Rapid production method of bow-shaped water tube boiler

A production method and a bow-shaped water tube technology are applied in the field of rapid production of bow-shaped water tube boilers, which can solve the problems of lowering fuel thermal efficiency, inconvenient use and management, and large floor space, so as to improve operating efficiency and economy, reduce thermal deviation and The effect of steam temperature deviation and preventing local metal overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1. A kind of bow-shaped water tube boiler rapid production method comprises the following steps:

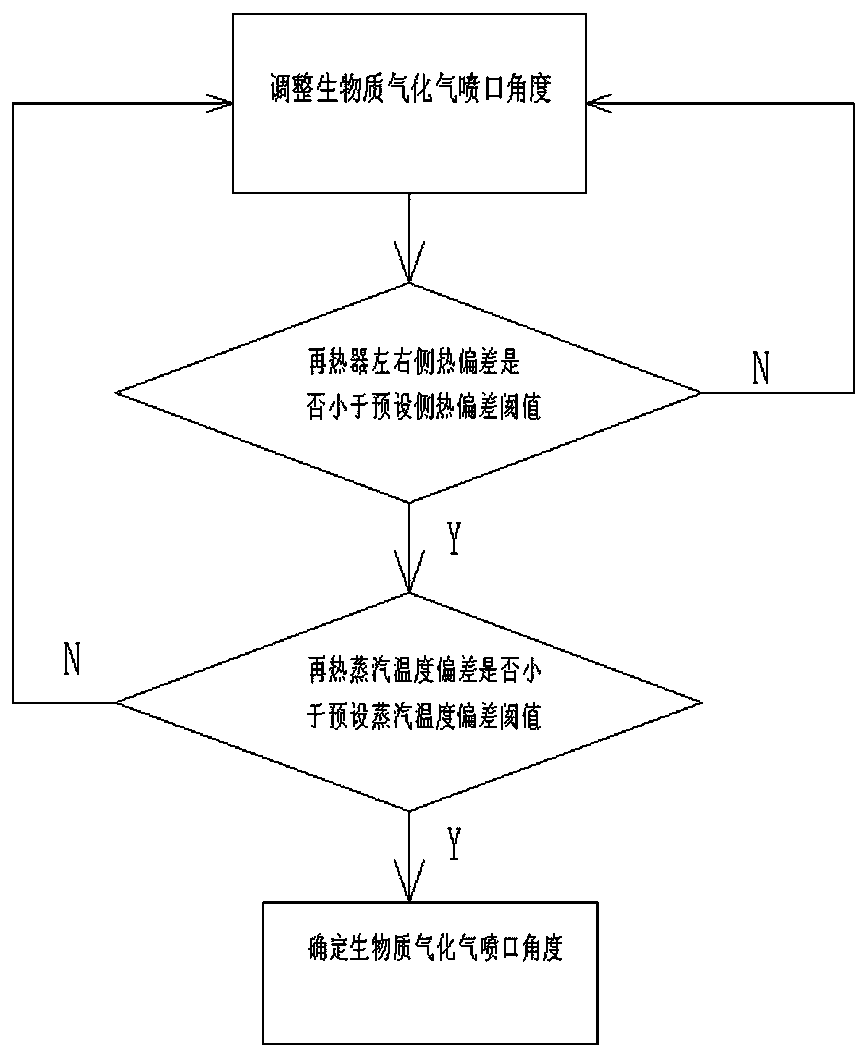

[0031] 1) Determine the angle of the nozzle of the biomass gasification gas. The injection angle formed by the biomass gasification gas nozzle and the furnace wall in the upper circle is 80±2°, and the injection angle formed by the biomass gasification gas nozzle and the furnace wall in the lower circle is The angle is 70±2°;

[0032] 2) The primary air is blown in from the bottom of the boiler furnace, and the primary air is composed of the air blown in by the blower and the flue gas recycled by the chimney;

[0033] 3) On the upper part of the secondary air inlet of the boiler wall, a biomass gasification gas nozzle is arranged. In the main combustion area of the boiler, the secondary air is mixed with the biomass powder to carry out high-temperature combustion, and the high-temperature combustion of the biomass powder It is further mixed with the biomass g...

Embodiment 2

[0041] Embodiment 2. A kind of bow-shaped water tube boiler rapid production method comprises the following steps:

[0042] 1) Determine the angle of the nozzle of the biomass gasification gas. The injection angle formed by the biomass gasification gas nozzle and the furnace wall in the upper circle is 75±2°, and the injection angle formed by the biomass gasification gas nozzle and the furnace wall in the lower circle is The angle is 60±2°;

[0043] 2) The primary air is blown in from the bottom of the boiler furnace, and the primary air is composed of the air blown in by the blower and the flue gas recycled by the chimney;

[0044] 3) On the upper part of the secondary air inlet of the boiler wall, a biomass gasification gas nozzle is arranged. In the main combustion area of the boiler, the secondary air is mixed with the biomass powder to carry out high-temperature combustion, and the high-temperature combustion of the biomass powder It is further mixed with the biomass g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com