Trans 1, 3-dichloropropene and cis 1, 3-dichloropropene compound, and technological process

A technology of dichloropropene and technological process, applied in fertilizer mixture, organic chemistry, biocide and other directions, can solve the problems of difficult control operation, large loss of agricultural production, large control dosage, etc., to reduce the harm of nematodes, promote the Strong root system, the effect of inhibiting soil-borne diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

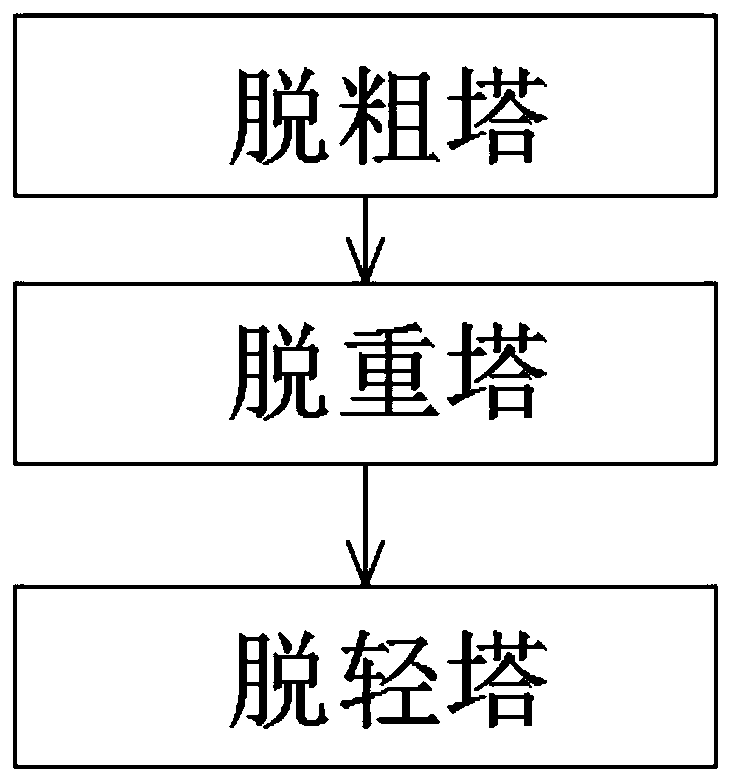

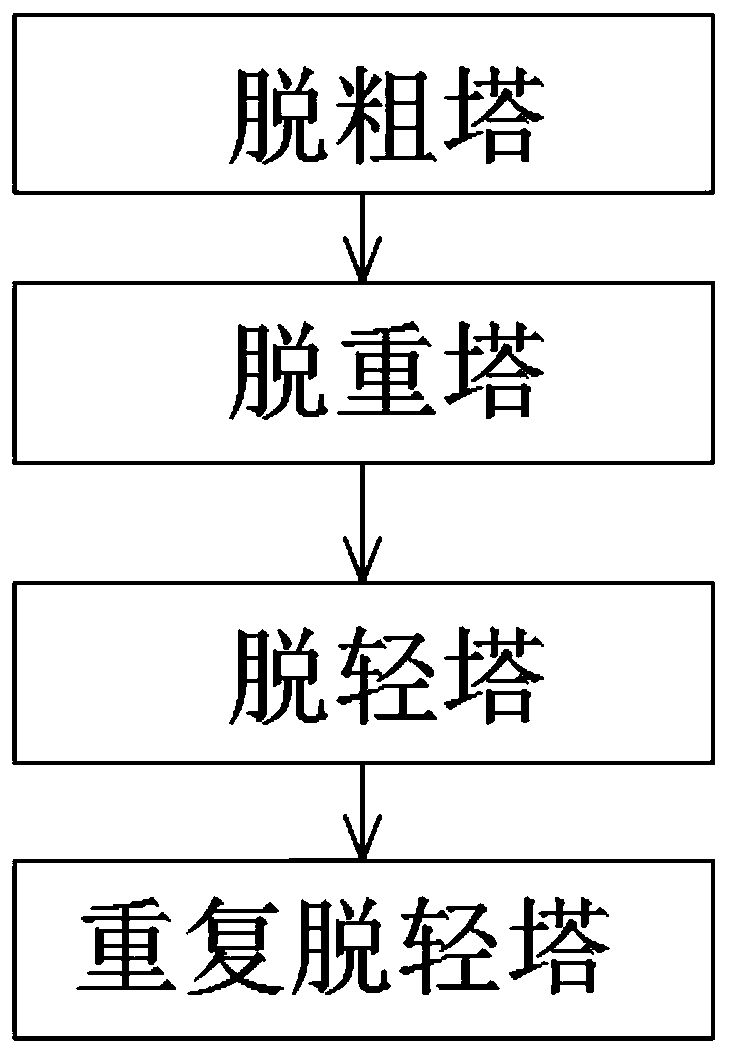

[0033] The trans-1,3-dichloropropene and cis-1,3-dichloropropene compounds and their technical process described in this embodiment adopt a three-tower continuous overall process, including the following steps:

[0034] The concrete operation of technological process of the present invention is as follows:

[0035] a. Crude dichloropropene is driven into a raw material storage tank in the tank area by an unloading pump, and mixed by an unloading pump and a pipeline static mixer; the crude dichloropropene in the tank area is sent into the rough stripping tower through a feed pump, and the liquid part of the tower still The circulation pump is used to automatically circulate the gas and liquid through the reboiler of the roughing tower, and part of the heavy components are pumped out through the flow control of the bottom pump of the roughing tower. -0.095MPa); after the tower top gas is condensed (temperature 40-66.8°C), the absolute pressure is 0.029-0.096MPa (gauge pressure -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com