Bearing adhesive tape and preparation method thereof

A tape and glue melting technology, which is applied in the direction of adhesives, film/sheet adhesives, non-polymer organic compound adhesives, etc., can solve the problems of poor aging resistance, inconvenient use, and high elongation, and achieve Good aging resistance, low cost of use, high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A load-bearing adhesive tape of the present invention comprises an acrylic modified hot-melt pressure-sensitive adhesive layer and a uniaxially stretched film layer, and the acrylic modified hot-melt pressure-sensitive adhesive layer is fixedly connected to the uniaxially stretched film layer.

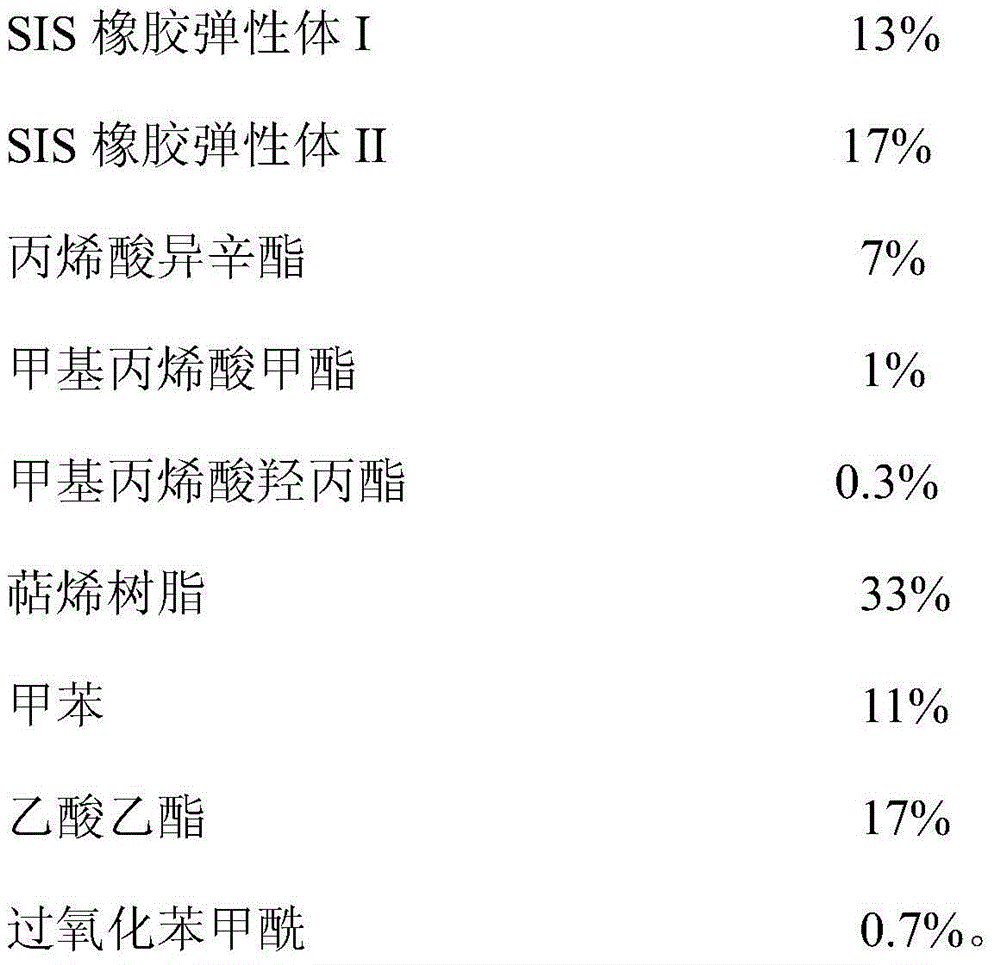

[0031] The acrylic modified hot-melt pressure-sensitive adhesive layer of the present embodiment comprises the following raw materials in mass percentage:

[0032]

[0033] The average molecular weight of the SIS rubber elastic body I in this embodiment is 380,000, and the average molecular weight of the SIS rubber elastic body II is 280,000.

[0034] The terpene resin in this embodiment is SBS, and the SBS is a styrene-butadiene-styrene block copolymer.

[0035] The uniaxially stretched film layer in this embodiment is a uniaxially stretched PP film layer.

[0036] The thickness of the acrylic modified hot-melt pressure-sensitive adhesive layer in this embodiment is 50 micr...

Embodiment 2

[0046] A load-bearing adhesive tape of the present invention comprises an acrylic modified hot-melt pressure-sensitive adhesive layer and a uniaxially stretched film layer, and the acrylic modified hot-melt pressure-sensitive adhesive layer is fixedly connected to the uniaxially stretched film layer.

[0047] The acrylic modified hot-melt pressure-sensitive adhesive layer of the present embodiment comprises the following raw materials in mass percentage:

[0048]

[0049]

[0050] The average molecular weight of the SIS rubber elastic body I in this embodiment is 350,000, and the average molecular weight of the SIS rubber elastic body II is 200,000.

[0051]The terpene resin in this embodiment is SBR, and the SBR is styrene-styrene-butadiene rubber.

[0052] The uniaxially stretched film layer of this embodiment is a uniaxially stretched PET film layer.

[0053] The thickness of the acrylic modified hot-melt pressure-sensitive adhesive layer in this embodiment is 40 mic...

Embodiment 3

[0063] A load-bearing adhesive tape of the present invention comprises an acrylic modified hot-melt pressure-sensitive adhesive layer and a uniaxially stretched film layer, and the acrylic modified hot-melt pressure-sensitive adhesive layer is fixedly connected to the uniaxially stretched film layer.

[0064] The acrylic modified hot-melt pressure-sensitive adhesive layer of the present embodiment comprises the following raw materials in mass percentage:

[0065]

[0066] The average molecular weight of the SIS rubber elastic body I in this embodiment is 300,000, and the average molecular weight of the SIS rubber elastic body II is 180,000.

[0067] The terpene resin in this embodiment is SBS, and the SBS is a styrene-butadiene-styrene block copolymer.

[0068] The uniaxially stretched film layer in this embodiment is a uniaxially stretched PP film layer.

[0069] The thickness of the acrylic modified hot-melt pressure-sensitive adhesive layer in this embodiment is 35 micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com