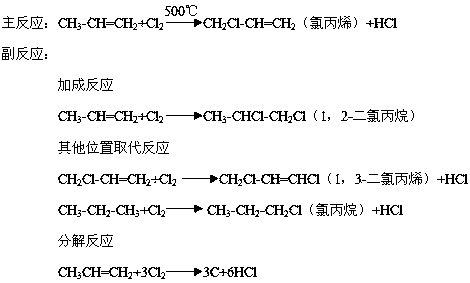

Chlorination process in chloropropene production

A technology of allyl chloride and propylene, applied in the field of allyl chloride production, which can solve the problems of low production continuity and many side reactions, and achieve the effect of improving production continuity and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The chlorination process in the production of chloropropene of the present invention, concrete steps are:

[0025] (1) After the liquid chlorine is vaporized by the chlorine evaporator, it enters the chlorine buffer tank and is sent to the mixing section of the chlorination reactor; the chlorine evaporator is heated by 0.4MPa low-pressure steam.

[0026] (2) The water content of raw material propylene is less than 10ppm, and it is divided into two paths together with the recovered propylene in the dry propylene tank. After mutual heat exchange in the propylene subcooler, one path is decondensed and evaporated to the top of the tower for spray cooling, and the other path passes through the chloride The cooler cools the reaction material entering the condensing and steaming tower, and vaporizes itself and then enters the vaporizer, and then enters the propylene buffer tank after being completely vaporized;

[0027] (3) In the heat exchanger, the reaction material from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com