Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236results about How to "Increase jet speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

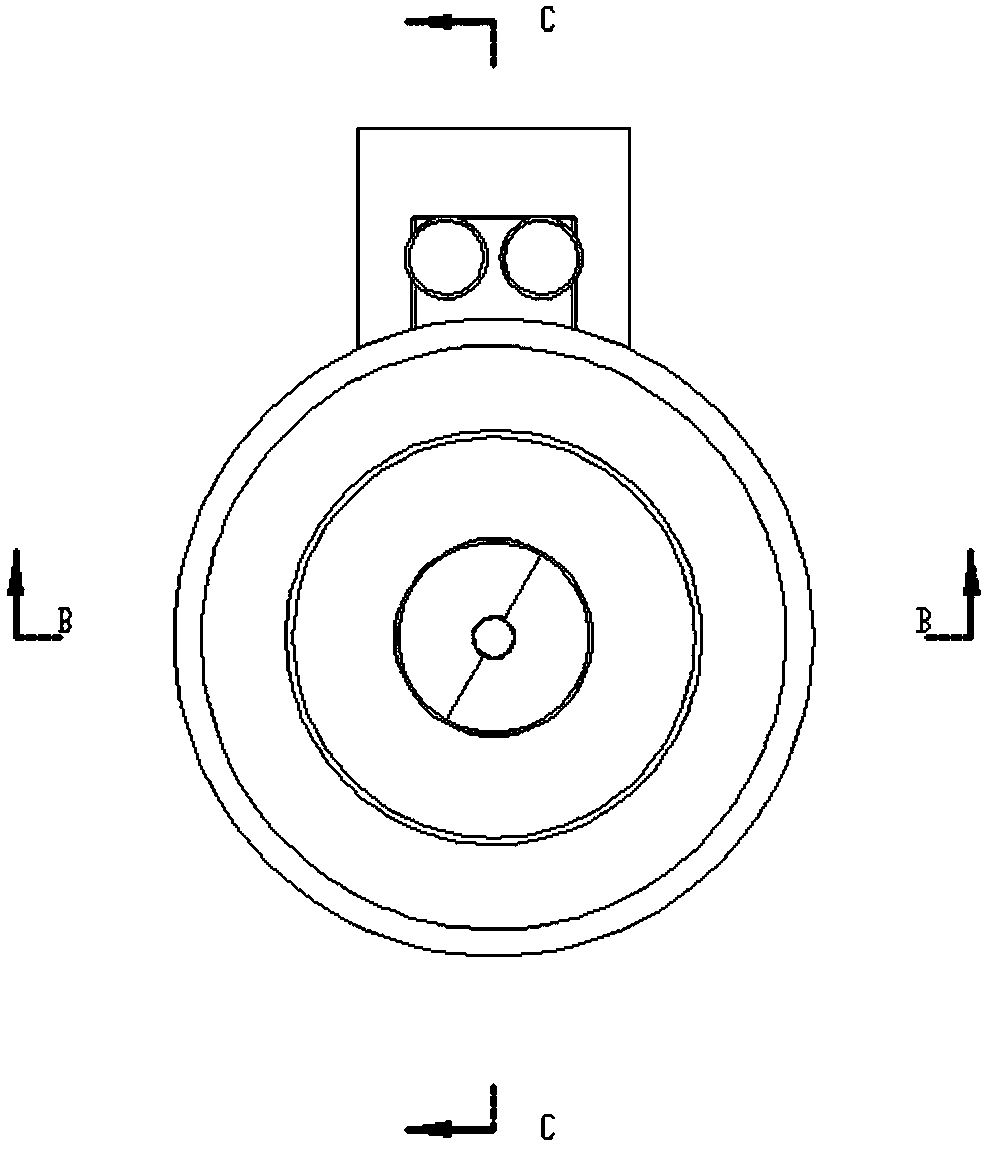

Thermally tempered glass, and method and apparatus for manufacturing the glass

InactiveUS20060121281A1Stable productionReduce distanceGlass/slag layered productsGlass tempering apparatusQuenchingCurve shape

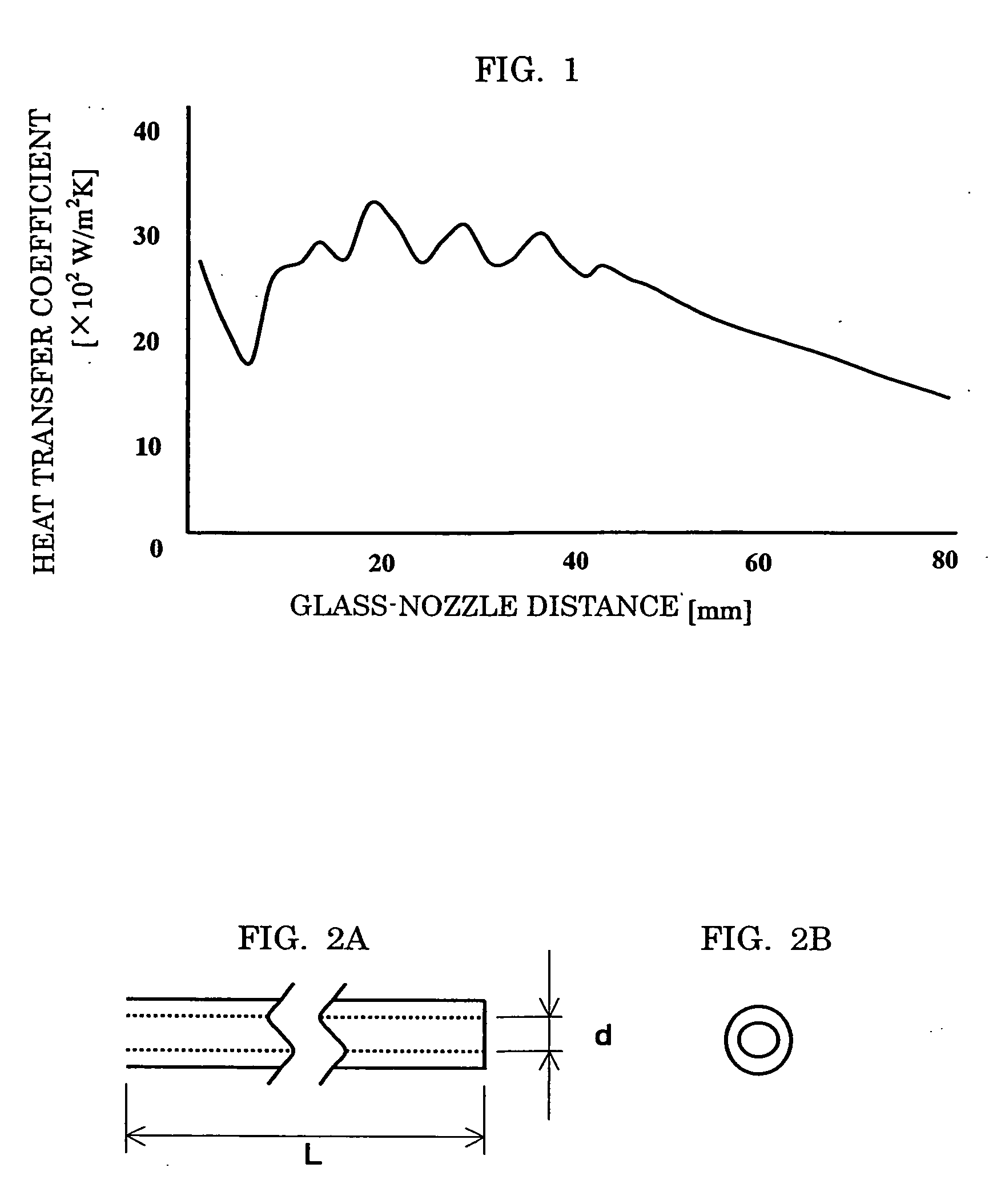

The invention relates, in case that a thermally tempered glass is produced by allowing an impact jet flow from quenching nozzles to blow against the glass, to a process for producing a curved shape, thermally tempered glass, characterized in that a quenching is conducted by simultaneously using at least two types of quenching nozzles having different exit diameters of the quenching nozzles. Furthermore, the invention relates to a curved, thermally tempered glass produced by this process and to an apparatus for producing the thermally tempered glass. In the invention, it is preferable that a exit diameter d is from φ1 mm to φ8 mm, a distance Z between the nozzle and the glass is 1 to 80 mm, a chamber pressure P is in a range of 0.1 to 0.8 MPa, and a heat flux difference is 150 kW / m2 or less. Furthermore, in the thermally tempered glass, it is preferable that a difference of surface compressive stress values within a glass surface is 20 MPa or less.

Owner:CENT GLASS CO LTD

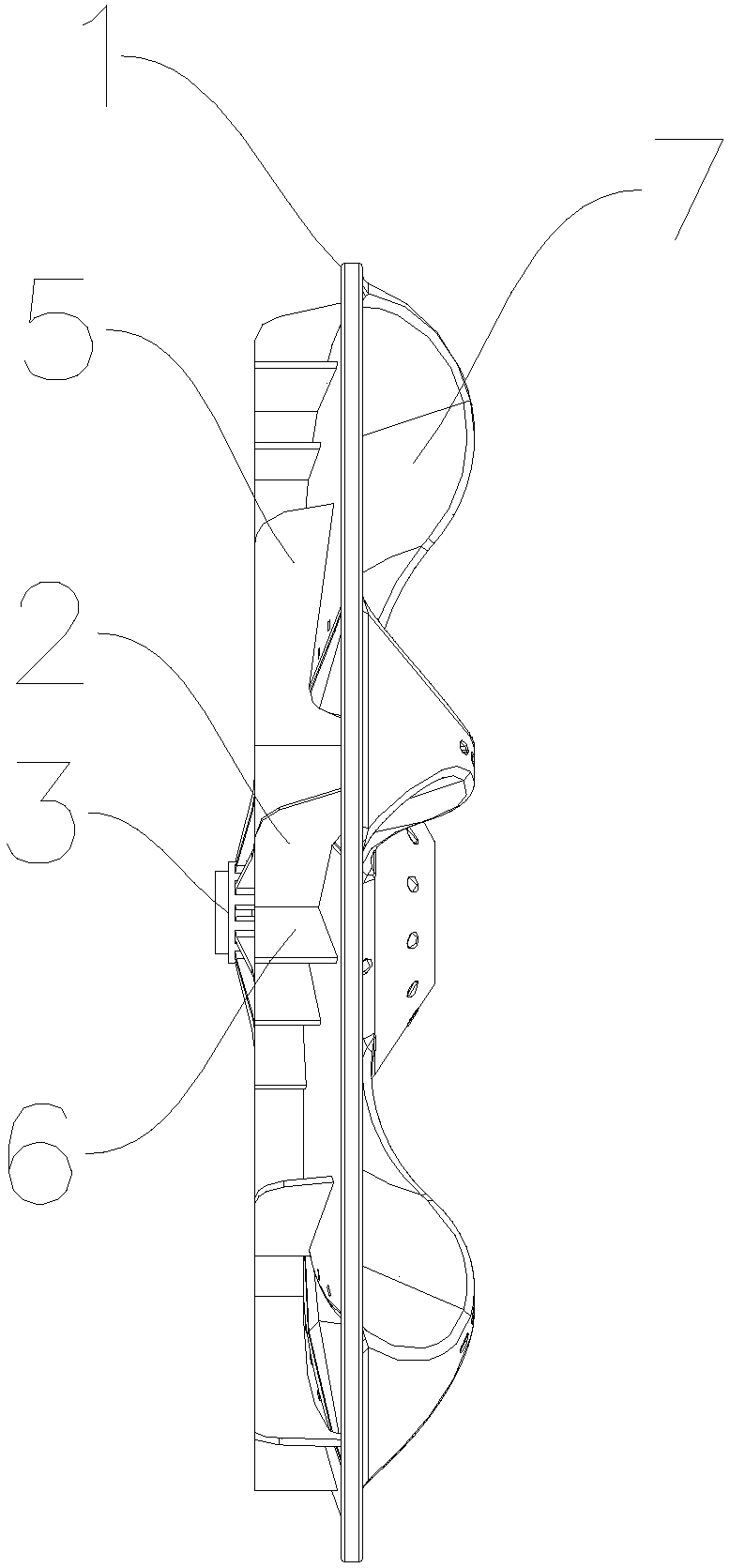

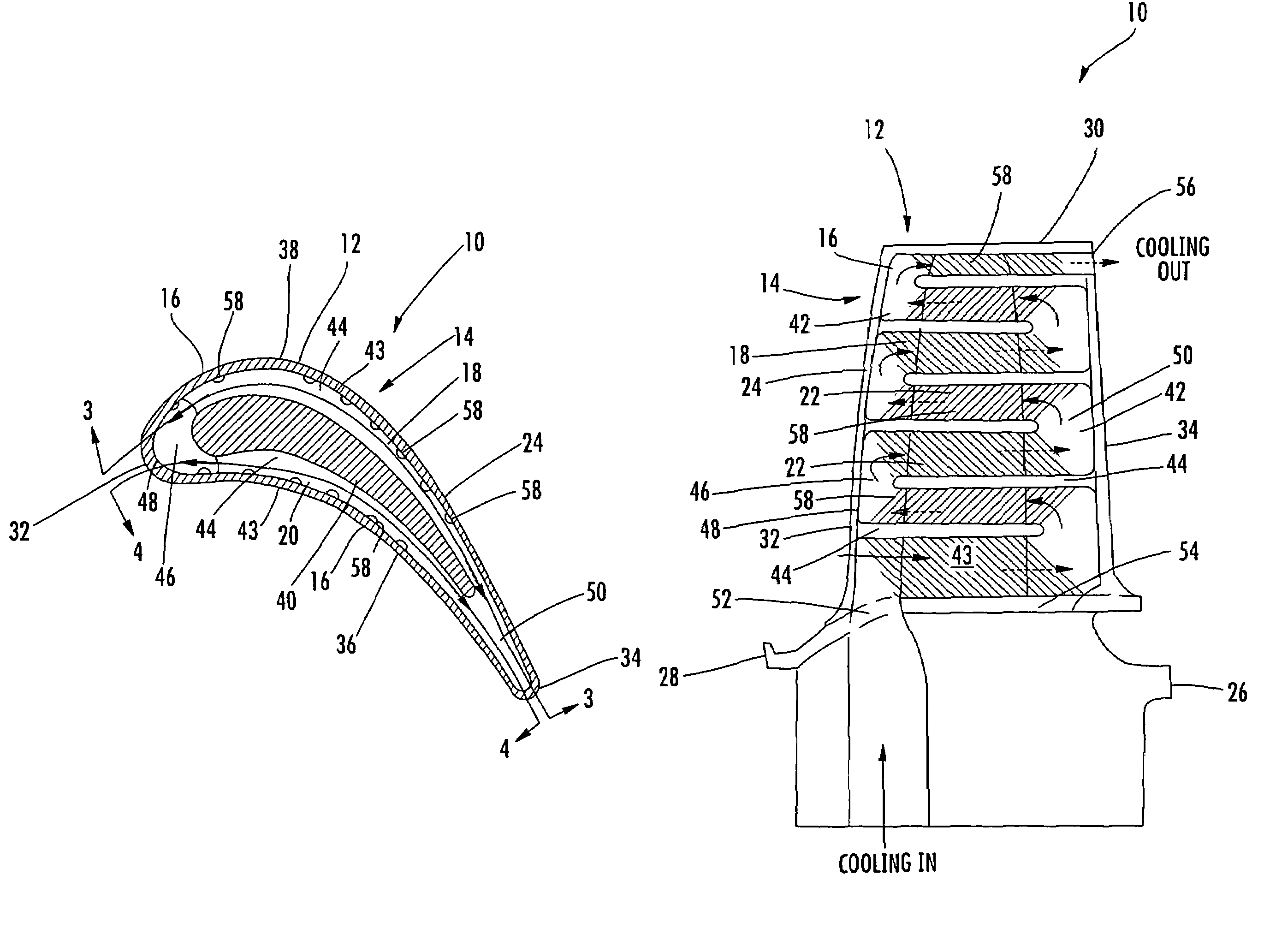

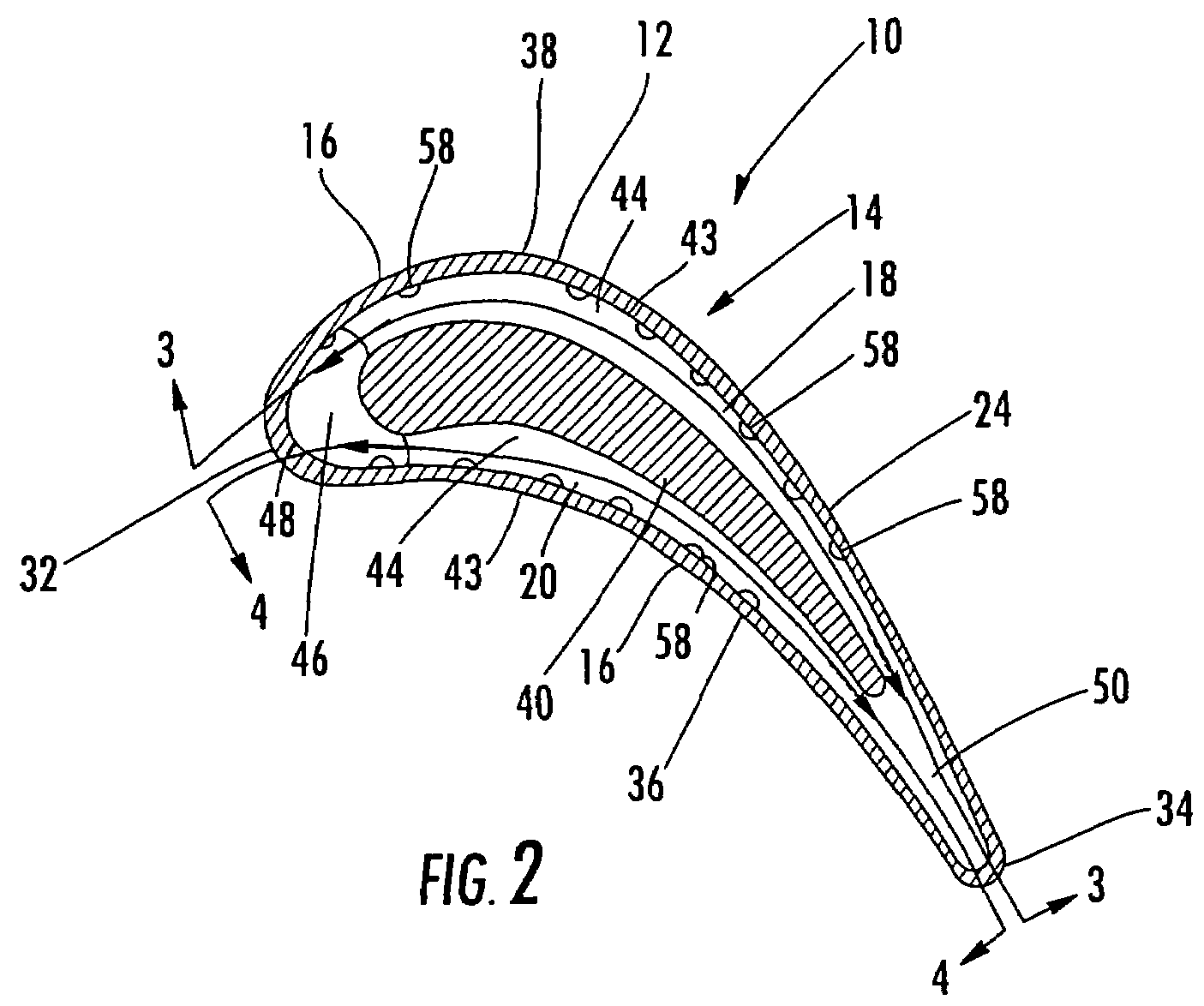

Turbine airfoil cooling system with axial flowing serpentine cooling chambers

InactiveUS20080050241A1Enhancing blade HCF capabilityIncrease cooling fluid air pressureEngine manufacturePump componentsLeading edgeCooling chamber

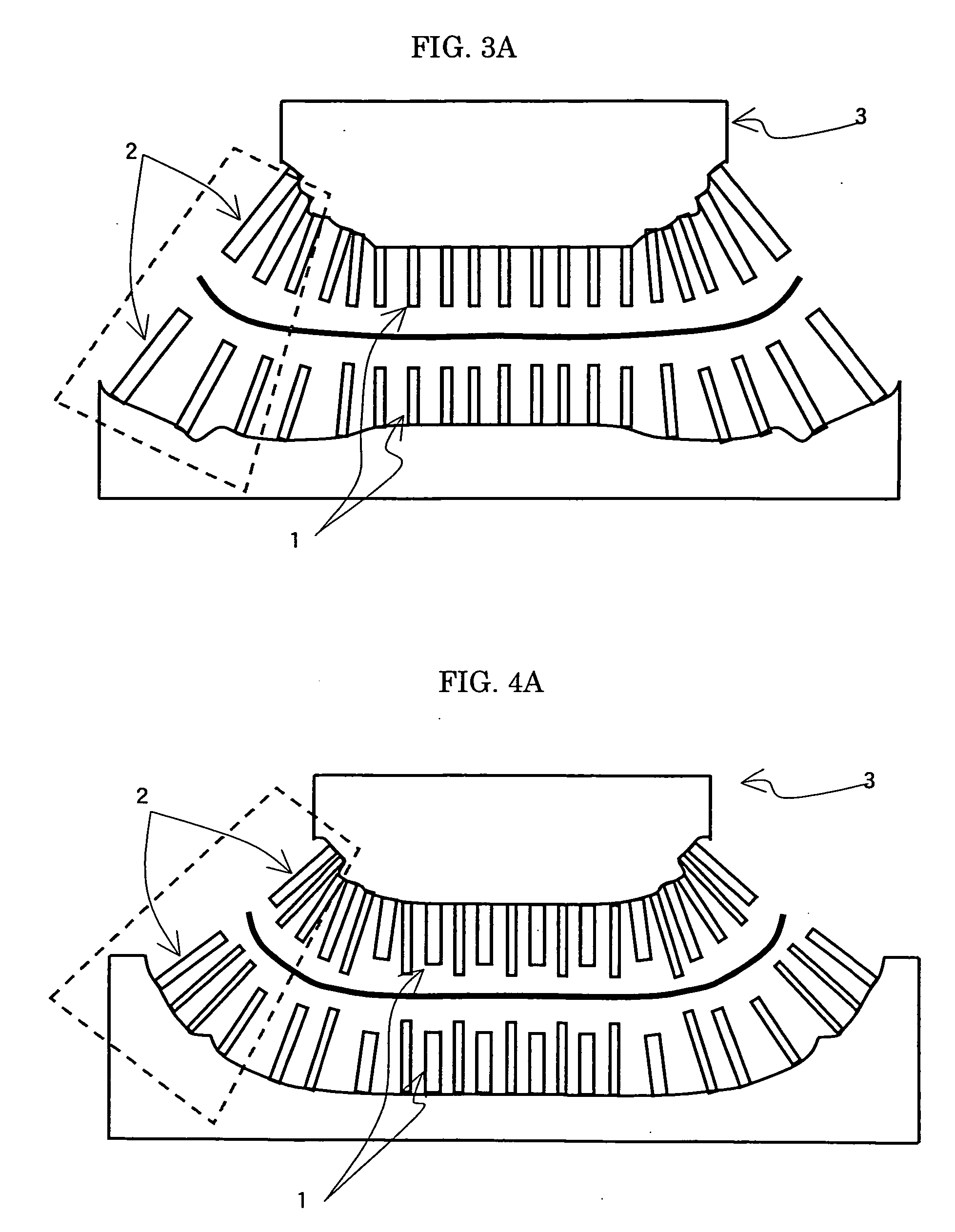

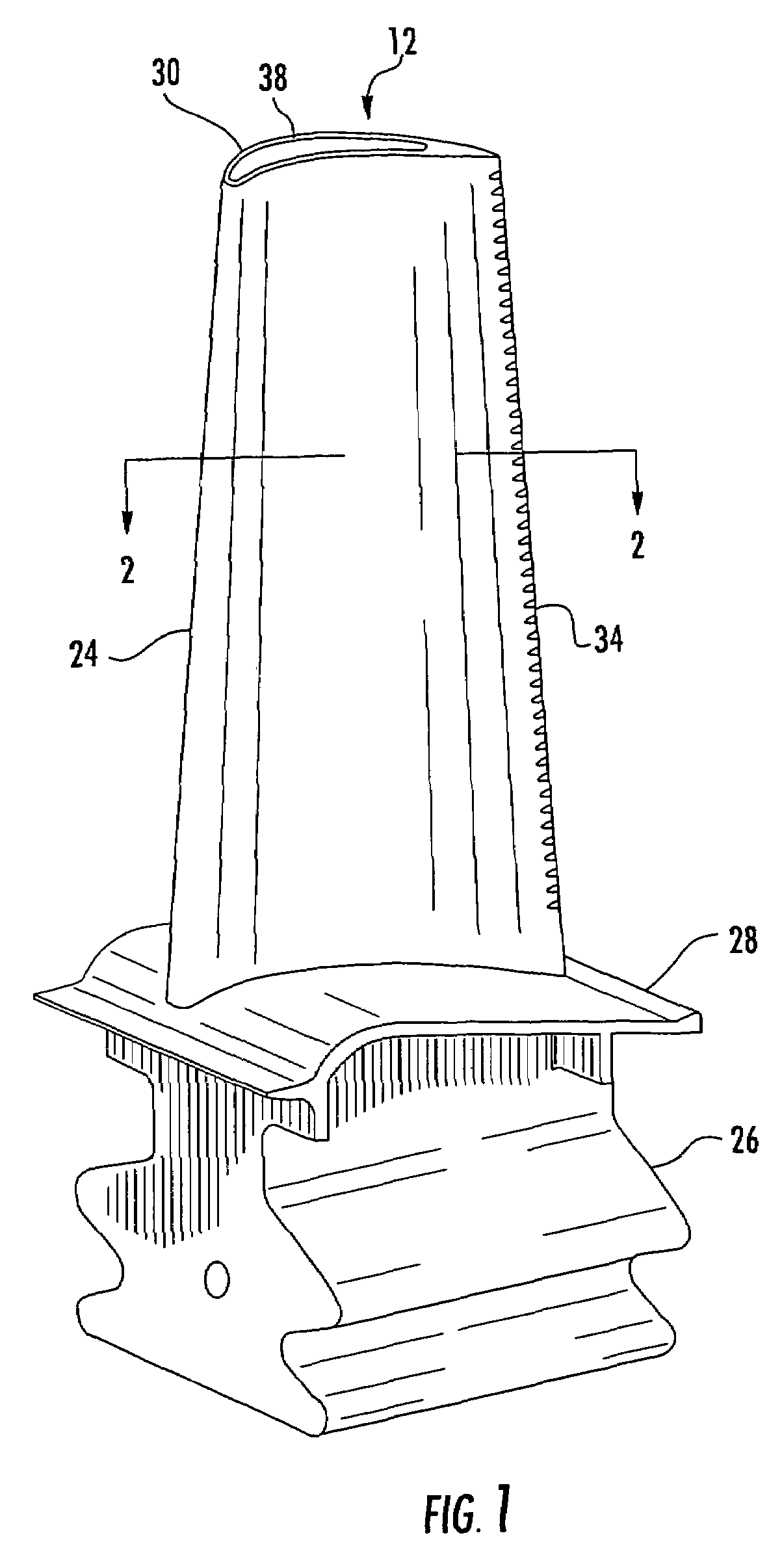

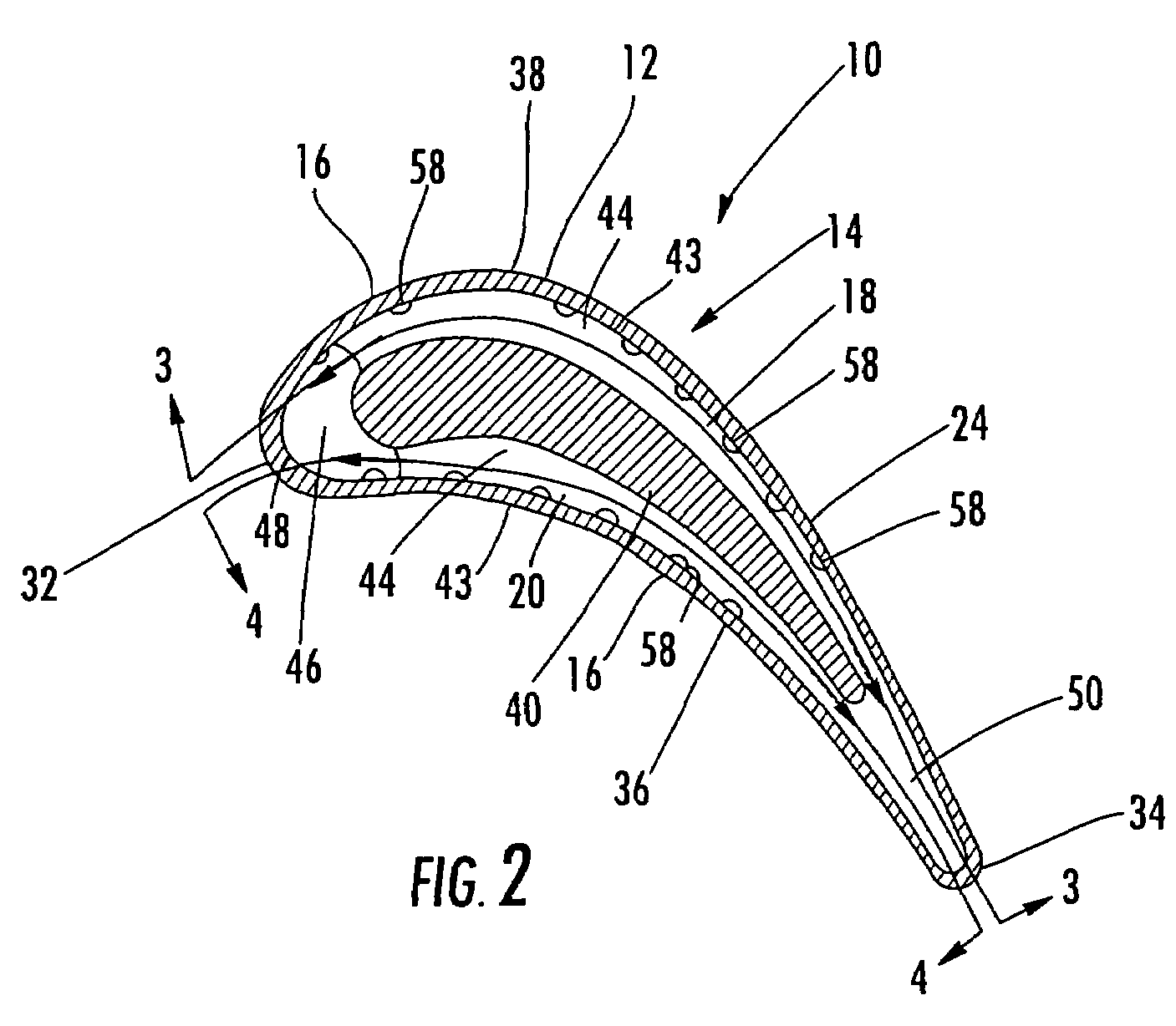

A cooling system for a turbine airfoil of a turbine engine having suction and pressure side serpentine cooling channels formed between an internal support core and an outer wall of the turbine airfoil. The suction and pressure side serpentine cooling channels may be formed from legs extending in a general chordwise direction between leading and trailing edges of the airfoil. The suction and pressure side serpentine cooling channels may receive cooling fluids from a cooling fluid supply source through a cooling fluid inlet, pass the cooling fluids through the cooling system and exhaust the cooling fluids through a cooling fluid exhaust orifice proximate to the tip section. The cooling system is particularly suitable for use with low cooling fluid flow.

Owner:SIEMENS ENERGY INC

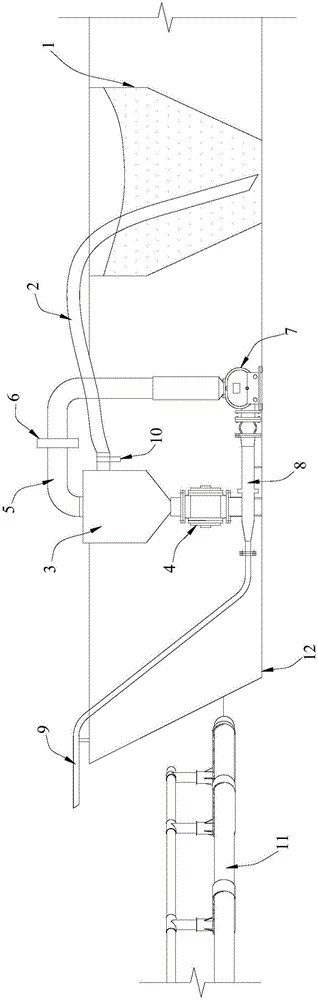

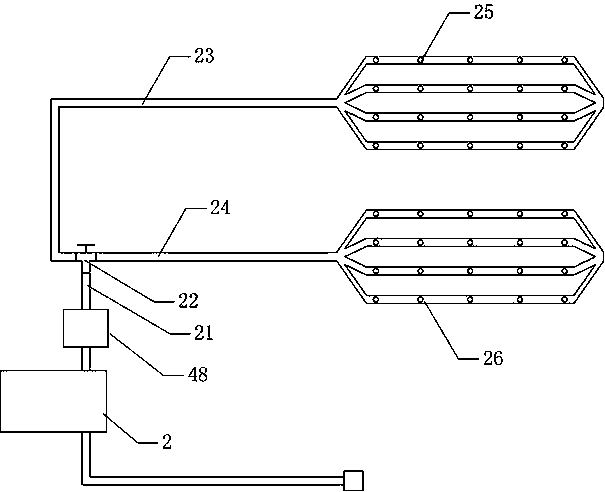

Deepwater net cage feeding method based on suction type onboard automatic feeding system

InactiveCN105918198AShorten feeding timeImprove efficiencyPisciculture and aquariaBlocked valvesEngineering

The invention discloses a deepwater net cage feeding method based on a suction type onboard automatic feeding system. The automatic feeding system comprises a stock bin, a sucking pipe, a sealing bin, a blocking valve, an air inlet pipe, a Roots blower, an air-feed mixing and spraying device, a discharge pipe and a power device. The sucking pipe and the discharge pipe are hoses. A feed port of the blocking valve is communicated with a sealed inner cavity of the sealing bin, and a discharge port of the blocking valve is communicated with a feed port of the air-feed mixing and spraying device. An air outlet of the Roots fan is communicated with an air inlet of the air-feed mixing and spraying device, an air-feed mixing outlet of the air-feed mixing and spraying device is communicated with an inlet of the discharge pipe, and an outlet of the discharge pipe extends from a head position of a cultivation work ship. The deepwater net cage feeding method includes loading, work ship positioning and feeding. The deepwater net cage feeding method has the advantages of shortened feeding time, high feed conveying efficiency, large coverage area and capability of saving labor, increasing feed utilization ratio and cultivation efficiency.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

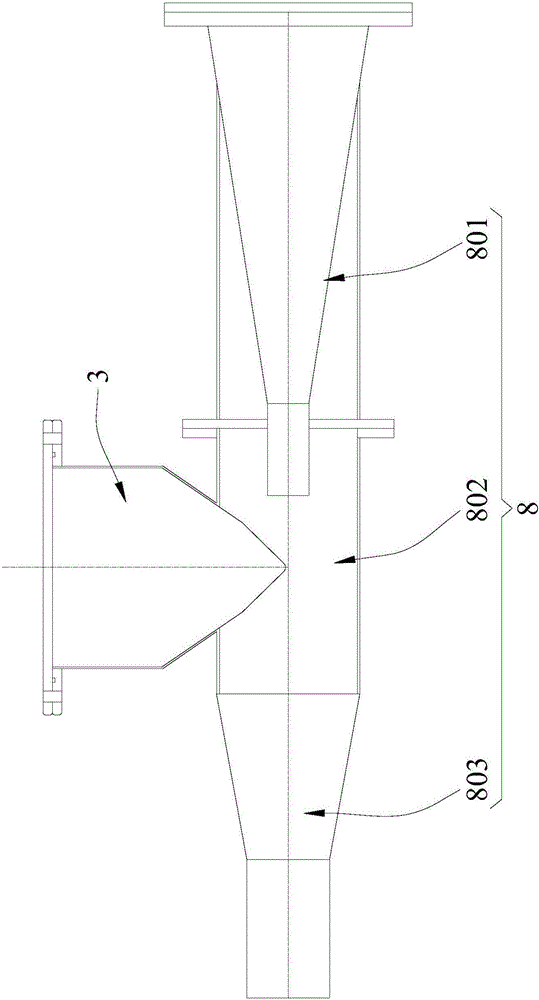

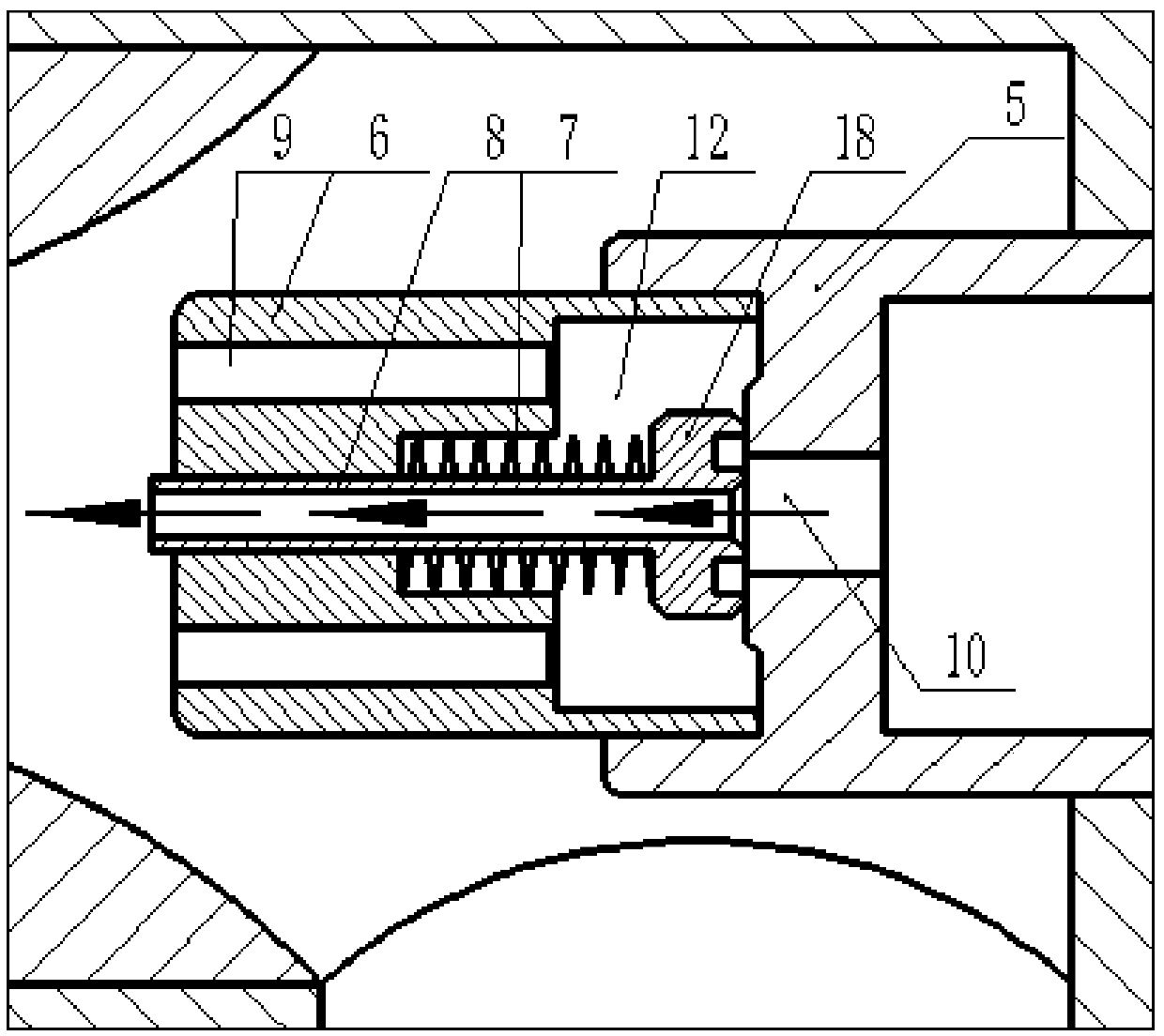

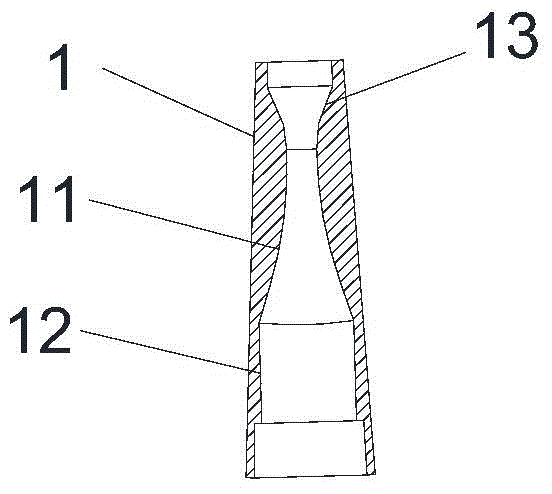

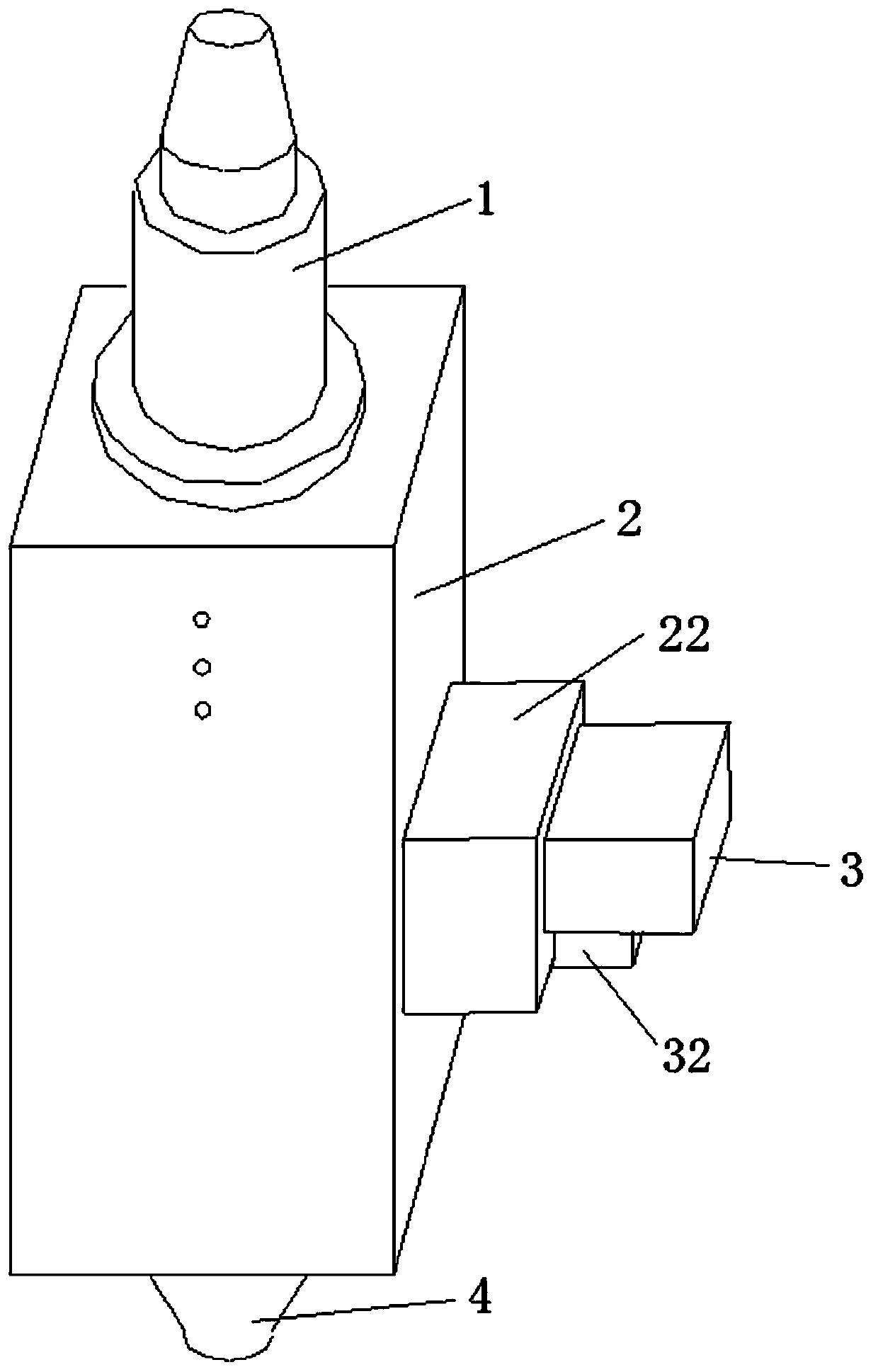

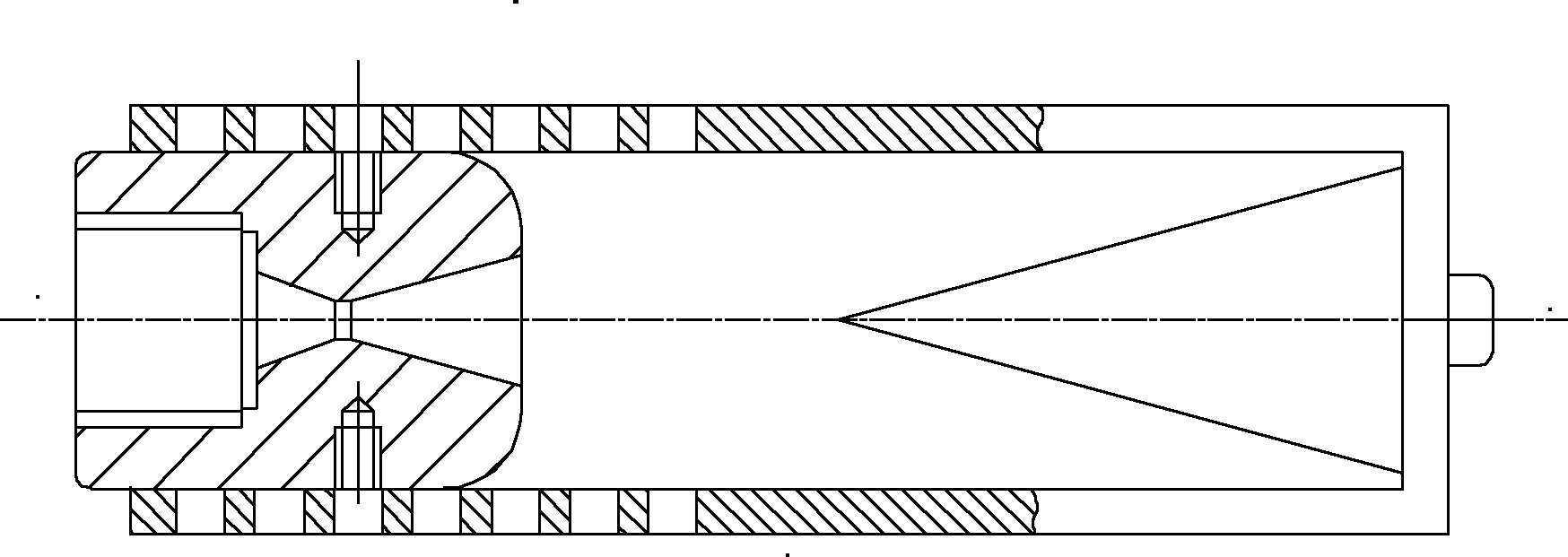

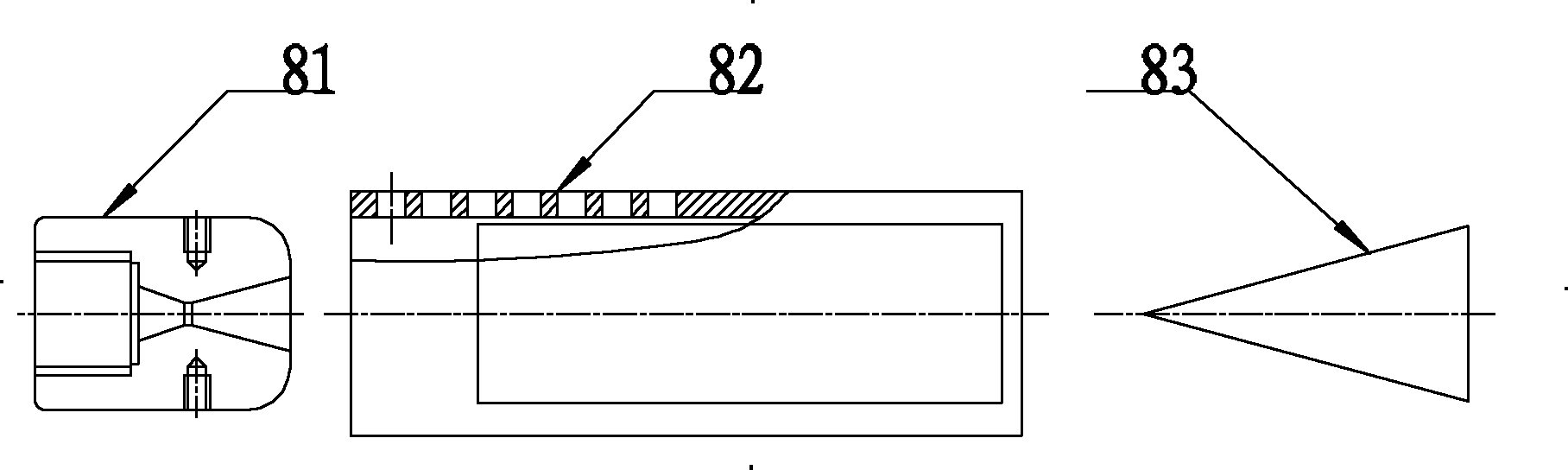

Nozzle, ejector based on nozzle and having adjustable flow characteristic, and application of ejector

InactiveCN109630479AImprove performanceReduce outlet pressureJet pumpsMachines/enginesAutomatic controlHydrogen

The invention discloses a nozzle, an ejector based on the nozzle and having an adjustable flow characteristic, and application of the ejector. The nozzle comprises a nozzle body, a small nozzle, a large nozzle and an elastic part; a thin and long hollow pipe with a valve is adopted as the small nozzle, and the elastic part is arranged between the set of large nozzle and the set of small nozzle; one end of the elastic part jacks the valve part of the small nozzle, and the other end of the elastic part jacks the large nozzle; and the elastic part can change the position of the valve of the smallnozzle under the effect of to-be-ejected gas, and then a flowing path of the to-be-ejected gas is controlled. The supply quantities of hydrogen and recycled hydrogen are automatically controlled by the nozzle according to system loads; when the low load exists, the small nozzle acts, the pressure of a nozzle outlet is small, the recovery rate of the recycled hydrogen is high, and the hydrogen utilization rate is increased; when the medium-high loads exist, the two sets of nozzles act simultaneously, and the large nozzle is used for enlarging the circulating area to provide the larger fuel flow; and the small nozzle is used for increasing the ejecting speed to improve properties of the ejector.

Owner:SHANDONG UNIV

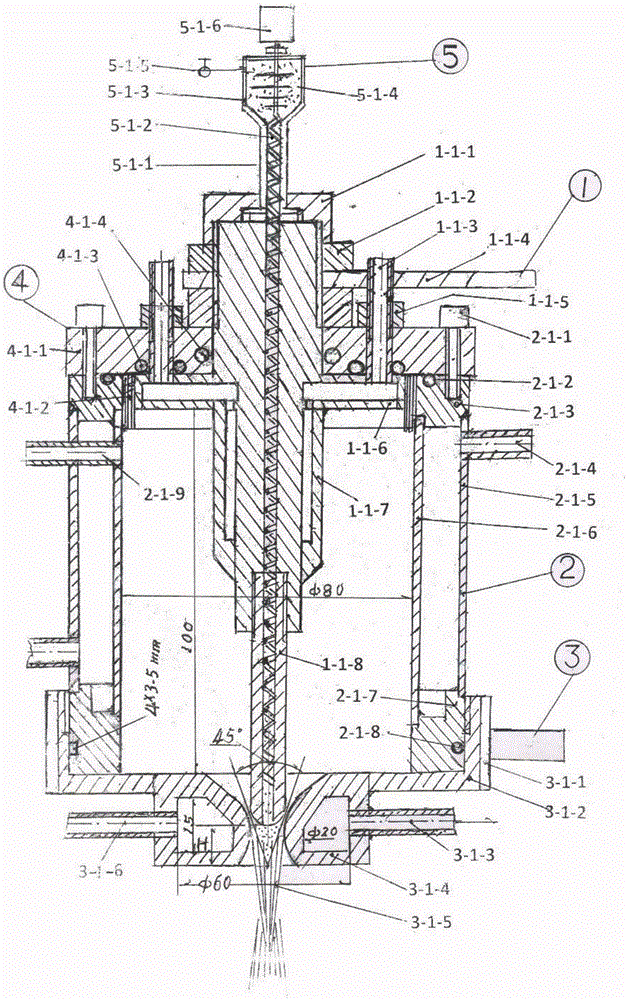

Direct-current argon arc plasma powder spray gun and manufacturing method

ActiveCN105755421AExpand the field of technology applicationImprove stabilityMolten spray coatingMetallurgyPlasma heating

The invention discloses a direct-current argon arc plasma powder spray gun and a manufacturing method and belongs to the field of flame spraying equipment and technology of metal powder and metal ceramic powder.Two novel technologies including a hollow tungsten cathode outer surface annular arcing direct-current plasma heating method and an axial powder feeding mechanism penetrating the core of an argon arc are adopted, and position matching of a negative voltage pressure of the electric arc and the powder feeding mechanism is utilized, so that stability of the spray gun during long-time working is improved, and uniformity in heating temperature of metal powder particles, uniformity in spray speed and stability of spray layer quality are guaranteed.In addition, due to structural changing of a gun body, technology application field of the gun is expanded obviously, and the gun is expected to make a beneficial contribution to development of high technology in the future.

Owner:UNIV OF SCI & TECH BEIJING

Compressed air foam extinguishing agent spraying gun and method thereof

The invention discloses a compressed air foam extinguishing agent spraying gun and a method thereof. Foam extinguishing agent liquid is sprayed out of an annular spraying channel which is positioned at an inlet of an extinguishing agent spraying gun pipe and is tightly attached to the wall surface to form a flowing liquid film attached to the wall; under impact and cutting of high-speed air flow injected by a convergence-shaped nozzle in the center of the inlet of the extinguishing agent spraying gun pipe, the liquid film is damaged; under the action of surface tension, the liquid film is contracted and wraps compressed air for cutting the liquid film, so that a plurality of air foam balls are generated, and foam extinguishing agent liquid becomes high-speed flowing compressed air foams; and the compressed air foams are accelerated in a 'laval nozzle' type gun pipe and then sprayed at high speed. By the compressed air foam extinguishing agent spraying gun and the method thereof, the compressed air and the foam extinguishing agent are mixed in a gun body to generate the compressed air foam which is sprayed at high speed; fuel fire can be quickly extinguished, and reignition is avoided; fire with the same intensity can be extinguished; and a large number of foam extinguishing agents can be saved.

Owner:中国人民解放军海军装备技术研究所

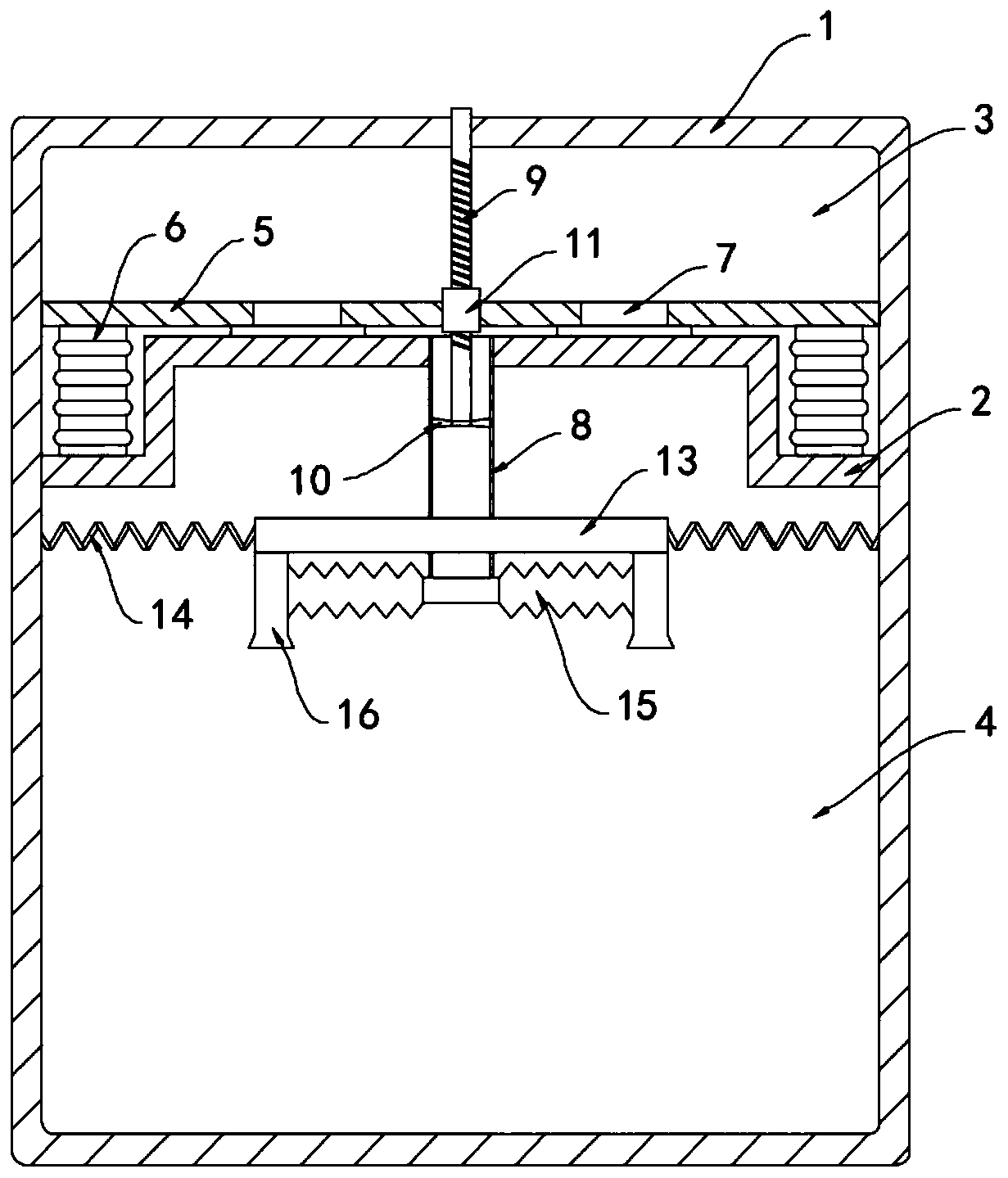

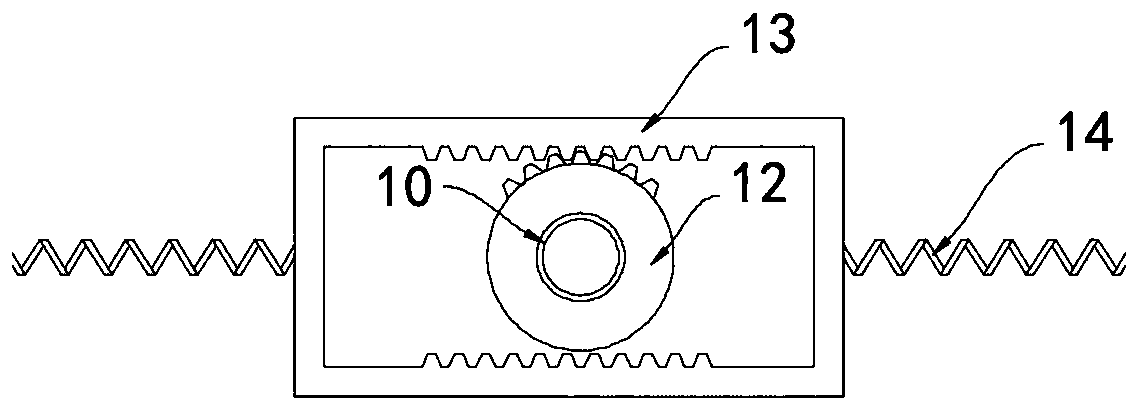

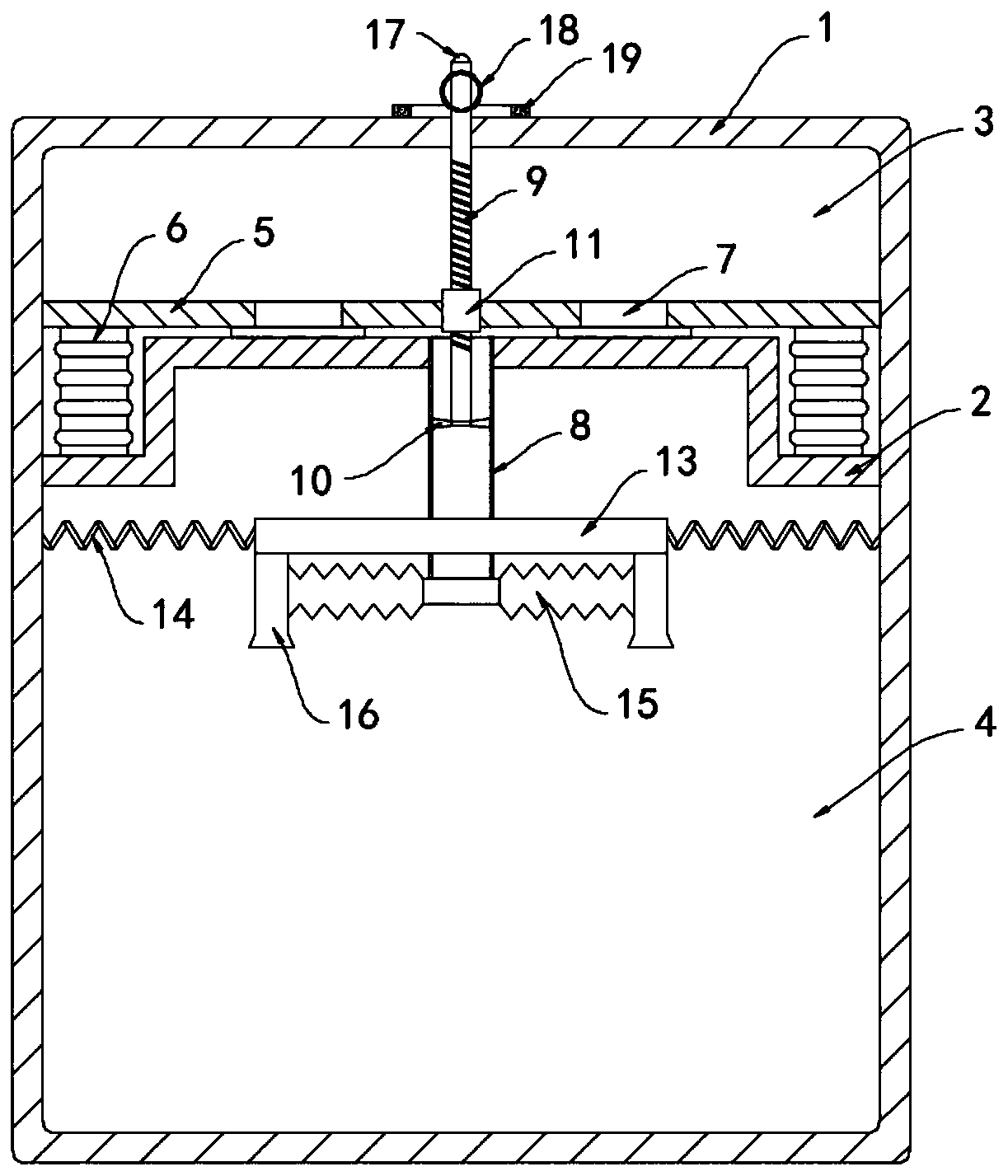

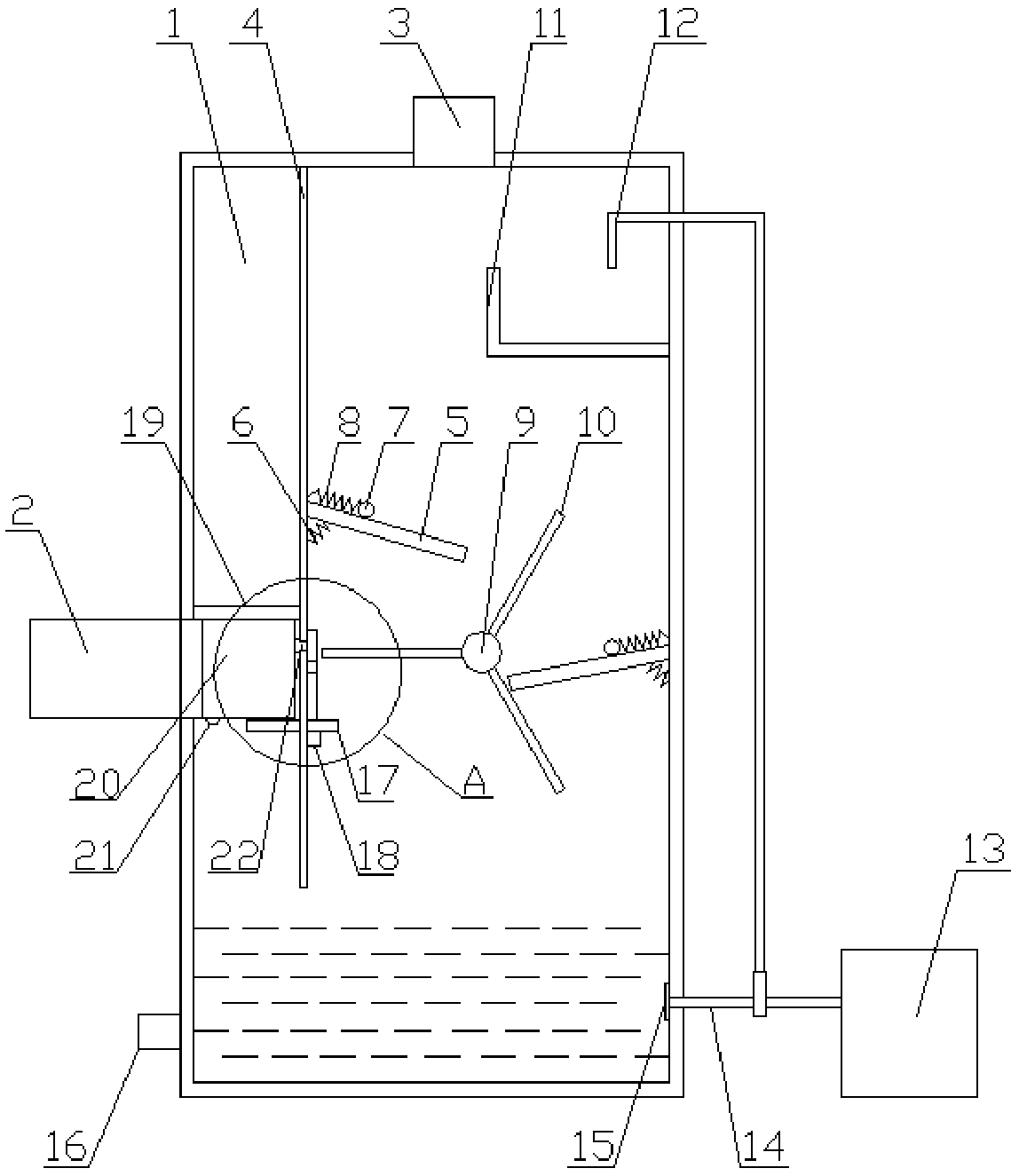

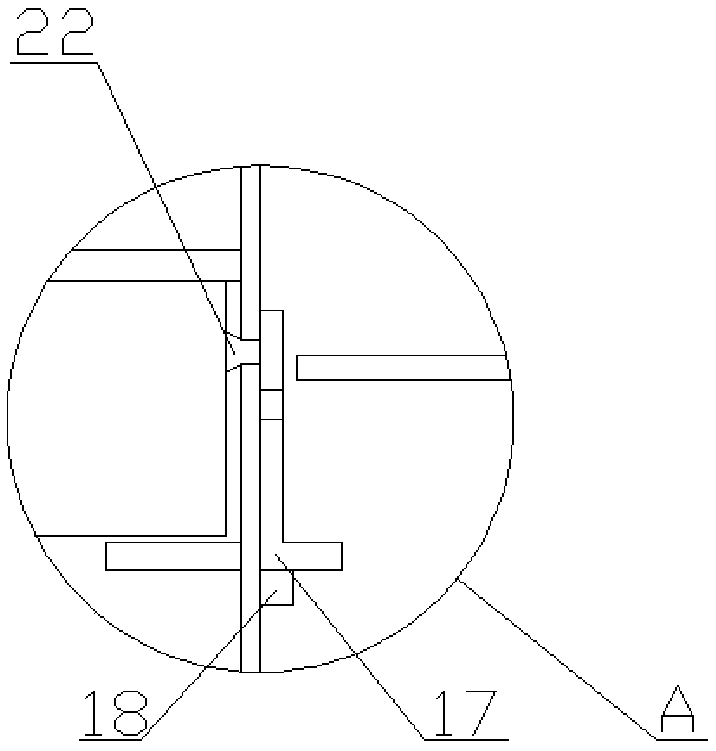

Outdoor power distribution cabinet with rapid self-extinguishing function

ActiveCN111555141AIncrease jet speedImprove fire extinguishing effectSubstation/switching arrangement casingsFire rescueStructural engineeringThreaded rod

The invention belongs to the field of power distribution cabinets, and especially relates to an outdoor power distribution cabinet with a rapid self-extinguishing function. The cabinet comprises a cabinet body, and a partition plate which is horizontally arranged is fixedly mounted on the inner side wall of the cabinet body; the partition plate divides the cabinet body into a fire extinguishing cavity and a mounting cavity; and the inner side wall of the fire extinguishing cavity is connected with a horizontally-arranged sealing plate in a sealed and sliding mode. The lower surface of the sealing plate is fixedly connected with a partition plate through an elastic air bag. The elastic air bag is filled with a thermal expansion and cold contraction medium, two through holes are formed in the sealing plate, and a vertically-arranged flow guide pipe rotationally penetrates through the partition plate, the flow guide pipe and the two through holes are arranged in a staggered mode, and a threaded rod arranged in the axial direction of the flow guide pipe is arranged in the flow guide pipe. When a fire occurs in the power distribution cabinet, a fire extinguishing agent in the fire extinguishing cavity can be automatically sprayed to electrical equipment in the mounting cavity, so that an automatic fire extinguishing effect is achieved, the fire in the cabinet body can be quickly controlled, and the possibility of economic loss and dangerous accidents is reduced.

Owner:胜利油田大源节能设备有限公司

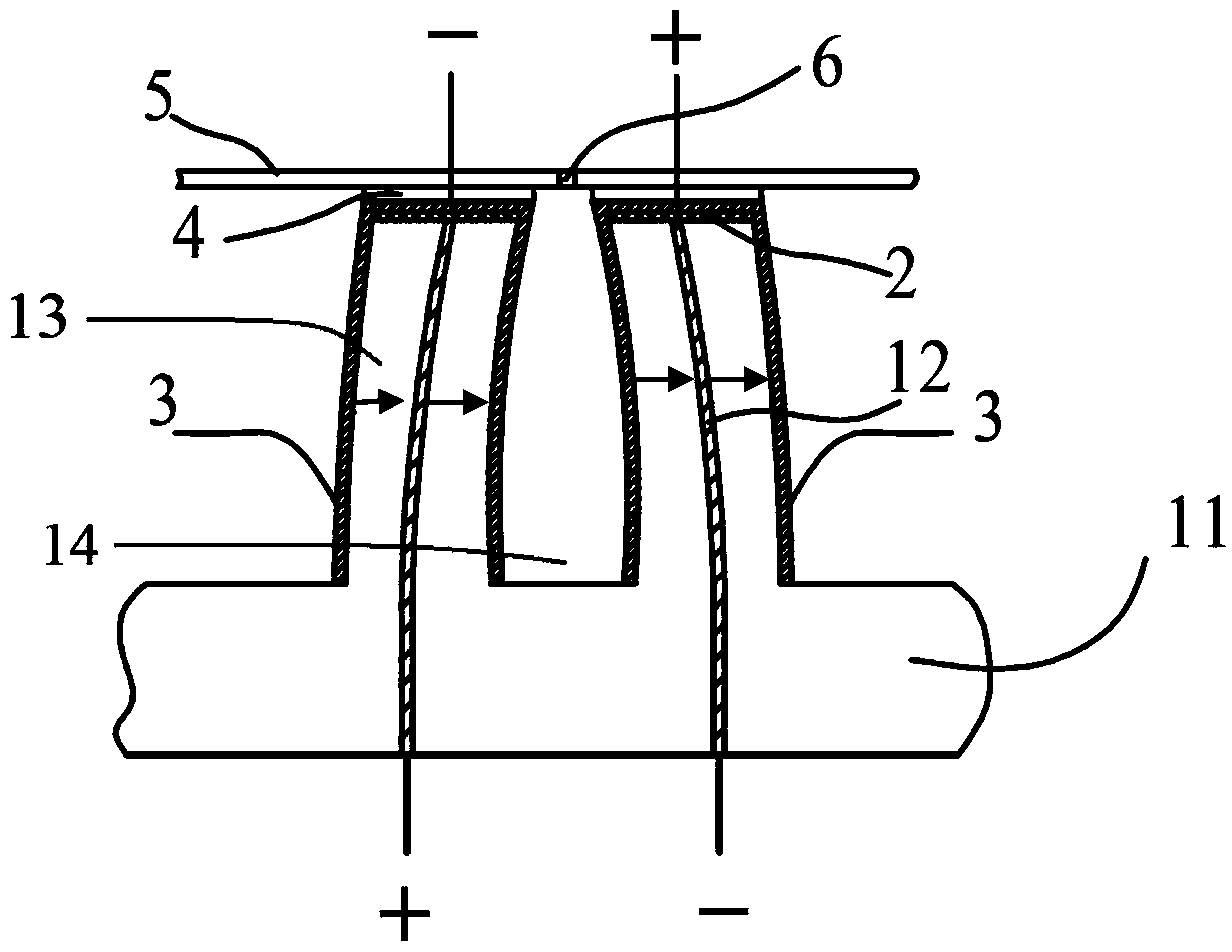

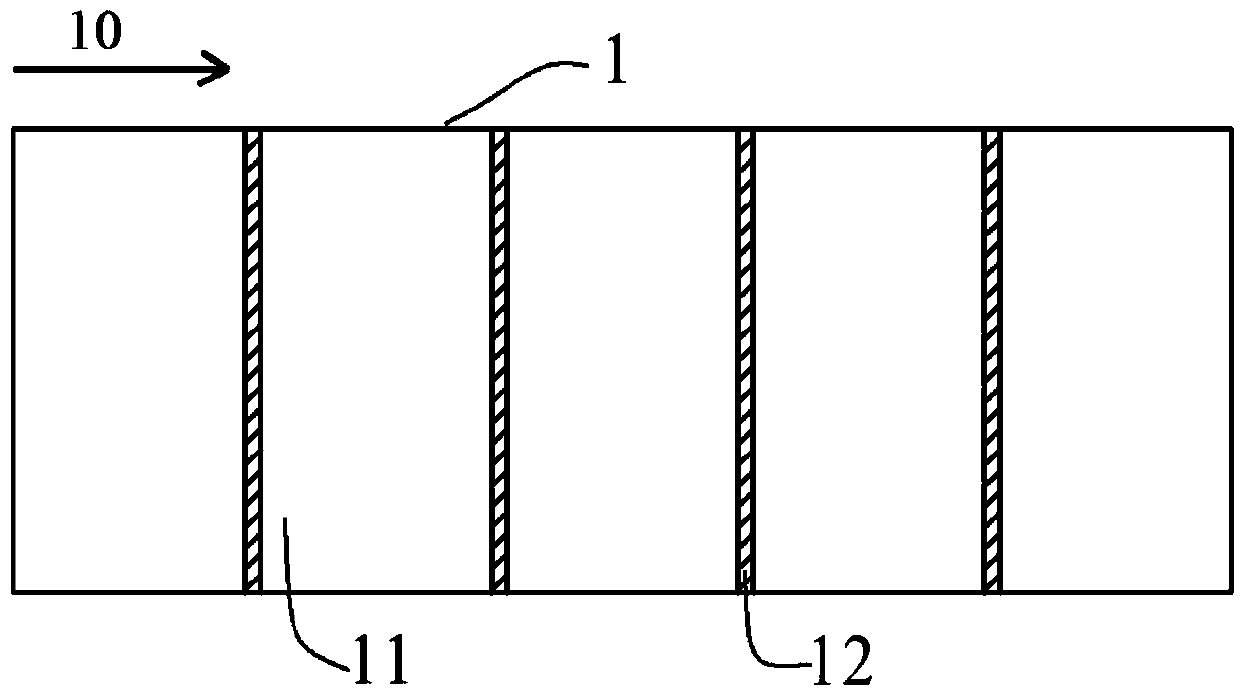

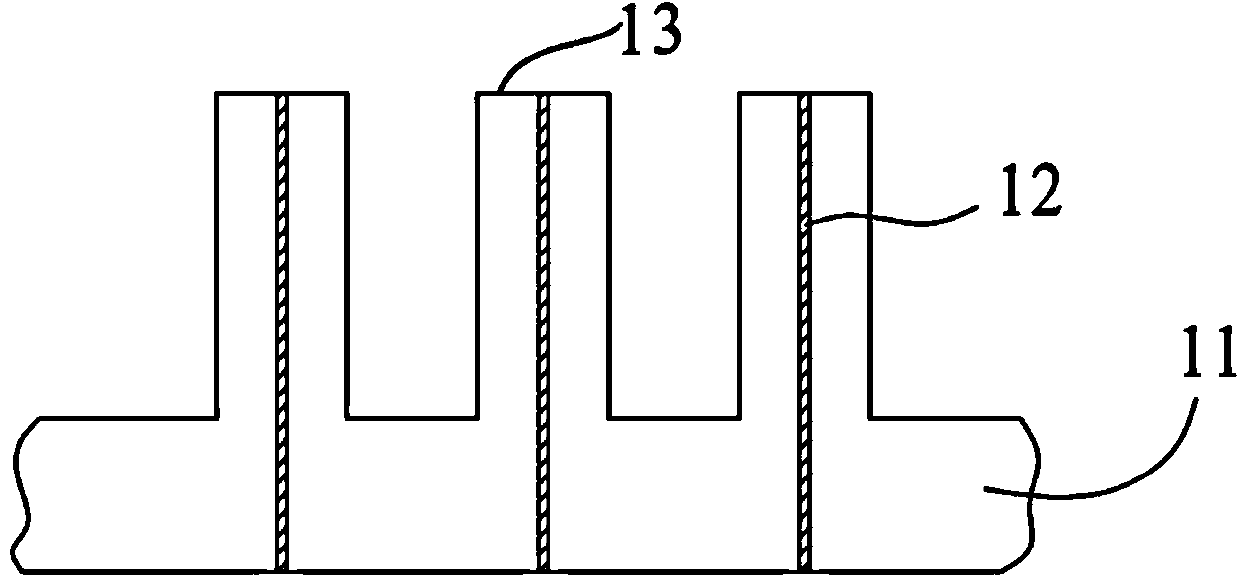

Piezoelectric ink jet head and printing device with piezoelectric ink jet head

The invention discloses a piezoelectric ink jet head and a printing device with the piezoelectric ink jet head, and belongs to the technical field of ink jet printing. The ink jet head comprises a piezoelectric ceramic and a nozzle plate. The piezoelectric ceramic is provided with a plurality of strip-shaped channel walls, a groove is formed between every two adjacent channel walls, metal inner electrodes are embedded in the channel walls to form a piezoelectric bimorph structure, and the outer surfaces of the channel walls are provided with outer electrodes. The nozzle plate covers the far end faces of the channel walls, a flexible sealing substance is arranged between the nozzle plate and the channel walls at intervals, the nozzle plate is provided with nozzles, the number of the nozzles is equal to the number of grooves, and the nozzles correspond to the grooves in position. According to the piezoelectric ink jet head, the channel walls are powered up and deformed in a d31 transverse bending mode, large deformation can be produced, large deformation pressure can be produced on ink in an ink channel, large-grain-size ink can be ejected, and the ejecting speed can be improved.

Owner:PAIHE SCI & TECH HLDG CO LTD BEIJING

Low-pressure oil film breaking and atomizing technology and device thereof

The invention discloses low-pressure oil film breaking and atomizing technology and device thereof. The low-pressure oil film breaking and atomizing technology is characterized in that fuel oil and an auxiliary gas are formed into gas-liquid two-phase fluids, the gas-liquid two-phase fluids are jetted into a furnace cavity through an oil gun, and the jetted gas-phase fluids enable a formed oil film to be broken by overcoming the surface tension of the jetted gas-phase fluids so as to realize the superfine atomization of the fuel oil; the outlet of a circular jet hole is provided with a secondary transverse ultrasonic air flow, the jet direction of the secondary transverse ultrasonic air flow is perpendicular to that of the circular jet hole, and the secondary transverse ultrasonic air flow further impacts initially-atomized fuel oil jetted from the circular jet hole to carry out secondary breakage and atomization on the fuel oil. The invention has the advantages of smaller average diameter of an oil drop, high penetrating capability of oil mist, good adjustability of an atomized taper angle and very little change of the average dimension of the oil drop when the viscidity of the fuel oil is enhanced or the ejection force of the oil gun is smaller; and in addition, the invention only needs lower fuel oil pressure of 0.4-0.5 MPa, thereby lowering the pressure of a fuel oil system, reducing the electricity consumption of an oil pump and saving the plant electrical consumption.

Owner:艾佩克斯科技(北京)有限公司

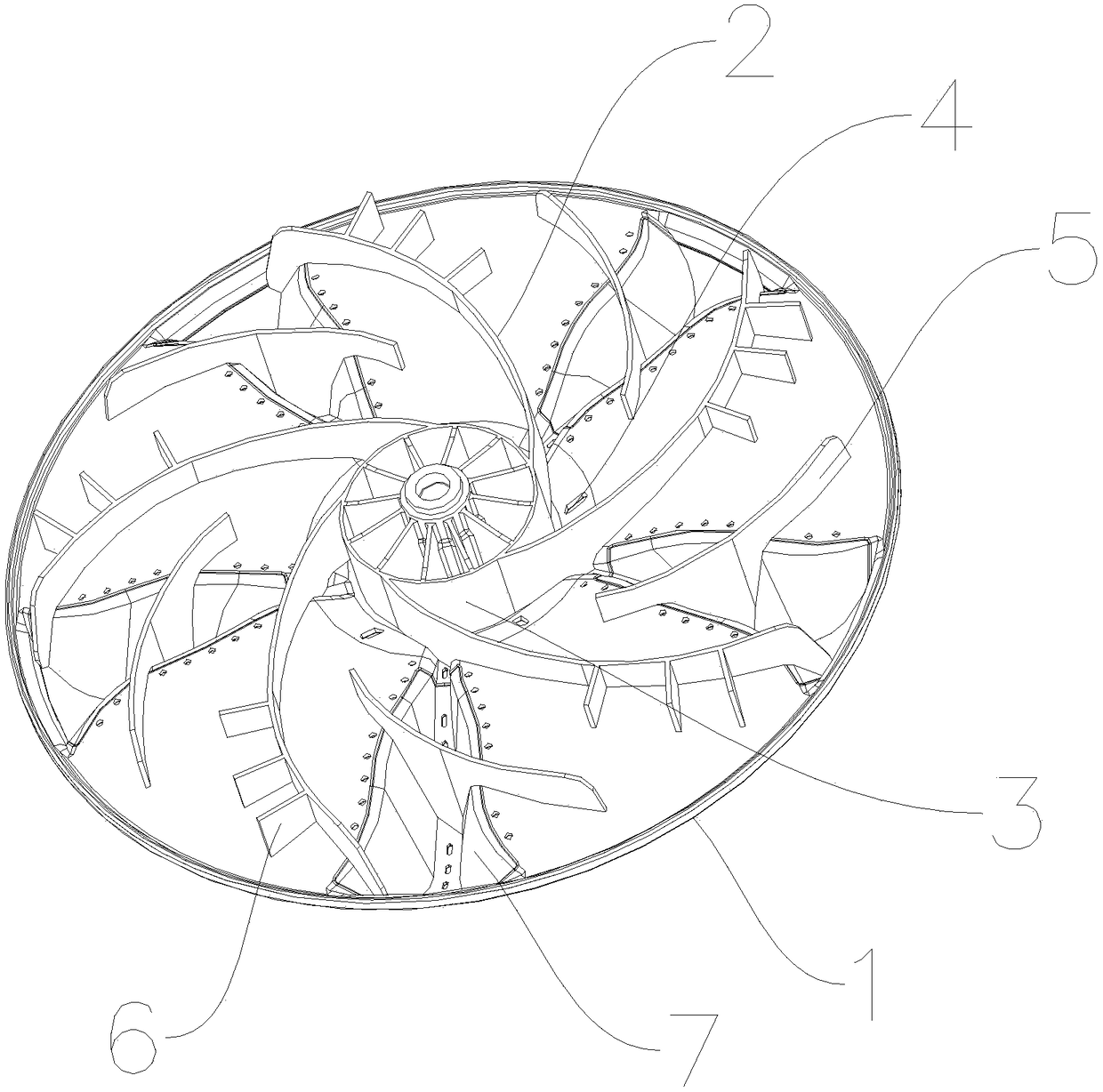

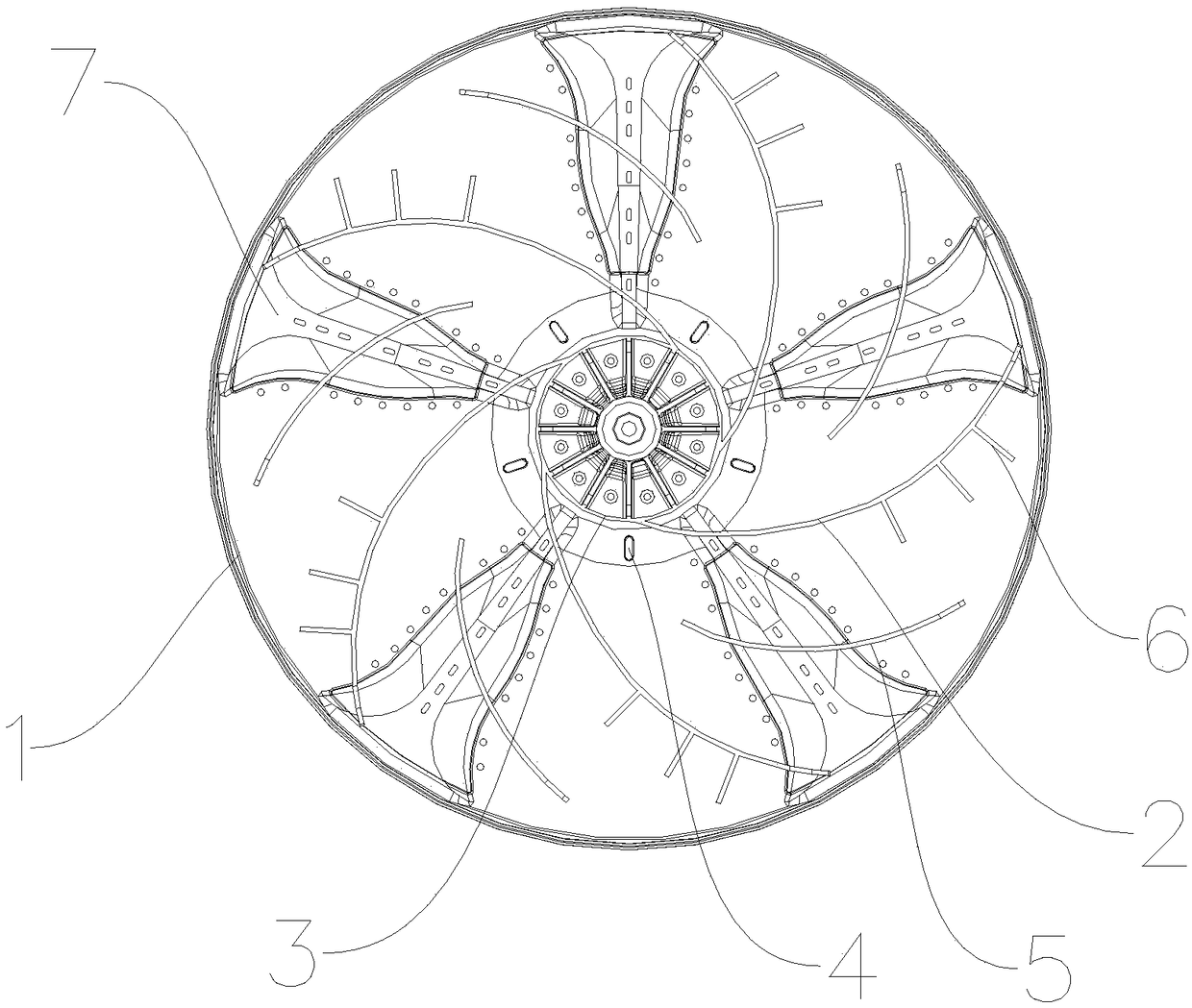

Pulsator mechanism for washing machine and washing machine

ActiveCN108221262AImprove washing effectMeet washing requirementsWashing machine with receptaclesTextiles and paperLaundry washing machineWater flow

The invention belongs to the technical field of washing machines and aims at solving the problem that a pulsator of an existing pulsator washing machine is simple in structure, and accordingly the effect of washing garments is limited. In order to solve the problem, a pulsator mechanism for a washing machine and the washing machine are provided. The washing machine comprises an inner drum, the pulsator mechanism comprises a pulsator at the bottom of the inner drum, one or more spray holes in the pulsator and a water retaining assembly at the bottom of the pulsator, and the water retaining assembly can make water form backflow and spray the water into the inner drum through the spray holes in the pulsator rotation process. Through the water retaining assembly at the bottom of the pulsator,the water can form backflow and is sprayed into the inner drum through the spray holes, the sprayed water flow can generate vertical application force on the garments in the inner drum, then the garments are continuously turned over, under the situation with cooperation of horizontal rotation of the pulsator, the effect of washing the garments can be improved, the washing requirement of a user ismet, and the user experience is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Turbine airfoil cooling system with axial flowing serpentine cooling chambers

InactiveUS7549843B2Lower and more uniform blade sectional massReduce the overall heightEngine manufacturePump componentsLeading edgeCooling chamber

A cooling system for a turbine airfoil of a turbine engine having suction and pressure side serpentine cooling channels formed between an internal support core and an outer wall of the turbine airfoil. The suction and pressure side serpentine cooling channels may be formed from legs extending in a general chordwise direction between leading and trailing edges of the airfoil. The suction and pressure side serpentine cooling channels may receive cooling fluids from a cooling fluid supply source through a cooling fluid inlet, pass the cooling fluids through the cooling system and exhaust the cooling fluids through a cooling fluid exhaust orifice proximate to the tip section. The cooling system is particularly suitable for use with low cooling fluid flow.

Owner:SIEMENS ENERGY INC

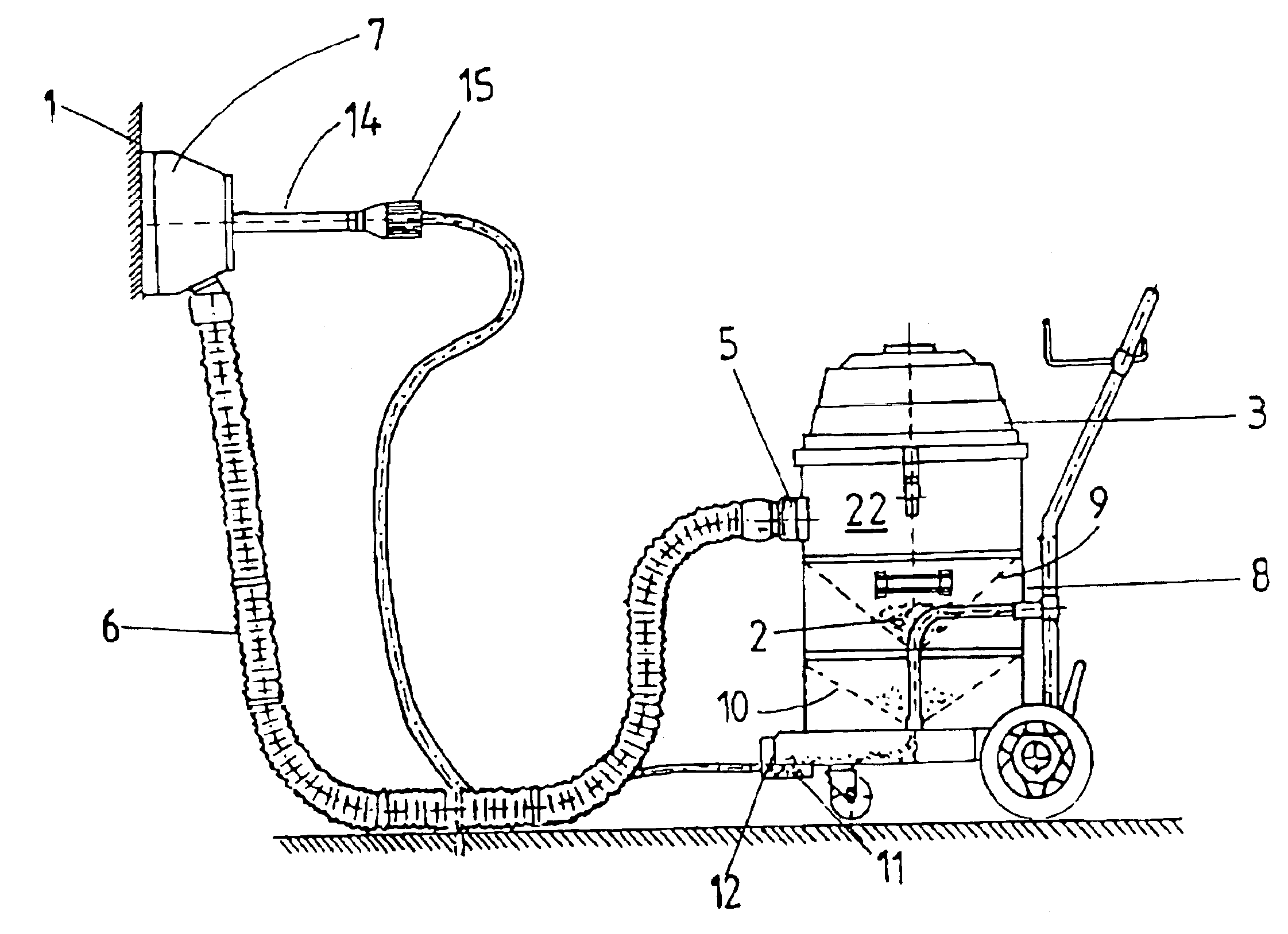

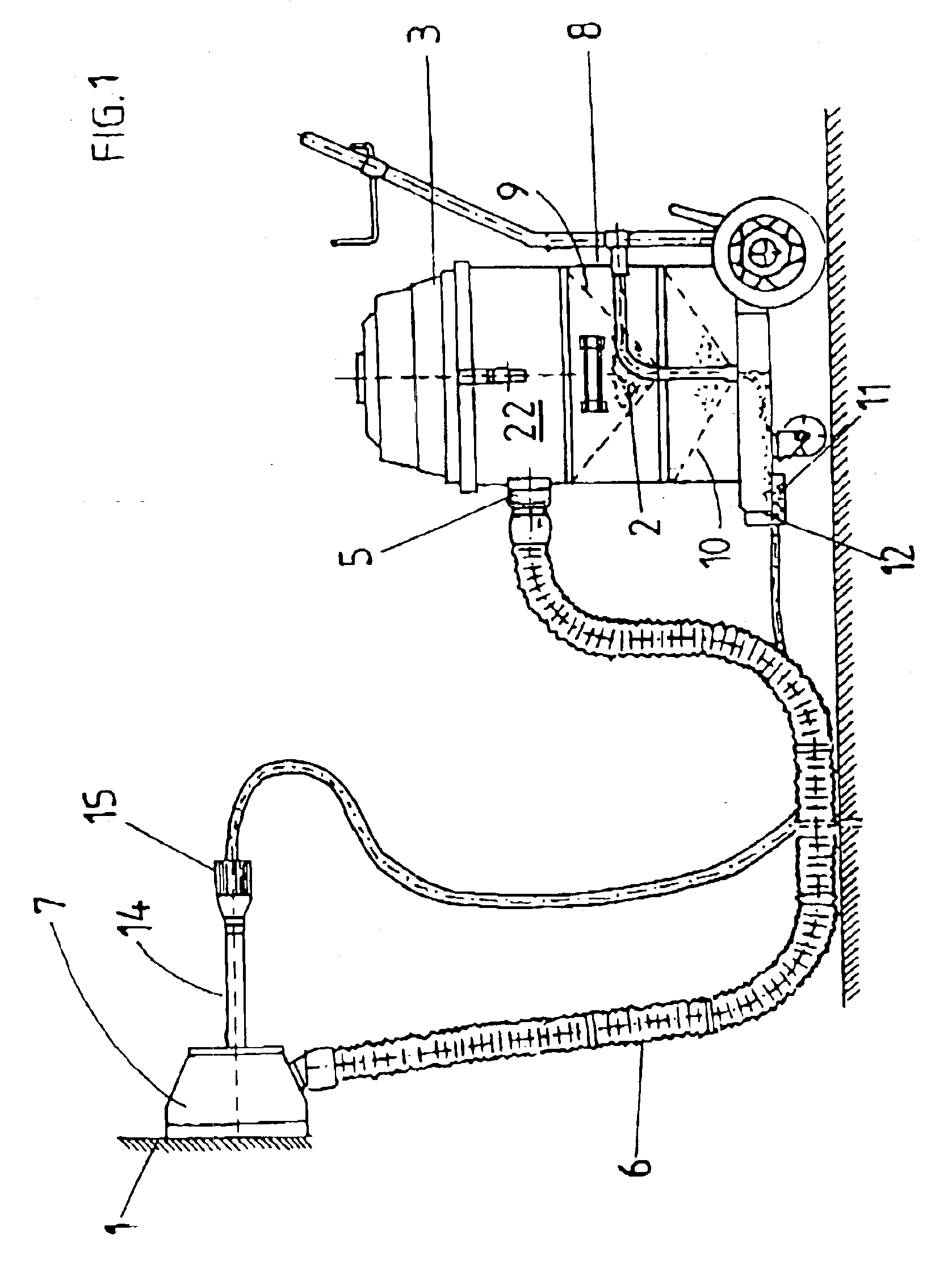

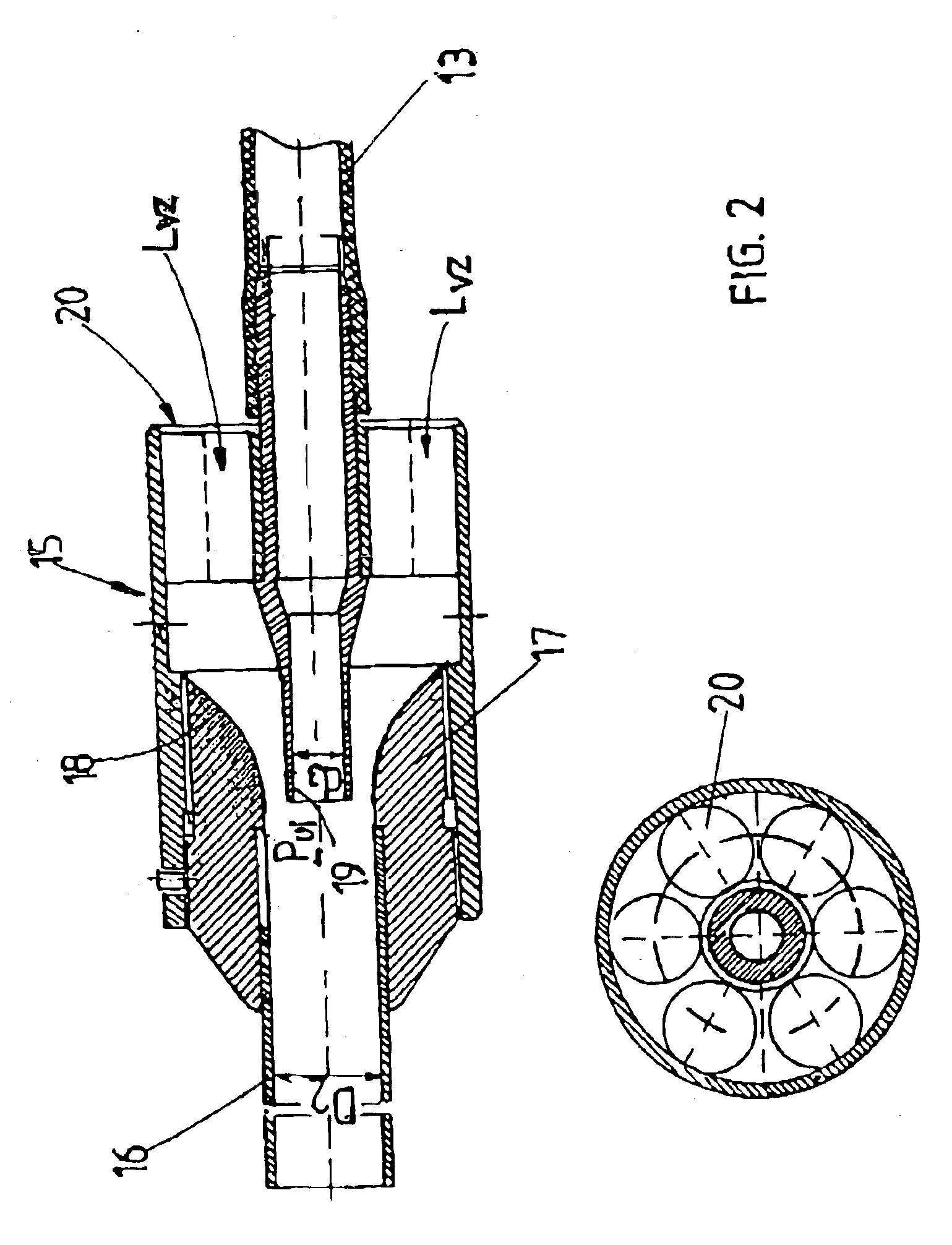

Method and device for sandblasting, especially removing in a precise manner and/or compacting and/or coating solid surfaces

The invention relates to a method and device for sandblasting, especially removing in a precise manner and / or compacting and / or coating solid surfaces, such as removing defective spots of paint from coats of lacquer, smoothing out soldered and welded joints, removal of contaminated concrete coatings or rust coatings, hardening, planing or coating metal surfaces, wherein a sandblasting agent is added by means of gravity and / or due to the effect of an injector to a carrier air flow produced by an underpressure, conveyed in a flexible hose- line system (13) to a jet lance (14) before being guided via a processing surface subject to low pressure by a sandblasting chamber, whereupon it is returned in the air flow, purified and returned to the circuit, whereby acceleration of the sandblasting agent is produced by the low pressure and the sandblasting chamber is displaced from one processing surface to another. The aim of the invention is to increase the sandblasting speed in a significant manner while at the same time economically adjusting the amount of power furnished to the processing surface for various wide-ranging fields of application using as little power as possible yet providing high flexibility and ecologically compatible recovery and reutilization of the sandblasting means. In order to achieve this, the sandblasting agent receives at least one additional energy pulse from a gas flow which is placed at least under atmospheric pressure and suctioned by the low pressure in order to reach a final speed which is significantly greater than the speed of the carrier air flow downstream from the area where dosing occurs. The final speed makes it possible to adjust the amount of power applied to the surface to be processed according to the following parameters: type and forms of the surface to be processed and the sandblasting agent, degree in which the carrier air flow is charged with the sandblasting agent, low pressure in the carrier air flow, and time and temperature of sandblasting.

Owner:PIEPER INNOVATIONSGMBH

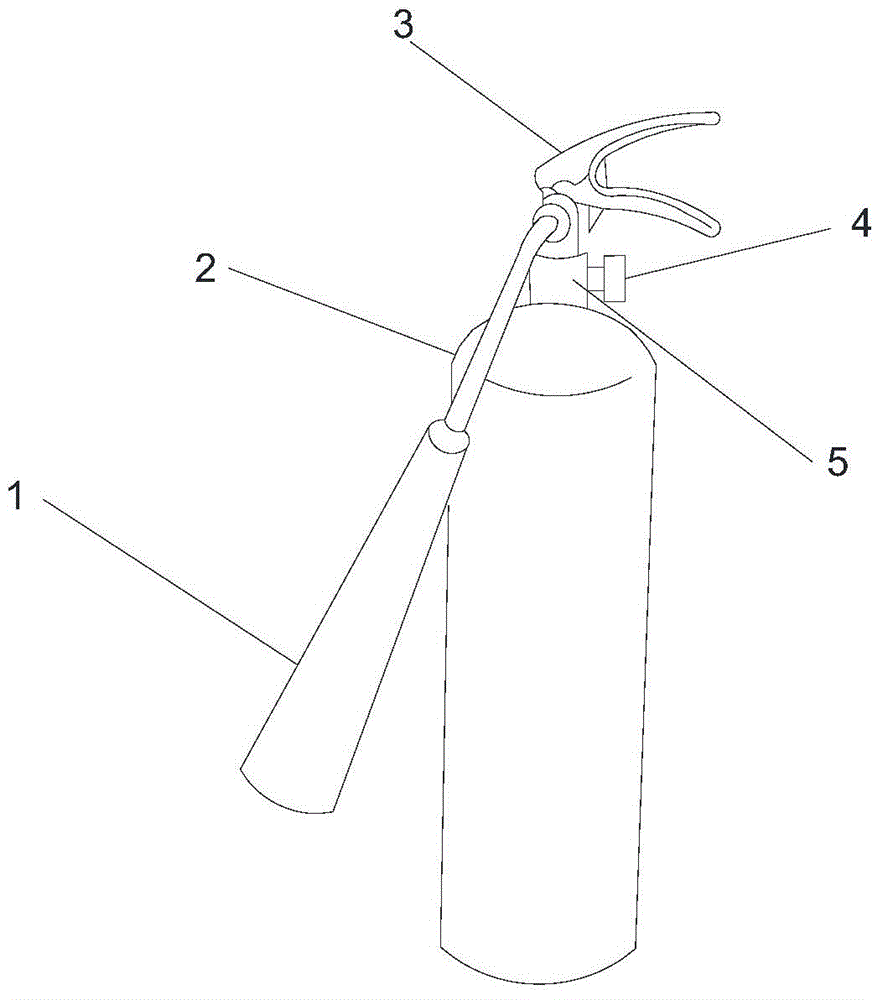

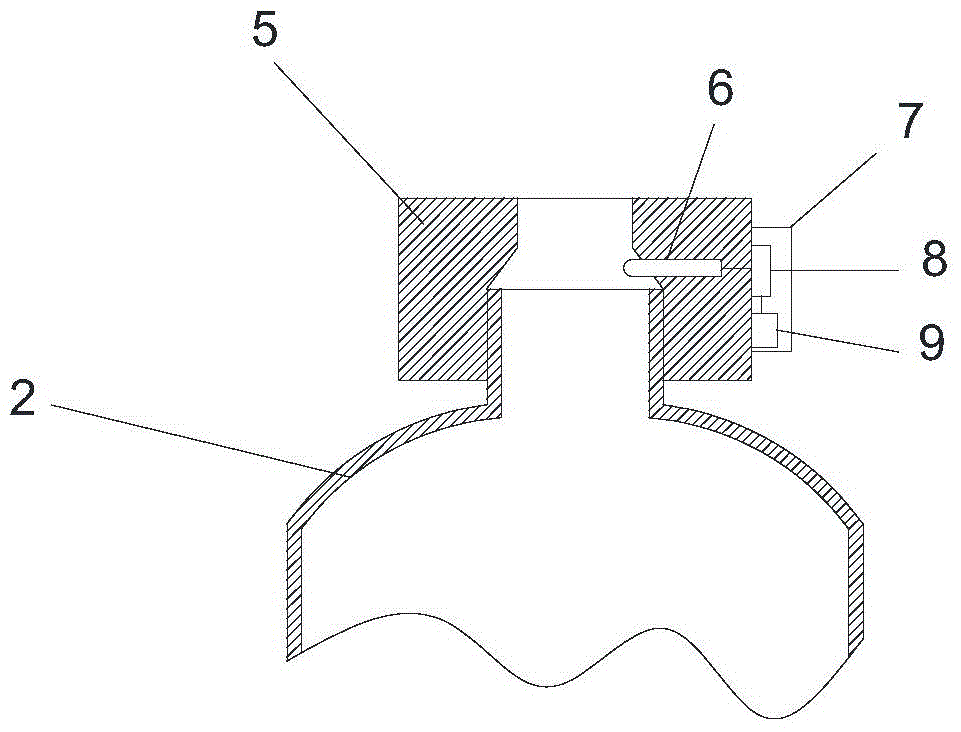

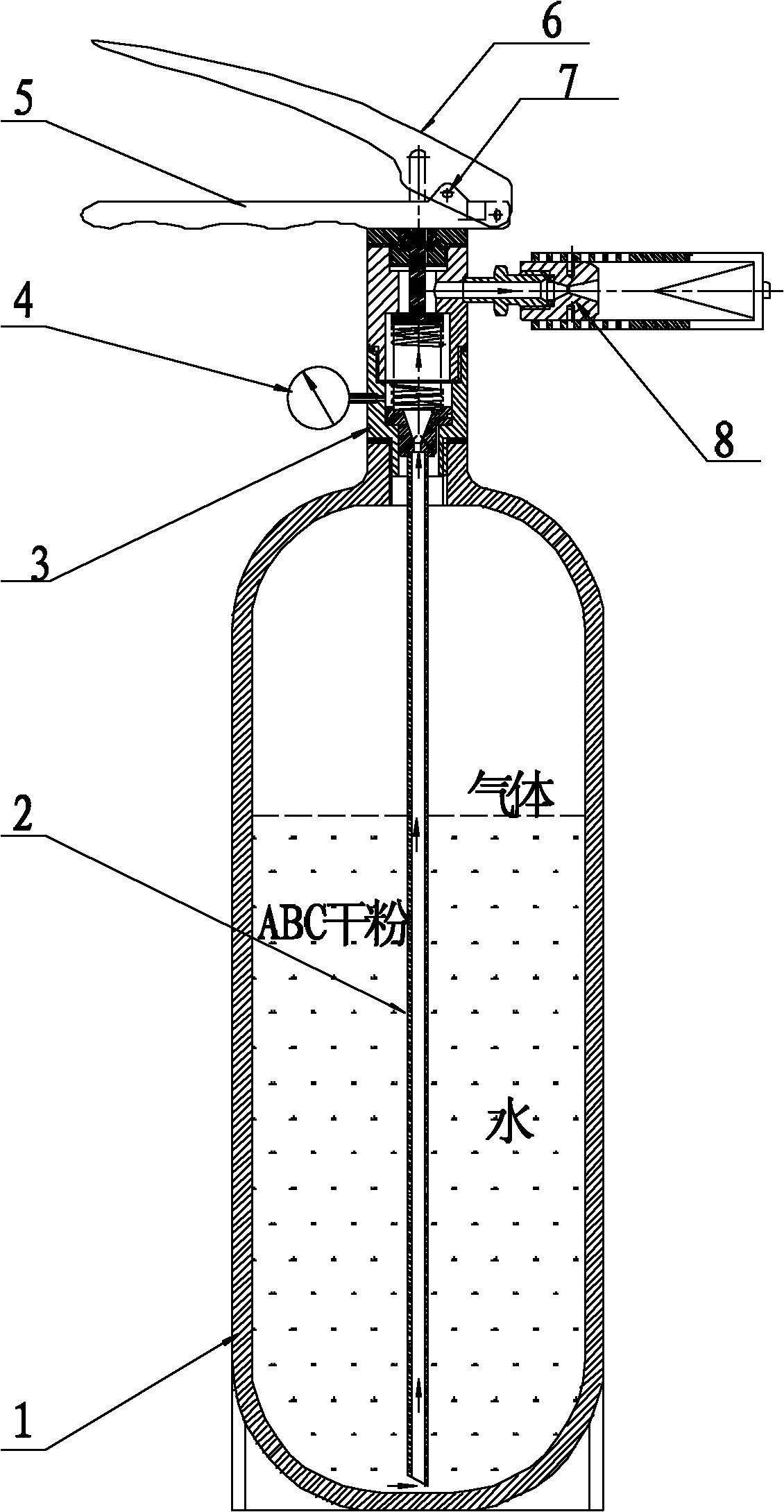

Remote pressure-detection fire extinguisher

The invention belongs to the field of fire extinguishers, and particularly relates to a vehicular remote pressure-detection fire extinguisher. The vehicular remote pressure-detection fire extinguisher comprises an adapter, wherein the adapter is arranged on a fire extinguisher bottle body and is provided with a switch device which controls the fire extinguisher; the switch device is connected with a spraying tube through a guide tube; the adapter is in threaded connection to the fire extinguisher bottle body and is provided with a pressure-detection system capable of detecting the pressure of the fire extinguisher bottle body; the pressure-detection system comprises a pressure sensor and a data processor; the pressure sensor is arranged on the adapter, is used for detecting the pressure of the fire extinguisher bottle body and is connected with the data processor; and the data processor is connected with a wireless transmitting module. The pressure of the fire extinguisher can be detected, the value of the pressure is transmitted to a vehicle through wireless signals, problems existing in the fire extinguisher in the vehicle can be found out in time, and the problem that the fire extinguisher cannot be used when needed is solved.

Owner:CHANGZHOU BOZHIYUAN INTELLIGENT EQUIP

Gas turbine combustor with active fuel distribution control function

InactiveCN106091009AIncrease the degree of premixingEmission reductionContinuous combustion chamberCombustion chamberCombustor

Disclosed is a gas turbine combustor with an active fuel distribution control function. The gas turbine combustor comprises an end cover, a fixing plate and a fuel distribution control unit. The fuel distribution control unit comprises a motor, a transmission mechanism and a rotating plate. The end cover is fixedly connected with the fixing plate, and an internal cavity is formed between the end cover and the fixing plate. The fixing plate is provided with K positioning holes located at a first circumference, and a main fuel tube is arranged in each positioning hole. The motor is arranged outside the end cover. The rotating plate is arranged in the internal cavity. The motor is connected with the rotating plate through the transmission mechanism. The rotating plate is provided with m groups of allocation holes located at a second circumference. The numbers Qi of the allocation holes in the groups are different, and Qi is smaller than or equal to K. The motor drives the rotating plate to rotate so that the i group of allocating holes can be aligned with the Qi main fuel tube, and accordingly Qi main fuel channels are formed. According to the gas turbine combustor, different numbers of main fuel channels are formed on different load conditions, so that the combustion stability of the combustor is guaranteed and the pollution emission amount is lowered.

Owner:HARBIN INST OF TECH

Spark discharge self-excitation jet plasma generating device

The invention discloses a spark discharge self-excitation jet plasma generating device which comprises at least one miniature discharge chamber. The discharge chamber is provided with one jet hole. The spark discharge self-excitation jet plasma generating device is characterized in that: the spark discharge self-excitation jet plasma generating device generates charged particles through applying a pulse high voltage and creating spark discharge in the miniature discharge chamber; and furthermore under the function of the air pressure which instantly increase in the discharge chamber, plasma is jet from a jet hole of the discharge chamber. According to the spark discharge self-excitation jet plasma generating device, the spark discharge manner is adopted. On condition that no outer blowing air exists, the plasma which is jet in high speed is generated under the function of the air pressure which increases instantly. The spark discharge self-excitation jet plasma generating device has high jet speed and high activity of the plasma and can be used for common-pressure and high-pressure environments because of adoption of the spark discharge manner, relatively high applied pulse voltage and relatively high obtained initial energy of the plasma.

Owner:XI AN JIAOTONG UNIV +3

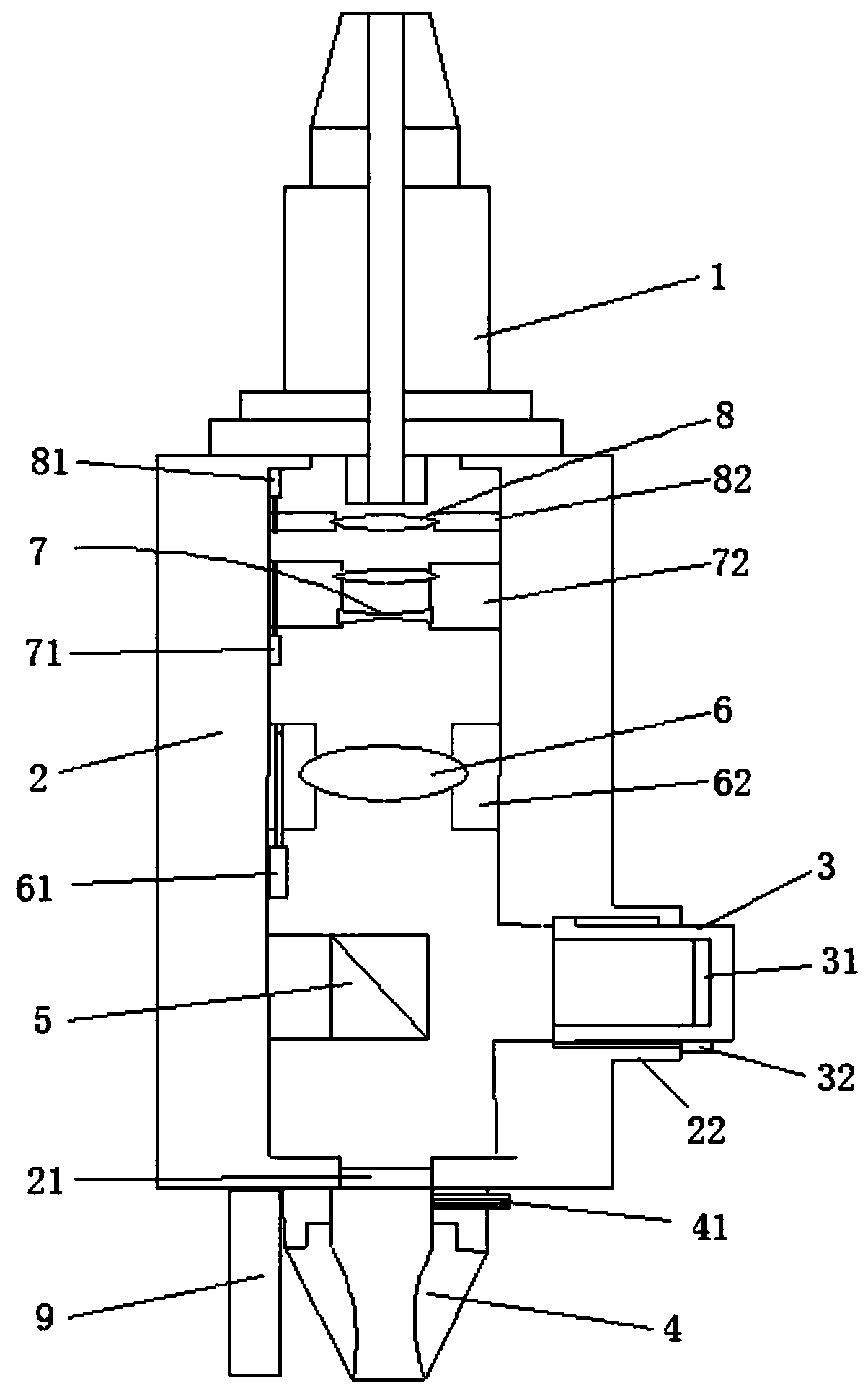

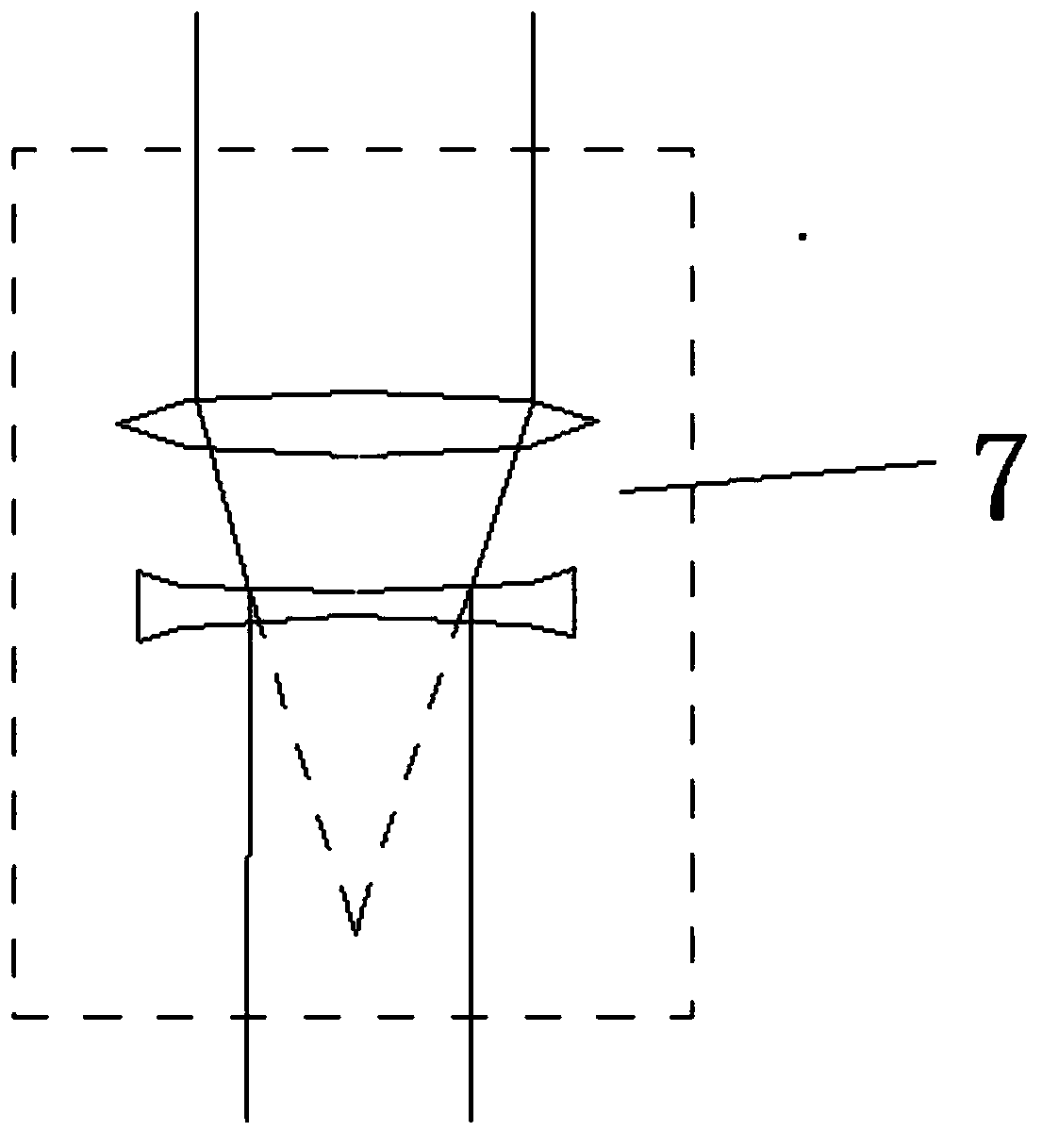

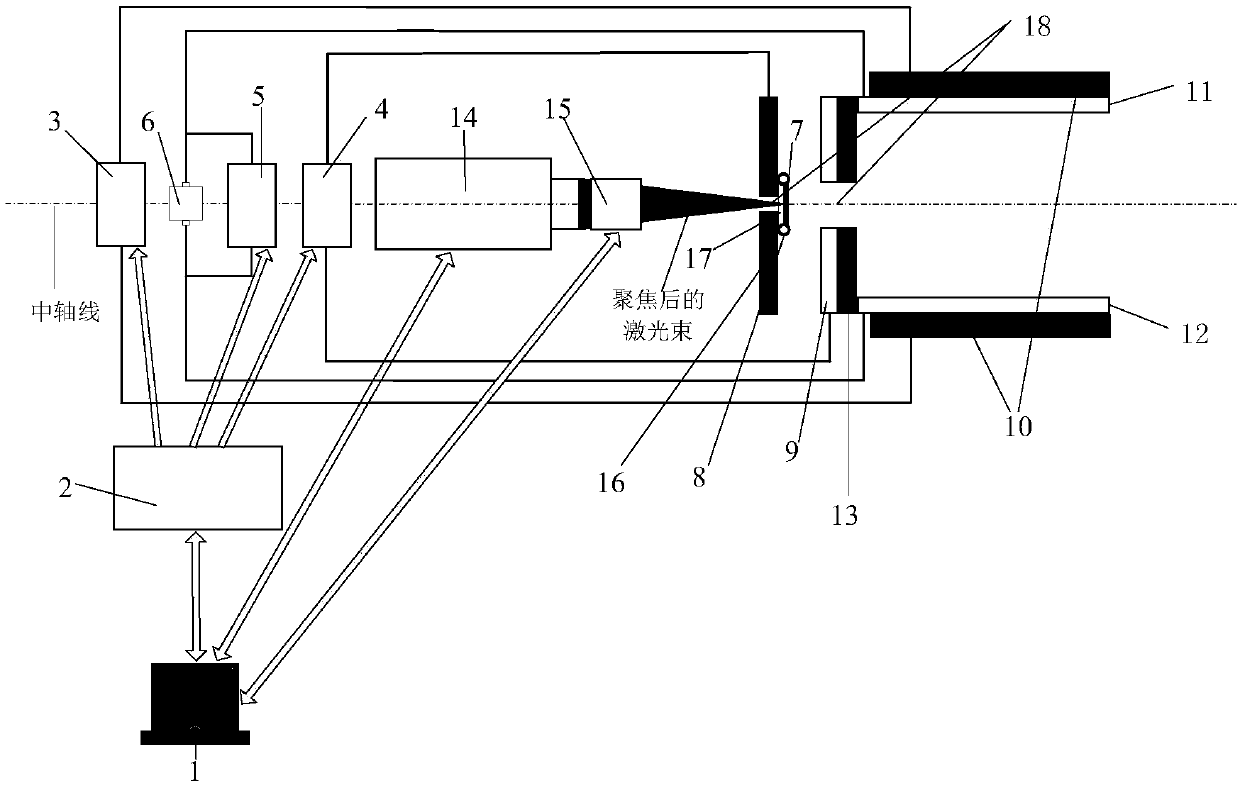

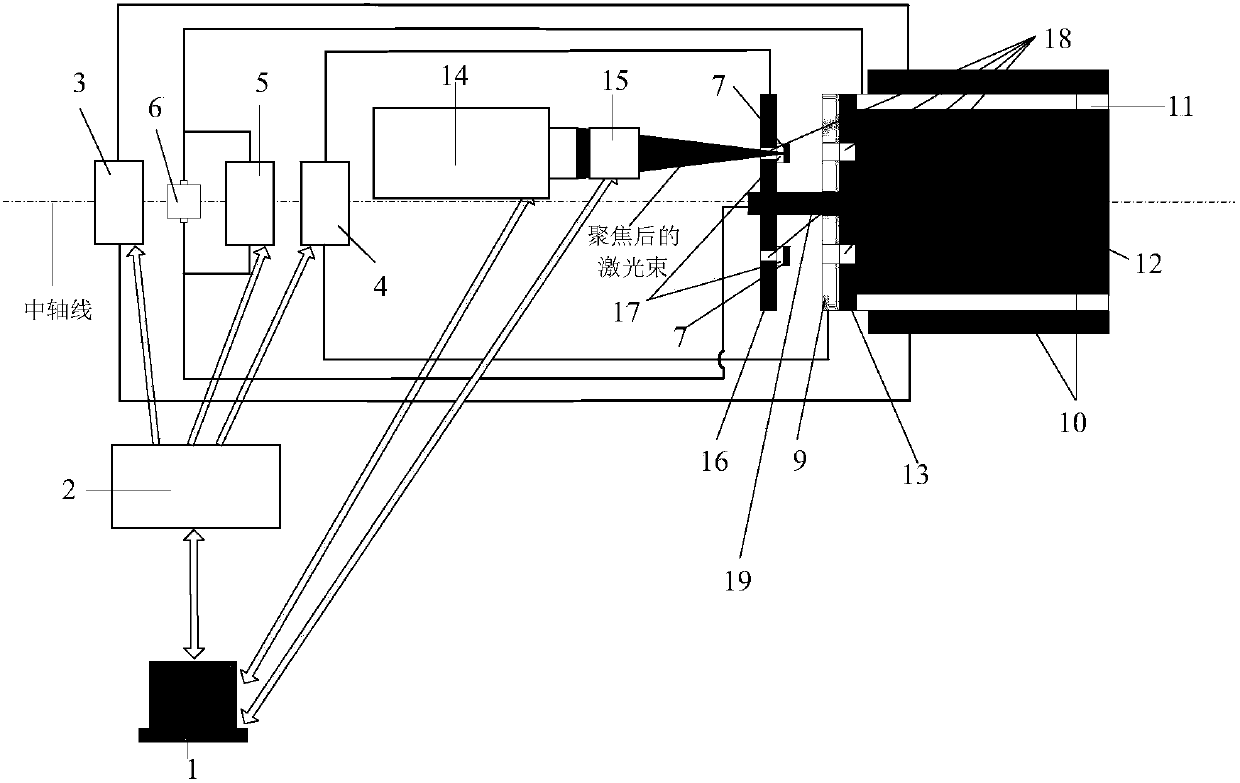

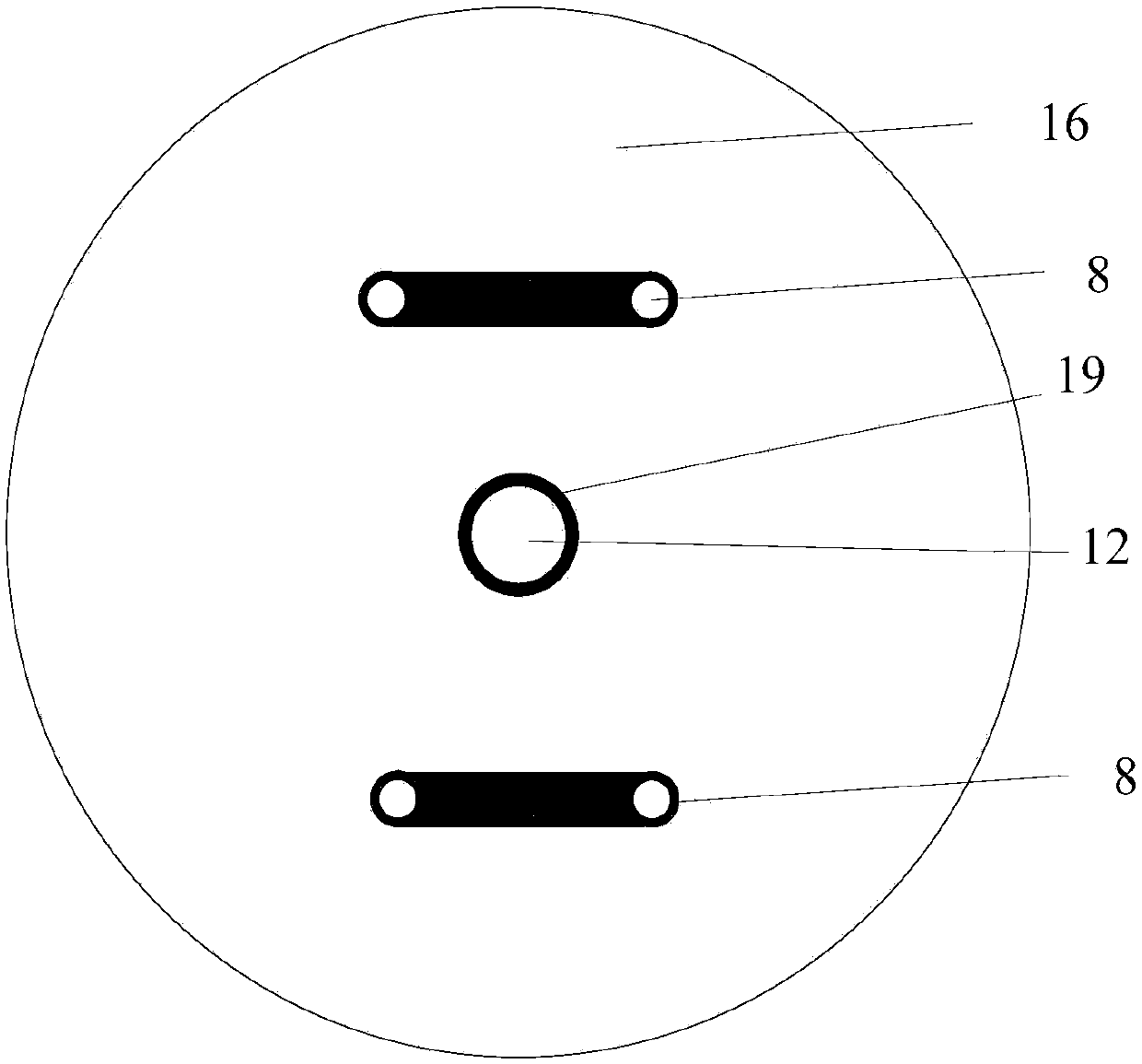

Focusing device and focusing method of laser cutting machine

ActiveCN111168230AAccurately determineHigh precisionLaser beam welding apparatusBeam splitterLight sensing

The invention provides a focusing device of a laser cutting machine. The focusing device comprises an optical fiber joint, a shell, a sleeve, a sliding barrel, a light sensing mechanism, a linear motor, a protective mirror, a nozzle, a distance measuring mechanism, a beam splitter prism and a lens set. The optical fiber joint is arranged at one end of the shell. The sleeve is arranged on the sidewall of the shell and is provided with the sliding barrel in a sliding manner. The linear motor drives the sliding barrel to move. The light sensing mechanism is arranged in the sliding barrel. The beam splitter prism and the lens set are arranged in the shell. The protective mirror and the nozzle are arranged at the other end of the shell. According to the focusing device of the laser cutting machine, through multiple times of quantitative moving of the sliding barrel, the focal position is measured precisely, the focal position and the preset focal position are compared to form feedback, andtherefore focusing is achieved more precisely; and after precise focusing, the distance measuring mechanism is used for cooperating with a controller to adjust the laser cutting machine, it is guaranteed that the focal point is located on the surface of a workpiece, and the workpiece cutting effect is guaranteed.

Owner:JINAN BODOR LASER CO LTD

Active energy ray-curable inkjet ink composition

InactiveUS20130139722A1High-frequency suitabilityLow viscosityDuplicating/marking methodsInksLake pigmentSingle pass

Specifically provided is a single pass-curable ink having high color reproducibility and high curing properties at the same time and having high dischargeability when used in printing at high frequency and high jetting speed, as compared with conventional ones. An active energy ray-curable inkjet ink composition contains a metal lake pigment of a rhodamine dye as a pigment, and the active energy ray-curable inkjet ink composition may contain 0.5 to 10% by weight of Pigment Violet 1, Pigment Violet 1:1, Pigment Violet 2, Pigment Violet 2:2, Pigment Red 81, Pigment Red 81:1, Pigment Red 81:2, Pigment Red 81:3, Pigment Red 81:4, Pigment Red 81:5, Pigment Red 169, or Pigment Red 173 as the metal lake pigment of the rhodamine dye based on the total weight of the ink.

Owner:TOYO INK SC HOLD CO LTD +1

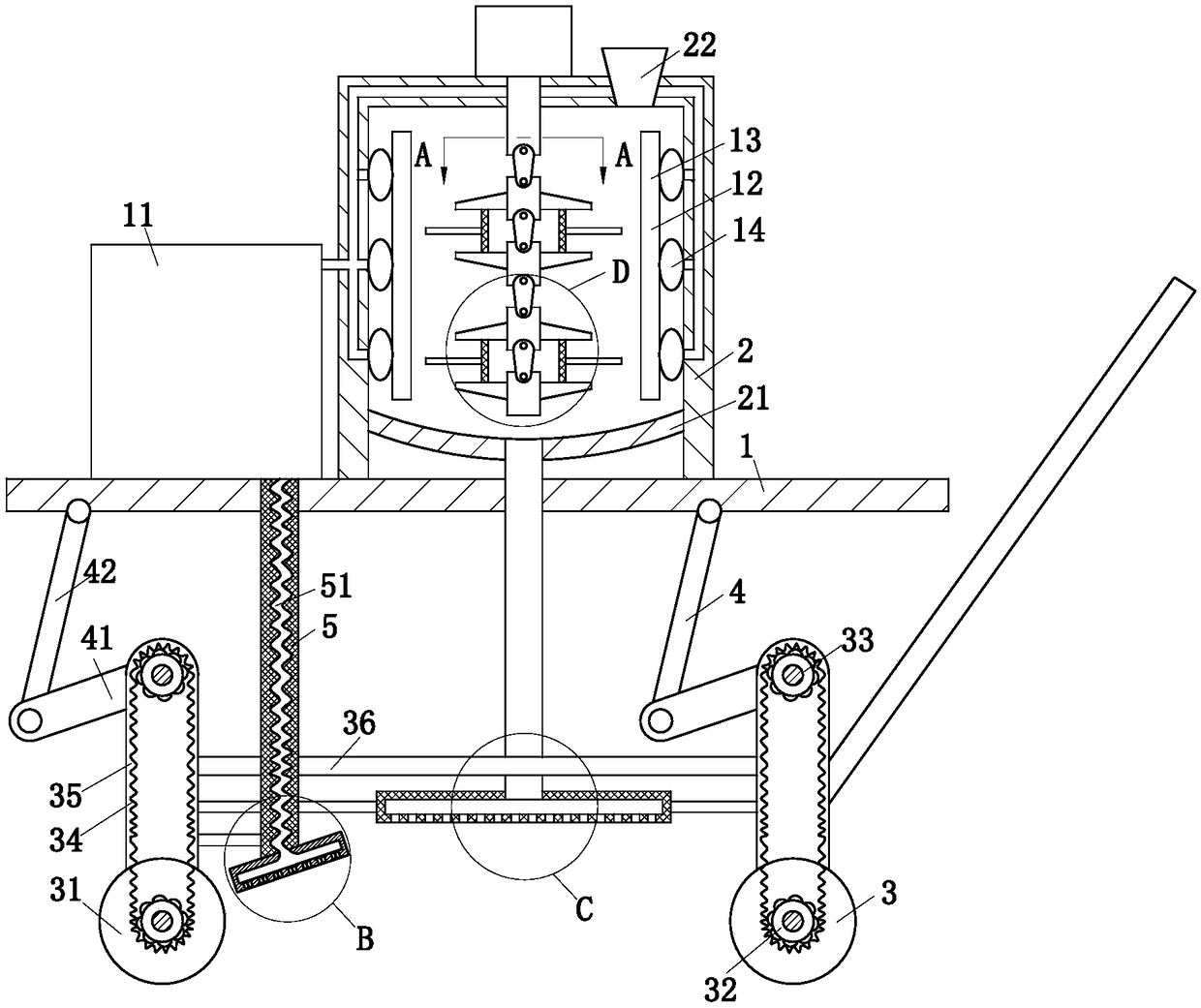

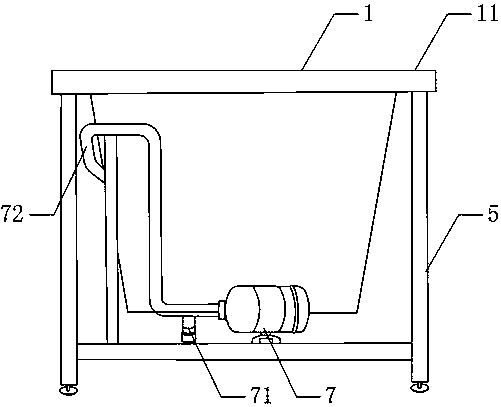

Acidified soil improvement system

ActiveCN109013696AImprove abilityStir wellContaminated soil reclamationSoil-working methodsSlagEngineering

The invention relates to the technical field of agricultural equipment, in particular to an acidified soil improvement system. The acidified soil improvement system comprises a fixing plate, a water tank and a stirring box, and further comprises a movement unit, a lifting unit, an elastic tube, a shower nozzle, a rigid tube, an agent dispersing device and a pushing handle. By arranging the movement unit, the lifting unit, the elastic tube, the shower nozzle, the rigid tube, the agent dispersing device, a stirring unit and the pushing handle, on one hand, through the mutual cooperation of a stirring shaft, a hinge block and a stirring plate, under drive of a motor, the stirring plate conducts sufficient stirring on alkaline powder materials such as pulverized fuel ash, alkali slag, phosphogypsum and papermaking waste residues which are input from a feed port, all component matters are sufficiently mixed, and therefore the improvement effect of acidified soil is improved; and on the other hand, through mutual cooperation of the pushing handle, the movement unit and the lifting unit, under the effect of the movement unit, the lifting unit is controlled to move up and down, increasingof an additional power source is avoided, and the utilization rate of resources is improved.

Owner:杭州市临安区农林技术推广中心 +1

Ammonia torch burner

InactiveCN103807857AIncrease contact timeIncrease exposureGaseous fuel burnerCombustion chamberCombustor

The invention relates to an ammonia torch burner which comprises a gas inlet barrel, a pilot burner ignition assembly, a fuel gas conveying part, a premixer and a combustion chamber. The premixer comprises a mixing cavity and an expanded cavity which is formed at the upper end of the mixing cavity and is communicated with the mixing cavity; the mixing cavity is formed at the upper end of the gas inlet barrel and is communicated with the gas inlet barrel; the upper end face of the gas inlet barrel extends into the mixing cavity; the combustion chamber is formed at the upper end of the expanded cavity and is communicated with the expanded cavity; the fuel gas conveying part comprises a fuel gas conveying main pipe, a fuel gas ring-shaped pipe communicated with the fuel gas conveying main pipe, and a plurality of fuel gas output tubes which are peripherally distributed on the fuel gas ring-shaped pipe and are communicated with the fuel gas ring-shaped pipe; the fuel gas ring-shaped pipe sleeves the periphery of the gas inlet barrel; spray nozzles of the fuel gas output tubes are radially inclined towards the axis of the gas inlet barrel and axially extend upwards into the mixing cavity; the spray nozzles adopt a necking-down form. The ammonia torch burner can realize complete combustion of ammonia and avoid the environment problem caused by residual ammonia.

Owner:杜建吉

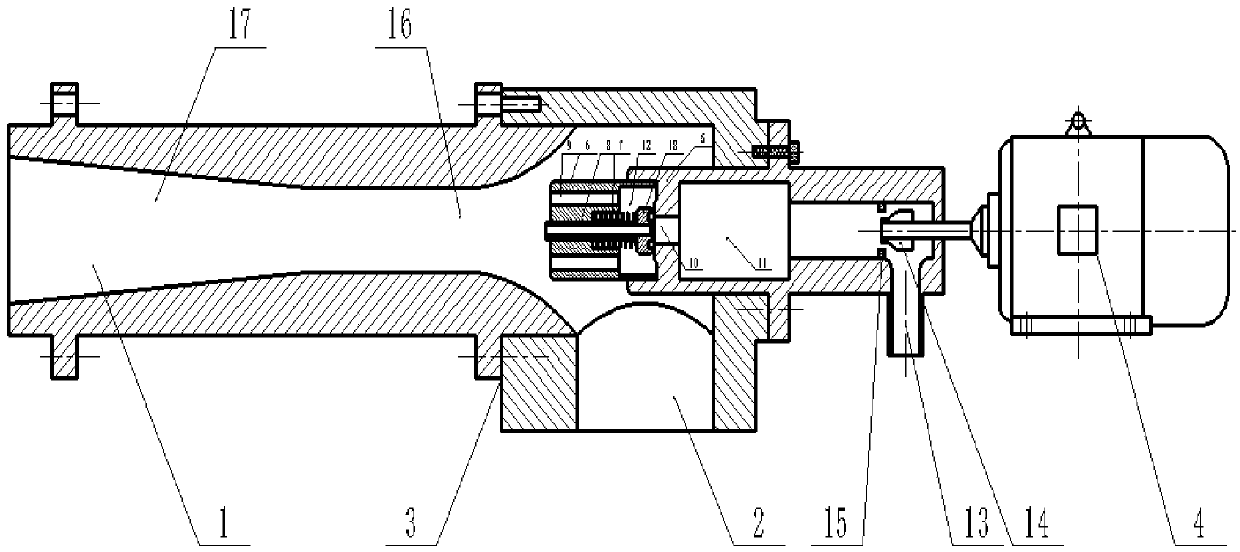

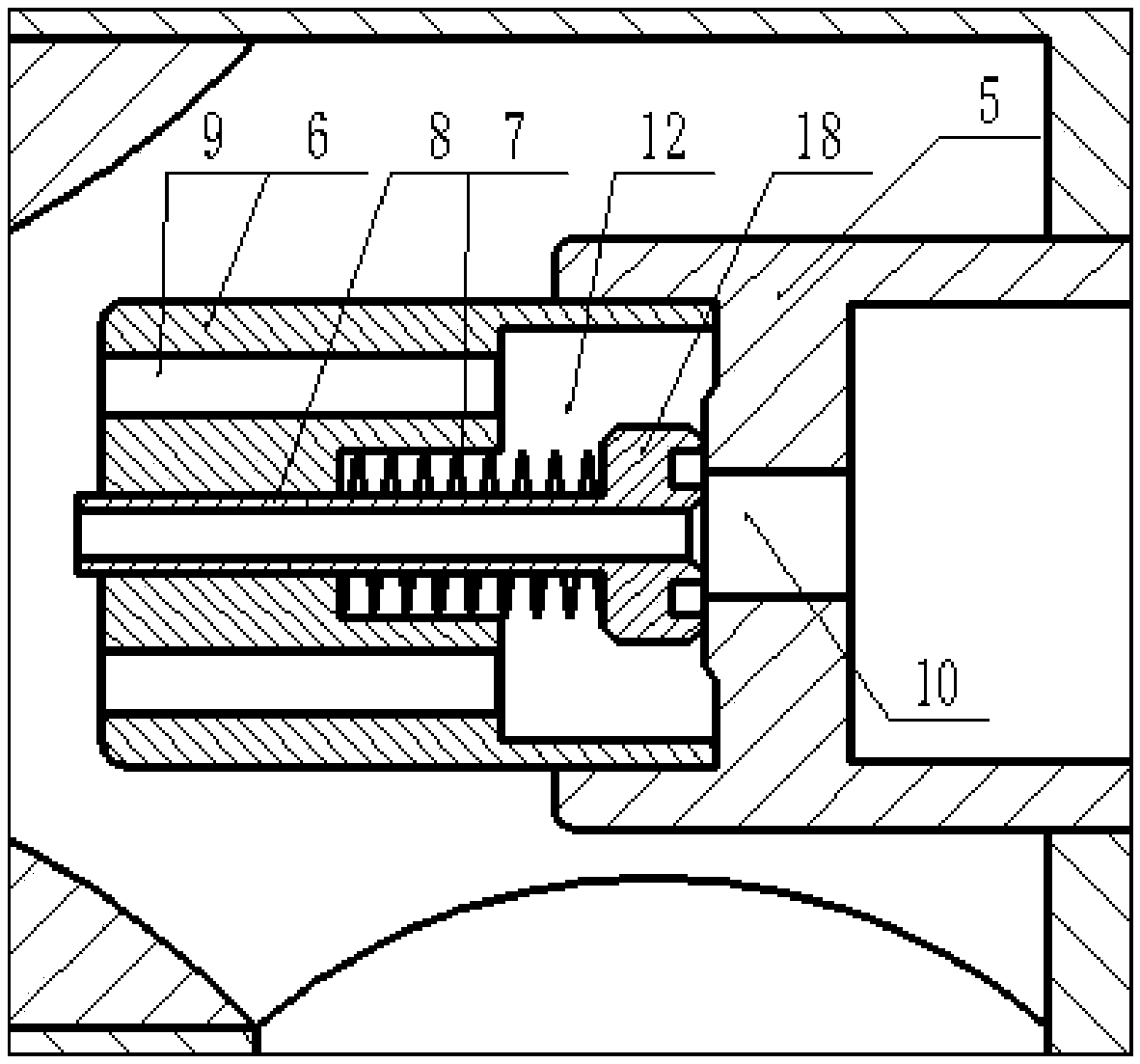

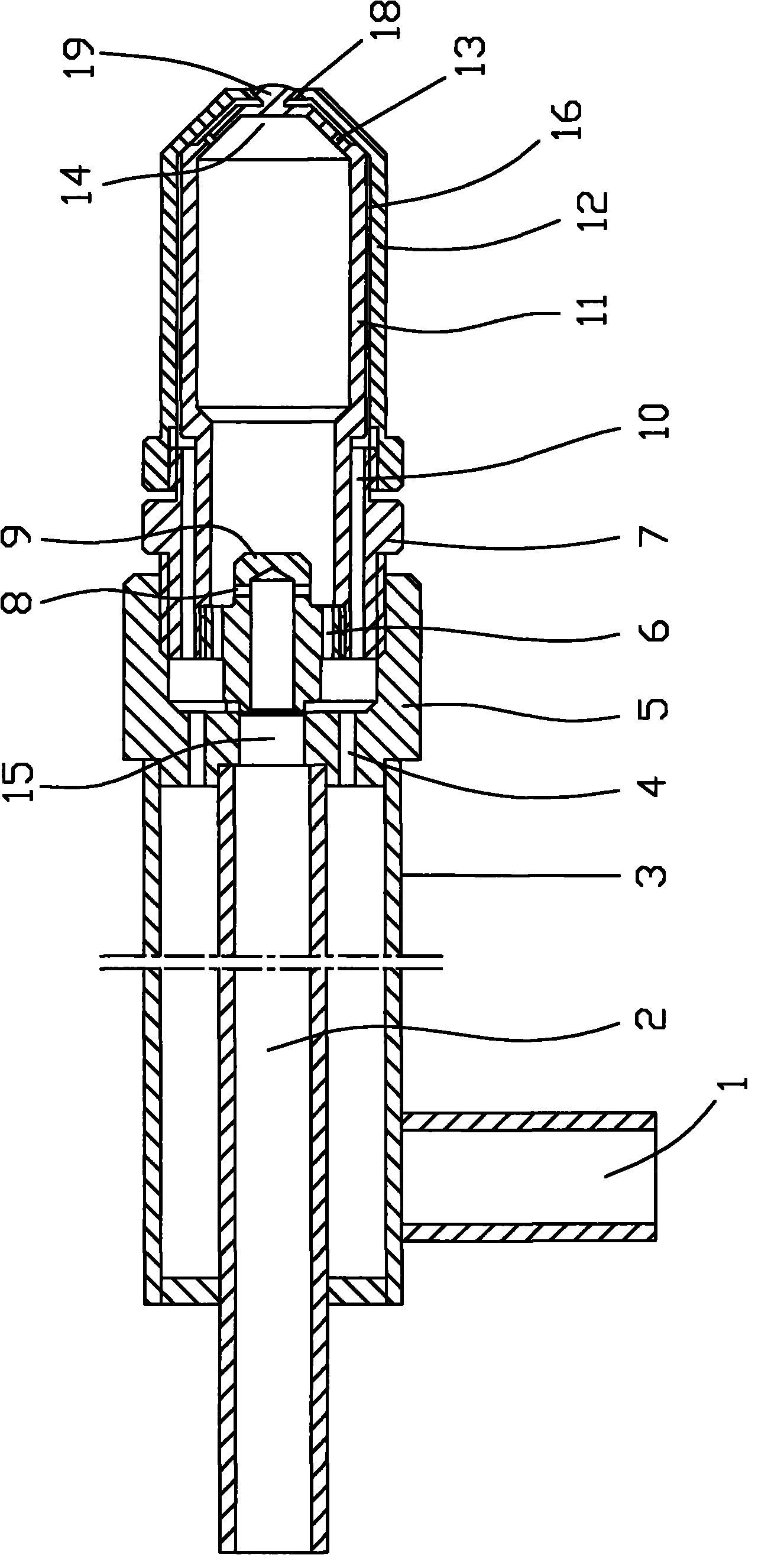

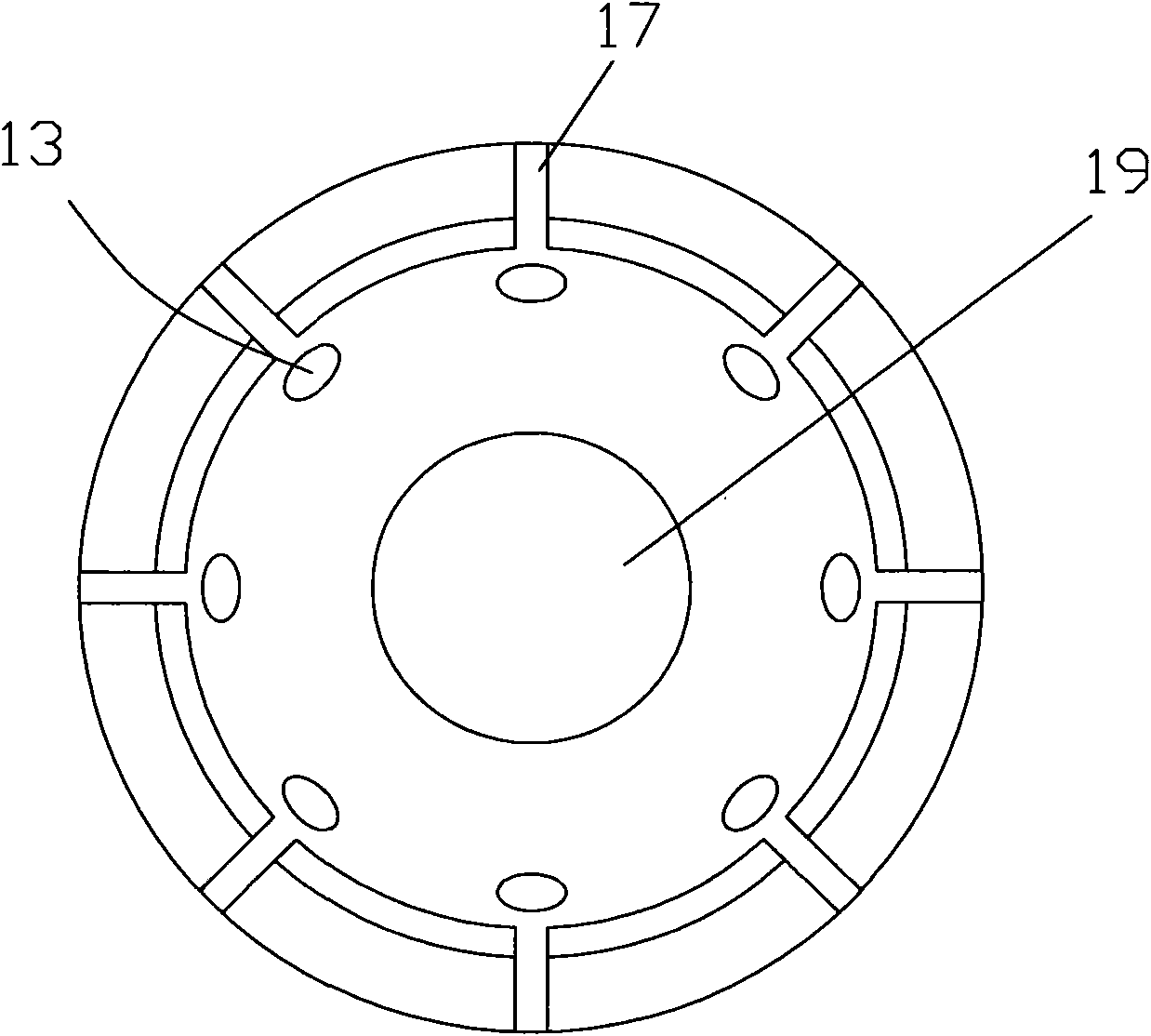

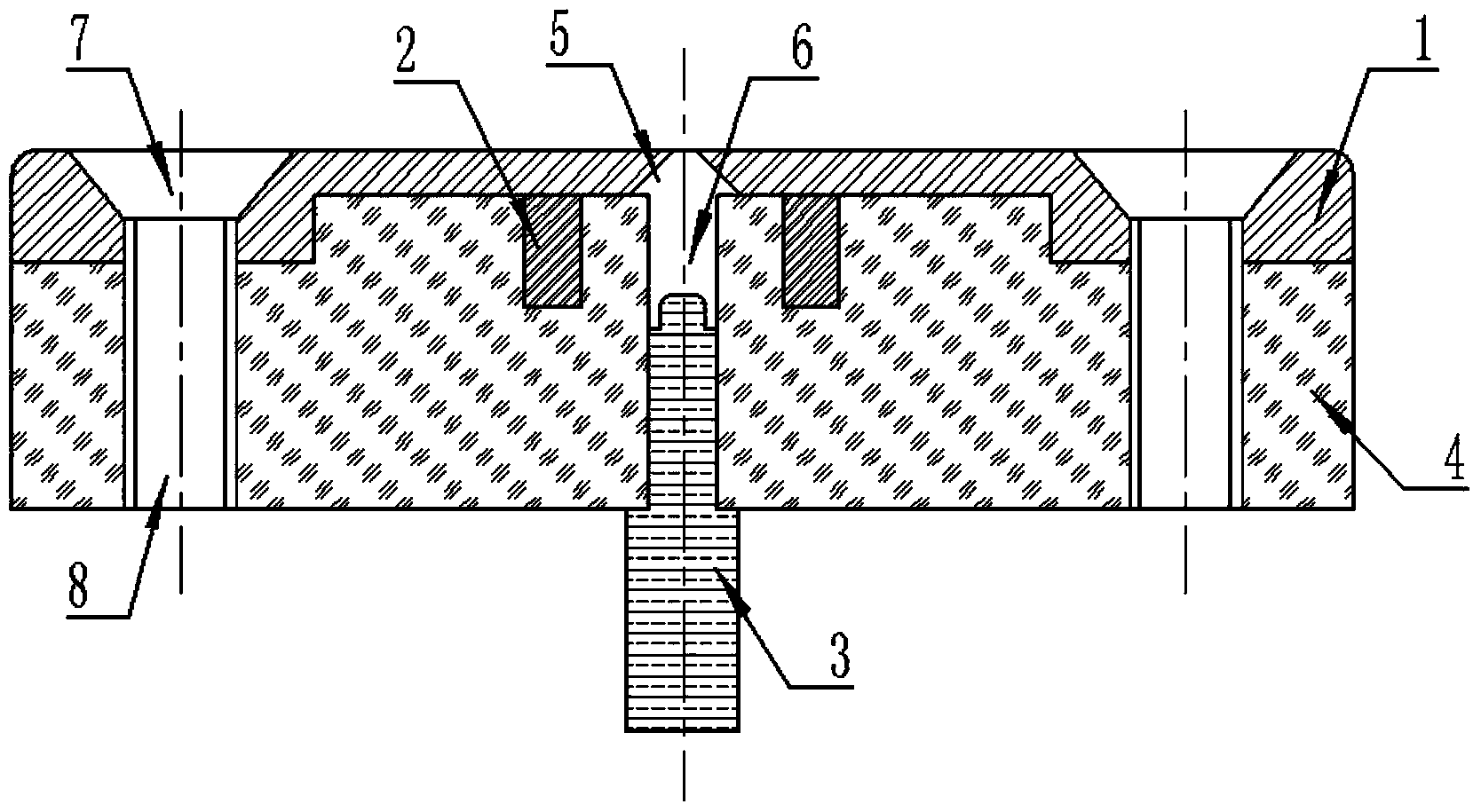

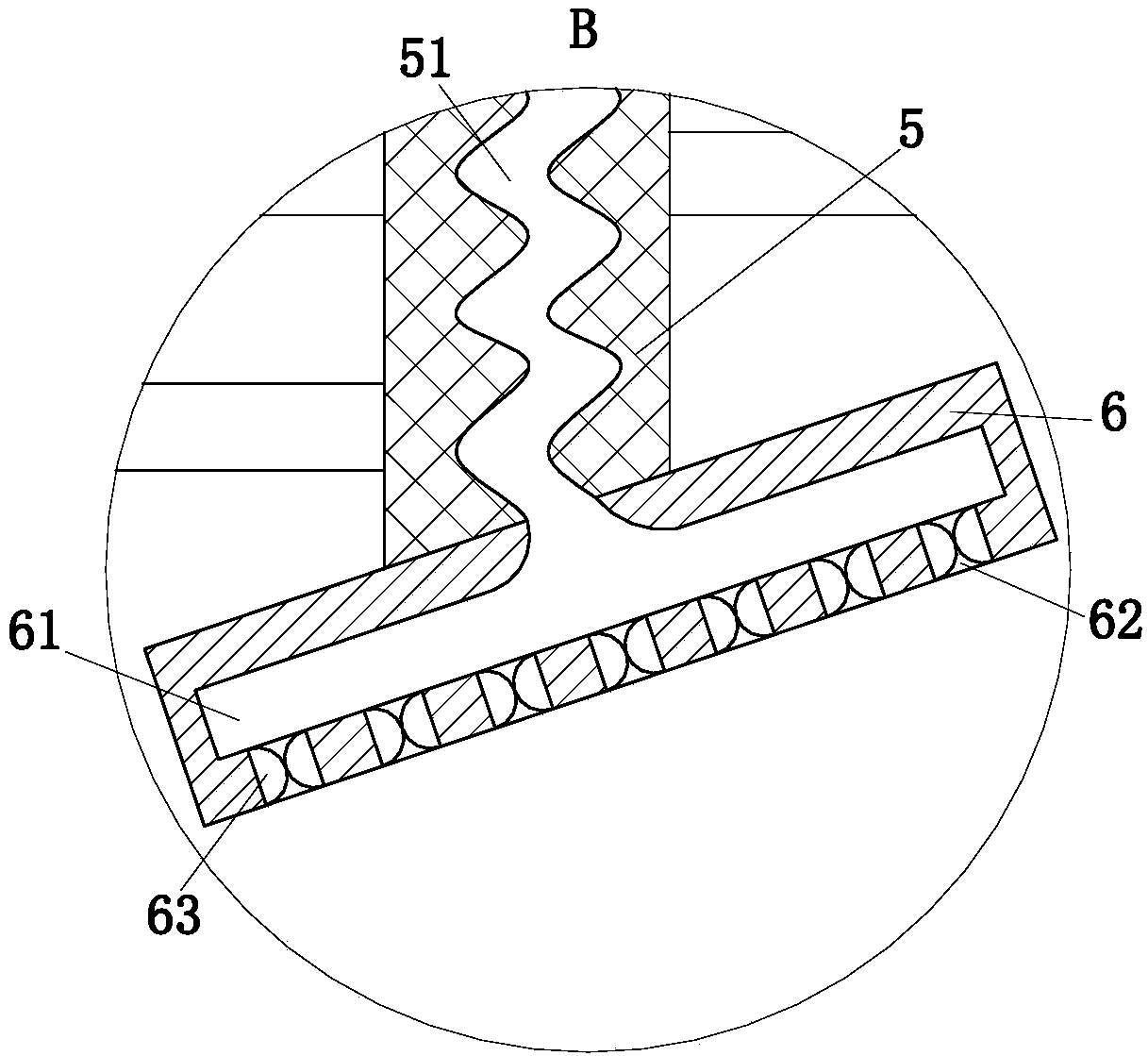

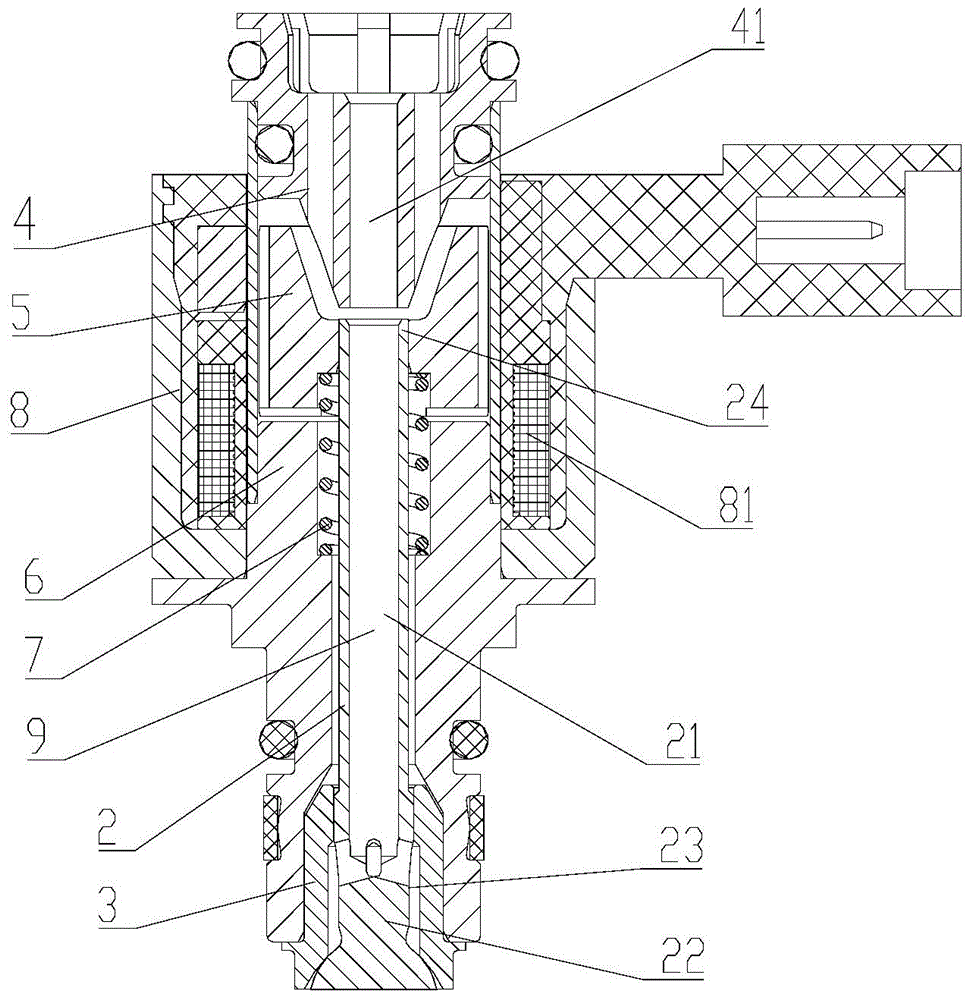

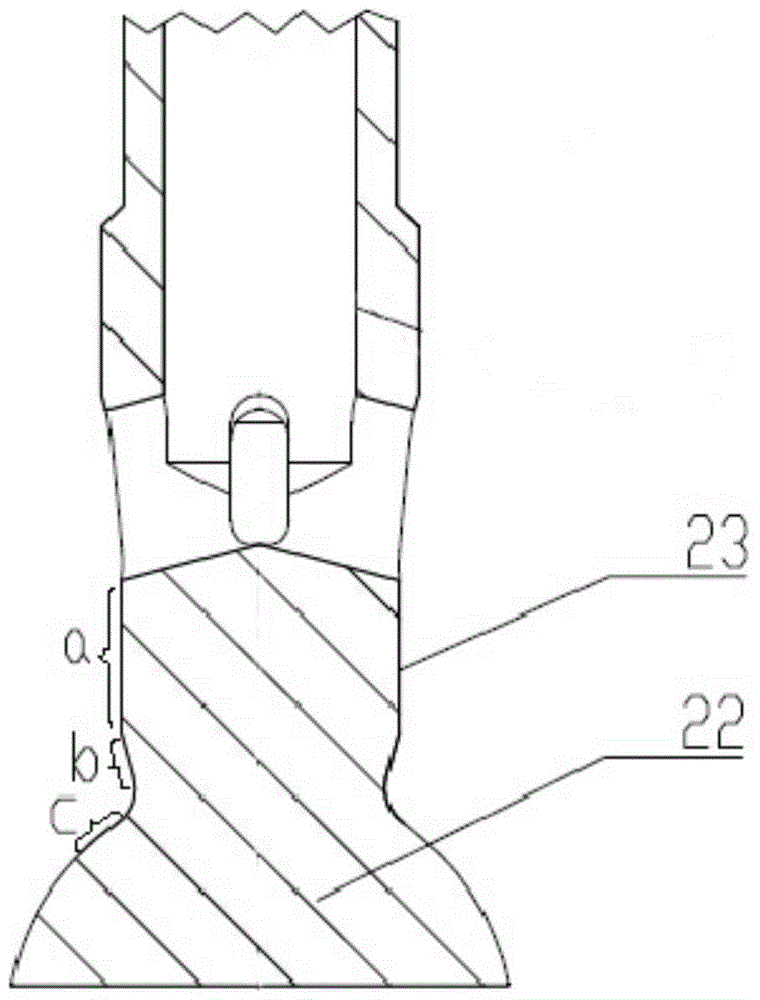

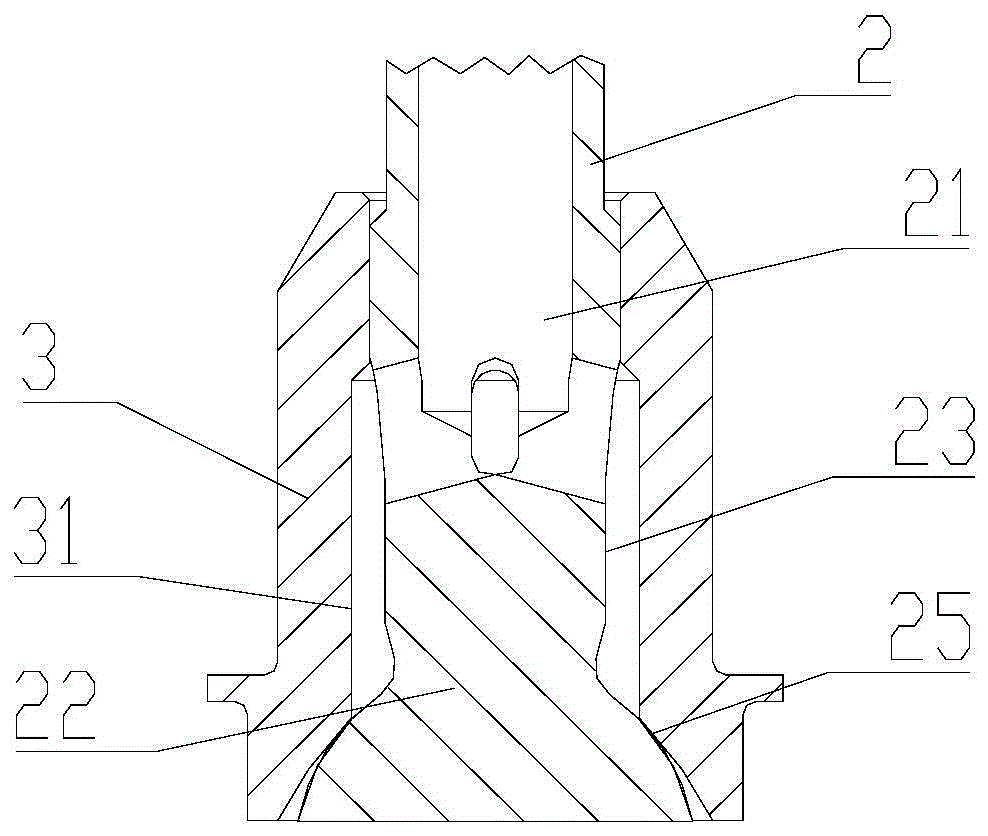

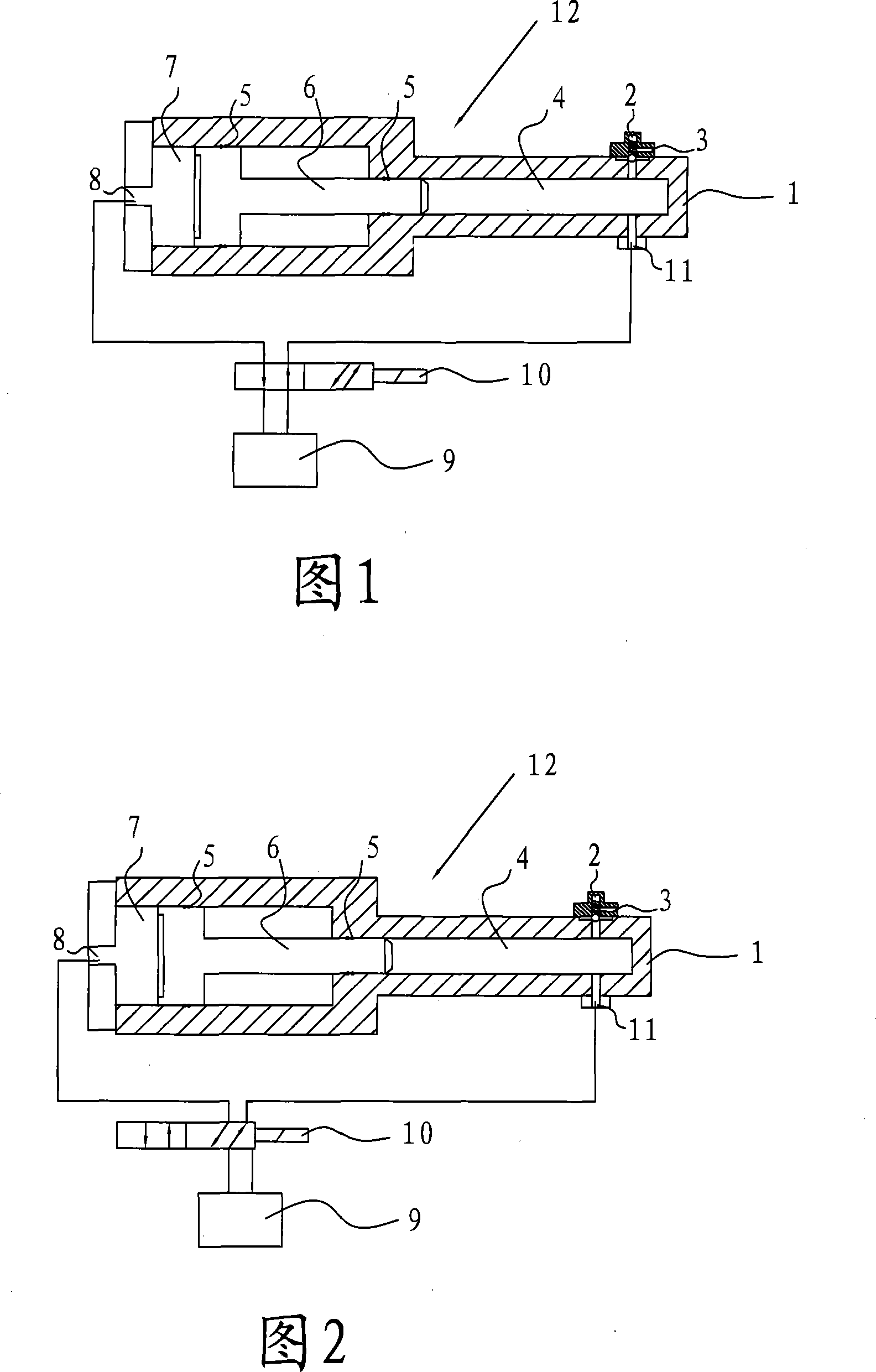

Fuel injector

ActiveCN104806400AIncrease jet speedImproved fuel atomization characteristicsFuel injection apparatusMachines/enginesEngineeringSupersonic speed

The invention discloses a fuel injector. The fuel injector comprises a needle valve and a valve seat, wherein the needle valve comprises a needle valve head and a needle valve tail; the needle valve tail is in a cavity structure; a cylindrical tube body forms between the surface of the needle valve head and the inner ring surface of the valve seat, and a gradually shrunk and expanded flow pipeline of the fuel injector forms in the cavity between the cylindrical tube body and the needle valve tail. According to the fuel injector, the fuel injection speed at the injection hole of the fuel injector can be improved, the fuel atomizing characteristics of the injection hole outlet are improved without increasing external conditions such as increasing of injection pressure or other parts, and the eddy current at the nozzle outlet can be further increased under the action of the aerodynamic force of the supersonic speed airflow to atomize towards the axis, so that the atomized particle size can be further detailed and the atomizing characteristics can be improved.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

Laser head of laser cutting machine

ActiveCN110936030ASmall diameterAchieve regulationLaser beam welding apparatusBeam splitterLight sensing

The invention provides a laser head of a laser cutting machine. The laser head comprises an optical fiber connector, a shell, a frame, a protective mirror, a nozzle, a linear motor, a sliding block, aphotometric cylinder, a beam splitter prism and a lens group; the optical fiber connector is cooperated with an optical fiber to connect the laser head with a laser generating device; a laser beam issplit by the beam splitter prism after passing through a zoom lens; most laser penetrates through the beam splitter prism, linearly penetrates through the protective mirror and is emitted out of thenozzle for laser cutting; a small amount of laser is reflected into the photometric cylinder through the beam splitter prism; a light sensing mechanism in the photometric cylinder senses the light irradiation position; and the beam splitter prism is connected with the nozzle; the positions of the transmitted laser and the reflected laser are synchronously changed along with change of the positionof the laser beam irradiated to the beam splitter prism, the movement of the frame is controlled according to the position information of the reflected laser, so that the position of the laser beam irradiated to the beam splitter prism is changed, and the transmitted laser can be always coaxial with the nozzle.

Owner:JINAN BODOR LASER CO LTD

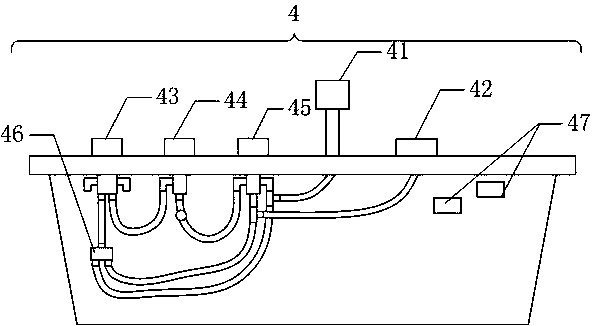

Multifunctional bathtub controlled by panel

The invention discloses a multifunctional bathtub controlled by a panel. The multifunctional bathtub comprises a bathtub body, a water pump pumping water from the bottom of the bathtub body, a frequency converter connected with the water pump, a water supply system supplying water for the bathtub, a support detachably installed at the bottom of a flange of the bathtub body, a magnet skirt installed on the support, an air pump installed on the support and delivering high-pressure air to a water pipe and the control panel installed on the flange of the skirt bathtub body, wherein the frequency converter, the air pump, the control panel and the water supply system are electrically connected with the controller, the bathtub can adjust water flowing direction, water level, water temperature, water pressure and other parameters through the control panel or manually according to the demand of a user, intelligence is achieved, and the multifunctional bathtub is convenient to package and transport, easy to install and good in massaging effect.

Owner:佛山市锦泽致盛智能科技有限公司

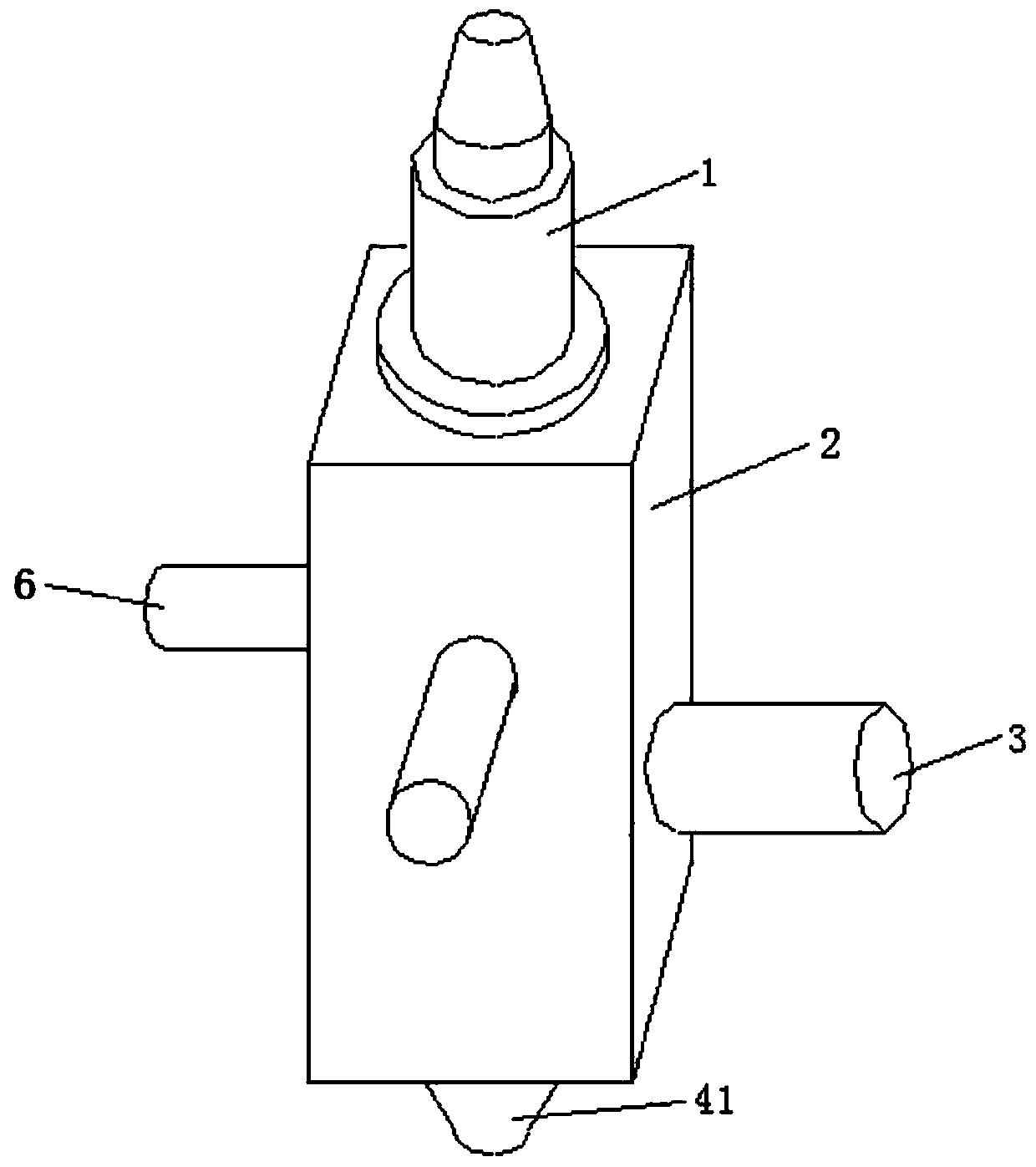

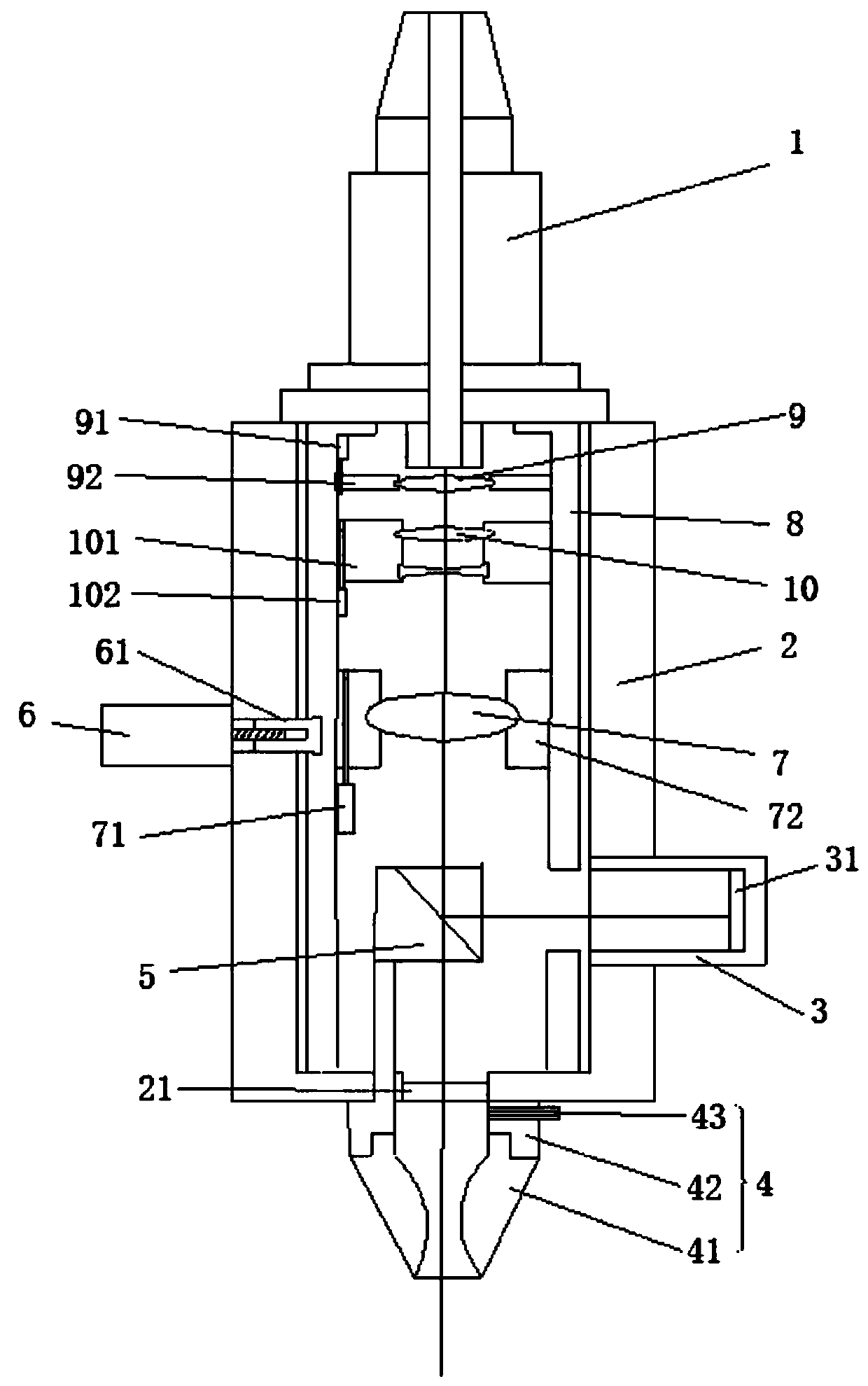

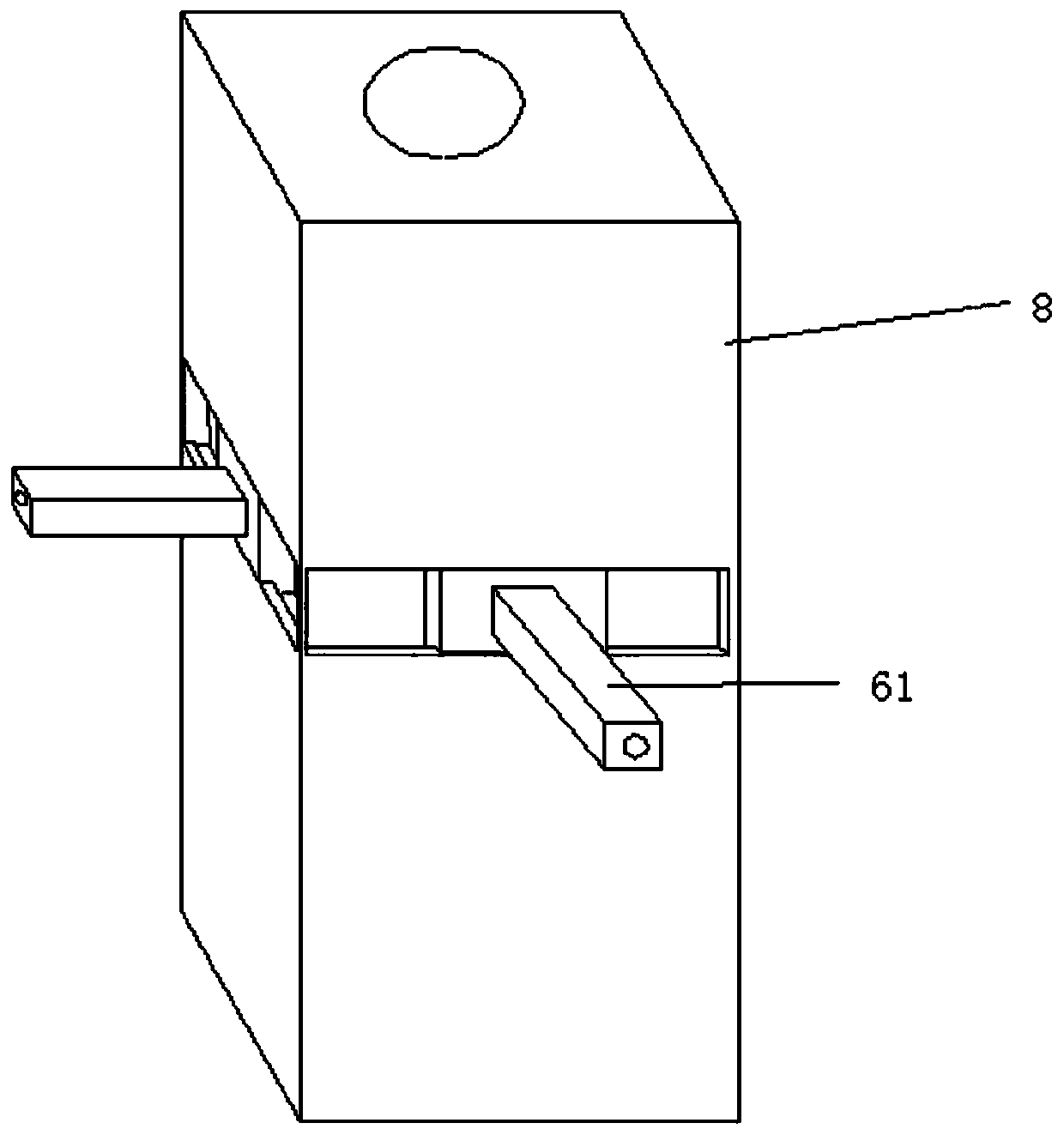

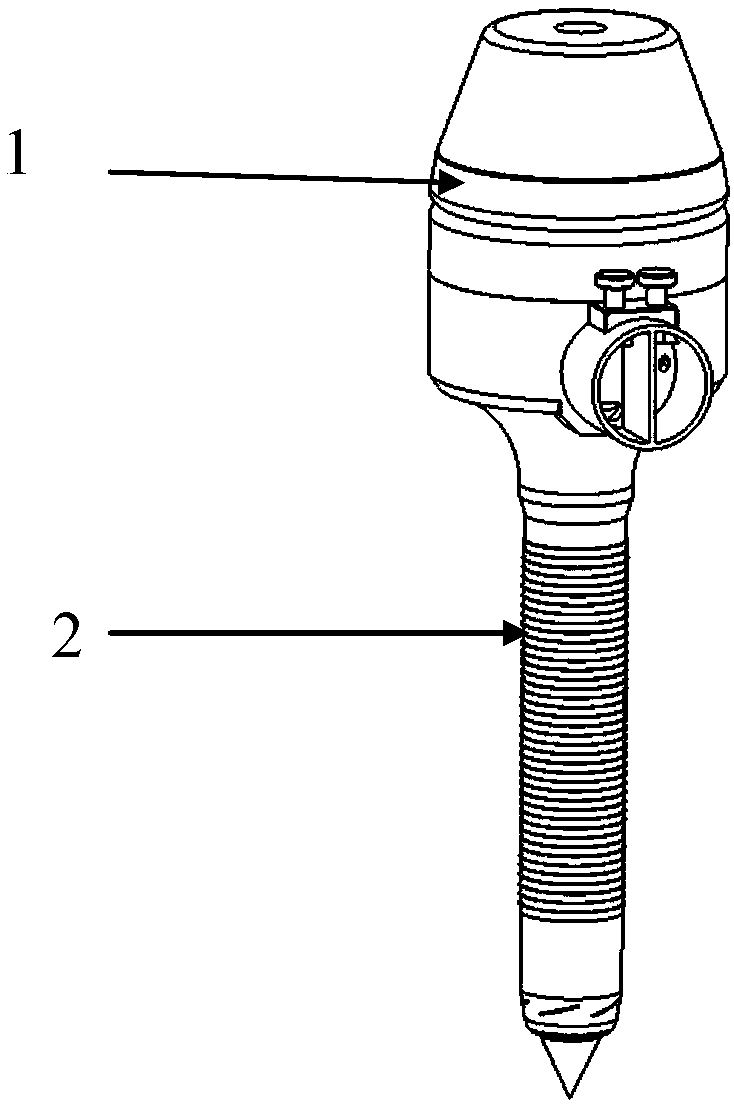

Puncture outfit

ActiveCN109498122AQuick suckIncrease jet speedCannulasSurgical needlesSurgical deviceSurgical instrument

The invention discloses a puncture outfit, which comprises a puncture rod, a sheath component and an exhaust port. The puncture rod is used for forming a through hole, and the sheath component sleevesthe outer side of the puncture rod and serves as a surgical channel. The sheath component comprises an inner tube and an outer tube, the outer tube sleeves the outer side of the inner tube to form aninterlayer, a thin end of the inner tube is provided with an opening, and the interlayer is internally provided with a smoke exhaust channel through which the opening and the vent port are communicated. Smoke is exhausted out of a surgical space when gas enters the surgical space, so that lens blurring caused by smoke can be eliminated, influences on sight of medical personnel are avoided, and surgical efficiency is improved. In addition, an air sac seal structure is delicate in design and reliable in sealing of surgical instruments in different sizes, and safety in product clinical application is achieved.

Owner:JIANGSU RECROWN MEDICAL TECH CO LTD

Tube furnace burner

InactiveCN101576256AAchieve high-intensity combustionIncrease jet speedGaseous fuel burnerLow noiseAir volume

The invention relates to a structure of a burner, in particular to a tube furnace burner. The tube furnace burner comprises an outer wall, an air inlet tube bank, an air inlet and an ignition tip, wherein a regulating door for regulating the air inlet amount is arranged on the outer wall; a pneumatic propeller is arranged at the bottom of the burner; a burning stabilizing cover is arranged at the top of the burner; a flame detection mounting pipe is arranged at the bottom or the side of the burner; and a flame viewing hole is also arranged at the bottom of the burner. The invention has the advantages of compact structure, stable burning, large regulation ratio, low noise, good flame spreadability, complete burning and easy control of burning and can be internally provided with a burning torch and a flame detection alarm system. The invention meets the current requirement on environmental protection, better saves the fuel and improves the burning efficiency.

Owner:ACRE AUTOMATION CO LTD MCC

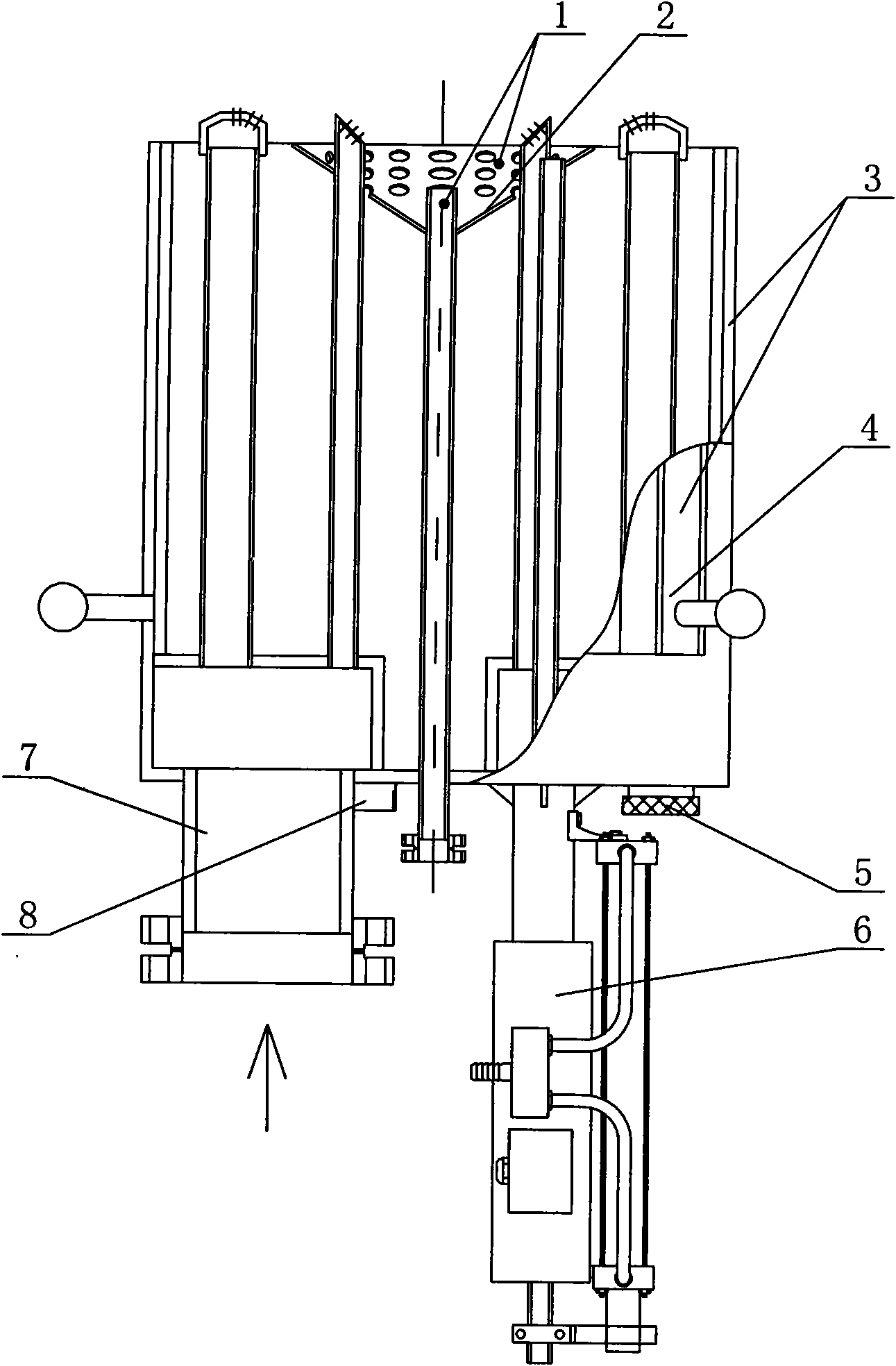

Three-phase jet extinguishing method

ActiveCN102078667AImprove fire extinguishing efficiencyGood fire extinguishing effectFire rescueFire extinguisherSingle phaseNitrogen gas

The invention relates to a portable three-phase jet extinguishing method. In the method, a portable two-phase flow water mist extinguishing device is used as a carrier; the surface of ABC dry powder is modified to be hydrophobic; the modified dry powder is shaken up with water and then injected into a gas-water mixed loading bottle of the extinguishing device; nitrogen or other inert gases are charged into the bottle; then the extinguishing device is placed for later use; and the dry powder is sprayed out from the portable two-phase flow water mist extinguishing device under the extrusion of high-pressure gas when the device is used for extinguishing. The method has a comprehensive gas-liquid-solid extinguishing effect; the temperature can be reduced, the oxygen concentration can be diluted, the surface of a fuel can be cooled, a combustion reaction chain can be quickly obstructed, and the like; a type-A fire disaster and a type-B fire disaster can be effectively extinguished; the extinguishing efficiency is high; the method is basically pollution-free to a protected place; and the extinguishing effect is obviously superior to those of a single-phase flow portable extinguishing device and a two-phase flow portable extinguishing device.

Owner:BEIHANG UNIV

Tail gas purification device

The invention discloses a tail gas purification device, and specifically relates to the technical field of manufacturing of environmental protection equipment. The tail gas purification device comprises a tank body with hollow interior, wherein a gas inlet and a gas outlet are formed in the tank body; a buffer plate is connected to the top of the tank body; a filtering area is formed on one side,which is near the gas outlet, of the buffer plate; a plurality of sloping plates are rotatably connected to the inner wall of the filtering area; a first spring is connected between each of the sloping plates and the inner wall of the filtering area; a bouncing ball is slidingly connected to each of the sloping plates; a second spring is connected with each of the bouncing balls and the inner wallof the filtering area; a rotating shaft is rotatably connected into the filtering area; three blades are distributed on the rotating shaft at equal intervals in the circumferential direction; a watercollecting groove is also arranged at the top of the filtering area; a water inlet pipe is arranged in the water collecting groove; a water pump fixed outside the tank body is connected with the water inlet pipe; a circulation water pipe is connected between the water pump and the bottom of the tank body. Through adoption of the technical scheme, the problem that in the prior art, the contact time of tail gas and water is short is solved, and the tail gas purification device can be used for purifying the tail gas of an automobile part baking room.

Owner:宁波高新区新柯保汽车科技有限公司

Ash removing device of tail flue of fluidized boiler

ActiveCN104613485AEfficient emissionsAchieve separationSolid removalAxial flow pumpsParticulatesFluidized bed

The invention relates to an ash removing device of the tail flue of a fluidized boiler. The ash removing device comprises a smoke inlet pipe, a cooling pipe, a separation pipe and a sedimentation pipe, wherein the axis of the columnar pipeline of the separation pipe is vertical to the ground, the open end of the columnar pipeline faces to the ground, and the smoke inlet pipe is arranged on the lateral wall of the columnar pipeline; one end of the smoke inlet pipe is communicated with the interior of the columnar pipeline, and the other end thereof is communicated with the tail flue of the fluidized boiler; the cooling pipe is mounted at the sealed end at the top of the separation pipe, the other end of the cooling pipe is communicated with the interior of the separation pipe, and a spraying component is mounted in the cooling pipe; a separator is disposed on the wall face of the separation pipe and comprises a plurality of filter plates, and the filter plates are arranged on the inner wall of the separation pipe in a zigzag and staggered manner; an exhaust pipe is arranged at the bottom of the separation pipe. The ash removing device has the advantages that smoke is absorbed through water, and separation of waste gas, particles and soluble impurities is achieved by the filtering separation mechanism.

Owner:BRIGHT THERMAL EQUIP CO LTD

Main blowing system for weft insertion

InactiveCN101158084AControl on and offIncrease jet speedLoomsAuxillary apparatusSolenoid valveEngineering

The invention relates to a main air-jet system used for weft insertion. The invention comprises a gas-holder used for holding high pressure gas, a chief nozzle used for spraying high speed air flow, and a solenoid valve which is connected with the gas-holder and the chief nozzle and used for controlling on-off of air flow. A pressure intensifier is arranged between the solenoid valve and the chief nozzle, and the pressure intensifier comprises a hollow pressure intensifier body and a piston which is arranged in the pressure intensifier body and slides along an inner cavity of the pressure intensifier body. The inner cavity of the pressure intensifier body is separated into a first air chamber and a second air chamber by the piston. The cross-sectional area of the first air chamber is smaller than the cross-sectional area of the second air chamber. A one-way valve arranged on the first air chamber conducts to the chief nozzle by a single way. At least two communicating states exist among the first air chamber, the second sir chamber, the gas- holder and atmosphere: under the first communicating state, the gas-holder conducts to the first air chamber and the second air chamber respectively; under the second communicating sate, the second air chamber conducts to atmosphere. The main air-jet system used for weft insertion can not only regulate the on-off of the air flow, but also increase the air flow pressure of the chief nozzle to obtain a larger jet velocity of the air flow and to improve the performance of accelerating weft.

Owner:JIANGSU WANGONG TECH GRP CO LTD

Transmission type laser-electromagnetic field coupling thruster

ActiveCN107842478AAccurate quality controlEnsure controllabilityMachines/enginesUsing photonsElectromagnetic field couplingOptoelectronics

A transmission type laser-electromagnetic field coupling thruster comprises a laser system, an electromagnetic accelerating electrode assembly, a working medium, a transparent base layer and an electrostatic field assembly. Focused laser beams enter the transparent base layer from a round hole formed in an electrostatic field accelerating positive electrode, the laser beams penetrate the transparent base layer and then erode the working medium, then laser plasma is generated, discharge arcs can be induced to be generated when the laser plasma sequentially penetrates a round hole in an electrostatic field accelerating negative electrode and a round hole in a high-temperature-resisting insulation plate to move to the position between an electromagnetic accelerating anode and an electromagnetic accelerating cathode after being accelerated by an electrostatic field, and the laser plasma is heated and further ionized through the discharge arcs; and a self-induced magnetic field is formed through a fast-changing alternating electric field between the electromagnetic accelerating electrodes, Lorentz force on the plasma is generated under the action of the electromagnetic field, and therefore the higher ionization rate and injection rate of the plasma are achieved, and then thrust pulses are formed. The transmission type laser-electromagnetic field coupling thruster has the beneficialeffects of being adjustable in thrust, high in propulsive efficiency, large in thrust density, small in pollution and the like.

Owner:NAT UNIV OF DEFENSE TECH

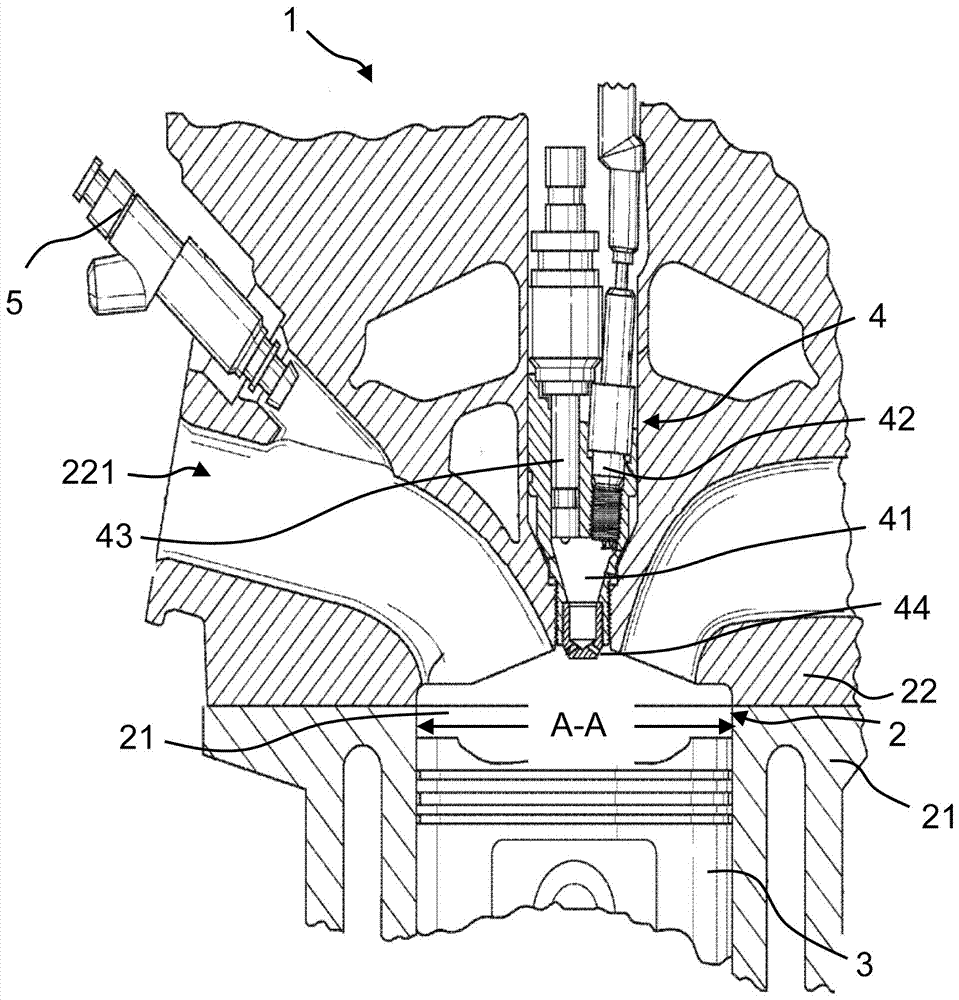

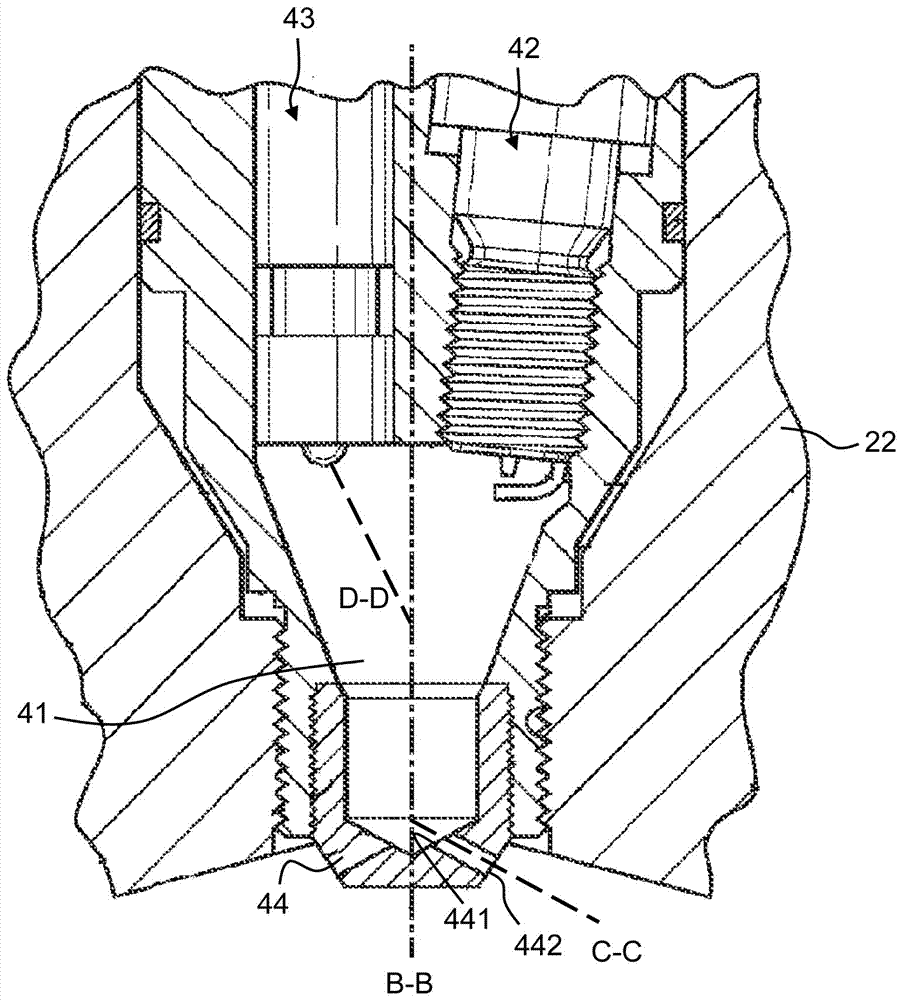

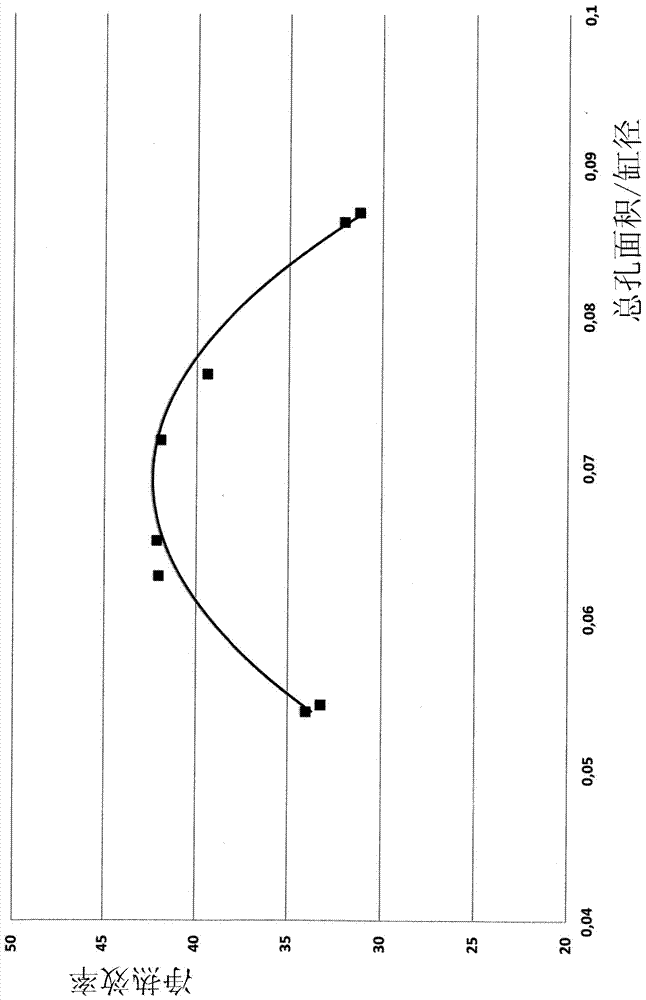

Internal combustion engine

ActiveCN107339149AAvoid smallIncrease jet speedElectrical controlInternal combustion piston enginesCombustorCombustion chamber

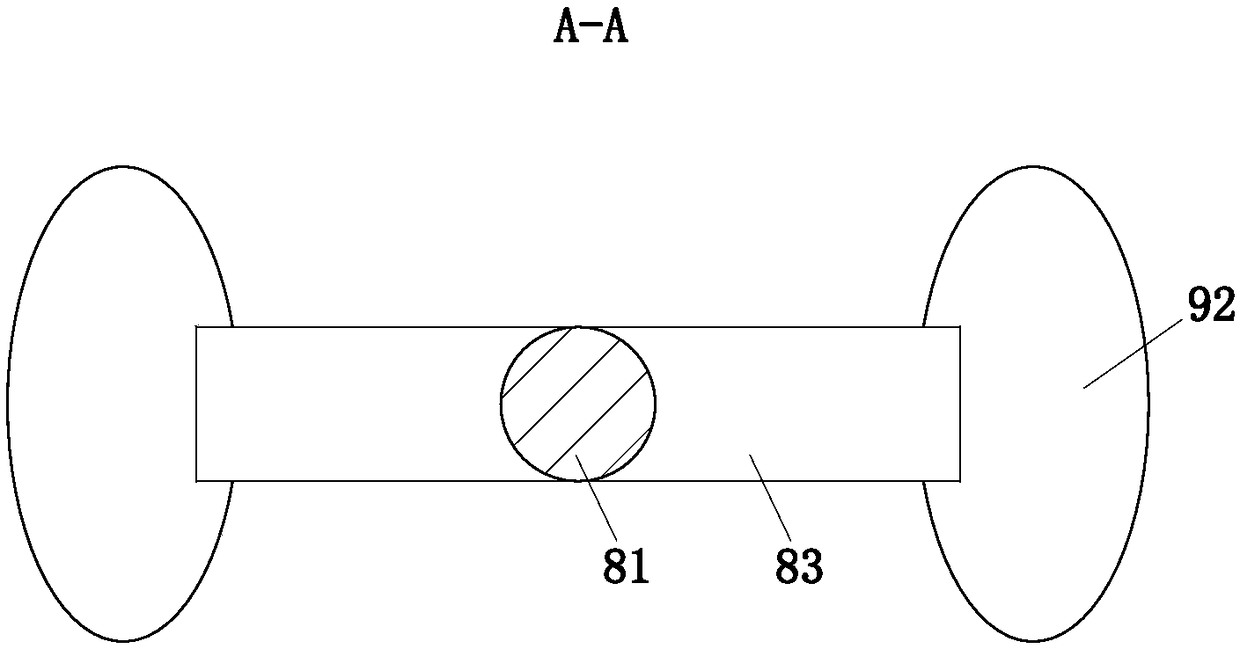

Internal combustion engine 1 comprising at least one cylinder 2 and a piston 3 supported for repeated reciprocal movement in the cylinder 2 so as to define a combustion chamber 21 of an engine bore diameter A-A, the internal combustion engine 1 further comprising an ignition device 4 arranged in said cylinder 2 having an igniter portion 42 and an fuel injector 43 which are both arranged in a pre-chamber 41, wherein the pre-chamber 41 comprises a plurality of orifices 44 for providing fluid communication between said pre-chamber 41 and the combustion chamber 21, and wherein the plurality of orifices 44 are of an overall orifice area so that the ratio between the overall orifice area and the engine bore diameter A-A ranges from 0.01 mm to 0.2 mm.

Owner:MAHLE INT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com