Ultra-low NOx emission heavy-load boiler gas burner

A gas burner, large load technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., to achieve uniform heat load, reduce the generation of NOx, and facilitate mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

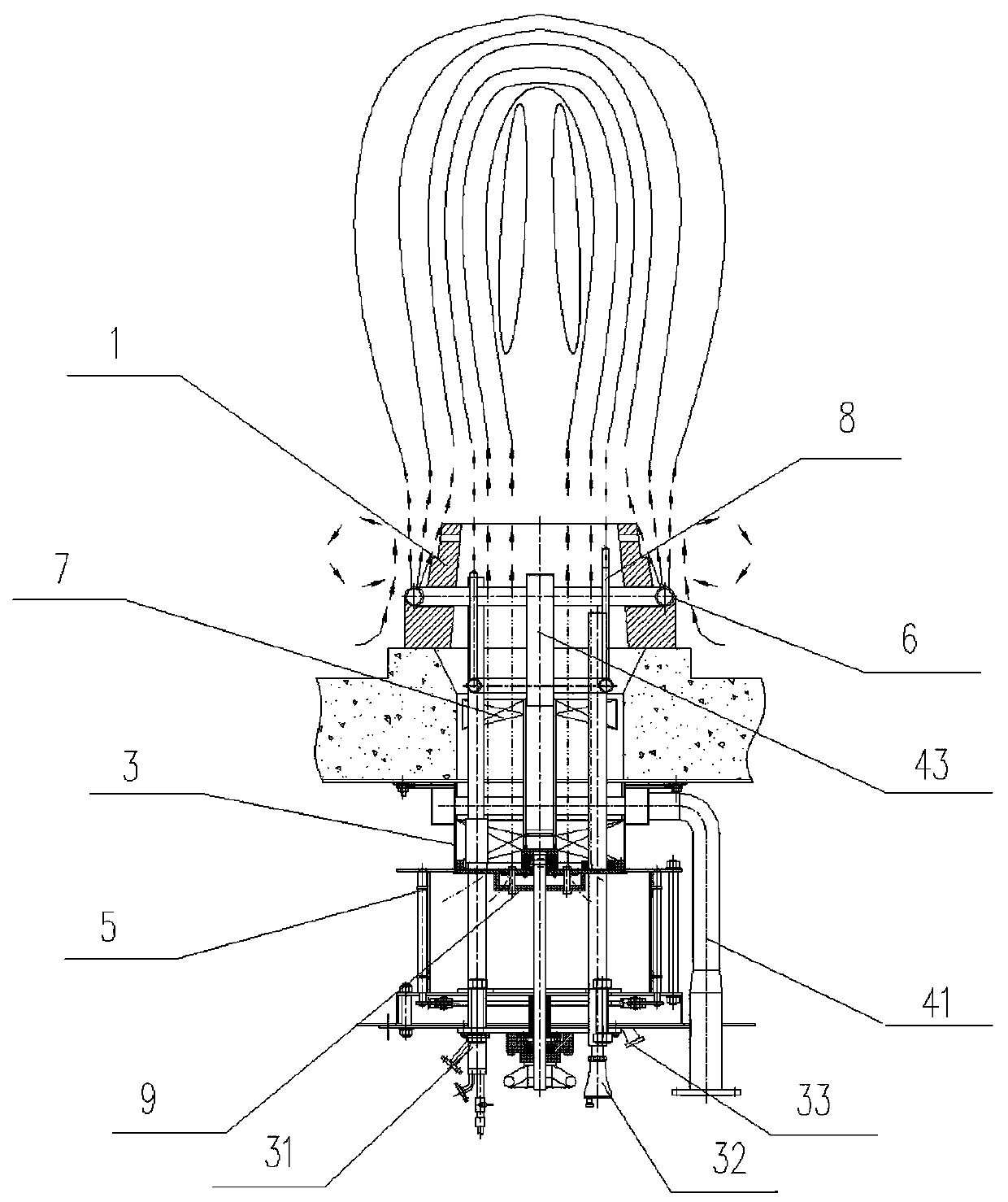

[0052] Such as figure 1 As shown, a gas burner for an ultra-low NOx emission heavy-duty boiler includes a control part, an always-on light assembly 31, a fire detection assembly 32, a brazier brick 1 connected in sequence from top to bottom, a cylinder body 3, and a louver air regulating mechanism 5 .

[0053] Wherein, the cylinder body 3 is provided with an upper and lower double swirl vane assembly 7 . A bellows sealing structure assembly 9 is provided on the louver air regulating mechanism 5 .

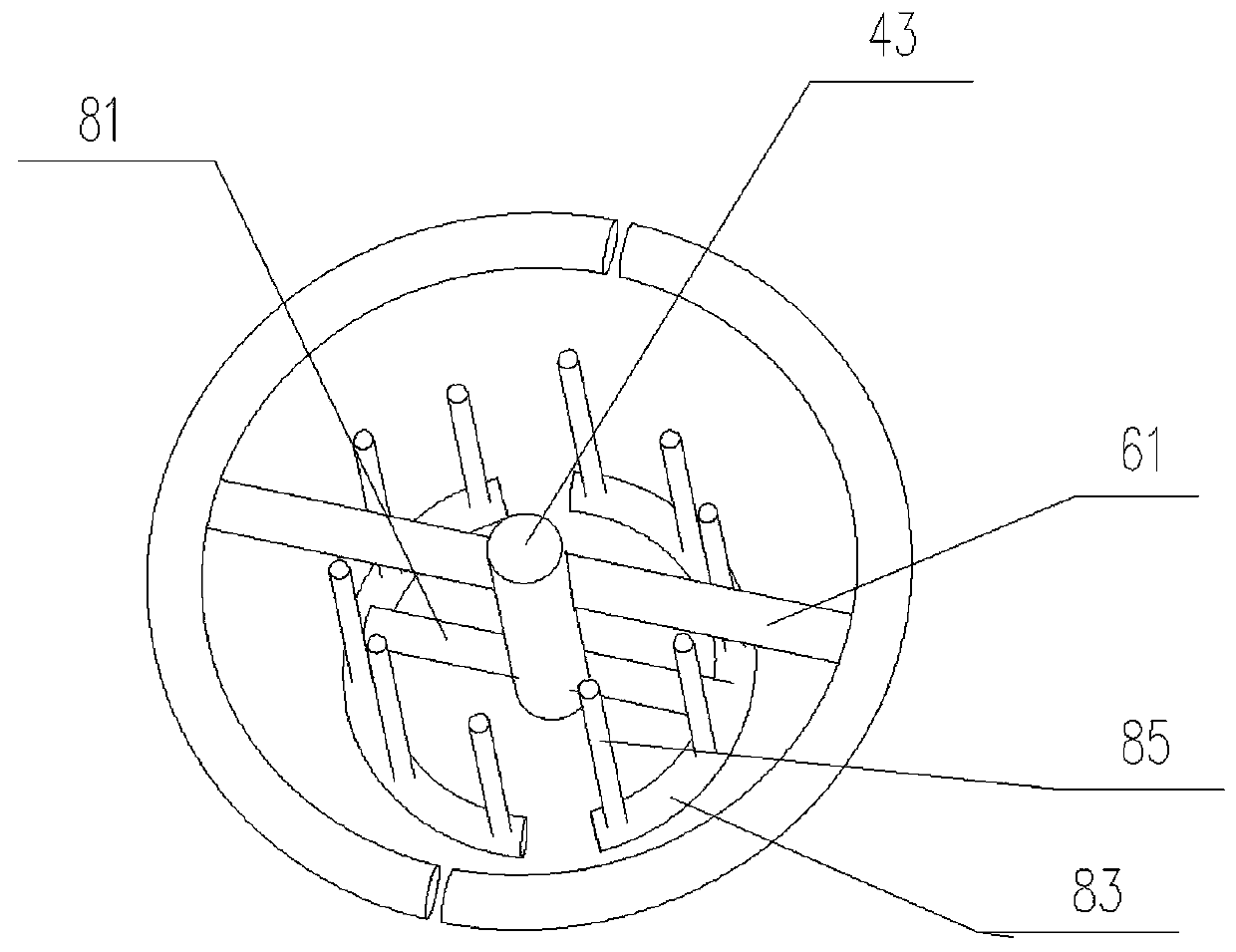

[0054] Specifically, such as figure 1 , image 3 , Figure 4 , Figure 5 As shown, the outer surface of the cylinder body 3 is surrounded by a gas ring pipe 4 . The gas ring pipe 4 communicates with the external feed gas pipe 41 . The outer surface of the brazier brick 1 is surrounded by an outer ring type air bag gun 6 . The gas connecting pipe 43 is arranged in the cylinder body 3 . The bottom of the gas connection pipe 43 communicates with the gas ring pipe 4 . The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com