Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154 results about "Dichloropropane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dichloropropane can refer to any of several chemical compounds: 1,1-Dichloropropane 1,2-Dichloropropane 1,3-Dichloropropane 2,2-Dichloropropane

Preparation method of improved 4,4-dichlorodiphenylsulfone

InactiveCN102351756AReduce manufacturing costImprove product qualityOrganic chemistryOrganic compound preparationDichloropropaneOrganic solvent

The invention discloses a preparation method of improved 4,4-dichlorodiphenylsulfone. The method comprises steps that: (1) Al2Cl3 is adopted as a catalyst; chlorobenzene, thionyl chloride are adopted as reaction materials; the materials are subject to a Friedel-Crafts reaction; a mother liquor obtained after the reaction is hydrolyzed; the hydrolyzed mother liquor is refluxed for 45 to 60min under a temperature of 95 to 100 DEG C; after refluxing, the mother liquor is cooled to below 20 DEG C, such that the liquor is divided into an organic phase and a water phase; the organic phase is processed through reduced-pressure distillation and centrifugal washing until the organic phase turns neutral, and the organic phase is preserved as a product M for later use, wherein a main component in the product M is 4,4-dichlorodiphenylsulfone; (2) the product M and an oxidizing agent of hydrogen peroxide are adopted as raw materials, and 1,2-dichloropropane is adopted as an organic solvent; an oxidizing reaction is carried out upon the main component 4,4-dichlorodiphenylsulfone in the product M under the effect of a composite catalyst, such that a 4,4-dichlorodiphenylsulfone crude product is synthesized, wherein the composite catalyst is phosphotungstic acid or silicotungstic acid loaded on active carbon. Therefore, the method provided by the invention has advantages of high yield and good product quality. With the method, wastewater can be circulated and reused.

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

Preparation method for chlorotrifluoropropylene

InactiveCN101168494AAvoid it happening againLow reaction temperaturePreparation by halogen replacementChemical industryDichloropropaneHydrogen fluoride

A monochloro-fluoropropene preparation belongs to the intermediate preparation technical field of coolant, foaming agent and fluorine compounds, which comprises that under catalyst condition, the telomeric reaction on chloromethane and chloroalkene is processed to prepare pentachloro-propane, which is fluorinated with hydrogen fluoride via the catalysis of composite catalyst to prepare trifluoro-dichloropropane, and hydrogen chloride is removed via the alkali alcohol liquid catalysis to obtain monochloro-fluoropropene as final product. The invention has the advantages that the preparation fluorinates pentachloro-propane into trifluoro-dichloropropane, to remove hydrogen chloride to obtain monochloro-fluoropropene, thereby avoiding azeotropic material and sub isomer generated in the fluorination from pentachloro-propane to monochloro-fluoropropene, while the whole process has low reaction temperature to save energy, and the monochloro-fluoropropene product has reach 99.0-99.6% purity and 80.70-88.05% yield, to meet industrial batch production.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS

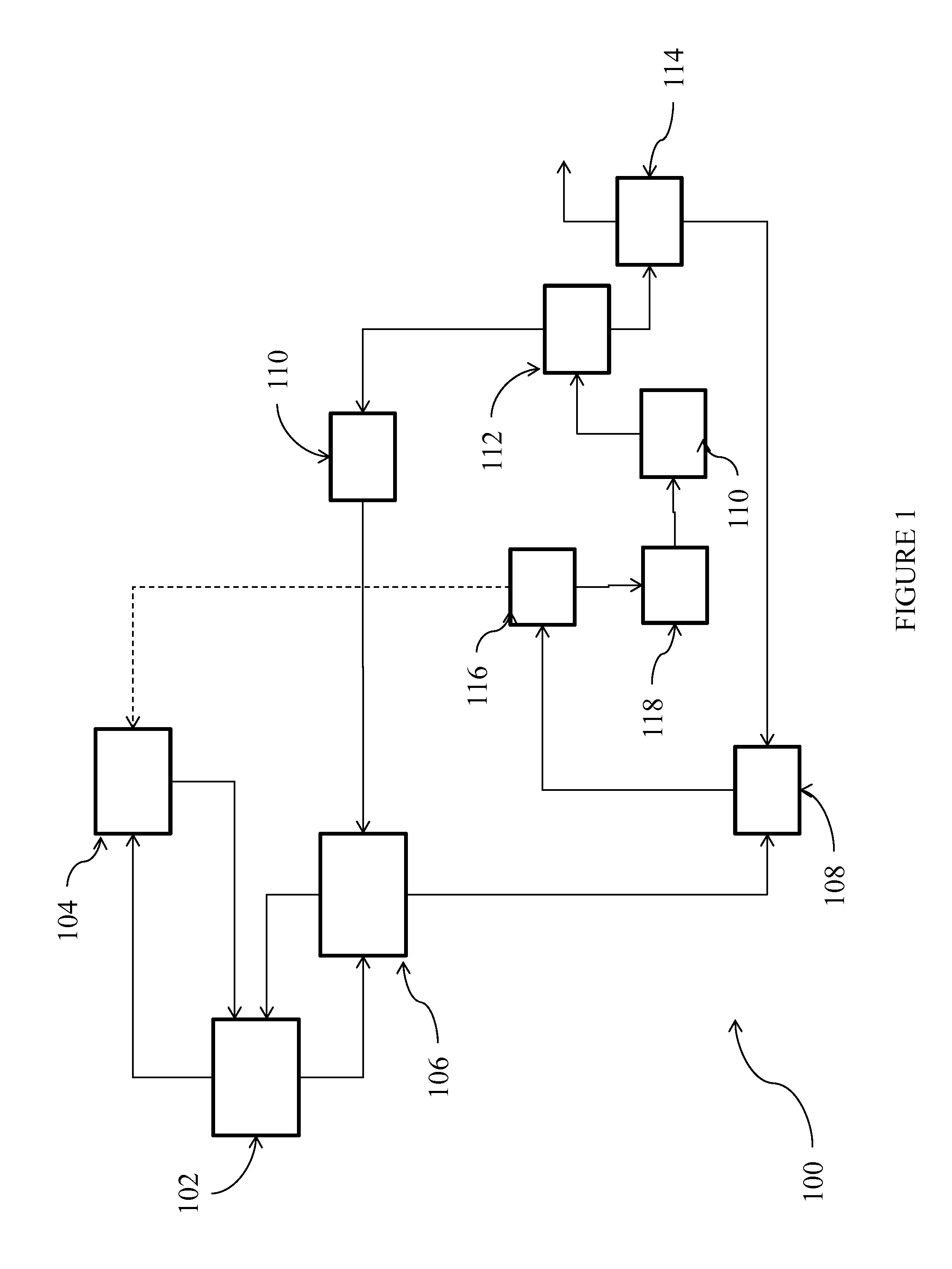

Process for the production of chlorinated propenes

InactiveUS20140081055A1Low costFew stepsPreparation by hydrogen halide split-offDichloropropaneGas phase

Processes for the production of chlorinated propenes are provided. The present processes make use of 1,2-dichloropropane, a by-product in the production of chlorohydrin, as a low cost starting material, alone or in combination with 1,2,3-trichloropropane. The present processes can also generate anhydrous HCl as a byproduct that can be removed from the process and used as a feedstock for other processes, providing further time and cost savings. Finally, the processes are advantageously conducted in the liquid phase, thereby presenting additional savings as compared to conventional, gas phase processes.

Owner:BLUE CUBE IP

Fluorine-carbon sufactant and preparing method

InactiveCN1743062AReduce surface tensionImprove solubilityTransportation and packagingMixingEthylenediamineDichloropropane

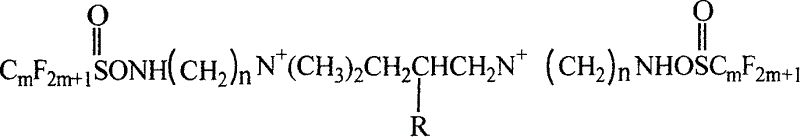

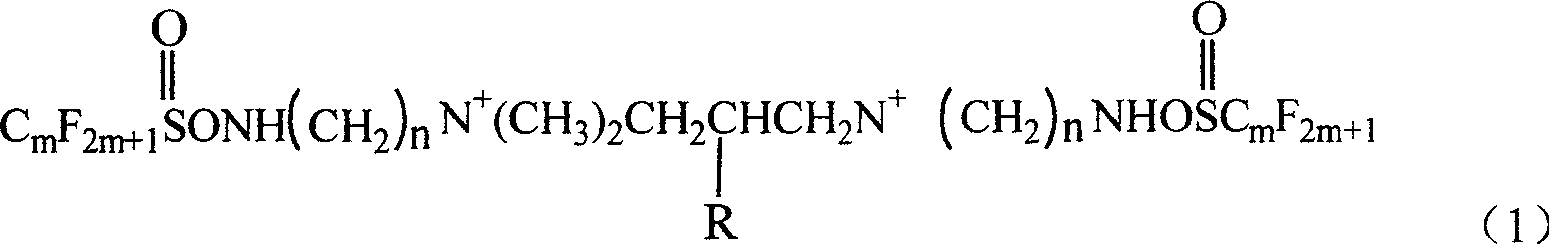

The present invention discloses a new-type double-ion type fluorocarbon surfactant. It is a double-ion type fluorocarbon surfactant using hydrophilic monoester dichloropropane as new-type hydrophilic flexible space group of coupling group, its chemical name is N,N,N',N'-tetramethyl-N,N'-bis [(perfluoroalkyl sulamine)-alkyl]-2-monoester group-propylenediammonium. Said surfactant utilizes reaction of perfluoroalkyl sulfuryl fluoride and N,N-dimethyl-1,2-ethylenediamine or N,N-dimethyl-1,3-propylenediamine to obtain intermediate product N-[(dimethylamino)-alkyl] perfluoroalkyl sulfamine, then makes the intermediate product and monoester dichloropropane undergo the process of quaterisation so as to obtain the invented product.

Owner:NANJING TECH UNIV

Method for preparing 2,3,3,3-tetrafluoropropylene

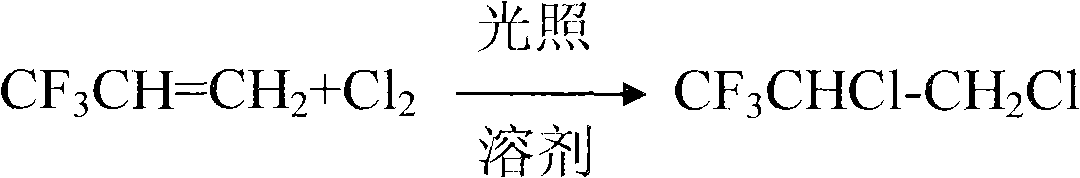

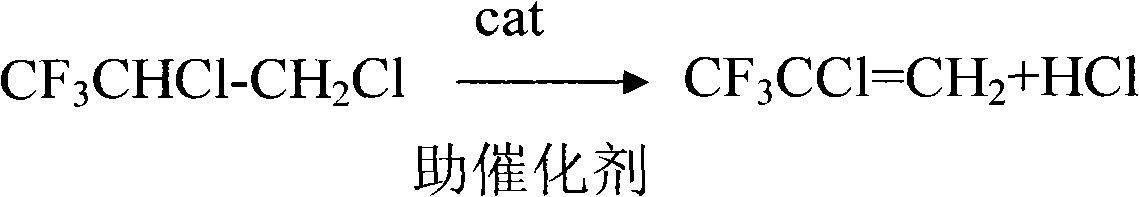

The invention relates to a method for preparing 2,3,3,3-tetrafluoropropylene, which comprises the following steps: 1, performing the addition reaction of 3,3,3-trifluoropropylene (CF3CH=CH2) (I) serving as a raw material and chlorine at -10 to 100 DEG C under the irradiation of a ultraviolet lamp in alkyl halide to prepare 3,3,3-trifluoro-1,2-dichloropropane (CF3CHClCH2Cl)(II); 2, performing the dehydrochlorination reaction of the compound of the formula (II) at 0 to 150 DEG C in the presence of an alkali metal hydroxide serving as a catalyst and a high molecular polyether or macromolecular ether serving as a cocatalyst to form CF3CCl=CH2 (III); 3, performing the addition reaction of the compound of the formula (III) and HF to form CF3CClFCH3 (IV) in the presence of a catalyst consisting of SnCl4, TiCl4 and fluosulfonic acid, wherein a polymerization inhibitor is aprotic inert compound, the reaction temperature is 5 to 100 DEG C and the pressure is 0.2 to 1.0MPa; and 4, performing thedehydrochlorination reaction of the compound (IV) at 0 to 100 DEG C and under 0 to 0.5MPa in the presence of an alkali metal catalyst and an organic amine halide serving as a phase transfer catalyst to obtain FO-1234yf.

Owner:衢州环新氟材料有限公司

Process for the production of chlorinated propenes

InactiveUS9056808B2Low costHigh selectivityPreparation by hydrogen halide split-offDichloropropaneGas phase

Processes for the production of chlorinated propenes are provided. The present processes make use of 1,2-dichloropropane, a by-product in the production of chlorohydrin, as a low cost starting material, alone or in combination with 1,2,3-trichloropropane. The present processes can also generate anhydrous HCl as a byproduct that can be removed from the process and used as a feedstock for other processes, providing further time and cost savings. Finally, the processes are advantageously conducted in the liquid phase, thereby presenting additional savings as compared to conventional, gas phase processes.

Owner:BLUE CUBE IP

Preparation method of 2,3,3,3-tetrafluoropropylene

ActiveCN109438170APlay a protective effectHigh yieldPreparation by hydrogen halide split-offPreparation by halogen replacementDichloropropanePropane

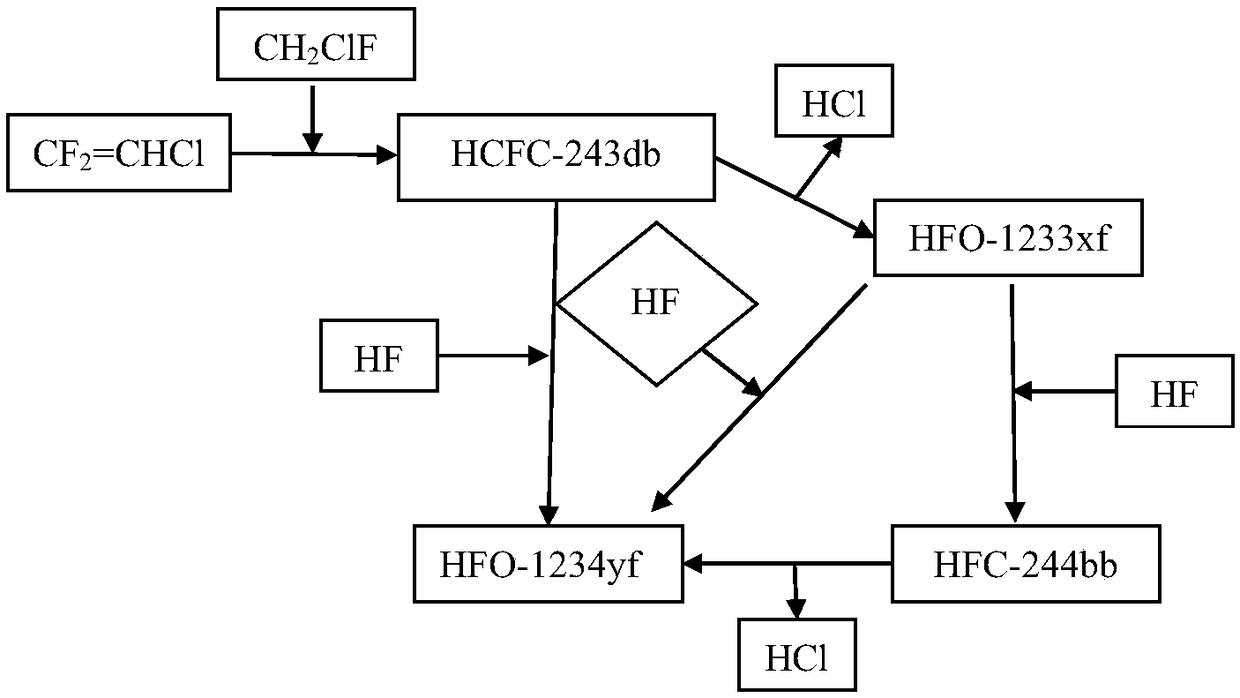

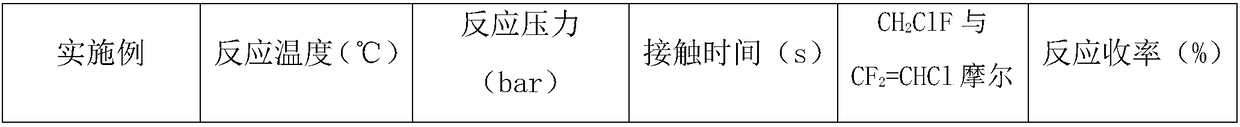

The invention discloses a preparation method of 2,3,3,3-tetrafluoropropylene. 1,1-difluoro-2-vinyl chloride and chlorofluoromethane are subjected to an addition reaction in presence of a catalyst to generate 1,1,1-trifluoro-2,3-dichloropropane, and 2,3,3,3-tetrafluoropropylene is prepared under catalysis of 1,1,1-trifluoro-2,3-dichloropropane through three routes. 1,1-difluoro-2-vinyl chloride which is harmful to human bodies and the environment is used as an initial material, and the environment is protected. A continuous tubular reactor is adopted for the reaction in the method, reaction conditions are easy to control, and equipment is simple to operate; conversion rate in each step of the preparation method is high, yield of the target product is higher, and the method has extensive industrial application prospect.

Owner:ZHEJIANG SANMEI CHEM IND

Precision electronic device on-line detergent and its production method

InactiveCN1884465AEasy to cleanReduce the risk of electric leakageNon-surface-active detergent compositionsDichloropropaneBiochemical engineering

The invention relates the cleaning agent and preparing method. The cleaning agent comprises 60-80% dichloropropane, 5-20% methylchloro-form and 5-20% difluo-monochloroethane. The cleaning agent has the advantages of good cleaning effect, non remain, and good insulativity. The cleaning agent has good withstand voltage, and the pressure resistance value is 25kv. The cleaning agent solves the problem that moisture coagulated on the surface of substance.

Owner:深圳市华晟科技有限公司

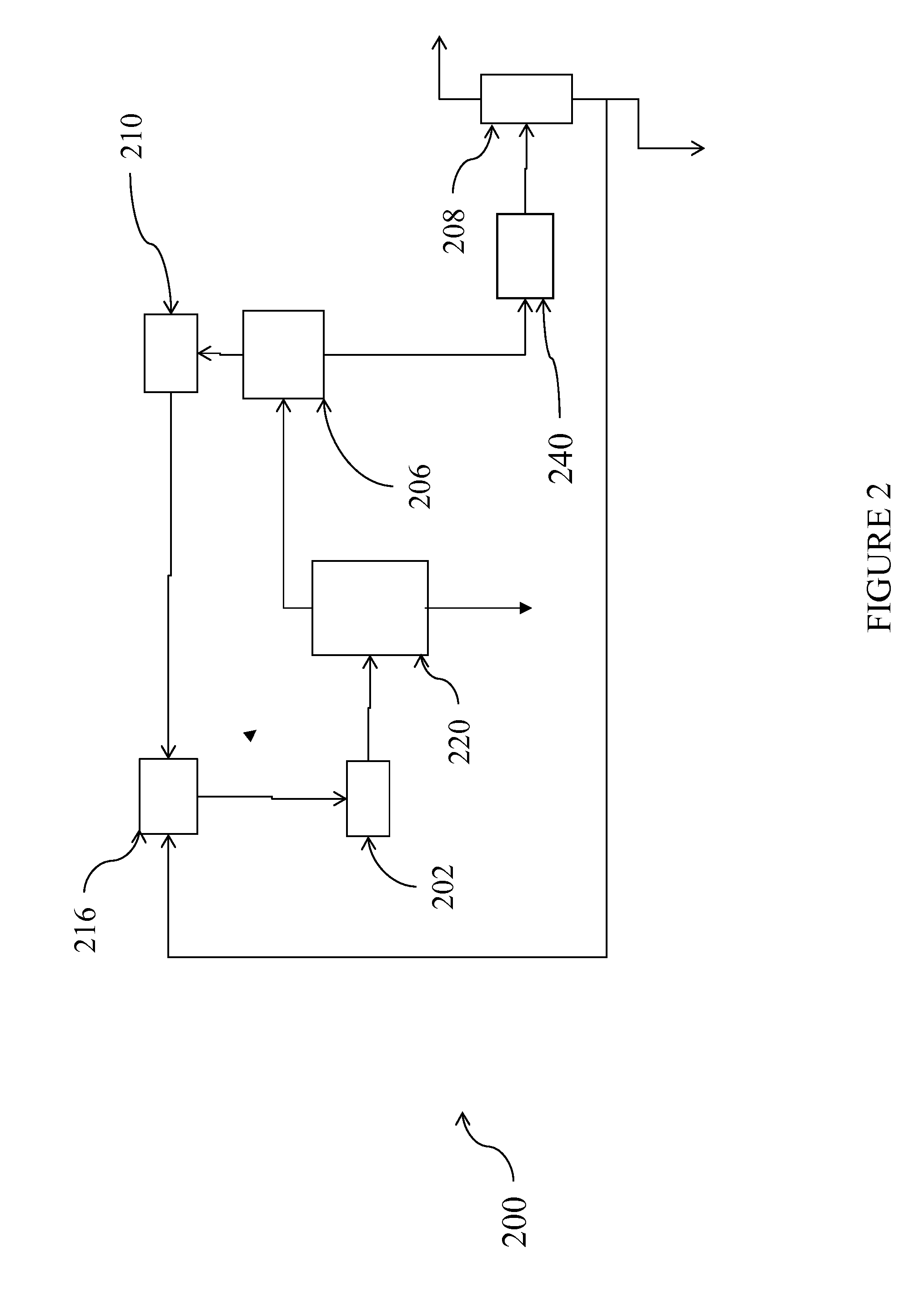

Process for producing trans-1233zd

ActiveUS8653309B2Preparation by dehalogenationOrganic compounds purification/separation/stabilisationDichloropropaneIsomerization

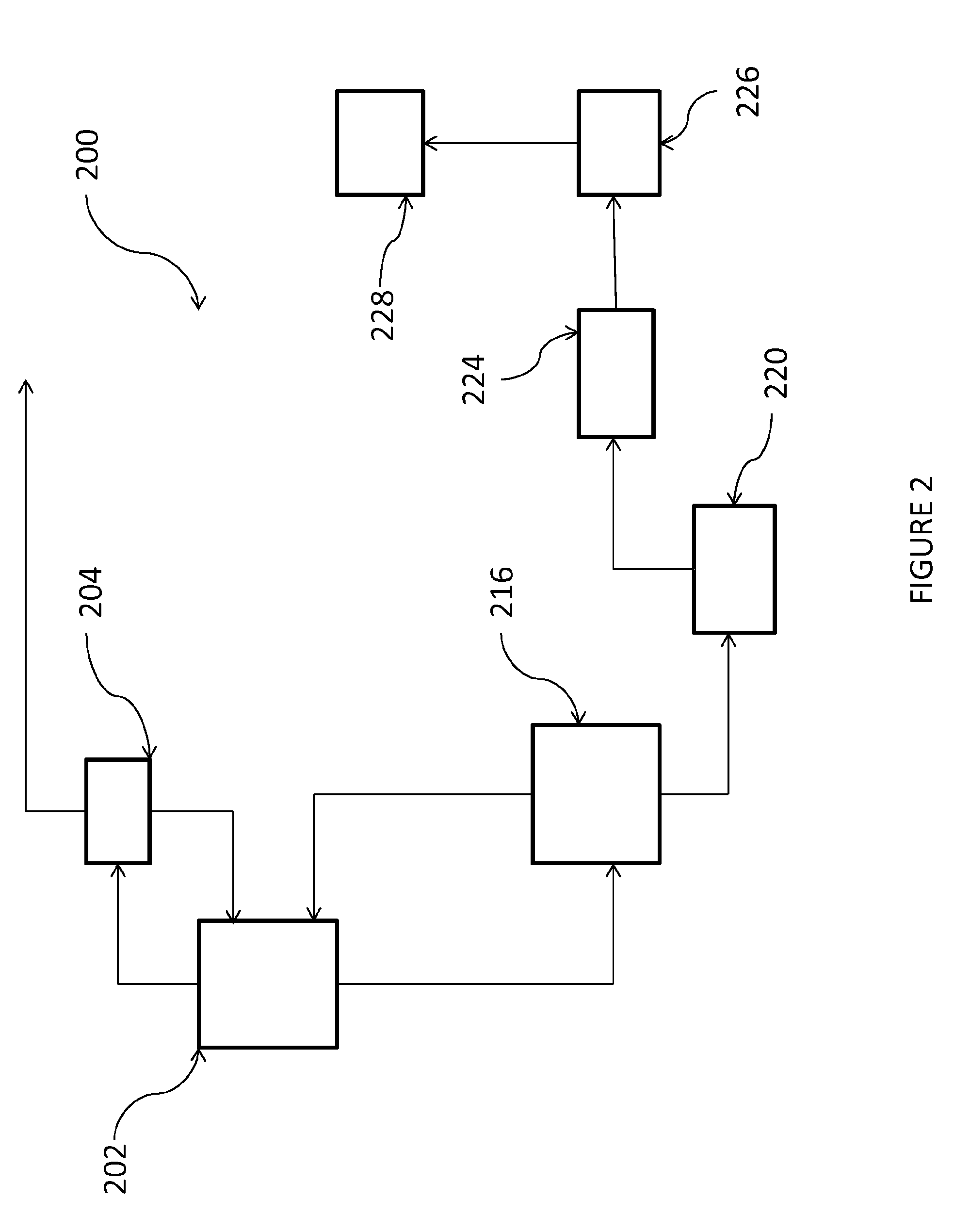

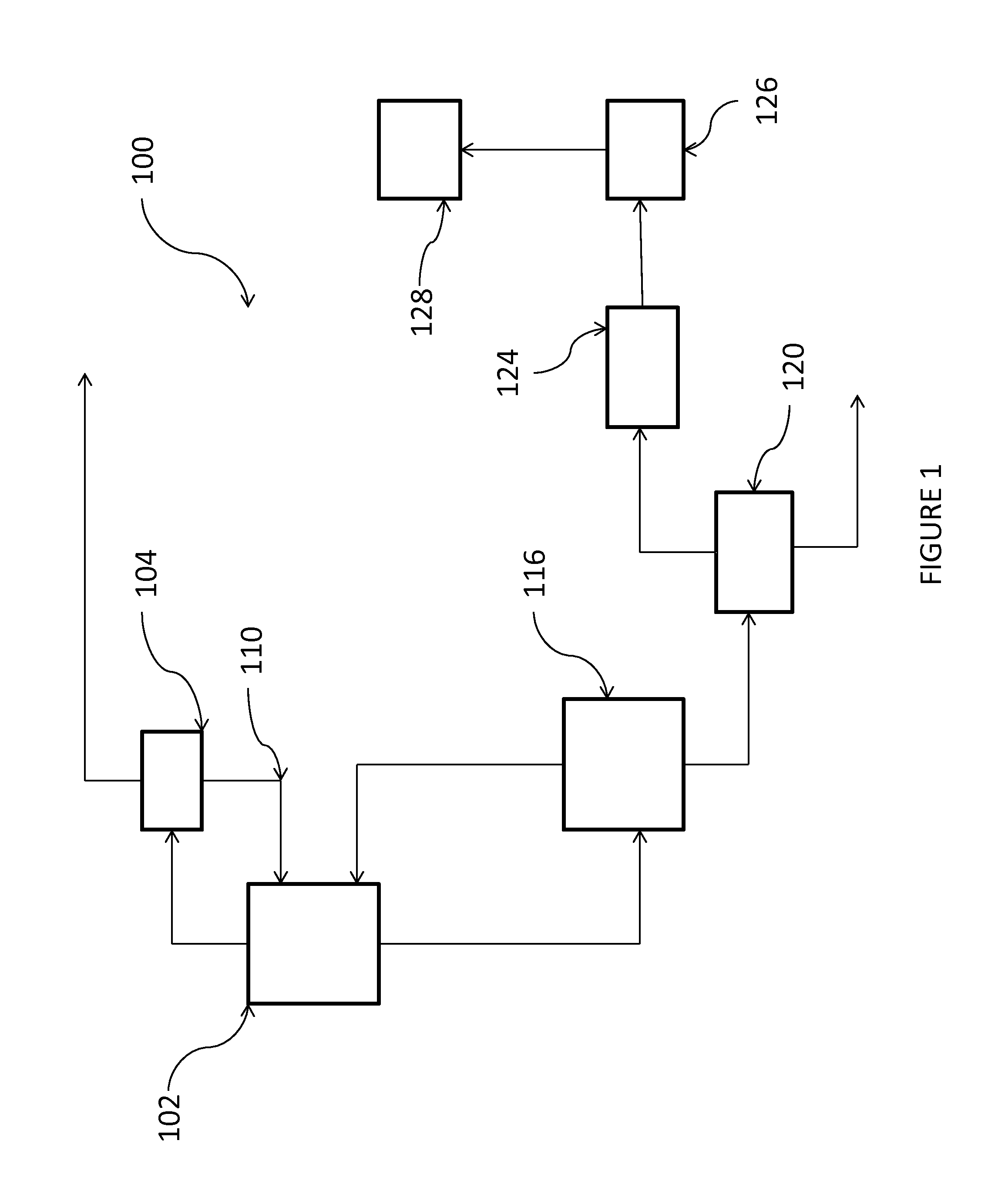

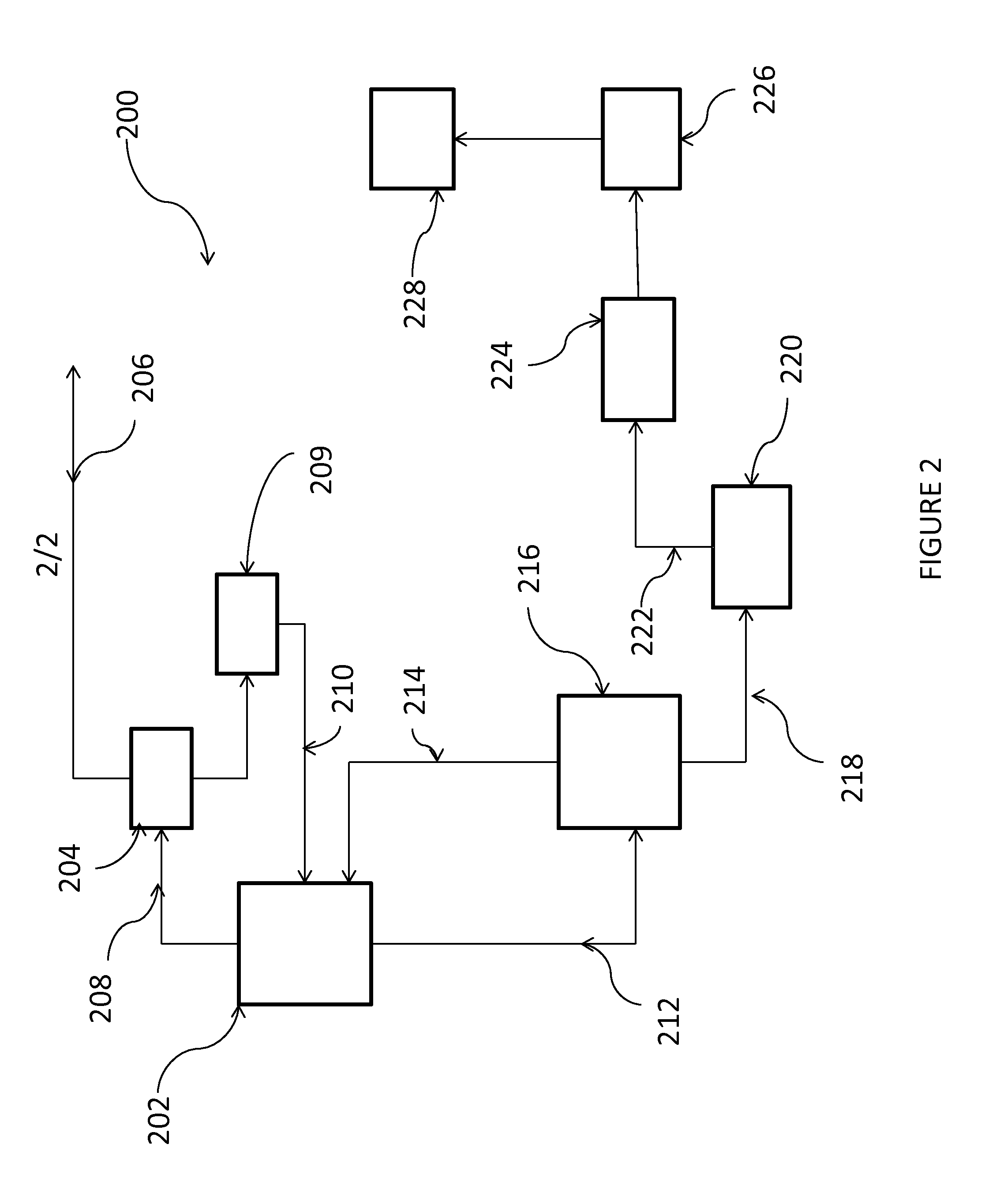

Trans-1233zd, the trans-isomer of 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd) can be used as blowing agents, solvents, cleaning agents, as well as monomers of macromolecule compounds, and can be prepared through the dehydrochlorination of 1,1,1-trifluoro-3,3-dichloropropane (HCFC-243fa) with the help of a catalyst. The present invention is directed to an integrated process is proposed to produce trans-1233zd from 243fa, which is consisted of the following four major unit operations: (1) Catalytic dehydrochlorination of 243fa into trans / cis-1233zd, (2) HCl recovery, (3) Catalytic isomerization of cis-1233zd into trans-1233zzd, and (4) Isolation of trans-1233zd.

Owner:HONEYWELL INT INC

Process for the production of chlorinated propenes

InactiveUS8907149B2Low costHigh selectivityPreparation by hydrogen halide split-offPreparation by halogen replacement1,2-DichloropropaneDichloropropane

Processes for the production of chlorinated propenes are provided. The present processes make use of a feedstream comprising 1,2-dichloropropane, a by-product in the production of chlorohydrin, as a low cost starting material, alone or in combination with 1,2,3-trichloropropane. Selectivity of the process is enhanced over conventional processes employing successive chlorinations and / or dehydrochlorinations, by conducting at least one chlorination in the presence of an ionic chlorination catalyst. The present processes may also generate anhydrous HCl as a byproduct that can be removed from the process and used as a feedstock for other processes, providing further time and cost savings.

Owner:BLUE CUBE IP

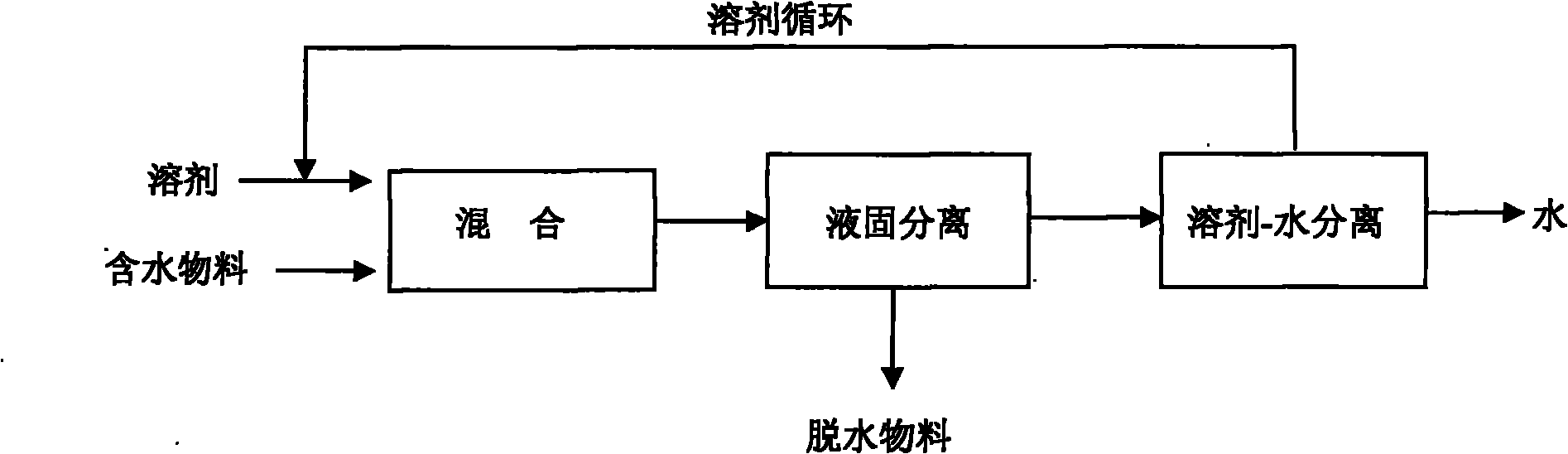

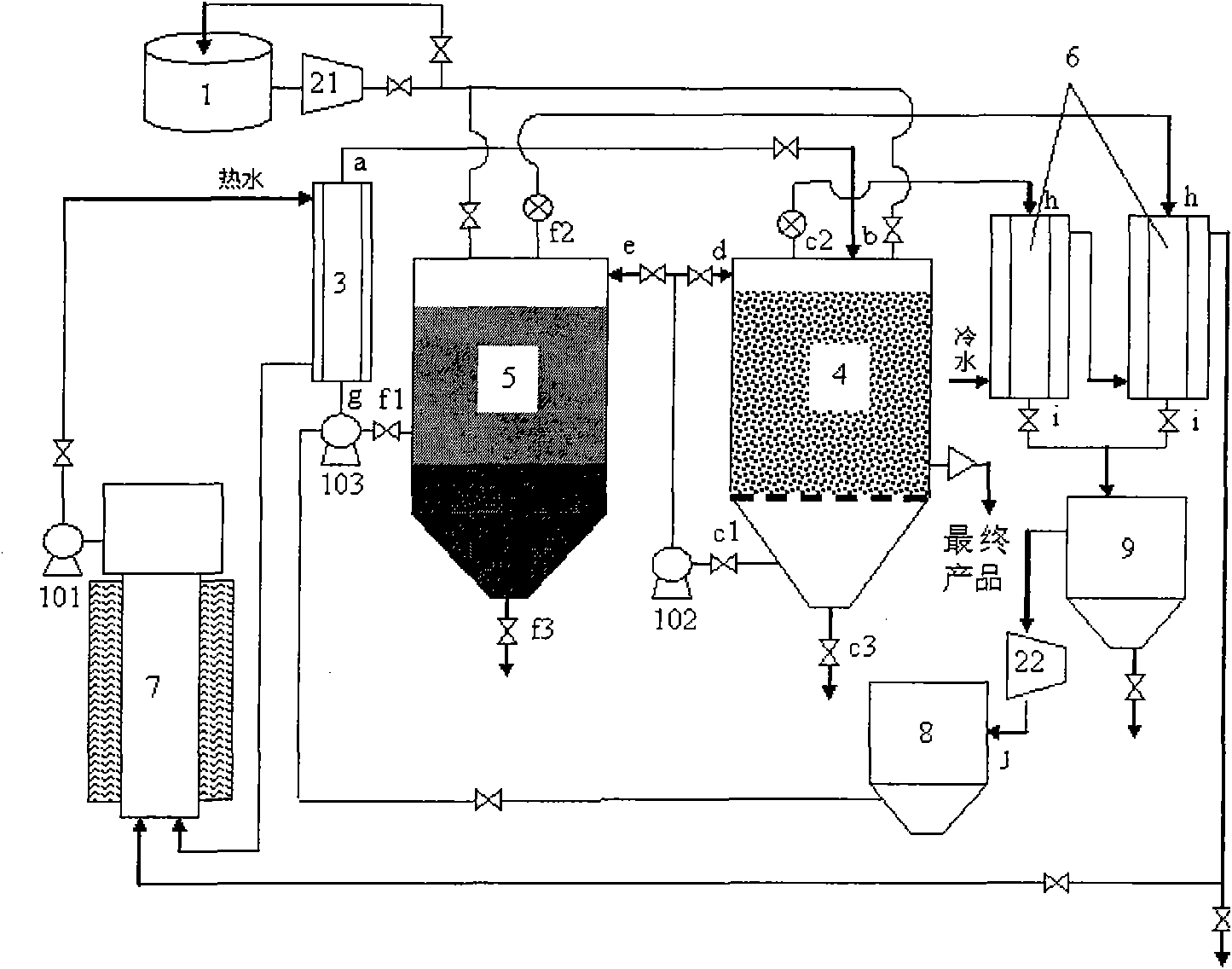

Substitution and dehydration method for water contained solid materials and device

InactiveCN101780390AAchieve recyclingReduce moisture contentGas-gas reaction processesDichloropropaneEpoxy

The invention provides a substitution and dehydration method for water contained solid materials and a device. In the method, the material is dehydrated by organic solvents with low boiling point and low latent heat, which are liquid at 0 DEG C to 60 DEG C and 0.1 MPa to 3 MPa, such as propane, dichloropropane, epoxy ethane, dimethyl ether, dimethyl sulphide and a mixture thereof or a mixture of the organic solvents and a surface active agent with low adsorbability and low latent heat, in dehydration equipment through the action of leaching, absorbing, substituting and the like and liquid-solid separation. The solvents and water can be separated and recycled by evaporating water bearing solvents in separation equipment and condensating the solvents in condensation recovery equipment or layering the solvents and water. Because the latent heat of the solvents is far less than that of the water, the solvent substitution and dehydration method and the device thereof of the invention can obviously reduce power consumption in the dehydration process, solve the problems of burning, wall built-up and the like through low operation temperature, and are suitable for dehydration of solid materials with different water contents.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

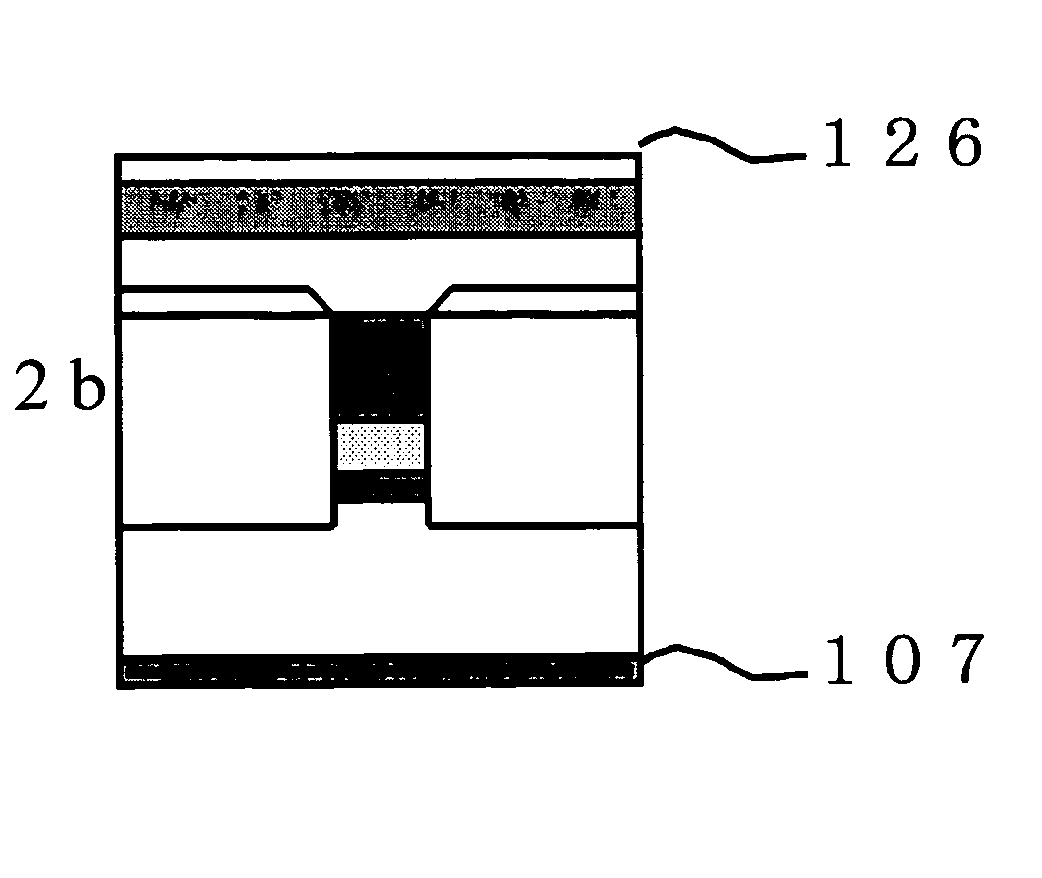

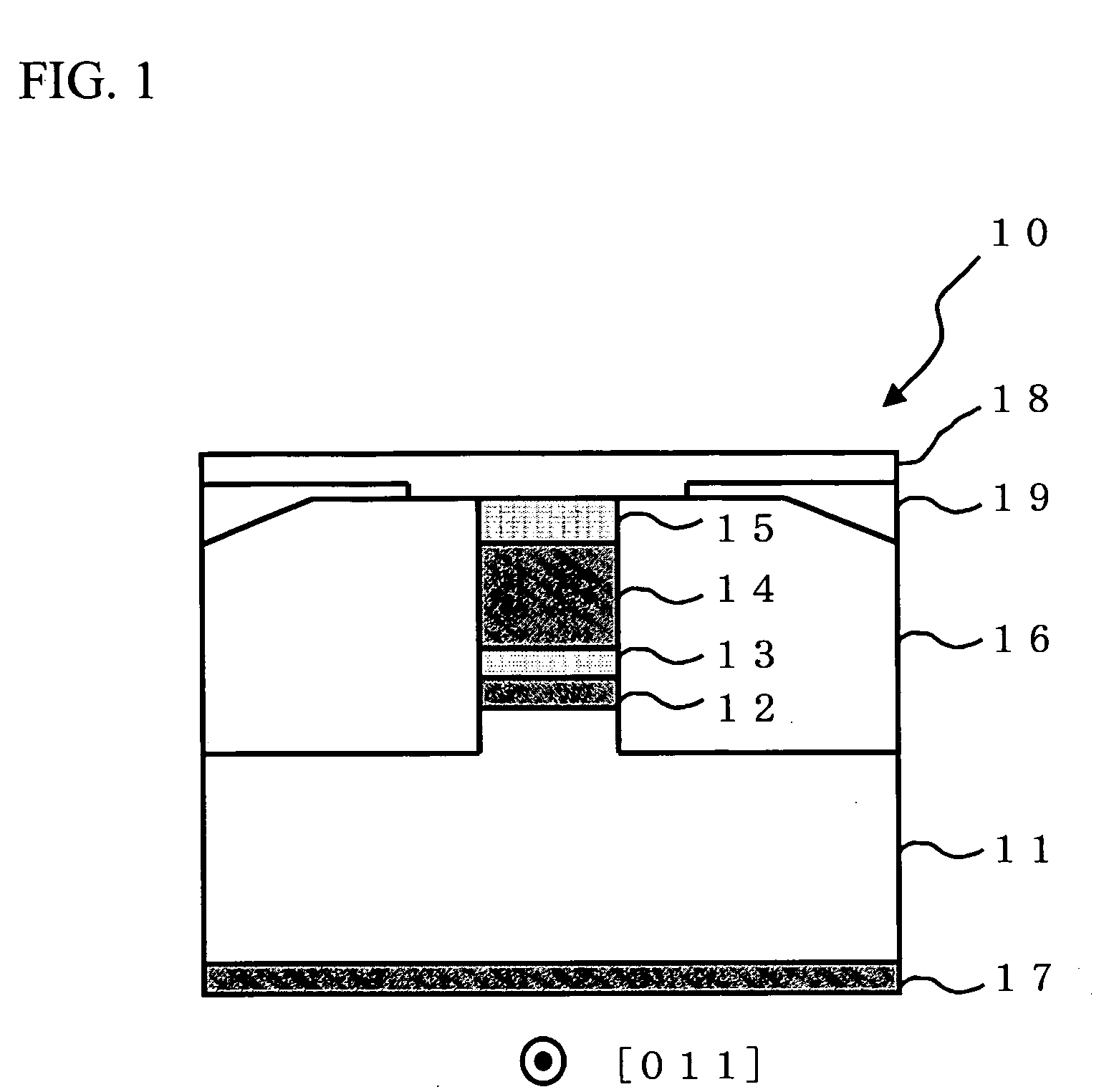

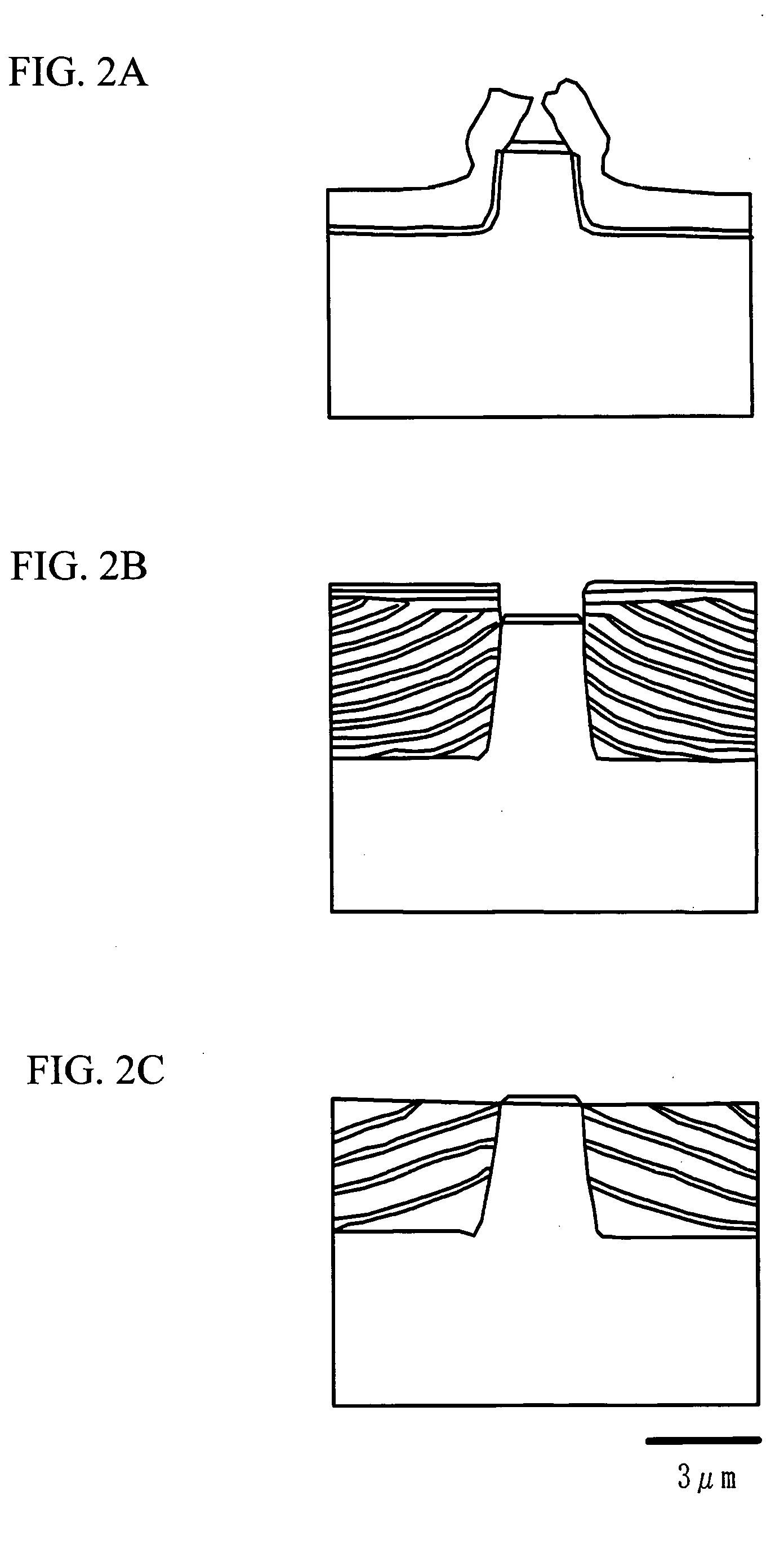

Method of fabricating semiconductor device

ActiveUS20060177953A1Laser detailsSemiconductor/solid-state device manufacturingDichloropropaneDevice material

A method of fabricating a semiconductor device includes the steps of forming a step region having a mesa shape in a direction of <011> or <0-11> on a (100) plane of an InP-based compound semiconductor crystal, and burying the step region with InP-based buried layers grown by vapor-phase growth by supplying a base gas to which a chlorinated organic compound is added, the organic chlorine compound including at least two carbon atoms, and each of the carbon atoms is bonded to one chlorine (Cl) atom in one molecule. The chlorinated organic compound is any one of 1,2-dichloroethane, 1,2-dichloropropane, and 1,2-dichloroethylene.

Owner:EUDYNA DEVICES INC

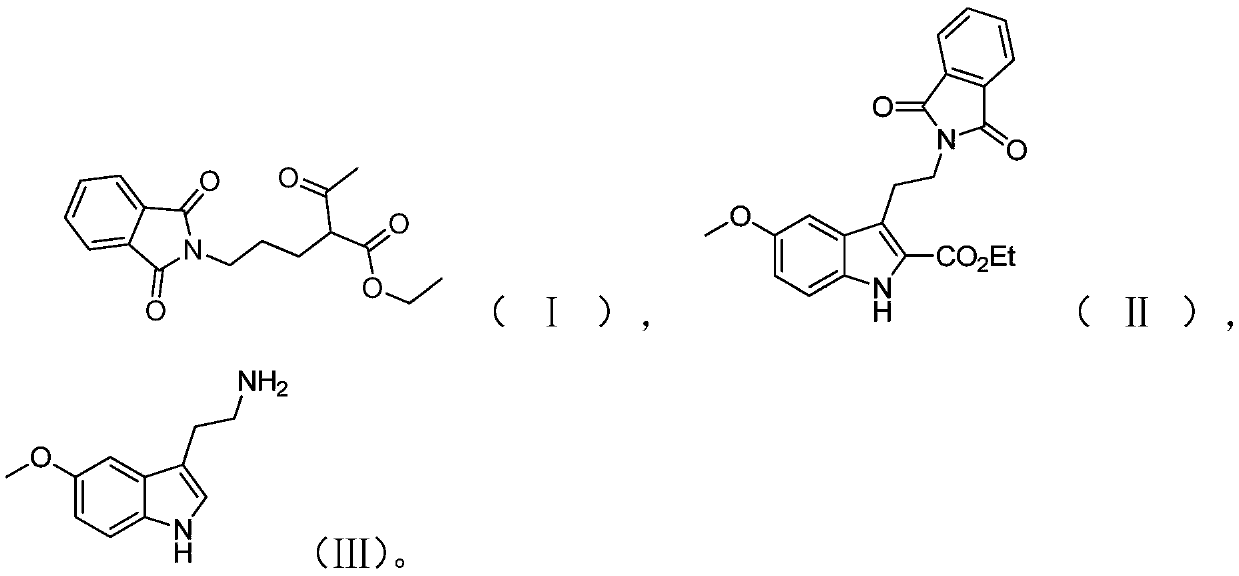

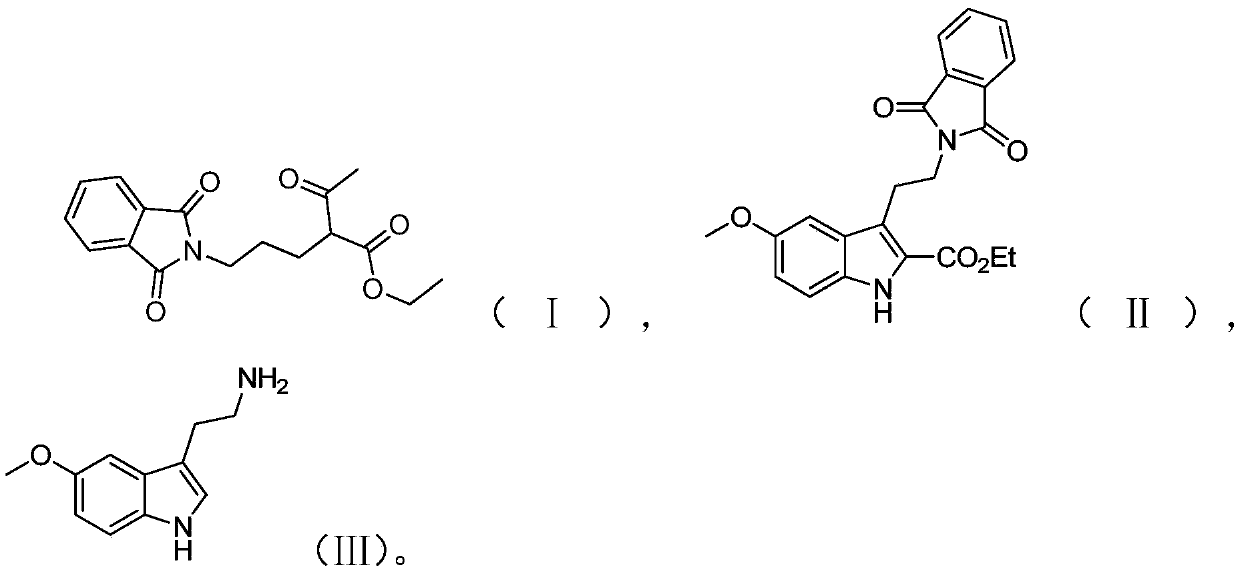

Preparation method of melatonin

The invention relates to the technical field of chemical synthesis of medicines, in particular to a preparation method of melatonin. The preparation method of the melatonin comprises the following steps: (a) subjecting phthalimide, 1,3-dichloropropane, sodium iodide and ethyl acetoacetate to a reaction in a solvent under the action of alkali to obtain a compound I; (b) performing a ring closing reaction on the compound I and p-methoxyphenyl diazonium salt in the presence of alkali and a solvent to obtain a compound II; (c) hydrolyzing the compound II under an alkaline condition, and carrying out decarboxylating under an acidic condition to obtain a compound III; and (d) carrying out an acetylation reaction on the compound III to obtain melatonin. According to the preparation method, phthalimide, 1,3-dichloropropane, ethyl acetoacetate and the like are used as raw materials, and the price of the raw materials is low; the intermediate compound I can be obtained through a one-step method,so reaction steps and time are shortened; moreover, the conditions of each reaction step are relatively mild, the raw materials are easy to obtain, and high yield can be obtained.

Owner:浙江财和生物科技有限公司

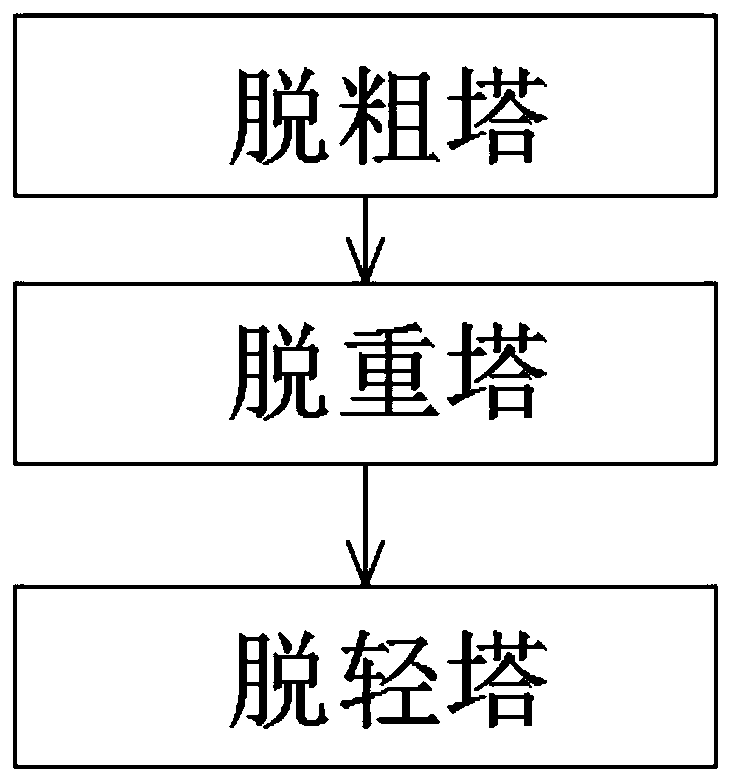

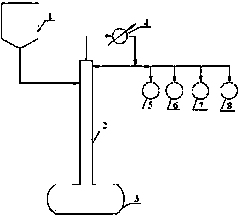

Trans 1, 3-dichloropropene and cis 1, 3-dichloropropene compound, and technological process

PendingCN110498728AHarm reductionReduce disease infectionBiocideAgriculture tools and machinesDichloropropaneChemical products

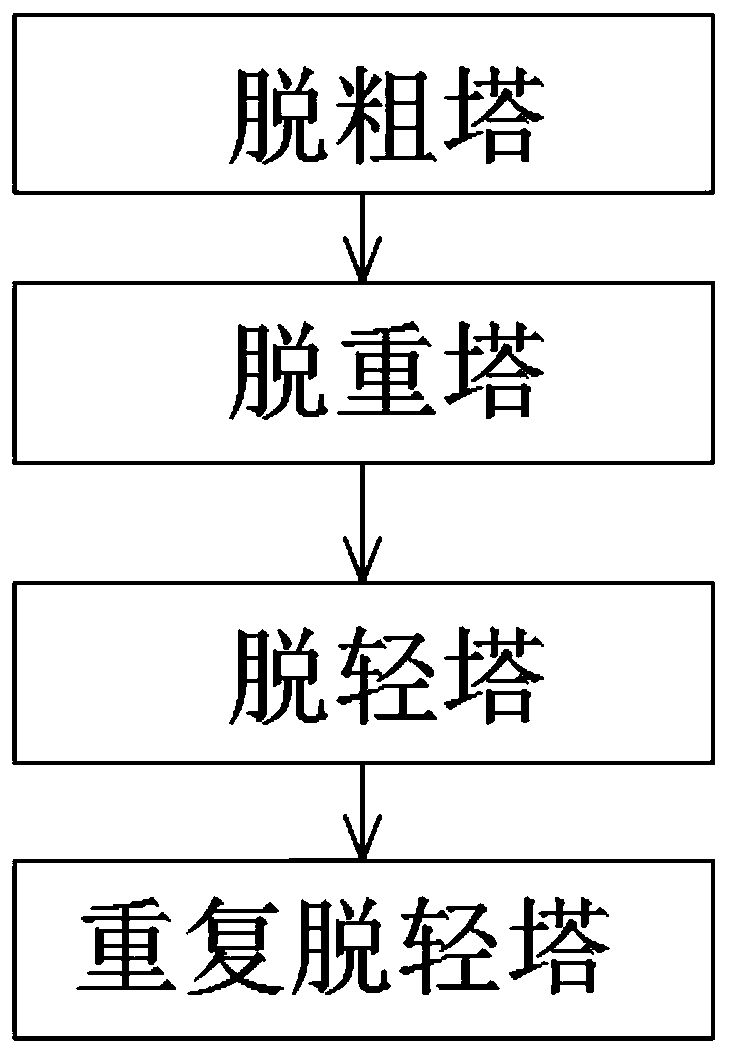

The invention discloses trans 1, 3-dichloropropene and cis 1, 3-dichloropropene compound, and technological process thereof, and belongs to the field of chemical technology. According to the technological process, three column continuous or four column continuous integral technology is adopted, an adopted first column is a crude extracting column, wherein a black raw material DD mixture (industrial dichloropropane) is converted to be white from black in the first column, and then is introduced into a second column; the second column is a weight-removing column, and is used for removing weightfractions in the discolored material obtained after passing of the raw material DD mixture through the crude extracting column, after weight removing, the material is introduced into a third column for production; the third column is a light-removing column, wherein after weight removing, the material is introduced into the third column for light removing, 1, 2-dichloropropene is removed, and sideline discharging is adopted for collection of trans 1, 3-dichloropropene and cis 1, 3-dichloropropene at the same time or collection of only cis 1, 3-dichloropropene; and a fourth column is a repeatlight removing column. Replacement of chemical products which are not beneficial for environmental protection is realized; insect and disease prevention rate is high; and it is beneficial for crop growth.

Owner:湖南莱万特化工有限公司 +1

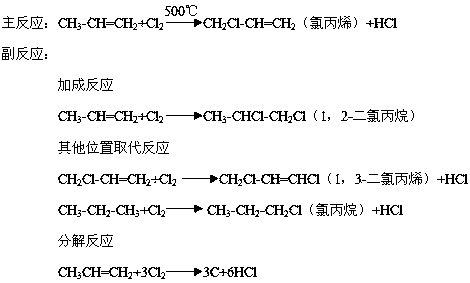

Chlorination process in chloropropene production

InactiveCN103724157ALess side effectsImprove production continuityHalogenated hydrocarbon preparationDichloropropaneWater chlorination

The invention discloses a chlorination process in chloropropene production. The process comprises the following steps: gasifying liquid chlorine through a chlorine evaporator, allowing the chlorine to enter a chlorine buffer tank, metering, and feeding the chlorine into a mixing section of a chlorination reactor; pretreating a raw material propylene, and feeding the propylene into the chlorination reactor to react with the chlorine, wherein the reaction product comprises mixed gas of chloropropene, 1,2-propylene dichloride+1,3-dichloropropene, excessive propylene and hydrogen chloride. The chlorination process is improved, the yield is 85% after improvement, side reactions are reduced, and the production continuity is improved.

Owner:SHANDONG HIYI CHEM TECH

Method for preparing 1-chloropropene by catalytic dehydrochlorination of 1, 2-dichloropropane

ActiveCN107759441APreparation by hydrogen halide split-offMolecular sieve catalystsDichloropropaneMolecular sieve

The invention discloses a method for preparing 1-chloropropene by catalytic dehydrochlorination of 1, 2-dichloropropane. The catalyst comprises an active ingredient and a carrier. The active ingredient is M1-M2-M3, M1 represents a chloride of Fe or Co, M2 represents a compound of Pt or Pd, and M3 represents a chloride of Ce or La. The carrier is gamma-Al2O3, molecular sieve or activated carbon. The method comprises putting the catalyst into a fixed-bed reactor, feeding nitrogen gas into the fixed-bed reactor, heating the nitrogen gas to 300 DEG C, and feeding 1, 2-dichloropropane into the reactor for a reaction at 300-400 DEG C, wherein a nitrogen airspeed is maintained at 500-2000h<-1>. A conversion rate of the raw material 1, 2-dichloropropane is in a range of 85.7% to 90.6% and the selectivity of the 1-chloropropene is 99.2% to 99.6%. A ratio of trans-1-chloropropene to cis-1-chloropropene is 3:1.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for the production of chlorinated propenes

InactiveUS20150344387A1Low costEfficiently dehydrochlorinatedPreparation by hydrogen halide split-off1,2-DichloropropaneDichloropropane

Processes for the production of chlorinated propenes are provided. The present processes make use of 1,2-dichloropropane, a by-product in the production of chlorohydrin, as a low cost starting material. 1,1,1,2,2-pentachloropropane produced by the process is subjected to catalytic dehydrochlorination and build-up of the same within the process is avoided.

Owner:BLUE CUBE IP

Process for the production of chlorinated propenes

InactiveUS20140100394A1Low costHigh selectivityPreparation by hydrogen halide split-offPreparation by halogen addition1,2-DichloropropaneDichloropropane

Processes for the production of chlorinated propenes are provided. The present processes make use of a feedstream comprising 1,2-dichloropropane, a by-product in the production of chlorohydrin, as a low cost starting material, alone or in combination with 1,2,3-trichloropropane. Selectivity of the process is enhanced over conventional processes employing successive chlorinations and / or dehydrochlorinations, by conducting at least one chlorination in the presence of an ionic chlorination catalyst. The present processes may also generate anhydrous HCl as a byproduct that can be removed from the process and used as a feedstock for other processes, providing further time and cost savings.

Owner:BLUE CUBE IP

Waterborne environmental friendly putty

The invention discloses waterborne environmental friendly putty used for priming the surfaces of wood, new materials, stone and the like, the putty comprises the following components by weight percent: 8 percent of novolak, 16 percent of diluent, 63 percent of putty powder, 9 percent of clear water and 4 percent of suspension liquid, the diluent comprises 50 percent of butyl acetate, 10 percent of ethyl acetate, 30 percent of dichloropropane and 10 percent of methyl ethyl ketone, and the putty powder comprises the following components by weight percent: 90 percent of calcium carbonate, 4 percent of calcium sulfate and 6 percent of magnesium silicate. The components are mixed together, the prepared putty is mildly acidic and is used for partially filling and fully filling the surface of a coated and scraped object, the putty can make the object surface smooth, enhance the polishing smoothness and improve the fullness of the object surface, and the operation is simple, safe and reliable.

Owner:ANHUI CHANGLIN ENERGY SAVING MATERIAL TECH

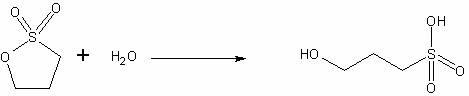

Method for preparing and refining 1,3-propanedisulfonate

InactiveCN102001973AStarting materials are cheapReduce dosageOrganic compound preparationSulfonic acids salts preparationDichloropropaneOrganic solvent

The invention relates to a method for preparing and refining 1,3-propanedisulfonate and aims to solve technical problems of raw material cost reduction, stability, process simplification and product yield improvement. The preparation method is to react 1,3-dichloropropane and sodium sulfite in a reaction solvent to obtain coarse 1,3-propanedisulfonate, wherein the mole ratio of the 1,3-dichloropropane to the sodium sulfite is 1:1-4. The refining method is to dissolve the coarse 1,3-propanedisulfonate in water, add crystallizing agent, namely an organic solvent which can be mixed with water, to obtain 1,3-propanedisulfonate, wherein the amount of water is 2 to 20 times the weight of the coarse 1,3-propanedisulfonate.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Preparation method of 1,2-propane diamine

InactiveCN103012158AThe process steps are simpleNo polluting emissionsAmino preparation by functional substitutionDichloropropaneHigh pressure

The invention discloses a preparation method of 1,2-propane diamine, which comprises the following steps of: adding 1,2-dichloropropane, water, liquid ammonia and a catalyst in a high-pressure reactor, raising the temperature to 160-180 DEG C and the pressure to 8-12MPa, and keeping the conditions for reacting for 4-5h; and sampling for carrying out GC (Gas Chromatograph) detection, completely reacting the 1,2-dichloropropane, cooling a reaction system to 20-25 DEG C, discharging excessive ammonia gas, preparing a mixture using the 1,2-propane diamine as a main component, and rectifying the 1,2-propane diamine to obtain a finished product. According to the preparation method, the process steps are greatly simplified, pollution emission does not exist basically, and the cost is lowered. Excessive ammonia after the reaction is ended can be recycled, and the preparation process can be completed in one high-pressure reactor, so that the investment and production efficiency of equipment are greatly reduced. According to the invention, complete reaction can be completed by adopting one catalyst, and low distillates obtained after rectification can be used as raw materials for recycling, so that the selectivity of the 1,2-propane diamine is greatly increased.

Owner:张家港市大伟助剂有限公司

Multipurpose adhesive

The invention relates to a multipurpose adhesive. The multipurpose adhesive is specifically prepared from the following components in parts by mass: 35 to 45 parts of chloroprene rubber, 10 to 15 parts of styrene, 25 to 40 parts of waterborne polyurethane resin, 2 to 5 parts of a dispersant, 5 to 8 parts of toluene, 3 to 9 parts of dimethyl carbonate, 1 to 4 parts of dichloropropane, 35 to 40 parts of methyl methacrylate, 1 to 4 parts of an emulsifier and 0.07 to 0.2 part of a catalyst. An experiment shows that the multipurpose adhesive provided by the invention has the characteristics that the dynamic viscosity is 9.7Pa.s or more and the peeling strength is 6.1kg / 25mm or more; an existing multipurpose adhesive has the characteristics that the dynamic viscosity only can reach 8.9Pa.s and the peeling strength is only 4.9kg / 25mm; it can be seen that adhering performances including the viscosity, the peeling strength and the like of the adhesive are greatly improved through improving raw materials and a production process of the adhesive; the multipurpose adhesive has a remarkable effect and a wide market prospect.

Owner:佛山市高明大都化工有限公司

Process for preparing aminomethylated bead polymers

ActiveUS20160108199A1High yieldComplex ion-exchangersAnion exchangersDichloropropane1,3-Dichloropropane

Aminomethylated bead polymers for use as ion exchangers, especially as anion exchangers, or for the preparation of chelate resins, are prepared in the presence of 1,3-dichloropropane as solvent and swelling agent

Owner:LANXESS DEUTDCHLAND GMBH

Method of separating 1,2-dichloropropane with DD mixture

InactiveCN1847205AOrganic compound preparationCarboxylic acid esters preparationDichloropropaneMethacrylate

The process of separating 1, 2-dichloropropane from DD mixture has the 1, 3-trichloropropane in DD mixture reacted with acrylic acid or methacrylic acid, alkali, catalyst and polymerization inhibitor to convert into 3-chloro-2-propenyl acrylate or 3-chloro-2-propenyl-2-methacrylate with boiling point different obviously to that of 1, 2-trichloropropane and distilled for separation from 1, 2-dichloropropane. The technological process includes the steps of: pre-treatment of the material, catalytic esterification reaction, and product separation. The present invention provides one comprehensive utilizing way of DD mixture, and the separated 1, 2-dichloropropane is one important organic intermediate and solvent.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Plastic-rubber high molecular composite synthetic resin adhesive

InactiveCN102816543AHigh bonding strengthStrong adhesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerDichloropropane

The invention relates to a plastic-rubber high molecular composite synthetic resin adhesive which comprises the following components: para-tertiary butyl phenol-formaldehyde resin, chloroprene rubber, magnesium oxide, C5 / C9 copolymerized petroleum resin, BTH (butylated hydroxytoluene) antioxidant, methyl acetate (refined), ethyl acetate, dichloropropane, methylbenzene and 120#solvent oil. On the basis of giving a full play to the advantages of the phenol-formaldehyde synthetic resin, the magnesium oxide is added and the chloroprene rubber linear high molecular material and the C5 / C9 copolymerized petroleum resin having high adhesion property and good heat resistance are introduced to perform grafting, chelation and other high molecular reactions on the molecular structure so as to form a copolymer with the phenol-formaldehyde resin, thus obtaining the plastic-rubber high molecular composite high-performance synthetic resin adhesive having multiple comprehensive performances. The plastic-rubber high molecular composite synthetic resin adhesive has high bonding strength and good water resistance, heat resistance and chemical stability, and has the composite high performances of a plastic-rubber high molecular elastomer such as pliability, flexibility and the like.

Owner:广东金万得胶粘剂有限公司

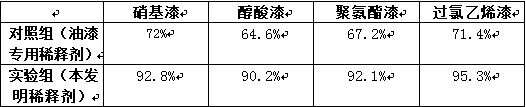

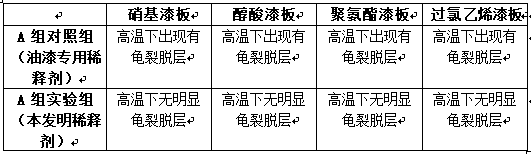

Multi-purpose paint diluting agent and preparation technology thereof

The invention discloses a multi-purpose paint diluting agent and a preparation technology thereof. The multi-purpose paint diluting agent is prepared from the following raw materials: ethylene glycolmonoethyl ether acetate, dichloropropane, pentaerythritol, cyclohexanone, tetrabutyl orthosilicate, ethyl cellosolve, diethoxymethane, methyl isopropyl ketone, turpentine and isophoron. The paint diluting agent prepared by the preparation technology does not contain benzene toxic substances, is safe and has no toxin, and has good stability and strong dissolubility; various types of paint can be dissolved through the multi-purpose paint diluting agent; the production flow is simple, the production cost is low and no three wastes are discharged, so that the multi-purpose paint diluting agent hasa good application prospect.

Owner:韩立志

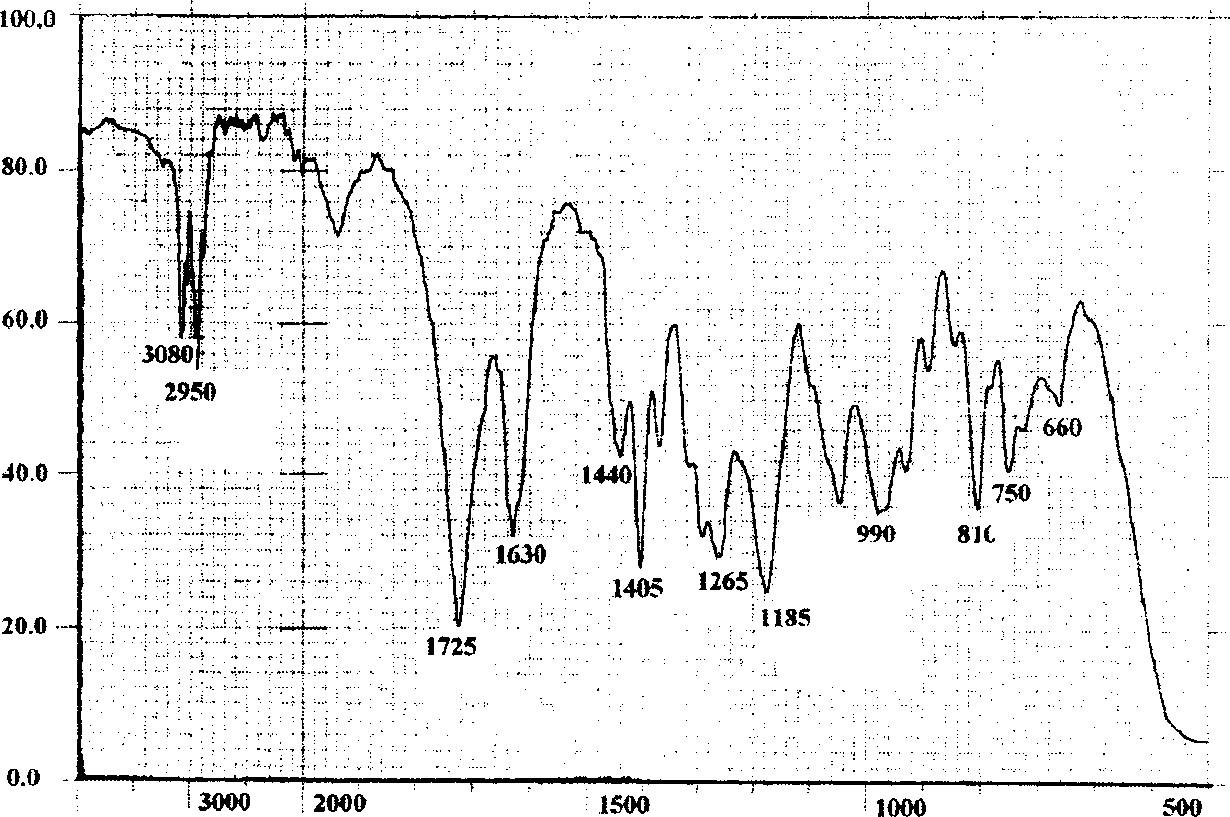

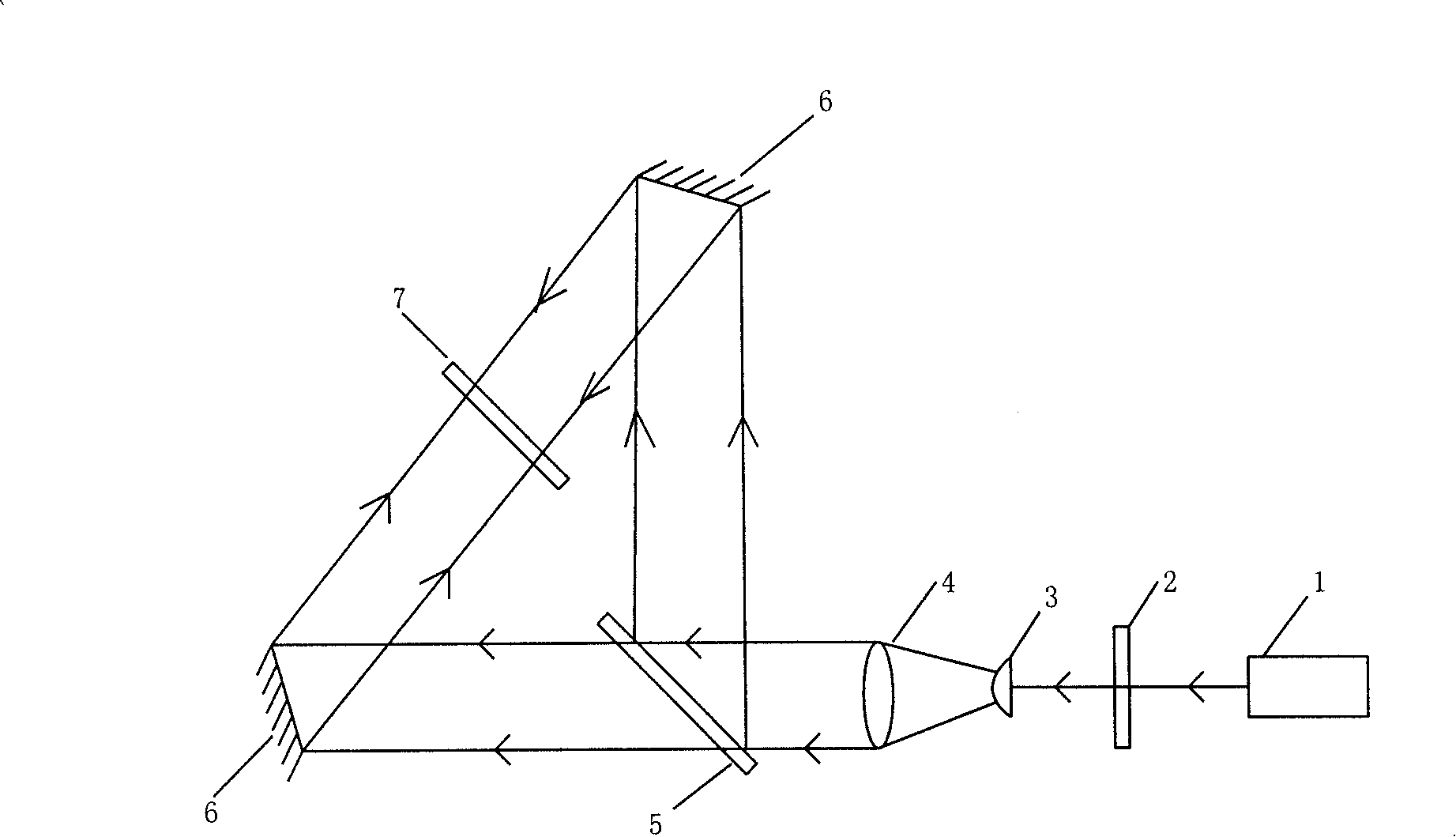

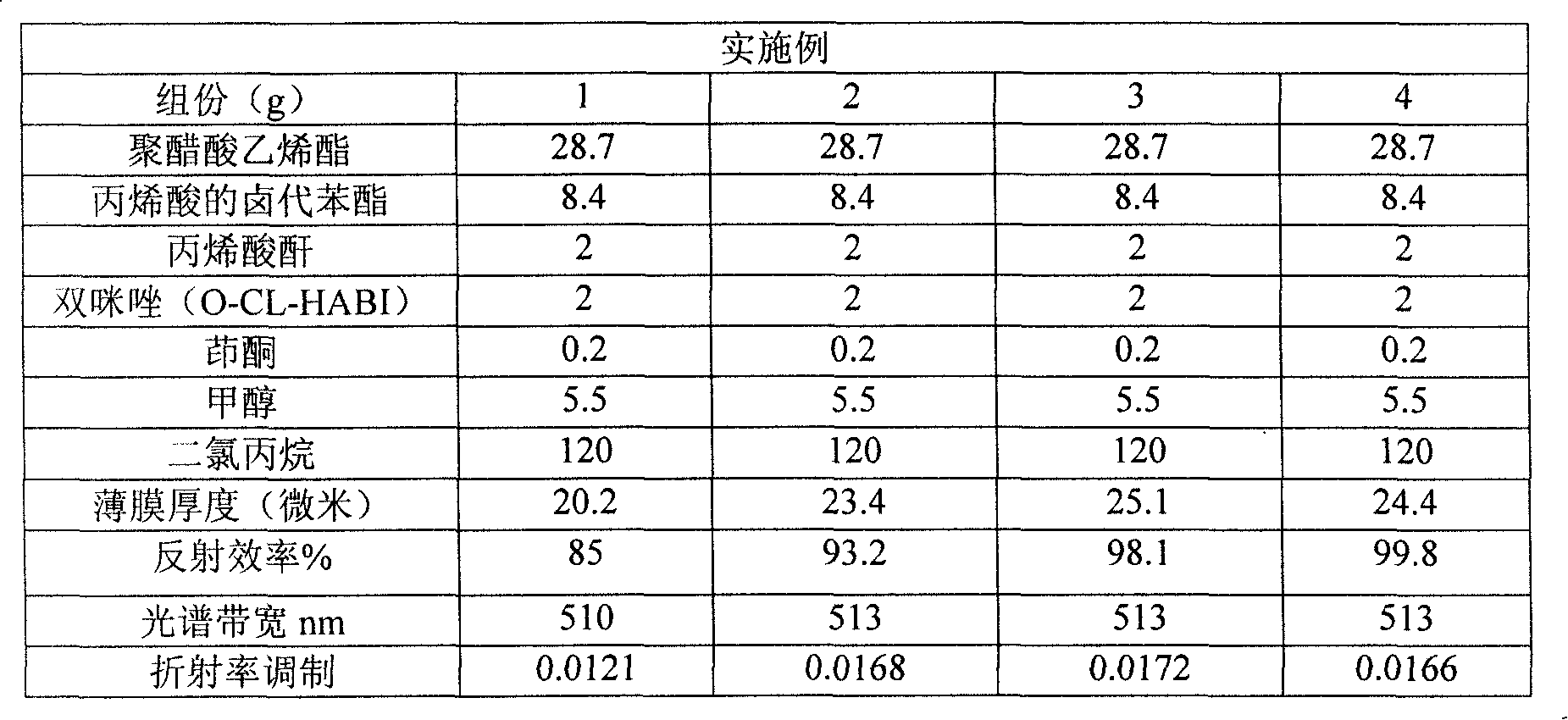

Preparation of hologram reflection-type photo-induced polyalcohol dry film

InactiveCN101231362APolyhalogenated compound compositionsPhotographic processesDichloropropanePolymer science

The invention relates to a holographic reflection type photopolymer film composition and preparation method thereof. The preparation method comprises the following steps of dissolving indenone, bis-imidazole (O-CL-HABI), polyvinyl acetate and acrylic anhydride in a dichloropropane / methanol mixed solution under red light condition, coating the obtained solution on transparent PETG (poly(ethylene terephthlate-co-cyclohexanedimethyllene terephthalate), and thermosetting in a convection thermostat. The film of the invention has very high diffraction efficiency and good light transmission performance, overcomes the disadvantages of the material prepared by the prior art including poor storage durability and easy fading away, and effectively solves problems of raw material including oversensitivity to ambient humidity and high volatility.

Owner:李妤 +1

Batch extractive distillation and separation method for ethanol-benzene azeotrope

InactiveCN103351276AFlexible operationReduce cost inputOrganic compound preparationDistillation purification/separationDichloropropane1,2-Dichloropropane

The invention discloses a batch extractive distillation and separation method for ethanol-benzene azeotrope, and belongs to the separation technology of ethanol-benzene azeotrope. The method adopts halogenated hydrocarbon or aromatic hydrocarbon, which contains two or more halogen substituents such as 1,2-dichloropropane, 1,2,3-trichloropropane, o dichlorobenzene, and 1,2,3-trichloro-benzenes, as the extractant. Operation condition of extractive distillation column is that the mass ratio of extractant to overhead is in the range of 0.5:1 to 10:1. Ethanol, ethanol-benzene transition section I, benzene, and benzene-benzene extractant transition section II are respectively extracted from the top of the extractive distillation column by controlling different temperature and different reflux ratio of the top of the extractive distillation column. When the composition of the extractant in the bottom of the column meets the requirement, the extractant is pumped into a high-position storage tank for recycling. The batch extractive distillation and separation method for ethanol-benzene azeotrope has the advantages that ethanol-benzene azeotropic system is broken by extractant, so high-pure ethanol and benzene products are extracted, operation of single column is simple, and equipment cost is low.

Owner:UNIV OF JINAN

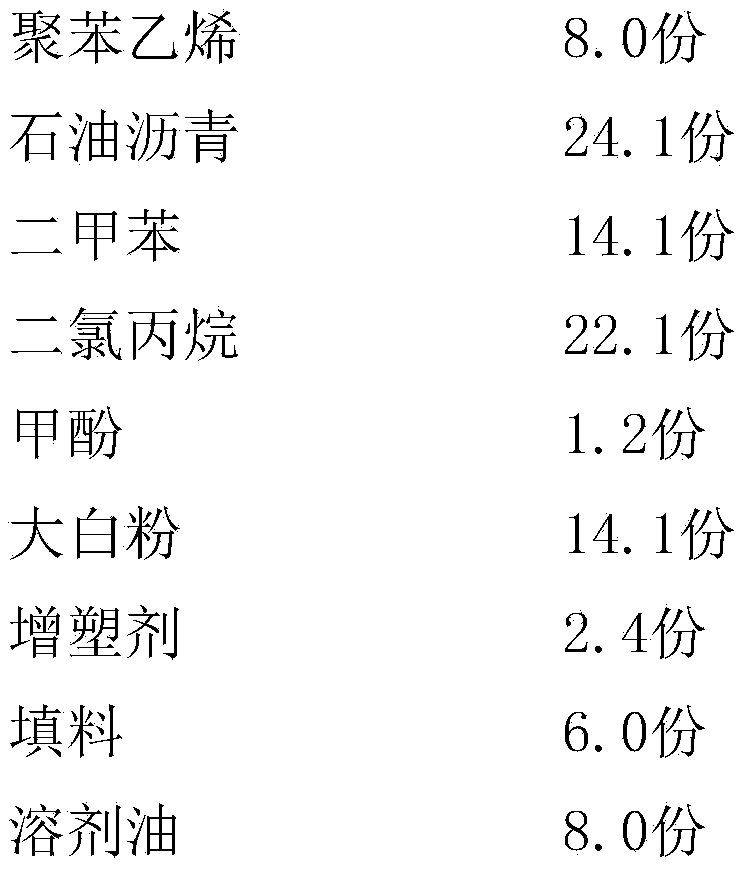

Preparation method of solvent-type polystyrene modified asphalt waterproof paint

InactiveCN104109478AHigh purityEasy to useBituminous coatingsDichloropropaneBituminous waterproofing

The invention discloses a preparation method of a solvent-type polystyrene modified asphalt waterproof paint, and relates to the technical field of chemical engineering. The paint is composed of the following raw materials in parts by weight: 7.9 to 8.1 parts of polystyrene, 24.0 to 24.2 parts of petroleum asphalt, 14.0 to 14.2 parts of xylene, 22.0 to 22.2 parts of dichloropropane, 1.1 to 1.3 parts of methylphenol, 14.0 to 14.2 parts of talcum powder, 2.3 to 2.5 parts of plasticizer, 5.9 to 6.1 part of stuffing material, and 7.9 to 8.1 parts of solvent oil. The preparation method has the advantages of simpleness, convenience, available raw materials, little equipment investment, and convenient operation. The prepared solvent-type polystyrene modified asphalt waterproof paint has the advantages of environment-friendliness, no pollution, high purity, good using effect, strong high-temperature resistant performance, safety, and reliability.

Owner:ANHUI PIONEER DOOR IND TECH

Environment-friendly diluent

The invention relates to an environment-friendly diluent which is characterized in that the diluent is prepared from 50-60kg of dichloropropane, 30-40kg of methylal, and 0-20kg of isophorone. The environment-friendly diluent is suitable to be used in epoxy wood coating primers. The diluent is advantaged in fast-dying paint film, easy polishing, low energy consumption, and low production cost. As a result of SGS testing, the product satisfies requirements by European Union ROHS directive 2002 / 95 / CE and subsequent directives.

Owner:张西华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com