Regenerant and processing method of three-way catalytic converter of gasoline automobile

The technology of a three-way catalytic converter and a treatment method is applied in the field of regeneration of products in the automotive field, which can solve the problems of the three-way catalytic converter's weakening function of purifying exhaust gas, consuming social costs, and increasing the fuel consumption of vehicles, so as to restore the exhaust gas purification function and prolong the service life. The effect of service life and maintenance cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Present embodiment provides a kind of regeneration agent of three-way catalytic converter of gasoline vehicle, is made up of following raw material by mass percentage:

[0028] Chlorine-containing solvent 0.006~0.03%

[0029] Hydrogen peroxide 0.01~0.04%

[0030] Methanol solvent 99.96~99.954%

[0031] Among them, methanol adopts a methanol solvent with a concentration of 99.99%; the solvent containing chlorine elements can use chlorine-containing compounds, specifically hydrogen chloride, dichloropropane, dichloroethane, carbon tetrachloride and other chlorine-containing compounds. A sort of;

[0032] The hydrogen chloride and hydrogen peroxide in the above raw materials are added into the methanol solvent and mixed to obtain the regeneration agent for the three-way catalytic converter of gasoline vehicles.

[0033] The working principle of the regenerant is: after the regenerant enters the combustion chamber from the engine intake pipe for combustion, a high-temper...

Embodiment 2

[0036] The present embodiment provides a method for regenerating a three-way catalytic converter of a gasoline vehicle, which is a method for regenerating the three-way catalytic converter of a gasoline vehicle using the regenerant given in Example 1 above, the method comprising:

[0037] Adopt the regeneration agent that above-mentioned embodiment 1 provides, the regeneration agent is joined in the engine combustion chamber by the vacuum tube on the automobile engine intake manifold;

[0038] After the regenerant is burned in the engine, a high-temperature oxidation environment containing chloride ions is established in the exhaust system, and the high-temperature oxidation environment is used to remove poisons such as carbon deposits and sulfur-phosphorus chemical complexes covered on the three-way catalyst in the three-way catalyst;

[0039] For the three-way catalyst deactivated due to chlorine loss and crystal grain aggregation, the regenerant can disperse the aggregated a...

Embodiment 3

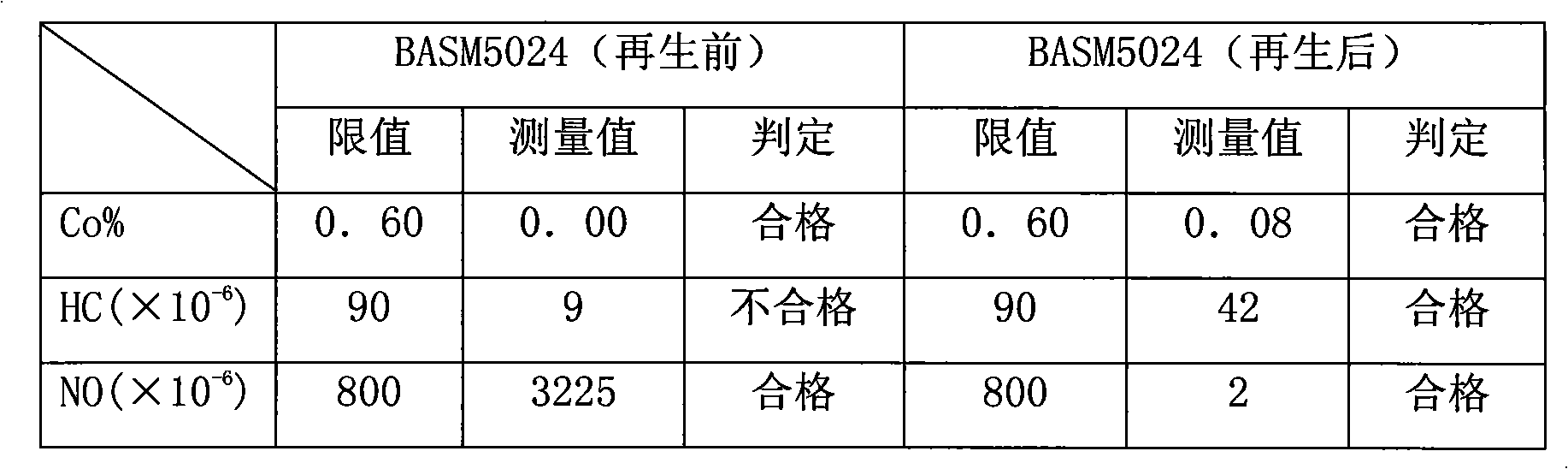

[0044] In this embodiment, the regeneration agent provided in the embodiment of the present invention is described to regenerate the three-way catalytic converter of the Jetta closed-loop EFI gasoline vehicle with the three-way catalytic converter installed:

[0045] The formula of used regeneration agent is, each raw material is by mass percentage:

[0046] Hydrogen chloride 0.01%

[0047] Hydrogen peroxide 0.02%

[0048] Methanol solvent 99.97%.

[0049] Use the Jetta closed-loop EFI gasoline car with a three-way catalytic converter installed, insert the hollow needle end of the infusion set into the rubber intake vacuum tube of the car engine, and input the regenerant of the above-mentioned formula of 750 milliliters (add the methanol solvent of hydrogen chloride and hydrogen peroxide) The regeneration agent formed), the engine runs at a speed of 1500 rpm, and the regeneration agent is sucked into the combustion chamber of the engine by the effect of atmospheric pressure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com