Large flange for sealing induction furnace lid and furnace stack

A furnace body sealing and large flange technology, which is applied in the field of large flanges, can solve the problems of high production costs, stainless steel prices and high processing costs, and achieve the effects of low processing costs, reduced production costs, and protection from burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

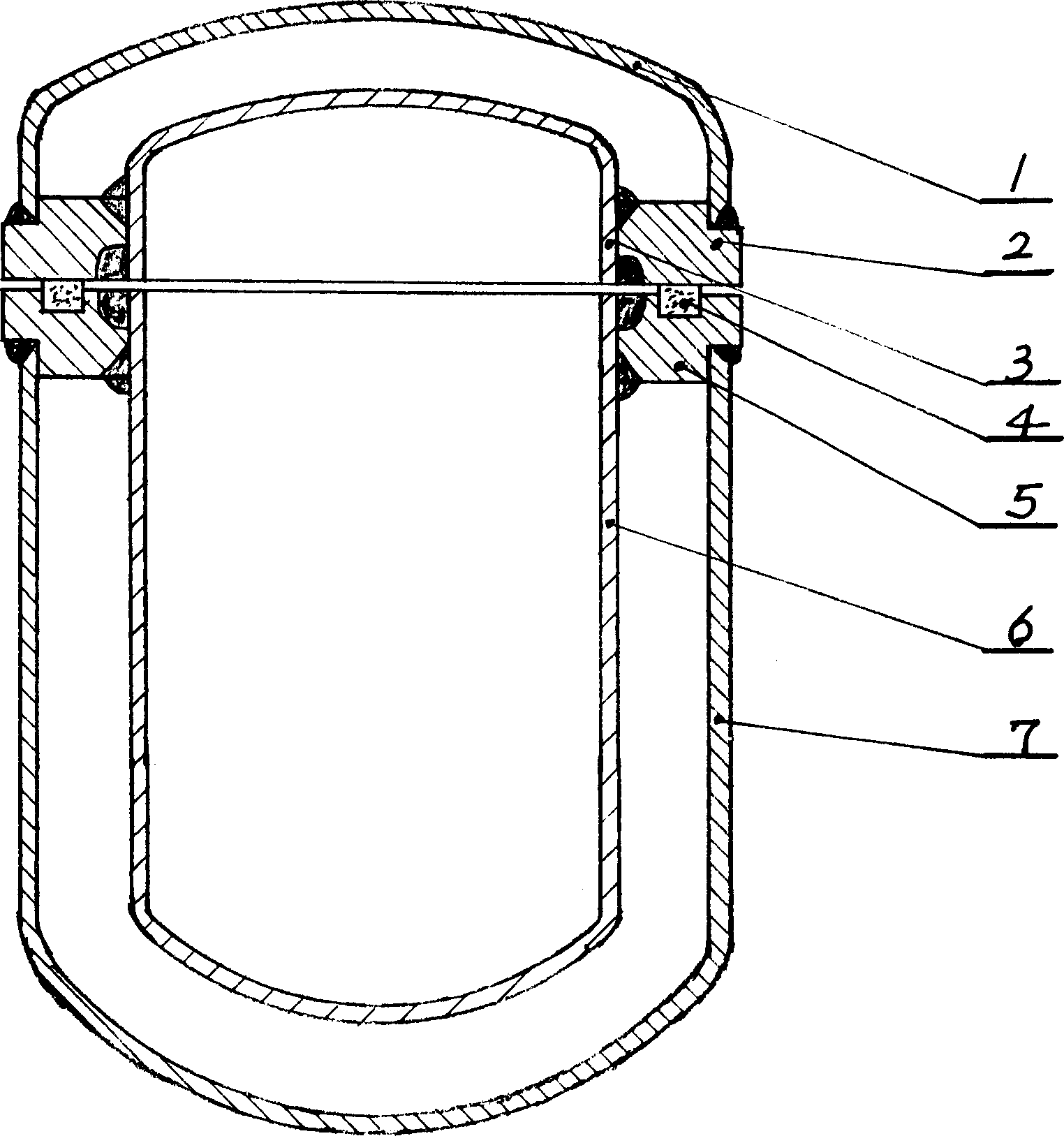

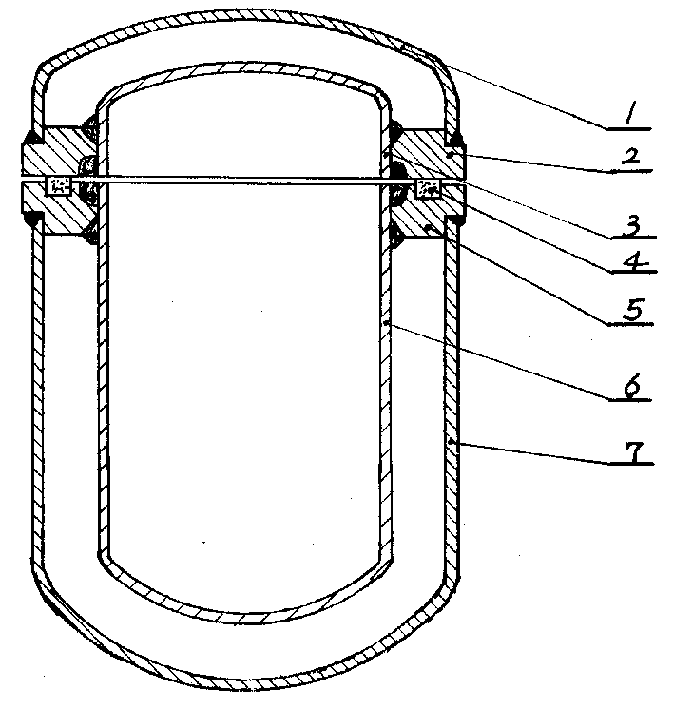

[0007] The outer wall 1 of the furnace cover made of ordinary steel and the inner wall 3 of the stainless steel furnace cover are installed on the flange 2 of the ordinary steel furnace cover, and the lower part of the inner wall of the stainless steel furnace cover is lined on the inner side of the ordinary steel furnace cover flange to form a composite furnace cover flange; Furnace body wall 7 and stainless steel furnace body 6 are contained on the common steel body of furnace flange 5, and the top of stainless steel furnace body is lined on the inner side of common steel body of furnace flange, forms composite type body of furnace flange. Taking the furnace body with a diameter of 1-1.5 meters as an example, the cross-section of the large flange is (60-80)×(40-60) mm, and the thickness of the inner stainless steel plate is 5-12 mm. Seal with sealing ring 4 between the furnace cover flange and the body of furnace flange, between the outer wall of the furnace and the furnace g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com