Biomass water-tube boiler capable of enabling fuel to be sufficiently combusted

A full combustion, water tube boiler technology, applied in water heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of large flue gas, low thermal efficiency, and insufficient environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

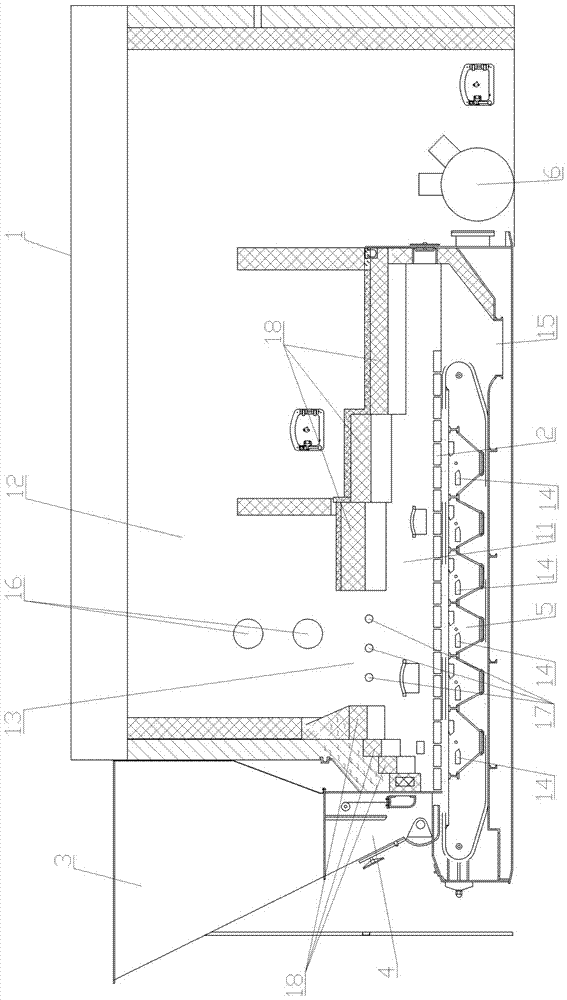

[0022] Such as figure 1 As shown, the biomass water tube boiler with fully combustible fuel includes a furnace 1 , a reciprocating grate 2 , a biomass feed hopper 3 and a fuel addition hopper 4 .

[0023] A group of horizontal horizontal plates 18 are respectively arranged on the two side walls inside the furnace 1, and a plurality of horizontal horizontal plates 18 included in a group of horizontal horizontal plates 18 are adjacent to each other up and down and extend upwards in a ladder shape. The interior is divided into a combustion chamber 11 at the lower end and a convection cavity 12 at the upper end. The convection cavity 12 is provided with serpentine coiled water pipes. Two sets of horizontal horizontal plates 18 form an opening at the highest point as a smoke rising port 13 , and the smoke rising port 13 communicates with the combustion chamber 11 and the convection tube cavity 12 . The flue gas rising port 13 is located above the feeding end of the reciprocating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com