Hydraulic down-the-hole drilling machine integrating impacting and rotating

A down-the-hole drilling rig and integrated technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. It can solve the problems of low efficiency and high energy consumption of air compressors, and achieve energy consumption reduction and torque The effect of large and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] 1. It is better to use the combined punching and turning method for the integrated hydraulic down-the-hole drilling rig, that is, once the drill gets stuck (the drill bit is stuck and does not turn), the impact will stop, so as to avoid drilling due to the deep deformation of the local chisel marks at the bottom of the hole scrapped.

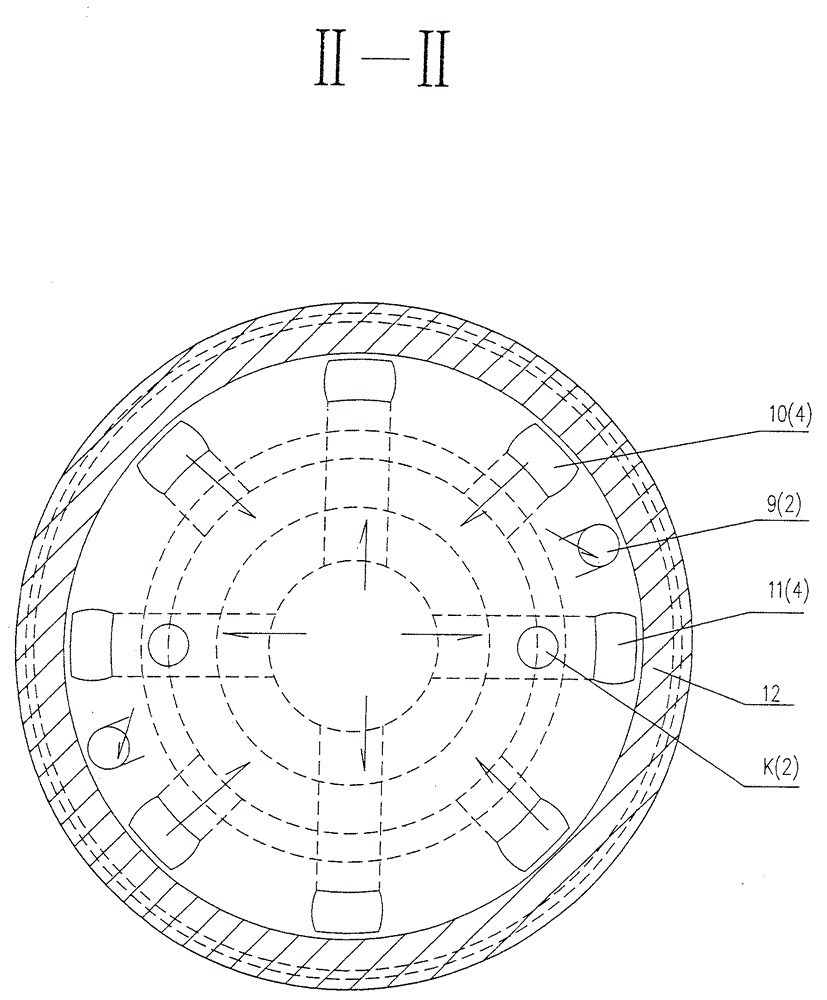

[0042] 2. In order to increase the torque without increasing the outer diameter, the blade can be lengthened longitudinally, or two to three gyrators can be connected in series, and the short shaft on the hub can be connected with a bushing.

[0043] 3. When the slewing mechanism is placed at the front of the impact mechanism, it can also be used in conjunction with the existing hydraulic rock drill impact mechanism, without gear transmission, and the structure is simple and compact.

[0044] 4. According to the patent principle of the present invention, a hydraulic down-the-hole hammer that only impacts can also be made to replace the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com