Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Stable and reliable combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engine starting control system and method

InactiveCN101922361AReduce overfillingIncrease temperatureElectrical controlInternal combustion piston enginesControl systemEngineering

Various example approaches are described, one of which includes a method for controlling injection of gaseous and liquid fuel to a cylinder during engine starting. Specifically, gaseous fuel is injected during or before an intake stroke of the cycle to form a well-mixed overall lean air-fuel mixture, and then liquid fuel is directly injected to the cylinder at least during one of a compression and expansion stroke of the engine cycle to form a rich air-fuel cloud near the spark plug, where a spark initiates combustion of the injected fuels. In one example, the rich cloud enables additional spark retard, and thus faster catalyst light-off, while maintain acceptable combustion stability of the gaseous fuel.

Owner:FORD GLOBAL TECH LLC

Internal combustion engine and combustion method of the same

InactiveCN101289964AStable and reliable combustionValve arrangementsElectrical controlCombustion chamberFlame propagation

An internal combustion engine, including a premixed mixture formation device that forms a premixed mixture of fuel and air in a combustion chamber, a fuel gas supply device that injects fuel gas directly into the combustion chamber, and an ignition device that ignites the fuel gas. The fuel gas supply device is configured to inject the fuel gas into the premixed mixture near a top dead center of a compression stroke such that a spray of the fuel gas passes through a firing position of the ignition device, to produce the spray of the fuel gas in a predetermined area substantially extending from one end of a cylinder bore to the other end as viewed in a cylinder-bore direction defined by a centerline of the cylinder bore.; The ignition device is configured to directly ignite the spray of the fuel gas and to ignite and burn the premixed mixture by way of flame propagation along the spray of the fuel gas.

Owner:NISSAN MOTOR CO LTD

Combustion method of low-pressure and low-concentration methane gas and device

InactiveCN101713538AEfficient combustionImprove ejection abilityIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberProduct gas

The invention discloses a combustion method of low-pressure and low-concentration methane gas. In the combustion method, an inner pipe and an outer pipe which are communicated with a combustion chamber are adopted as an air inlet pipe, wherein the inner pipe is a fuel gas channel, and a channel between the inner pipe and the outer pipe is an air channel; air inside the air channel enters the combustion chamber at high speed and forms negative pressure at the outlet of the fuel gas channel; and the low-pressure and low-concentration methane gas inside the fuel gas channel is absorbed into the combustion chamber and combusts in the combustion chamber in a mixing mode. The invention also provides a combustion device for realizing the combustion method. By utilizing the negative pressure formed at the outlet of the inner pipe when the air enters into the combustion chamber through the air channel and a great injection action generated by the negative pressure on the low-pressure low-concentration methane gas inside the inner pipe, the invention promotes the low-pressure and low-concentration methane gas to enter into the combustion chamber to mix with the air for combustion, and has the advantages of low combustion cost and less discharged pollution of the combustion.

Owner:CHONGQING UNIV

Heat accumulating type heating furnace totally using blast furnace gas as fuel

The invention belongs to the technical field of heating furnace combustion. A heat accumulating type heating furnace totally using blast furnace gas as a fuel comprises a heating furnace body, a blast furnace gas heat accumulating chamber, an air heat accumulating chamber, a blast furnace gas ignition burner, a blast furnace gas pipeline system, a combustion air pipeline system, an air side exhaust pipeline system and a gas side exhaust pipeline system; a hearting furnace hearth is arranged in the heating furnace body; the blast furnace gas heat accumulating chamber and the air heat accumulating chamber are formed on two side walls of the heating furnace body; and the blast furnace gas ignition burner is arranged on the end wall or the side wall of the soaking zone of the heating furnace body. The heating furnace is characterized in that: a resistance wire heating ignition device is arranged in the hearting furnace hearth and positioned in front of a nozzle of the blast furnace gas ignition burner planed to be first opened during ignition or in front of a nozzle of the blast furnace gas heat accumulating chamber, and the resistance wire heating ignition device is positioned in thehearting furnace hearth. The ignition operating process is simple, convenient and reliable to implement when the drying furnace or the cold furnace is ignited.

Owner:WISDRI WUHAN WIS IND FURNACE

Novel method for melting liquid glass by submerged combustion

InactiveCN104176907AEase of useSimple and convenient replacement processGlass furnace apparatusCombustionMetallurgy

The invention relates to a novel method for melting liquid glass by submerged combustion. A fluid oxidizer and a fluid fuel are respectively injected into liquid glass and are mixed and combusted in the liquid glass to form a combustion cavity, the generated high-temperature gas stirs the liquid glass, and most heat is transferred to the liquid glass and admixture, so that the glass is quickly molten.

Owner:徐林波

Gas back-jetting pre-mixing low-NOx combustion apparatus and combustion method of combustion apparatus

The invention discloses a gas back-jetting pre-mixing low-NOx combustion apparatus and a combustion method of the combustion apparatus, which belongs to the technical field of a high-power industrial combustor. The combustion apparatus is characterized in that: a centre cylinder is axially arranged at a throat opening centre; the end part of the centre cylinder is connected with a whirlcone which is coaxially arranged; an inner diameter and an outer diameter of the centre cylinder are consistent with the inner diameter and the outer diameter of an inner ring of the whirlcone; a peripheral axial wind channel is arranged between the periphery of the outer ring of the whirlcone and the inner wall of a throat opening; back-jetting hammer gas guns are radically distributed on the throat opening. The combustion method of the combustion apparatus is characterized in that: the gas is divided into two parts, namely the gas which is jet from a straight back-jetting hole, is backwards jet in an axial direction and rushes with axial wind at the periphery oppositely, and gas which is jet from an inclined back-jetting hole and rushes tangentially with swirl wind, after the gas enters the channel from a combustible gas hammer-type gas gun. The gas back-jetting pre-mixing low-NOx combustion apparatus disclosed by the invention has the beneficial effects that: the gas and the air are jet and oppositely rushed to be fully and uniformly mixed, so that a little of NOx smaller than 29ppm is generated without generation of CO (carbonic oxide). The combustion is stable and reliable, and the highest power of a single machine can be up to over 70MW.

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

Ignition device in supersonic concave cavity combustion chamber and super-combustion stamping engine

ActiveCN110822480APromote disseminationIncrease the equivalence ratioContinuous combustion chamberCombustion chamberEquivalence ratio

The invention provides an ignition device in a supersonic concave cavity combustion chamber and a super-combustion stamping engine. The supersonic combustion chamber is internally provided with a fuelinjection hole and a concave cavity, the fuel injection hole is arranged at the upper stream of the concave cavity, and the fuel injected through the fuel injection hole propagates in the direction of the supersonic airflow propagation in a main flow channel of the supersonic combustion chamber; and a flow guide plate is obliquely arranged on the bottom wall of the concave cavity in the directionof the supersonic airflow propagation in the main flow channel, the lower end of the flow guide plate is connected to the bottom wall of the concave cavity, a gap is formed in the lower end of the flow guide plate, and a spark plug used for ignition is arranged on the portion, below the inner side of the flow guide plate, of the bottom wall of the concave cavity. According to the ignition device,the flow guide plate is applied to the interior of the concave cavity so as to improve the local flow rate and the equivalence ratio in the concave cavity, so that the ignition enhancement effect isachieved.

Owner:NAT UNIV OF DEFENSE TECH

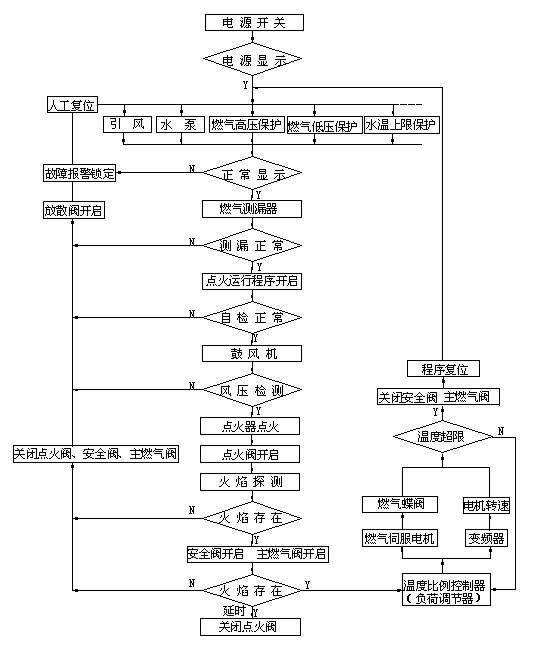

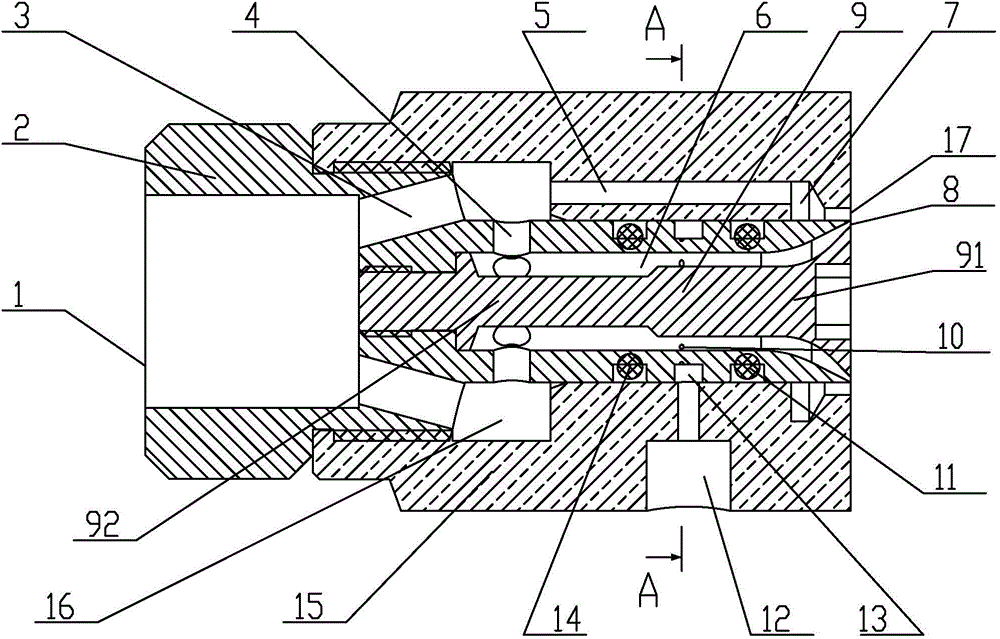

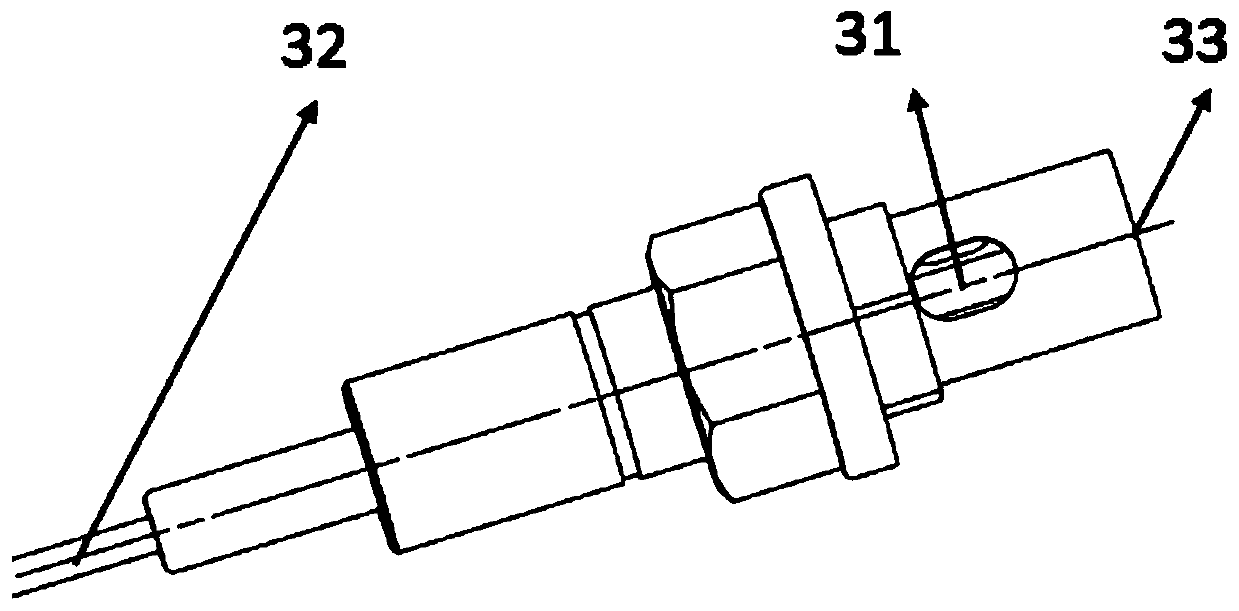

Fully-premixing full-automatic ignition burner

InactiveCN101871656ABurning safetyStable and reliable combustionElectric spark ignitersChemical industryFlame detection

The invention discloses a fully-premixing full-automatic ignition burner which combines ignition with flame detection into a whole. An ignition system and a flame monitoring system are arranged in a pipe of which the maximum inner diameter is only phi 52mm; the ignition burner has stable, safe and reliable operation, can be combined with a warming ignition burner for use and has superior ignition reliability, safety, stability, installation and disassembly than a common ignition burner. The fully-premixing full-automatic ignition burner is used for majority of chemical industry furnaces, comprising heating furnaces, hot coal furnaces, gasification furnaces, reforming furnaces and the like.

Owner:西安拓沃能动科技有限公司 +3

Micropulsation combustor

The invention relates to a micropulsation combustor which consists of a micro-combustor, a gas inlet pipe, a platinum metallic fiber net and a high-voltage electrode igniter, wherein the micro-combustor is a high-temperature-resistant hollow circular tube; a gas inlet is arranged at the lower end of the micro-combustor; a gas outlet is arranged on the upper end part of the micro-combustor; the inner diameter of the micro-combustor is 10-14mm; the thickness of the wall of the micro-combustor is 1.5-2.1mm; the length of the micro-combustor is 20-30cm; the draw ratio of the micro-combustor is 20-30; the platinum metallic fiber net is fixed at the position which is 1 / 4 of the inner lower end of the micro-combustor; the high-voltage electrode igniter is arranged at the position which is 1-2mm of the upper part of the platinum metallic fiber net inside the micro-combustor; and the gas inlet pipe is arranged inside the end of the gas inlet at the lower end of the micro-combustor, and a gas overflow hole is formed at the front end of the gas inlet pipe. The micropulsation combustor disclosed by the invention has the advantages that the combustion position is stable, the combustion is full, the pulsation combustion is reliable, the combustion speed is fast, the time is short, the strength is high, the heat loss is less, the heat efficiency is high, and the like; and the micropulsation combustor has application prospect applied to a micro-energy system.

Owner:TIANJIN UNIV OF SCI & TECH

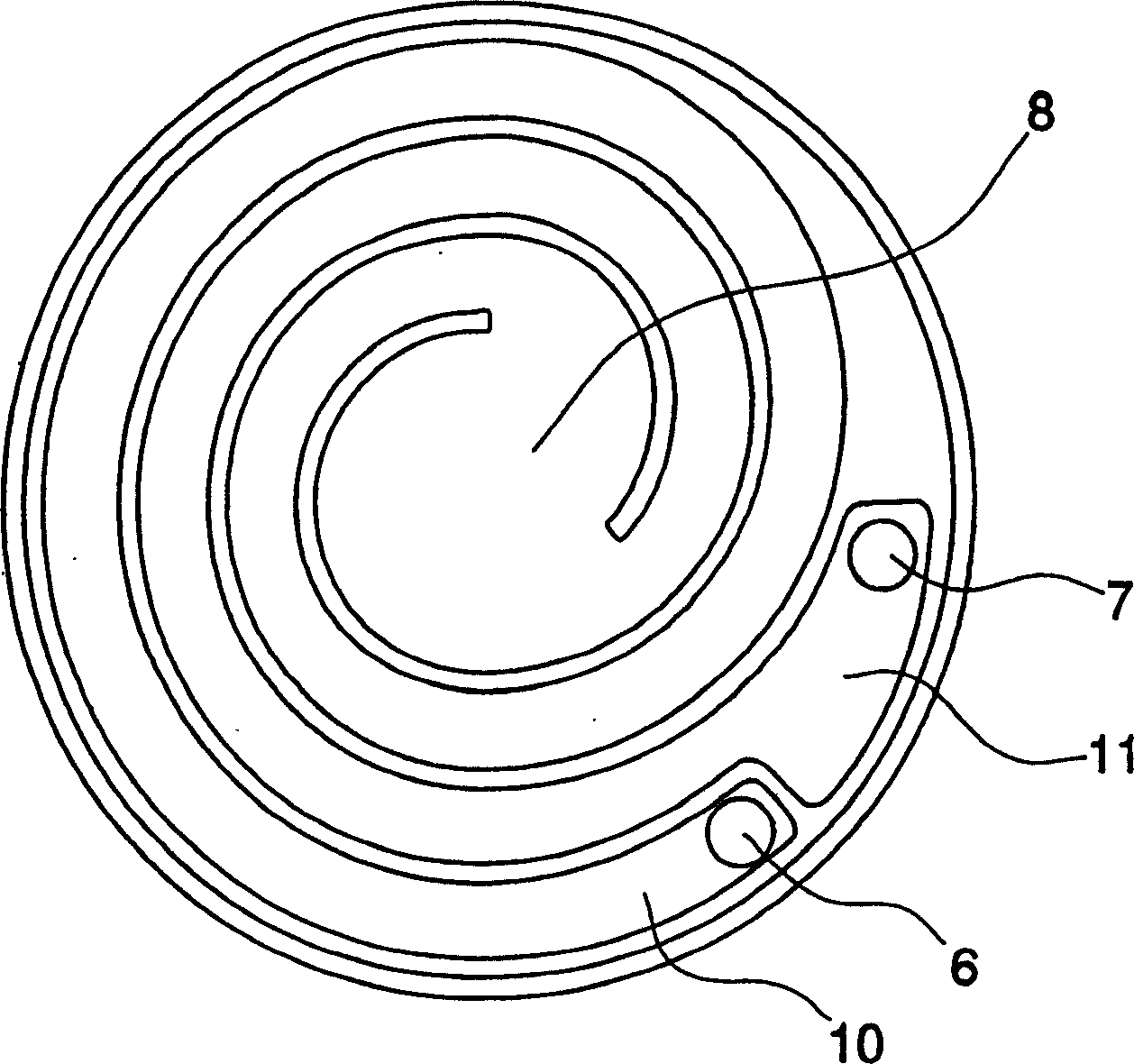

Microcombustion heater having heating surface which emits radiant heat

InactiveCN1219997CStable and reliable combustionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberRadiant heater

A small microcombustion heater which can realize reliable combustion. The heater has a premixed gas passage which reaches a combustion chamber, and a passage for a combustion gas drawn from the combustion chamber. The passages are arranged in a spiral form in a manner such that a heating wall is provided between the passages. The width of the premixed gas passage is a quenching distance or less, where the quenching distance is determined depending on the premixed gas. The heater has two outer faces for holding the spiral passages from both sides of the upper and lower edges of the heating wall, and at least one of the outer faces is a heating surface for emitting radiant heat. Typically, the spiral passages are placed between a heat-resisting heating plate and a heat insulating plate, and an outer face of the heat-resisting heating plate functions as the heating surface.

Owner:丸田薰 +1

Combustion device for gaseous fuel with low heating values

ActiveCN102563646AStable and reliable combustionPrevent flashback from happeningGaseous fuel burnerCombustion regulationAutomotive engineeringEngineering

Owner:唐山亿昌热能科技有限公司

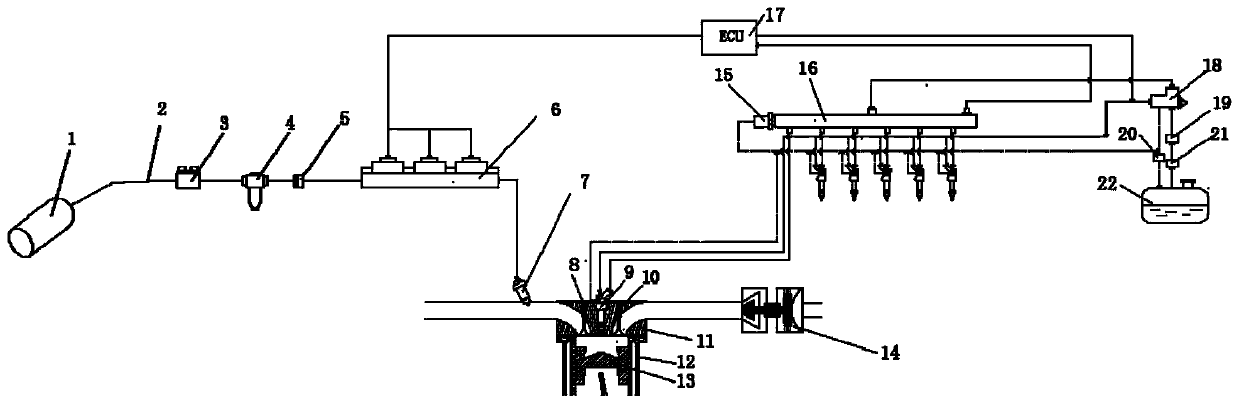

Multi-mode combustion organization method of natural gas/diesel oil dual-fuel engine

ActiveCN110318891AShortened afterburn periodEmission reductionElectrical controlInternal combustion piston enginesCombustionInlet channel

The invention aims to provide a multi-mode combustion organization method of a natural gas / diesel oil dual-fuel engine. Natural gas used as a low-reaction-activity fuel is injected into a gas channelby a natural gas low-pressure injection system, is preliminarily mixed with air in a gas inlet channel and enters a gas cylinder through a gas inlet valve; diesel oil used as a high-reaction-activityfuel is directly injected into the gas cylinder by a high-pressure common-rail fuel injection system; after the diesel is spontaneously combusted, the mixed gas with the natural gas and the air is ignited so as to supply power to the engine. According to the multi-mode combustion organization method of the natural gas / diesel oil dual-fuel engine, through independent or collaborative control of thehigh-pressure common-rail fuel injection system and the natural gas low-pressure injection system, multi-mode combustion of the natural gas / diesel oil dual-fuel engine can be achieved under differentconditions, so that the engine can operate more flexibly; the problems of difficult cold starting, high emission of low-load THC and high-load knocking can be avoided; and reliable operation and efficient and clean combustion of the engine can be achieved.

Owner:HARBIN ENG UNIV

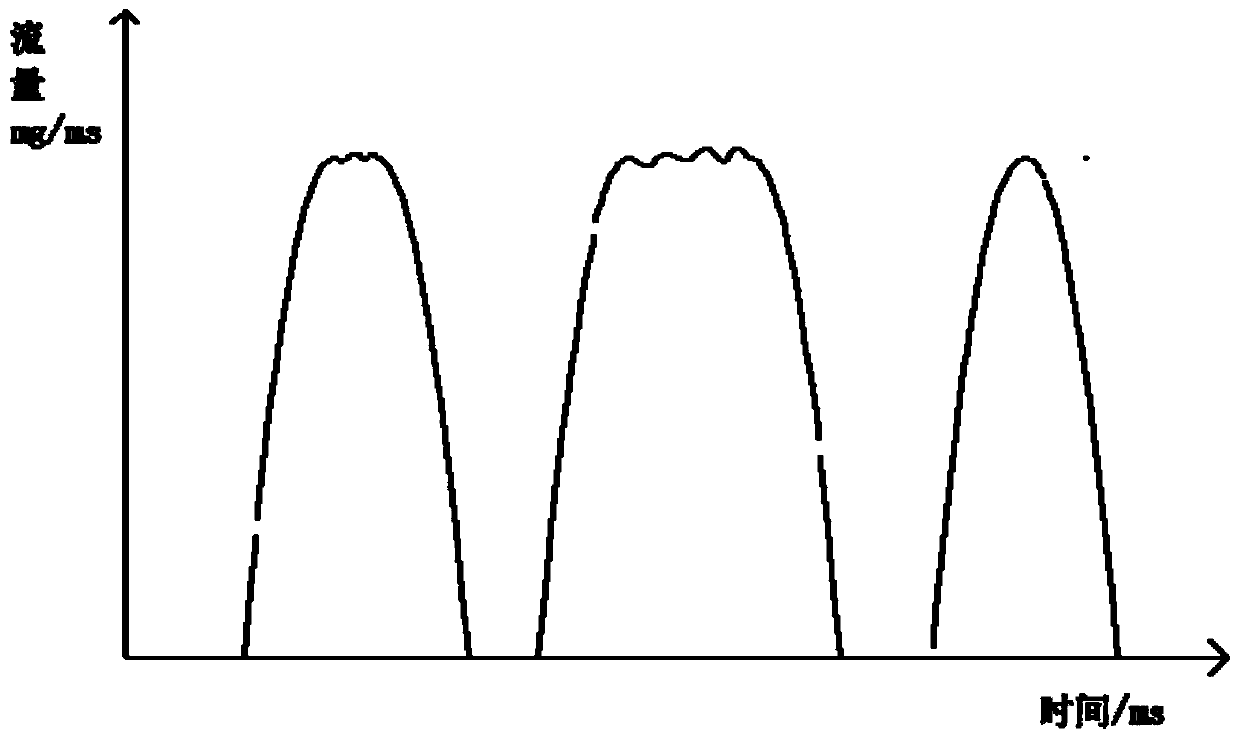

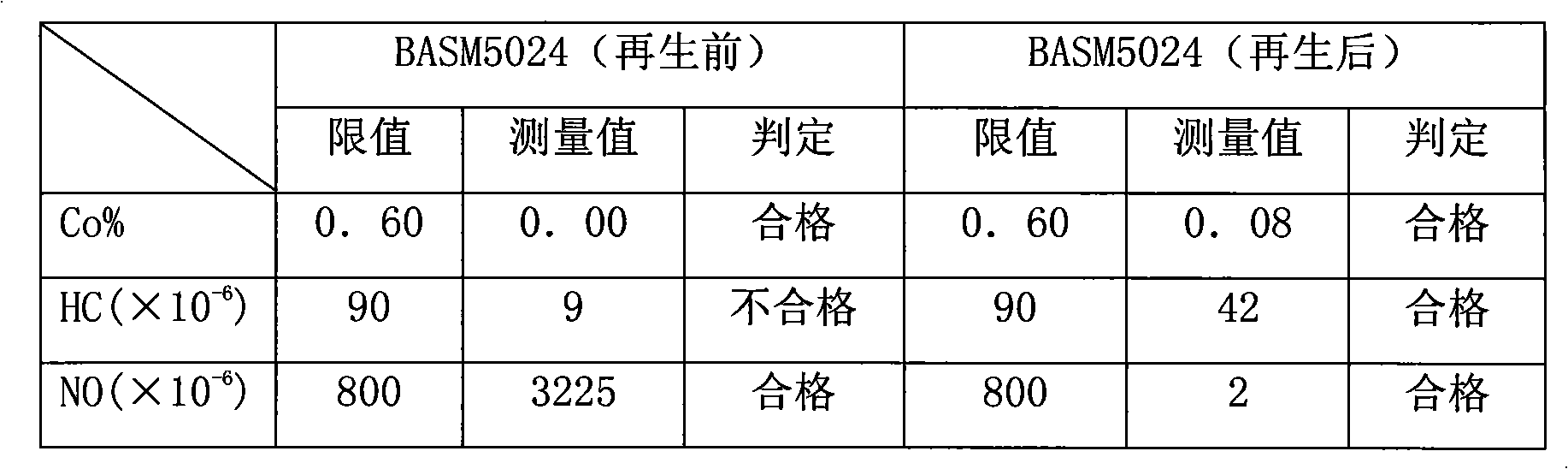

Regenerant and processing method of three-way catalytic converter of gasoline automobile

InactiveCN101884940AReduce pollutionRestore exhaust gas purification functionInternal combustion piston enginesExhaust apparatusCombustion chamberSolvent

The invention discloses a regenerant and a processing method of a three-way catalytic converter of a gasoline automobile. The regenerant comprises the following raw materials in mass percent: 0.006-0.03% of chlorine-containing solvent, 0.01-0.04% of hydrogen peroxide and 99.96-99.954% of methanol. The chlorine-containing solvent and the hydrogen peroxide in the raw materials are added into the methanol to be mixed to obtain the regenerant of the three-way catalytic converter of the gasoline automobile. The regenerant can be input into a burning chamber of an automobile engine for fully burning, then a high-temperature oxidation environment containing chlorine ions can be established in an exhaust system, the high-temperature oxidation environment can be used for removing deposited carbon and sulfur-phosphorus chemical complexes covering on the three-way catalyst in the three-way catalytic converter, and simultaneously, chlorine is replenished for the three-way catalyst which is deactivated caused by chlorine loss and grain accumulation to enable the grown grains accumulated on the surface thereof to be dispersed again, thereby realizing the regeneration of the three-way catalyst in the three-way catalytic converter.

Owner:倪初宁

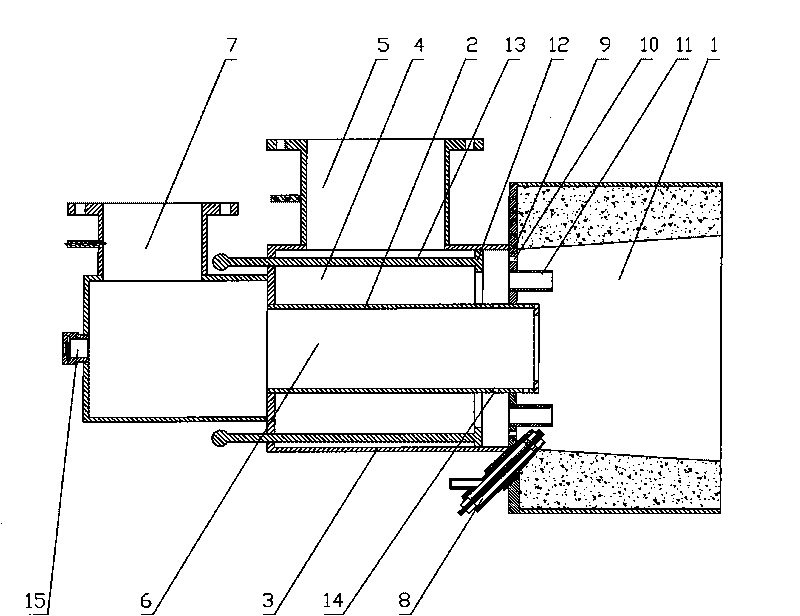

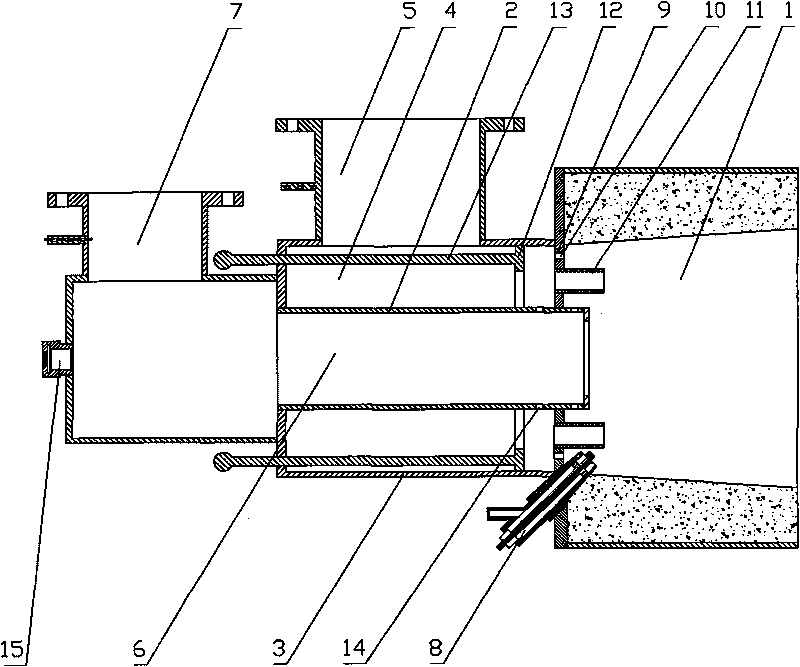

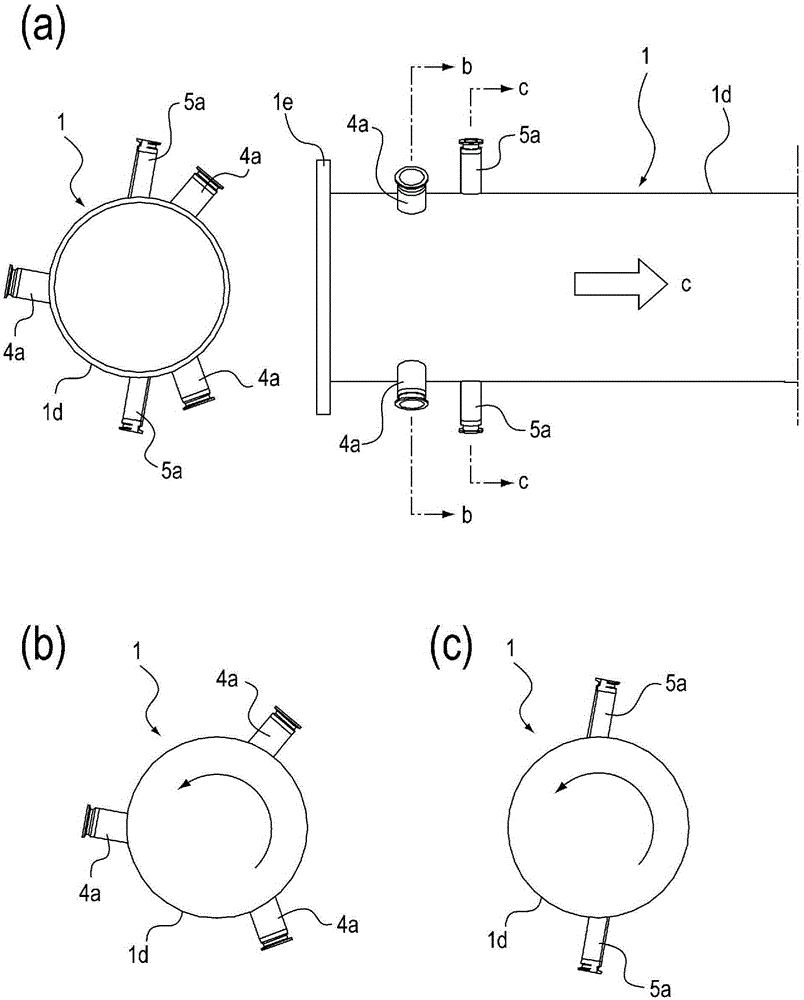

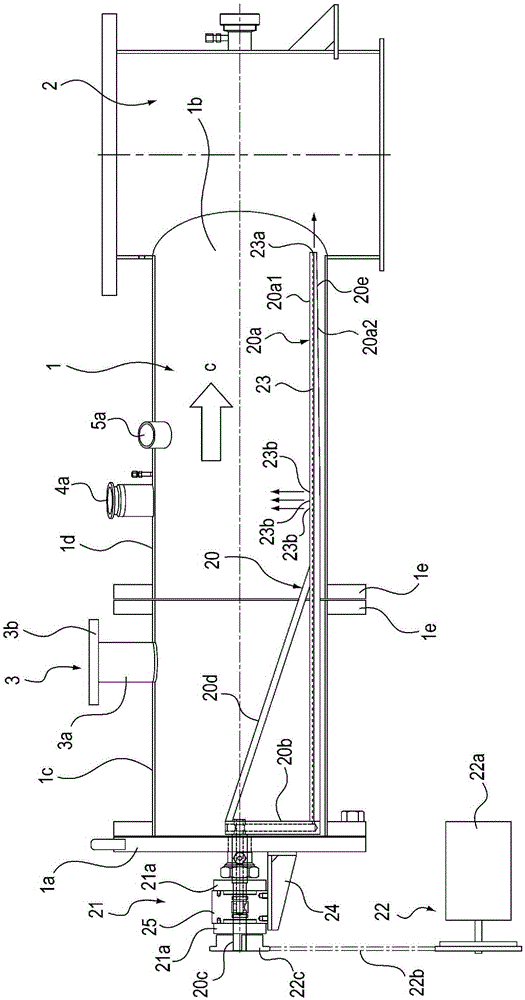

Exhaust gas treatment equipment

ActiveCN105358911AElimination of hypoxiaPromote combustionIncinerator apparatusCombustorCombustion chamber

To provide exhaust gas treatment equipment for removing an exhaust gas by burning or pyrolyzing the same in a rational manner. Treatment equipment (A) having: a combustion chamber (1) for removing a supplied exhaust gas by burning or decomposing the same, one end part (1a) of the combustion chamber (1) being closed; an exhaust pipe (2) for discharging the removed exhaust gas and connected to an other end part (1b) of the combustion chamber (1); and a housing (10) for accommodating the combustion chamber (1) and the exhaust pipe (2). In the combustion chamber, an exhaust gas supply port (3) for supplying the exhaust gas to be removed to the closed one end part (1a) side is provided, a burner (4) is provided closer to the exhaust pipe (2) side than is the exhaust gas supply port (3), and a combustion-sustaining gas supply nozzle (5) for supplying a combustion-sustaining gas is provided between the burner (4) and the exhaust gas supply port (3), or is provided closer to the exhaust pipe (2) side than is the burner (4).

Owner:KOIKE SANSO KOGYO CO LTD

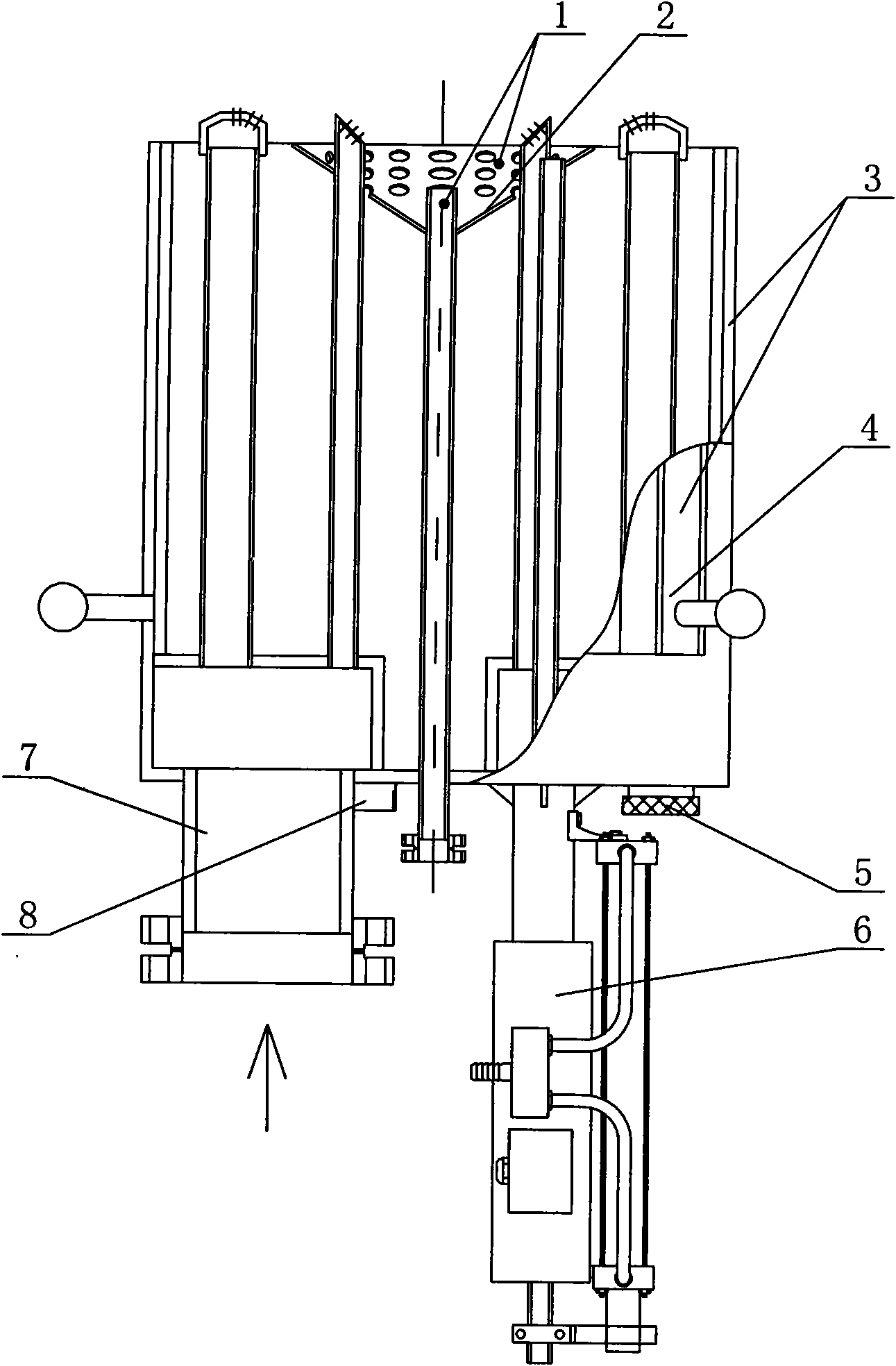

Tube furnace burner

InactiveCN101576256AAchieve high-intensity combustionIncrease jet speedGaseous fuel burnerLow noiseAir volume

The invention relates to a structure of a burner, in particular to a tube furnace burner. The tube furnace burner comprises an outer wall, an air inlet tube bank, an air inlet and an ignition tip, wherein a regulating door for regulating the air inlet amount is arranged on the outer wall; a pneumatic propeller is arranged at the bottom of the burner; a burning stabilizing cover is arranged at the top of the burner; a flame detection mounting pipe is arranged at the bottom or the side of the burner; and a flame viewing hole is also arranged at the bottom of the burner. The invention has the advantages of compact structure, stable burning, large regulation ratio, low noise, good flame spreadability, complete burning and easy control of burning and can be internally provided with a burning torch and a flame detection alarm system. The invention meets the current requirement on environmental protection, better saves the fuel and improves the burning efficiency.

Owner:ACRE AUTOMATION CO LTD MCC

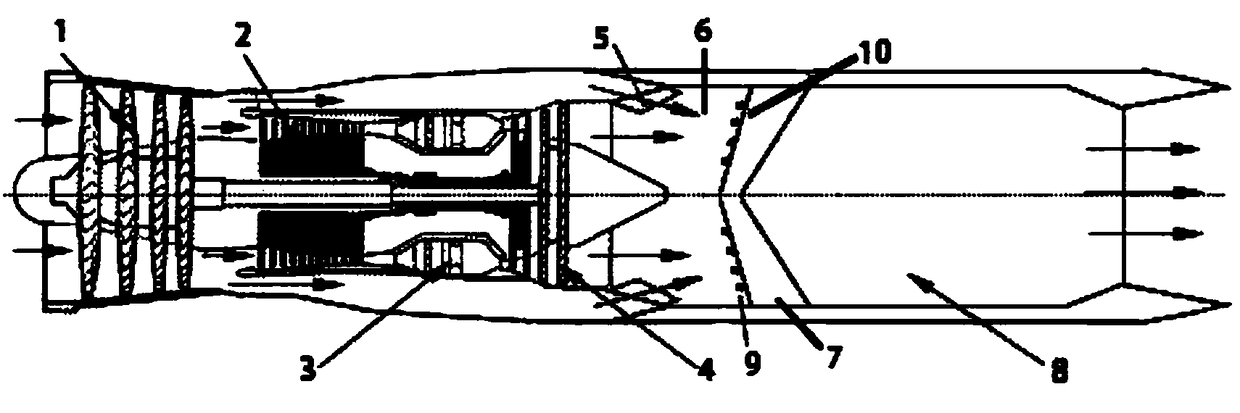

Afterburner adopting planar fan nozzles for oil supply

ActiveCN108844094AStable and reliable combustionAchieve atomizationContinuous combustion chamberSpray nozzlePerpendicular direction

The invention discloses an afterburner adopting planar fan nozzles for oil supply, and belongs to the field of aero-engines. The afterburner adopting the planar fan nozzles for oil supply is characterized in that supporting plates are arranged on an oil supply device in the afterburner, and are uniformly arranged along the circumference of the afterburner in the perpendicular direction; and oil spraying rods are arranged on the inner sides of the supporting plates in the radial direction, the planar fan nozzles are arranged on the side walls of the oil spraying rods in the radial direction, and the opening cross section of each planar fan fuel nozzle is V-shaped. According to the design of the afterburner adopting the planar fan nozzles for oil supply, the fuel spray extending angle is enlarged, the number of the nozzles is reduced, the diameter of each nozzle is increased, and meanwhile, the fuel radial and circumferential concentration distribution is more uniform, so that reliable and stable combustion of the afterburner is facilitated, and the problems in the prior art are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-speed fuel oil atomizing spray nozzle for thermally spraying fuel gas

ActiveCN104674156AImprove uniformityCompact structureMolten spray coatingLiquid spraying apparatusSpray nozzleFuel oil

The invention discloses a high-speed fuel oil atomizing spray nozzle for a thermally spraying fuel gas. The high-speed fuel oil atomizing spray nozzle comprises a primary cavity, wherein a secondary cavity is assembled on the outer wall of the primary cavity; a gas inlet is formed in the inlet end of the primary cavity, an inner cavity is formed in the outlet end of the primary cavity, a similar cone is mounted in the inner cavity, a ring-shaped primary chamber which is gradually expanded towards the peripheral side in the shape of horn from the inside to the outside is formed between the outer wall of the similar cone and the inner wall of the inner cavity, a ring-shaped primary spray nozzle is formed in an opening in the outlet end of the primary cavity, a gas inlet is communicated with the end part, which is arranged on the inner part of the primary cavity, of the primary cavity through a gas conveying channel, an oil injection hole is formed in the secondary cavity, the oil injection hole is communicated with the middle part of the primary chamber through an oil conveying channel, a ring-shaped secondary chamber for conveying secondary gas flow is formed in the secondary cavity, the secondary chamber is communicated with the outer part through a ring-shaped secondary spray nozzle, the secondary spray nozzle is positioned at the peripheral side of the primary spray nozzle, so that secondary gas flow sprayed out by the secondary spray nozzle and mixed gas flow sprayed out by the primary spray nozzle are crossed at a set included angle and collide. The high-speed fuel oil atomizing spray nozzle is used for atomizing the fuel oil through gas power, so that the gas and the fuel oil are uniformly mixed and atomized, and stably combusted.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Solid-liquid treating machine and its heating system

InactiveCN1868569ALower specific resistanceSpeed up filteringStationary filtering element filtersSlagControl system

A solid-liquid treating and heating system is composed of a solid-liquid treating machine with a filter unit arranged in a constant-temp space at 60-750 deg.C, a heat generating unit for heating the gas medium filled in said constant-temp space, and a control unit. It can save energy, use filtered slags to prepare gas, solid, or liquid fuel, and extracting the useful substances from filtered dregs.

Owner:张民良

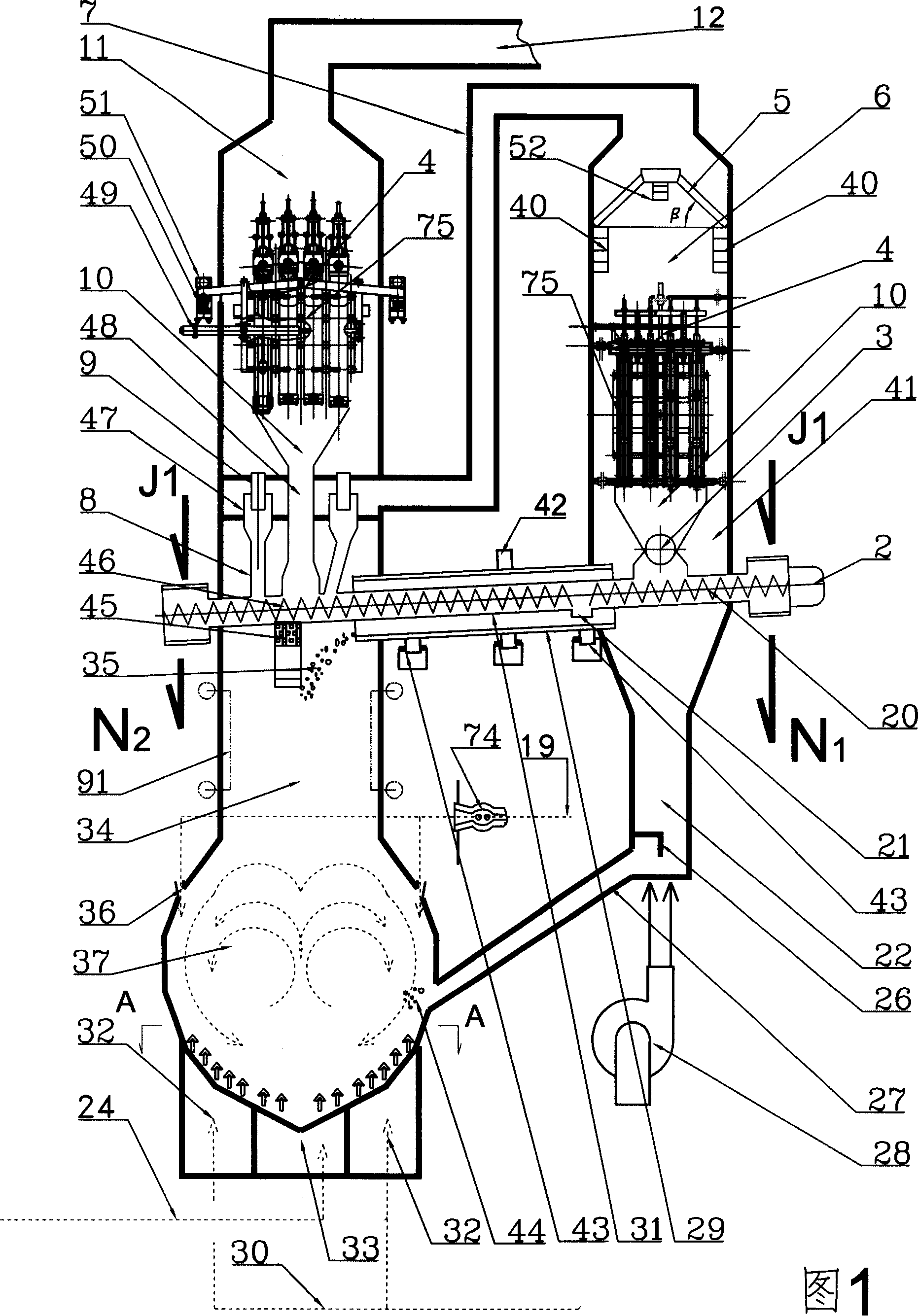

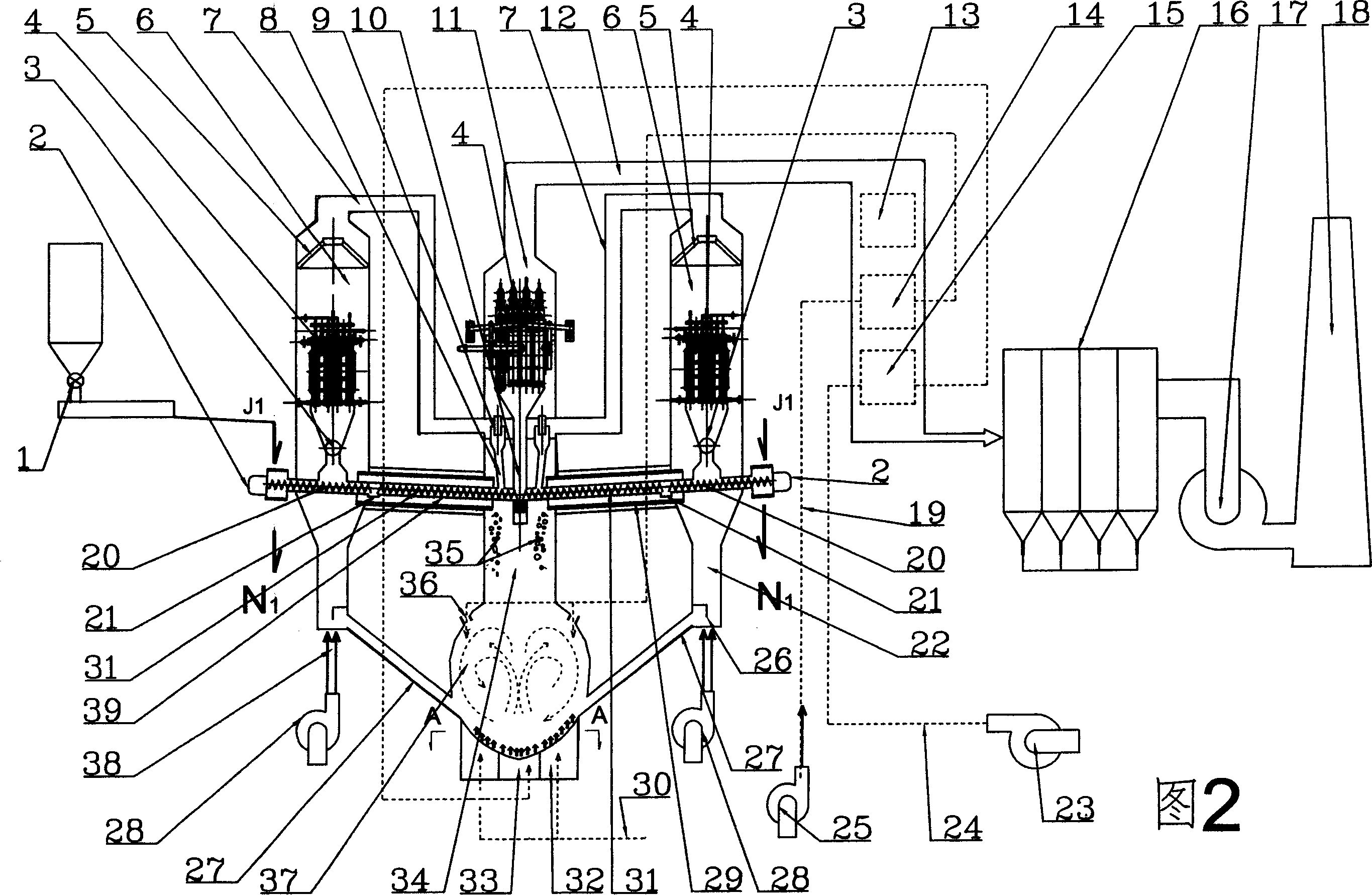

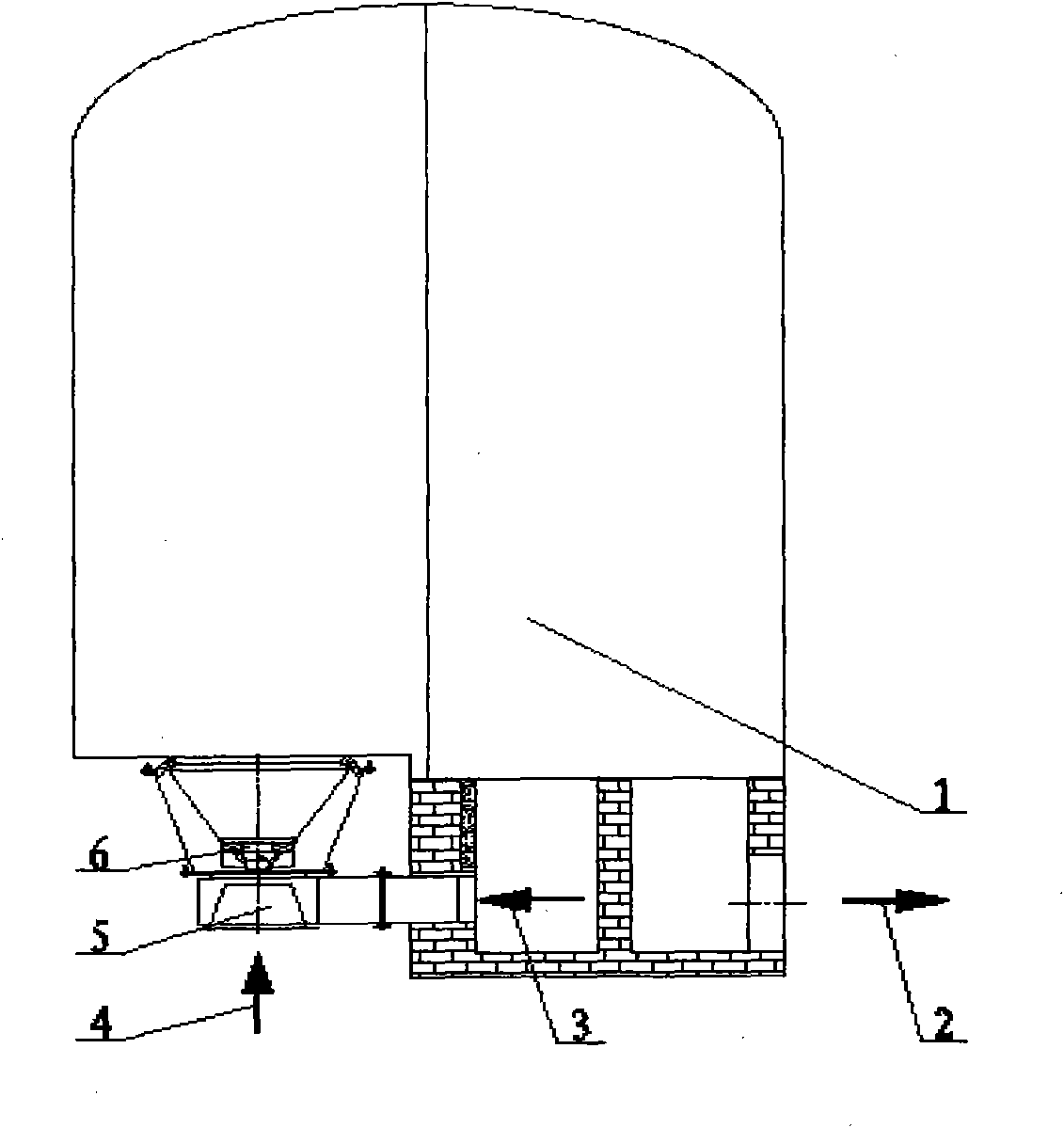

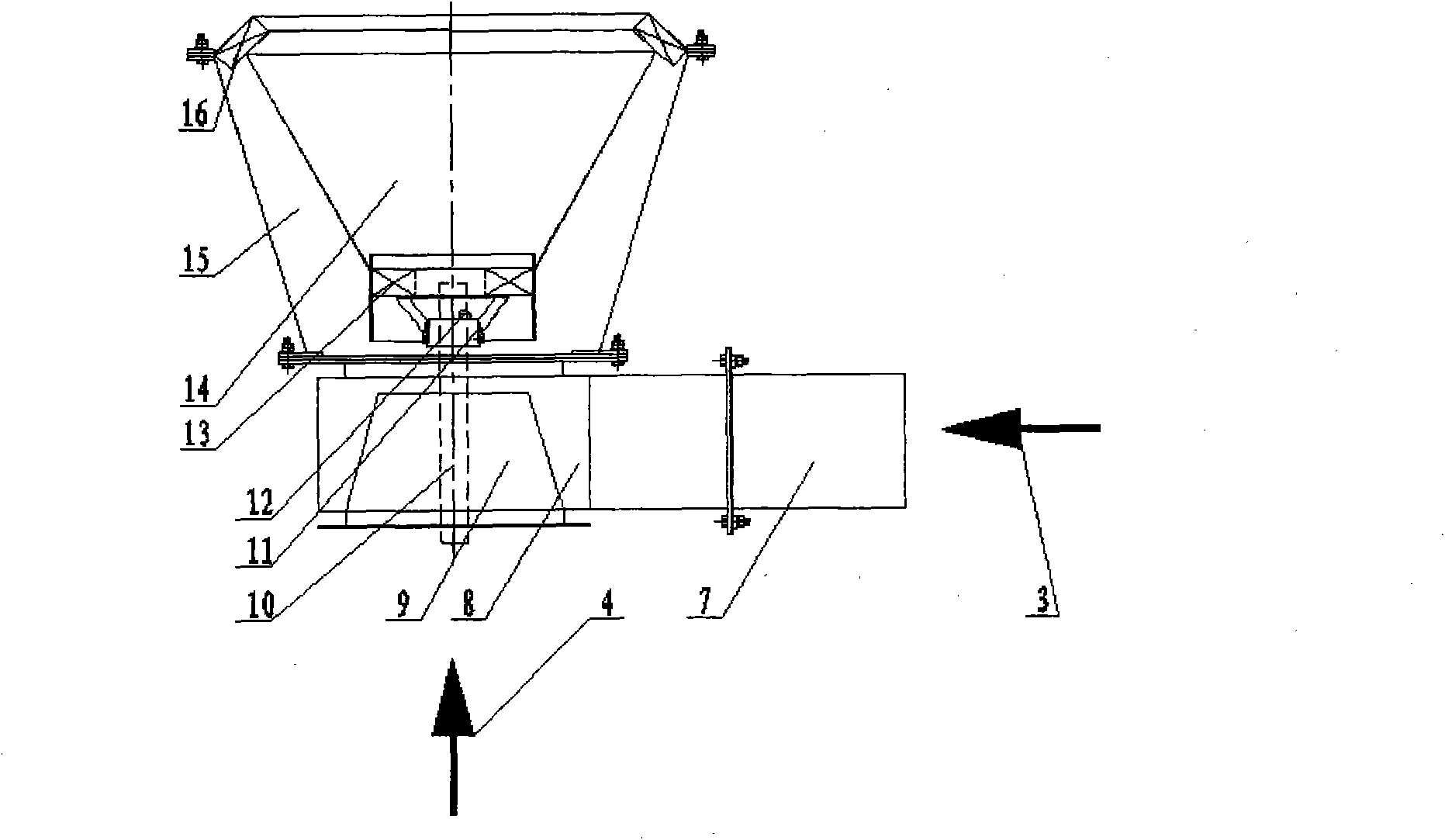

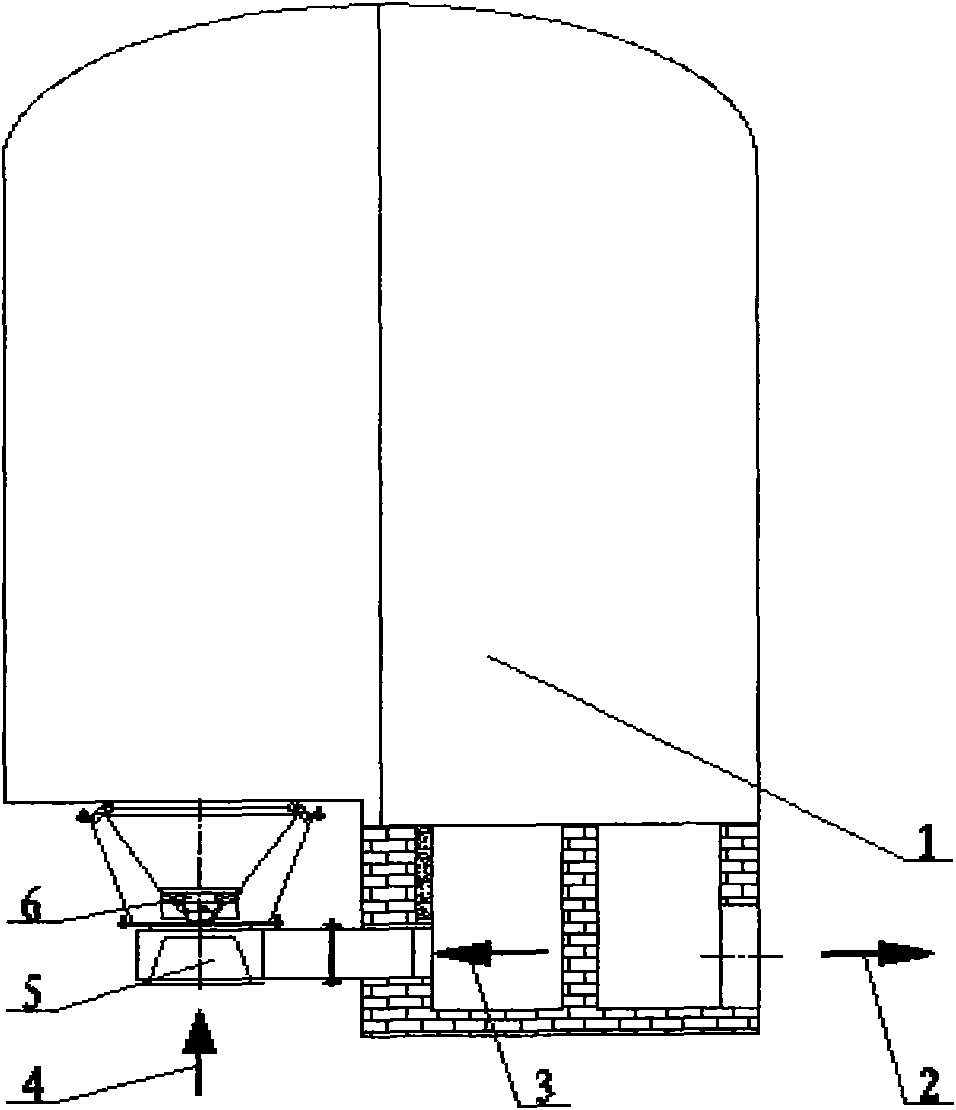

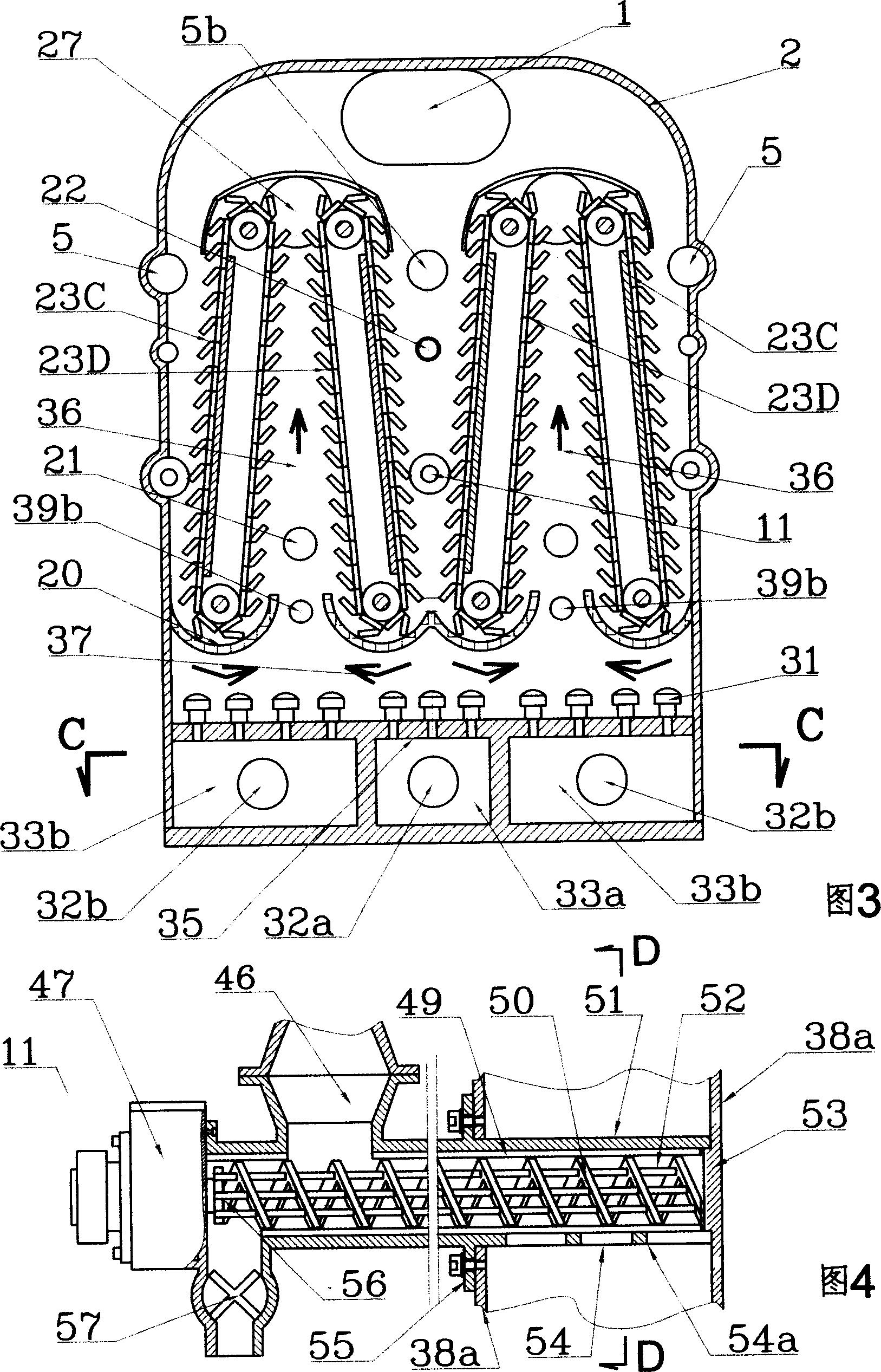

Low volatile coal water slurry combustion device

InactiveCN102374526ASimple structureEasy to use and maintainCombustion using gaseous and pulverulent fuelBurnersCombustion chamberEvaporation

The invention relates to a low volatile coal water slurry combustion device. The device mainly comprises a loop-shaped combustion chamber 1, an ejector 5, a combustion head 6 and the like. When combustion air provided by main air flow 4 enters an ejector mixing chamber at high speed from an ejector nozzle, the high temperature fuel gas is sucked in a combustion head mixing chamber, wherein the high temperature fuel gas flows in the ejector mixing chamber from a high temperature reflow fuel gas pipeline; the high temperature fuel gas in the combustion head mixing chamber enters a primary combustion chamber by ejecting with a primary swirler, such that the temperature of the air flow is increased. A fuel oil combustion system of the combustion head starts to ignite, and a nozzle injects oil to burn. When the air flow temperature inside the whole combustion chamber reaches (exceeds) the temperature for coal water slurry evaporation, firing and burning, a coal water slurry lance is started to inject the coal water slurry fuel to the primary combustion chamber. When the coal water slurry fuel burns stably, the work of the fuel system is stopped, and the coal water slurry continuously burns.

Owner:GUIZHOU AERONAUTICAL ENGINE INST

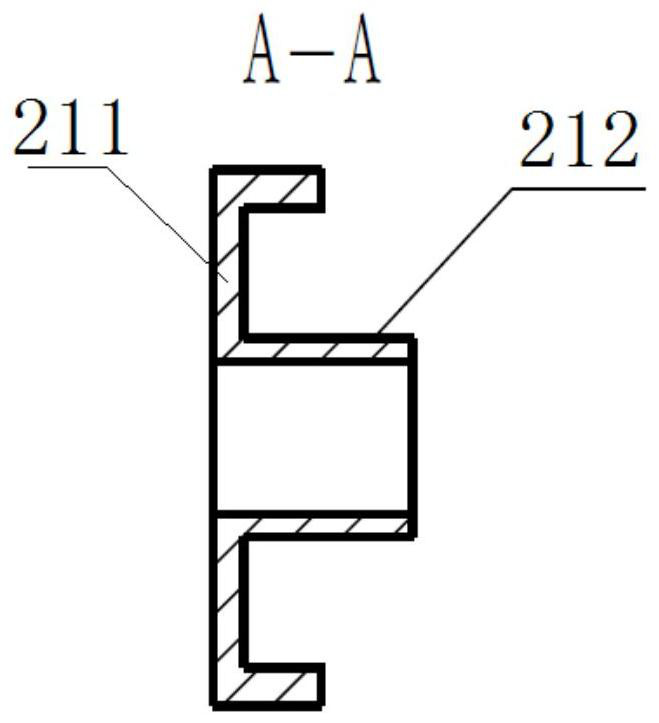

Burner for synthesis gas

InactiveCN1571905APrevent backfireStable and reliable combustionContinuous combustion chamberTurbine/propulsion fuel valvesForming gasCombustion chamber

The invention relates to a burner which essentially consists of a swirl generator (1) for a combustion air flow, and means for introducing fuel into said combustion air flow (9). Said swirl generator (1) comprises combustion air inlets for the combustion air flow (9) entering the burner, and the means for introducing fuel into the combustion air flow (9) comprise at least one first fuel admission (19) and a group of first fuel outlets (18) which are arranged in a distributed manner on an end of the burner on the side of the combustion chamber, about the burner axis (25). Said burner is characterised in that the at least one fuel admission (19) and the group of first fuel outlets (18) are mechanically decoupled from the swirl generator (1). The inventive burner enables synthesis gas to be used in a reliable and safe manner, both in a rarefied and in a non-rarefied form.

Owner:GENERAL ELECTRIC TECH GMBH

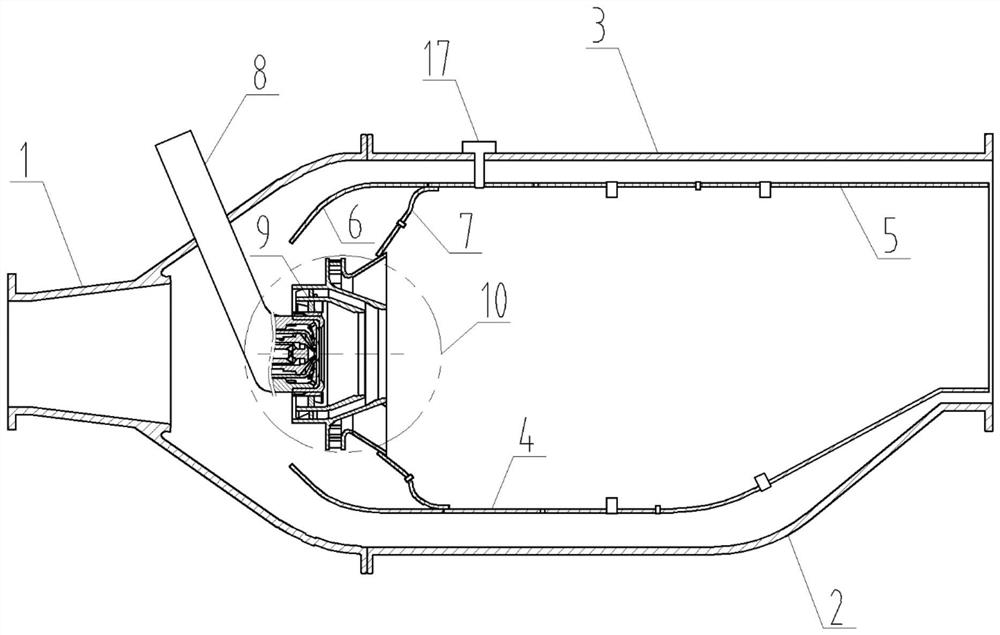

Plasma ignition and combustion-supporting combustion chamber for combusting low-calorific-value gas fuel

ActiveCN111006241AReliable ignitionReduced ignition conditionsContinuous combustion chamberIncandescent ignitionCombustion chamberJet flow

The invention provides a plasma ignition and combustion-supporting combustion chamber for combusting low-calorific-value gas fuel, which is characterized in that an engine brake is arranged outside the combustion chamber; a gas pipe connector is arranged at the head of the engine brake, and an air baffle connected with the combustion chamber is arranged at the tail; a swirler fixing bracket is arranged at the front part in the combustion chamber; a swirler is mounted on the swirler fixing bracket; one end of the gas pipe serves as a gas pipe inlet and is arranged on the gas pipe connector, andthe other end of the gas pipe serves as a gas pipe outlet and is connected with a central pipeline of the swirler; a plasma generator extends from an inlet of the gas pipe, and the head of the plasmagenerator is fixed to an outlet of the central pipeline of the swirler; cooling holes are formed in the outer surface of the combustion chamber; a mixing nozzle and a jet nozzle are arranged on the central pipeline of the swirler; and the jet nozzle is located at the front end of the central pipeline. The plasma generator is used for ignition and combustion supporting, and the combustion chamberof a gas turbine can be ignited more reliably and combusted more stably through active particles generated by plasmas.

Owner:HARBIN ENG UNIV

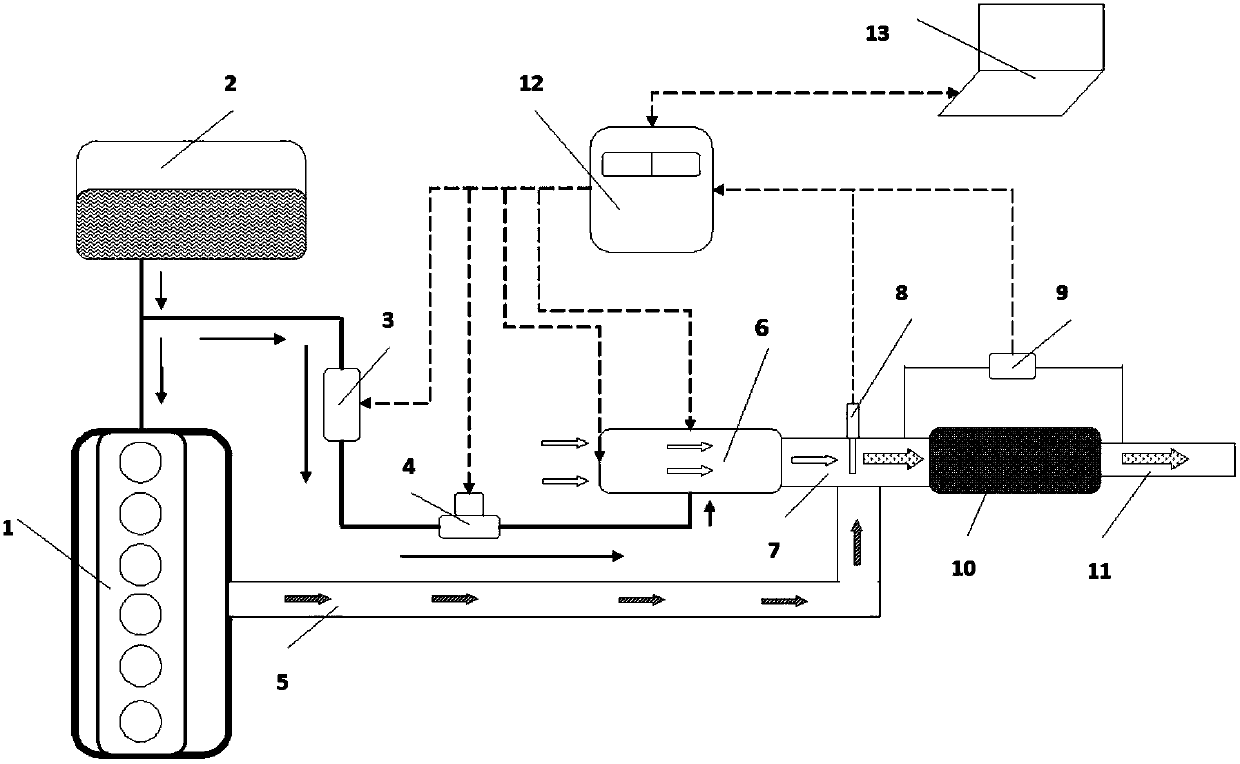

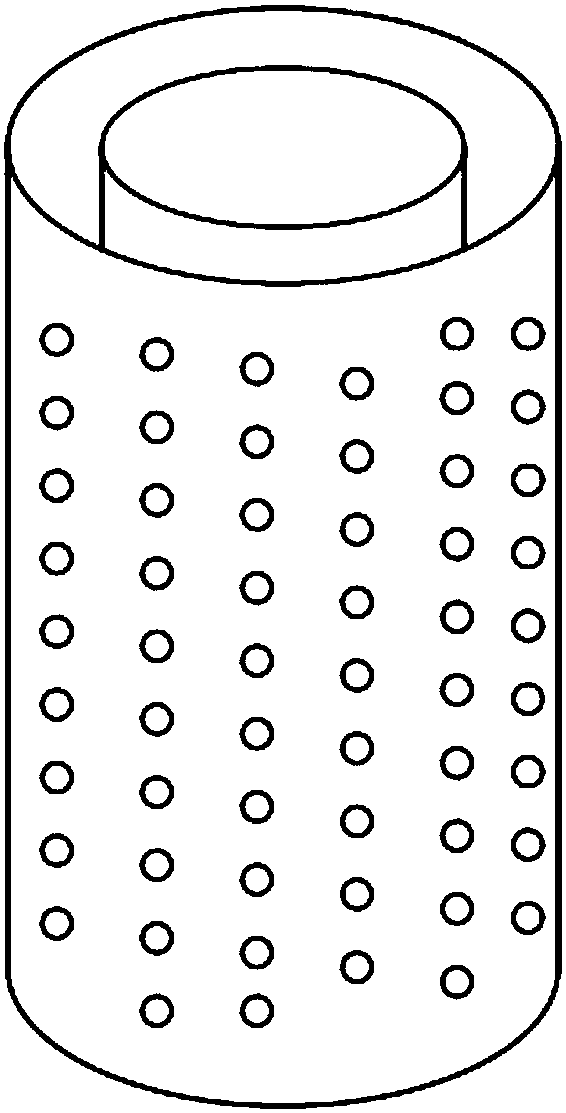

Device system integrating DPF (diesel particulate filter) heat regeneration and mechanical regeneration

PendingCN107642391AImprove regenerative abilityImprove efficiencyInternal combustion piston enginesExhaust apparatusCombustorFuel tank

The invention provides a device system integrating DPF (diesel particulate filter) heat regeneration and mechanical regeneration, comprising an engine, a DPF active regeneration system, and a diesel particulate filter; the DPF active regeneration system is connected with the intake end of the diesel particulate filter through a first exhaust pipe, and the engine system is connected with the intakeend of the diesel particulate filter through a second exhaust pipe, the exhaust end of the diesel particulate filter is connected with a third exhaust pipe, wherein the DPF regeneration system is characterized in that a fuel outlet of a fuel tank is connected with a fuel inlet of a fuel pump through a fuel pipe, a fuel outlet of the fuel pump is connected with a fuel inlet of an oil-level adjusting valve through a fuel pipe, a fuel outlet of the oil-level adjusting valve is connected with a turbine combustor through a fuel pipe, and the turbine combustor is connected with the intake end of the diesel particulate filter through the first exhaust pipe. The device system combining mechanical regeneration and heat regeneration has compact structure, DPF regeneration efficiency can be improved, PDF' service life can be extended, and the cost of the DPF regeneration system is reduced.

Owner:天津亿科汽车电子有限公司

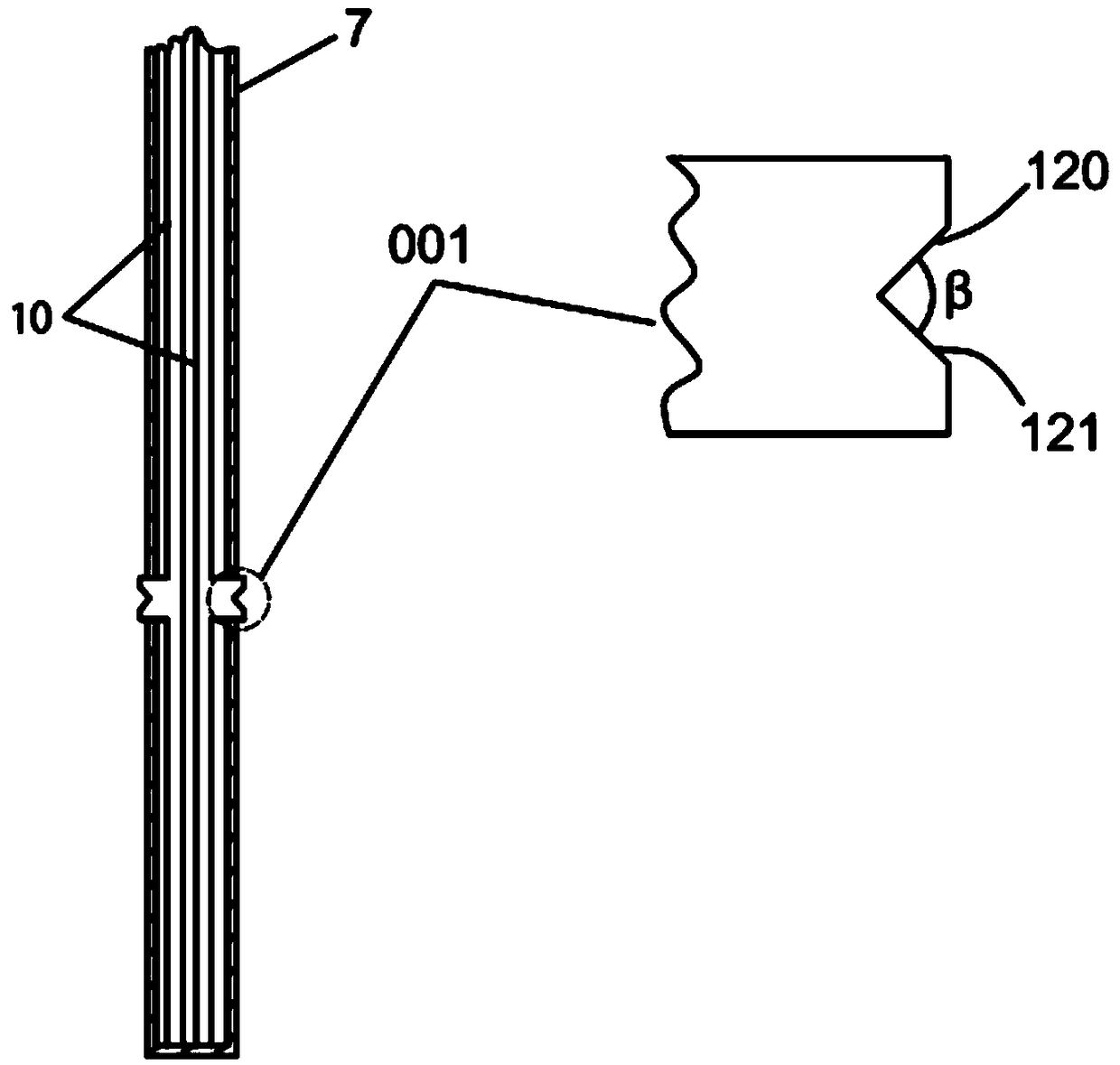

Double-necking combined spiral-flow type center grading high-temperature-rise combustion chamber

ActiveCN114526497AAchieve stratified combustionWell mixedContinuous combustion chamberEfficient propulsion technologiesCombustion chamberFuel oil

The invention provides a double-necking-down combined spiral-flow type center grading high-temperature-rise combustion chamber which comprises a diffuser, an inner casing, an outer casing, a flame tube, a cap cover, a splash blocking disc, a fuel nozzle and a flame holder, the inner casing and the outer casing are connected with the tail end of the diffuser, and the fuel nozzle is used for conveying fuel oil to the flame tube; the flame holder is arranged on the outer side of the nozzle shell at the downstream end of the fuel nozzle in a sleeving manner and is coaxial with the nozzle shell; the flame holder comprises a first-stage swirler, a second-stage swirler and a third-stage swirler which are sequentially arranged in a sleeved mode, the outlet end face of the downstream of the first-stage swirler is connected with an inner necking opening, the outlet end face of the downstream of the second-stage swirler is connected with an outer necking opening, and the outlet end face of the downstream of the third-stage swirler is connected with a variable cross-section circular ring. The flame tube comprises a flame tube inner ring and a flame tube outer ring. By means of multi-path grading and echelon utilization of air, reliable ignition and combustion stability under the low working condition can be considered, and high-efficiency smoke-free combustion under the high working condition can also be considered.

Owner:TSINGHUA UNIV

Biomass, especially active sludge chain dry pyrolytic oil maker and system

InactiveCN1940016ACompact processSimple processEnergy inputSpecial form destructive distillationAir preheaterSludge

Biomass active mud chain oil maker with drying and pyrolyzing functions and its system are disclosed. It consists of heat generating system, constant-temperature space, electromechanical integrated equipments of biomass oil purifying system and controlling system; heat generating system consists of heating furnace, feeding system, at least a set chain heat exchanger, air preheater and tailed gas treater, temperature in constant-temperature space is kept between 80-900 degree, constant-temperature space is closed case set with thermal-insulating layer periphery, each set of chain heat exchanger consists of at least one chain rope, driver, heat-transferring wall, driving chain wheel and driven chain wheel; ascending chain and descending chain get through by each chain rope, steering chain containing driving chain wheel and driven chain wheel are closed. Raw material with high-water content passes by ascending chain and descending chain as water-content evaporating section, and pyrolyzed gas evaporating section and high-temperature section. The process is carried out by evaporating, pyrolyzing, crushing for mud carbon, drying and burning. It can be used to manufacture inflammable gas, mud carbon and liquid fuel.

Owner:张民良

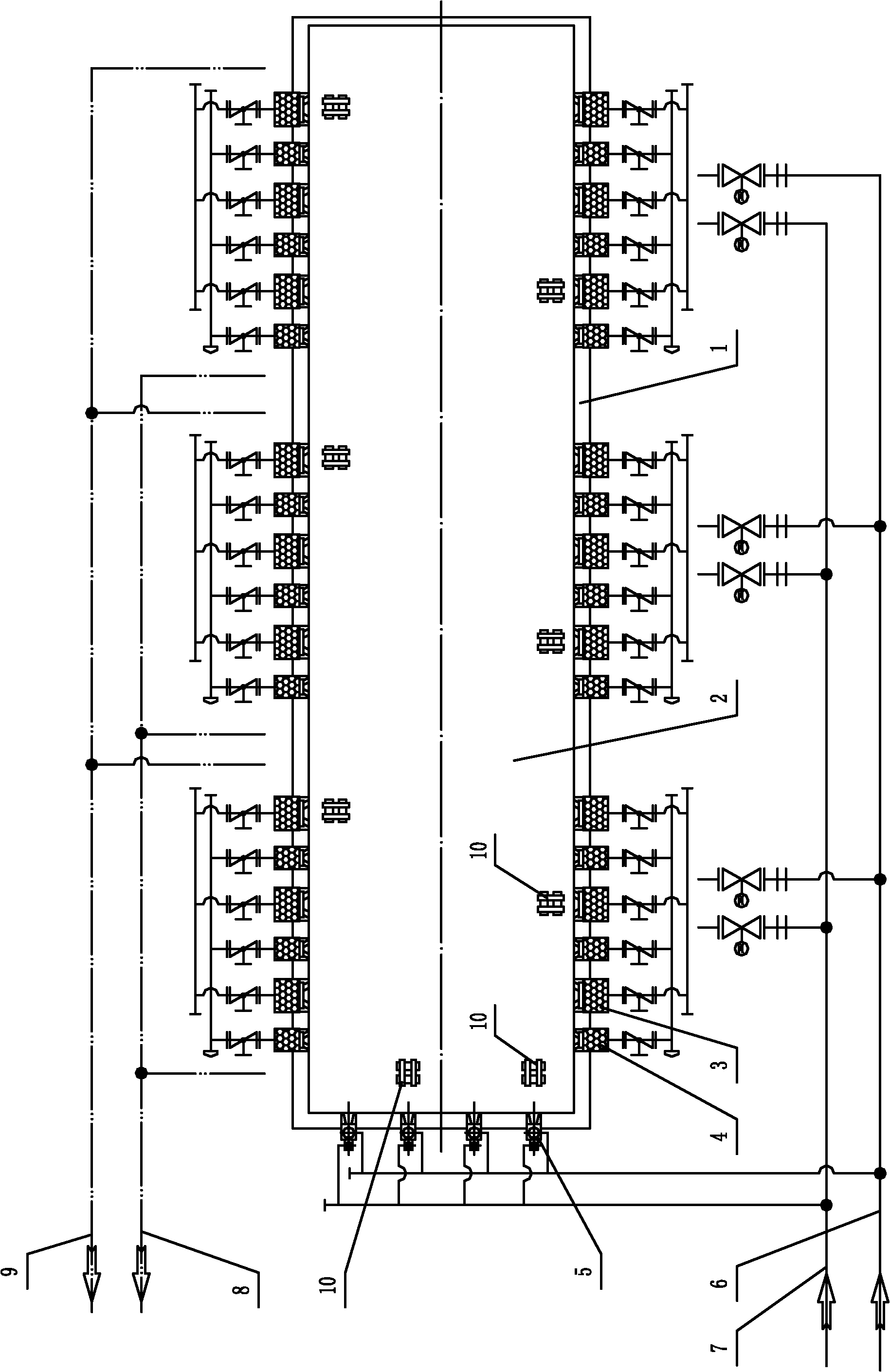

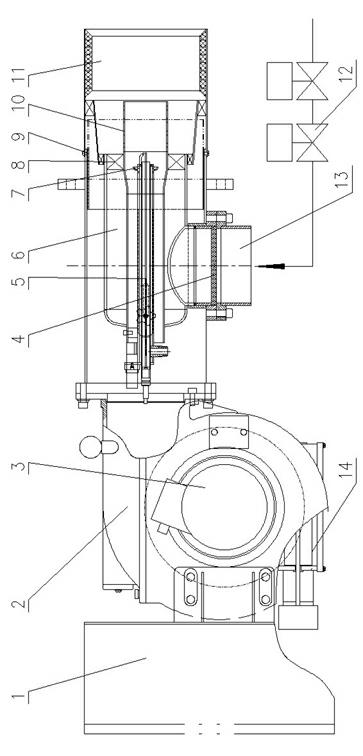

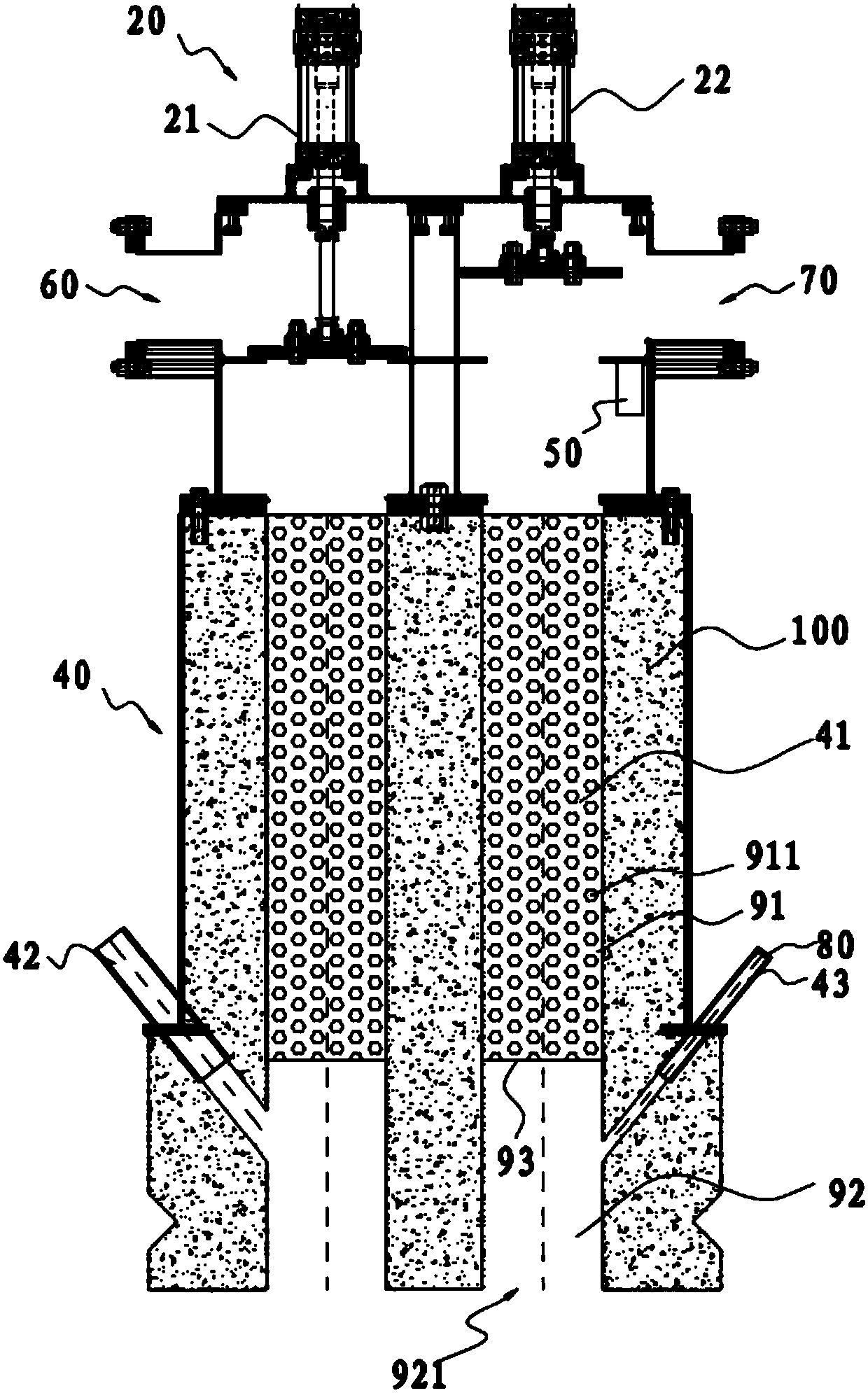

Regenerative combustion system and control method

ActiveCN107842851ANo flameoutStable and reliable combustionIndirect carbon-dioxide mitigationControl devices for furnacesTemperature controlFurnace temperature

The invention discloses a regenerative combustion system and a control method. The regenerative combustion system comprises a first reversing valve group, a second reversing valve group, a first regenerative combustion group and a second regenerative combustion group which are connected with the first reversing valve group and the second reversing valve group separately, and a controller electrically connected with the first reversing valve group and the second reversing valve group. According to the regenerative combustion system and the control method, heat release and smoke discharge are carried out simultaneously, reversing of air or smoke is stable, a reversing duration time is short, and the fluctuation of a furnace pressure is avoided; moreover, the first regenerative combustion group and the second regenerative combustion group are cooperated to implement uninterrupted continuous combustion, and a flameout phenomenon in the midway is basically avoided; and therefore, the regenerative combustion system is stable and reliable in combustion, low in combustion power, small in furnace temperature fluctuation, and capable of accurately controlling a temperature, and the temperature control accuracy achieves the control level of an electric furnace.

Owner:广州龙鑫蓄热工业炉有限公司

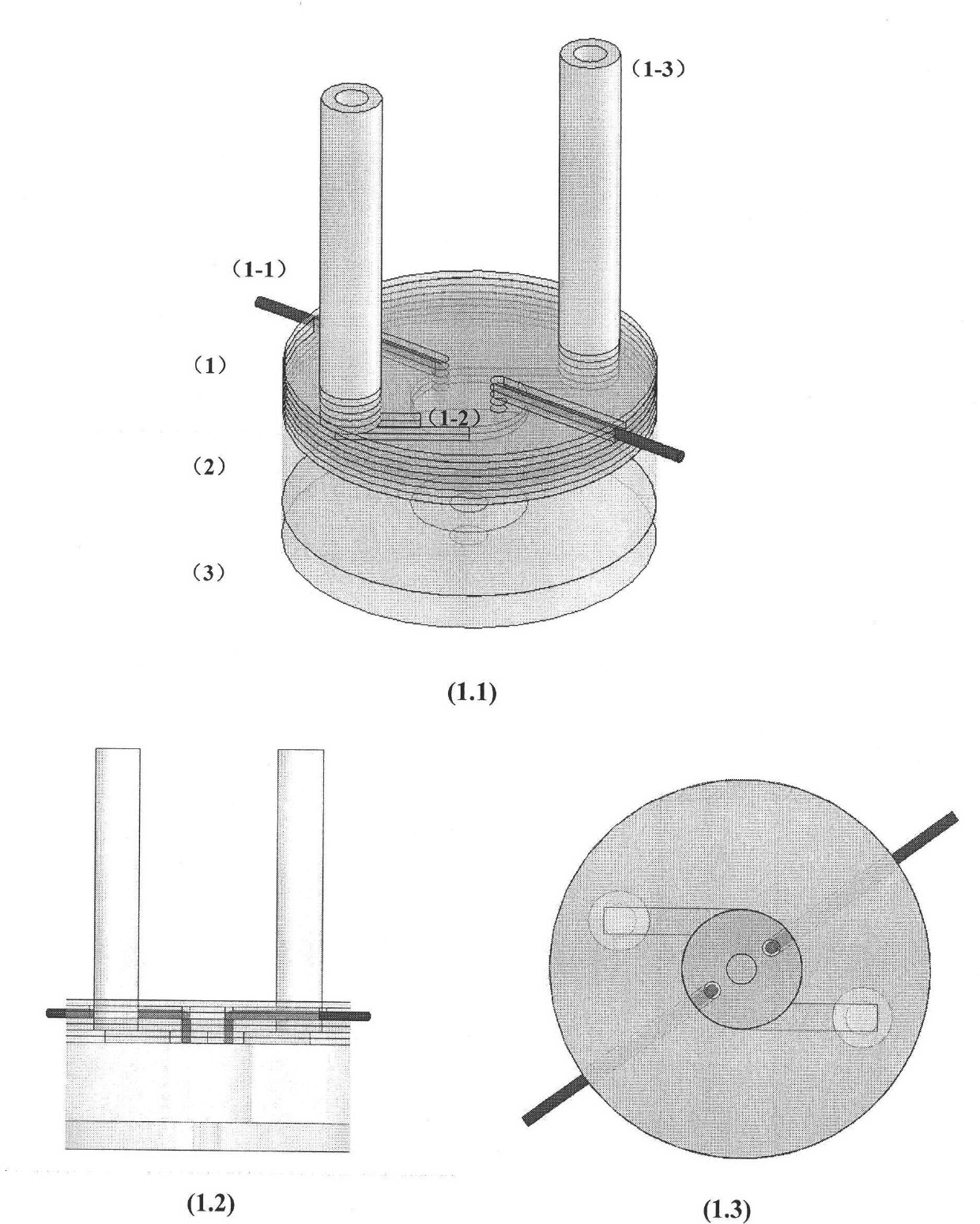

NOFBX thrust chamber based on micro-channel regenerative cooling technology

InactiveCN113074064AImprove thermal conductivityImprove heat transfer effectRocket engine plantsCombustion chamberPorous medium

The invention relates to an NOFBX thrust chamber based on a micro-channel regenerative cooling technology. The NOFBX thrust chamber aims to solve the problem that liquid film cooling and regenerative cooling of an existing liquid rocket engine cannot meet the cooling requirement of an NOFBX combustion chamber. The thrust chamber includes a combustion chamber, an injector, an electric spark plug, and a propellant inlet conduit. The combustion chamber comprises an inner shell, an outer shell, a cover plate and an annular blanking cap, the inner shell and the outer shell are coaxially arranged, a first channel is formed between the inner shell and the outer shell, the cover plate is arranged at the front end of the outer shell, and the annular blanking cap is arranged at the rear end of the first channel. The injector comprises an injector main body and an injector core body, an annular groove is formed in the front end face of an annular injection plate of the injector main body, a plurality of direct-current injection holes are formed in the bottom of the groove, and the injector core body is made of a first porous medium material and is arranged in the annular groove. The injector is arranged on the inner side of the front end of the inner shell, a second channel is formed between the injector and the cover plate, and regeneration cooling channel cores made of a second porous medium material are arranged in the first channel and the second channel.

Owner:XIAN AEROSPACE PROPULSION INST

High-ignition-point fuel compression ignition and combustion regulation and control device based on flame jet flow control

PendingCN114278426ASolve high load knockingIncreased turbulence intensityInternal combustion piston enginesGaseous engine fuelsAutomotive engineeringInjector

The invention discloses a high-ignition-point fuel compression ignition and combustion regulation and control device based on flame jet flow control. The high-ignition-point fuel compression ignition and combustion regulation and control device comprises a spark plug (1), a pre-combustion chamber ejector (2), a main combustion chamber ejector (3) and a pre-combustion chamber body (4). The pre-combustion chamber main body (4) is arranged on the main combustion chamber (6), a pre-combustion chamber cavity (5) is formed in the pre-combustion chamber main body (4), the pre-combustion chamber ejector (2) and the pre-combustion chamber spark plug (1) are installed at two different positions on one side of the pre-combustion chamber main body (4) respectively, and the head of the pre-combustion chamber ejector (2) and the head of the pre-combustion chamber spark plug (1) extend into the pre-combustion chamber cavity (5). The pre-combustion chamber cavity (5) is communicated with the main combustion chamber (6) through a spray hole; the main combustion chamber ejector (3) is fixed to the other side of the pre-combustion chamber body (4), and the head of the main combustion chamber ejector (3) extends into the main combustion chamber (6). The use performance of the low-carbon zero-carbon fuel can be effectively widened, and wide popularization and application are facilitated.

Owner:XI AN JIAOTONG UNIV

Novel method for submerged combustion melting of glass fluid by using non-gaseous gunpowder as fuel

InactiveCN104098252ALow costSimple and convenient replacement processGlass furnace apparatusMelting tankCombustion

A novel method for submerged combustion melting of glass fluid by using non-gaseous gunpowder as fuel is characterized in that a non-gaseous oxidizing agent and a reducing agent are mixed to prepare the gunpowder; the gunpowder is filled into a long tubular container or added with adhesive to prepare the powder in solid state, pasty state or serous state so as to serve as the fuel and be continuously fed into a melting pool of the molten glass fluid to be ignited and kept combusted stably and continuously; the feeding speed and the combustion speed of the fuel are kept t basically identical, the glass fluid is stirred by generated high-temperature gas, and most heat is transferred to the glass fluid and batches so as to melt glass materials quickly.

Owner:徐林波

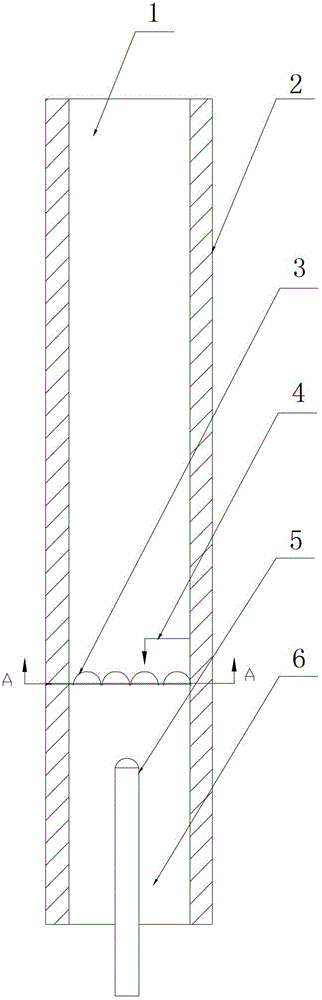

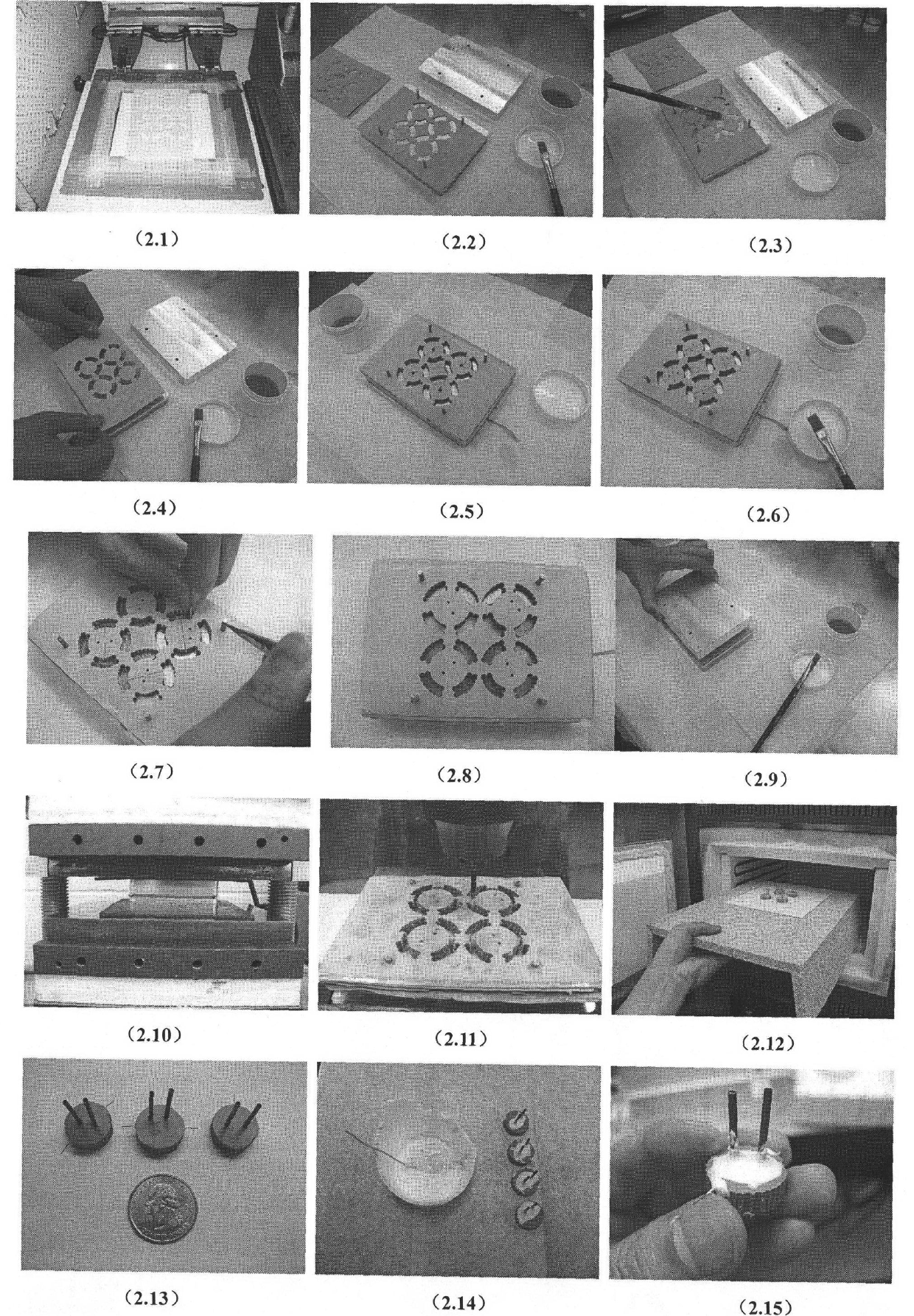

Coaxial high-temperature cofiring ceramic microburner and processing mode thereof

InactiveCN101793395AStable and reliable combustionStable combustionGaseous fuel burnerHydrogenCombustor

The invention relates to a coaxial high-temperature cofiring ceramic microburner and a processing method thereof. Unique processing materials and processing technology realize the processing of a middle micro size coaxial microburner with a complex inner cavity structure and the function of mechanical and electrical integration according to specific processes. Combined with the special design and the structural concept via many times of test verification, the microburner can realize reliable ignition and continuous stable burning of 'hydrogen / oxygen' under small flow condition, can also be used as a micro energy generating device to be applied in the micro actuation field or the aerospace boost field, and has the potential of industrialized large-scale production due to the characteristics of the processing method.

Owner:BEIHANG UNIV

Afterburner oil spraying device with high fuel oil regulation ratio

ActiveCN110822479AShorten the lengthReduce complexityContinuous combustion chamberAviationCombustion chamber

The invention relates to the technical field of aviation power, and discloses an afterburner oil spraying device with a high fuel oil regulation ratio. The afterburner oil spraying device comprises anannular pipe, an oil inlet pipe, an adapter seat and oil spraying rods, wherein large oil spraying rods and small oil spraying rods are arranged on the inner side and the outer side of the annular pipe correspondingly. Each large oil spraying rod comprises an oil spraying rod inner wall and an oil spraying rod outer wall, the oil spraying rod inner walls and the oil spraying rod outer walls are connected with the adapter seat, a boss is fixedly arranged on the inner side of each oil spraying rod inner wall, a stop block is arranged on the upper side of each boss, a compressed spring is arranged on each stop block, oil passing holes communicating with the oil spraying rod outer walls are formed in the oil spraying rod inner walls on the annular sides of the stop blocks, and second oil nozzles communicating with the outer sides of the oil spraying rod inner walls are arranged on the outer annular sides of the oil spraying rod outer walls. According to the afterburner oil spraying device, the problems of high complexity and difficult joint matching work debugging of an existing engine afterburner, a control system and an oil way system can be solved, reliable operation of the oil spraying device under the condition of high regulation ratio can be realized, and efficient and stable combustion of an afterburner in a wide flow range can be realized.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com