Cycling and precipitate recovering device for aluminum-air cells

An aluminum-air battery and recycling device technology, applied in battery recycling, battery pack parts, recycling technology and other directions, can solve problems such as frequent electrolyte replacement, and achieve the effect of improving power generation efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

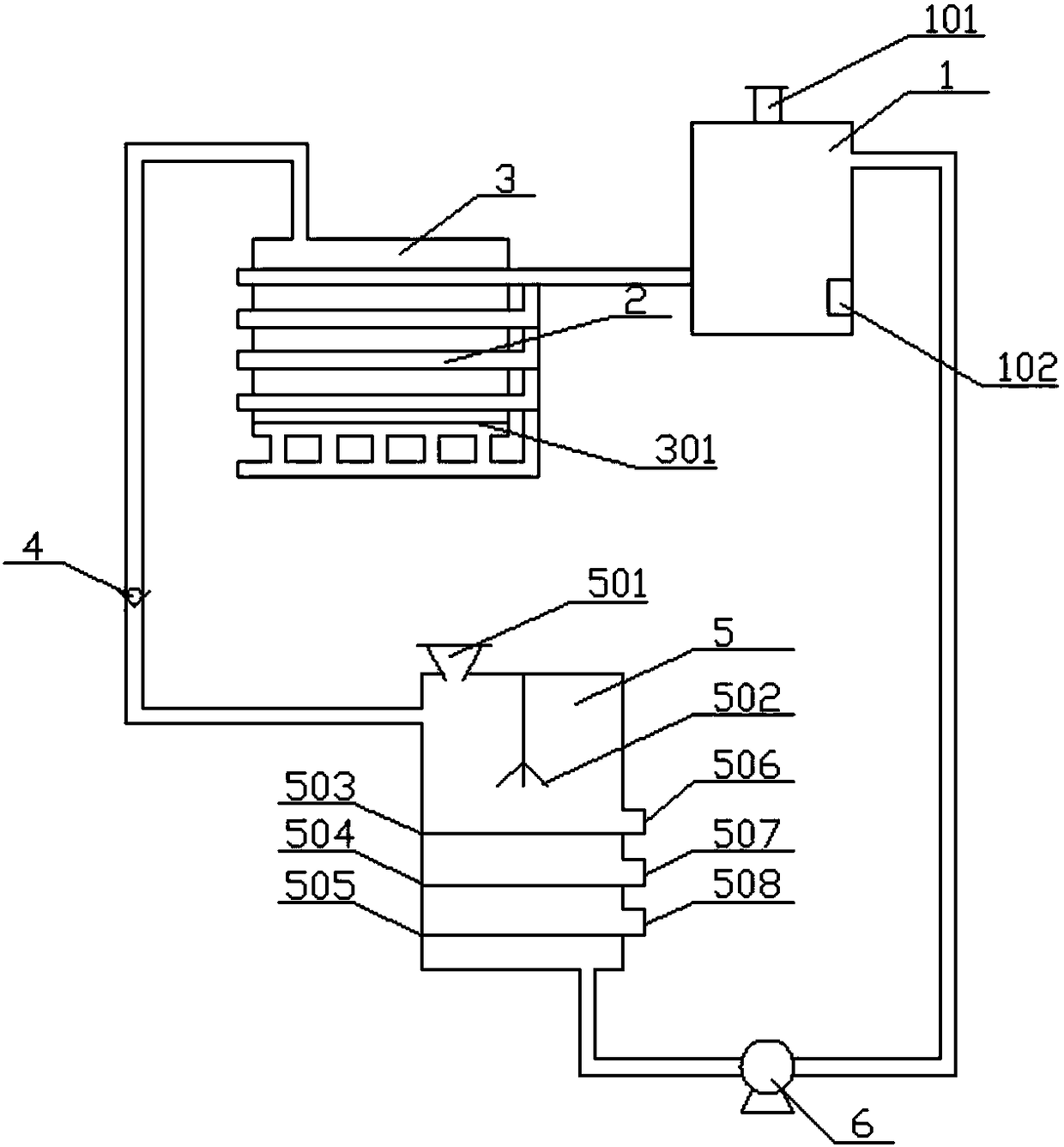

[0020] Such as figure 1 As shown, it is an aluminum-air battery circulation and precipitation recovery device involved in this embodiment, which includes: an electrolyte tank 1, a cooling circulation pipeline 2, an aluminum-air battery pack 3, a precipitation filtration system 5 and a pressure Pump 6, wherein: the output end at the bottom of the electrolyte tank 1 is connected to the liquid inlet of the cooling circulation pipe 2 arranged outside the aluminum-air battery pack 3, and the liquid outlet at the top of the aluminum-air battery pack 3 is connected to the input of the sedimentation filtration system 5 The end is connected through a one-way valve 4, and the bottom output end of the sediment filtration system 5 is connected with a pressure pump 6.

[0021] The bottom of the electrolyte tank 1 is provided with a concentration detector 102 .

[0022] The liquid inlet of the cooling circulation pipeline 2 adopts a parallel branch pipe structure.

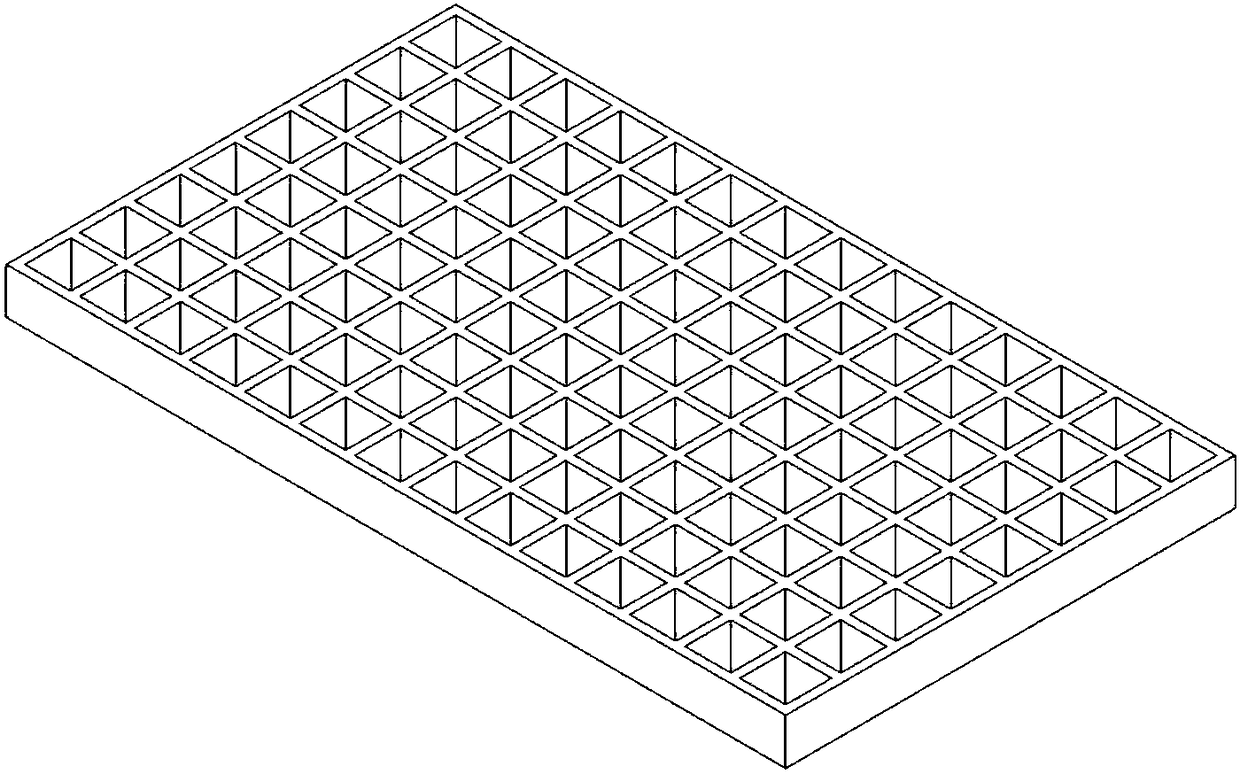

[0023] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com