Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Water-tube boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A high pressure watertube boiler (also spelled water-tube and water tube) is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which heats water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam.

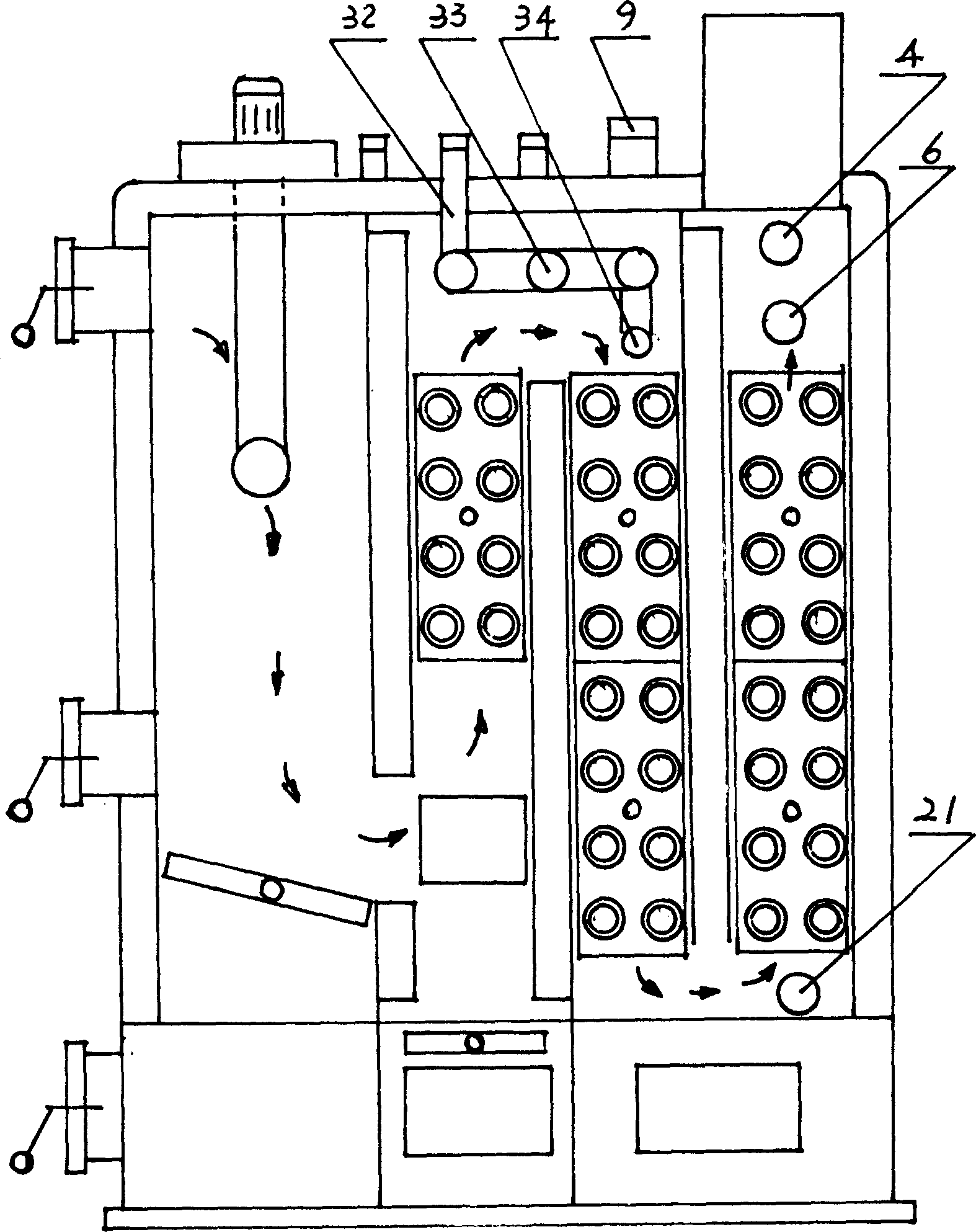

Biomass boiler

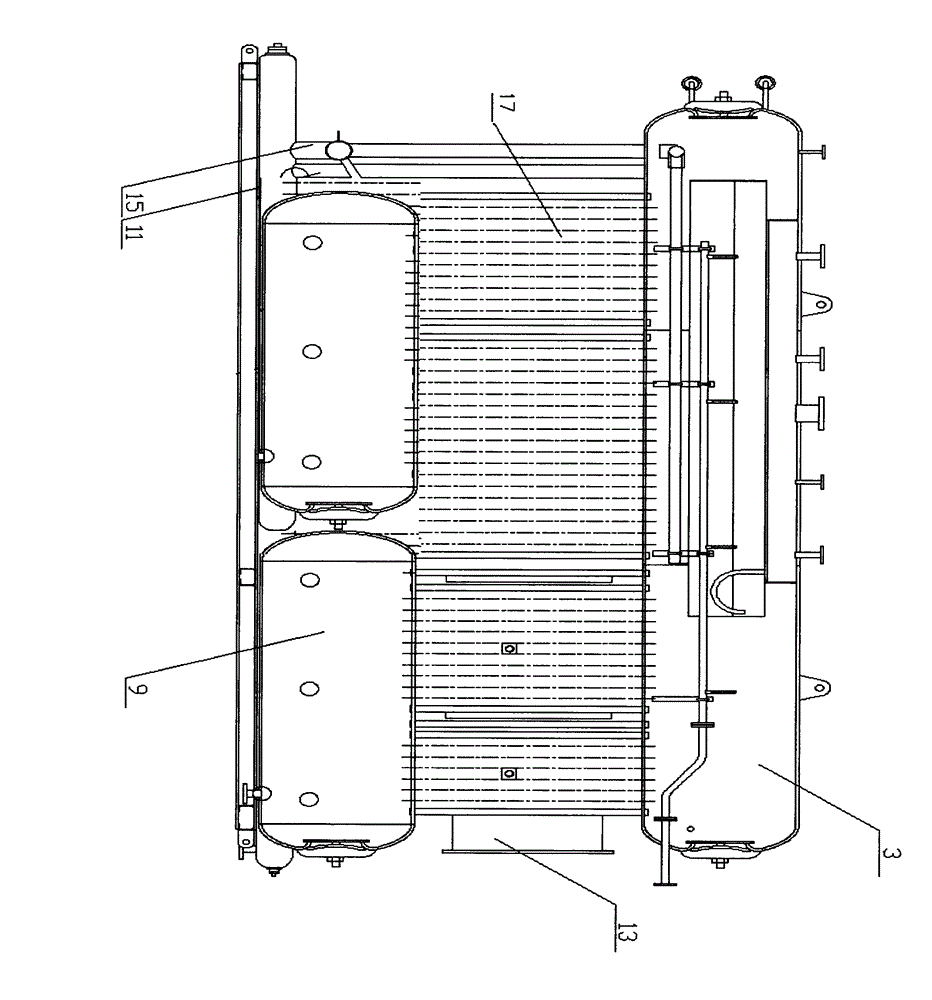

InactiveCN102913889ALess heat storageReduce lossesBoiler water tubesWater-tube boilersRefractoryPulp and paper industry

The invention relates to a biomass boiler. The biomass boiler comprises a base plate, an upper boiler, two lower boilers and a controller, wherein the two lower boilers are arranged end to end and connected with each other through a pipeline. The novel structure of the biomass boiler causes less heat accumulation of a furnace wall, so that construction for a thick furnace wall can be avoided when the biomass boiler is arranged, a refractory material can be saved or used fewer, the cost can be reduced, the arrangement cost can be reduced, and the arrangement complexity can be reduced. Therefore, the biomass boiler is simple in structure and convenient in use, can reduce the arrangement and complexity of a water-tube boiler can be effectively reduced, the boiler heat is prevented from losing, and the heat efficiency of the water-tube boiler can be improved.

Owner:青岛华泰锅炉热电设备有限公司

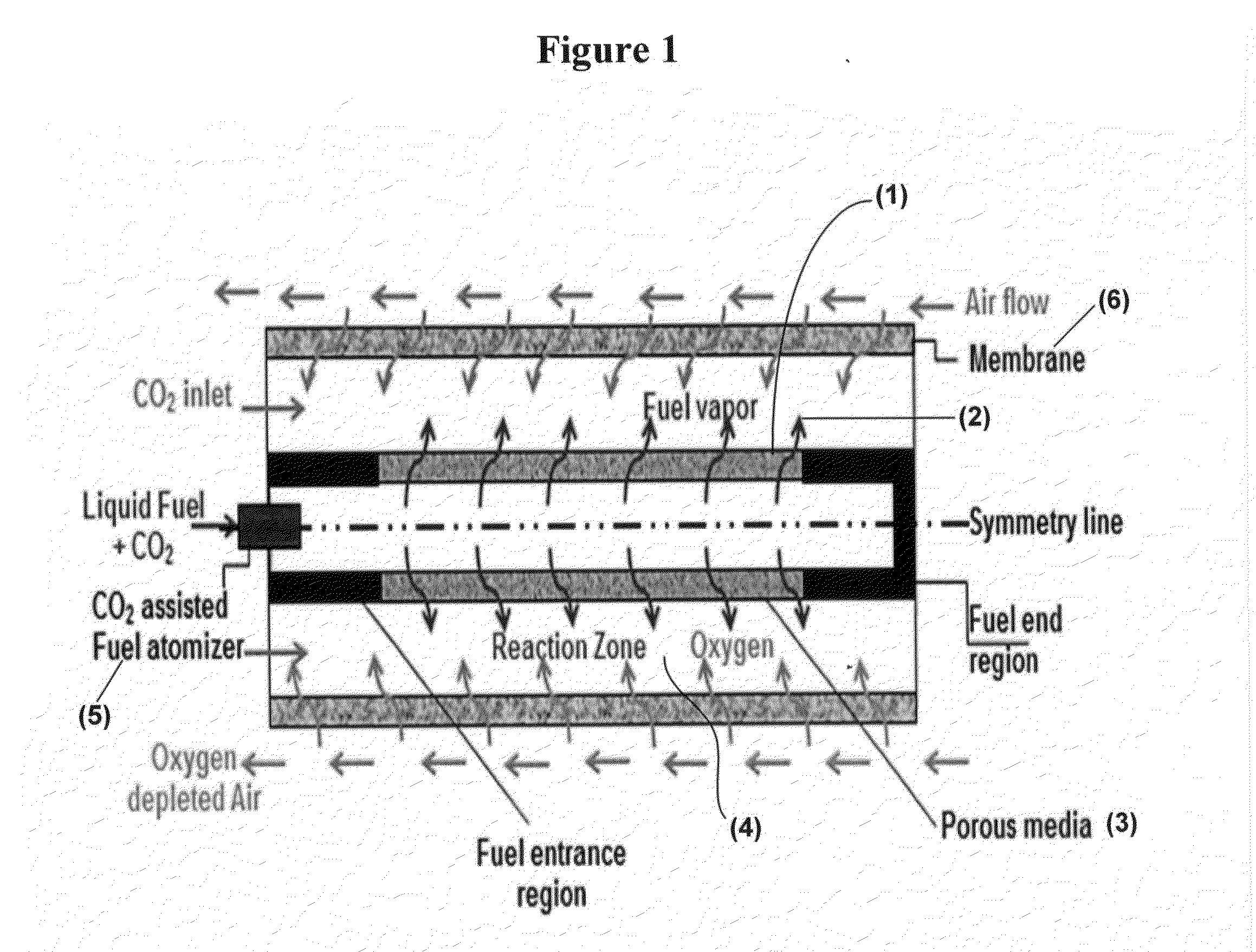

Carbon-free low-nox liquid fuel oxygen transport rector for industrial water tube boilers

ActiveUS20150176487A1Combustion using gaseous and pulverulent fuelSemi-permeable membranesSmall dropletLiquid fuel

An oxygen transport reactor for boiler furnaces and gas turbine combustors that utilizes a liquid fuel that is oxidized as a gaseous fuel in a membrane reactor. A liquid fuel is introduced by vaporizing the fuel inside a porous pipe surrounded by an annulus reaction zone which is surrounded by an annulus air zone. An oxygen transport membrane separates the annulus reaction zone containing the porous vaporized fuel and sweeping CO2 from the air feed side zone. Oxygen is transported from the outer annulus through the membrane to the annulus reaction zone containing the vaporized fuel and sweeping CO2. Fuel is first cracked to very small droplets in the intake fuel atomizer utilizing part of the intake CO2 then completely vaporized inside the porous pipe utilizing the heat coming from the surrounding reaction zone. The oxygen transport reactor is applicable for carbon free boiler furnaces and gas turbine combustors which utilize oxygen transport reactors for combined oxygen separation and combustion.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

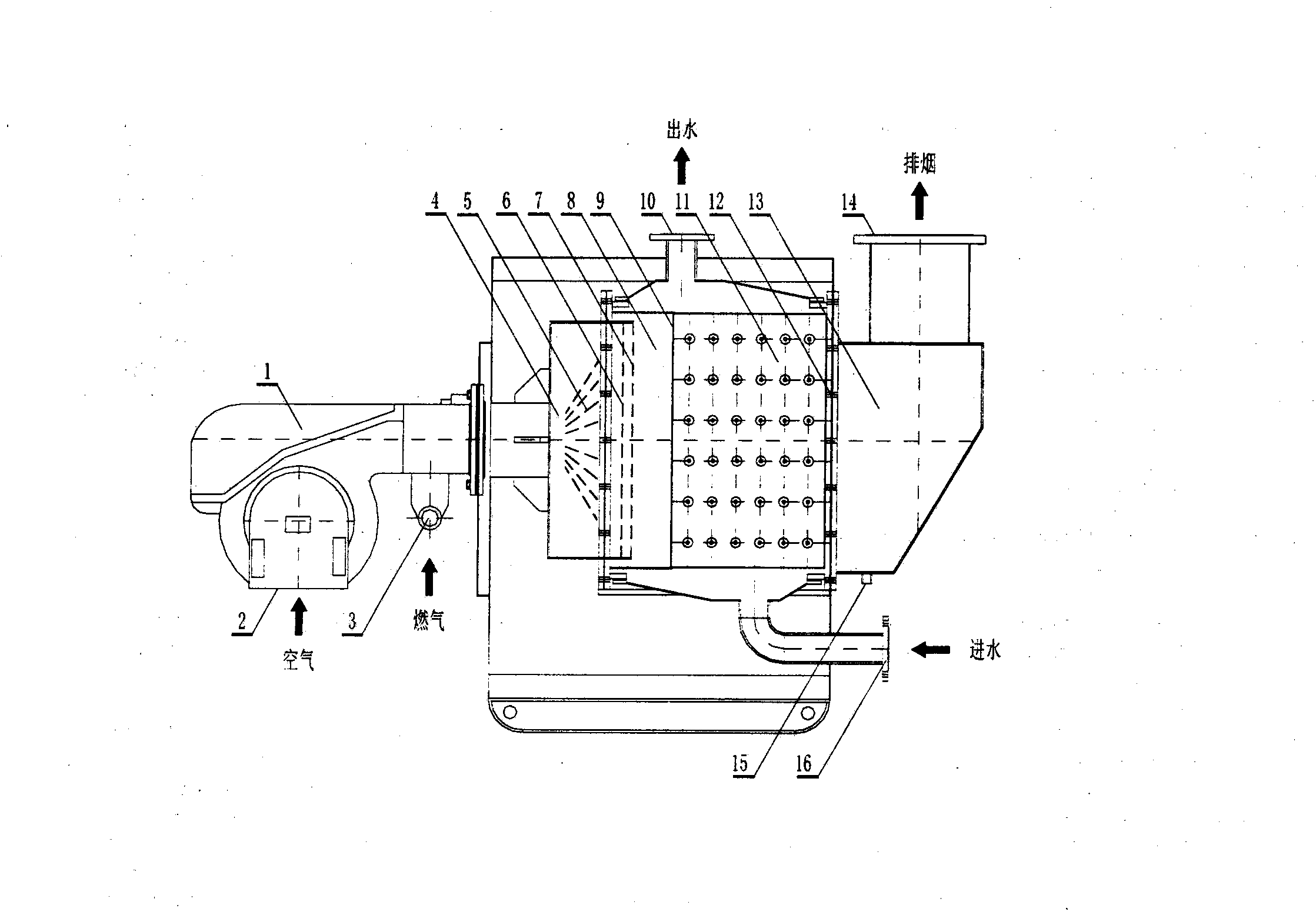

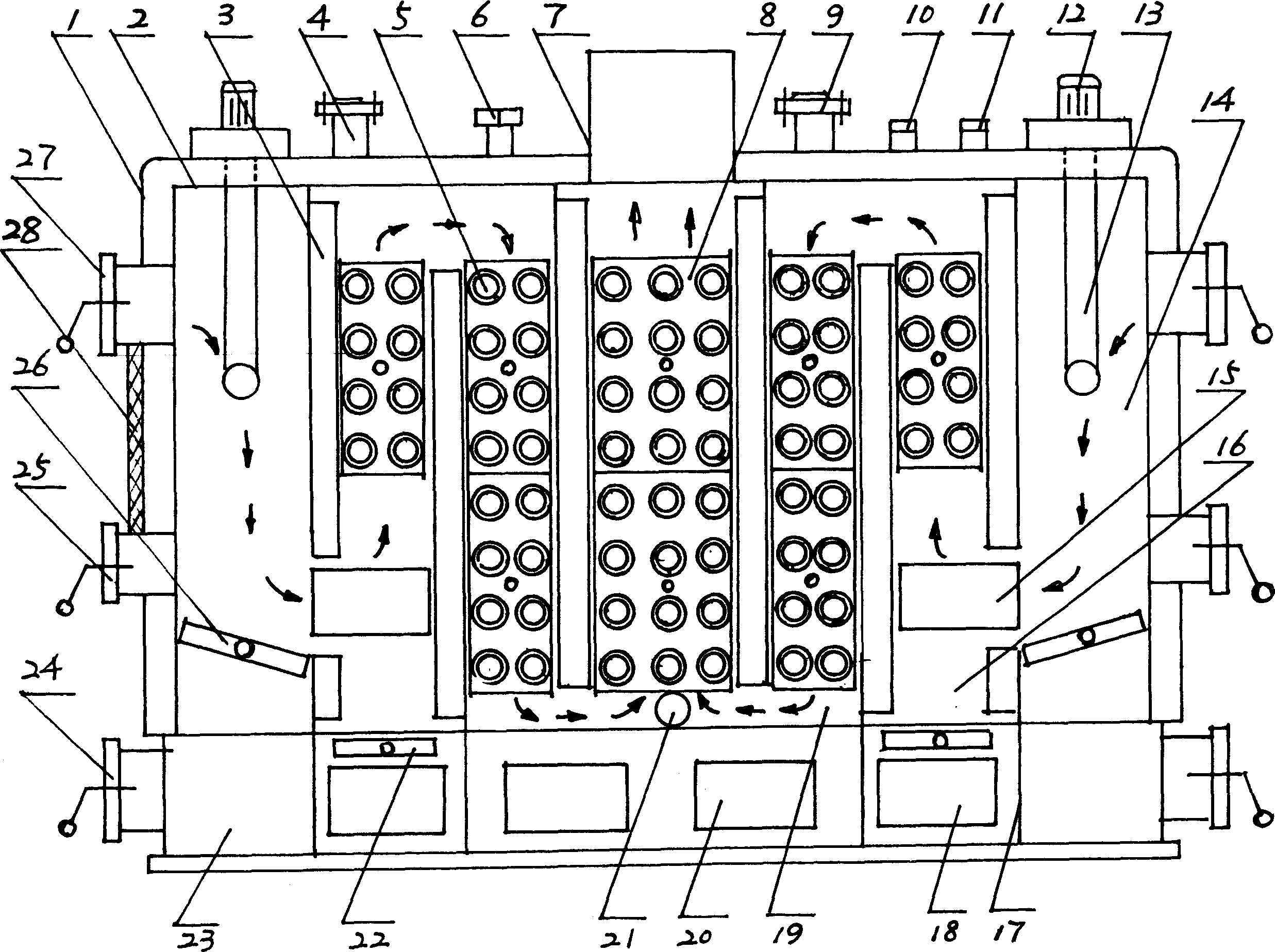

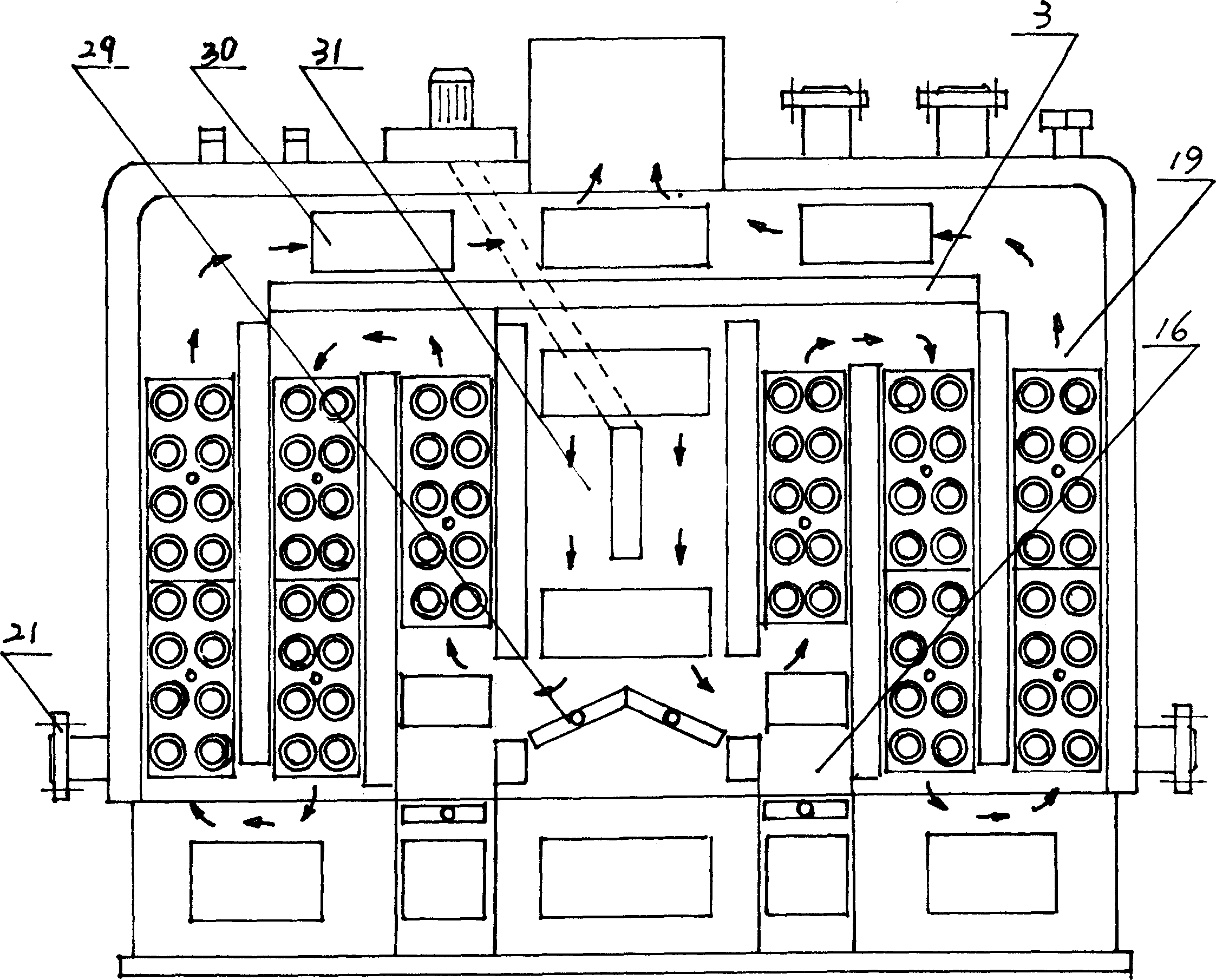

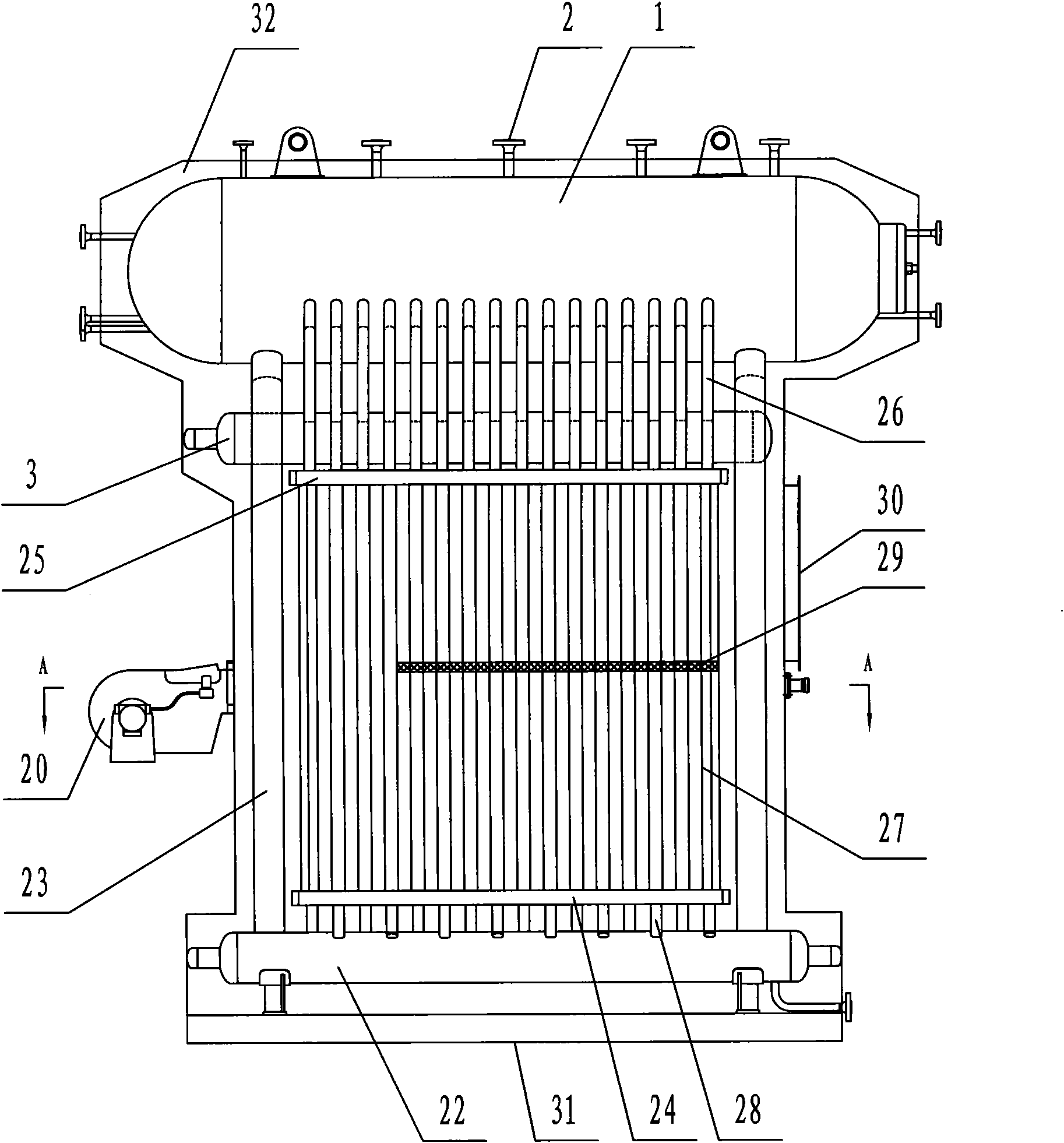

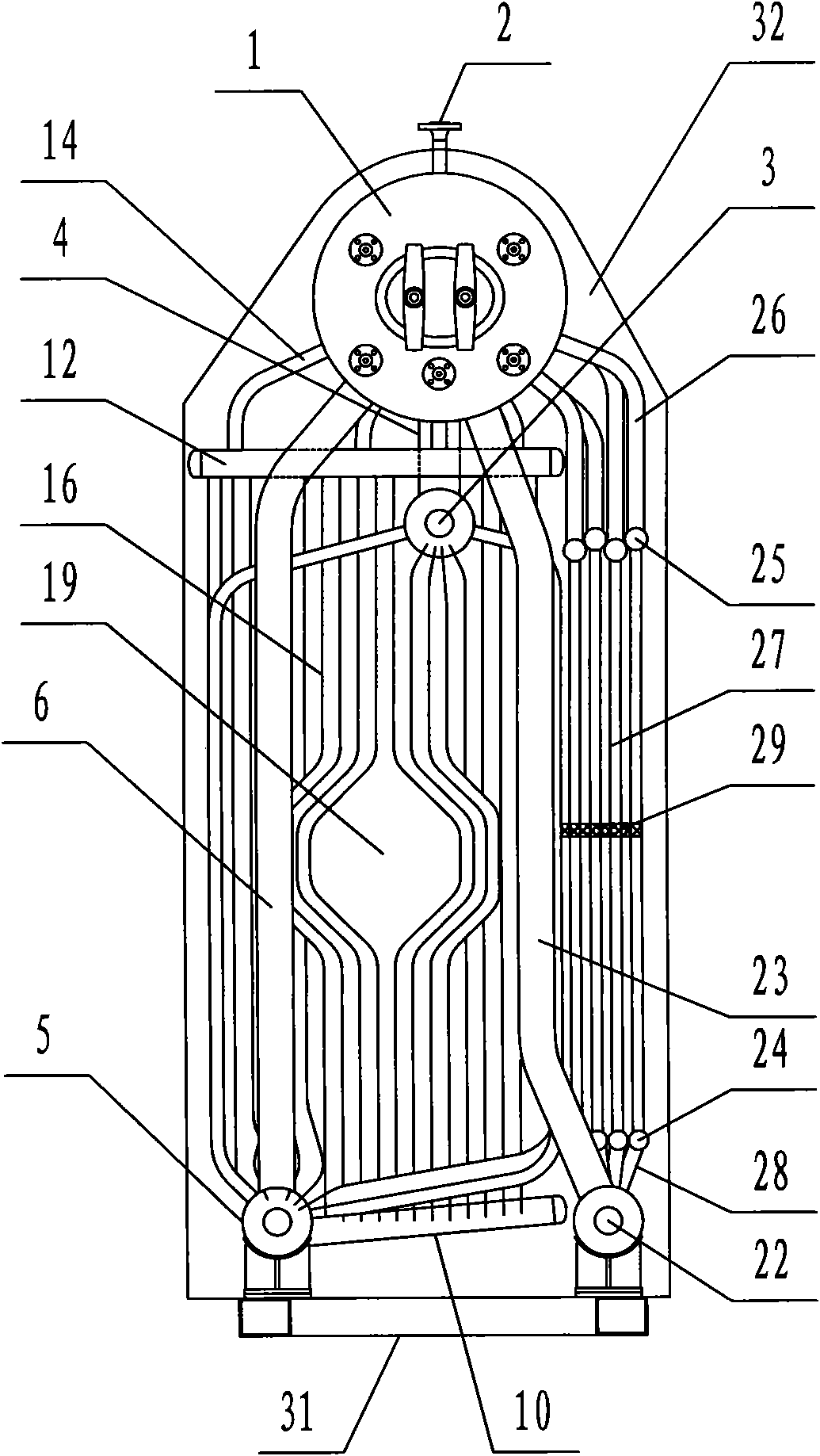

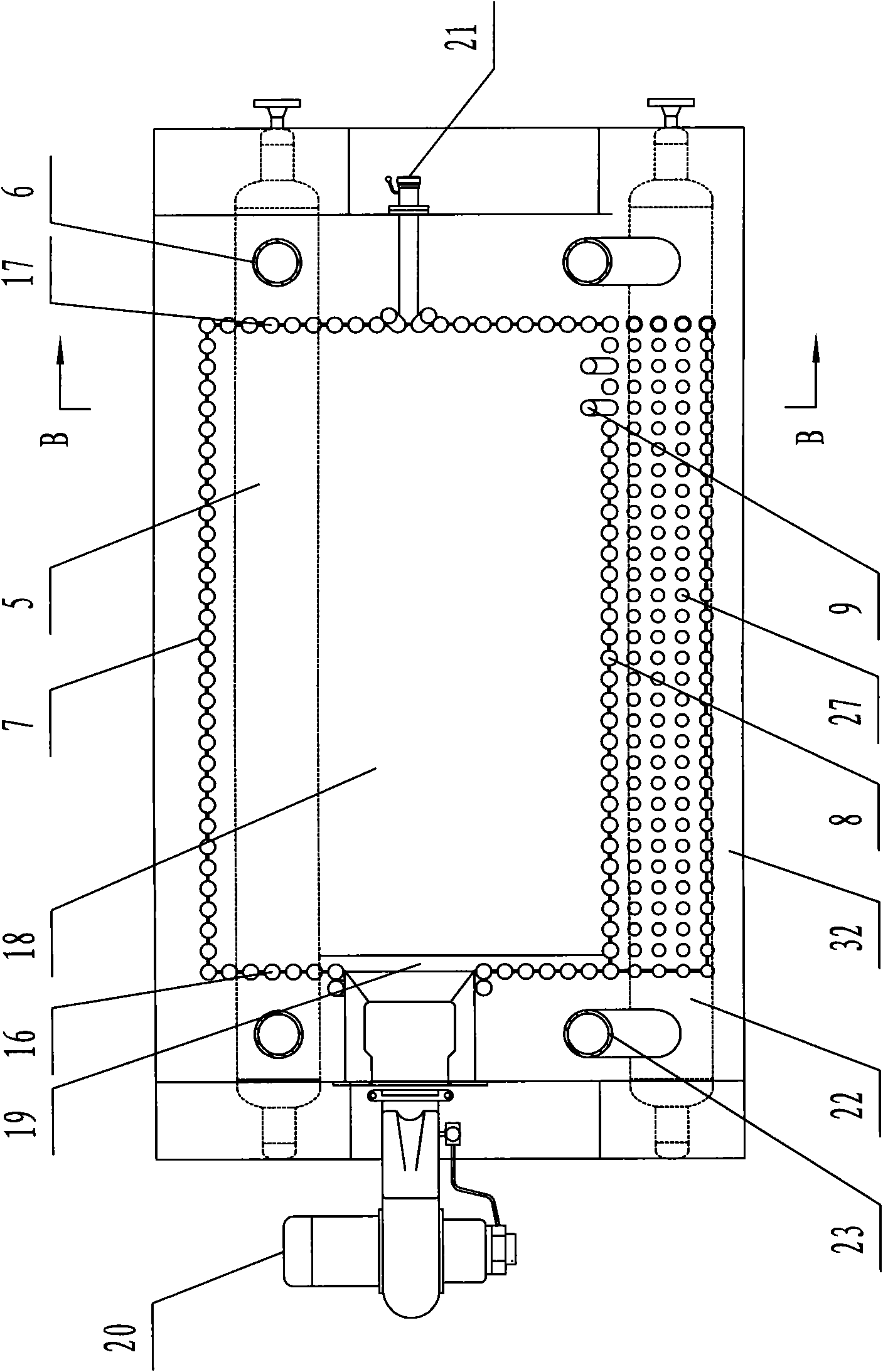

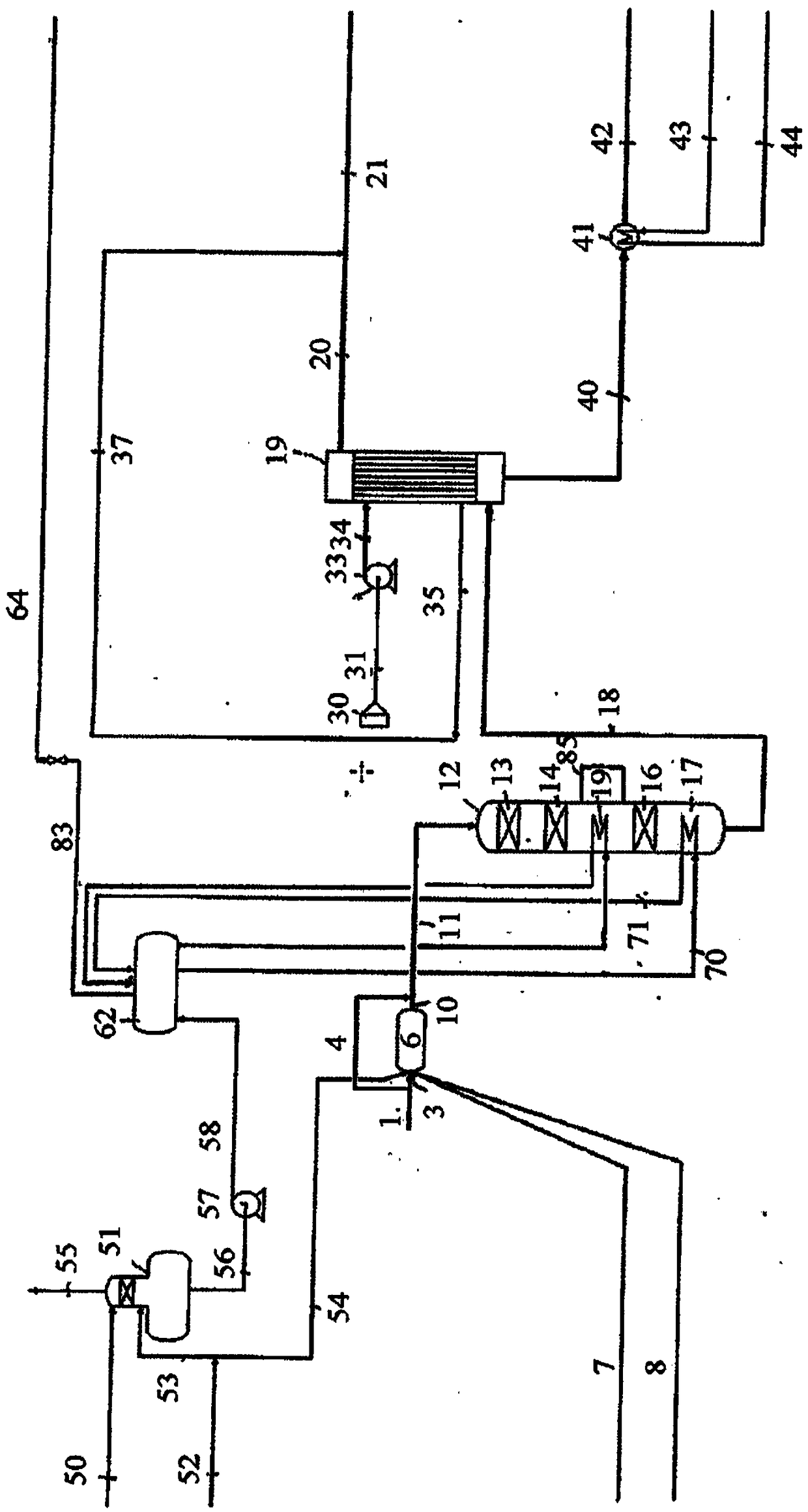

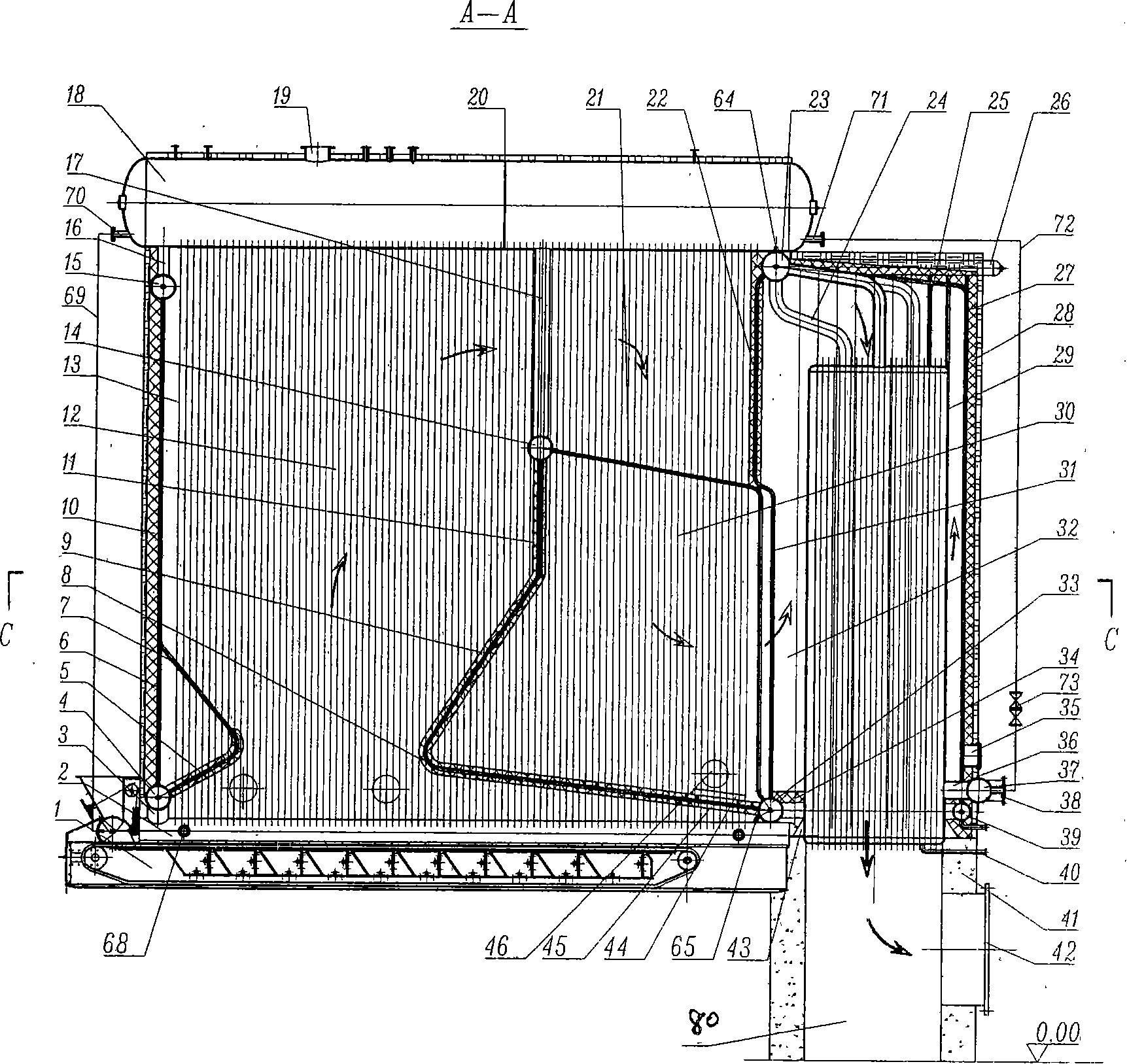

Full reverse convection unsealed water tube boiler

InactiveCN101957059AImprove production efficiencyReduce steel consumptionWater heatersWater channelEngineering

The invention discloses a full reverse convection unsealed water tube boiler. Upper and lower center headers, laterally symmetrical water wall headers, a water wall tube, upper and lower laterally symmetrical convection bank headers, a convection bank, front, rear, upper and lower transverse headers, communicating tubes and the like are respectively communicated to form a radiation convective heating surface and a natural circulation water channel; furnace walls are constructed on the outer side of the water wall and the outer sides of a ceiling and the convection bank to form a hearth and a three-return flue, so that the volume of the hearth can be increased with the same boiler volume to facilitate fully burning and settling dust in a soot furnace; the water channel and a soot channel are subjected to full reverse convection transverse washing to facilitate improving the heat exchange effect and reducing soot formation on the convective heating surface; and because of an unsealed structure, the natural circulation is safe, reliable and small in flow resistance, the overall structure process is advanced, the manufacturing is simple, and large, medium and small tubes can be adopted to replace drums of various boilers, so the steel consumption can be reduced by 30 percent, the manufacturing efficiency can be improved by 40 percent, the power consumption can be reduced by 20 percent, the initial discharge concentration of the soot can be reduced by 70 percent; therefore, the boiler has obvious advantages of energy saving, consumption reduction and emission reduction.

Owner:王森

Carbon-free low-NOx liquid fuel oxygen transport reactor for industrial water tube boilers

ActiveUS9383096B2Combustion using gaseous and pulverulent fuelSemi-permeable membranesSmall dropletLiquid fuel

An oxygen transport reactor for boiler furnaces and gas turbine combustors that utilizes a liquid fuel that is oxidized as a gaseous fuel in a membrane reactor. A liquid fuel is introduced by vaporizing the fuel inside a porous pipe surrounded by an annulus reaction zone which is surrounded by an annulus air zone. An oxygen transport membrane separates the annulus reaction zone containing the porous vaporized fuel and sweeping CO2 from the air feed side zone. Oxygen is transported from the outer annulus through the membrane to the annulus reaction zone containing the vaporized fuel and sweeping CO2. Fuel is first cracked to very small droplets in the intake fuel atomizer utilizing part of the intake CO2 then completely vaporized inside the porous pipe utilizing the heat coming from the surrounding reaction zone. The oxygen transport reactor is applicable for carbon free boiler furnaces and gas turbine combustors which utilize oxygen transport reactors for combined oxygen separation and combustion.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

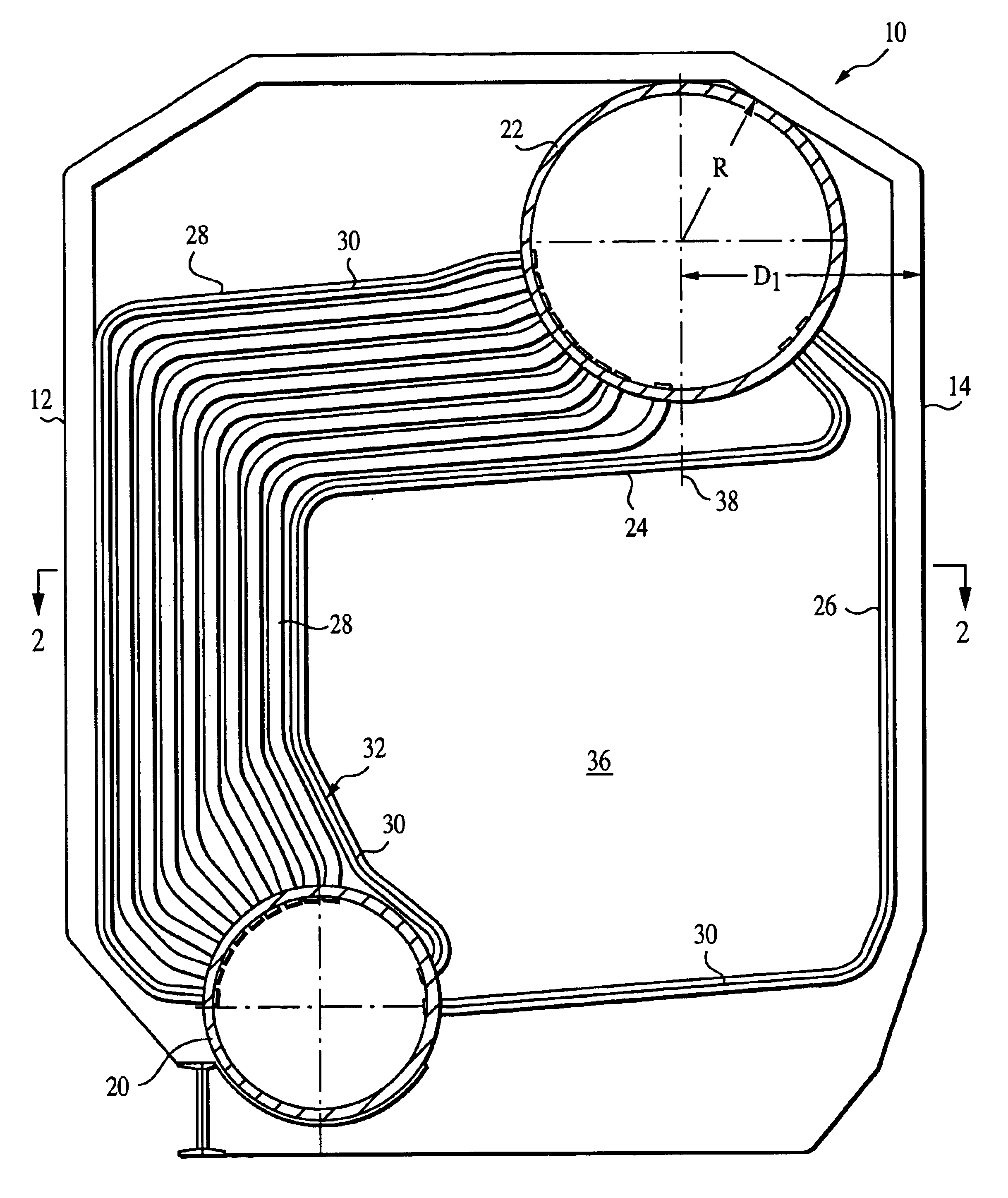

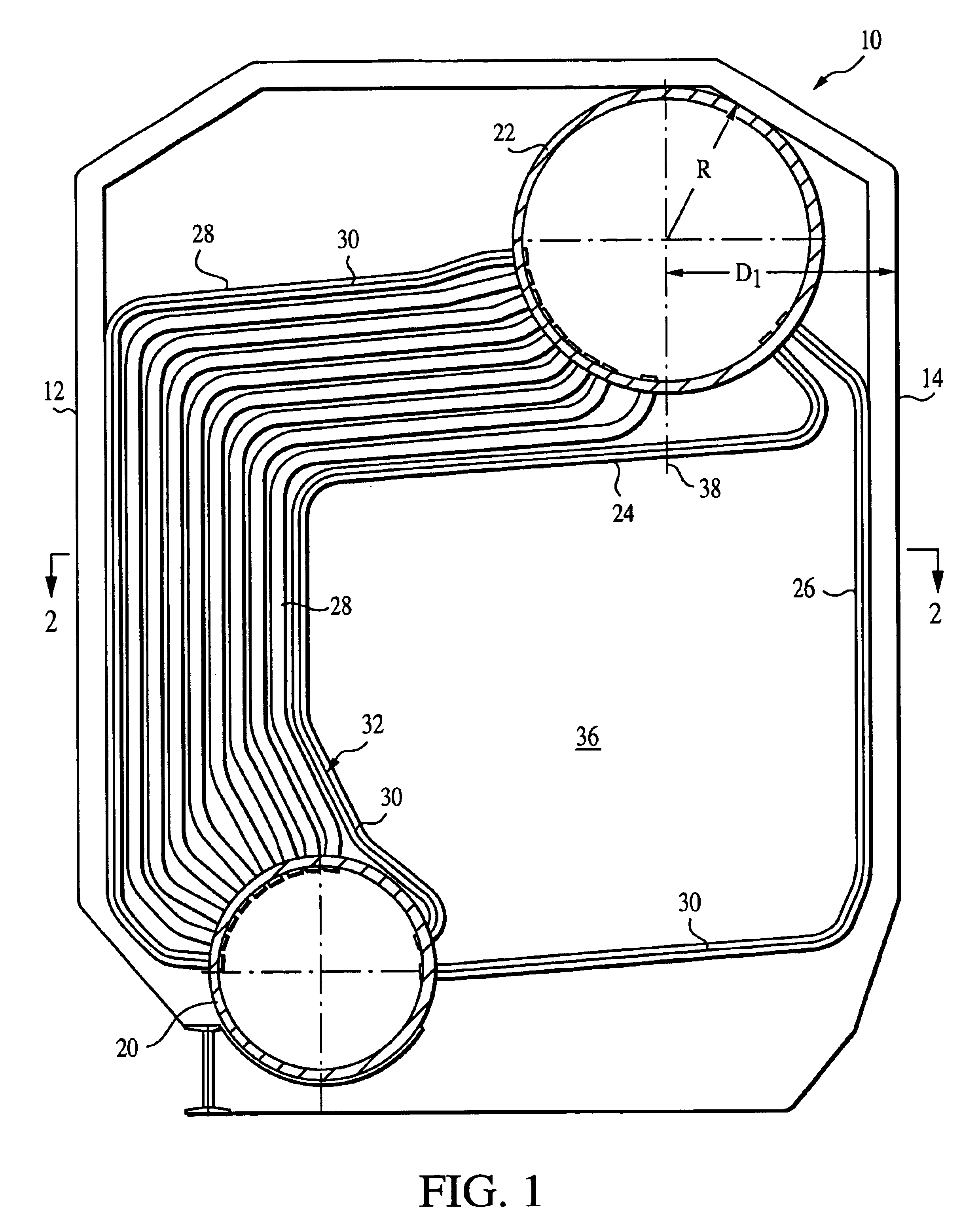

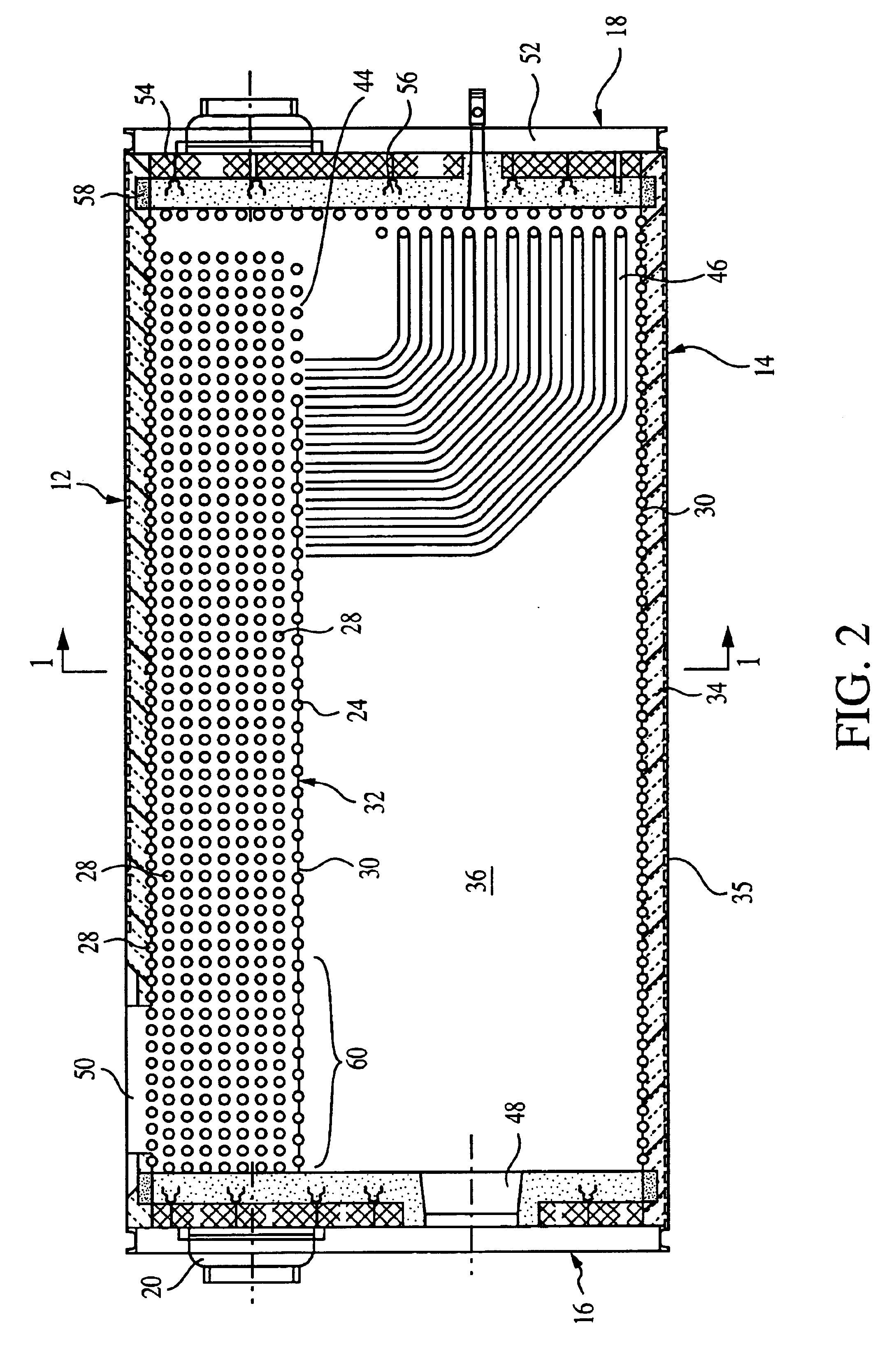

Package water tuble boiler having two offset drums

ActiveUS6901887B2Reduce maximum permissible widthReduce foamingBoiler water tubesDrum steam boilersCombustion chamberVertical plane

A package water tube boiler has offset upper and lower steam and water drums located adjacent its opposite side walls, with a generally square combustion chamber between the drums. Connecting the drums are generally L-shaped riser and downcomer tubes including convection tubes and radiant tubes extending in vertical and horizontal runs along the sides, top, and bottom of the combustion chamber. The tubes, especially the inboard radiant tubes, are configured, and their entrances and exits to and from the drums are located, so as to permit increased efficiency and steam generation capacity without increasing the package boiler's outside dimensions, to shield the drums from thermal radiation emanating from the combustion chamber, to locate the boiler's center of gravity equidistant from its side walls, and to fix the upper drum to and support it by the boiler's end walls. Preferably, the relationships between the radiant tubes and the upper drum are such that the inboard radiant tubes in their generally horizontal run extend past the vertical plane including the drum's longitudinal axis by a distance of at least 60% of the drum's radius, the inboard radiant tubes bend in an acute angle just before entering the drum, the distance between the inboard radiant tubes and the drum are substantially less than the drum's radius, and the entrances of the radiant tubes in the drum are spaced radially from those of the convection tubes.

Owner:ENGLISH BOILER LLC

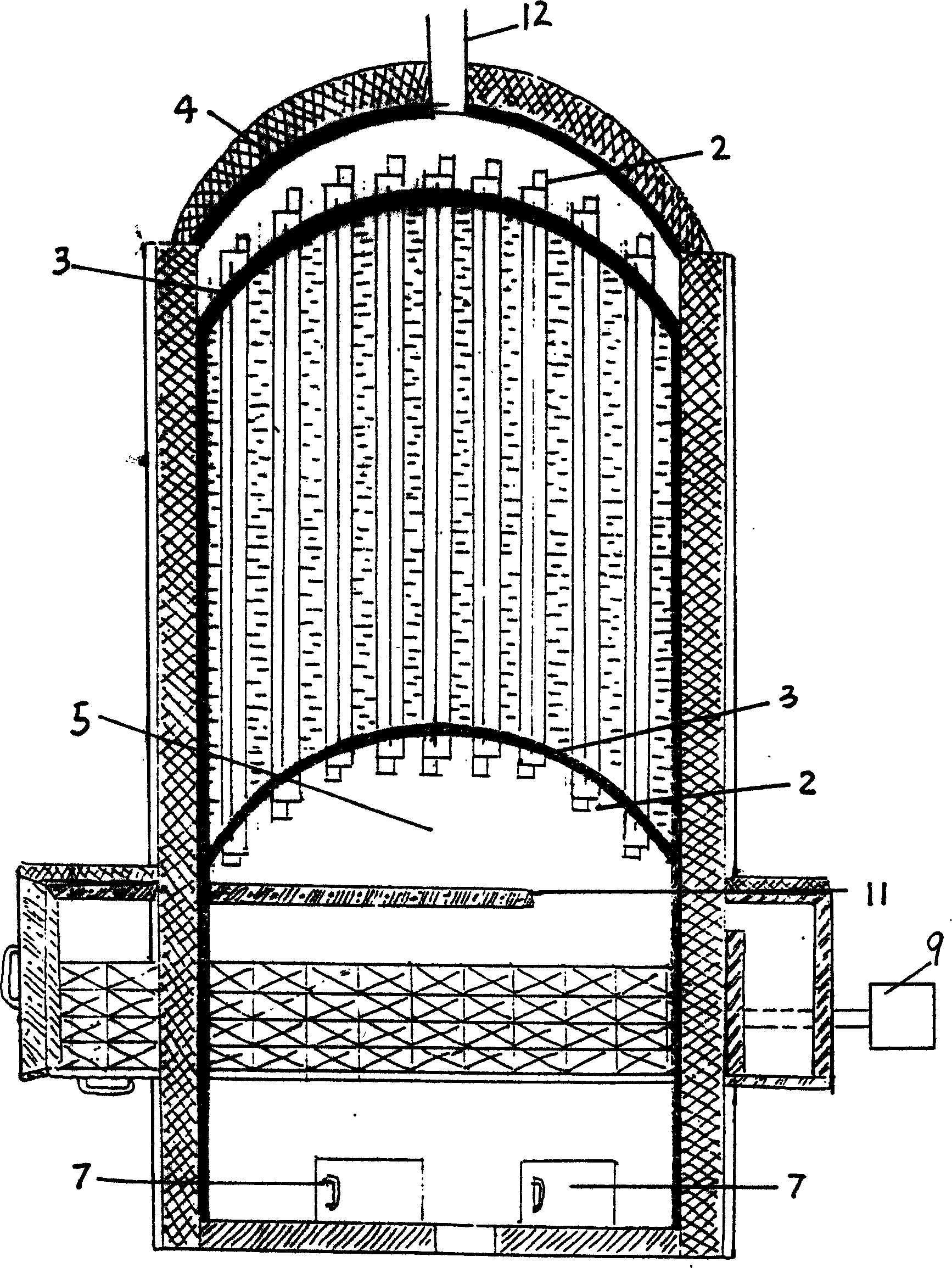

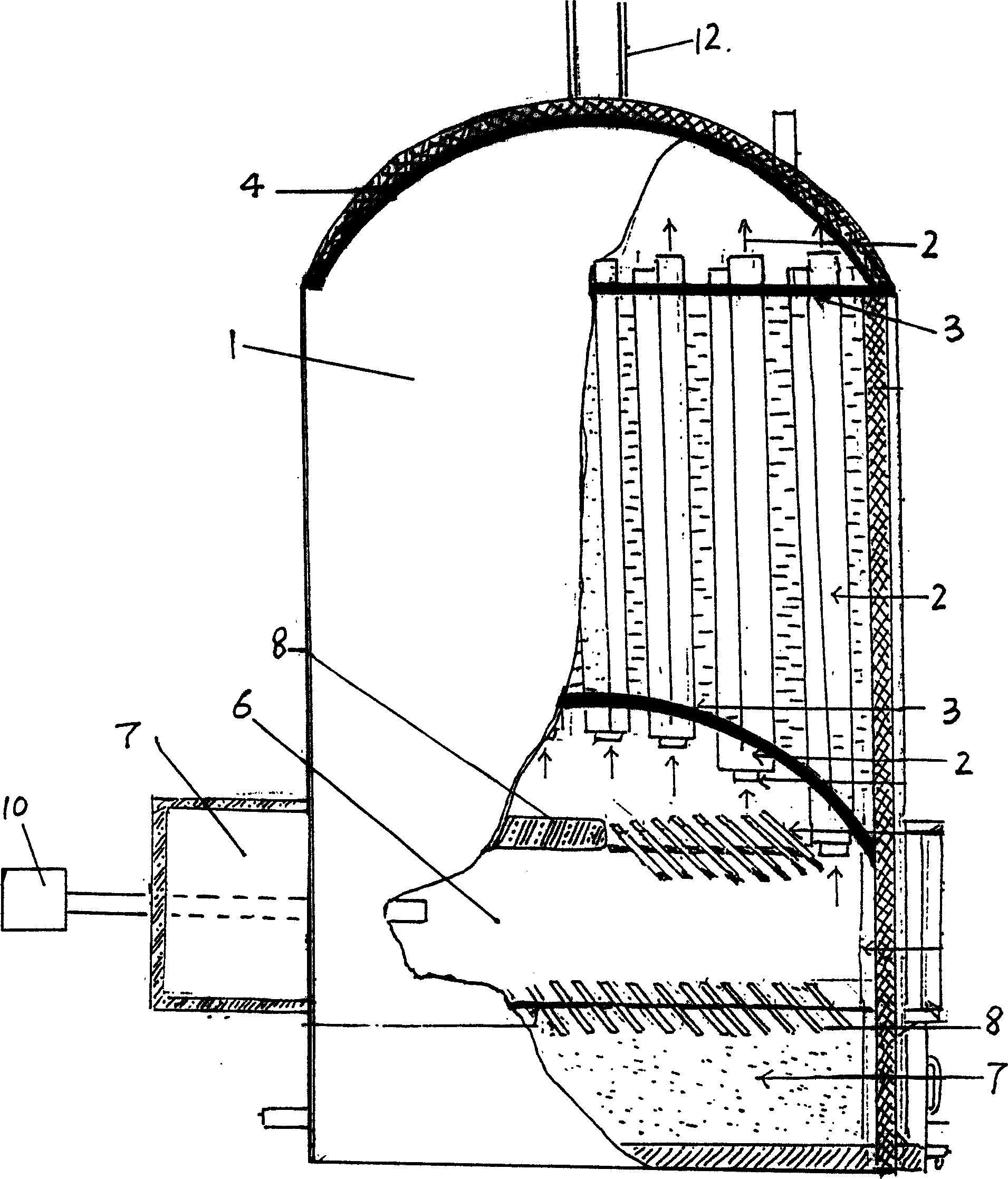

Coal firing boiler with N-shaped fire tubes

The invention discloses a coal fired boiler with an N shaped fire tube. The boiler includes a boiler body 1, a closure head 4, a chimney 12, a clinker chamber 7, a fire tube 2, and a connection seal head 3 arranged at upper end and lower end of the fire tube 2. The boiler is characterized in that said fire tube 2 is an N shaped fire tube consisting of tubes of three segments or above. The invention is provided with a small boiler body and high thermal efficiency.

Owner:黄全刚

Industrial boiler water treatment method

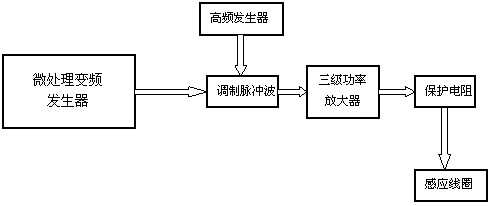

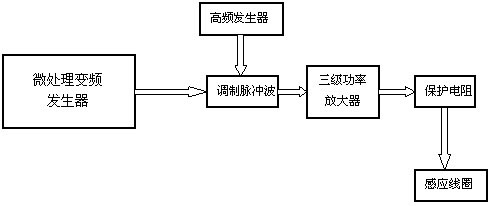

InactiveCN101962243AAvoid depositionImprove heat exchange efficiencyScale removal and water softeningWater/sewage treatment by magnetic/electric fieldsChemical treatmentSulfite salt

The invention discloses an industrial boiler water treatment method which comprises the following two steps: (1) physical water treatment: installing an electromagnetic water treatment device on an water inlet pipe of an industrial boiler, and ensuring that the electromagnetic water treatment device is in the normal operation state in the operating process of the boiler; and (2) chemical water treatment: simultaneously adding 0.2-4mg / L of 1-hydroxy ethylidene-1,1-diphosphonic acid or 2-phosphono-1,2,4-butane tricarboxylic acid or polyacrylic acid or hydrolytic polymaleic anhydride, 5-50mg / L of molybdate or tungstate and 1-20mg / L of sodium sulfite to boiler inlet water. By organically combining electronic water treatment and chemical water treatment, the invention prevents the deposition of inorganic scales on the heat exchange surface of the industrial boiler and can remove the previously formed scales to slow metal corrosion, thereby greatly improving the heat exchange efficiency of the boiler. Compared with the traditional chemical treatment method, the technology improves the scale and corrosion inhibiting effects of the industrial boiler, reduces the consumption of chemical scale and corrosion inhibitor and has the characteristic of environment friendliness.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

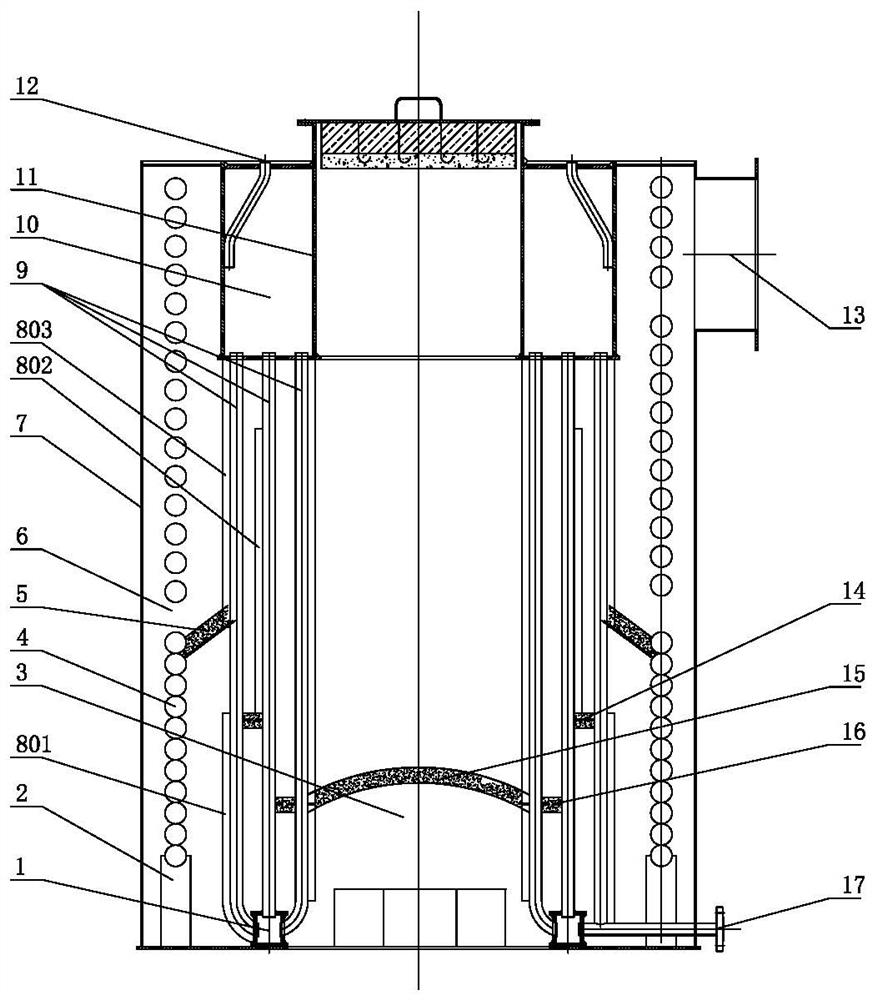

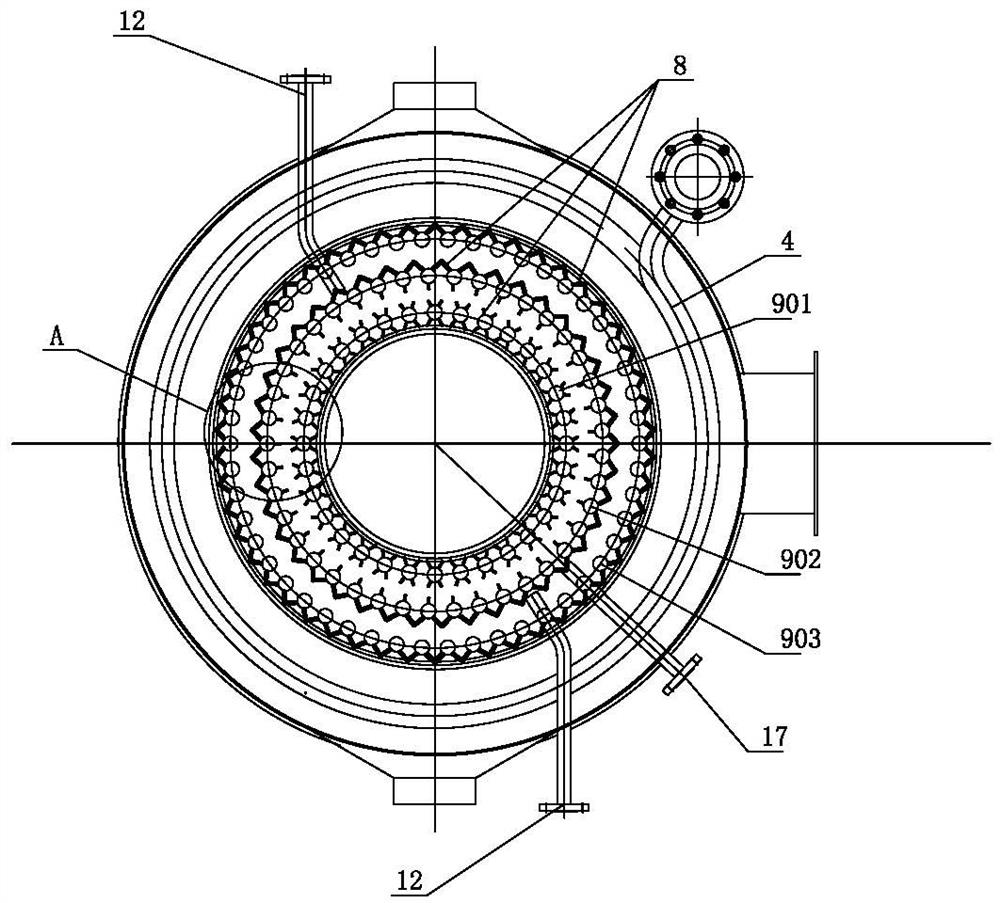

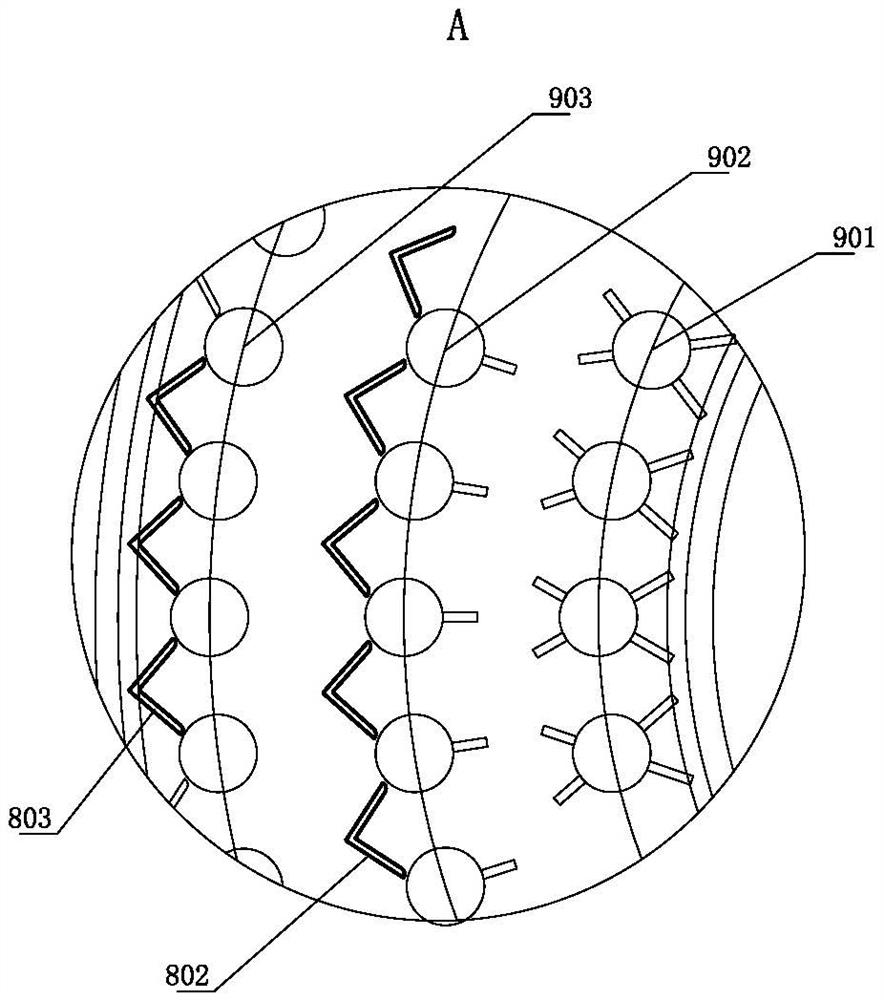

Cylindrical low-nitrogen energy-saving pressure-bearing water pipe boiler

PendingCN111853747AReduce heat lossIncrease the average heat transfer coefficientWater-tube boilersThermodynamicsCombustor

The invention discloses a cylindrical low-nitrogen energy-saving pressure-bearing water pipe boiler which comprises an upper seal head, a shell, a burner distribution head, a water-cooled wall tube bundle, a water-cooled flame tube bundle, a radiation tube bundle, a high-temperature convection tube bundle, a low-temperature convection tube bundle, a descending tube bundle, a lower seal head, an external condenser, a pre-mixer and a matched fan, a water supply pump, a gas valve group, a controller and the like. A burner achieves side face gas feeding, and densely-arranged pipes, a metal pore plate, a ceramic pore plate and the like are adopted for preventing fire return and stabilizing flame. The burner is detachable, thereby facilitating maintenance and repair. The water-cooled flame tubebundle of the burner distribution head is arranged in a plane or convex shape, so that the space of a hearth is utilized to be maximum; and the water-cooled flame tube bundle on a boiler body is adopted to cool the flame, so that the heat distribution problem of the water-cooled burner is solved. Machine-boiler integration of plane and curved surface burners is achieved, the structure is compact,low-nitrogen and ultra-low-nitrogen combustion are achieved at lower excess air coefficients, and the technical monopoly of foreign low-nitrogen burner manufacturers in the field of steam boilers is broken through.

Owner:BRIGHT THERMAL EQUIP CO LTD

Plate-type gas combustion condensing water boiler

The invention relates to a plate-type gas combustion condensing water boiler using gas as fuel. A burner of the boiler is a plate-type gas burner instead of an original flame burner. A combustion chamber of the boiler is in a smoke-water plate-type heat exchange structure, instead of an original tubular heat exchanger, and the function of condensing steam in smoke is improved for low-temperature water. The plate-type gas burner and a smoke-water plate-type heat exchanger are disposed in the boiler, and heat efficiency of the boiler can be greatly improved. The plate-type gas combustion condensing water boiler is mainly used to produce normal-pressure normal-temperature hot water, heating, living and process hot waters for buildings and the like.

Owner:苗苏宁

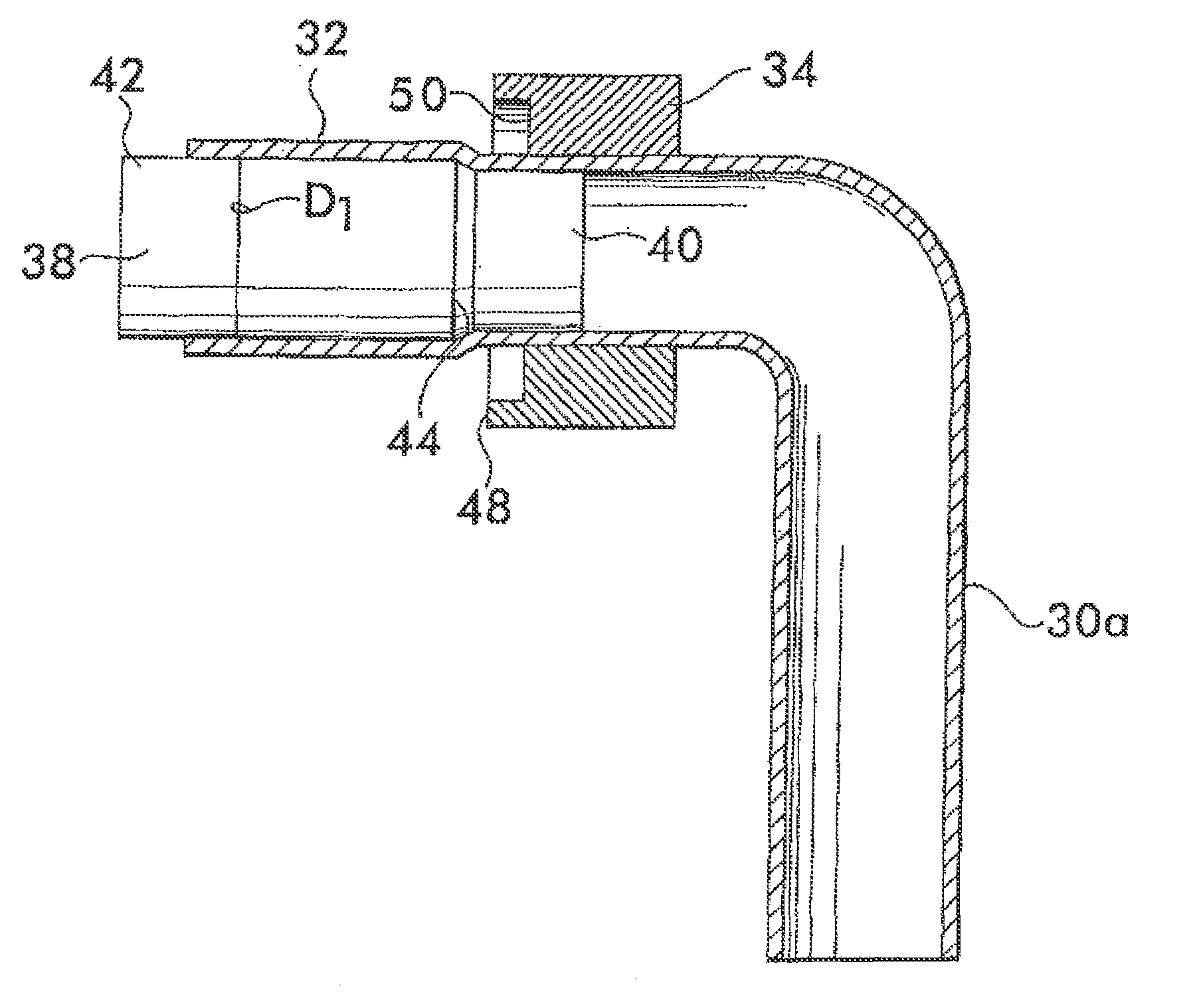

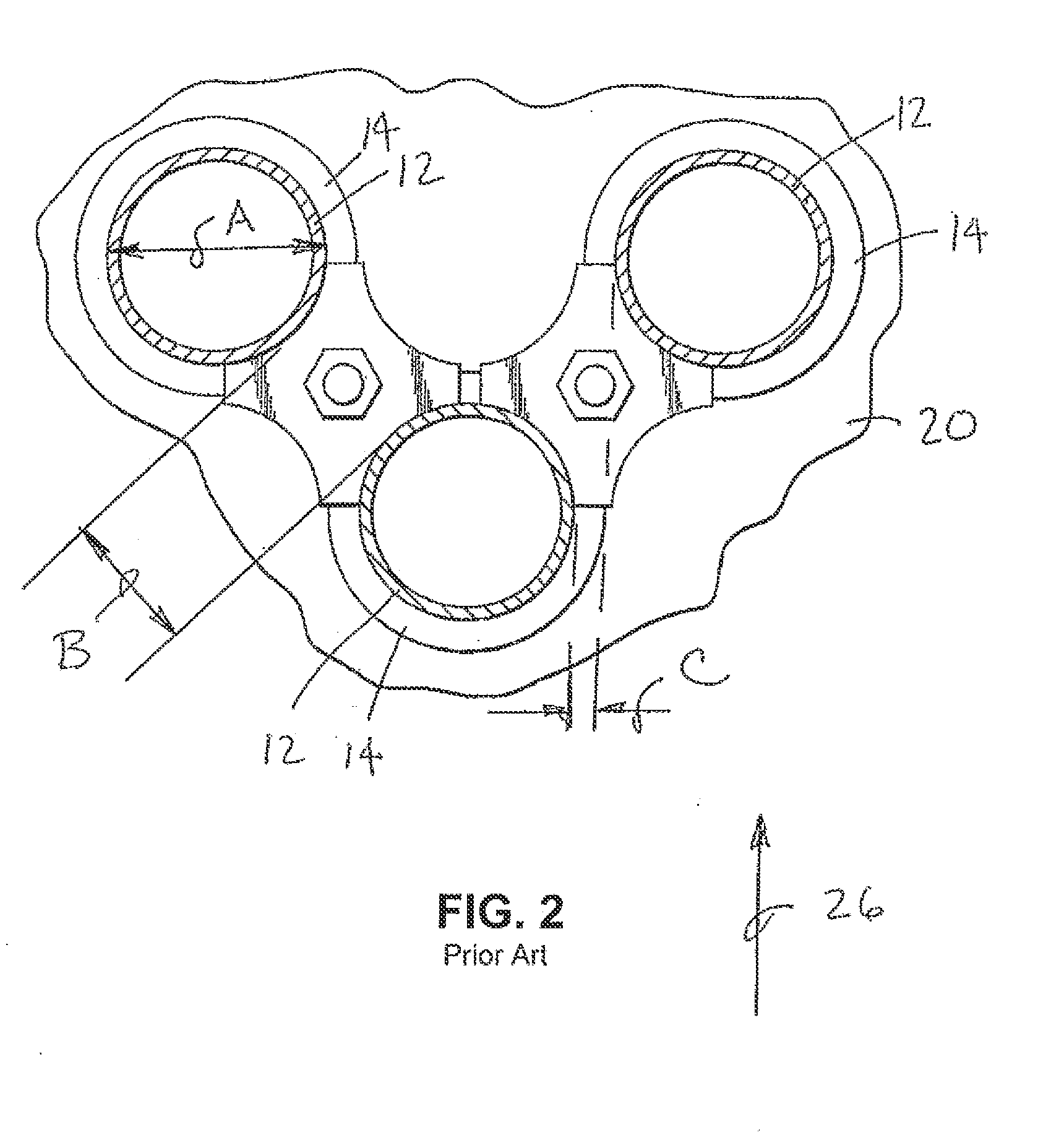

Watertube and method of making and assembling same within a boiler or heat exchanger

InactiveUS20100071635A1Reduce the overall diameterTighter engagementBoiler water tubesStationary conduit assembliesCombustion chamberExtremity Part

A one-piece tube for use as a watertube within a watertube boiler or heat exchanger has a free end section that is formed to have an integral, outward-extending circumferential ring, or flange, a spaced distance from an adjacent end face of the tube. A boiler is provided that has an elongate header and a plurality of separate watertubes each having an intermediate section and opposite end sections. An end section of each watertube is connected to the header. The intermediate section of each watertube has a substantially constant outer diameter along its full length and is closely spaced to adjacent watertubes within the combustion chamber. At least one of the end sections of each watertube has a transition that reduces the diameter of the watertube as it extends from the intermediate section to an outwardly-extending circumferential flange. This arrangement permits close spacing of the connection sites of the watertubes to the header and permits the connection sites to be provided in a linear array.

Owner:BURNHAM SERVICES

Gasification coal-saving environmental protection normal pressure hot-water boiler

InactiveCN1635313AIncrease the heating areaHigh thermal efficiencySolid fuel combustionWater heatersCombustion chamberEngineering

The invention is an improvement to the design of an indoor heating furnace, and relates to a gasification, coal-saving, environment-friendly, normal-pressure hot water boiler. It is characterized in that: the furnace shell of the gasification coal-saving environmental protection atmospheric hot water boiler is connected to the lower part of the furnace, the flue is connected to the top of the furnace shell, and its shape is a vertical furnace; 4 combustion chambers are set in the furnace, Among them, the gasification combustion chamber and the secondary combustion chamber are divided into three heat exchange chambers by the water jacket partition in the middle of the furnace; the left and right sides of the hot water pipe, the water jacket partition and the furnace The side plates are connected to form the heating surface in the furnace, and the hot water pipes are water pipe bundles arranged horizontally and vertically; movable grates and grates are set at the bottom, and the flue gas starts from both ends of the furnace and merges in three processes. The central process exits the flue. The invention has the characteristics of reasonable design, beautiful appearance, high thermal efficiency, hygienic and convenient use, and no environmental pollution. It saves energy and has large heat supply. Compared with traditional heating furnaces, it can save energy by more than 40%.

Owner:陈喜春

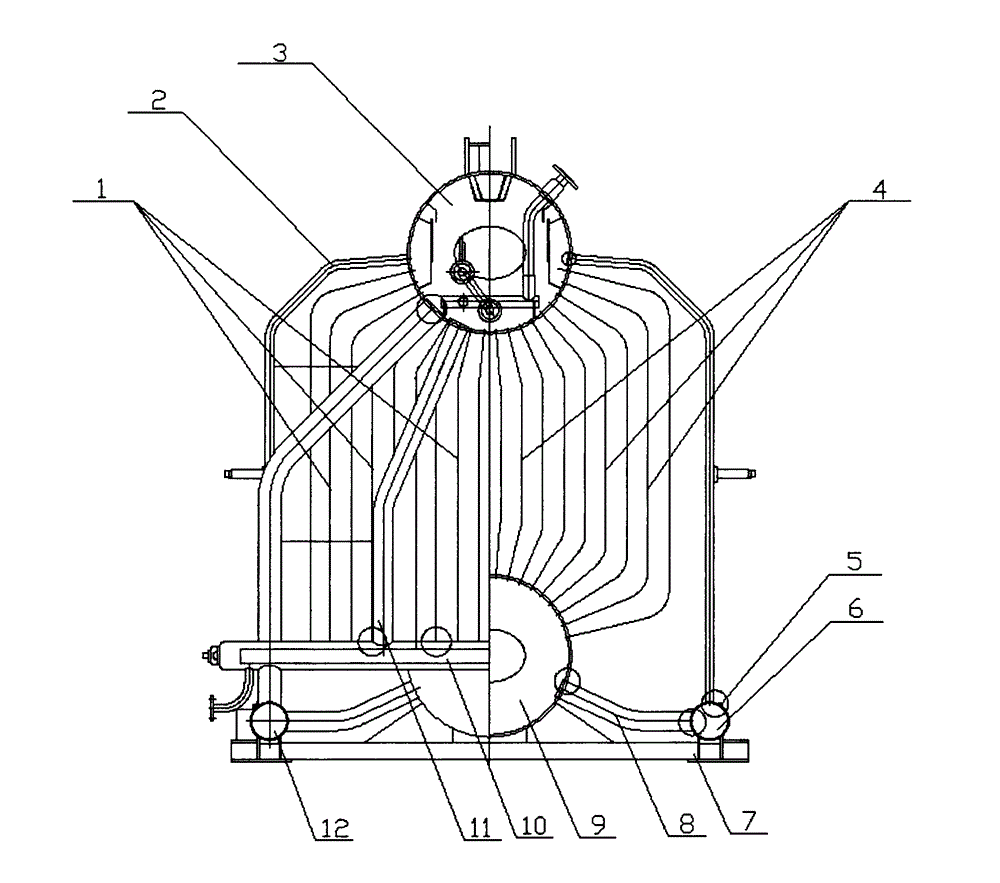

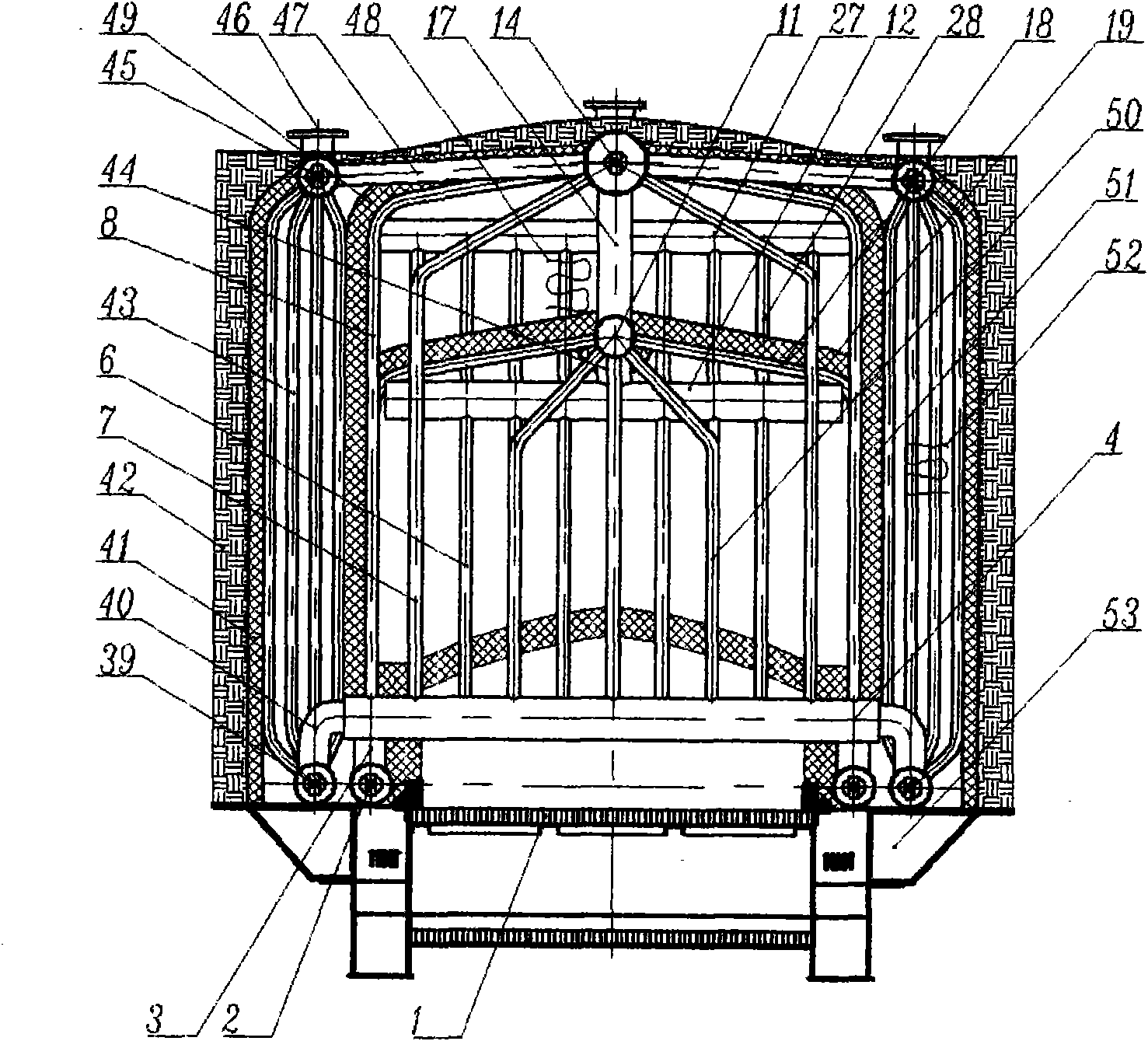

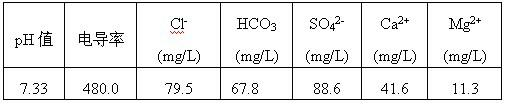

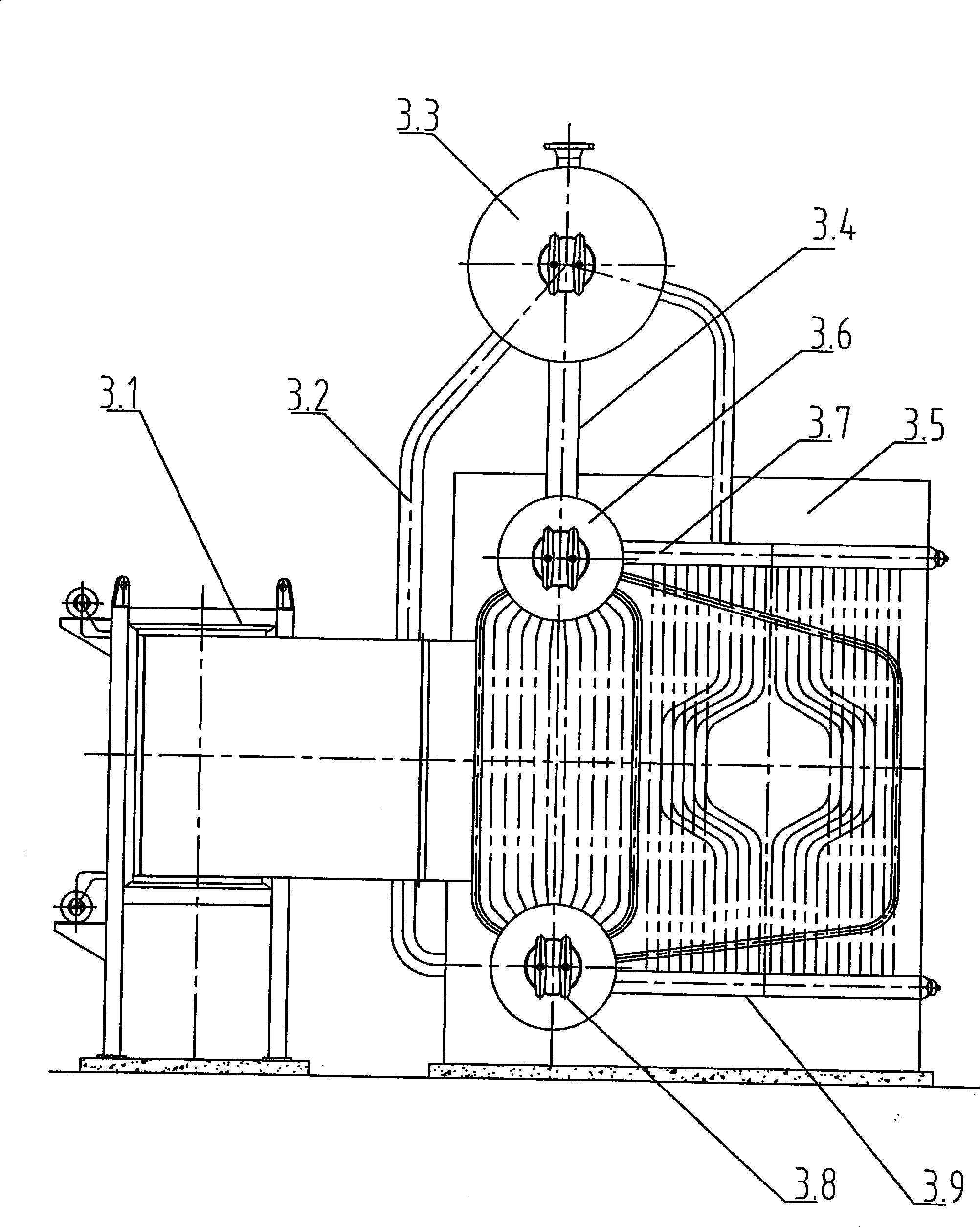

Novel three-barrel structure quick-fixing water tube boiler

ActiveCN101324327AQuality assuranceReduce on-site workloadWater-tube boilersWater heatersCombustionPositive pressure

The invention relates to a novel water tube packaged boiler with three-drum structure, which entirely adopts a three-drum vertical 'D'-shaped arrangement structure and comprises a coal saver (3.1), a downcomer (3.2), a top-mounted drum (3.3), a riser tube (3.4) and a boiler main body (3.5). The boiler main body (3.5) includes an intermediate drum (3.6), a lower drum (3.8), a convection tube bundle (3.10), a furnace (3.11), an upper header (3.7) and a lower header (3.9), wherein the furnace (3.11) is surrounded by a left membrane wall (3.13), a right membrane wall (3.14), a front membrane wall (3.12) and a rear membrane wall (3.15), wherein the left membrane wall (3.13) and the right membrane wall (3.14) are directly communicated with the intermediate drum (3.6) and the lower drum (3.8); the front membrane wall and the rear membrane wall are communicated with each other through the intersection of the upper header and the lower header; the upper header is communicated with the intermediate drum; the lower header is communicated with the lower drum; and the top-mounted drum is communicated with the lower drum through the downcomer and is communicated with the intermediate drum through the riser tube. The boiler of the invention is produced in five parts and has positive pressure combustion to achieve packaged production of medium-pressure oil and gas burning boiler.

Owner:JIANGSU SHUANGLIANG BOILER

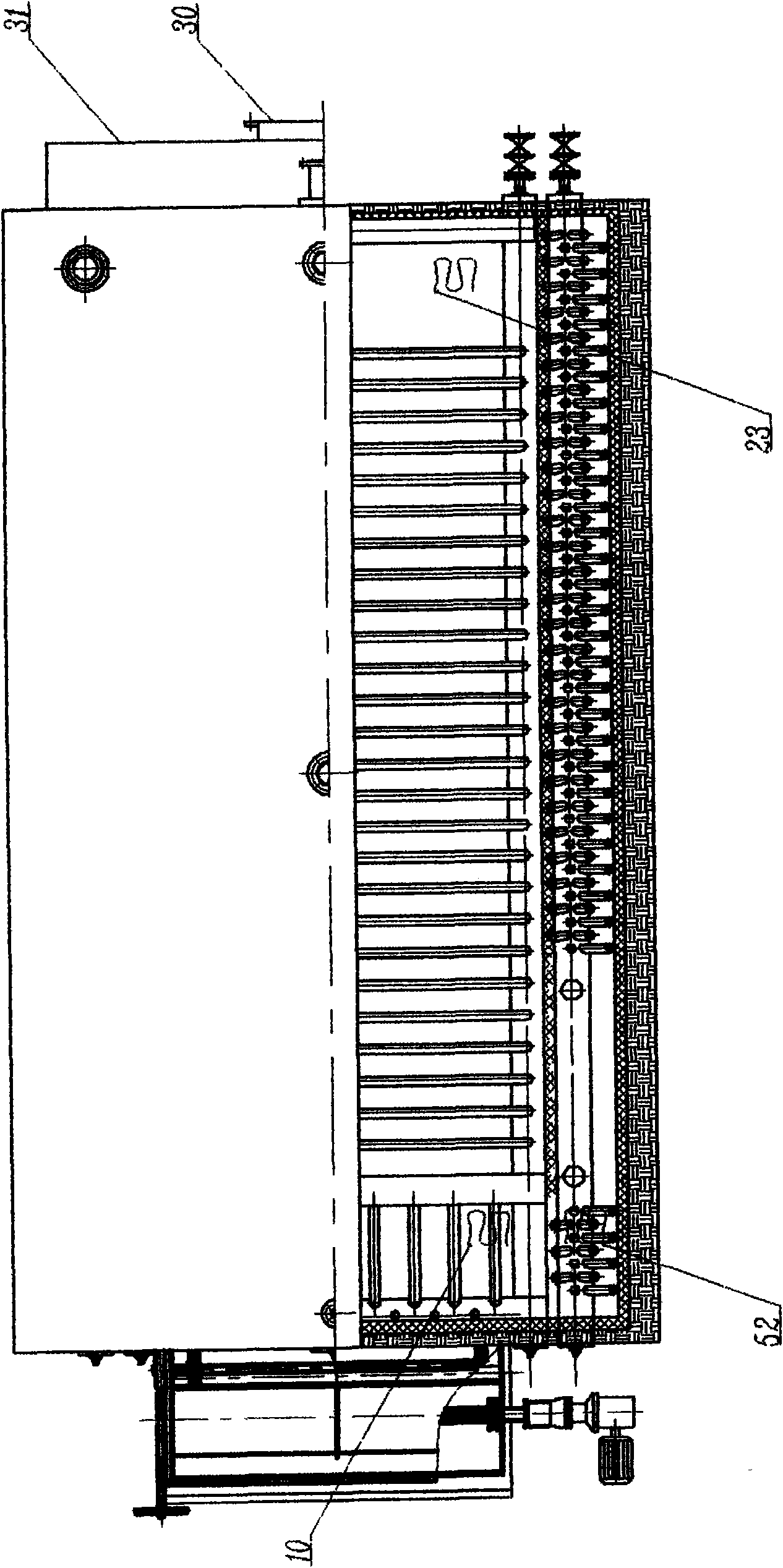

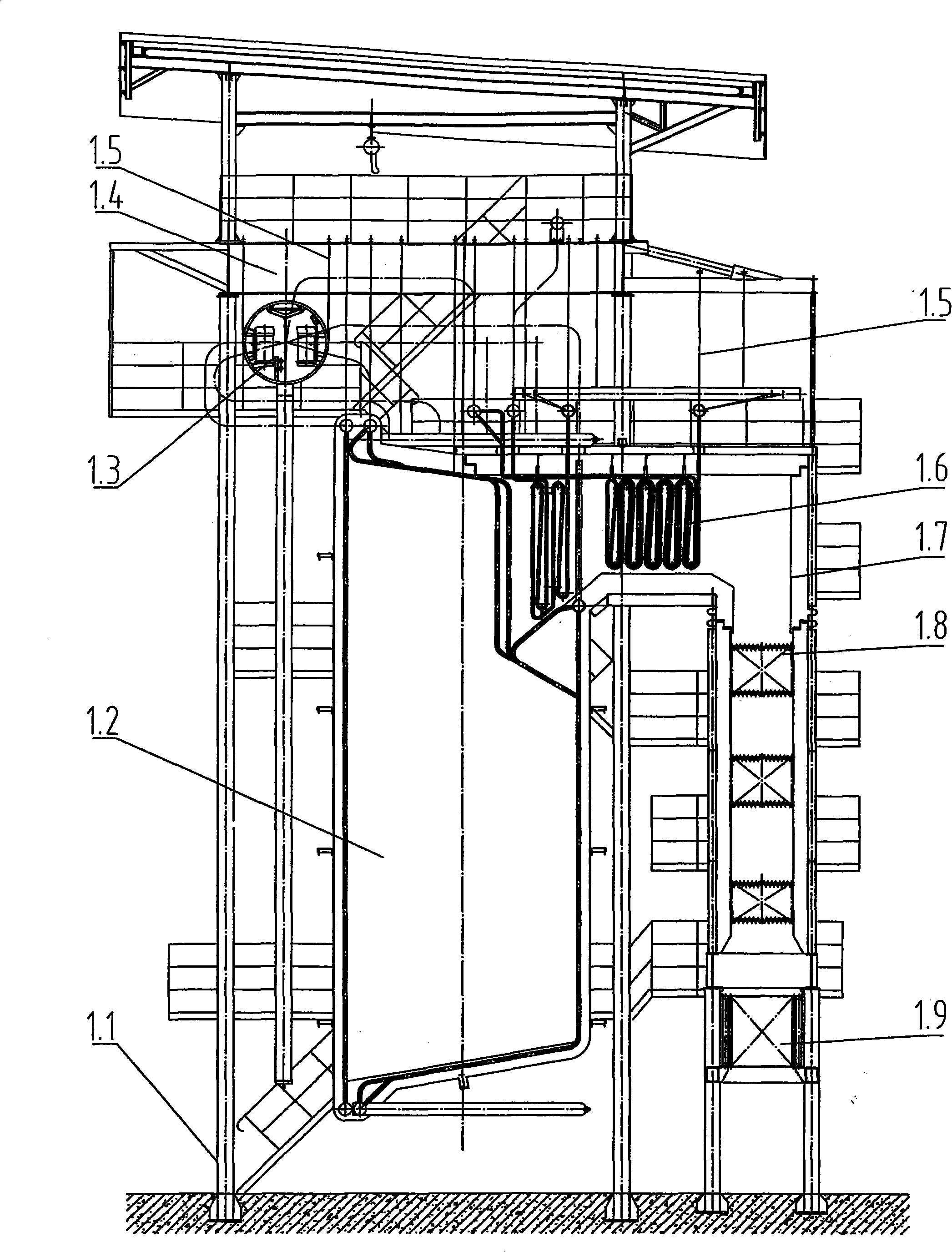

Rapid-installation water pipe boiler with medium and high pressure single-boiler barrel structure

ActiveCN102062386AReduce manufacturing difficultyWeaken smallWater-tube boilersCombustorInsulation layer

The invention relates to a rapid-installation water pipe boiler with a medium and high pressure single-boiler barrel structure. The boiler provided by the invention comprises a boiler barrel, wherein a water cooling device is arranged at the lower part of the boiler barrel; the water cooling device comprises an upper collection tank, a lower collection tank, a small collection tank below a front wall, a small collection tank below a rear wall, a small collection tank above the front wall and a small collection tank above the rear wall; a hearth is formed through four water cooling walls among the collection tanks; each water cooling wall is a welding membrane type wall tube; one water cooling wall is provided with a burner connecting port; the lateral part of one water cooling wall is provided with a convection device; the convection device comprises a water distribution collection tank; a small collection tank below a convection tube beam and a small collection tank above the convection tube beam are arranged at the upper part of the water distribution collection tank; the small collection tank above the convection tube beam and the small collection tank below the convection tube beam are mutually communicated through the convection tube beam; a smoke baffle is arranged at the middle part of the convection tube beam; and the exterior of the whole boiler is provided with a heat insulation layer. The boiler provided by the invention has the advantages that the containable space of the hearth can be increased, the boiler can be rapidly installed and manufactured, and the integral heat treatment does not need to be carried out on the boiler.

Owner:ZHANGJIAGANG GREENS SHAZHOU BOILER

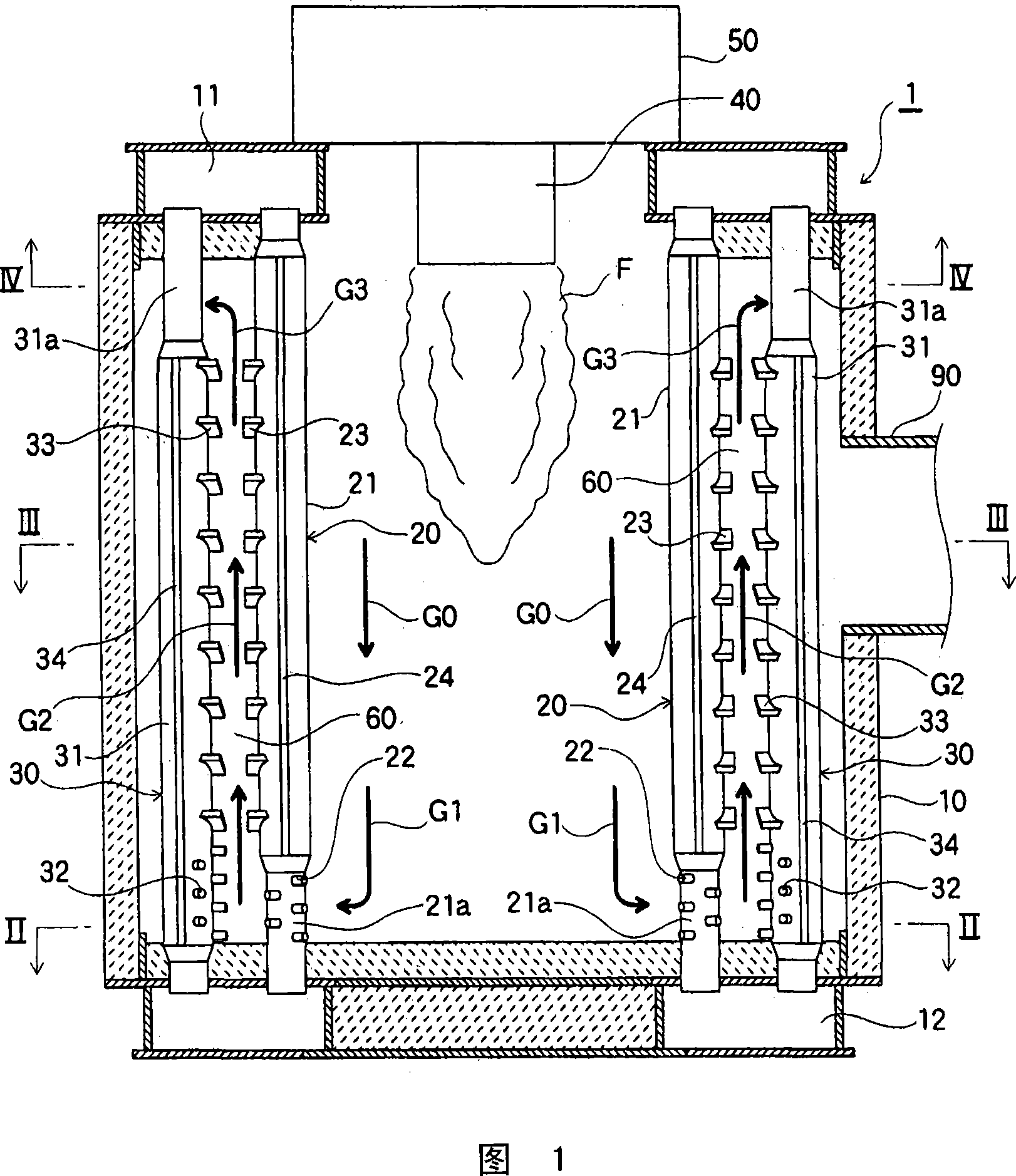

Boiler

ActiveCN101191662AEfficient heat recoveryIncreased durabilityHeat exhanger finsStationary tubular conduit assembliesCombustorEngineering

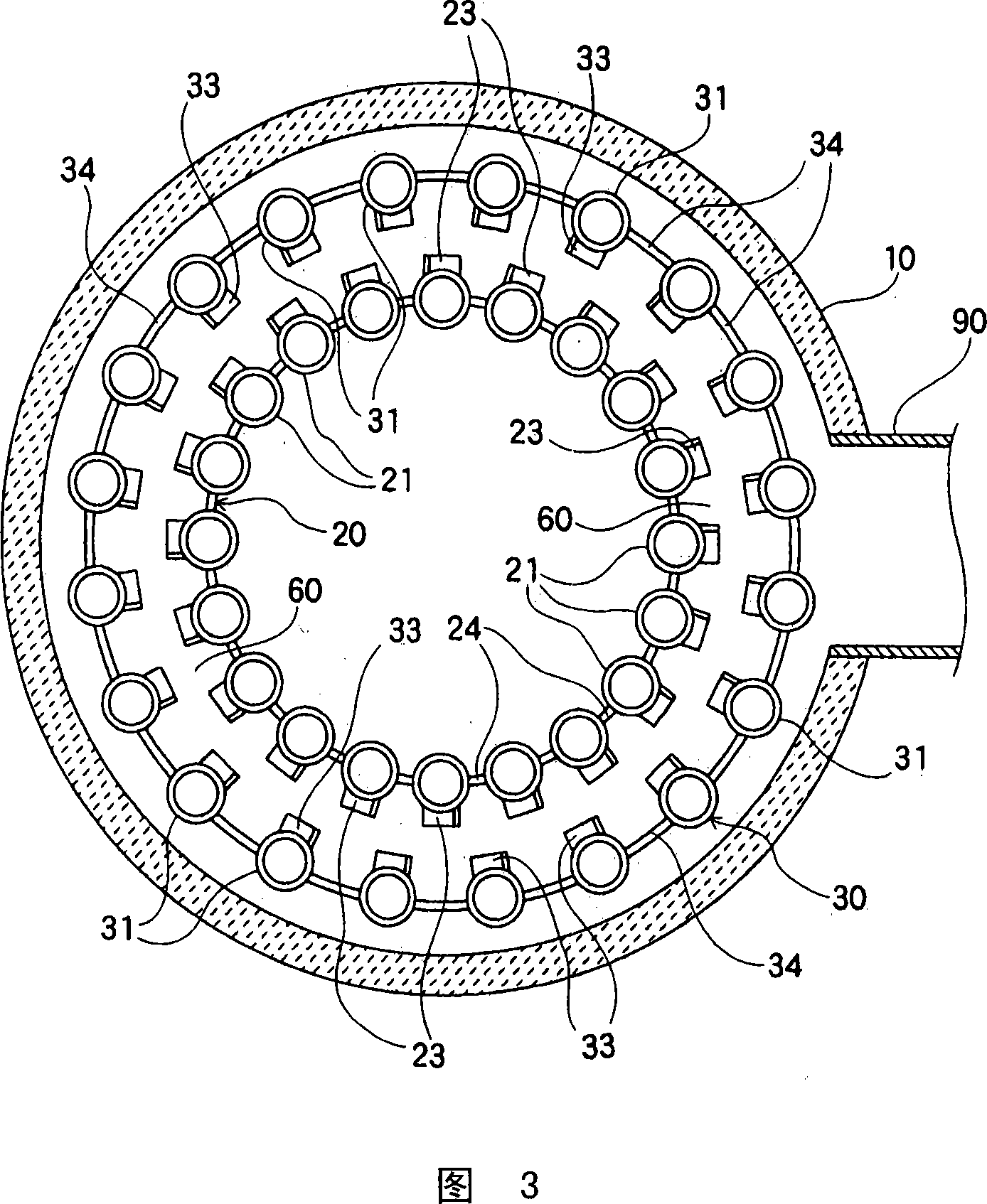

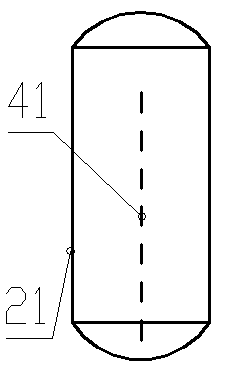

An object of the present invention is to provide a boiler having a water tube group having an enlarged heat transfer surface (fins, etc.) that efficiently recovers heat and has high durability. The present invention is a boiler (1) comprising a tank body (10) having an inner water pipe group (20) and an outer water pipe group (30) arranged in a ring, and a combustion engine disposed in the center of the inner water pipe group (20). A device (40), characterized in that the adjacent inner water pipes constituting the inner water pipe group (20) are closed except for the part where the gas flow path is provided, and the inner water pipe group near the gas flow path (20) and at least one of the above-mentioned outer water tube group (30) is provided with column fins (22, 32).

Owner:MIURA COMPANY LIMITED

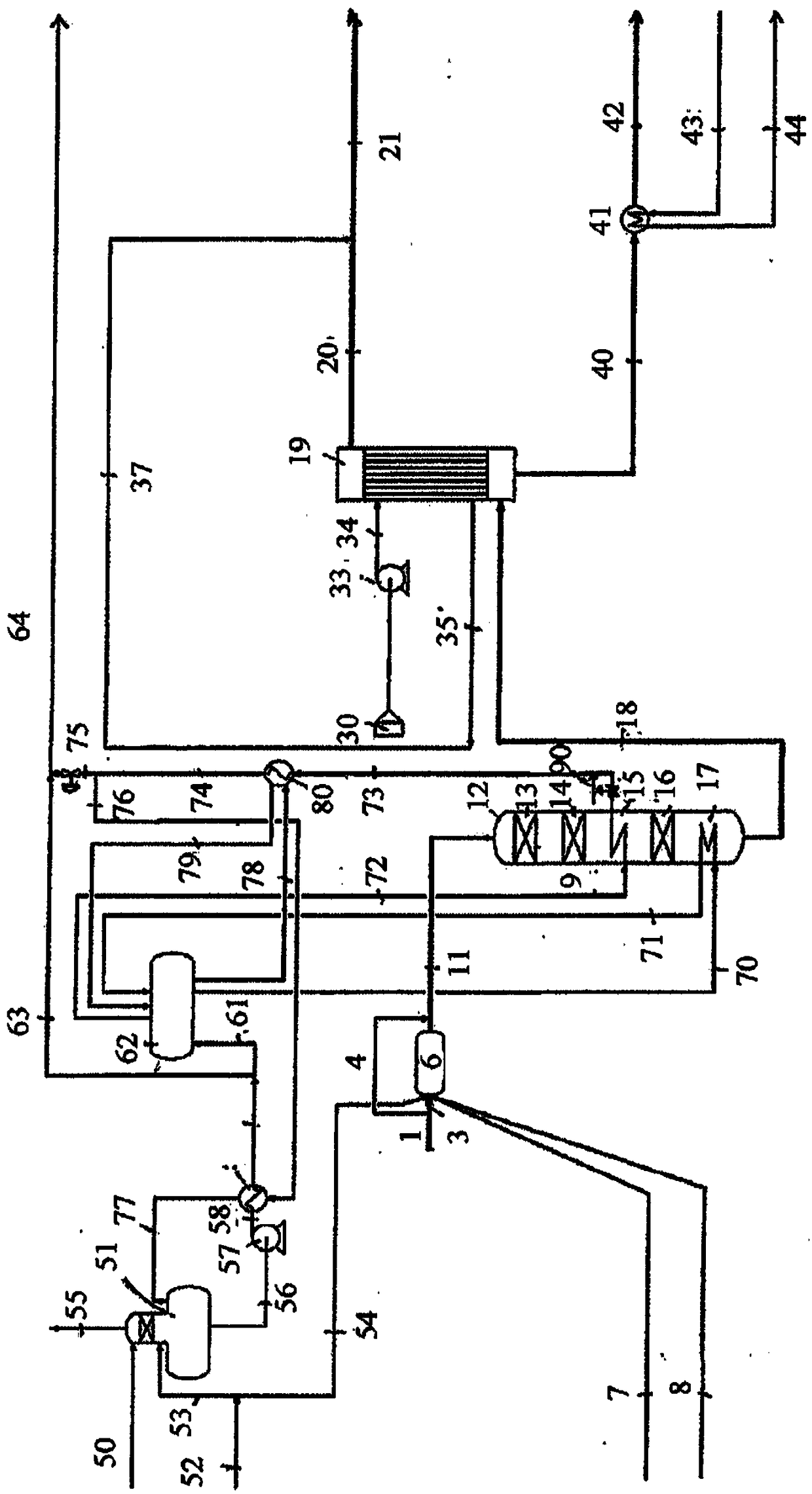

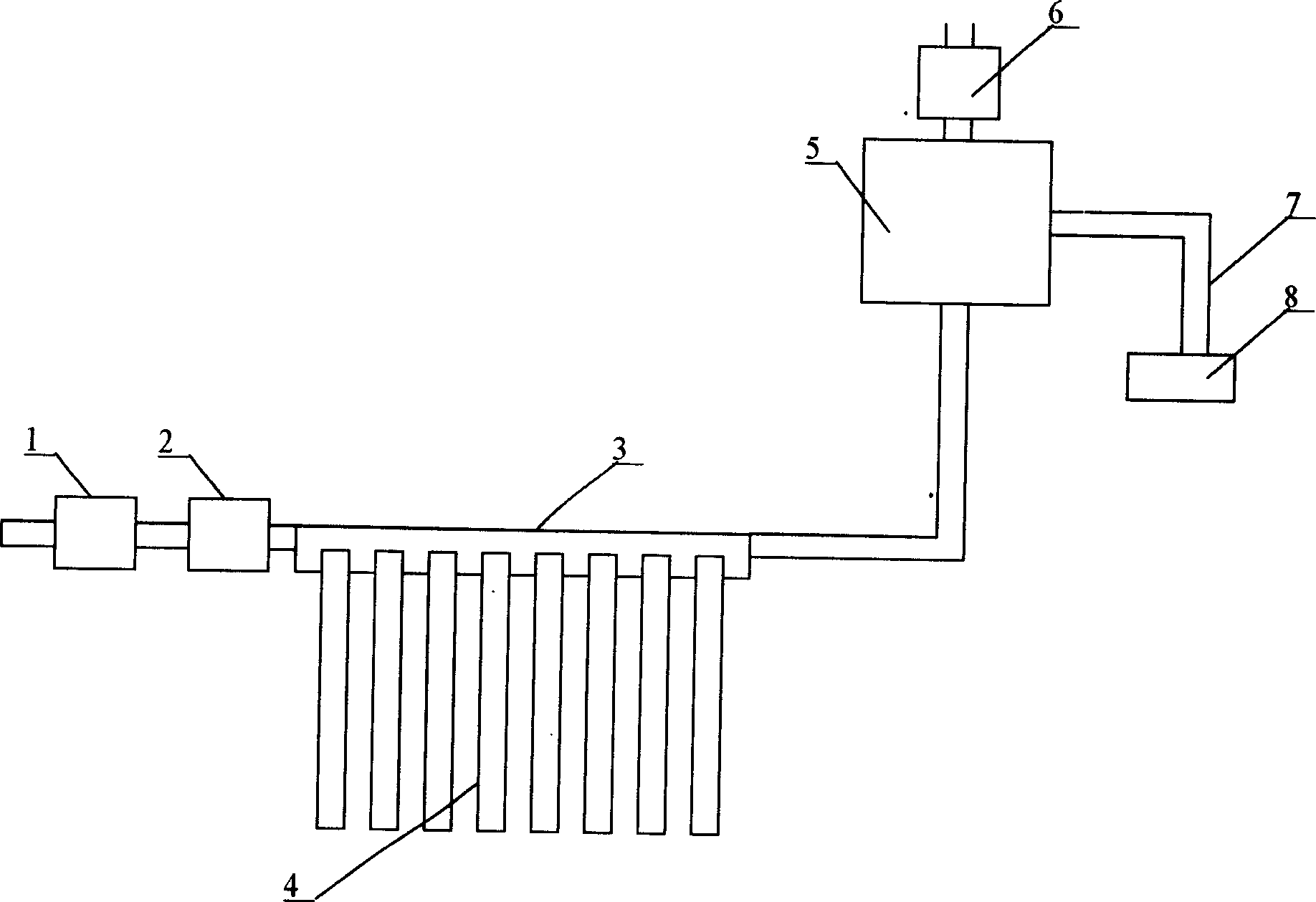

Boiler blow-down water heat energy utilization system

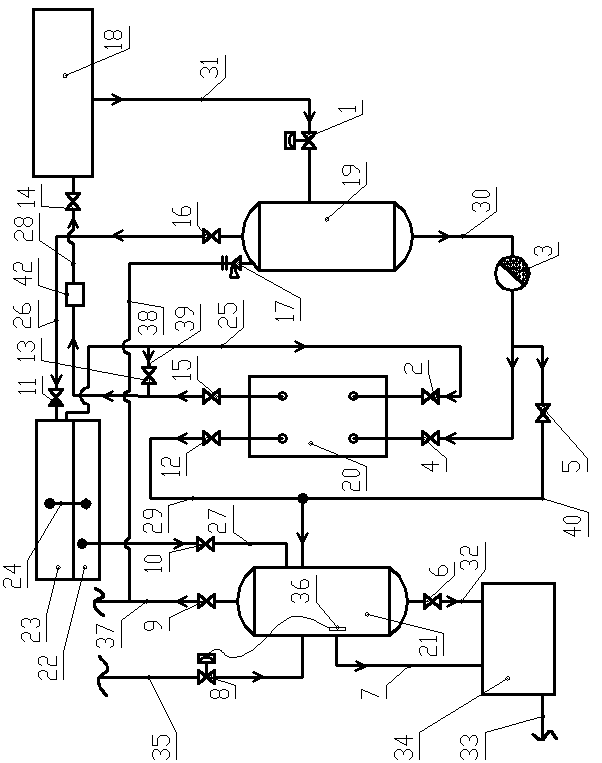

ActiveCN104033880AReduce the temperatureTemperature double heatingSteam generation heating methodsLiquid degasificationWater softeningBoiler blowdown

The invention discloses a boiler blow-down water heat energy utilization system which comprises a water softening station, a boiler, a flash tank, a heat exchanger and a cooling tank. The water softening station comprises a water softener and a water tank, the water softener is connected with the water tank through a soft water outlet tube, and the water softener is connected with a backwash water outlet tube. The heat exchanger is connected with a boiler water supply tube, a cooling tank water inlet tube, a flash tank connecting tube and a water tank outlet tube. The boiler is connected with a boiler water supply tube and a boiler blowdown tube. The top of the flash tank is connected with the water tank through a water tank connecting tube, and the bottom of the flash tank is connected with the heat exchanger through the flash tank connecting tube. The cooling tank is connected with the heat exchanger through the cooling tank water inlet tube, and the bottom of the cooling tank is connected with a cooling tank blowdown tube. The side wall of the cooling tank is connected with an overflow tube, and the overflow tube is connected with a sewage pool. According to the boiler blow-down water heat energy utilization system, boiler blow-down water is used for heating boiler inlet water, flash steam is used for heating water in a hot water tank, so that the temperature of the boiler blow-down water is lowered, the temperature of the boiler inlet water is dually heated, and heat energy needed by the boiler is saved.

Owner:CHINA TOBACCO HENAN IND

Solar steam generator

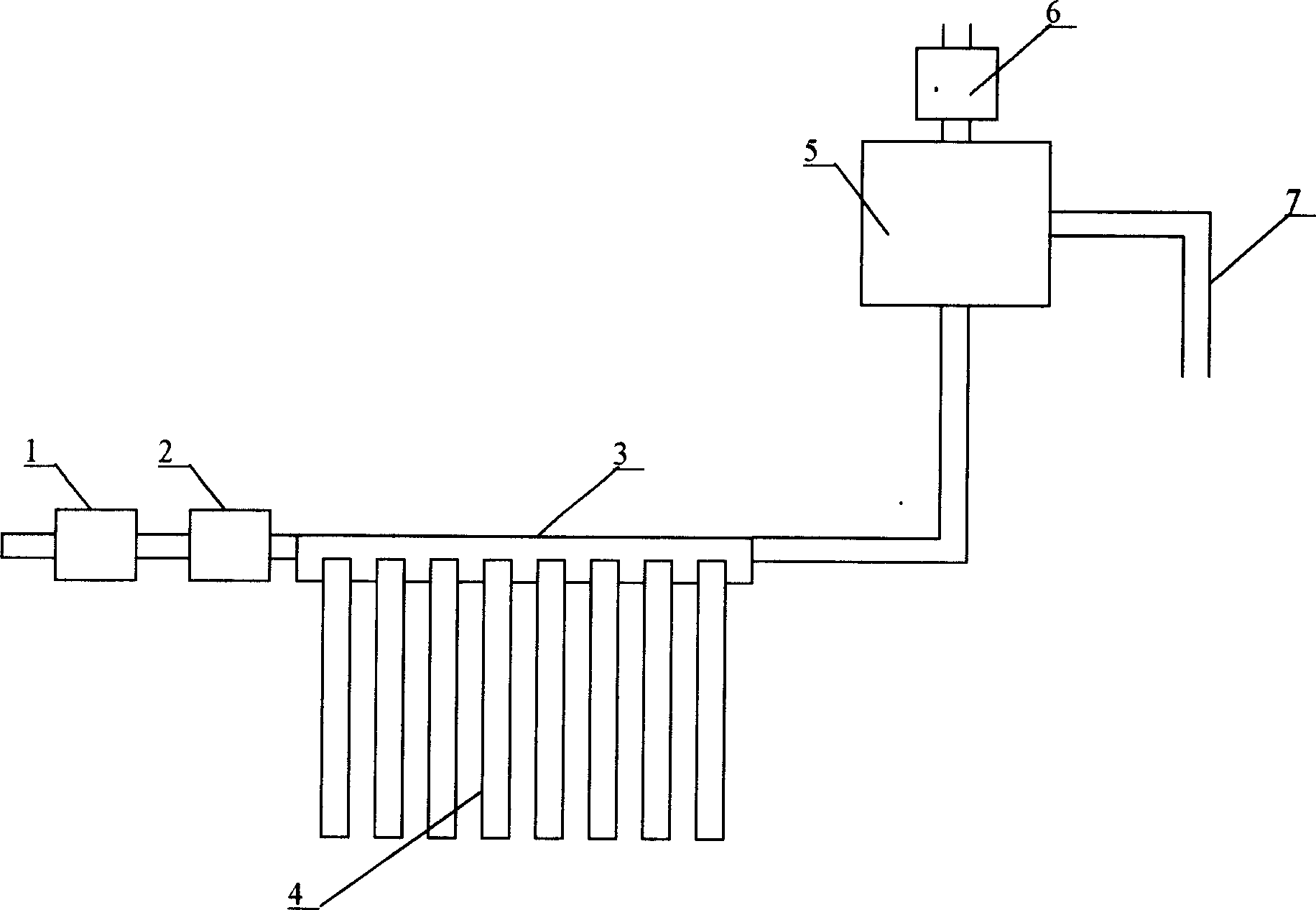

InactiveCN1892105ABeautiful shapeEasy to operateSteam generation heating methodsSolar heat devicesAutomatic controlCollection system

The invention discloses a solar steam generator, comprising one-way valve, solar vacuum heating pipes, pressure relief valve, and steam output pipe, where by pipeline, a flow control valve is connected in order with the one-way valve, a water tube boiler, a cylinder, the pressure relief valve, and the steam output pipe; the solar vacuum heating pipes are arranged in the water tube boiler, and a computer chip able to automatically control water level is arranged in the flow control valve. And it heats the water in water tank by the solar vacuum heating pipe, controls the water level by the flow control valve and reduces the pressure after the pressure in the cylinder reaches the highest index. And it specially designs the solar heat collection system to continuously convert the water into steam by heating to output, and it is convenient to install and operate and simple in use.

Owner:SHANGHAI JIUNENG ENERGY SCI & TECH DEV

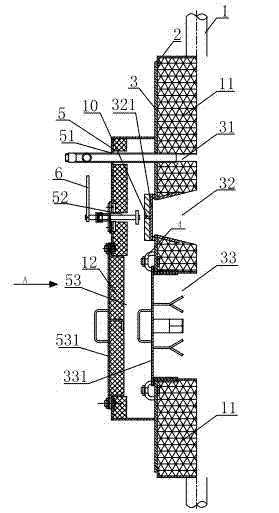

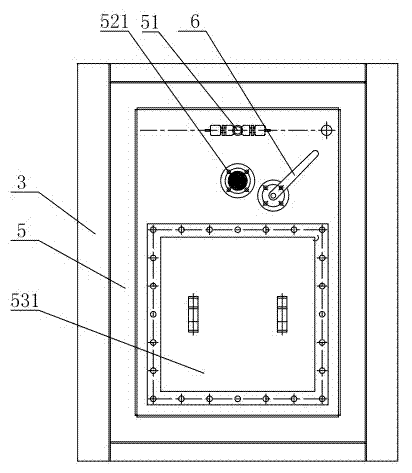

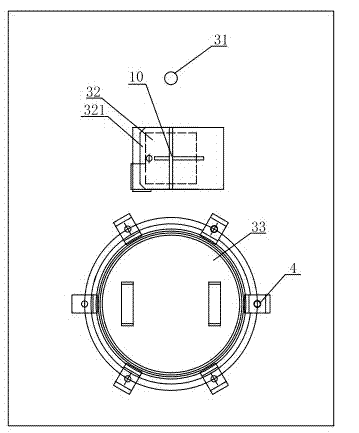

Film-type wall water pipe boiler inspection door structure

ActiveCN102242938AOvercome the shortcoming of single functionSimple structureChamber doorsChamber safety arrangementAgricultural engineeringEngineering

The invention discloses a film-type wall water pipe boiler inspection door structure which comprises an embedded part which is fixedly arranged on a service port surrounding film-type wall, wherein a door seat plate is fixedly arranged on the embedded part, and a packaging cover plate is fixedly arranged on the outside of the door seat plate; an inner test port and an outer test port, an inner fire-observing port and an outer fire-observing port as well as an inner manhole and an outer manhole are respectively arranged on the door seat plate and the packaging cover plate in one-to-one correspondence; an inner fire-observing port cover plate is arranged on the inner fire-observing port, and the inner fire-observing port cover plate is articulated with the door seat plate; an openable manhole cover plate is arranged on the inner manhole, and test sensors are install in the inner test port and the outer test port; and an outer fire-observing cover plate is arranged on the outer fire-observing port, an openable outer manhole cover plate which is installed on the packaging cover plate is arranged on the outer manhole, and a driving device is arranged between the packaging cover plate and the inner fire-observing port cover plate. The film-type wall water pipe boiler inspection door structure provided by the invention has the advantages of simple structure, good heat insulation and heat preservation, comprehensive function and suitability for being applied to all film-type wall water pipe boilers.

Owner:ZHANGJIAGANG GREENS SHAZHOU BOILER

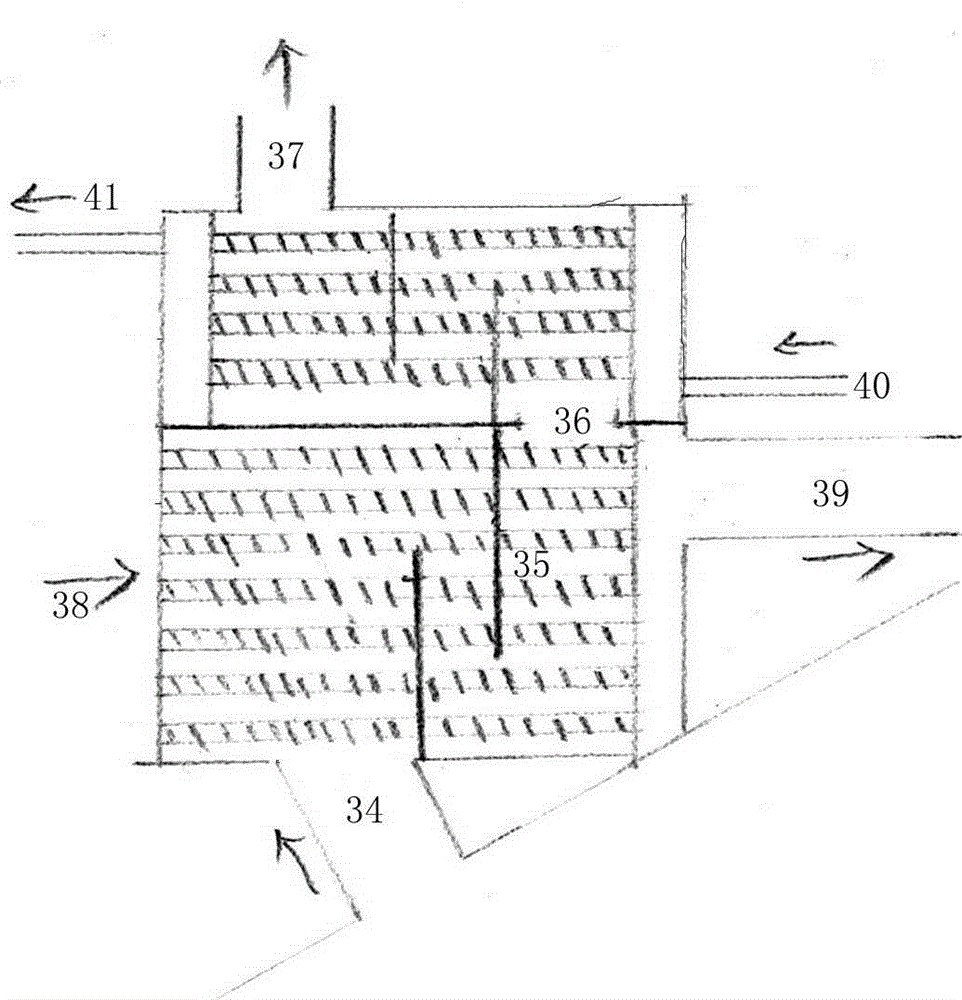

Water-tube boiler achieving internal circulation of flue gas and low-nitrogen combustion control method

ActiveCN105485897AReduce generationWill not increase the loadWater heatersCombustion regulationCombustorLow nitrogen

The invention relates to the technical field of boilers, in particular to a water-tube boiler achieving internal circulation of flue gas and a low-nitrogen combustion control method. The water-tube boiler achieving internal circulation of the flue gas comprises a boiler wall and a boiler chamber which is communicated with an outlet of a combustor, an outer side water-cooling wall is installed on the side wall of the boiler chamber, an inner side water-cooling wall is installed in the boiler chamber, and a water-cooling interlayer is formed between the outer side water-cooling wall and the inner side water-cooling wall; a flue gas backflow inlet is formed in the end, far away from the outlet of the combustor, of the water-cooling interlayer, and a lower-temperature flue gas backflow outlet is formed in the end, close to the outlet of the combustor, of the water-cooling interlayer; a low-temperature flue gas backflow zone is formed by the water-cooling interlayer, and a high-temperature flue gas radiation zone is formed by the portion, located on the inner side of the inner side water-cooling wall, of the boiler chamber. According to the water-tube boiler achieving internal circulation of the flue gas and the low-nitrogen combustion control method, by means of the circulation mode of flue gas in the boiler chamber, decreasing of combustion temperature is facilitated, generation of nitrogen oxides is reduced, the load of an induced draft fan cannot be increased, the system is easy to control, and combustion stability is good.

Owner:QINGDAO QUANNENG ENERGY SAVING ENVIRONMENTAL PROTECTION BOILER CO LTD

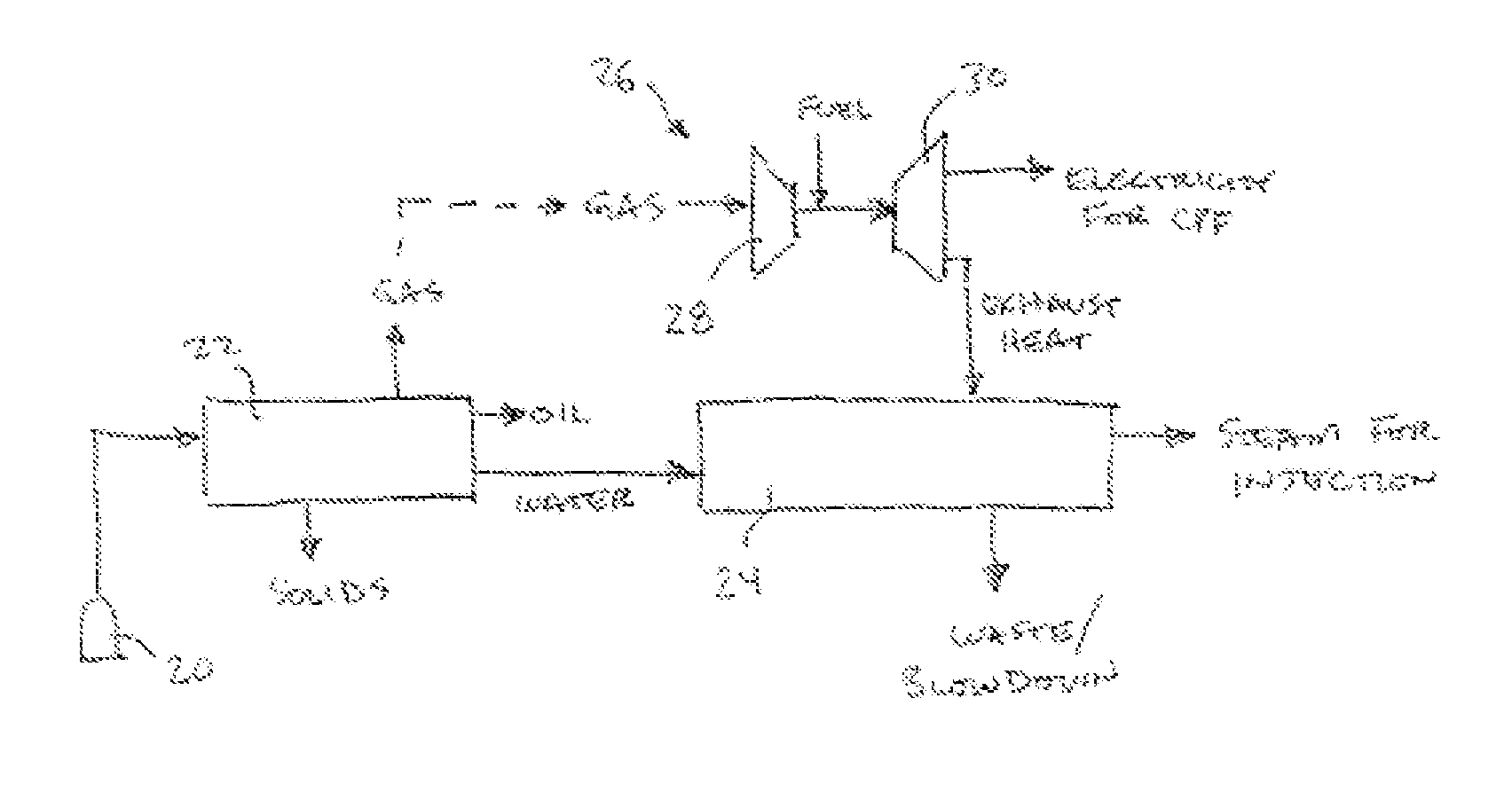

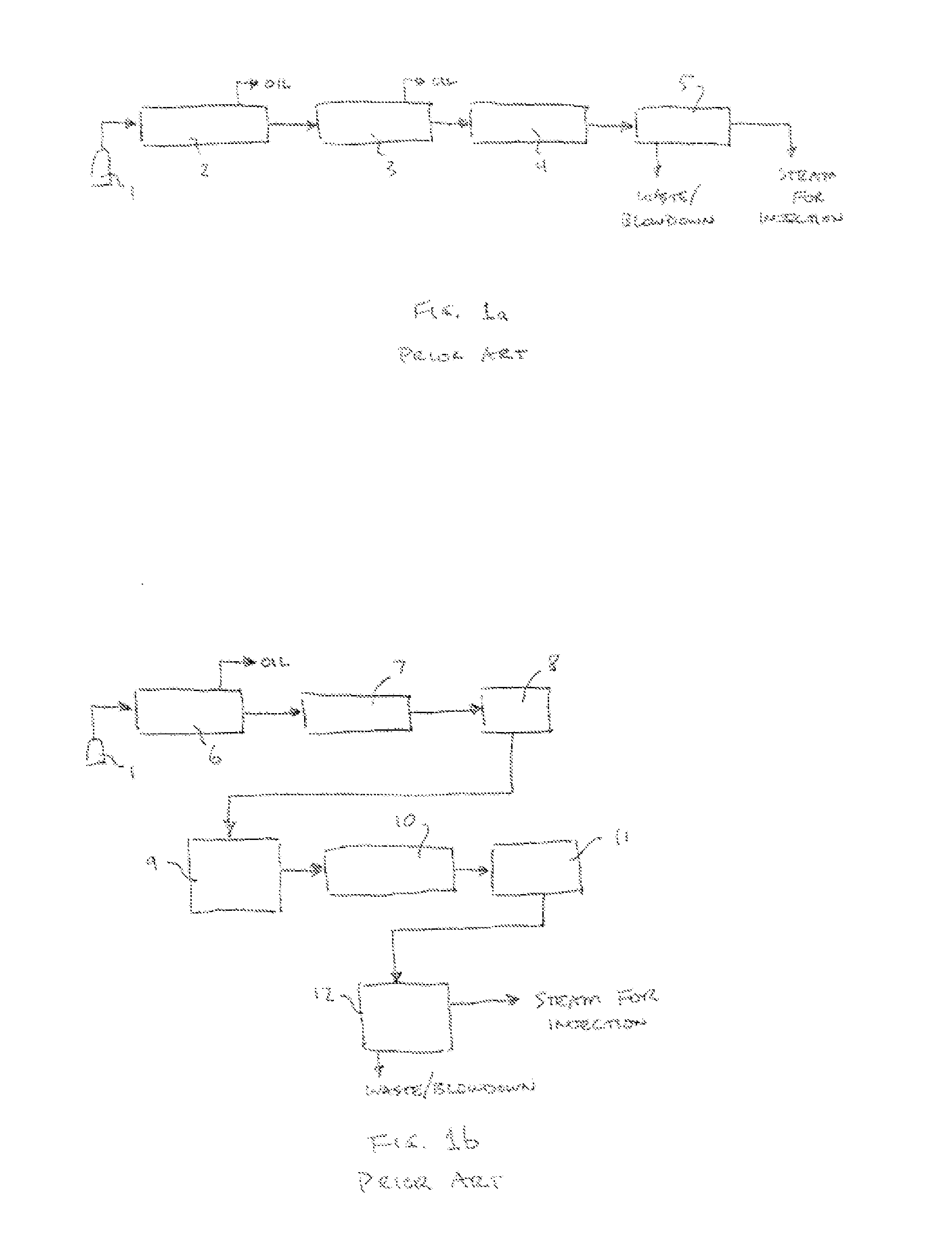

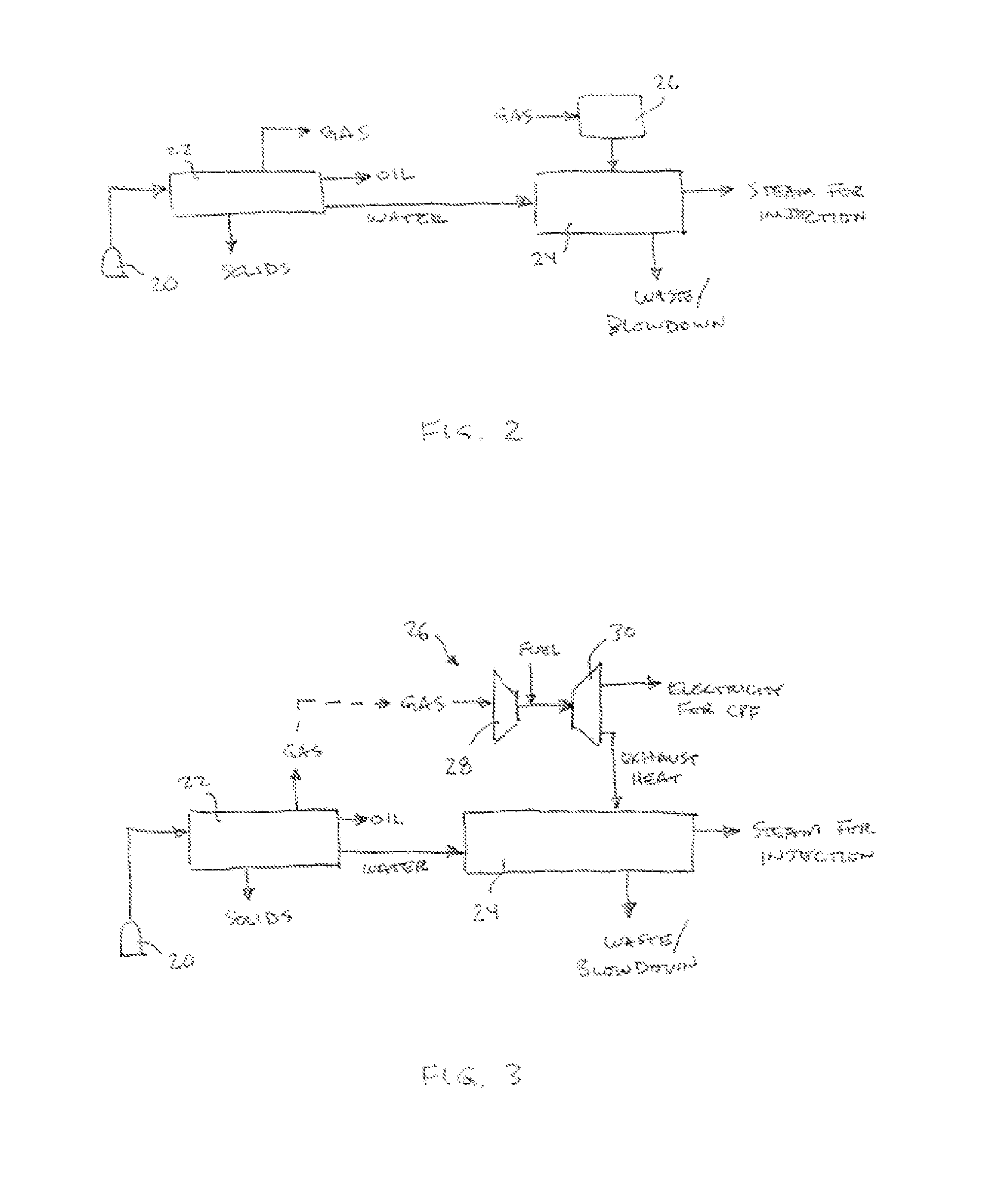

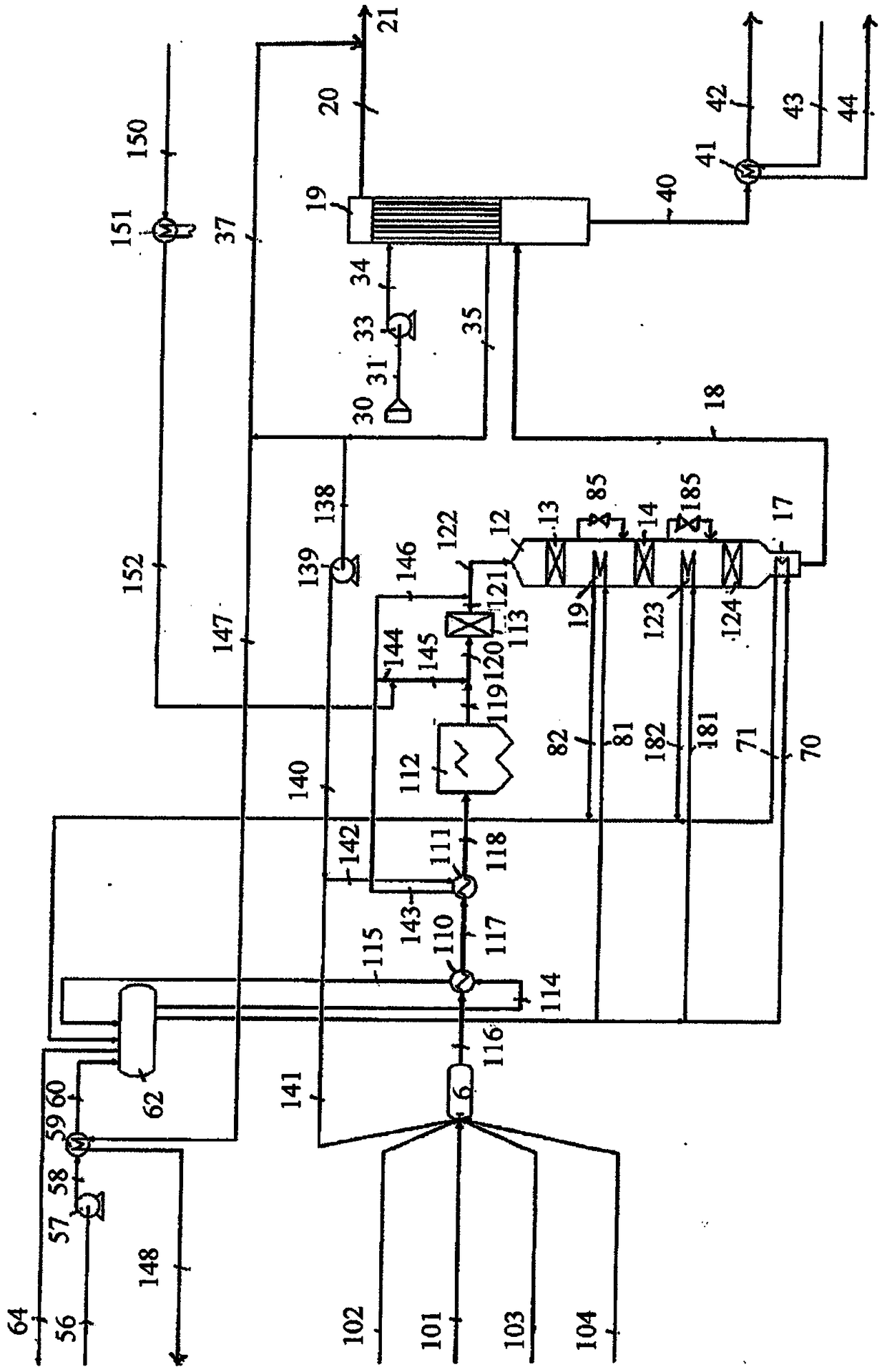

Produced water steam generation process using produced water boiler with gas turbine

InactiveUS20160076345A1Avoids heat transfer surface area duplicationValue-added and simplified line-upInsulationFluid removalPiggingProduced water

A method and system for producing steam for use in heavy hydrocarbon recovery operations. Water, containing impurities, produced from the well is separated from hydrocarbons and other materials, and subsequently directly passed to a produced water boiler with online pigging. The boiler is indirectly heated by means of a hot flue gas, such as a gas turbine exhaust, which produces electricity (for powering a central processing facility, or alternatively a burner to heat the boiler) and exhaust heat for heating the boiler.

Owner:HUSKY OIL OPERATIONS

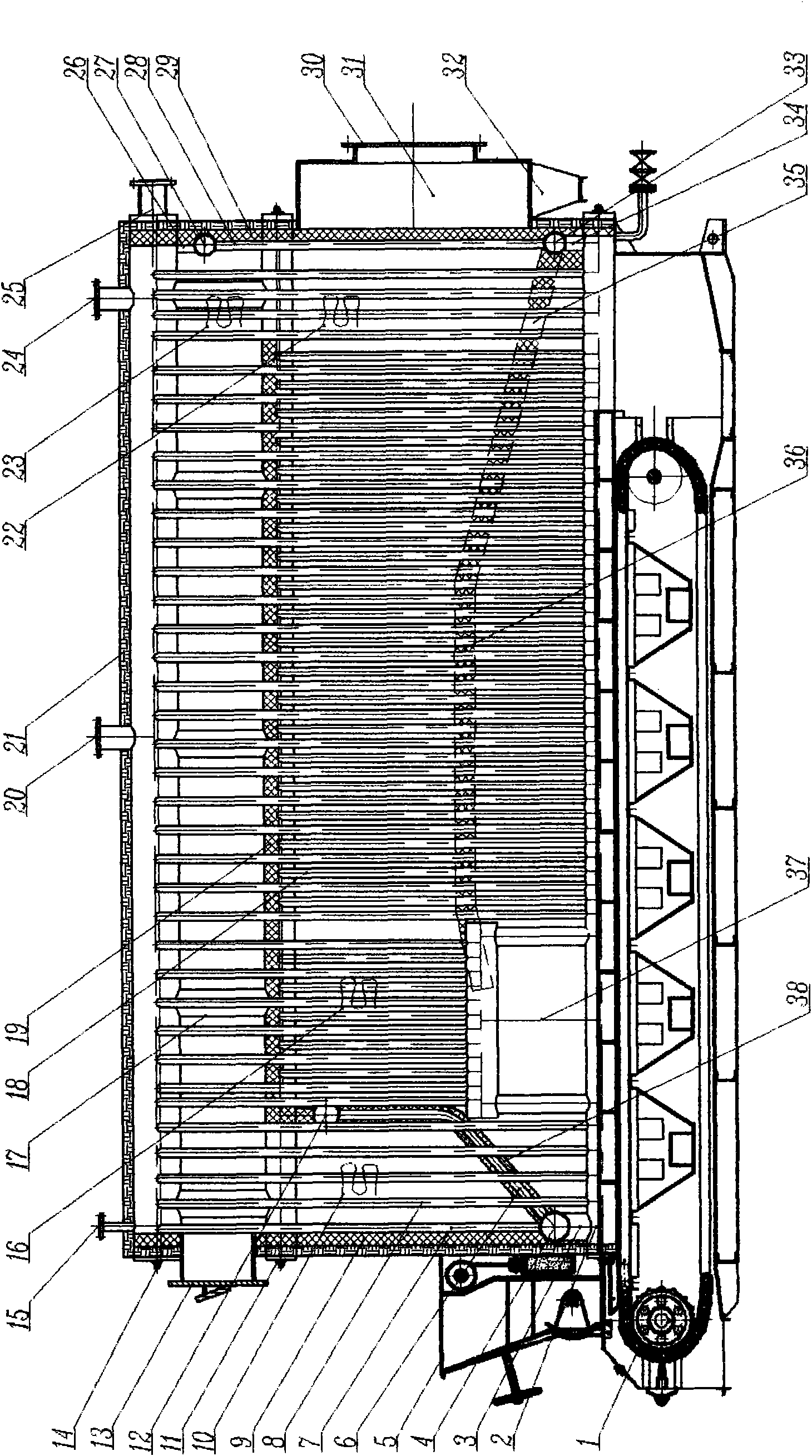

Low discharging and high-energy effect novel industrial boiler

InactiveCN101457981ARaise the outlet temperatureReduce carbon contentWater-tube boilersWater heatersHigh energyCogeneration

The invention discloses a novel industrial boiler with low emission and high energy efficiency, and relates to the series of twenty boilers which are different in fuels and mediums, namely large-scale grate firing: scattered coal, moulded coal and biomass and chamber firing: fuel gas, oil-fired hot water, steam, phase-conversion heat exchange and distributed heat and power cogeneration boilers. The novel industrial boiler comprises a transverse boiler, a transversal and longitudinal container, a water wall tube, a vertical boiler shell, a thread smoke tube, and the like. The invention integrates the advantages of a water-tube boiler, a water-fire tube boiler and a corner-tube boiler, more particularly solves the different defects of three types of boilers; namely, the water-tube boiler has the defects of complicated technology as well as large volume and steel consumption; the water-fire tube boiler has the defects of tube plate crackle, tube explosion, smoke tube abrasion, and the like; the corner-tube boiler has the defects that the technology is complicated technology and the dust deposition at the tail part is difficult to be eliminated; and the invention also greatly improves the difficult problems of the three types of boilers that the initial emission concentration of smoke and dust is higher generally. The invention has the advantages of advanced installation technology and extremely obvious energy conservation and emission reduction.

Owner:王森

Multifunctional fuel energy-saving hot-water steam boiler

InactiveCN105258097AClean dischargeNo pollution in the processWater heatersSteam boilersFuel efficiencyHearth

The invention belongs to the technical field of hot-water boilers and particularly relates to a multifunctional fuel energy-saving hot-water steam boiler. The problem that a traditional coal-fired boiler does not adapt to novel fuel is solved. The multifunctional fuel energy-saving hot-water steam boiler comprises a support. An inclined boiler body is arranged on the support. A hearth, a water chamber, a primary heat exchange chamber and a secondary heat exchange chamber are arranged inside the boiler body. A water inlet, a water return opening, a condensate water draining outlet and a sewage draining outlet are formed in the water chamber. The hearth is connected with the primary heat exchange chamber. The primary heat exchange chamber is connected with the secondary heat exchange chamber through a gas return pipe. The secondary heat exchange chamber is connected with an air preheating chamber. According to the multifunctional fuel energy-saving hot-water steam boiler, clean fuel such as coal gas, natural gas, fuel oil, methyl alcohol and alcohol groups can be burnt, the burning efficiency is brought into full play, the 100-percent complete combustion is achieved, drainage is thorough and no pollution is caused.

Owner:王兴

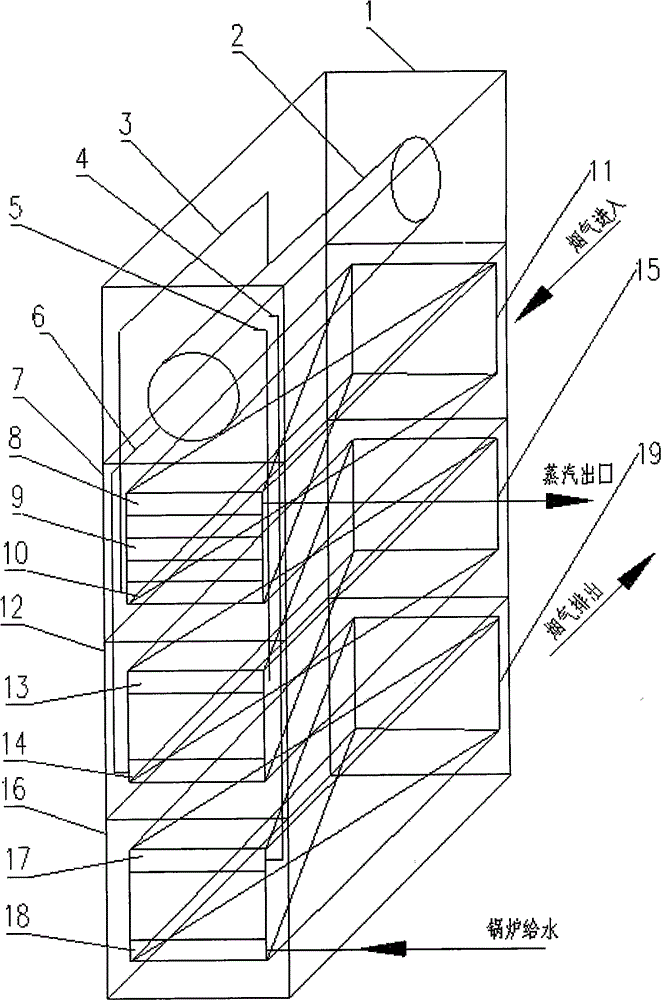

Novel modularization vertical type water pipe waste heat boiler

InactiveCN104406145ASave heavy steel framesSave steelSteam generation using hot heat carriersSteel frameSuperheater

The invention relates to a novel modularization vertical type water pipe waste heat boiler. The novel modularization vertical type water pipe waste heat boiler is composed of a boiler barrel box group, a super heater box group, an evaporator box group, a coal economizer box group and the like, wherein the boiler barrel box group is composed of a plurality of boiler barrel boxes, the super heater box group is composed of a plurality of super heater boxes, the evaporator box group is composed of a plurality of evaporator boxes, and the coal economizer box group is composed of a plurality of coal economizer boxes. The novel modularization vertical type water pipe waste heat boiler has the advantages of firstly using double independent structures of an outer box, a built-in boiler barrel flue, a heating face and the like, and thereby not only guaranteeing relative static status and load supporting of the outer box, but also meeting thermodynamics dynamic change and pressure bearing requirements of the built-in boiler barrel flue, the heating face and a heating body component, and secondly saving usage amount of steel frames and steel materials for an existing vertical water tube boiler, shortening a manufacture period of a device due to standardized production, reducing installation engineering quantity of the boilers of the same type due to modularization, and reducing the occupied area and energy consumption of the boilers of the same type.

Owner:张德志

A method for inter-bed cooling in wet gas sulfuric acid plants

InactiveCN109205574AAvoid cold areasReduce condensationGas treatmentChemical industryPhysical chemistrySuperheater

A method for cooling of process gas between catalytic layers or beds in a sulfuric acid plant is disclosed. In the method, one or more boilers, especially water tube boilers, are used instead of conventional steam superheaters to cool the process gas between the catalytic beds in a SO2 converter of the plant; and in this sulfuric acid device, sulfuric acid is produced from feed gases containing sulfurous components like SO2, H2S, CS2 and COS or liquid feeds like molten sulfur or spent sulfuric acid, and therefore a less complicated and more cost efficient heat exchanger layout is obtained.

Owner:HALDOR TOPSOE AS

Low discharge high energy efficiency vertical shell type water-fire tube boiler

InactiveCN101187467AIncrease the lengthShorten the lengthSteam generation plantsHigh energyCogeneration

A vertically-arranged spiral-cased water-gas-tube boiler which is low discharge and high energy efficiency relates to the thirties big boilers series, namely that large-size and middle-sized water-gas-tube grate firing boilers of loose coal, molded coal and biological energy, or gas and fuel oil of boilers in household, and comprises a hot-water boiler, a vapor boiler, a phase-change heat transfer hot-water boiler and a distributed thermo-electricity cogeneration boiler. The invention comprises a longitudinally-arranged barrel, a crossbar collection chamber, a wall-cooling pipe, a vertically-arranged spiral casing, and a thread flue tube and the like. The invention changes the flue way of a current water-gas-tube boiler from a longitudinal flue way which horizontally returns front and rear to a transverse flue way which vertically returns up and down. Smoke is naturally realized two large flashes before entering the flue tube. The vertically-arranged spiral casing is totally exposed and heated in the tail flue way of the boiler. With the same volume of the boiler and steel consumption, the invention significantly enlarges the capacities of a hearth and the flue way and radiating convection heating area. Only one baffle is arranged in five returns of a coal-fired hot water total forced-circulation waterway, and three returns of a gas-fired total forced-circulation waterway is not provided with a baffle, which not only completely eliminates tube explosion, tube plate crack and fuel tube abrasion, but also a smoke sedimentation chamber is arranged on the front bottom portion of a smoke-discharge mouth, which largely reduces the initial discharge concentration of smoke.

Owner:王森

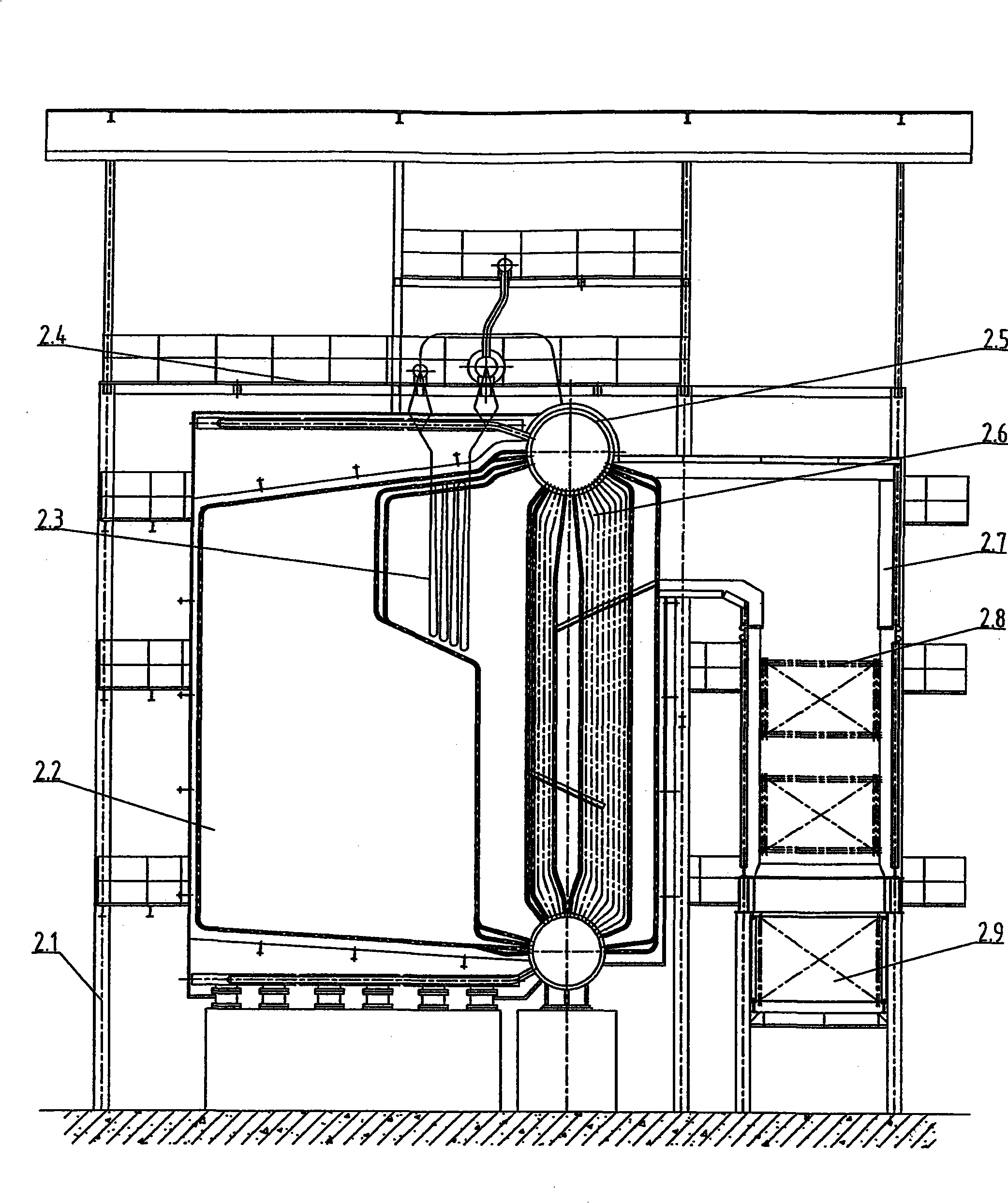

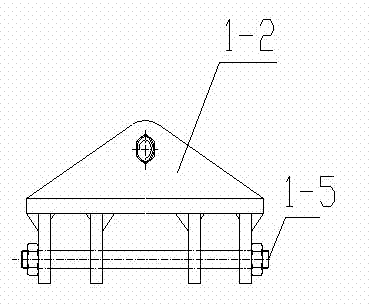

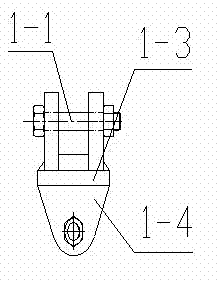

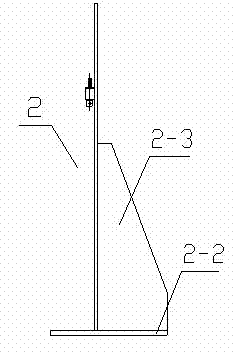

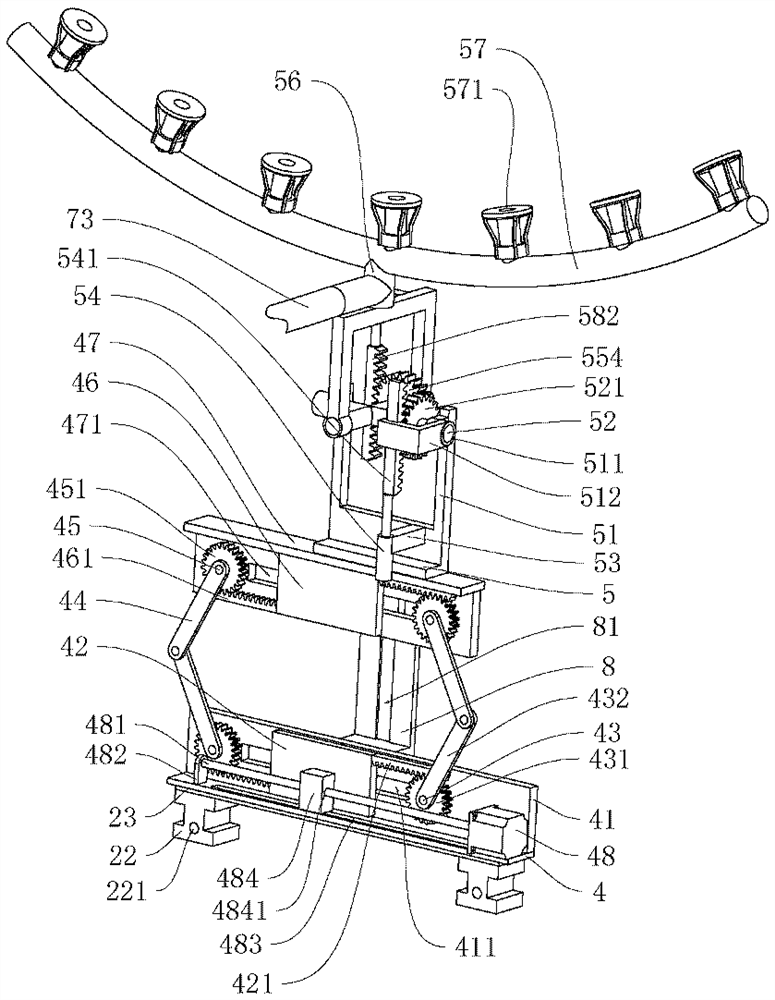

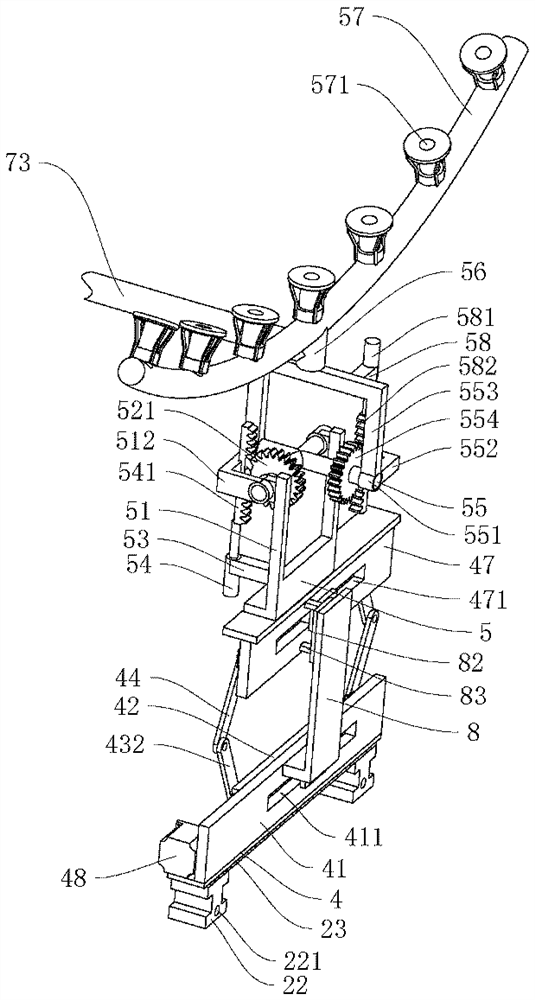

Turnover hoisting tooling of water tube boiler body

The invention relates to a turnover hoisting tooling of a water tube boiler body, which belongs to the technical field of boiler making and comprises a hoisting frame (1) and supports (2), wherein the hoisting frame (1) is provided with a hoisting beam (1-3); the top of the hoisting beam (1-3) is connected with upper connecting hoisting plates (1-2) which are connected through hoisting screws (1-1); the bottom of the hoisting beam (1-3) is connected with lower connecting hoisting plates (1-4) which are connected through connecting bolts (1-5); each support (2) comprises a base plate (2-2), a support plate (2-1) and a rib plate (2-3); a circular arc groove (2-5) is arranged in the center of the top of each support plate (2-1); and an adjusting bolt (2-4) is arranged on the edge of each circular arc groove (2-5). The turnover hoisting tooling of the water tube boiler body reduces the requirements on sites, skills of operators and manufacturing cost, and is convenient for realizing production adjustment.

Owner:JIANGSU SHUANGLIANG BOILER

Iron solar steam generating device

InactiveCN1892104ABeautiful shapeEasy to operateSolar heating energySteam generation heating methodsAutomatic controlCollection system

The invention discloses an electric iron-used solar steam generator, comprising one-way valve, solar vacuum heating pipes, pressure relief valve, and steam iron, where by pipeline, a flow control valve is connected in order with the one-way valve, a water tube boiler, a cylinder, the pressure relief valve, and a steam outlet pipe; the solar vacuum heating pipes are arranged in the water tube boiler, and a computer chip able to automatically control water level is arranged in the flow control valve. And it heats the water in water tank by the solar vacuum heating pipes, controls the water level by the flow control valve, and reduces the pressure by the pressure relief valve when the pressure in the cylinder reaches the highest index. And it specially designs the solar heat collection system to continuously convert the water into steam by heating to output. And it is convenient to install and operate, and simple to use.

Owner:邹乾林

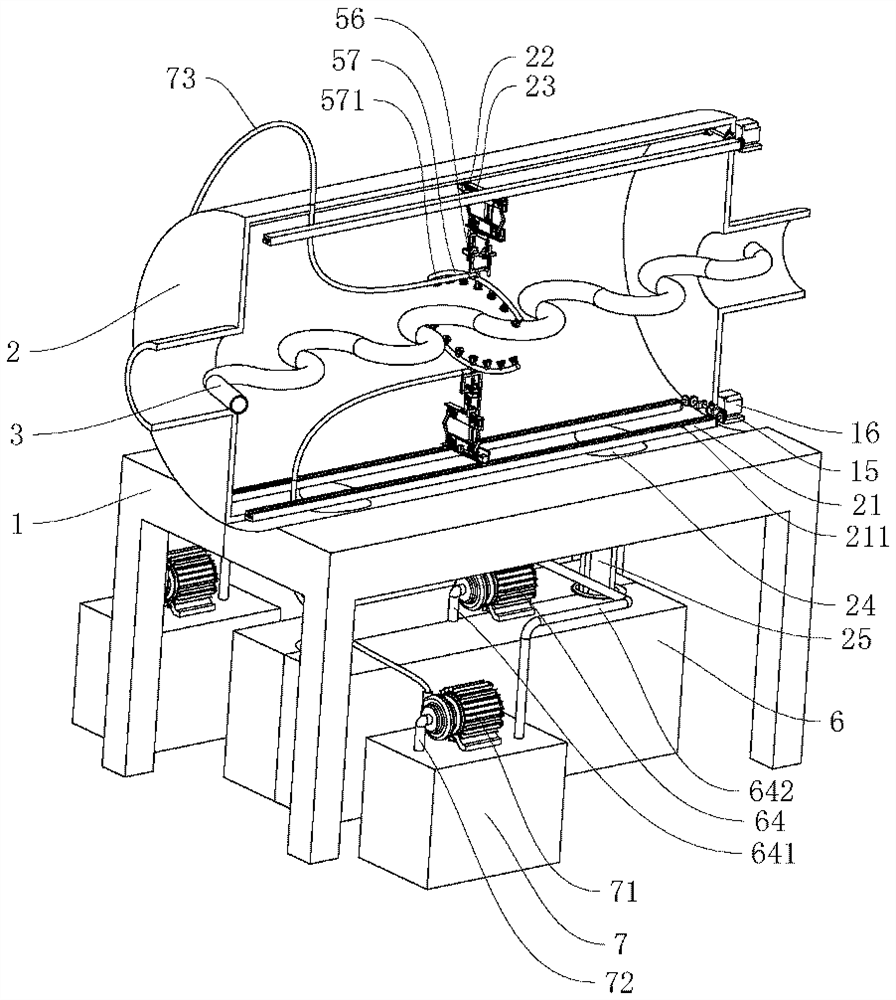

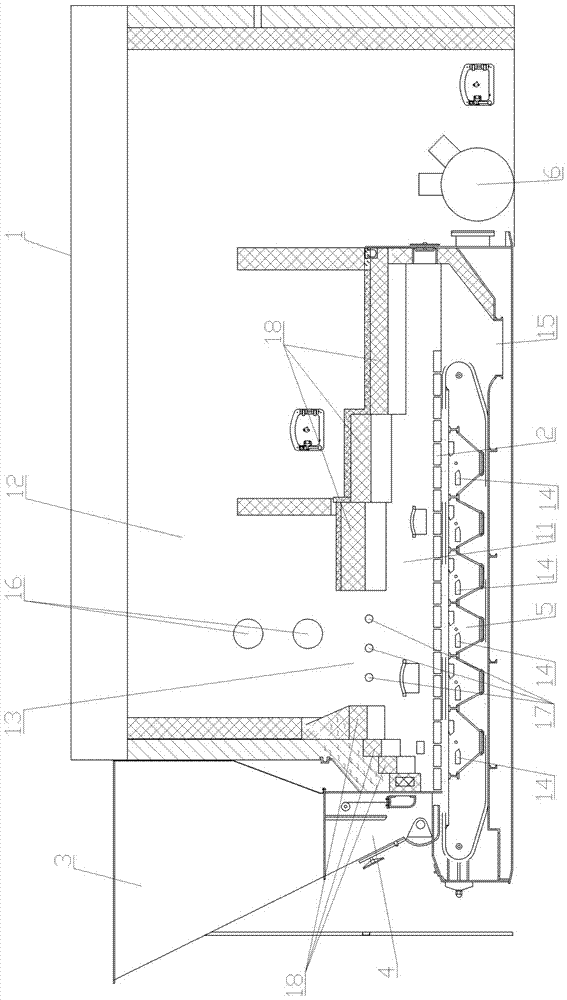

Energy-saving and efficient ash removal device of waste heat boiler

ActiveCN112212309AEasy automatic spray cleaningEasy to cleanBoiler water tubesUsing liquid separation agentMechanical engineeringWater spray

The invention relates to an energy-saving and efficient ash removal device of a waste heat boiler, and belongs to the technical field of boiler ash removal structures. The device comprises a bottom frame, a boiler body arranged on the bottom frame and multiple water pipes arranged in the boiler body. Ash removal mechanisms are symmetrically arranged in the boiler body and comprise guide plates symmetrically arranged on the inner side wall of the boiler body, sliding plates are slidably connected to the two guide plates through moving assemblies, and a moving plate is jointly connected to the two sliding plates at the same time. A water collecting pipe is arranged on the side, deviating from the sliding plates, of the moving plate through a driving assembly, one end of the water collectingpipe communicates with an arc-shaped water pipe, the arc-shaped water pipe communicates with multiple water spraying heads, and a water supply assembly communicating with the water collecting pipe isarranged on one side of the bottom frame. According to the device, the water pipes can be conveniently and automatically sprayed and cleaned, so that dust adhering to the water pipes is effectively cleaned away, and therefore the heat exchange efficiency of the water pipes and the boiler body can be improved; and the ash removal efficiency can be improved, and the labor intensity of workers can bereduced.

Owner:佛山市腾辉锅炉制造有限公司

Biomass water-tube boiler capable of enabling fuel to be sufficiently combusted

The invention discloses a biomass water-tube boiler capable of enabling fuel to be sufficiently combusted. The biomass water-tube boiler comprises a hearth, a reciprocating type fire grate, a biomassfeeding hopper and a fuel adding hopper; a combustion chamber and a convection tube cavity are formed in the hearth; the convection tube cavity is located at the upper end of the combustion cavity; the convection tube cavity communicates with the combustion cavity through a flue gas ascending opening; an air inlet and a total slag outlet are formed in the outer side the hearth; a spraying openingis formed in the hearth; the reciprocating type fire grate is arranged in the combustion cavity; one end of the reciprocating type fire grate is a feeding end, and the other end of the reciprocating type fire grate is a slag discharging end; the fuel adding hopper is connected to the lower end of the biomass feeding hopper and communicates with an inner cavity of the biomass feeding hopper; and asecondary air supply port communicating with the flue gas ascending opening inside the hearth is further formed in the hearth. The biomass water-tube boiler has the advantages that secondary air supply is adopted, and combustion in the hearth can be more sufficient; and the secondary air supply port communicating with the flue gas ascending opening is further formed in the hearth, a part of freshair blown from the secondary air supply port is supplemented in the combustion cavity and is used for enabling biomass in the combustion cavity to be combusted more sufficiently, and the other part ofthe flesh air is supplemented into the convection tube cavity and is used for enabling combustible gas in the convection tube cavity to be combusted more sufficiently.

Owner:湖南长宏南雁锅炉修理安装有限公司

Flame pressing type water tube boiler

PendingCN113606566AReasonable designSufficient heat exchangeSteam generation using pressureWater-tube boilersWater storageFuel oil

The invention discloses a flame pressing type water tube boiler in the field of steam generation devices, which comprises a vertically arranged boiler body, tubes are vertically arranged in the boiler body, the tubes are arranged in a concentric annular array, three layers of tubes are arranged from inside to outside, a flame pressing plate is arranged in a circular cavity formed by the tubes on the inner layer, and a hearth is arranged below the flame pressing plate; a spiral coil pipe is also arranged on the periphery of the tube array in the boiler body; and smoke baffles are arranged between the tubes on the adjacent layers and between the tubes on the outer layer and the spiral coil pipe respectively, flow separation components are arranged between the tubes on the same layer and on the inner sides or the outer sides of the tubes on the same layer, a vertically reciprocating baffling channel is formed between the flow separation components and the smoke baffles in the space in the hearth, and the outermost side of the baffling channel is connected to a smoke outlet. The flame pressing type water tube boiler is small in water storage amount and large in steam production amount. The flame pressing type water tube boiler can be made into fire coal, fuel oil, natural gas or biomass energy boilers and can be applied to various places needing steam.

Owner:扬州大唐热能机械制造有限公司

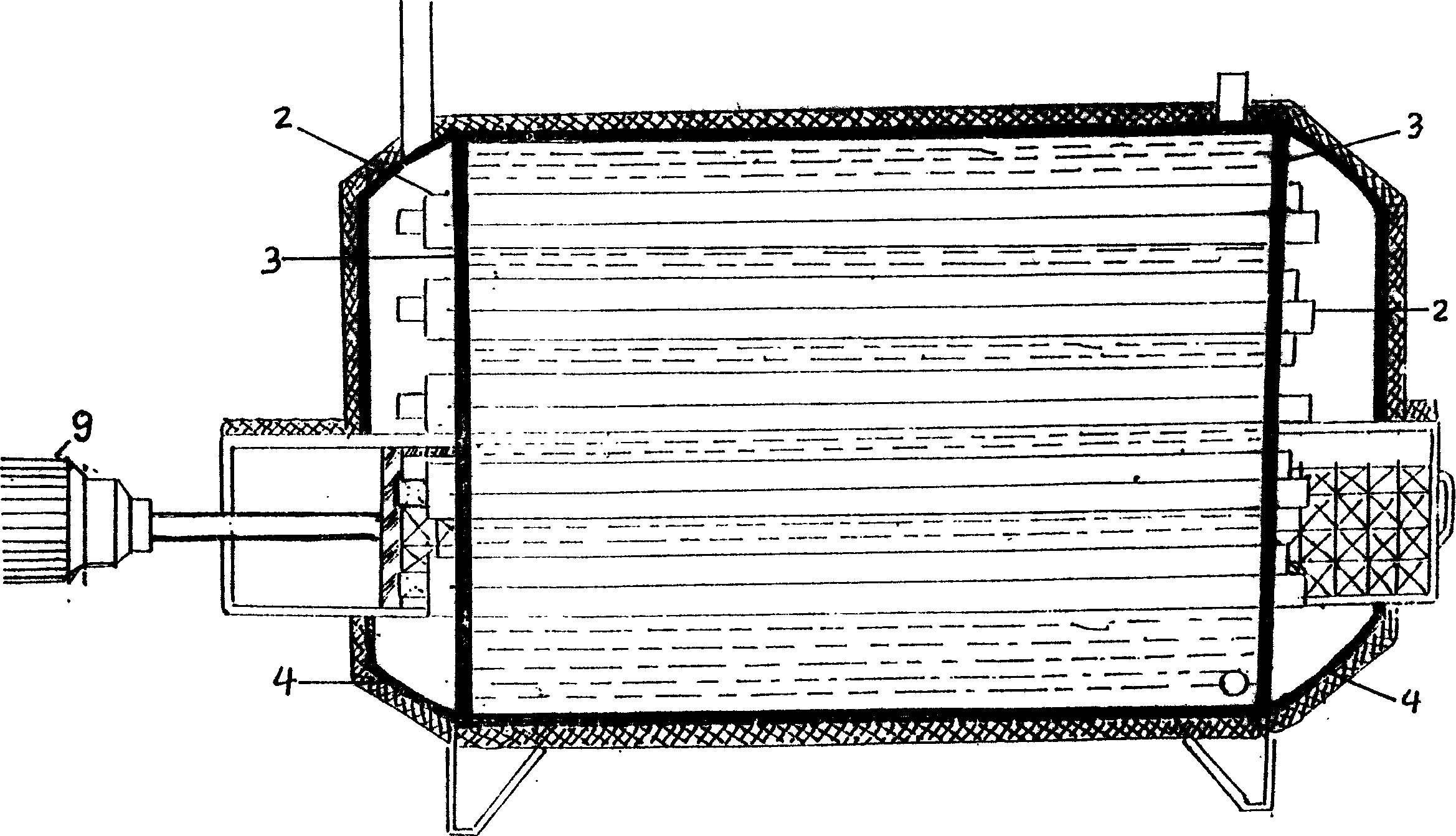

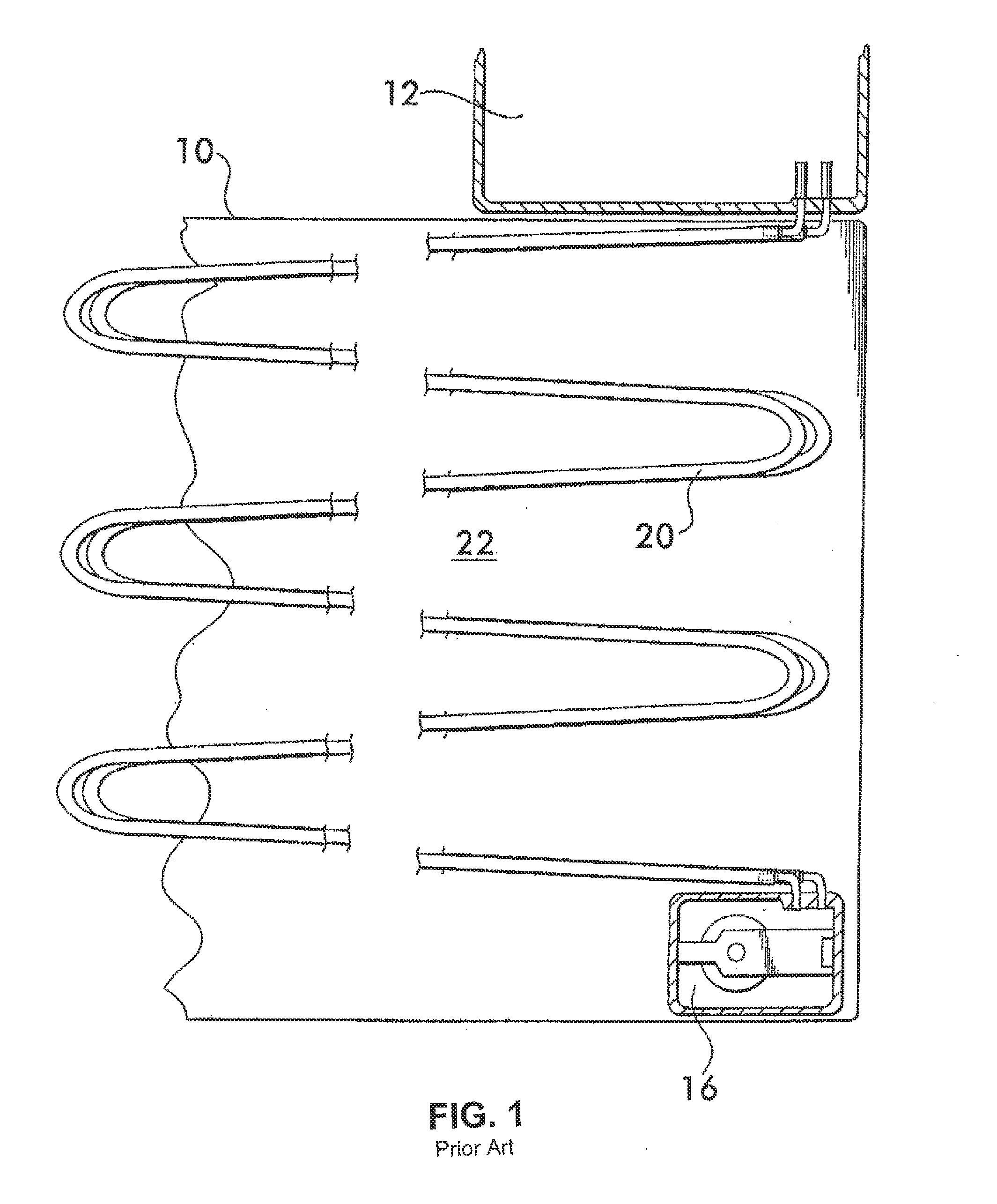

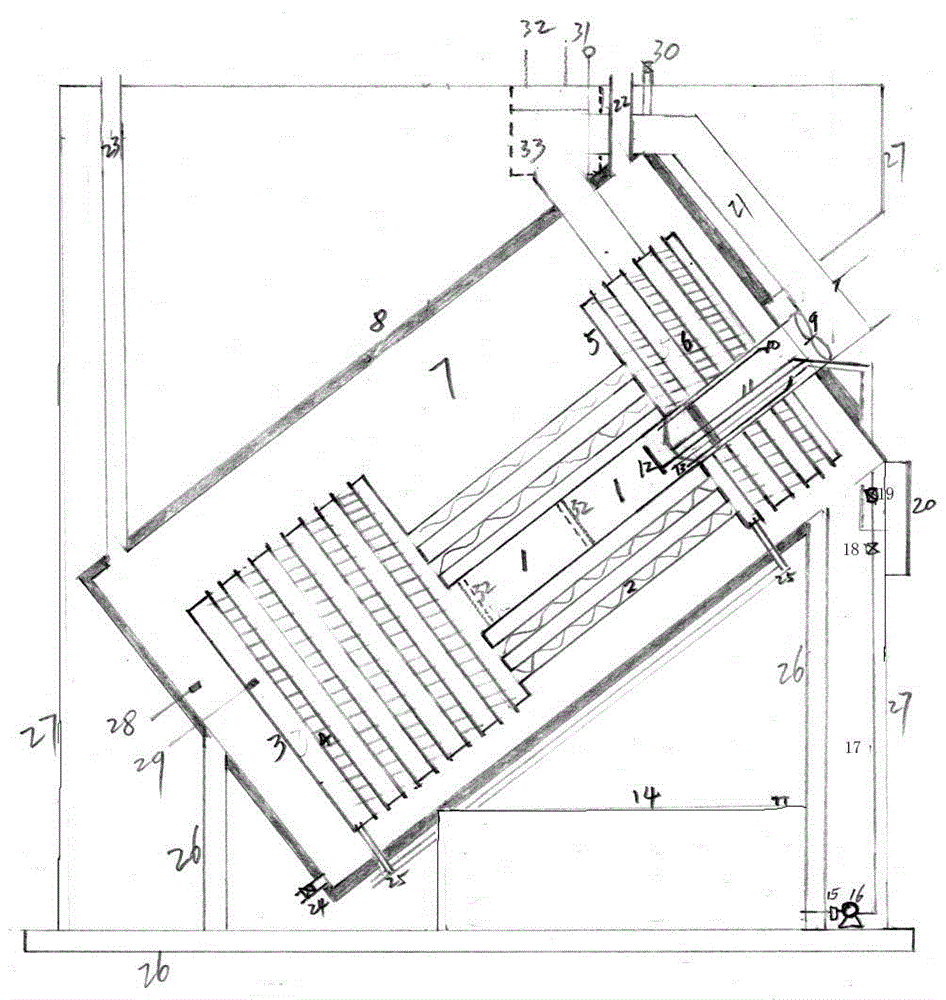

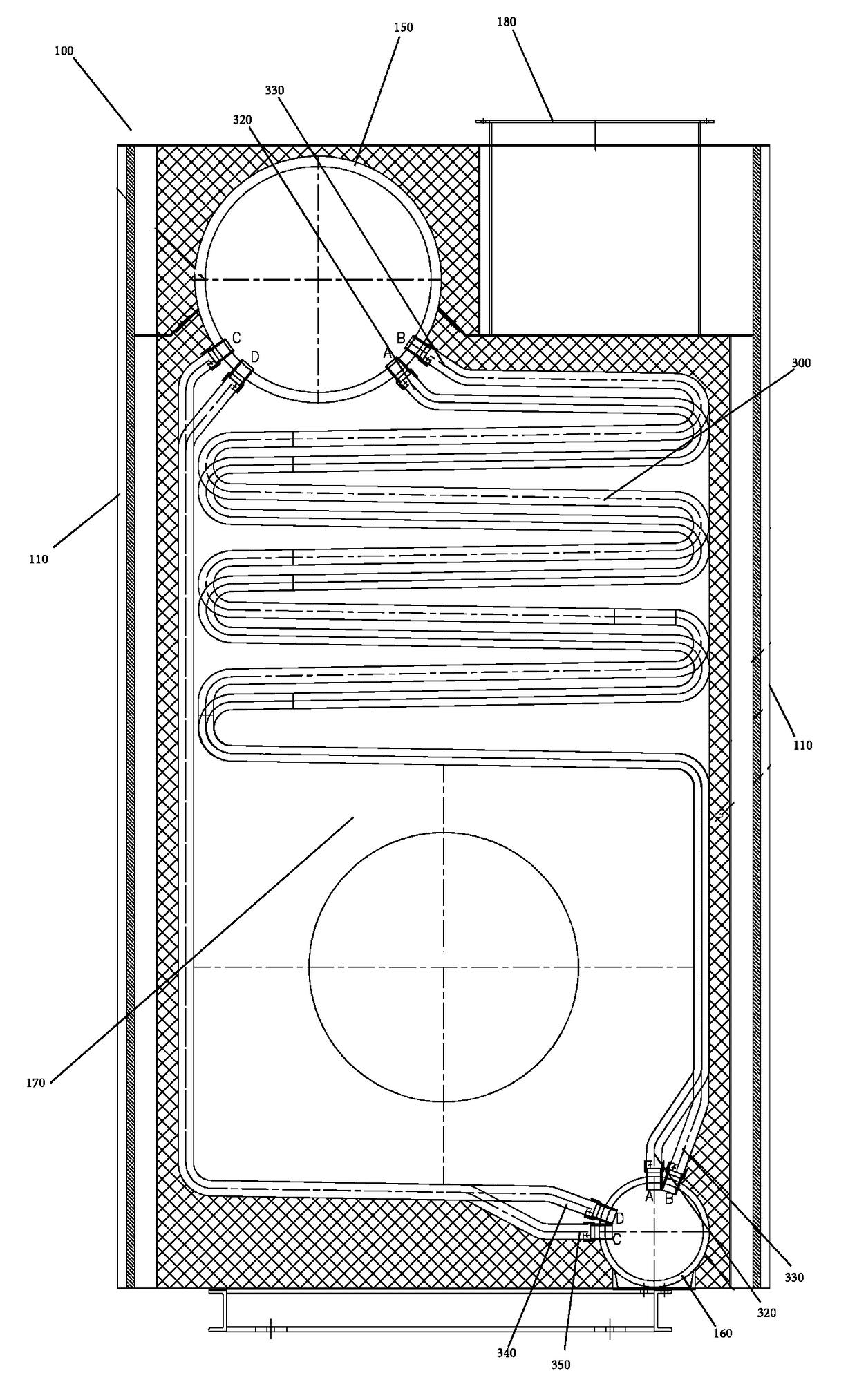

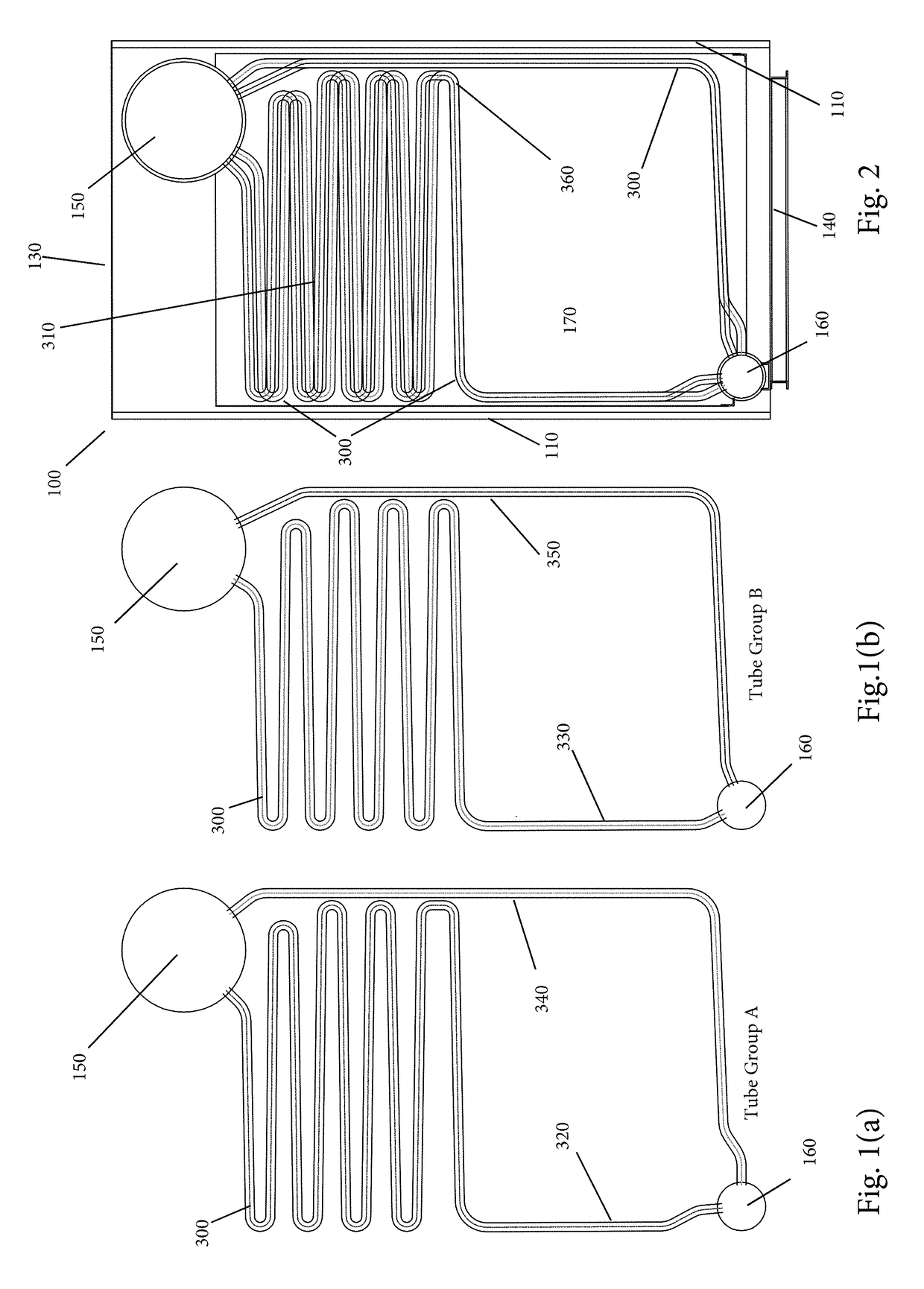

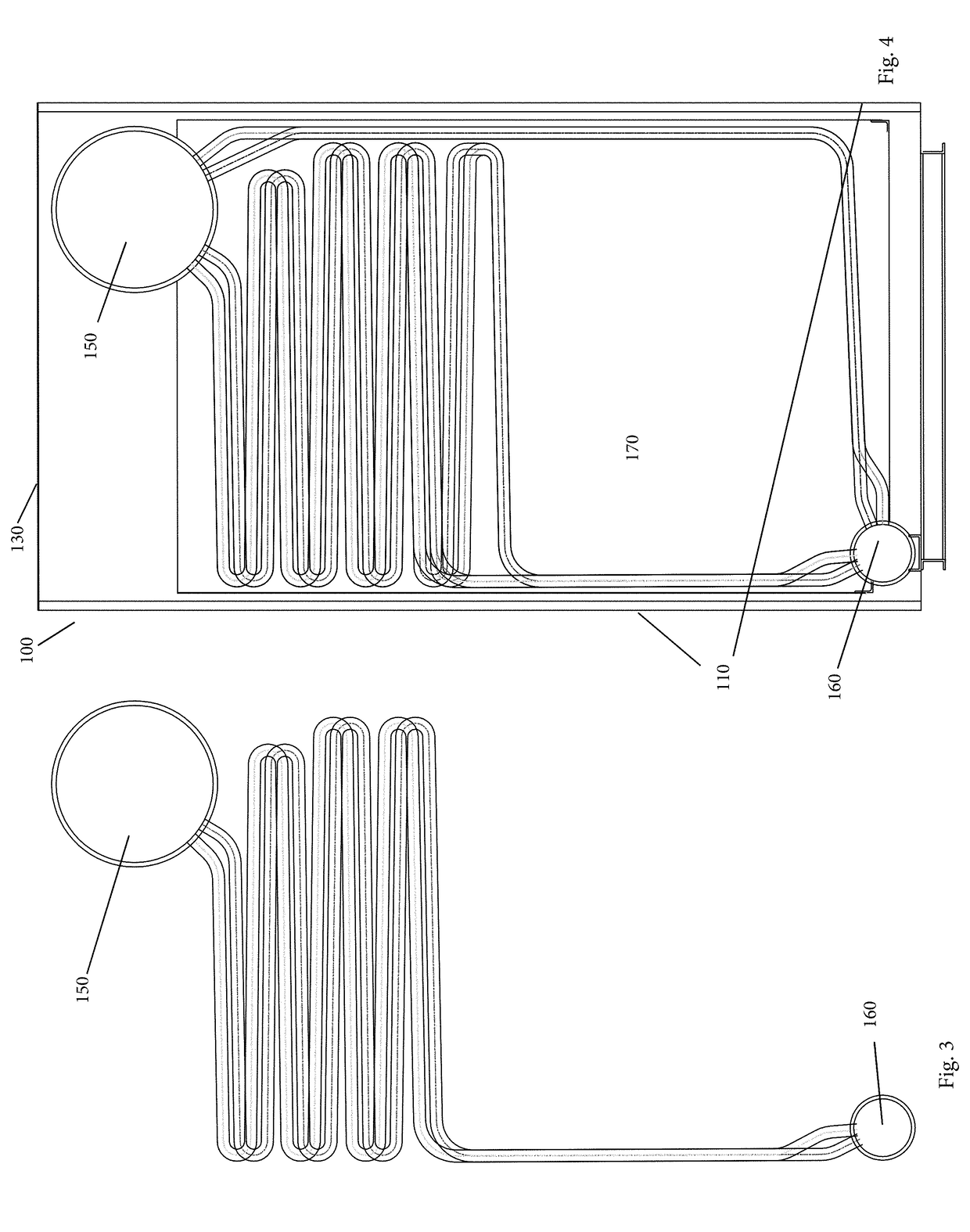

Multiple Pass Flexible Water Tube Boiler

A package multiple pass flexible water tube boiler for converting water to steam. The boiler having an enclosure and diagonally offset upper and lower drums. The drums are connected by a series of staggered or offset water tubes. The water tubes comprise two sets of repeating tubes that are bent to substantially similar but not identical designs. The staggered tube arrangement optimizes heat transfer and minimizes the footprint of the unit.

Owner:SUPERIOR BOILER LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com