Method for preparing and refining 1,3-propanedisulfonate

A kind of technology of sodium propanedisulfonate and purification method, which is applied in the field of preparation and purification of 1,3-sodium propanedisulfonate, and achieves the effects of low cost, high yield and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

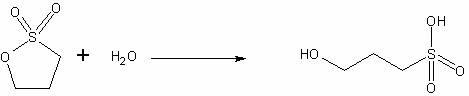

Image

Examples

Embodiment 1

[0040] Add 150 g of deionized water and 11.3 g (0.10 mol) of 1,3-dichloropropane into the reaction flask, stir, and add 25.2 g (0.20 mol) of anhydrous sodium sulfite for 8 hours. Cool to room temperature, add 300ml of absolute ethanol, stir for 30min, let stand for 2hr, filter with suction, wash the filter cake with a small amount of ethanol, and dry in vacuum to obtain 23.6g of crude sodium 1,3-propanedisulfonate (white solid), The content is 95.6%.

Embodiment 2

[0042] Add 150 g of deionized water and 11.3 g (0.10 mol) of 1,3-dichloropropane into the reaction flask, stir, add 30.3 g (0.24 mol) of anhydrous sodium sulfite, and reflux for 8 hours. Cool to room temperature, add 250ml of absolute ethanol, stir for 30min, let stand for 2hr, filter with suction, wash the filter cake with a small amount of ethanol, and dry it in vacuum to obtain crude sodium 1,3-propanedisulfonate, yield 22.4g, content 89.3%.

Embodiment 3

[0044] Add 150 g of deionized water and 11.3 g (0.10 mol) of 1,3-dichloropropane into the reaction flask, stir, add 20.1 g (0.16 mol) of anhydrous sodium sulfite, and reflux for 8 hours. Cool to room temperature, add 400ml of absolute ethanol, stir for 30min, let stand for 2hr, filter with suction, wash the filter cake with a small amount of ethanol, and dry in vacuum to obtain 20.4 crude sodium 1,3-propanedisulfonate with a content of 97.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com