Bypass intake amount controller

A control device and air intake technology, which is applied in the direction of electrical control, idle speed device, electromechanical device, etc., can solve the problems of stepping motor capacity increase, motor can not be miniaturized, and screw mechanism is difficult to move, so as to reduce size, Effects of suppressing leakage and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

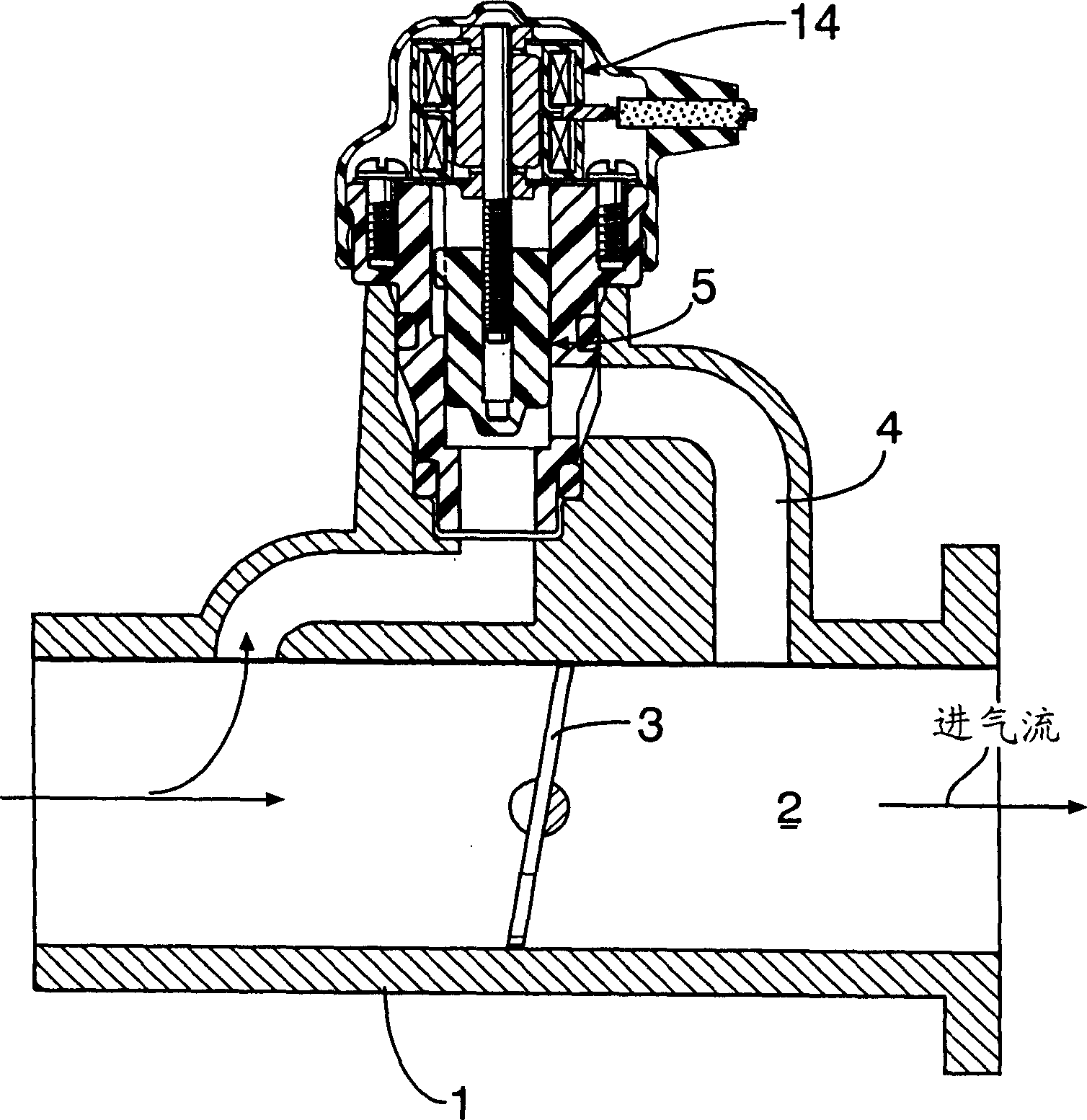

[0031] First, from Figure 1 ~ Figure 3 The first embodiment of the invention shown begins. figure 1 Among them, the throttle valve body 1 has an intake runner 2 that runs through its central part and communicates with the intake port of the engine. The throttle valve 3 used to switch the central part of the intake runner 2 is pivotally supported on the throttle body. Flow valve body 1. In addition, a bypass passage 4 that bypasses the throttle valve 3 and communicates with the intake air passage 2 is formed on the throttle valve body 1. In the middle of the bypass passage 4, a bypass valve for switching the passage is provided. 5.

[0032] Such as figure 2 As shown, the valve housing 6 of the bypass valve 5 is embedded in the installation hole 7 of the throttle valve body 1, and inserted into the middle part of the bypass passage 4 through the sealing parts 8, 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com