Coaxial high-temperature cofiring ceramic microburner and processing mode thereof

A technology of high-temperature co-fired ceramics and micro-combustion, which is applied in the direction of burners, combustion methods, gas fuel burners, etc., can solve the problems of inability to process, unfavorable mechatronics, and low temperature, and achieve reliable ignition and stable combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

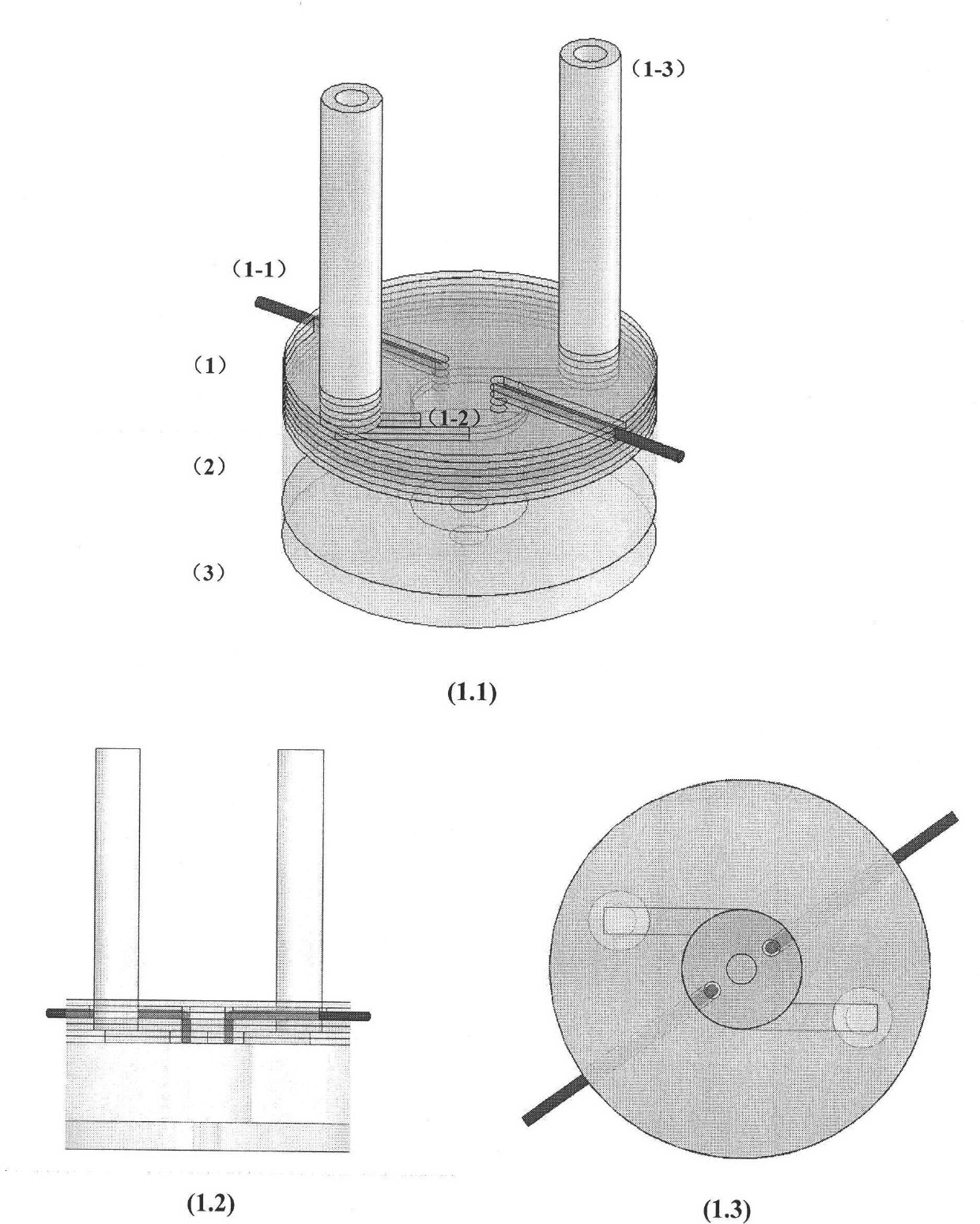

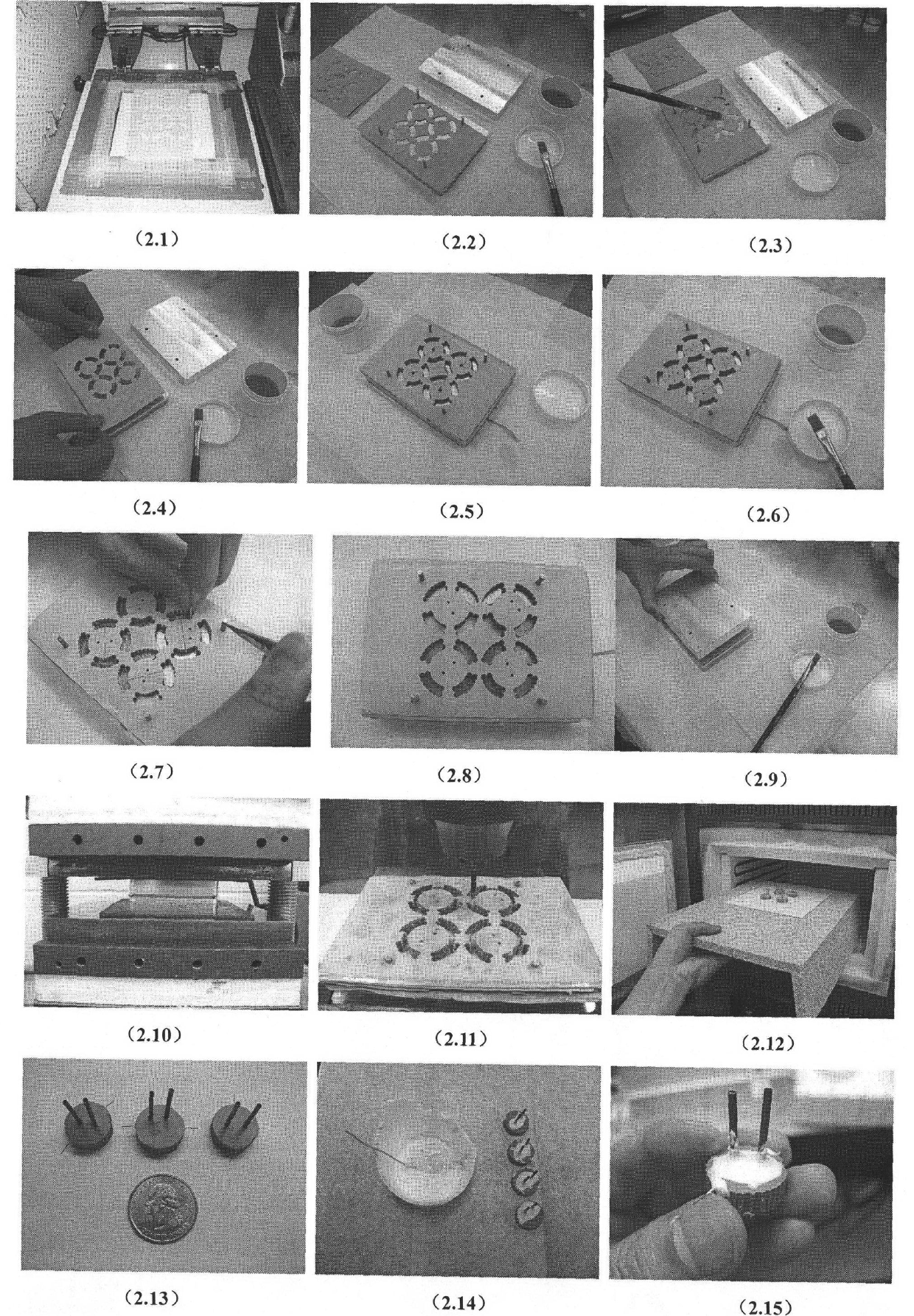

[0011] The use mode and specific processing procedures of the micro burner in the present invention will be further described below in conjunction with the accompanying drawings.

[0012] exist figure 1 In .1, the two capillary metal tubes (1-3) are respectively connected with the hydrogen supply pipeline and the oxygen supply pipeline. The exposed sections of the built-in wire igniter (1-1) reserved on both sides of the burner are respectively connected with the positive and negative electrodes of the ignition power supply. When working, open the gas supply valve of the oxygen circuit and the gas circuit to feed hydrogen and oxygen. The total gas flow rate is selected according to the volume of the burner body. The "hydrogen-oxygen" equivalent mixing ratio can be adjusted arbitrarily between 0.1 and 1. Hydrogen and oxygen will respectively flow in and mix in tangential direction from the outlet of the side wall of the combustion chamber through the internal cavity and the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com