Supercritical carbon dioxide coal-fired circulating fluidized bed boiler, power generation system and power generation method

A circulating fluidized bed, carbon dioxide technology, applied in the combustion method, fluidized bed combustion equipment, fuel burning in the molten state, etc., can solve the problem of low system flexibility, limited high temperature strength, high temperature oxidation corrosion resistance, and investment cost. Improve heat transfer and control wall temperature, ensure safe and reliable operation, and improve power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

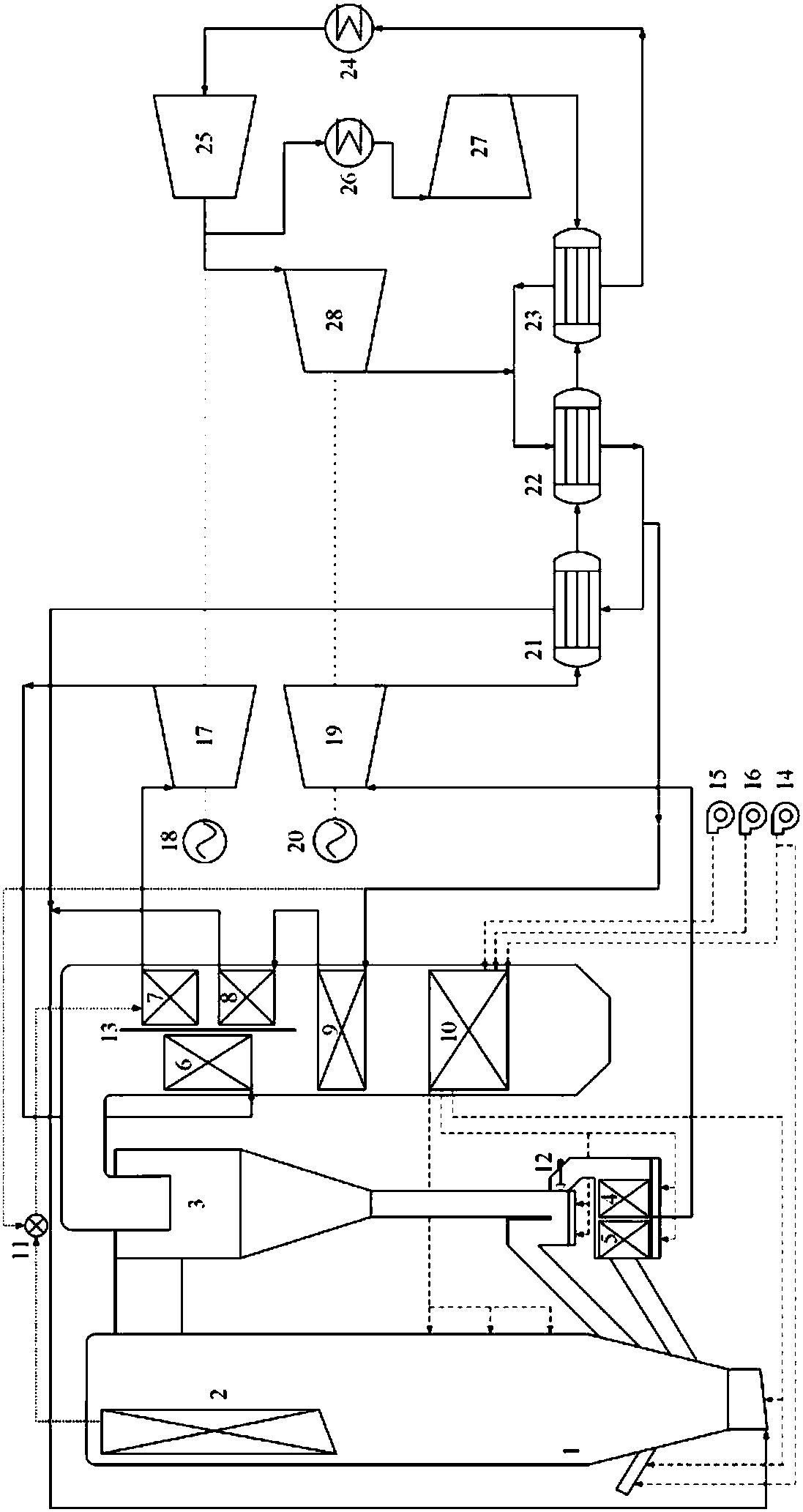

[0032] Circulating fluidized bed boiler high-temperature superheater 7 outlet 28Mpa, 600 ℃ high-temperature, high-pressure supercritical carbon dioxide working fluid enters high-pressure turbine 17 and expands to do work to 12.3Mpa, 493 ℃, then enters low-temperature reheater 6, high-temperature reheater 4 Reheat to 620°C, then enter the low-pressure turbine 19 to expand and do work to 5.35Mpa, at 515°C, the exhaust gas from the outlet of the low-pressure turbine 19 enters the low-pressure side of the high-temperature regenerator 21, the low-pressure side of the medium-temperature regenerator 22, and the low-temperature regenerator 23 The low-pressure side is cooled, and then enters the pre-cooler 24 to cool to 32°C, and is compressed by the pre-compressor 25 to 7.65Mpa at 67°C. About 41.7% of the working fluid enters the re-compressor 28 and is compressed to 28.6Mpa at 188°C. Part of the working fluid enters the intercooler 26 to cool to 32°C, is compressed by the main compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com