed. With the adoption of the manufacturing technology, the voltage withstanding property and the anti-ageing property of the product are improved, the production efficiency is high, and the service life of the product is prolonged remarkably.

Owner:佛山市顺德区铭派电子有限公司

Bunched cable stripper

ActiveCN111130024AEasy to install, disassemble and replaceWon't cutApparatus for removing/armouring cablesElectric power equipmentPower equipment

The invention relates to the technical field of power equipment, and particularly relates to a bunched cable stripper. The bunched cable stripper comprises a base and a supporting seat, wherein the two ends of the upper surface of the base are connected with the supporting seat through supporting plates; a roller is connected between the two supporting plates through a rotating shaft; positioningdevices are correspondingly arranged on the inner walls of the two supporting plates; a shell with an inner cavity is arranged on the supporting seat; a driving bevel gear and a driven bevel gear meshed with the driving bevel gear are arranged in the inner cavity; the driving bevel gear is provided with a transmission rod extending out of the shell; the driven bevel gear is provided with a rotating shaft; the upper end of the rotating shaft is rotatably connected to the shell; the lower end of the rotating shaft is provided with an adjusting screw; the adjusting screw is in threaded connectionwith a lifting rod; the supporting seat is provided with a lifting hole; and the bottom of the lifting rod is connected with a blade. The bunched cable stripper is convenient to use, high in stripping efficiency and high in stability during operation, and does not cut the fingers.

Owner:国网浙江省电力有限公司丽水供电公司 +2

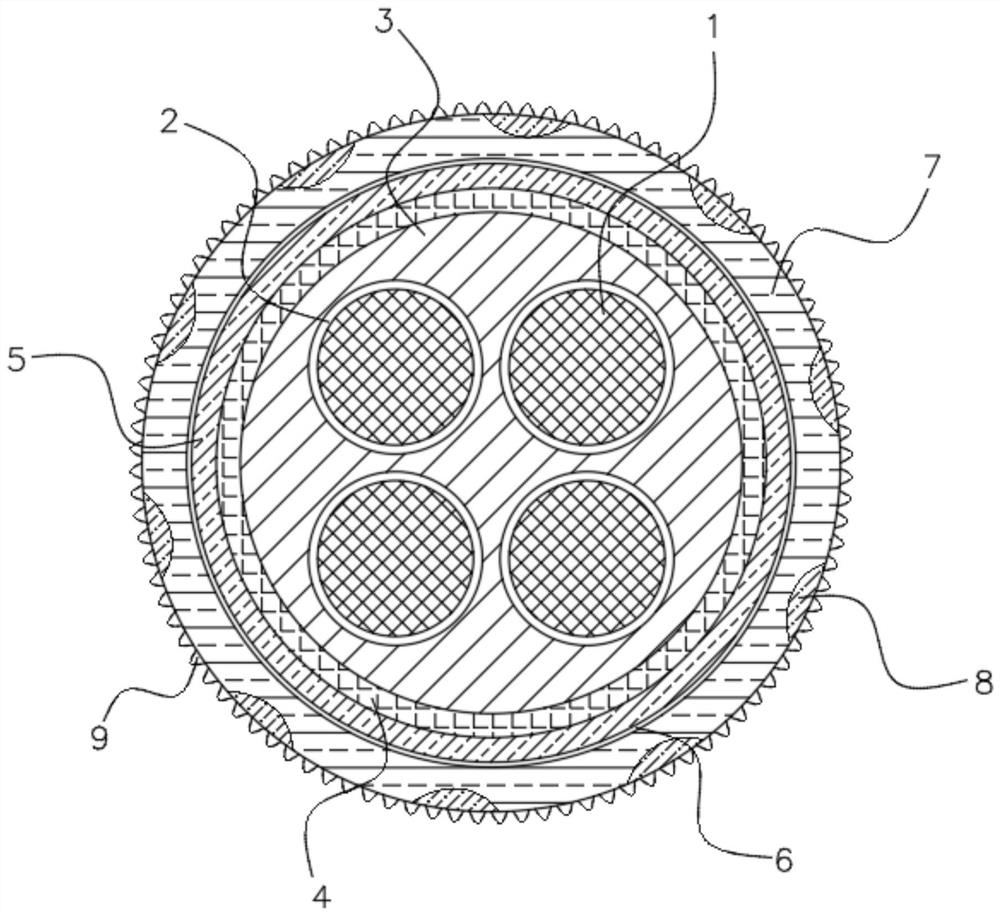

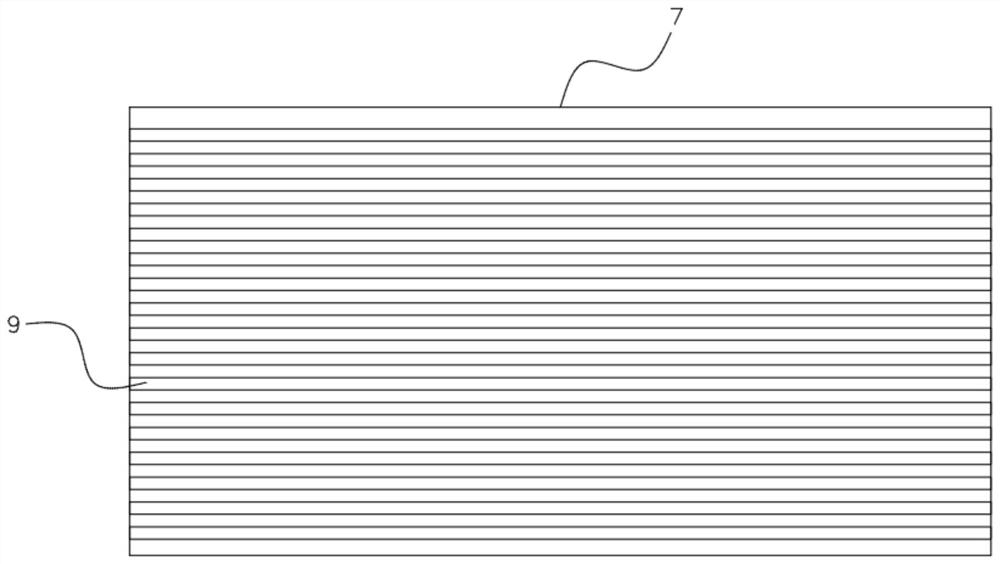

High-performance double-layer co-extrusion insulating flame-retardant fire-resistant computer cable

InactiveCN111799028AImprove heat resistanceImprove rigidityPlastic/resin/waxes insulatorsInsulated cablesPolypropyleneSteel belt

The invention relates to the technical field of power cables. The invention further discloses a high-performance double-layer co-extrusion insulating flame-retardant fire-resistant computer cable. Thecable comprises conductors, insulators, a wrapping tape, an inner sheath, an armor and an outer sheath. The insulators are arranged on the outer sides of the conductors and are made of polypropylenematerials, the plurality of conductors are embedded in the wrapping tape, fillers are embedded among the conductors in the wrapping tape, the inner sheath is arranged on the outer side of the wrappingtape, and the armor is arranged on the outer side of the inner sheath. According to the high-performance double-layer co-extrusion insulating flame-retardant fire-resistant computer cable, the insulators at the outer sides of the conductors are made of a polypropylene material; therefore, the heat resistance, rigidity and tensile strength of the cable are improved; and the armor is a linkage armor made of an aluminum alloy belt, and compared with a common double-steel-belt wrapping mode adopted by a common cable, the aluminum alloy belt and a non-magnetic material adopted by the linkage armordo not generate eddy currents, and the heat dissipation performance, the side pressure resistant performance and the anti-collision performance are good, , the inside is smooth and the insulator is not cut, and the safety coefficient is high.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

Hard material blanking four-column hydraulic cutting machine

InactiveCN108213173AReduce labor intensityIncrease productivityMetal working apparatusEjection devicesWater pipeEngineering

The invention discloses a hard material blanking four-column hydraulic cutting machine. The hard material blanking four-column hydraulic cutting machine comprises a cutting head and a cutting table, wherein the cutting head is arranged on the cutting table through four hydraulic column supports and fixedly connected with an automatic unloading device; the inside of an unloading rack is provided with a rolling slot for accommodating a wheel; an unloading head module is rotatingly hung on the unloading rack through cooperation between the wheel and the rolling slot; a limiting fixing device is arranged between the unloading head module and the unloading rack; the unloading rack module comprises a T-shaped rack connected with the unloading rack and a sucker fixedly connected with the T-shapedrack, the T-shaped rack is provided with a vacuum pump, and the sucker is connected with a water pipe. The hard material blanking four-column hydraulic cutting machine can complete automatic unloading operation during a cutting process, save additional personnel or time for unloading, reduce the labor intensity, improve the production efficiency and avoid cutting arms of operators and the like.

Owner:JIANGSU MAOLONG MACHINERY MFG

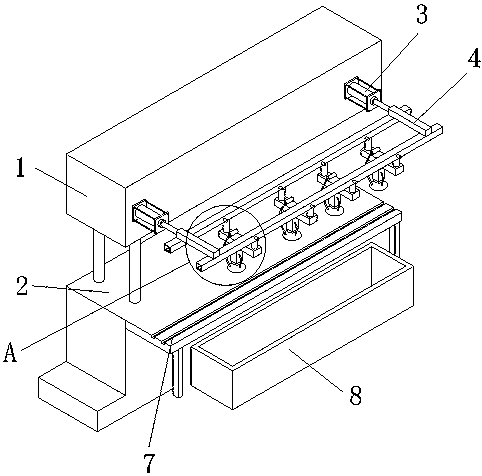

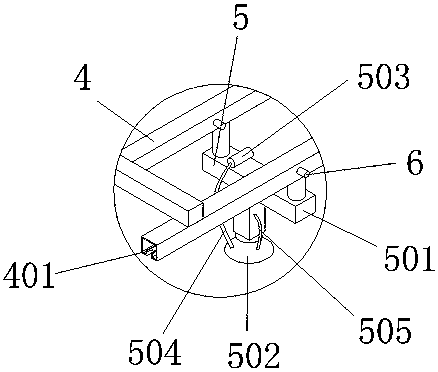

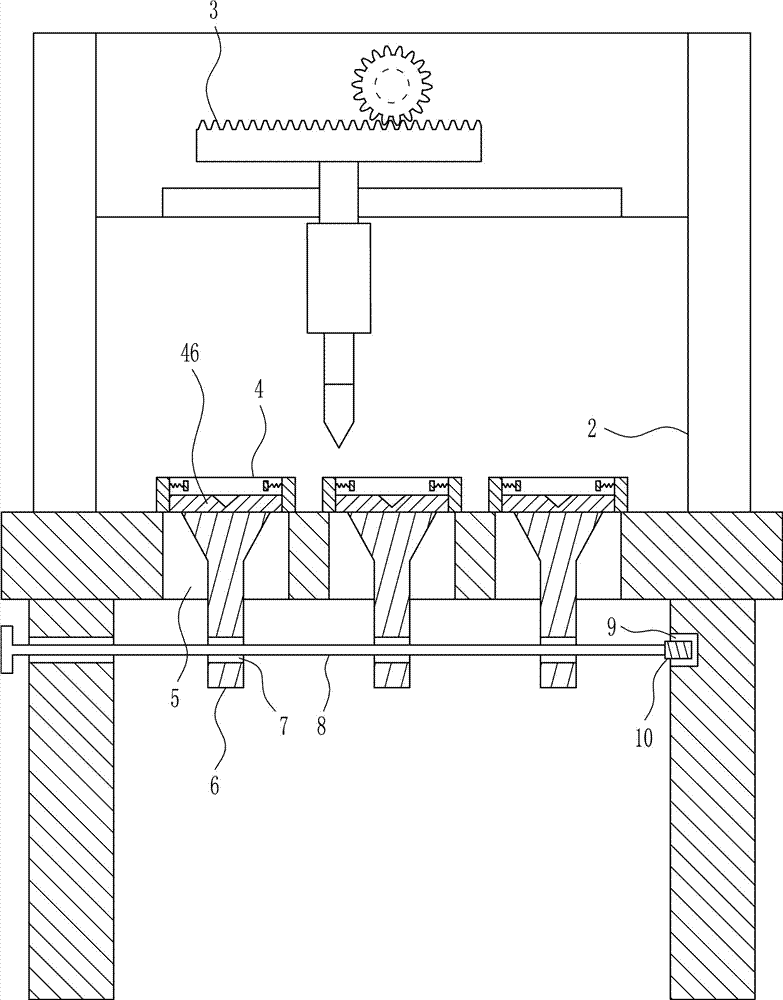

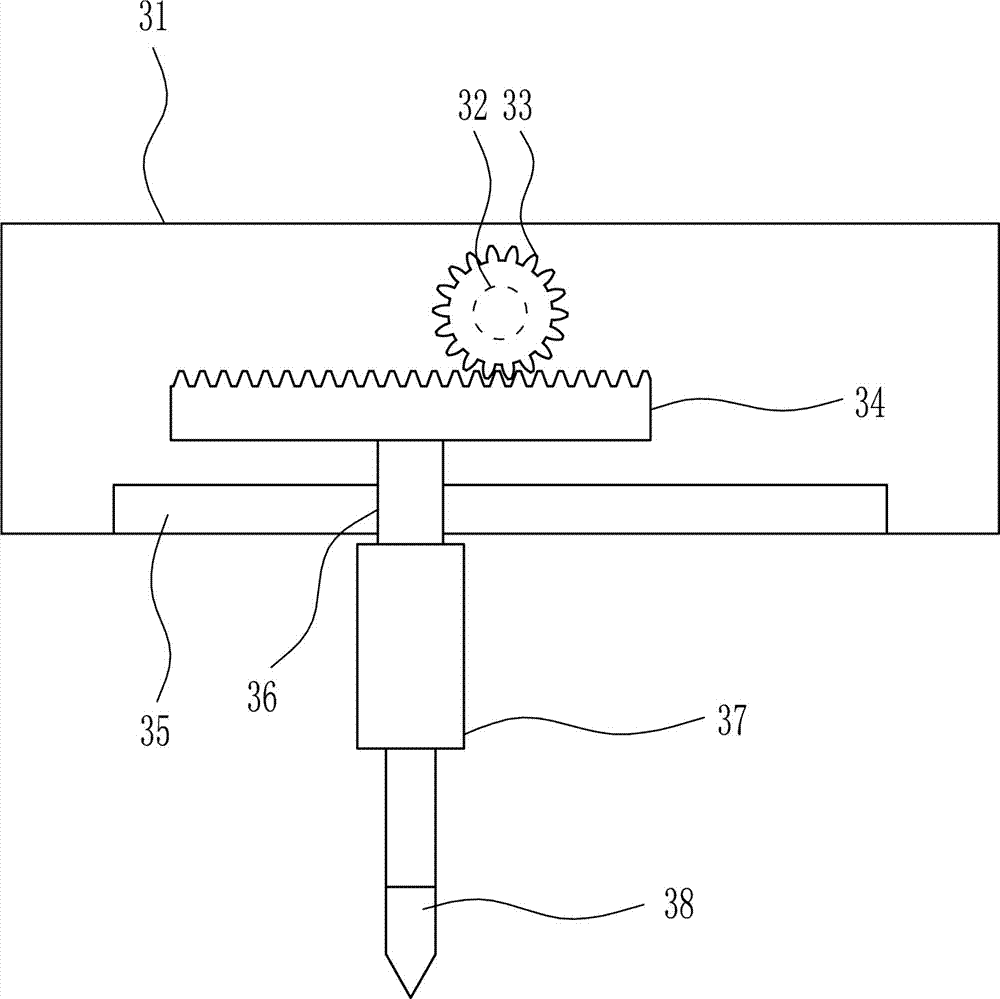

Easily-torn opening automatic cutting device for medicine packaging bag

ActiveCN107351145AEasy to cutImprove work efficiencyMetal working apparatusMechanical engineeringEngineering

The invention relates to an automatic cutting device, in particular to an easily-torn opening automatic cutting device for a medicine packaging bag. According to the technical aims, the easily-torn opening automatic cutting device for the medicine packaging bag can automatically cut easily-torn opening of the medicine packaging bag in batch and improve efficiency. In order to achieve the above technical aims, the easily-torn opening automatic cutting device for the medicine packaging bag is provided and comprises a working table and the like; a support is connected to the top of the working table, containing mechanisms are evenly placed above the working table, a cutting mechanism is arranged above the containing mechanisms, and the cutting mechanism and the containing mechanisms are located in the support. The easily-torn opening automatic cutting device for the medicine packaging bag is designed, the cutting mechanism is arranged on the device, and therefore the easily-torn opening of the medicine packaging bag can be conveniently cut, and the working efficiency is high.

Owner:鹤山市诚汇包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com