Full reverse convection unsealed water tube boiler

A water-tube boiler, non-sealed technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of strict power failure protection management requirements, difficult to remove, affecting safe operation, etc., and achieve safe and reliable natural circulation. The effect of improving manufacturing efficiency and reducing operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

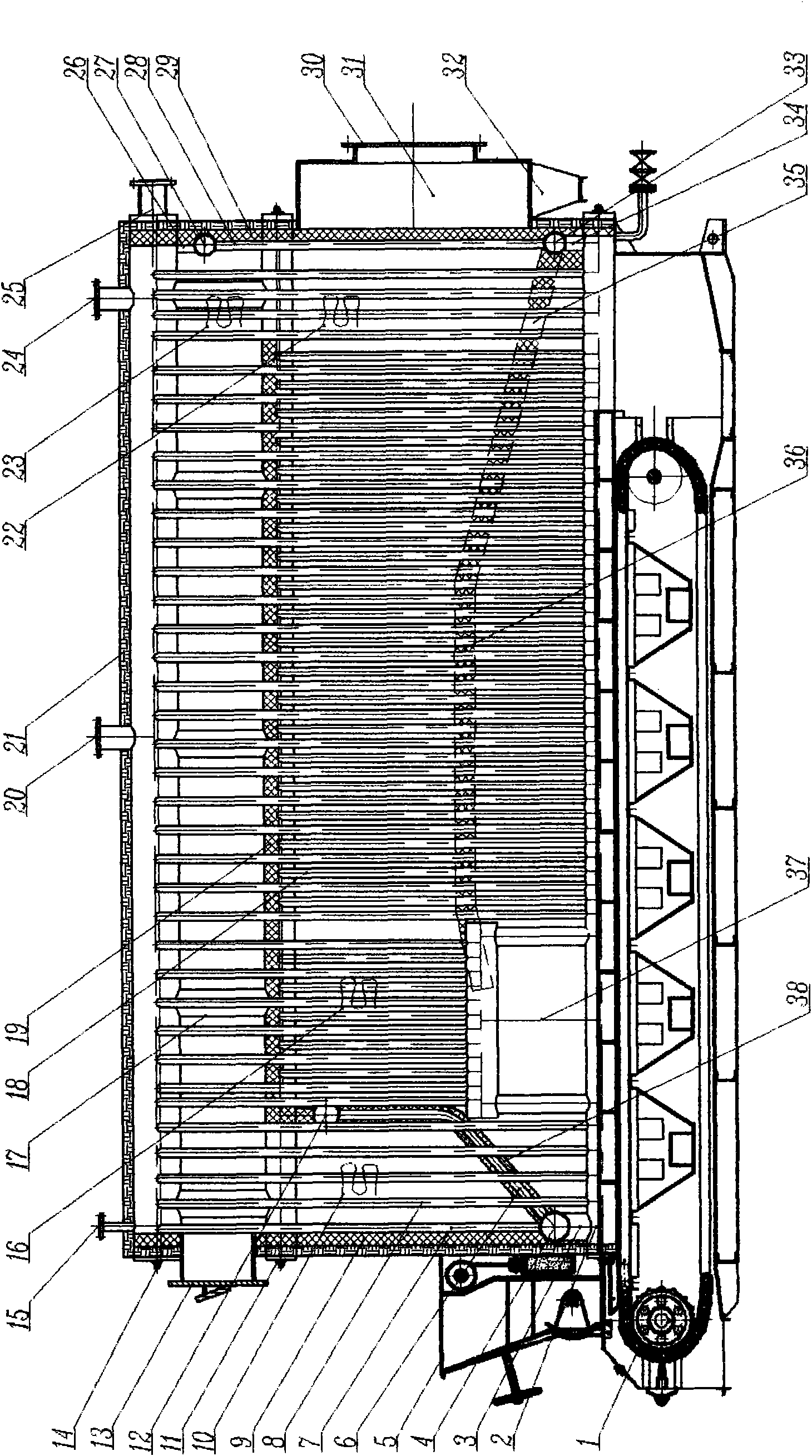

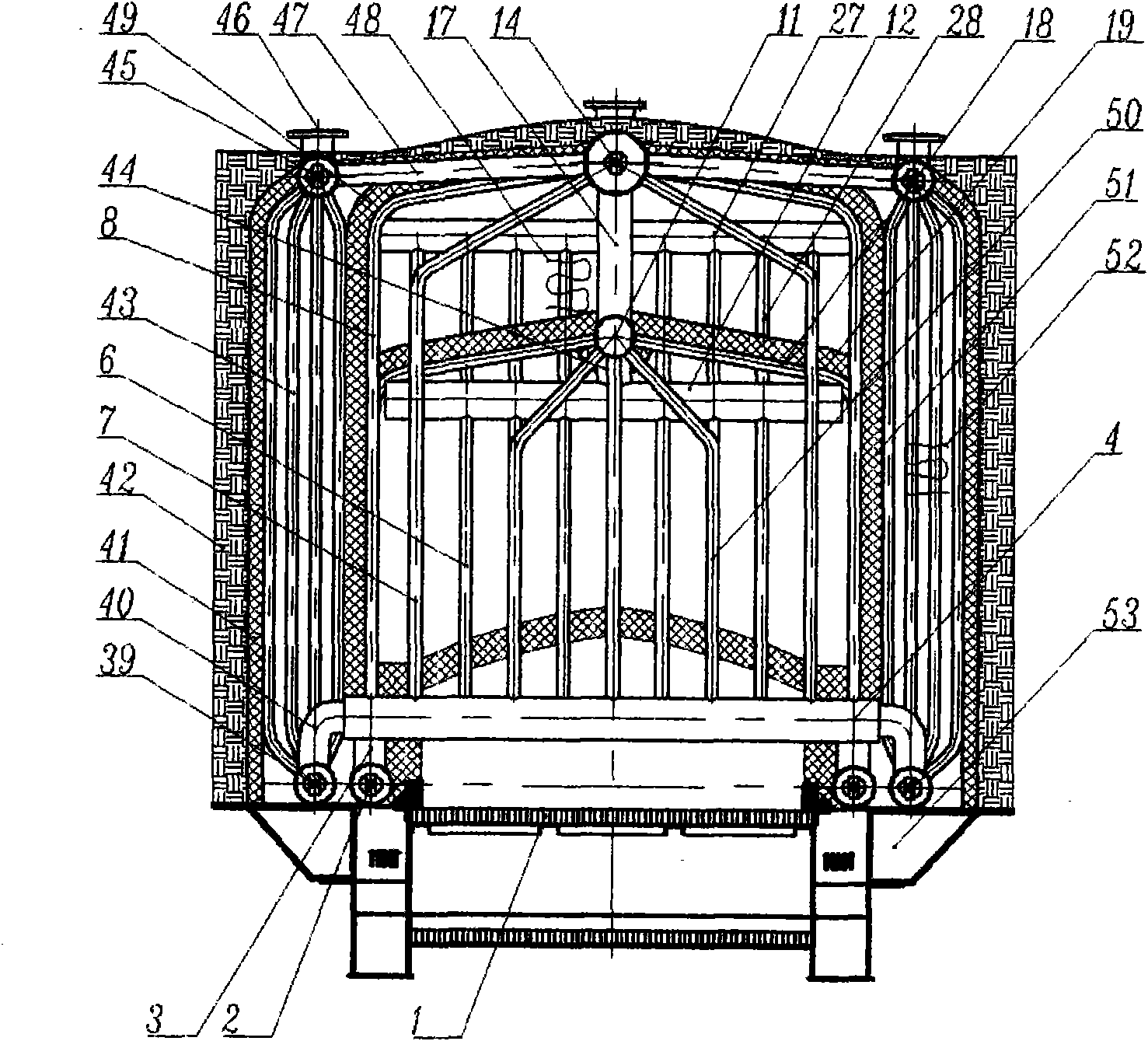

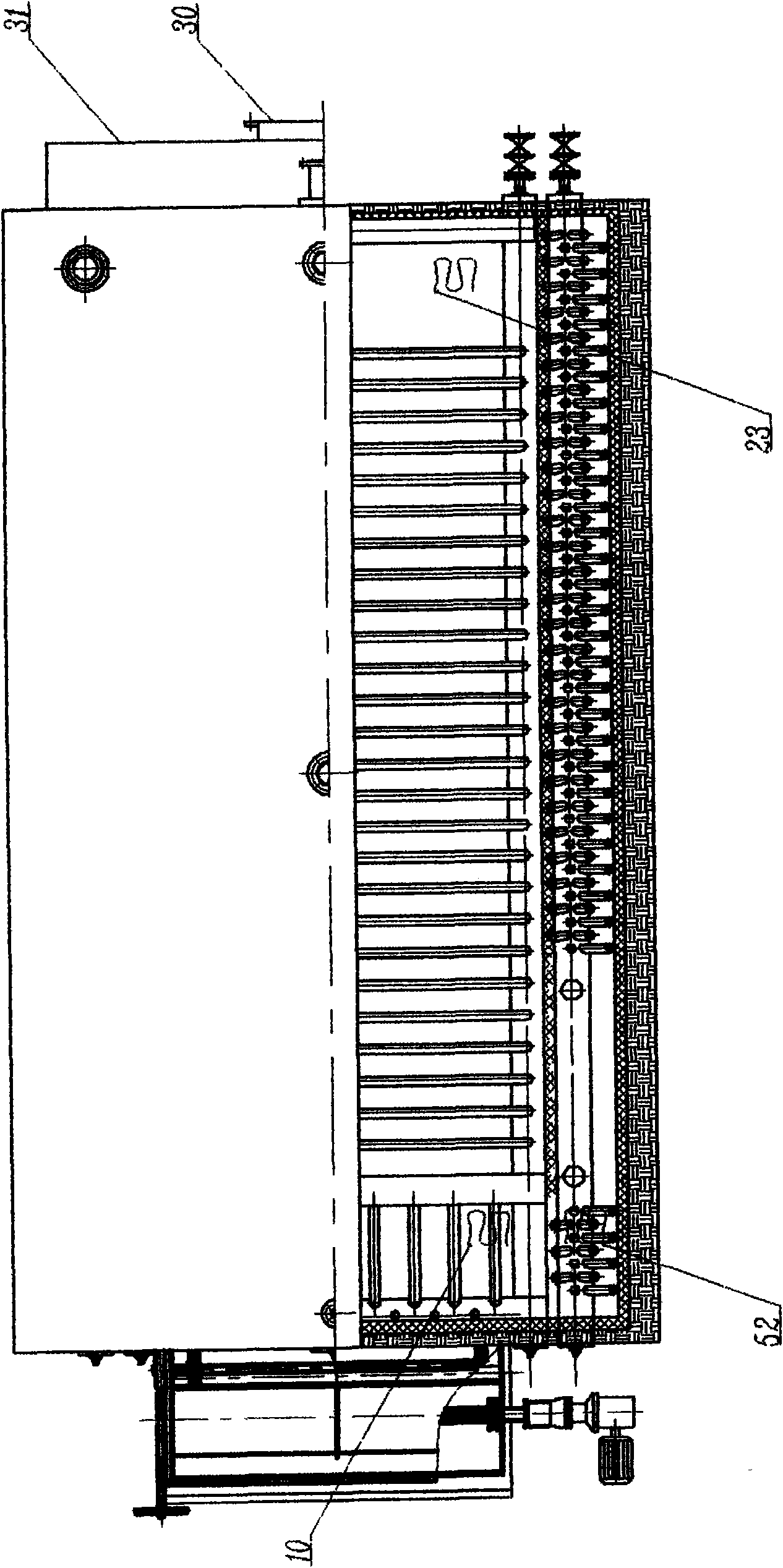

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings. A full reverse convection non-sealed water tube boiler includes upper and lower central headers (14) (11), side symmetrical water wall headers (2), and upper and lower side symmetrical convection tube bundles. Header (45) (39), front and rear upper and lower horizontal headers (12) (4) (27) (33), etc., are characterized in that the upper end of the connecting pipe (17) is vertically connected to the lower center of the upper center header Uniformly distributed and connected, its lower end is parallel to the upper part of the lower central header (11), and its upper and lower ceilings (49) (19) to the space of the furnace wall (51) constitute a secondary return flue (48). The upper end of the first and second return side symmetrical water wall pipes (8) communicate with the longitudinal sides of the upper center header (14), and its lower end is symmetrical with the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com