Gas burner for flat fan-shaped flame ultra-low NOx emission large-load cracking furnace

A gas burner and fan-shaped flame technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of high average and peak flame temperatures, uneven heat distribution in the furnace, and high NOx emissions, so as to reduce the average Effect of temperature and peak temperature, suppression of NOx emission, and reduction of NOx emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

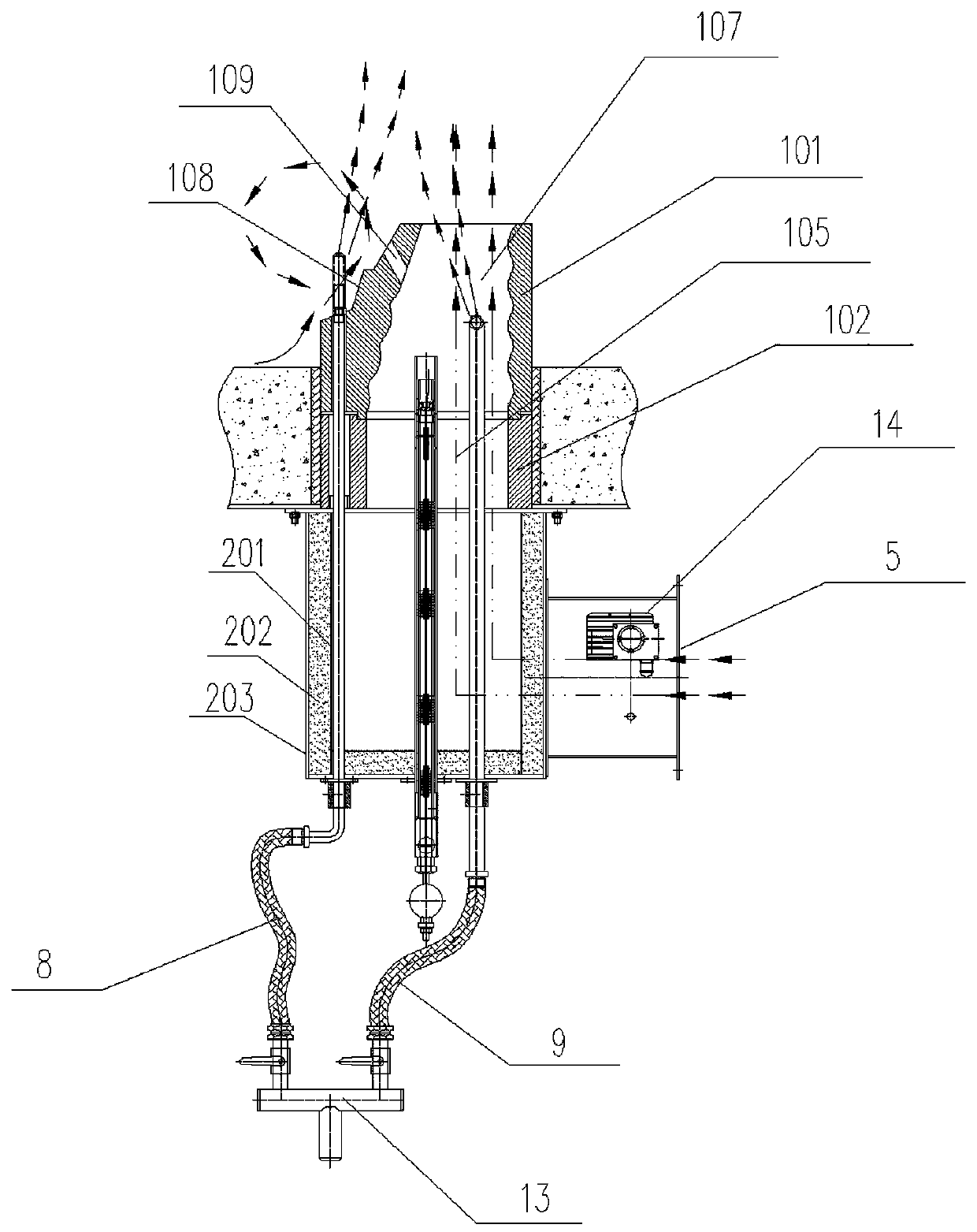

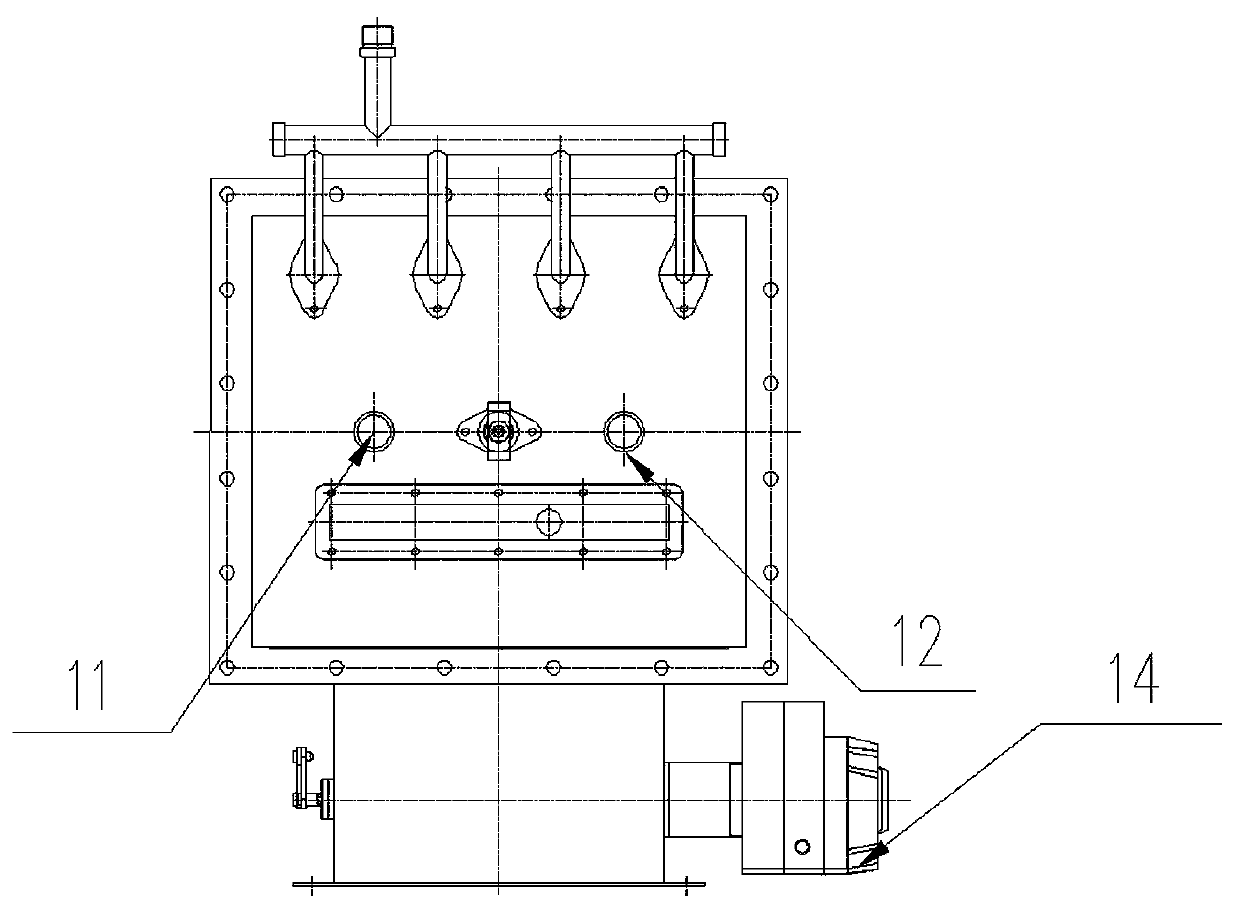

[0040] see Figure 1 to Figure 10 A gas burner for a flat fan-shaped flame ultra-low NOx emission large-load cracking furnace is arranged in a heating furnace and includes a brazier brick assembly 1, a cylinder body 2, a T-shaped gun assembly 3, and four outer gun assemblies 4.

[0041] Such as figure 1 and figure 2 , the barrel 2 is arranged at the bottom of the fire pot assembly 1 and communicates with the inside of the fire pot assembly 1 . The back of the cylinder body 2 is provided with an air regulating butterfly valve assembly 5 communicating with the inside of the cylinder body 2 . Such as Figure 9 , each outer gun assembly 4 is evenly distributed on the gas bag tube 6 and communicated with the gas bag tube 6 . The two ends of the air bag tube 6 are respectively provided with a plug 7 . The gas bag pipe 6 communicates with the gas feed pipe 8 of the outer gun.

[0042] Such as figure 1 , figure 2 , Figure 4 to Figure 8 , The brazier brick assembly 1 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com