Paddy-field grass-burying roller

A paddy field and grass board technology, which is applied to suppressors, applications, agricultural machinery and implements, etc., can solve the problems of aggravating the load and resistance of the rotary tiller, affecting the effect of burying grass, affecting the effect of ploughing, etc., and achieves low cost. , good effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing the implementation details of the present invention are described as follows:

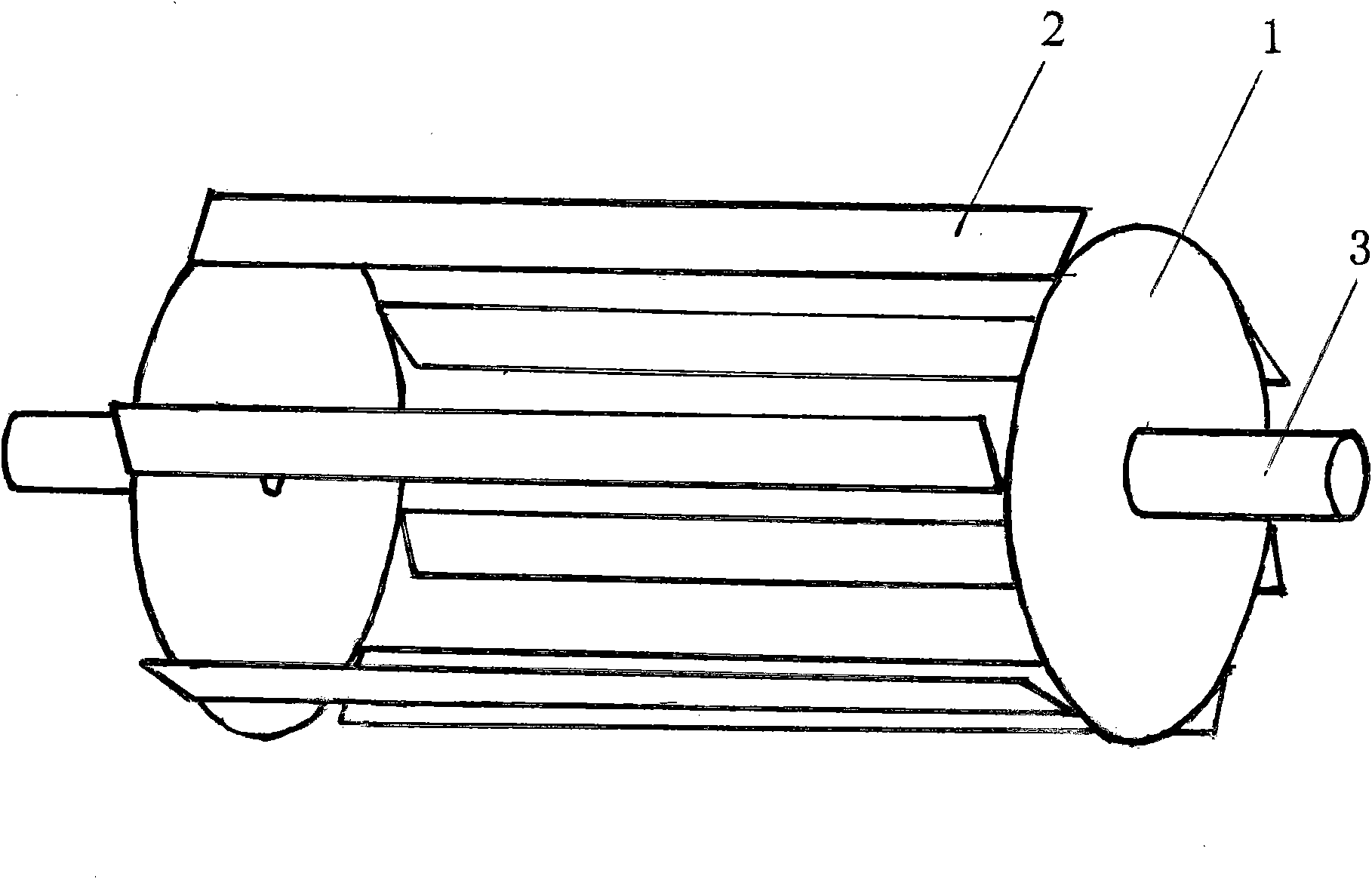

[0014] Such as figure 1 As shown, a paddy field grass-burying roller is characterized in that it consists of two roller end plates 1 corresponding to each other and several strip-shaped grass-burying plates 2 with a reclining angle connected between the roller end plates in an orderly manner and located at the roller end plates. The central roller shaft 3 constitutes.

[0015] The shape of the roller end plate 1 is a circle or a regular polygon. The orderly connection is in the several strips of grass burying boards 2 with a reclining angle between the roller end plates, and the orderly connection refers to the 6-15 equally divided connection points on the outer edge of the roller end plates. The described orderly connection is among several strip-shaped grass-burying boards 2 with a reclining angle between the roller end plates, and the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com