Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Will not increase the load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligence platform interface management apparatus and server

InactiveCN101488878AImprove manageabilityWill not increase the loadData switching by path configurationManagement systemRemote management

The invention embodiment discloses a distributed substrate management controller, the substrate management controller comprises a substrate management controller and a local area network interface processor connected with the substrate management controller, wherein, the local area network interface processor is used for distributing intelligent platform management system messages from the remote management control terminal to the substrate management controller and acquires the information of a local server, transmits the information of the local server to the connected network; the substrate management controller is used for receiving the intelligent platform management system messages transmitted by the local area network interface processor to implement the management and control of the intelligent platform management system. Correspondingly, the invention embodiment also discloses a server to improve the management performance of the substrate management controller.

Owner:HUAWEI TECH CO LTD

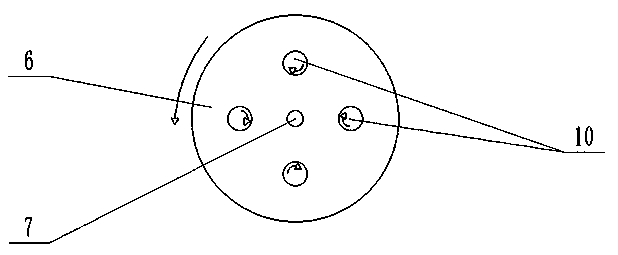

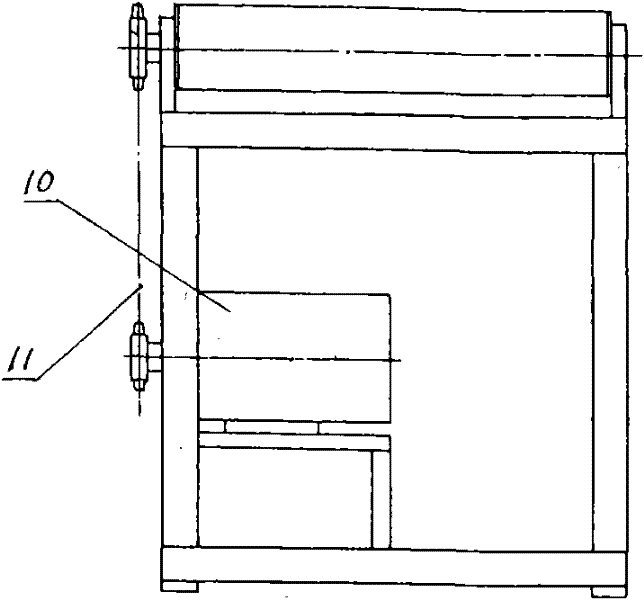

Post-rolling control cooling process for hot-rolled H-shape steel

ActiveCN101758091AHigh strengthImprove toughnessTemperature control deviceWork treatment devicesMartensite transformationRight flank

The invention provides a post-rolling control cooling process for hot-rolled H-shape steel. The hot-rolled H-shape steel enters a cooling device after the rolling is finished, an upper nozzle and a lower nozzle are respectively aligned with upper / lower R parts of the hot-rolled H-shape steel to carry out water spray cooling, and a left nozzle and a right nozzle are respectively aligned with left / right flank centers of the hot-rolled H-shape steel to carry out water spray cooling. The invention is characterized in that the pressure of cooling water is within 0.7 to 1.2MPa, the water quantity is within 1,200 to 2,000m3 / hour, the cooling rate is within 75 to 150 DEG C / s and the cooling time is within 3 to 5 seconds; and the hot-rolled H-shape steel is cooled to 20 to 30 DEG C above the martensitic phase transformation point of the corresponding steel grade after the rolling under the temperature of 850 to 1,000 DEG C is finished. By adopting the cooling process in the invention, the actual grain size of ferrite at the core part of the hot-rolled H-shape steel can be refined from 8-10 grades to 10-12 grades, and a tissue of bainite plus sorbite can be formed on the surface of the hot-rolled H-shape steel, thereby obviously improving the strength and toughness of the hot-rolled H-shape steel and improving the yield strength of the hot-rolled H-shape steel by more than 70MPa.

Owner:MAANSHAN IRON & STEEL CO LTD

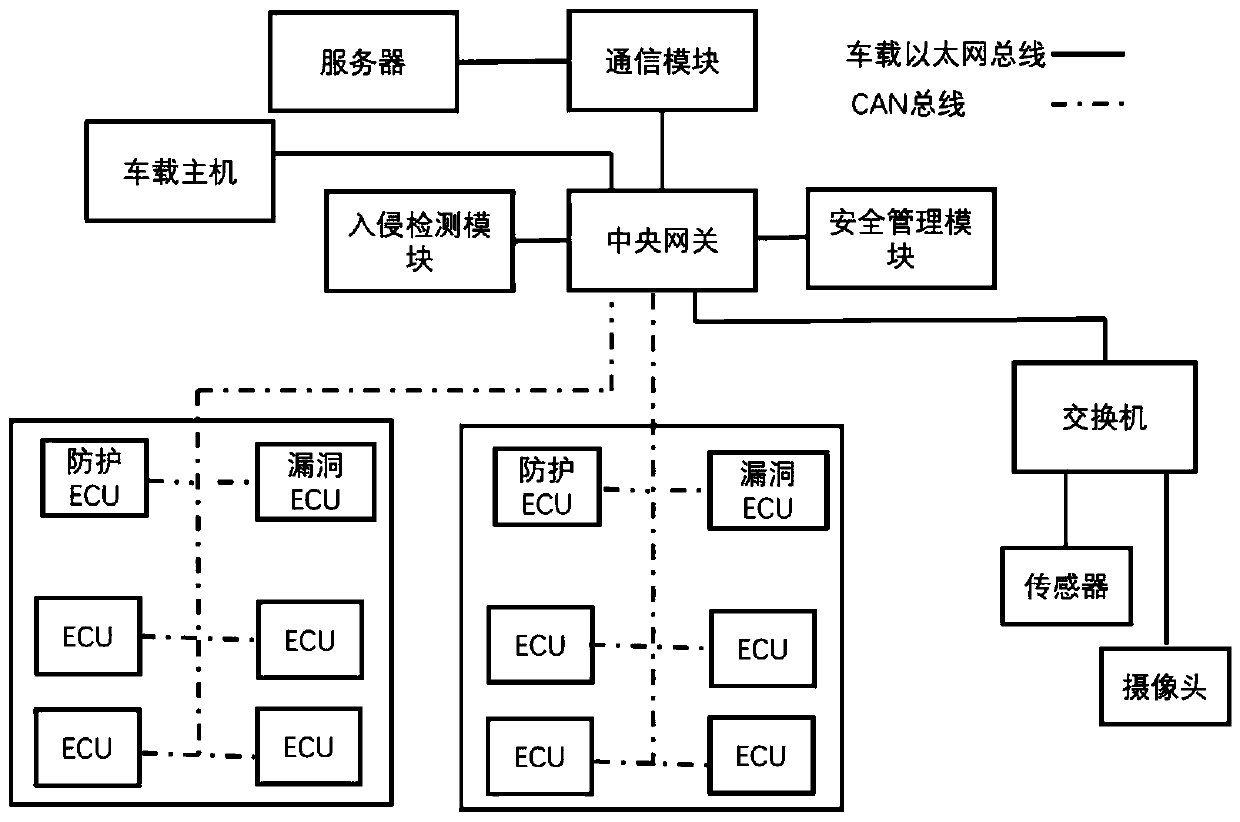

Safety upgrading management system and method applied to automobile ECU

ActiveCN110460573AReduce risk of damageMake sure not to be attackedSoftware deploymentBus networksNetwork packetIn vehicle

The invention provides a safety upgrading management system and method applied to an automobile ECU. The system comprises a safety management module, an intrusion detection module and a central gateway, a protection ECU and a vulnerability ECU, wherein the intrusion detection module monitors an in-vehicle network in real time; when it is found that in-vehicle network upgrading is attacked, attackinformation can be fed back to the safety management module in time; the safety management module issues a control instruction to the protection ECU; the protection ECU sends the resistance strategy to the ECU which may be attacked or has been attacked to resist the attack; according to the ECU upgrading method and device, the small compensation package is introduced into the upgrading file in theupgrading process, the compensation package is introduced to replace service packs of different historical versions, the size of the data package needed by upgrading can be greatly reduced, and meanwhile the transmission time of ECU upgrading service packs is saved.

Owner:SHANGHAI HEQIAN ELECTRONICS TECH CO LTD

Video interactive live broadcast method and system

InactiveCN111263177ADoes not increase computational complexityWill not increase the loadSelective content distributionComputer graphics (images)Engineering

The invention discloses a video interactive live broadcast method and system. The method comprises the following steps: a client terminal receives and decodes a surround video transmitted by a live broadcast server, and displays a video of a part of angles of the surround video on a display screen; the client terminal detects a sliding gesture of a user on the display screen, and generates a display view angle switching instruction according to the sliding gesture; the client terminal acquires current display view angle information of the video of a part of angles, and calculates target display view angle information of the next moment according to the display view angle switching instruction and the current display view angle information; and the client terminal acquires a video of a target view angle according to the target display view angle information of the next moment, and switches to display the video of the target display view angle. The system comprises a live video sending module, a live video receiving module, a view angle switching instruction generation module, a view angle information acquisition module and a view angle switching module. According to the invention, auser can autonomously select the viewing angle of watching the video and can freely switch the viewing angle of displaying the video.

Owner:杭州皮克皮克科技有限公司

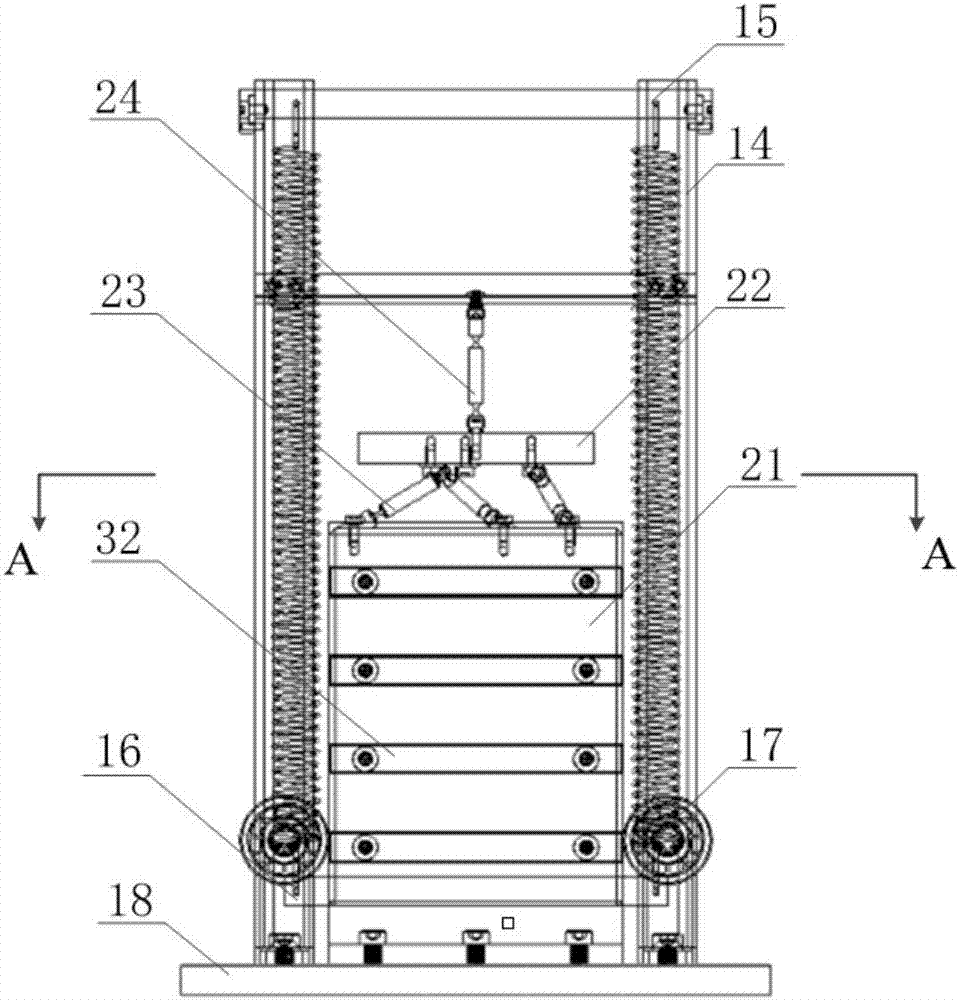

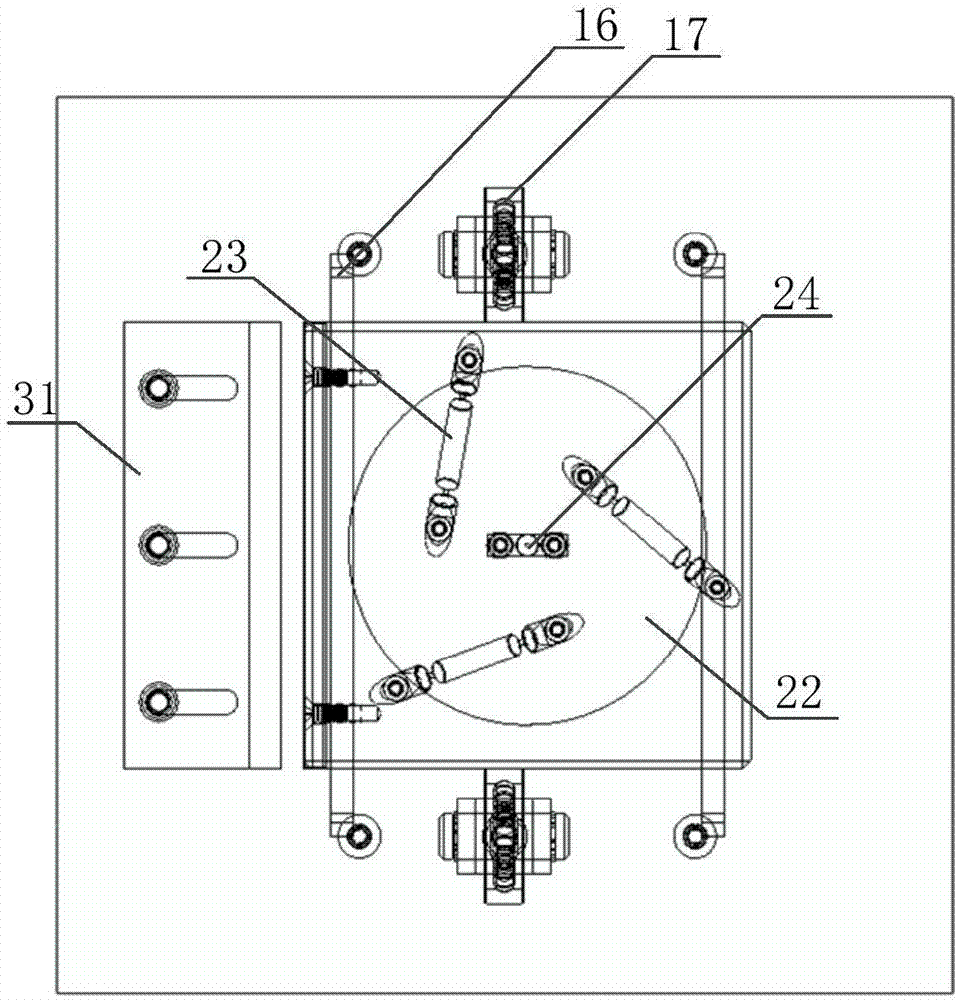

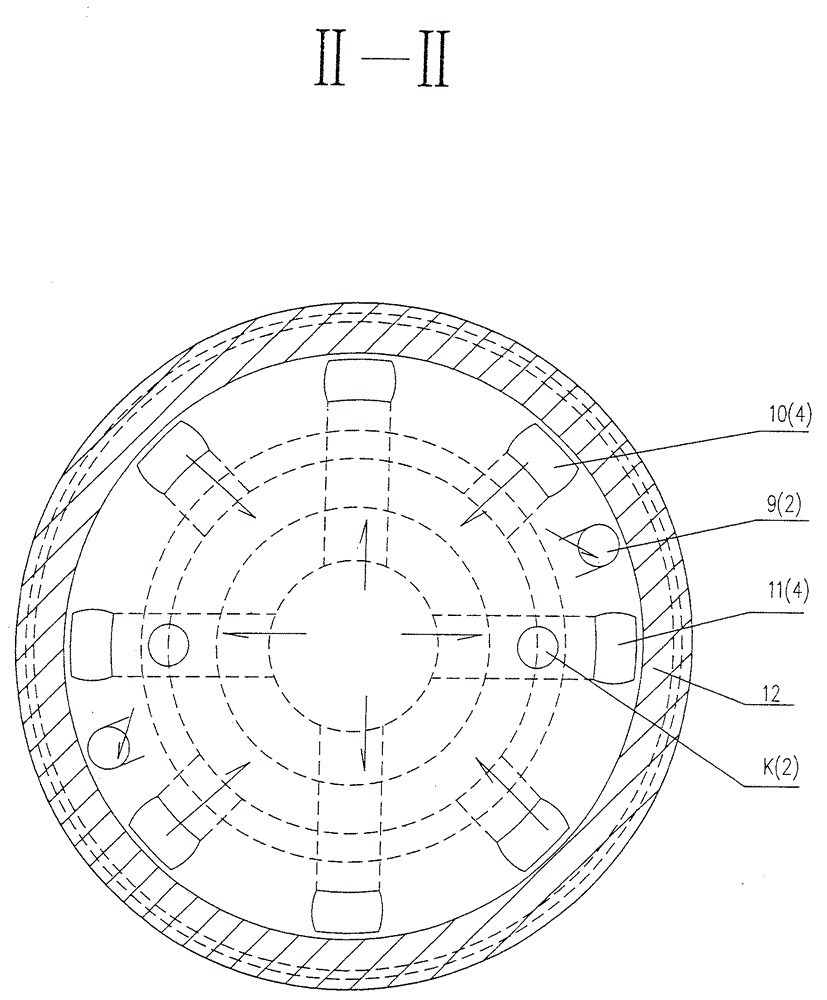

Permanent magnet type ultralow-frequency vertical tuned mass damper

ActiveCN107228147ASmall sizeSolve the problem of excessive static elongationNon-rotating vibration suppressionShock absorbersEngineeringFlywheel

The invention discloses a permanent magnet type ultralow-frequency vertical tuned mass damper. The permanent magnet type ultralow-frequency vertical tuned mass damper comprises an inertia mass system, an electromagnetic damping system and a support system, wherein the inertia mass system comprises a counterweight block, a flywheel, an inclined flexible hinge and a vertical flexible hinge; the electromagnetic damping system comprises a conductor plate and a permanent magnet; and the support system comprises a bearing bracket, a flexible hinge fixed plate, an extension spring, a bearing frame, an upper spring cross beam, a lower spring cross beam, a bearing and a base. A straight circular flexible hinge is adopted as a linear-rotary motion conversion mechanism; the space structure of the flexible hinge is well designed; and when the main structure is slowly and slightly vibrated, a small linear motion of the counterweight block can be effectively converted to a rotating motion of the flywheel, so that the problem of excessive static elongation of the spring of the ultralow-frequency vertical tuned mass damper is solved, and the vibration isolating performance of the tuned mass damper in the field of ultralow-frequency weak vibration is improved.

Owner:ZHEJIANG UNIV

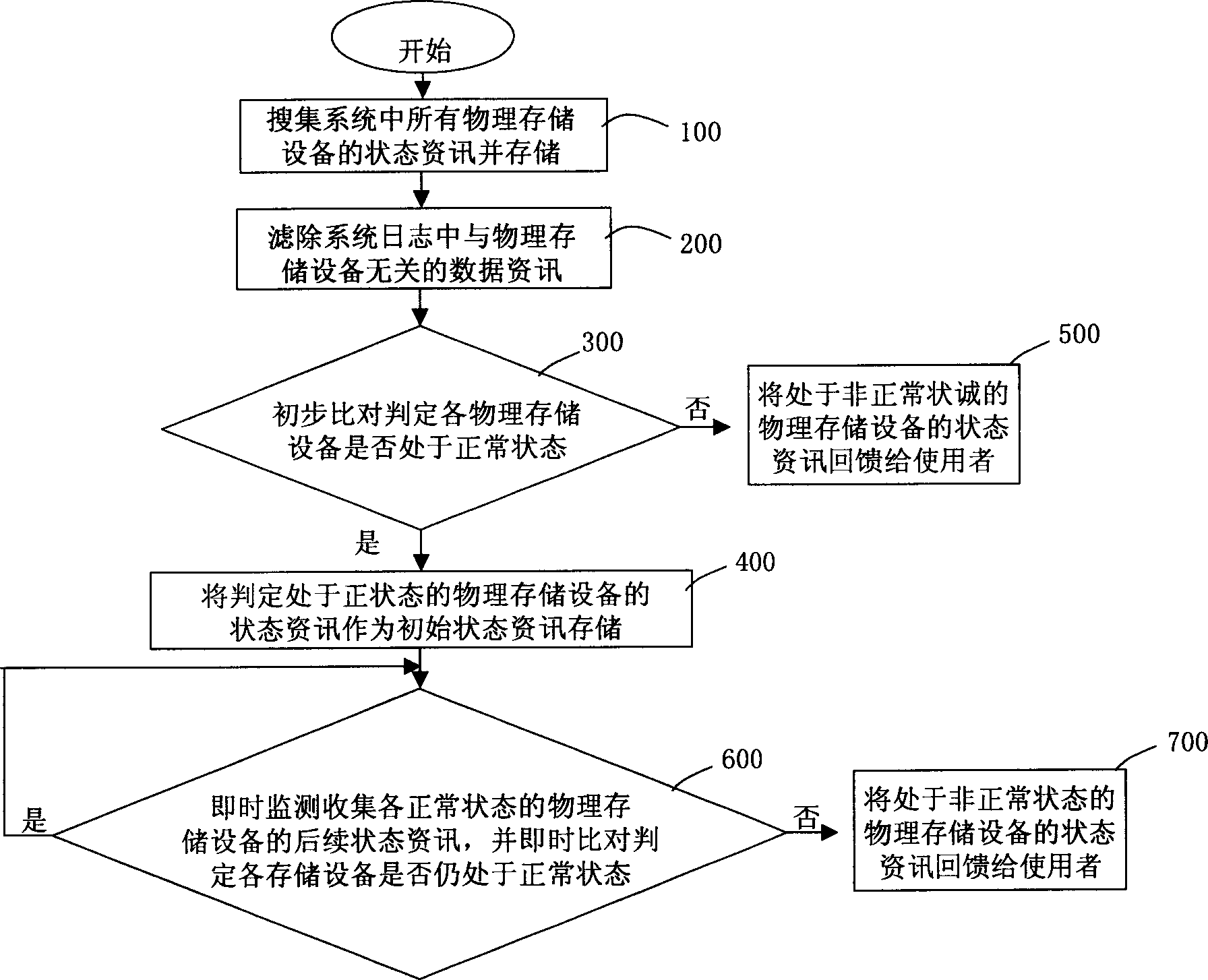

Method for automatic diagnosing system information

ActiveCN1889053AImprove real-time and flexibilityImprove monitoring efficiencyHardware monitoringDisk arraySystem information

A self-diagnostic method of the system information to monitor the state of the physics memory device in the system detects the bad devices according to the change of the state of the memory device. The method collects the all present state information of the physics memory device by the system management module, also it detects if the memory device is in the normal condition according to the comparing of the state information and the system log, the data information in the system management module, the normal information. The method can aim at many physic memory device such as the SATA / SCSI hard disk, the hard disk array and the memory device, especially it can detect the hard disk accurately and sensitively.

Owner:ZHIGU HLDG

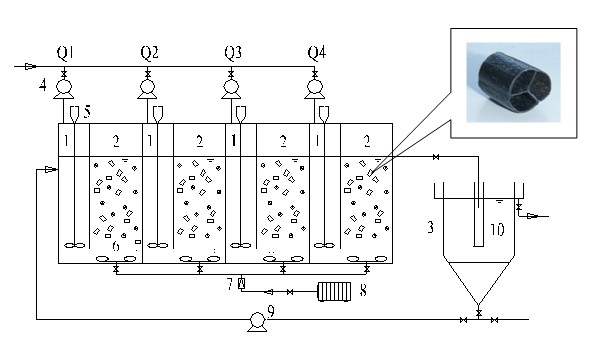

Four-stage three-phase fluidized bed step-feed deep nitrogen removal system

InactiveCN102358676ANot easy to loseSmall volumeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeNitrogen removal

The invention belongs to the field of domestic sewage purification, and relates to a method for treating domestic sewage by adopting a four-stage three-phase step-feed deep nitrogen removal system. The method solves the problems that the conventional domestic sewage treatment process is poor in nitrogen removal effect and difficult to reach the specified standards, and can fulfill the upgraded reforming goal of the conventional sewage plant on the premise that the civil facilities are not changed. The method comprises the step of respectively delivering the domestic sewage to a reactor from anoxic zones of four stages, wherein the anoxic zones and aerobic zones are arranged at intervals, so that nitration liquid reflux facilities of the system are saved; and sludge reflux is only performed in the first anoxic zone, so that the energy is saved and nitration liquid required by denitrification can be supplied to the first anoxic zone. A fluidized filling material is added into the aerobic zones, and a fluidized bed is organically combined with a step-feed process, so that the advantages of increasing the biomass and the bioactivity of the system, reducing sludge, enhancing the three-phase system in the system and the like are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

System and method applied to automobile ECU upgrade file

The invention provides an upgrading file system and method applied to an automobile ECU. The method comprises the following steps: respectively carrying out difference analysis on a new file and a plurality of old files to form a plurality of patch packs, selecting one of the patch packs as a reference patch pack, and respectively carrying out difference analysis on the selected reference patch pack and the remaining patch packs to form a plurality of make-up packs;carrying out data packet synthesis on the reference service pack and a make-up packet matched with the to-be-upgraded ECU to forma service pack corresponding to the to-be-upgraded ECU; and carrying out data packet synthesis on the service pack corresponding to the to-be-upgraded ECU and the old file of the current ECU to form anew file needing to be upgraded. By introducing the make-up packet to replace patch packets of different historical versions, the size of the data packet required by upgrading can be greatly reduced,and meanwhile, the transmission time of the ECU upgrading patch packet is saved, and the ECU upgrading patch packet does not need to be downloaded from the server every time.

Owner:SHANGHAI HEQIAN ELECTRONICS TECH CO LTD

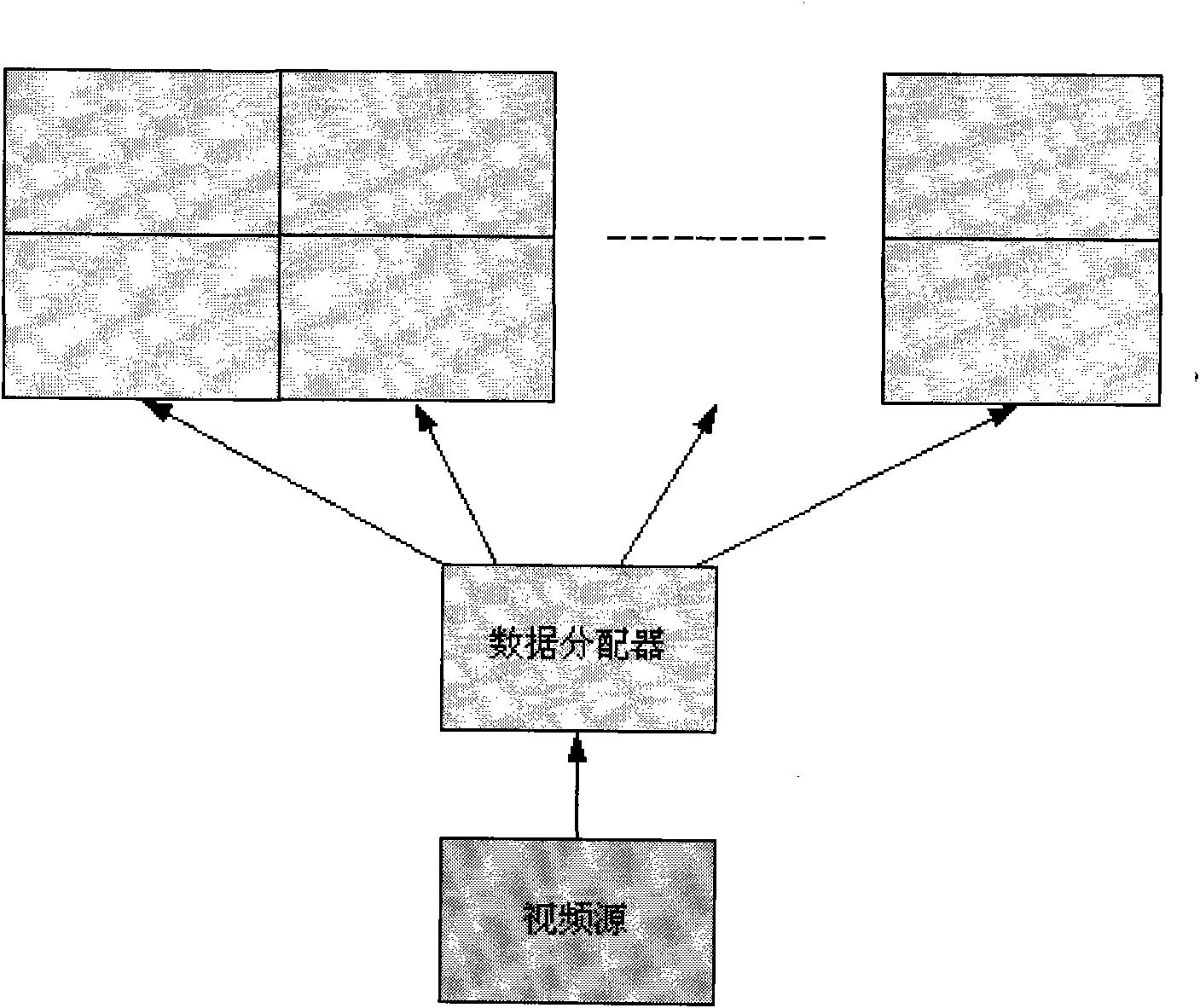

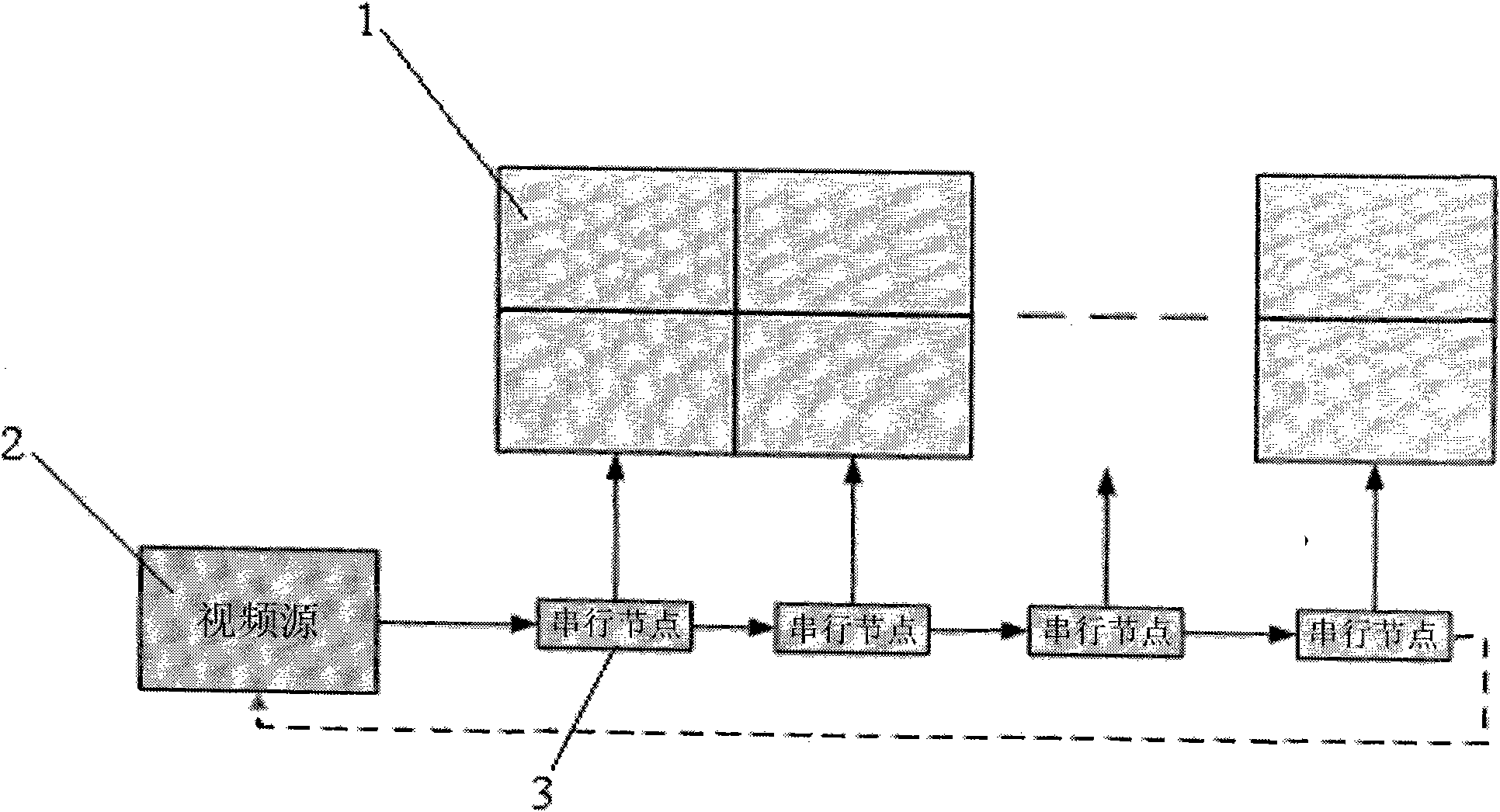

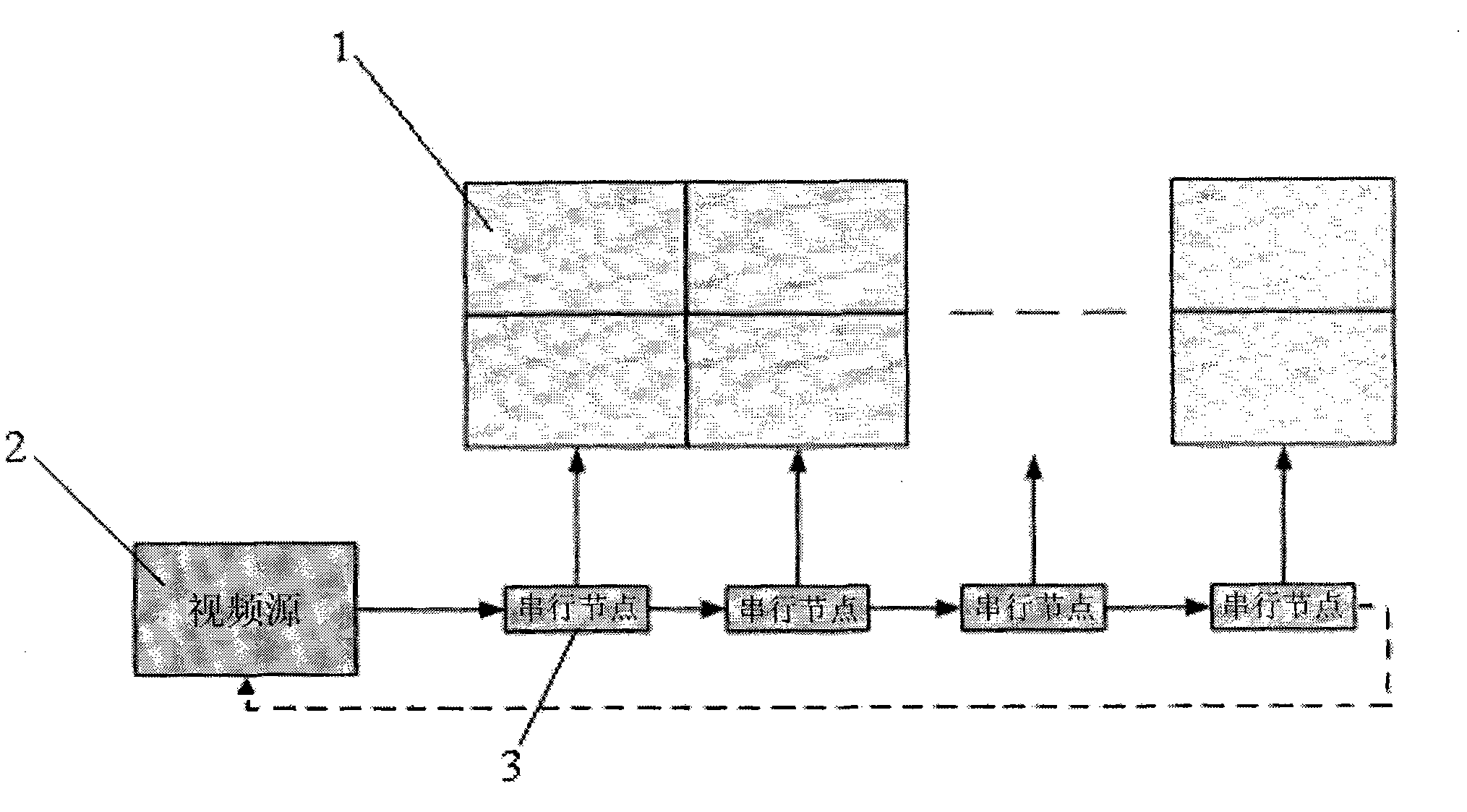

Method and device for jointing display screens

ActiveCN101872605ADisplay rich contentLight in massCathode-ray tube indicatorsInfinite numberTime difference

The invention relates to a jointed screen system, in particular to a method and a device for jointing display screens. The method forms a serial bus of video data and makes the display screens connected with the bus in series. The data bandwidth of the serial bus does not increase with the increase in the number of the display screens, so the system may comprise an almost infinite number of screens. Thus, a problem of the prior is solved successfully. The method and the device have the advantages of allowing an infinite number of screens to be added in the system without increasing the load of the system nor reducing the quality of video frequency, and making the time differences between the arrivals of video data at the screens extremely small at the same time. When the method is used, the problem of limited number of screens of the jointed screen system is solved, so that the jointed screen system has a larger display area and more display contents.

Owner:ZHE JIANG PEARMAIN ELECTRONICS

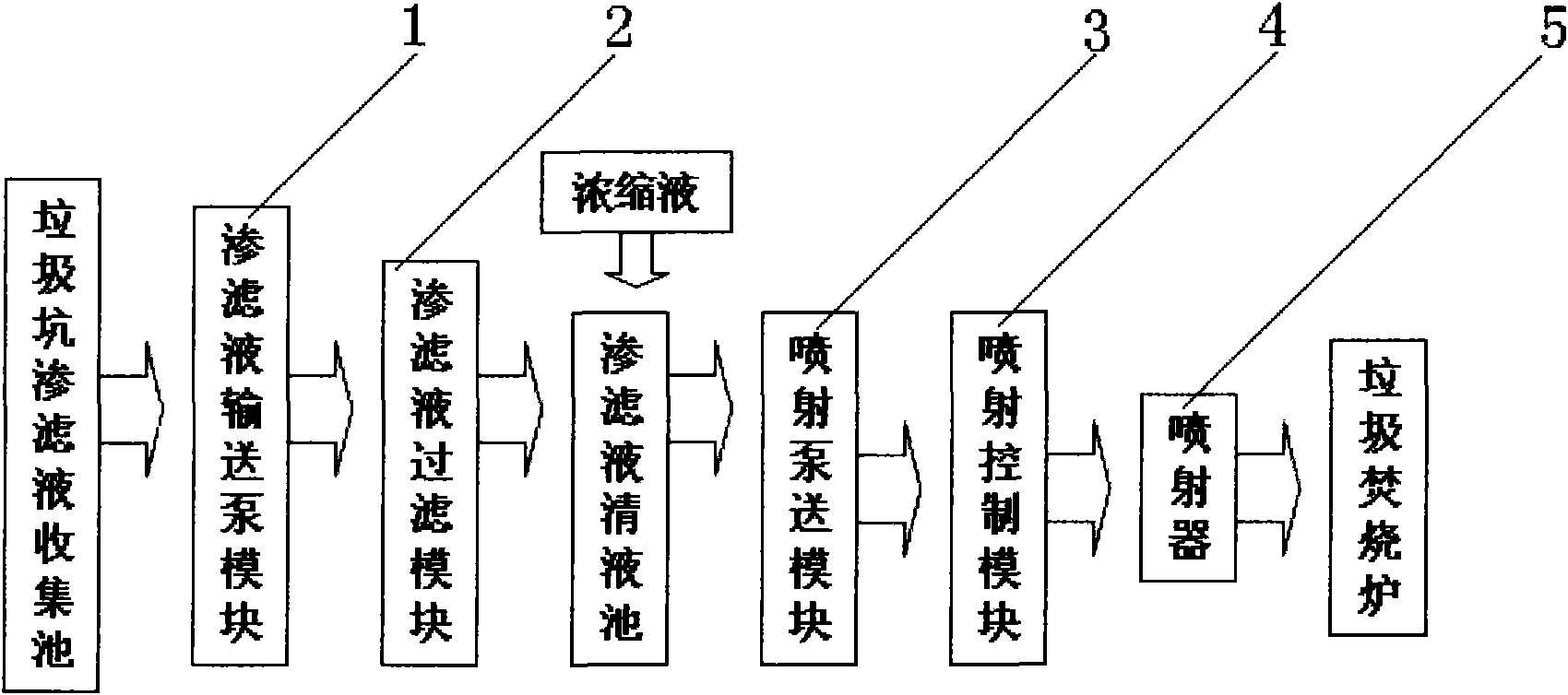

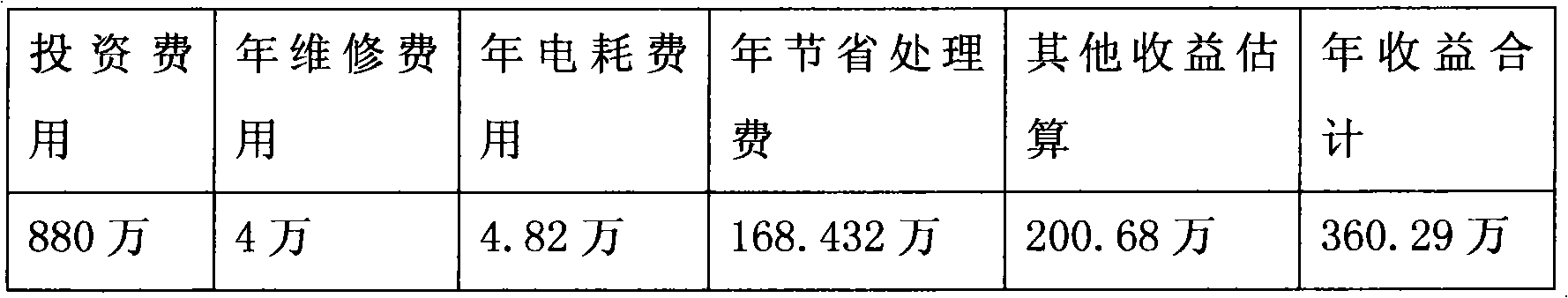

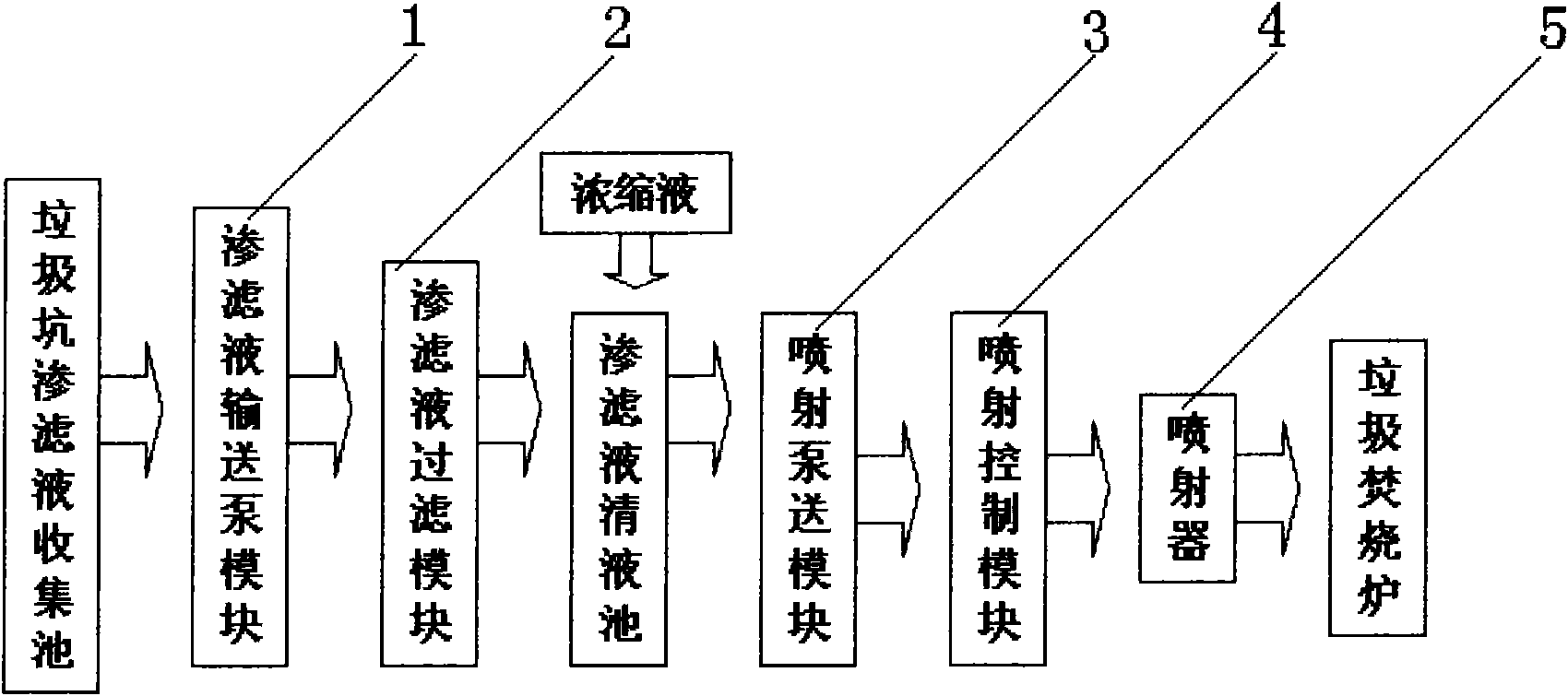

Process for spraying and treating percolate

ActiveCN101979921AExtended operating cycleReduce cokingIncinerator apparatusAutomatic controlBurn treatment

The invention relates to a process for treating garbage percolate, in particular to a process for spraying and treating percolate and aims to provide a reliable and efficient garbage percolate treatment method for spraying the garbage percolate for burning treatment. The garbage percolate can be prevented from polluting the environment and the pollution problem can be solved completely. In order to fulfill the aim, the process for spraying and treating the percolate is provided and comprises the following steps of: collecting the percolate; filtering the percolate; and spraying the percolate. A technical process for spraying, burning and treating the percolate is simple and is convenient to operate. Stock garbage percolate can be decomposed fully or concentrated solution produced in other treatment modes can be treated simultaneously and secondary pollution is avoided; and compared with other treatment modes, the process has low construction, operation and maintenance costs, small floor area and high automatic control degree and is convenient to operate.

Owner:SHANGHAI TECHSPRAY ENG

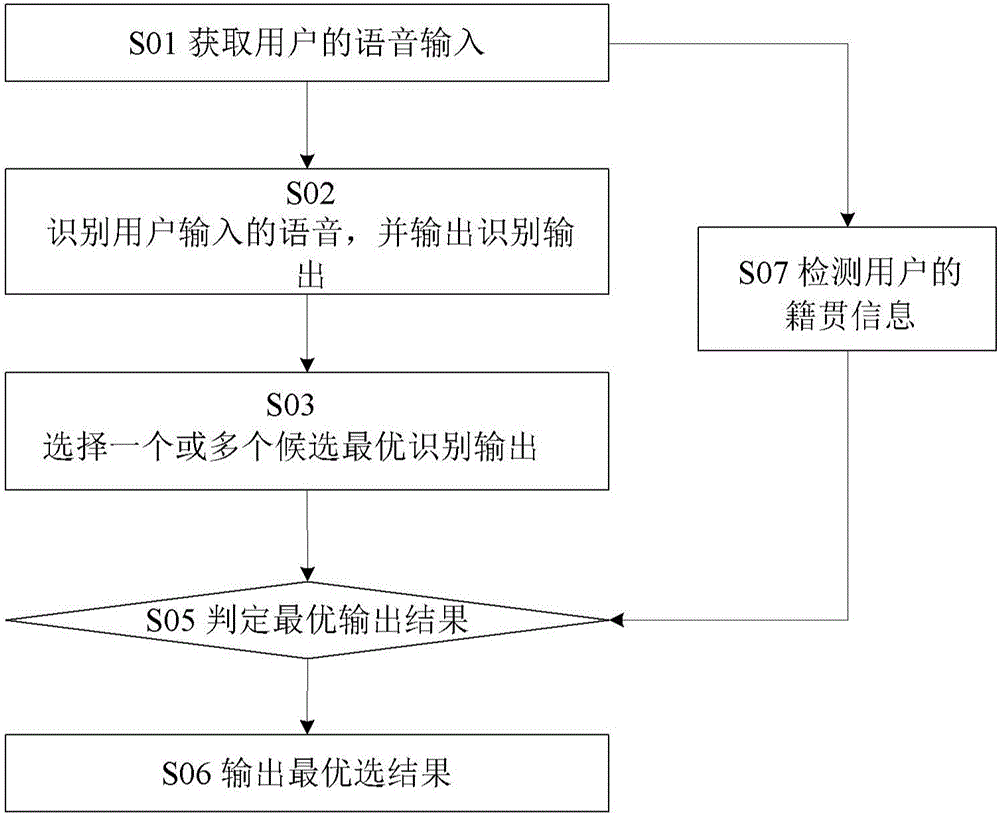

Speech recognition method, apparatus and system

ActiveCN105931642AAchieve multi-level outputWill not increase the loadSpeech recognitionSpeech identificationSpeech output

The invention provides a speech recognition method, a speech recognition apparatus and a speech recognition system. The method includes the following steps that: speech input of a user is obtained; a speech database is selected to recognize speech inputted by the user, and recognition outputs adopted as results are outputted; and domain determination is adopted to select one or more candidate optimal recognition outputs from the recognition outputs; and an optimal recognition output in the one or more candidate optimal recognition outputs is determined with the personality identification information of the user adopted as a determination condition. With the speech recognition method provided by the above technical schemes of the invention adopted, the accuracy of speech recognition can be improved under a condition that response time is not increased.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

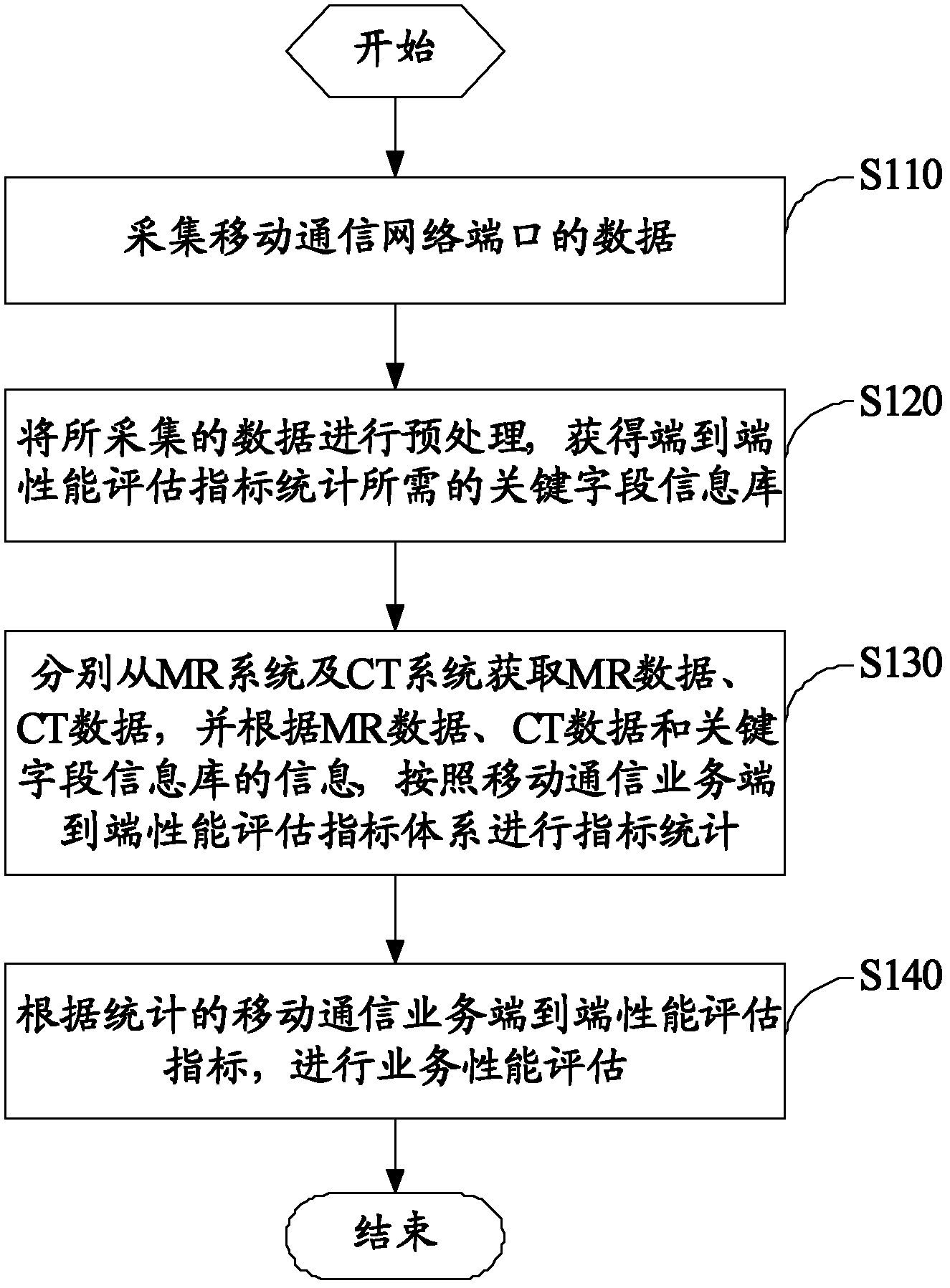

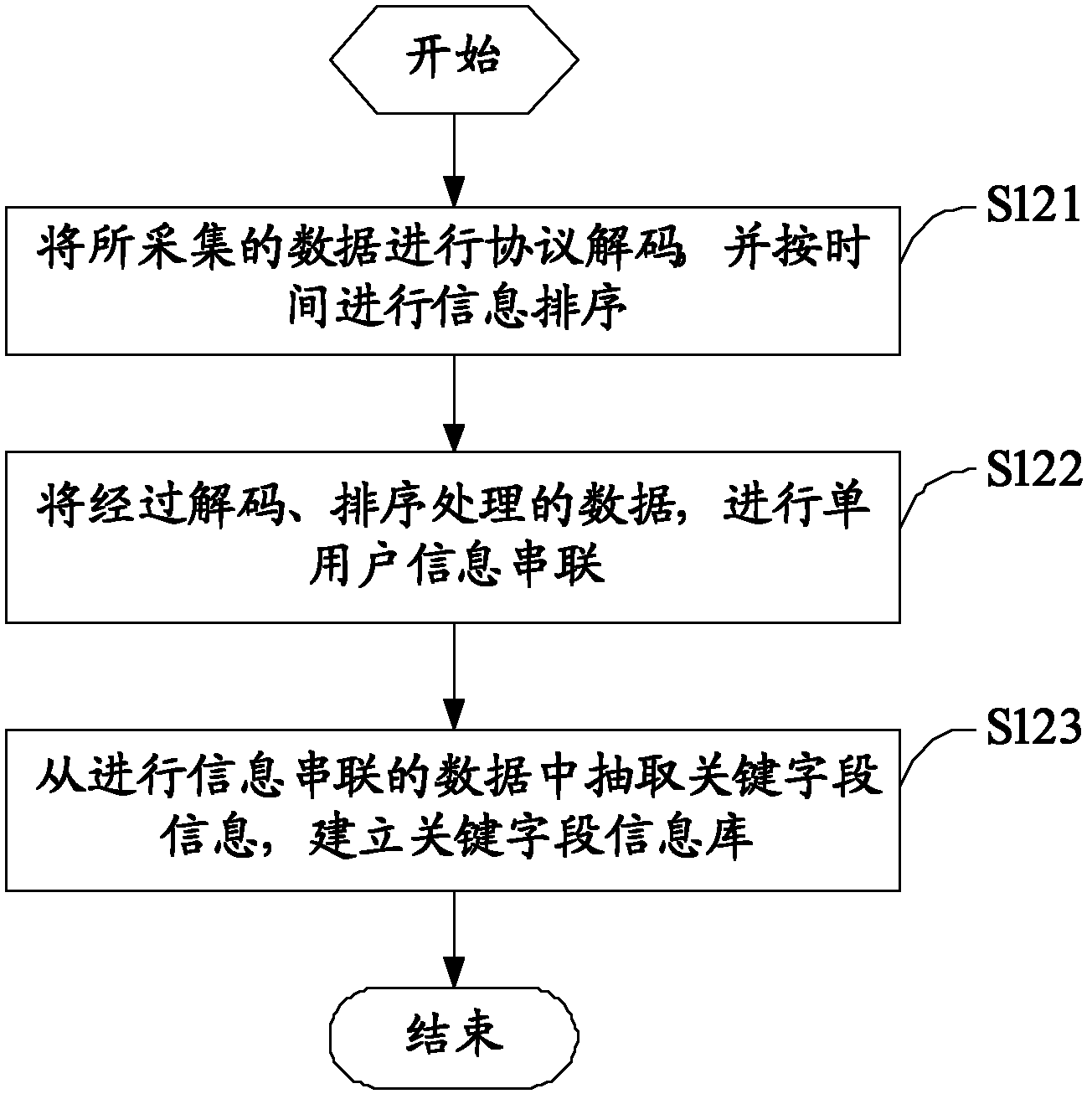

Mobile communication service end-to-end performance evaluation method and system

InactiveCN103024767AInnovation in Performance Evaluation MethodsGet goodWireless communicationInformation repositoryUser perception

The invention discloses a mobile communication service end-to-end performance evaluation method and a system. The method comprises the following steps: collecting data of a mobile communication network port; carrying out preprocessing on the collected data and obtaining a key field information database which is needed for the end-to-end performance evaluation index statistics; obtaining MR data and CT data from a measurement report MR system and a call tracking CT system respectively, and according to the information of the MR data, the CT data and key field information database, carrying out index statistics in accordance with a mobile communication service end-to-end performance evaluation index system; and carrying out service performance evaluation according to the statistic mobile communication service end-to-end performance evaluation index. The mobile communication service end-to-end performance evaluation method and the system disclosed by the invention carries out innovation on the performance evaluation method of the mobile communication service by taking a user perception as a basis and the service as an analysis object, so that operators can evaluate the mobile communication service end-to-end performance which reflects the user perception.

Owner:ZTE CORP

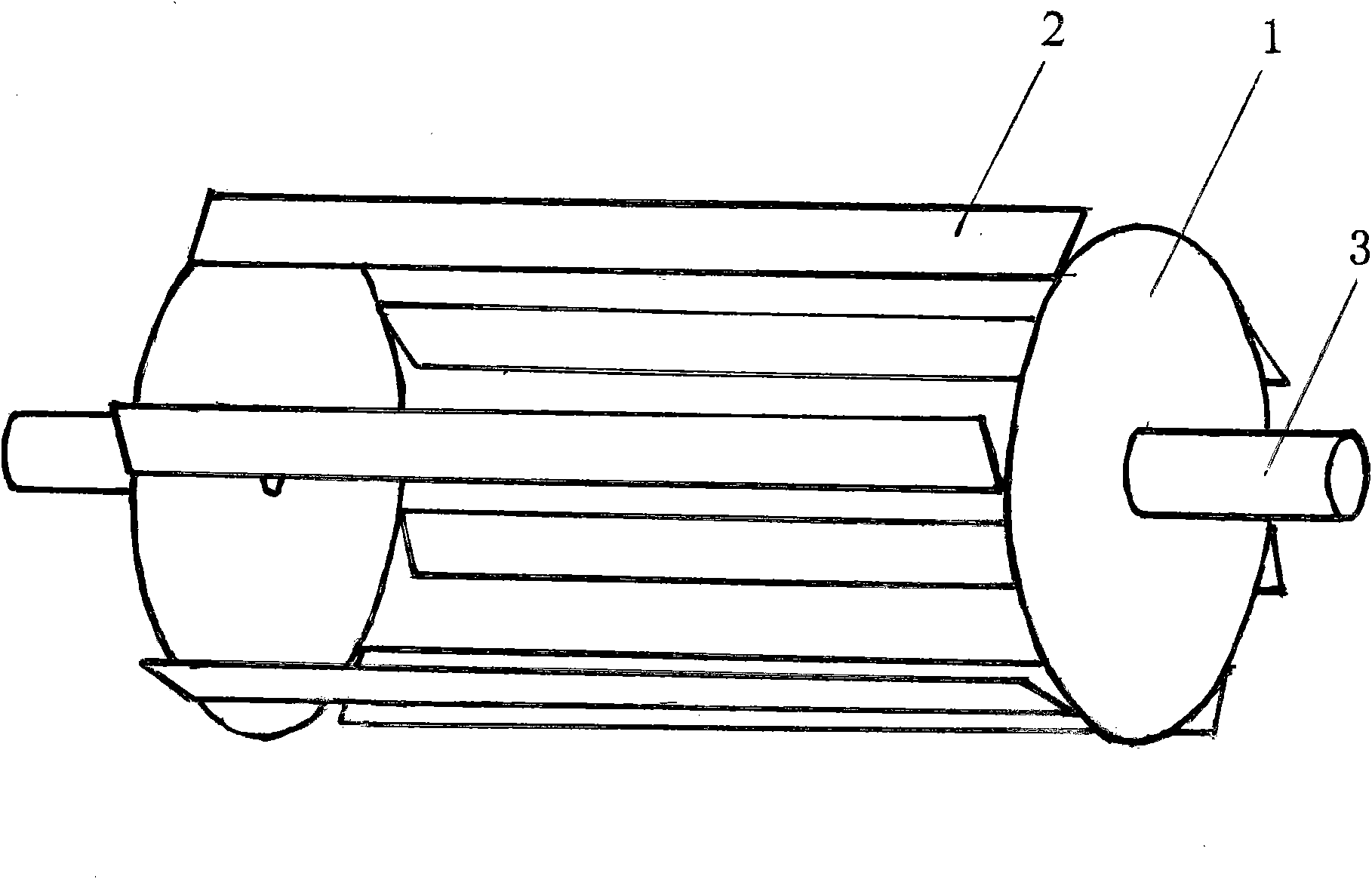

Paddy-field grass-burying roller

InactiveCN101574026AWill not increase the loadNo added dragAgricultural rollersAgricultural engineeringPaddy field

The invention relates to a paddy-field grass-burying roller belonging to spare parts of agricultural machinery and aiming at the defects that the prior paddy-field grass-burying operation part is uniformly designed on a rotary blade, not only increases the resistance of the rotary blade and enables a tractor to work in an overload working state, but also influences the grass-burying operation effect and has the problem of often bringing up straw and weeds justly buried. The paddy-field grass-burying roller comprises two corresponding roller end boards, strip grass-burying boards and a roller shaft, wherein the strip grass-burying boards are sequentially connected between the two corresponding roller end boards and respectively have a backward angle, and the roller shaft is arranged in the center of the roller end boards. The invention has the following advantages after tests that the paddy-field grass-burying roller can not increase the resistance of the rotary blade so as not to influence the normal operation of the tractor, not only can press crop straw and weeds into paddy-field mud, but also adds the functions of puddling and leveling a paddy field by crushed clods, is suitable for matching with tractors of various models and can be towed by animal labor or connected with a dry-field operation compression roller for the paddy-field grass-burying operation, thereby being a grass-burying operation part with good suitability, simple structure and low cost.

Owner:王森豹

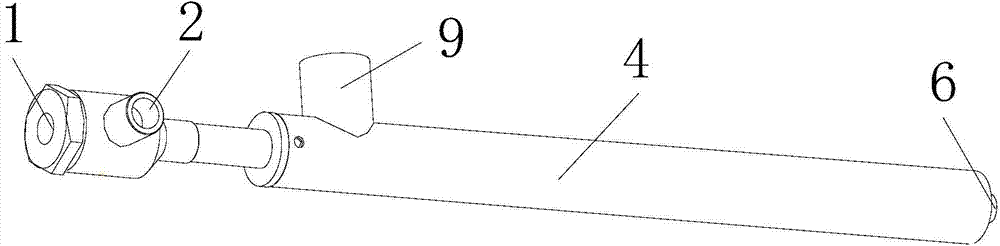

Atomizing spray gun

ActiveCN103759260APower Generation Efficiency ImpactAvoid damageBurnersIncinerator apparatusEngineeringScrew thread

The invention relates to an atomizing spray gun. Four leachate return and spray nozzles are arranged on two sides of the outlet sidewall of a burning hearth furnace and are parallel to a secondary air inlet. The atomizing spray gun comprises a compressed air nozzle, a leachate nozzle, a flange, a protective sleeve, a gun rod and an atomizing nozzle. The compressed air nozzle is screwed to the larger end of the leachate nozzle in a threaded manner, the gun rod is screwed to the smaller end of the leachate nozzle in a threaded manner, and one end of the atomizing nozzle provided with a thread is screwed to the outer thread of one end of the gun rod. The gun rod is fixed to the flange in a welded manner, and the flange is sleeved with a seal ring. One end of the protective sleeve with a mounting hole sleeves the flange and is fixed through a screw to prevent from dropping. The atomizing spray gun has the advantages that dual-fluid design is adopted, the leachate and the compressed air are mixed in the nozzle under certain pressure, fine atomized particles are produced, and service life is super long.

Owner:无锡卓能环境科技有限公司

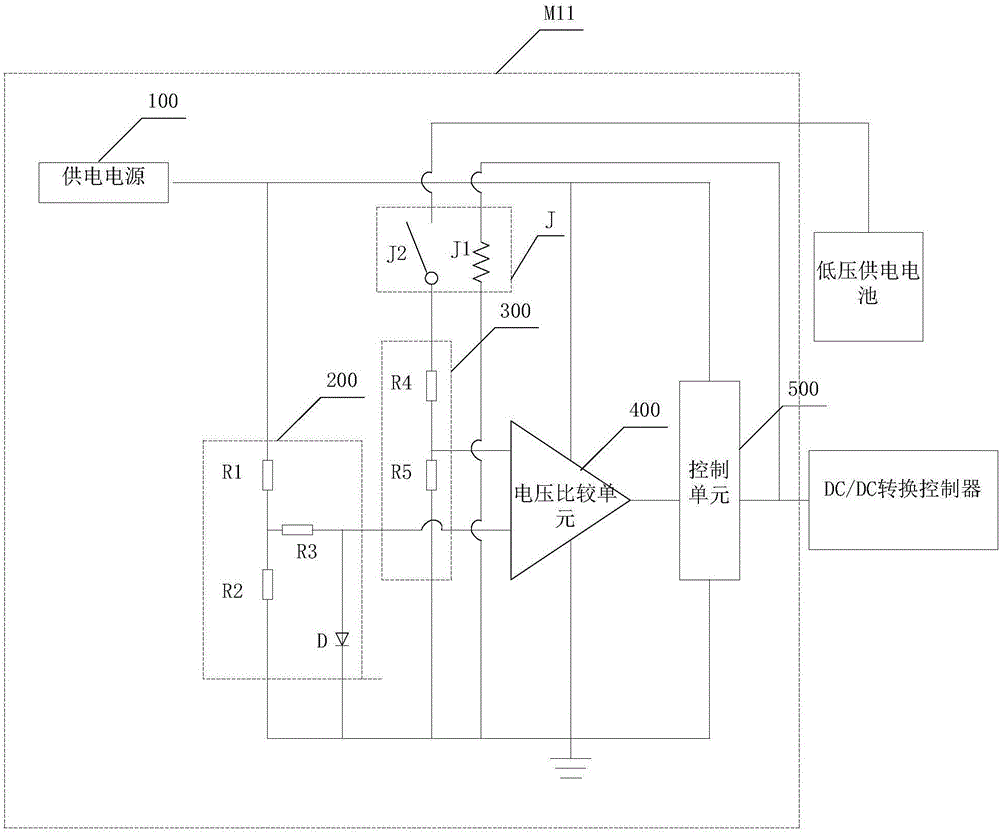

Electric automobile, DC/DC converter and control system thereof

InactiveCN105720653AMeet start-up needsWill not increase the loadElectric powerElectric/fluid circuitElectricityPower battery

Owner:力帆科技(集团)股份有限公司

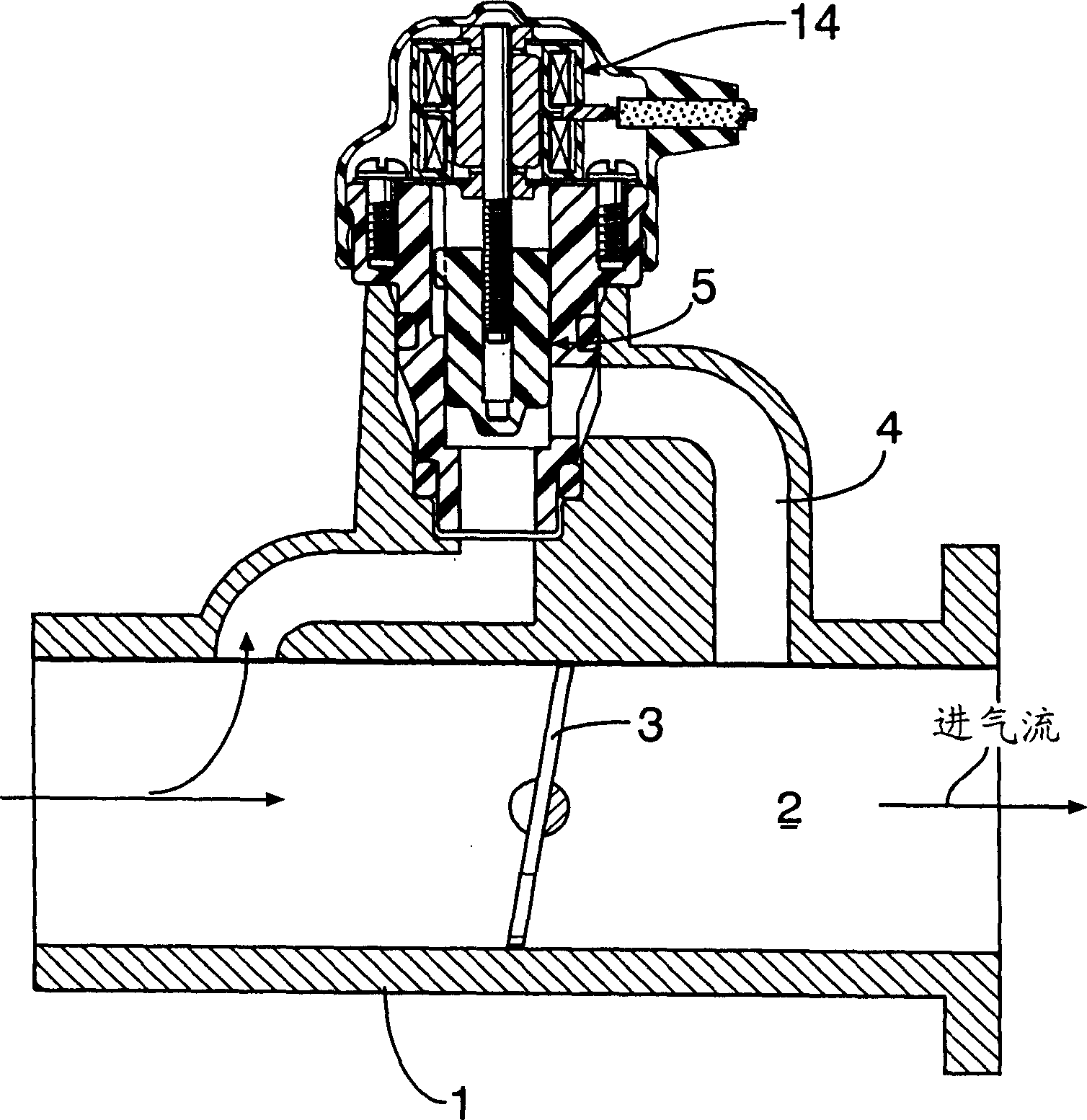

Bypass intake amount controller

InactiveCN1437679AAvoid stickingContainment leakElectrical controlInternal combustion piston enginesControl systemEngineering

In a bypass intake control system, a bypass valve (5) is formed from a valve housing (6) having a valve hole (10), an inlet port (11) connecting to the upstream side of a bypass (4) and an outlet port (12) connecting to the downstream side of the bypass (4), and a valve piston (13) fitted in the valve hole (10) in a slidable and non-rotatable manner, the valve piston (13) being linked to an output shaft (23) projecting out of an end surface of a rotor (22) of a stepping motor (14) via a screw mechanism (29) on the side opposite to the bypass (4) relative to sliding surfaces of the valve housing (6) and the valve piston (13). It is thereby possible to prevent the screw mechanism from being exposed to backfire gas. The engine negative boost pressure does not impose a high load on the stepping motor thus making it possible to reduce the capacity of the motor. <IMAGE>

Owner:KEIHIN CORP

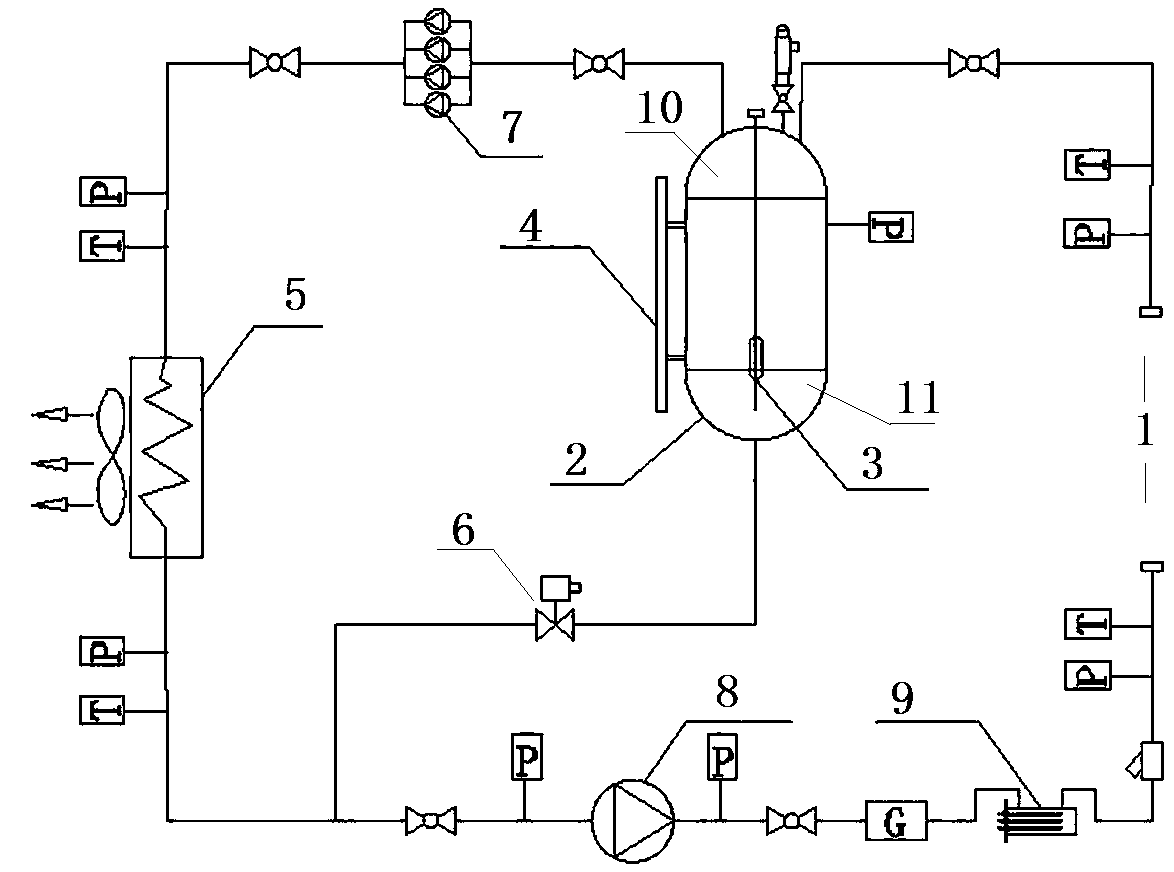

Air conditioner for machine room

InactiveCN102353097AAvoid condensationAvoid quality problemsFluid circulation arrangementAir conditioning systemsEngineeringControl valves

The invention relates to an air conditioner for a machine room, wherein an outlet of a compressor is connected to an inlet of a condenser through a first unidirectional control valve, an outlet of the condenser is connected to an inlet of a liquid-storing device, an outlet of the liquid-storing device is connected to an inlet of an evaporator through a first throttling device, an outlet of the evaporator is connected to an inlet of an on-off control valve, and an outlet of the on-off control valve is connected to an inlet of the compressor. The air conditioner for the machine room is characterized by also comprising a liquid pump, a second throttling device and a second unidirectional control valve, wherein the liquid pump is connected in parallel to both ends of the first throttling device after being connected in series with the second throttling device, an inlet of the liquid pump is connected with the outlet of the liquid-storing device, an outlet of the liquid pump is connected with an inlet of the second throttling device, an outlet of the second throttling device is connected with the inlet of the evaporator, an inlet of the second unidirectional control valve is connected onto a pipeline between the evaporator and the on-off control valve, and an outlet of the second unidirectional control valve is connected onto a pipeline between the first unidirectional control valve and the condenser. The air conditioner for the machine room has an obvious energy-saving effect, the load of a fan is not increased, and fresh-wind condensation and air-quality problems are avoided.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

Vehicle

ActiveCN102378700AFull securityGuaranteed mobilityElectric devicesRigid suspensionsDrive wheelAcceleration Unit

Disclosed is a user-friendly vehicle which can be used comfortably in safety and can ensure motion performance as much as possible while guaranteeing adequate security even when the body is fixed while leaning heavily to either the left or right side by reducing the transverse acceleration limit of the vehicle when a body tilting link mechanism is fixed. The vehicle comprises right and left drive wheels (12) fixed rotatably to the body, a body tilting link mechanism which tilts the body to the right or left, a link brake which fixes the body tilting link mechanism, and a vehicle controller which controls the position of the body by controlling the drive torque to be imparted to each drive wheel (12) and the link torque to be imparted to the body tilting link mechanism, wherein the vehicle controller reduces the transverse acceleration limit of the vehicle when the link brake fixes the body tilting link mechanism.

Owner:EQUOS RES

Method for realizing photoelectric pulse wave detection by using earmuffs

InactiveCN102613963AWill not increase the loadDoes not affect work abilityCatheterEngineeringEarmuffs

The invention relates to a method for realizing photoelectric pulse wave detection by using earmuffs. The method for adding a photoelectric pulse wave detecting function on the earmuffs is provided to people who need normal operation and cannot conveniently wear sensors on the hands. The operation of a user is not affected during detection. Circuits used for detecting pulse waves are additionally arranged on the earmuffs; double-wavelength photoelectric sensors are arranged on surfaces of soft cushions contacted with a human body; and a part of other circuits is arranged in cavities of the earmuffs. When people wear the earmuffs to normally work, two routes of photoelectric pulse waves can be detected through the sensors contacted with the human tissues around auriculas and the detecting circuits arranged in the cavities of the earmuffs, and the blood oxygen saturation parameter is calculated. Photoelectric pulse wave detection is performed by the earmuffs worn on an operator, and a new detection device is not added, so that the load of the operator is not increased, and the operation ability is not affected.

Owner:AVIATION MEDICINE INST AIR FORCE PLA +1

Barrage sending period setting method, storage medium, electronic equipment and system

ActiveCN109660831AGuaranteed display effectImprove experienceSelective content distributionUser identifierServer-side

The invention discloses a barrage sending period setting method, a storage medium, electronic equipment and a system, and relates to the field of network live broadcast. The method comprises the stepsthat: after carrying out partitioning and classification on all live broadcast rooms according to live broadcast themes of all the live broadcast rooms which need to be subjected to barrage sending period setting, a server side sets at least two levels of continuous user number intervals for each of the same type of live broadcast rooms; after users log in a live broadcast room, when the server side monitors that a partitioning identifier exists in the current broadcast room and a user number of the live broadcast room is greater than a user number thread of the live broadcast room, the server side determines a barrage sending period of the user number interval corresponding to the number of the uses viewing the current live broadcast room is determined and used as an actual barrage sending period; and the server side carries out association on the actual barrage sending period and user IDs of current users. According to the invention, on the basis of not abandoning barrages, the number of the barrages in the live broadcast room can be controlled, so that not only can barrages sent by the users be guaranteed to be displayed, but also a load of the server side cannot be increased.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

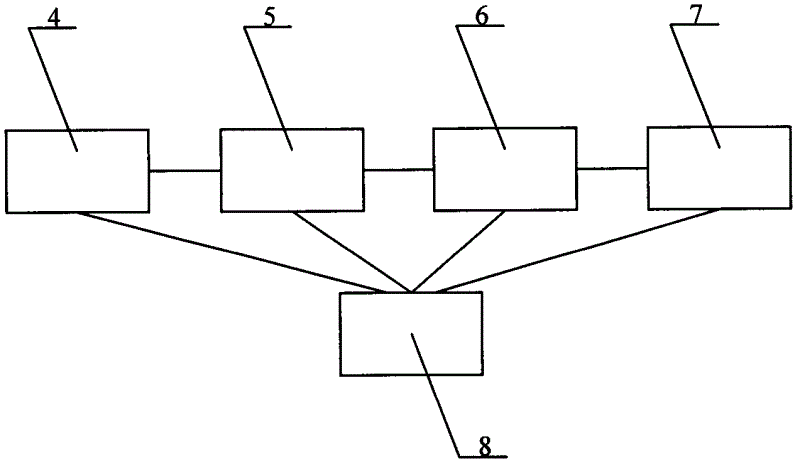

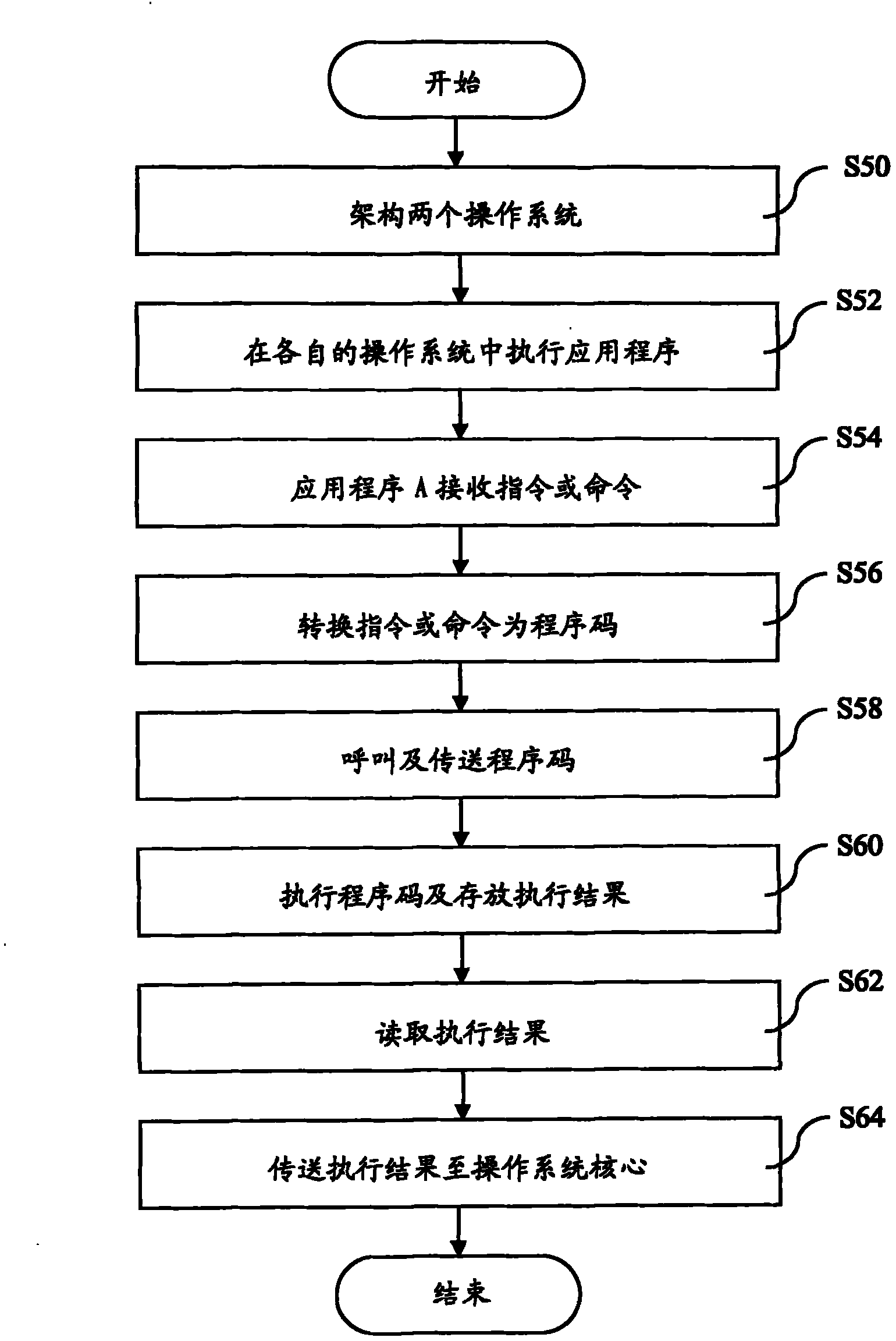

Parallel processing method for dual-operation system

ActiveCN102043677ADoes not affect the original schemaWill not increase the loadInterprogram communicationOperational systemFile system

The invention discloses a parallel processing method for a dual-operation system. A main operation system and a sub operation system are formed on an operation system core, wherein a first application program is executed on the main operation system; a second application program is executed on the sub operation system; an instruction or a command of hardware received by the operation system core is transmitted to the first application program; the instruction or the command is converted into a program code to be executed by the second application program by the first application program; the program code is transmitted to the second application program by the first application program; the program code is executed by the second application program; the execution result is stored in a storage or a file system; the execution result of the second application program in the storage or the file system is read by the first application program; and the read result is transmitted to the operation system core by the first application program.

Owner:INSYDE SOFTWARE

Potato peeling machine

InactiveCN109892671AWill not increase the loadEasy to separateVegetable peelingGear wheelSpiral blade

The invention discloses a potato peeling machine. The machine is characterized by comprising a base, moving wheels and a peeling cylinder, a motor is arranged in the center of the inner bottom of a cavity of the peeling cylinder, the output end of the motor extends to the middle of the peeling cylinder, and a rotating disc is fixedly connected to the end of the motor; a pushing roller shaft is arranged at the center of the top of the rotating disc, a spiral blade is arranged on the pushing roller shaft, and a driven gear sleeves the end of the portion, at the bottom of the rotating disc, of apeeling roller; the driven gear is meshed with a gear ring, and a steel wire brush is arranged on the portion, at the top of the rotating disc, of the peeling roller; peel outlet through holes are formed in the side wall, between the bottom of the rotating disc and the gear ring, of the peeling cylinder; inner trays are arranged on the portions, at the ends of the peel outlet through holes in thecavity of the peeling cylinder, on the side of the peeling cylinder; outer trays are arranged on the portions, at the ends of the peel outlet through holes outside the cavity of the peeling cylinder,on the side of the peeling cylinder; water drainage pipes are arranged at the bottoms of the outer trays, the side of the peeling cylinder is provided with a discharge door and an observation door, and a ventilation strip hole is formed in the observation door. The machine has the advantages of being simple in structure, good in peel separation effect and high in working efficiency.

Owner:史玉花

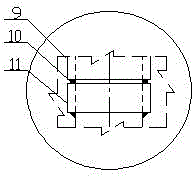

Anti-abrasive device for heat exchange tube bundle in trichlorosilane synthetic furnace

InactiveCN104591190AReduce the frequency of maintenance and replacementLow costHalogenated silanesBiochemical engineeringSieve

The invention relates to an anti-abrasive device for a heat exchange tube bundle in a trichlorosilane synthetic furnace. The anti-abrasive device comprises a synthetic furnace heat exchange tube bundle composed of an inner ring heat exchange tube bundle, a middle ring heat exchange tube bundle and an outer ring heat exchange tube bundle, wherein an outer fixing ring is arranged on the outer side of the outer ring heat exchange tube bundle; a middle fixing ring is arranged on the outer side of the middle ring heat exchange tube bundle; an inner fixing ring is arranged on the outer side of the inner ring heat exchange tube bundle; the middle fixing ring is respectively connected with the outer fixing ring and the inner fixing ring through sieve plates; base plates are arranged between the outer side of the outer ring heat exchange tube bundle, between the outer side of the middle ring heat exchange tube bundle and the middle fixing ring, and between the outer side of the inner ring heat exchange tube bundle and the inner fixing ring; 99 porcelain aluminum oxide ceramic clamp sleeves are arranged on the outer surfaces of the middle parts of the inner ring heat exchange tube bundle and the middle ring heat exchange tube bundle; O-shaped seal rings made of chloroprene rubber resin are arranged at two ends of the ceramic clamp sleeves; and ceramic fixing rings are arranged on the O-shaped seal rings. According to the anti-abrasive device, the service life of equipment is prolonged; and the maintenance and replacement frequency and cost of the tube bundles are reduced.

Owner:ASIA SILICON QINGHAI

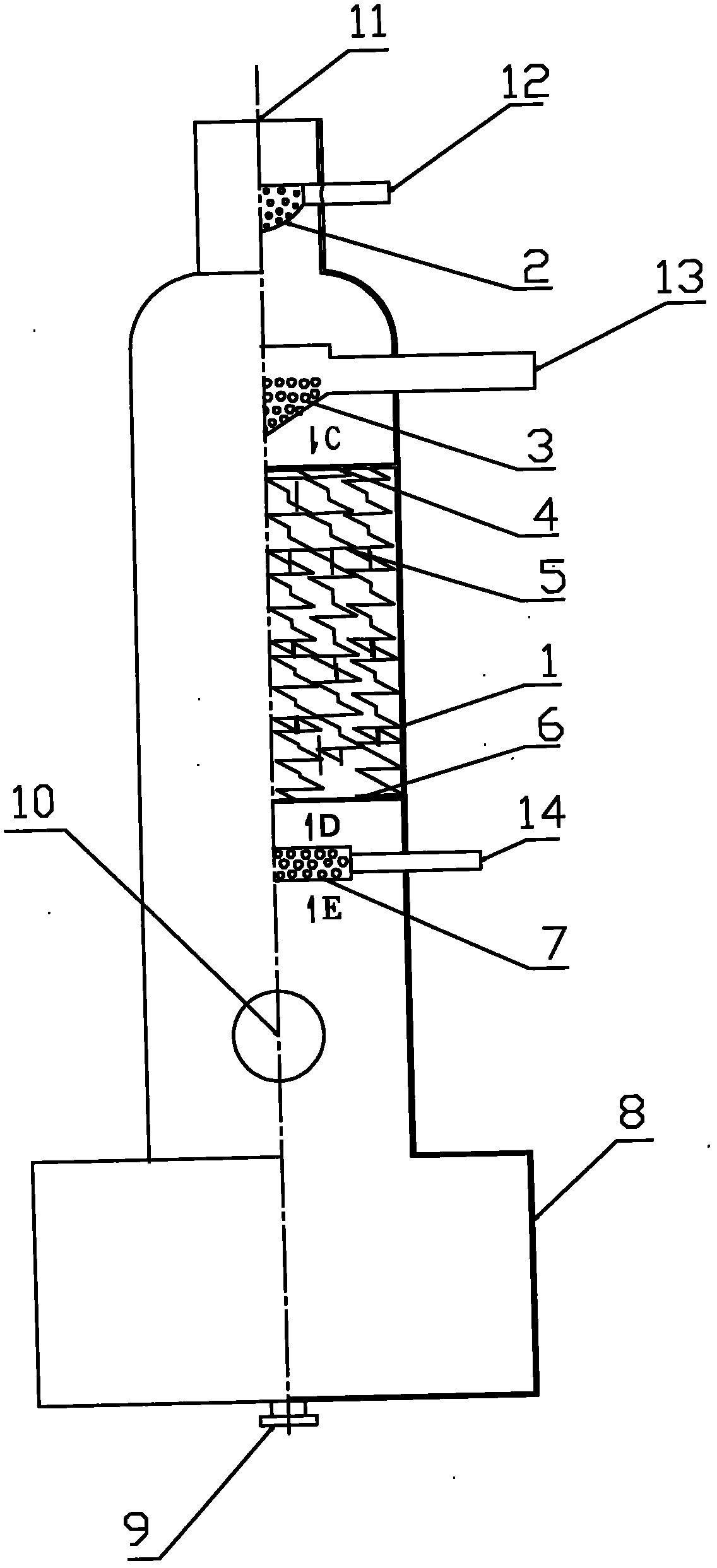

Vulcanizing dead steam waste heat recovery device

InactiveCN102116583AEnsuring Atmospheric Discharge RequirementsThere is no "pressurization" phenomenonTrickle coolersPlate heat exchangerWater storage tank

The invention discloses a vulcanizing dead steam waste heat recovery device, comprising a dead steam heat exchanger and a water storage tank; the dead steam heat exchanger comprises a shell, a gas discharge hole is arranged at the top end of the shell, a dead steam inlet is arranged at the bottom end of the shell, the water storage tank which is integrally communicated is arranged at the tail end of the bottom of the shell, the water storage tank is connected with a water reservoir by a pipeline, and a water distribution device, a membrane type adsorbing device and a jetting mixing device are sequentially arranged in the inner cavity of the shell from top to bottom, the water distribution device is provided with a first spray head and a second spray head; the membrane type adsorbing device comprises an upper support plate and a lower support plate, a filler is arranged between the upper support plate and the lower support plate, and through holes are arranged on the upper support plate and the lower support plate; a closed circular tube spraying head is used as the jetting mixing device, the first spray head and the second spray head and the closed circular tube spraying head are all provided with cooling water pipes which penetrate to the outside of the shell, and nozzles are distributed on the first spray head, the second spray head and the closed circular tube spraying head. The vulcanizing dead steam waste heat recovery device has the characteristics of small volume and high heat transferring efficiency, and can fully recover heat in the vulcanizing dead steam.

Owner:吴增伟

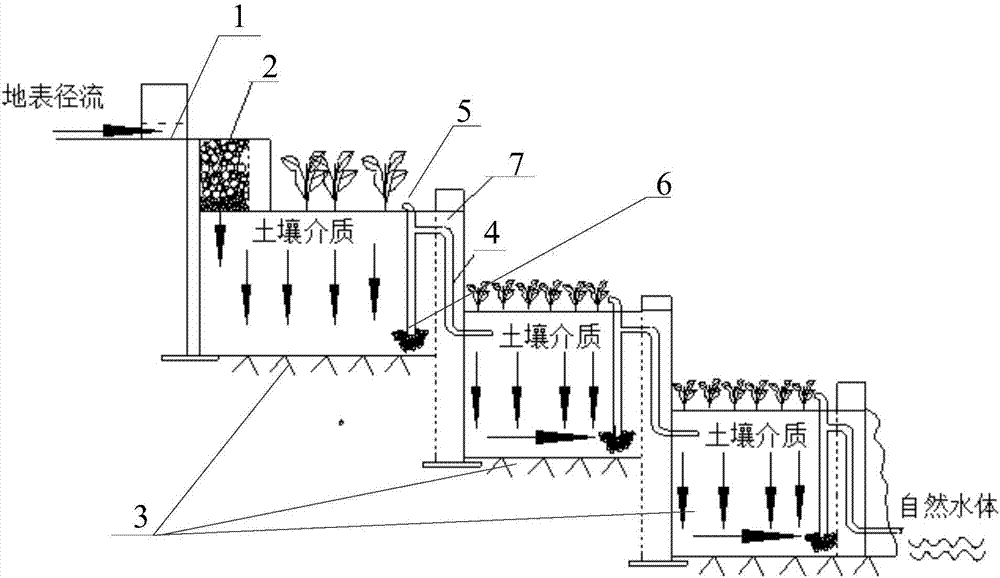

System and method for treating surface runoff

InactiveCN107117772AReduce pollutionWill not polluteWater contaminantsTreatment involving filtrationNitrogenSurface runoff

The invention provides a system and method for treating surface runoff. The system comprises a collecting device, a primary filtering device and at least one secondary soil filtering device, wherein the collecting device is used for converging the surface runoff; the primary filtering device is used for carrying out primary filtering on the surface runoff; the at least one secondary soil filtering device are used for collecting primary-filtered surface runoff by using pipelines, carrying out secondary filtering on the surface runoff and draining secondary-filtered surface runoff into rivers. Thus, the treatment system can be arranged along river bank sides in a long distance manner and is used for carrying out multistage decontamination treatment on the surface runoff and then removing carrying contaminants such as suspended matters, COD, nitrogen and phosphorus from the surface runoff, and then, water is drained into the rivers, so that the rivers cannot be contaminated, the load of the sewage treatment system cannot be increased, and the drainage of municipal pipe networks cannot be affected; civic landscape plants can be planted on the at least one secondary soil filtering device so as to beautify environments.

Owner:武汉钢铁有限公司

A load-bearing plane conveying device

InactiveCN102259747AAchieve self-lubricating effectWill not increase the loadConveyorsGraphiteEngineering

The invention discloses a load-bearing plane conveying device, which is composed of driving rollers, bearing seats, conveyor belts, graphite gaskets, pallets, brackets, brackets, racks, driven rollers, reduction motors and transmission chains , the driving roller is installed on the left side of the frame, the driven roller is installed on the right side of the frame, the geared motor installed in the middle of the left side of the frame drives the driving roller and the conveyor belt forward through the transmission chain, and the graphite gasket under the conveyor belt , the supporting plate and the bracket are connected together, the graphite gasket is supported by the supporting plate, and the bracket is installed on the frame through the bracket. The present invention designs the load-bearing structure according to the lubricating characteristics, horizontal heat conduction characteristics and transfer characteristics of graphite. The graphite gasket supports the conveyor belt for load-bearing and plays a lubricating role in the relative friction movement. Due to the transfer characteristics of graphite, the graphite will move from The graphite gasket is transferred to the conveyor belt to achieve self-lubrication and reduce the friction coefficient.

Owner:郝钰 +1

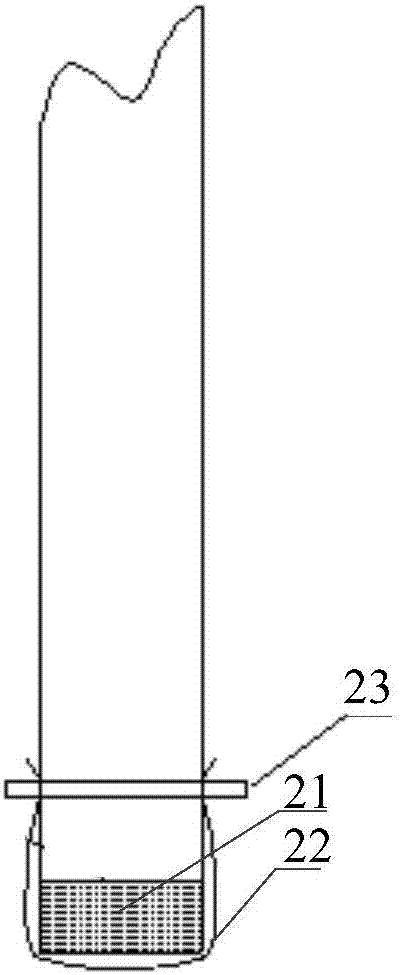

Card reissue device of card issue machine

InactiveCN103793952AWill not increase the loadExtend your lifeTicket-issuing apparatusFailure rateEngineering

The invention provides a card reissue device of a card issue machine. A through groove is formed in one side of a main card box. A supporting plate and a card supporting mechanism are arranged in the main card box. The supporting plate is used for supporting cards. The card supporting mechanism exerts force on the supporting plate in the card outlet direction. A driving mechanism and a stirring block are arranged outside the main card box. The driving mechanism drives the stirring block to move in the longitudinal direction of the main card box. The stirring block penetrates through the through groove to be connected with the supporting plate and can push the supporting plate to move. A card reissue opening is formed in the side, not provided with a card outlet, of the main card box. The card reissue opening is lower than the card outlet. A card reissue sensor used for positioning the supporting plate in the card reissue process is arranged below the card reissue opening. A card reissue box is located outside the main card box. A card issue opening of the card reissue box is higher than the card reissue opening of the main card box. The card issue opening of the card reissue box and the card reissue opening of the main card box are communicated through a guide groove. According to the card reissue device, the card containing capacity of the card storage boxes can be greatly improved, the structure can be simplified, the failure rate can be lowered, and the use reliability of the device can be improved.

Owner:广州市西埃斯智能系统科技有限公司

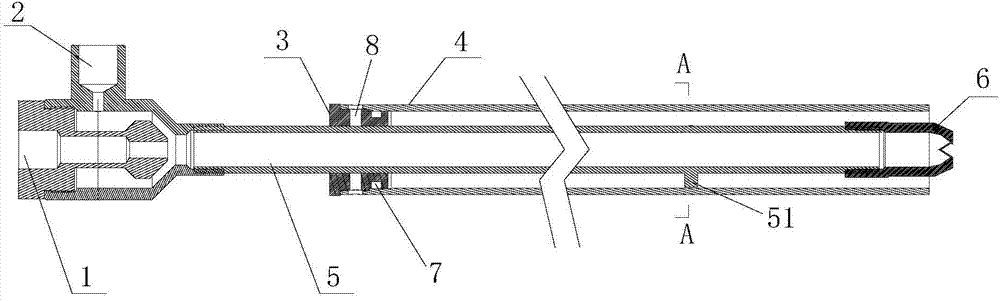

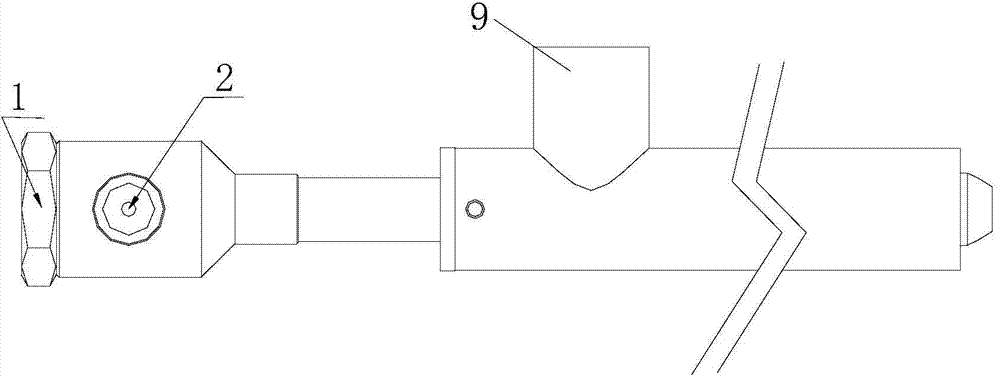

Hydraulic down-the-hole drilling machine integrating impacting and rotating

InactiveCN106285460AWill not increase the loadImprove drilling efficiencyBorehole drivesEngineeringHigh pressure

A hydraulic down-the-hole drill integrating impacting and rotating is composed of a concentric three-cavity tube, a flow divider, a swing mechanism, an impacting mechanism and a machine tail, wherein the shell end portions of the concentric three-cavity tube, the flow divider, the swing mechanism, the impacting mechanism and the machine tail are integrated. According to the hydraulic down-the-hole drilling machine integrating impacting and rotating, high pressure oil (or emulsified liquid) is transported by the three-cavity tube to serve as power drive so as to generate impacting and swinging, oil returning and powder discharging are boosted through compressed air, the overall drilling machine is submerged in a drilling hole, a drilling rod does not rotate, load is not increased because of lengthening of the drilling rod, and more ultra-deep drilling and underwater exploration drilling can be achieved. Because hydraulic pressure (10-20 MPa) is ten to twenty times higher than air pressure (1.2 MPa), through adopting the hydraulic pressure, ballistic work is high, torque is high, the drilling efficiency is high, and energy consumption is reduced by two thirds.

Owner:邹叔仪

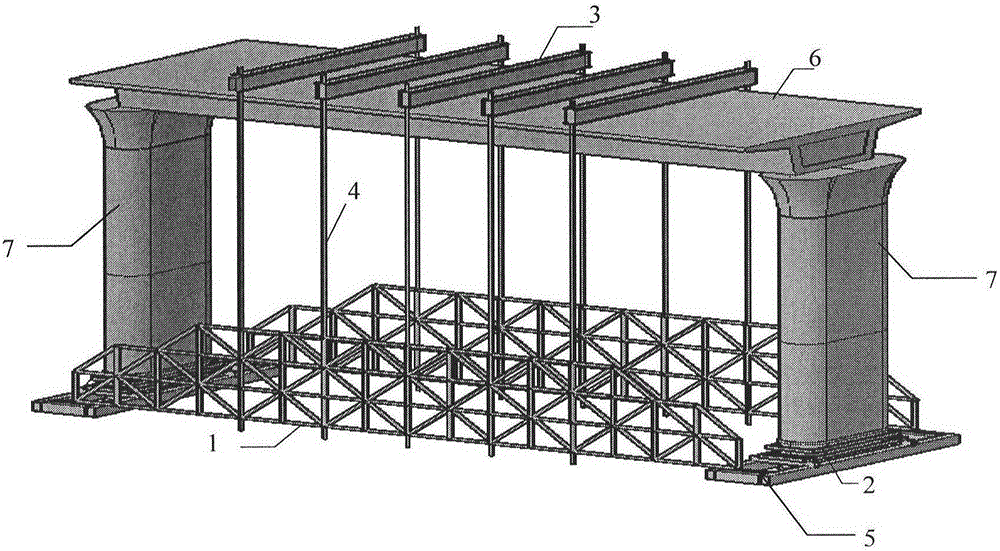

A pier counterforce closing force system self-balance-type railway cast-in-situ beam static load test apparatus

InactiveCN106610343AReduce construction difficultyImprove securityStructural/machines measurementStaticsCounterforce

Provided is a pier counterforce closing force system self-balance-type railway cast-in-situ beam static load test apparatus. The invention relates to a railway cast-in-situ simply-supported box girder static load test pier counterforce closing force system self-balance-type loading device. The device comprises main portions such as a counterforce beam, crossbeams, pull bars, bridge pier holt hoop irons and bridge pier holt hoop iron linking beams. The counterforce beam and the bridge pier holt hoop iron linking beams adopt a hinged construction to transmit forces. The linking beams transmit the counterforce to the bridge pier holt hoop irons, and further transmit the counterforce to a bridge pier through a holt hoop iron frictional force. The crossbeams form a force bearing integral body through the pull bars and the counterforce beam. As for the loading device, the jack is used to jack the crossbeams; the counterforce of the jack is loaded on the tested cast-in-situ beam; the counterforce at the two ends of a beam body are transmitted to the bridge pier through a support base; the counterforce is self-balanced at the bridge pier; the loading device is a force system self-balance system; no base load burden is added in a test process; the advantages such as a simple structure, simple and clear force transmission, convenient assembly, allowing turnover and relatively low cost are realized; requirements of railway cast-in-situ beams at different spans and of different beam types for graded loading and unloading can be satisfied; and relatively high applicability is realized.

Owner:张志国 +1

Cold plate type heat dissipation system and liquid cooling source

InactiveCN110213933AWill not increase the loadDoes not affect the condensation effectCooling/ventilation/heating modificationsVapor–liquid separatorEngineering

The invention relates to a cold plate type heat dissipation system and a liquid cooling source. The cold plate type heat dissipation system comprises a cold plate and the liquid cooling source connected with the cold plate. A heat exchange medium is arranged in the cold plate. The heat dissipation system is provided with a heat generating device at the position close to the cold plate. The liquidcooling source comprises a condenser. The condenser is provided with a gas pipeline and a liquid return pipeline which are used for connecting with the cold plate to form a heat exchange medium circulation circuit. The gas pipeline is provided with a gas path interface for connecting with the gas outlet of the cold plate. The liquid return pipeline is provided with a liquid path interface for connecting with the liquid inlet of the cold plate. A gas-liquid separator is connected in sires on the gas pipeline. The gas storage chamber of the gas-liquid separator is communicated with the gas pipeline. The liquid storage chamber of the gas-liquid separator is connected with the liquid return pipeline through a liquid outlet pipeline. According to the cold plate type heat dissipation system, thecondensation effect of the condenser can be ensured without increasing the load of the condenser so as to have good heat dissipation effect.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com