Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

537results about "Idling devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

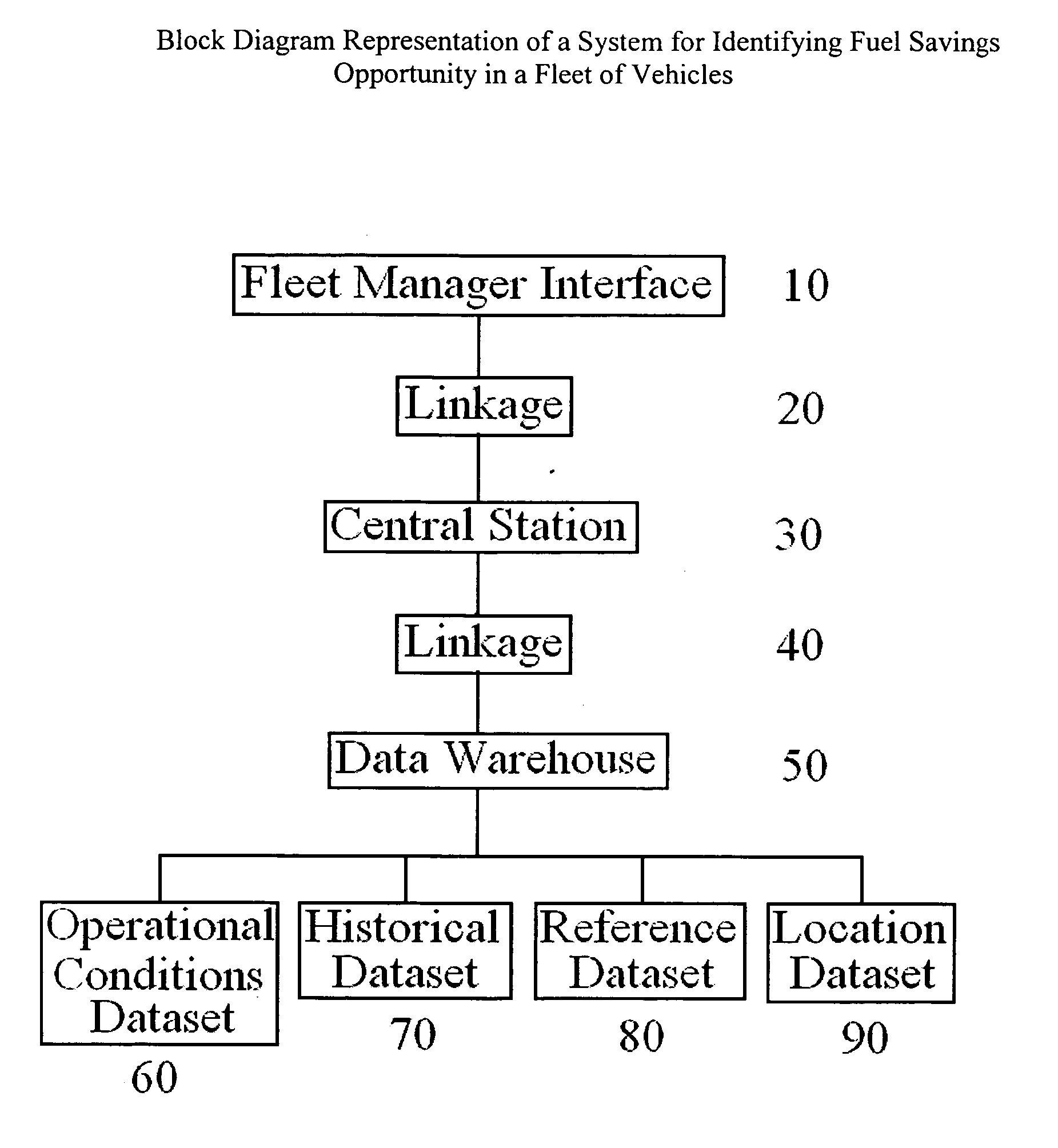

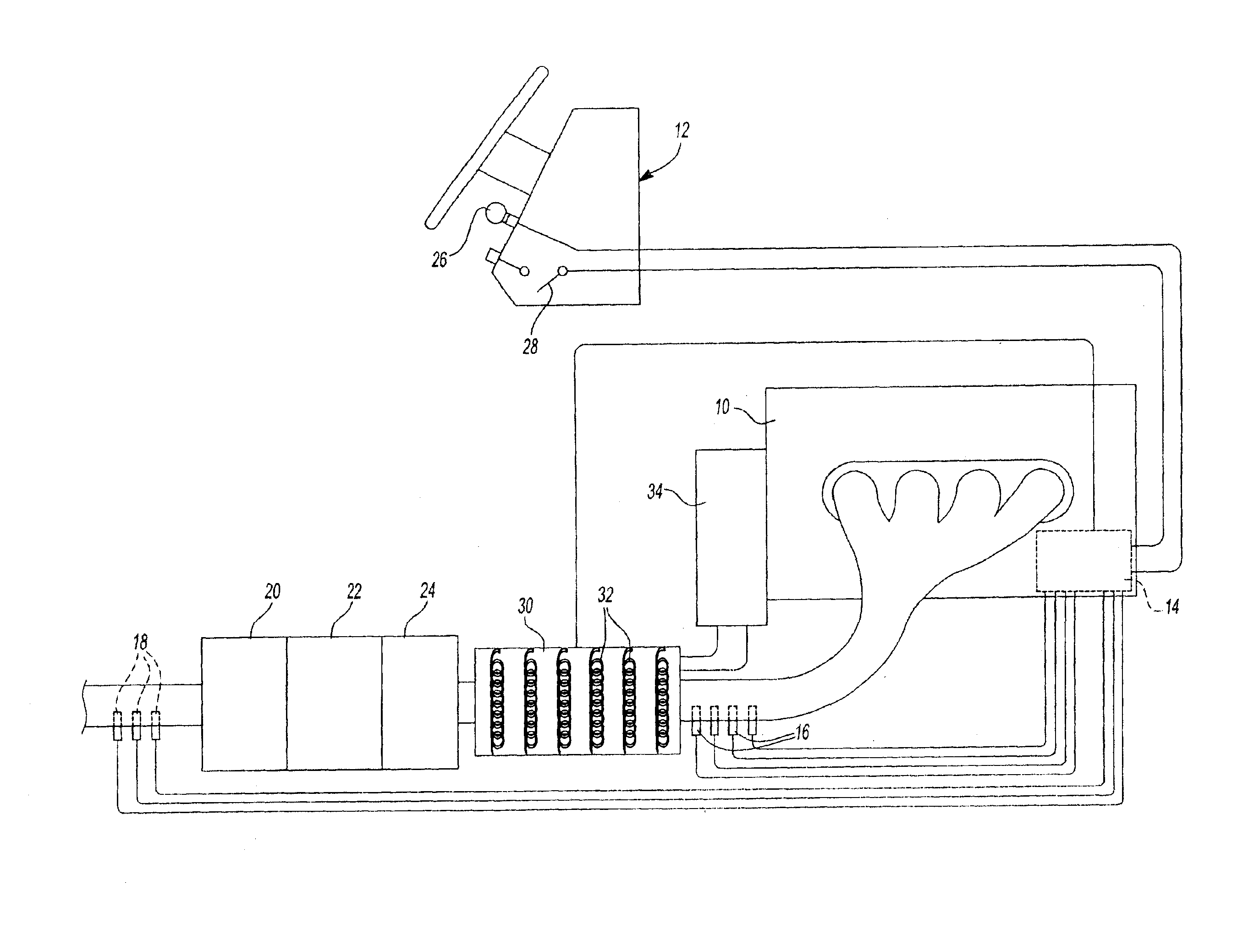

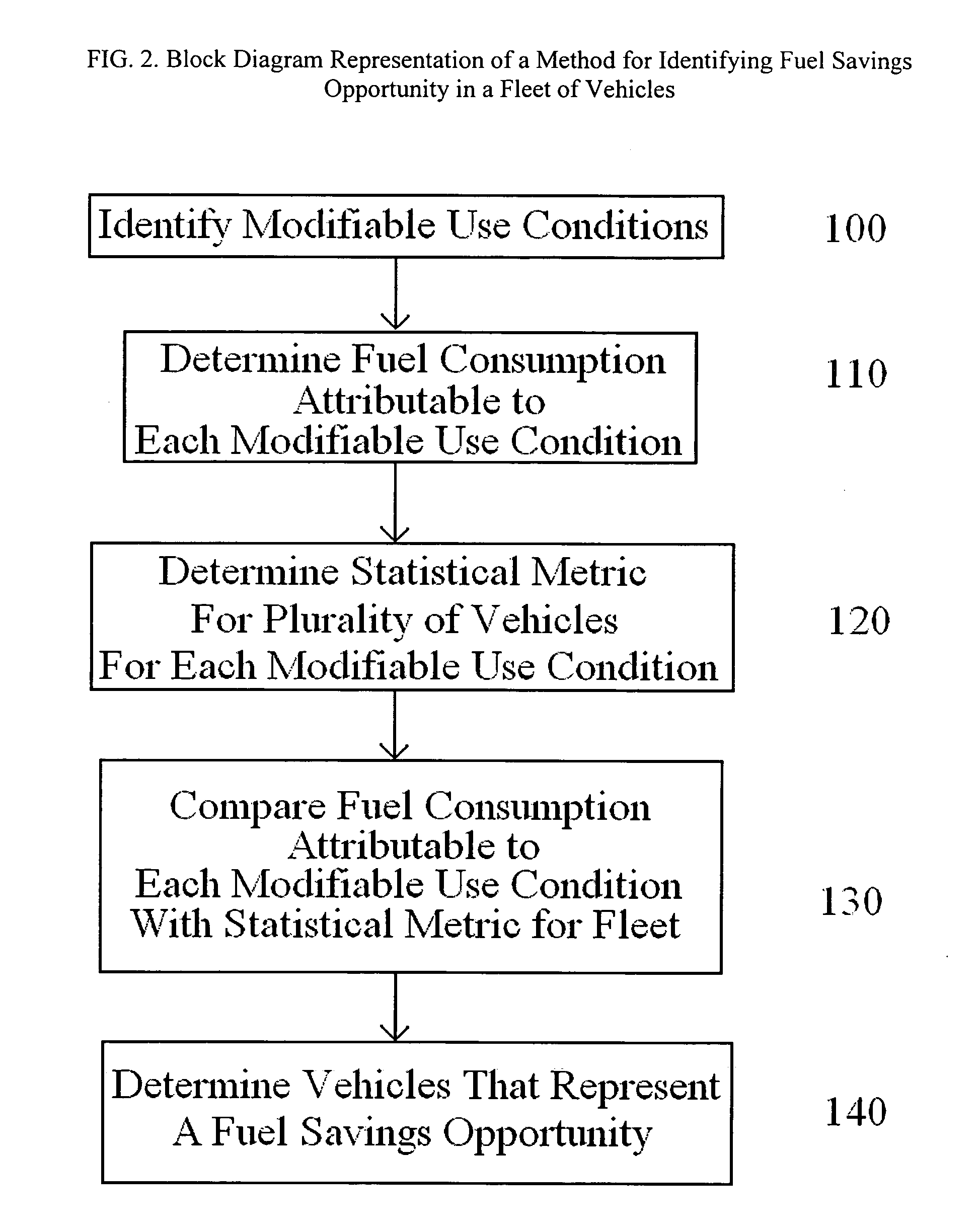

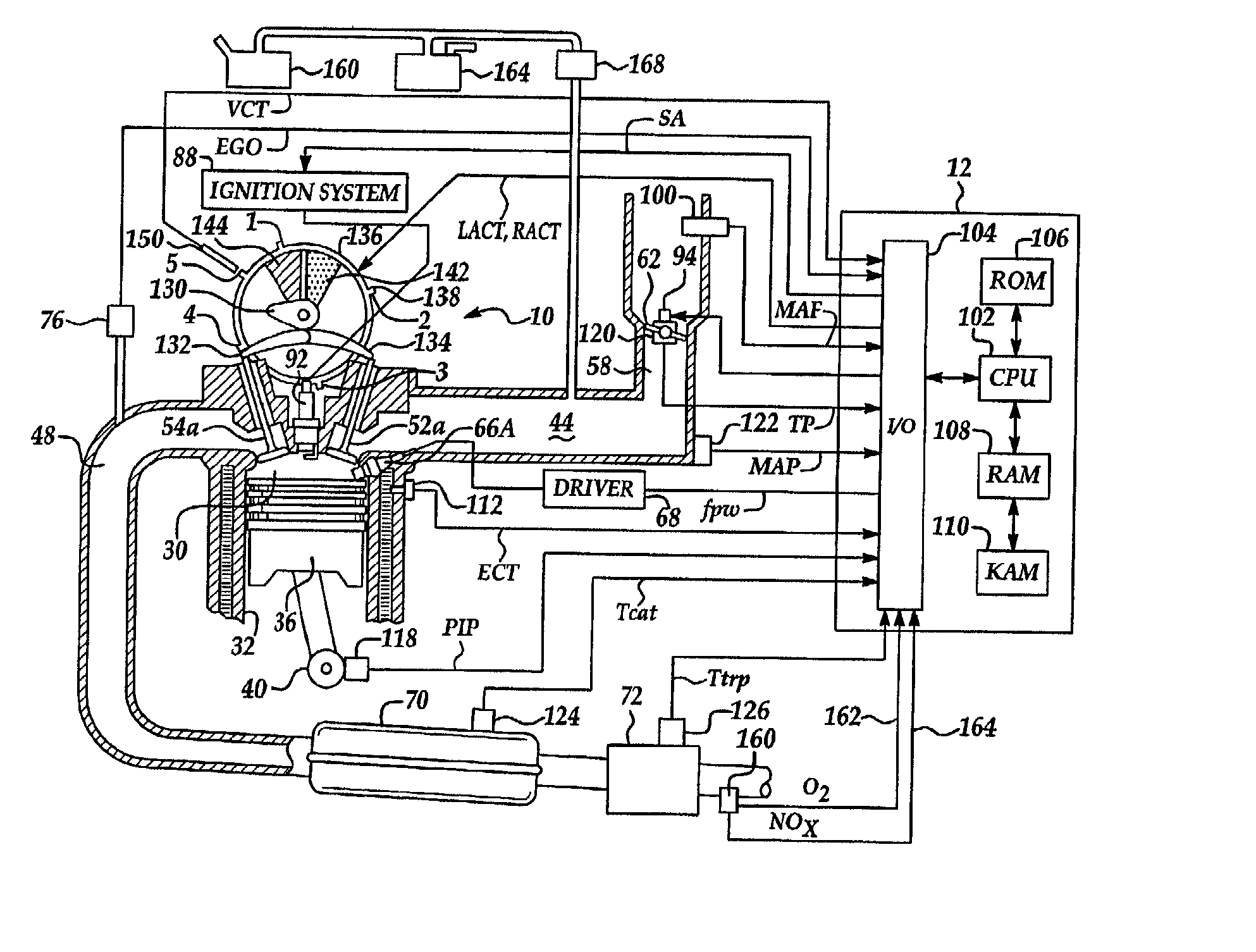

System and method for identifying fuel savings opportunity in vehicles

ActiveUS20070174004A1Reduce fuel consumptionLow costVehicle testingAnalogue computers for vehiclesIn vehicleSimulation

A system and method of identify fuel savings opportunity in a fleet of vehicles based on a determination of fuel consumption due to modifiable use conditions is described. Modifiable use conditions, such as unauthorized usage, speeding and excessive idling, which represent opportunities for fuel savings are identified and fuel consumption based on the modifiable use conditions is determined. A user-defined statistical metric for the fleet, or a portion of the fleet, can be determined for each of the modifiable use conditions evaluated. Fuel consumption of an individual vehicle, or a group of vehicles, resulting from modifiable use conditions can be compared with a larger group of vehicle, or the fleet, to determine vehicles which correspond to a metric of the fleet. Fleet managers can use this information to modify the use conditions of individual or group of vehicles to provide fuel savings for the fleet.

Owner:GE GLOBAL SOURCING LLC

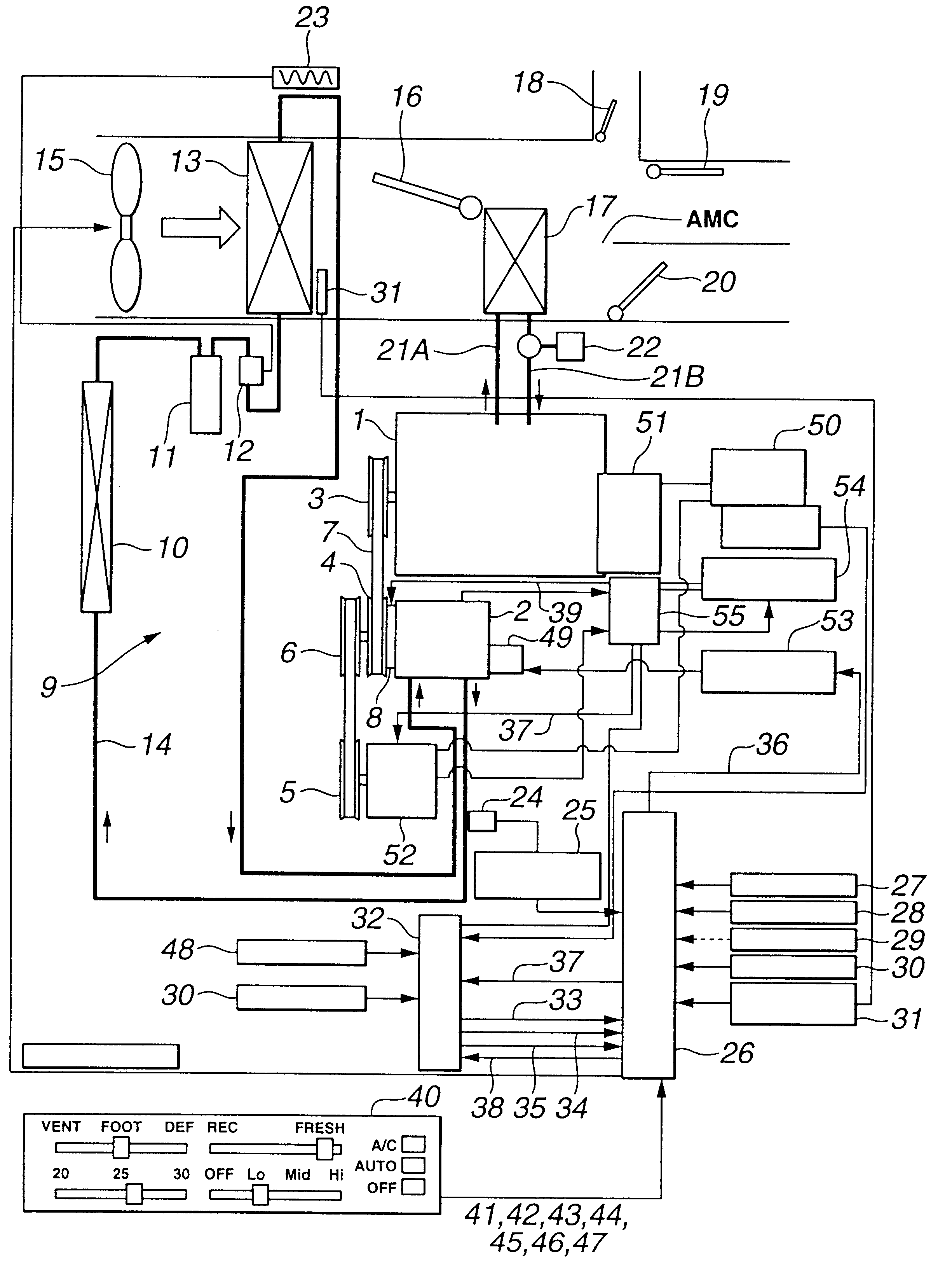

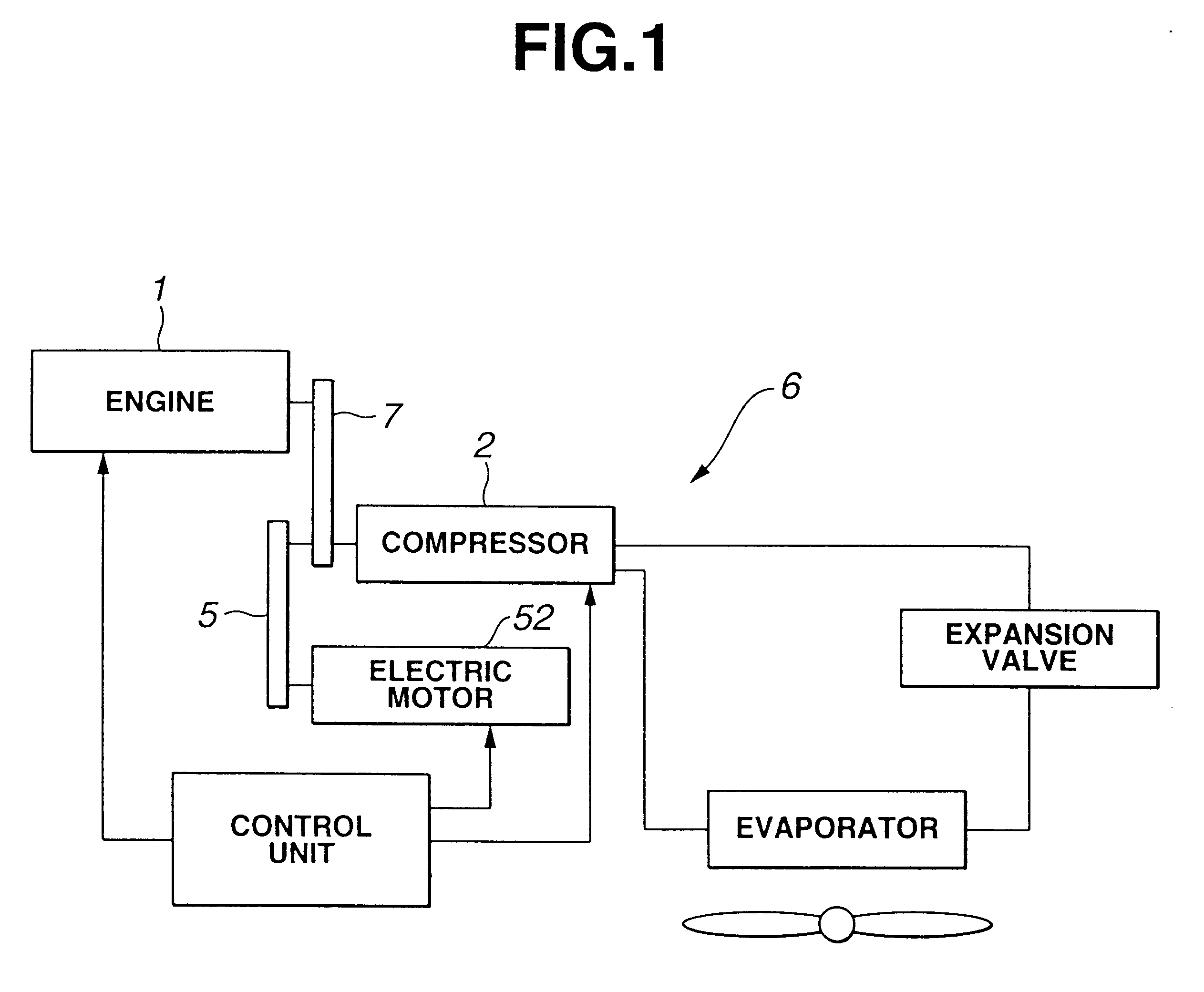

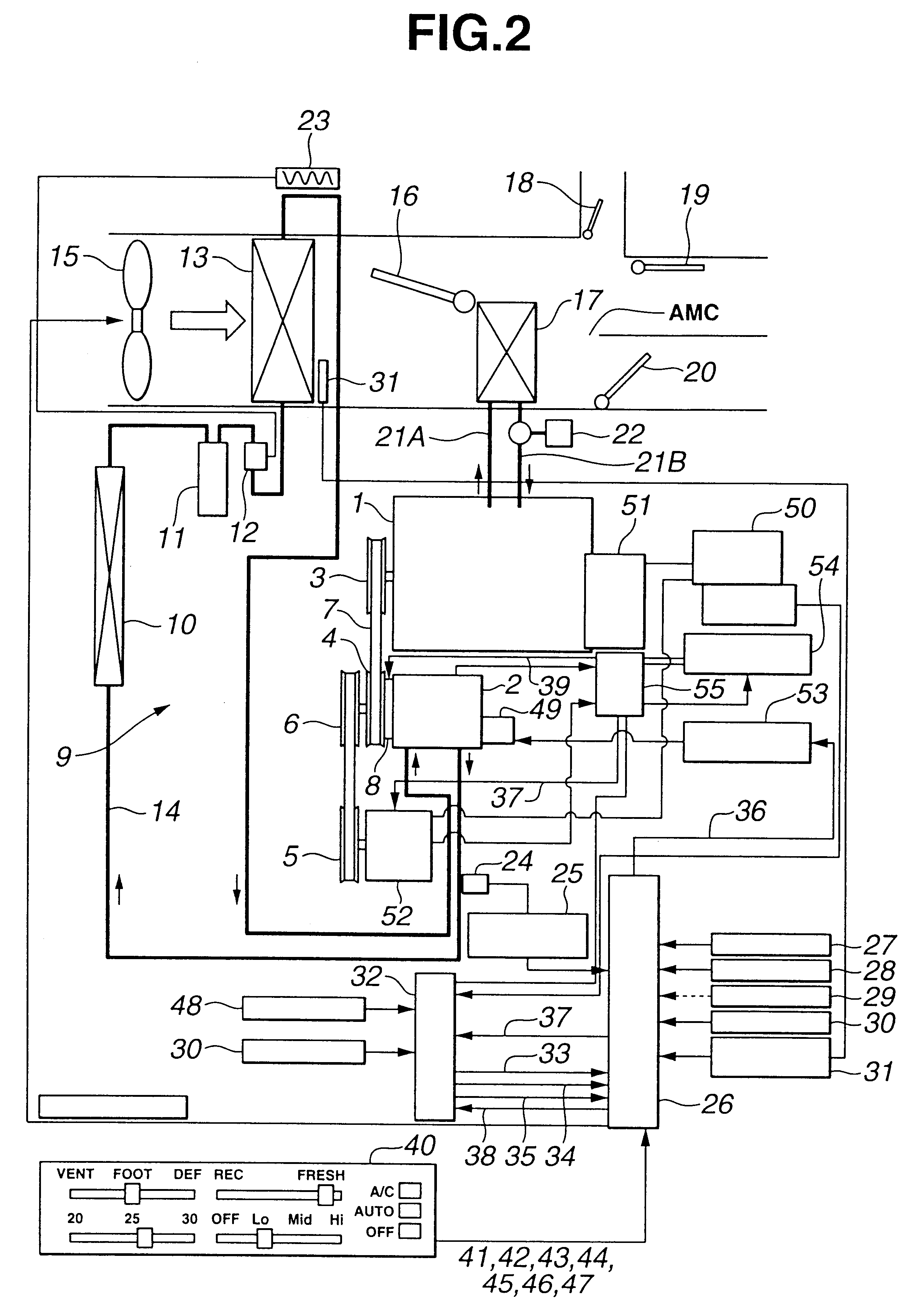

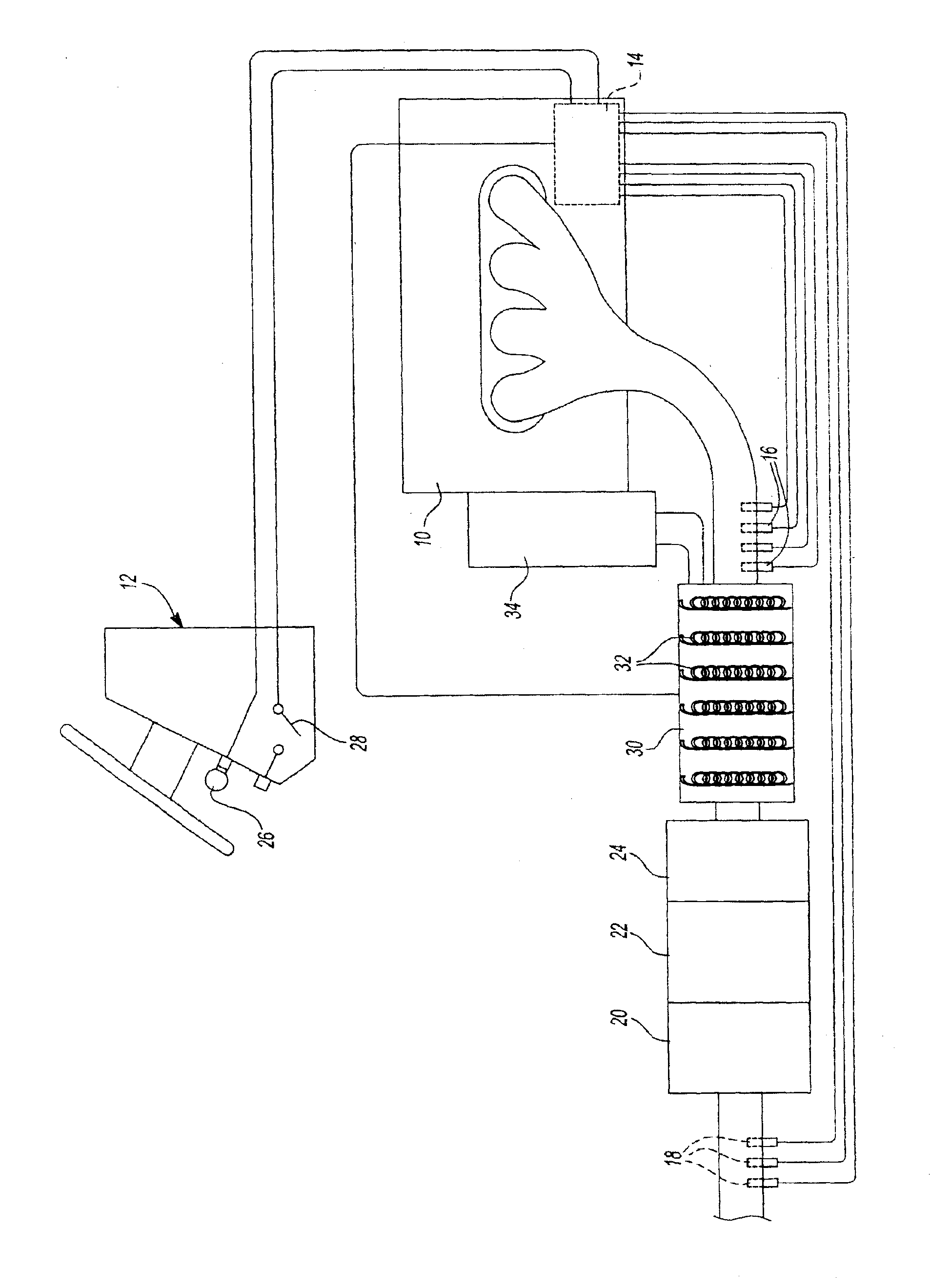

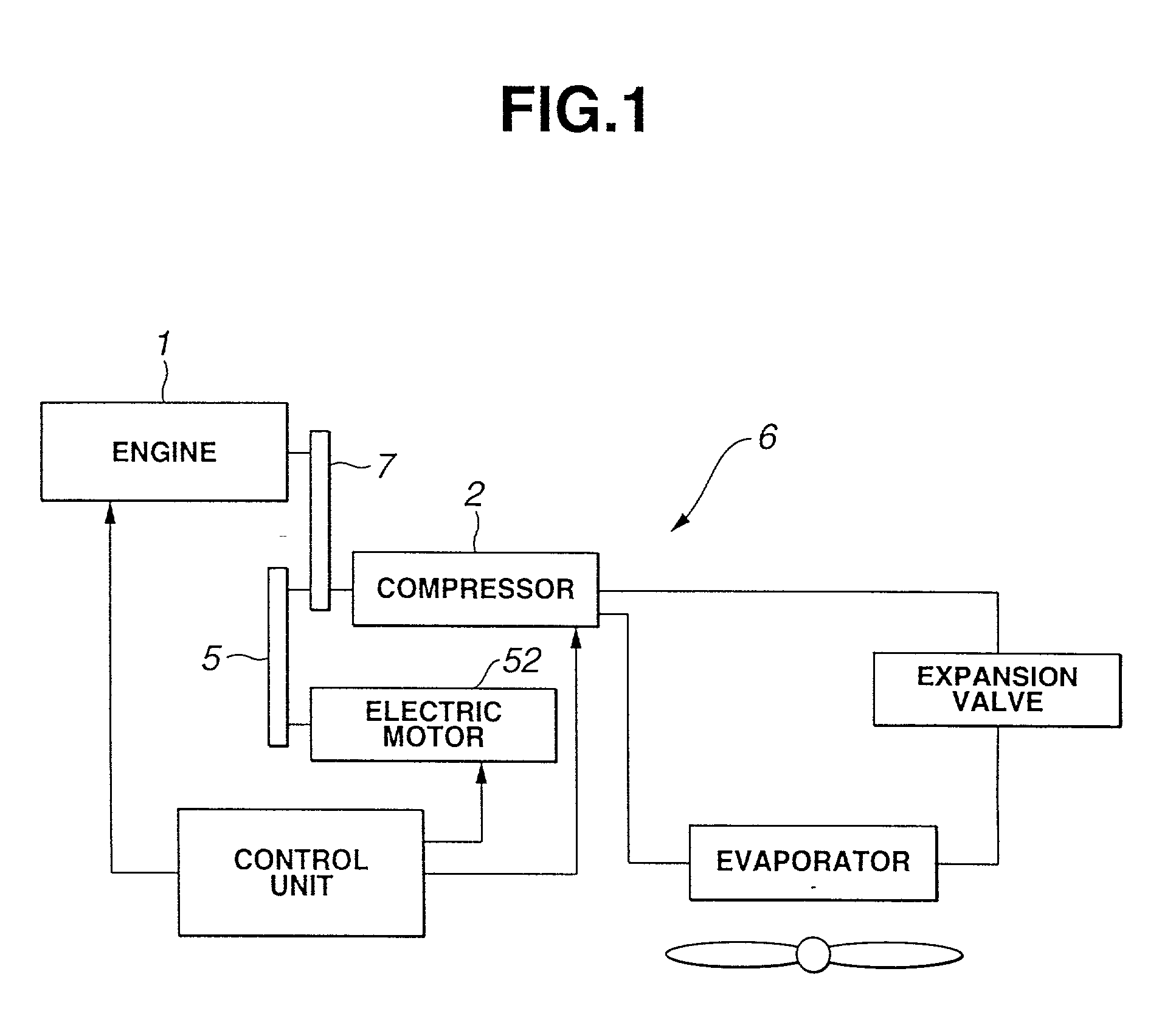

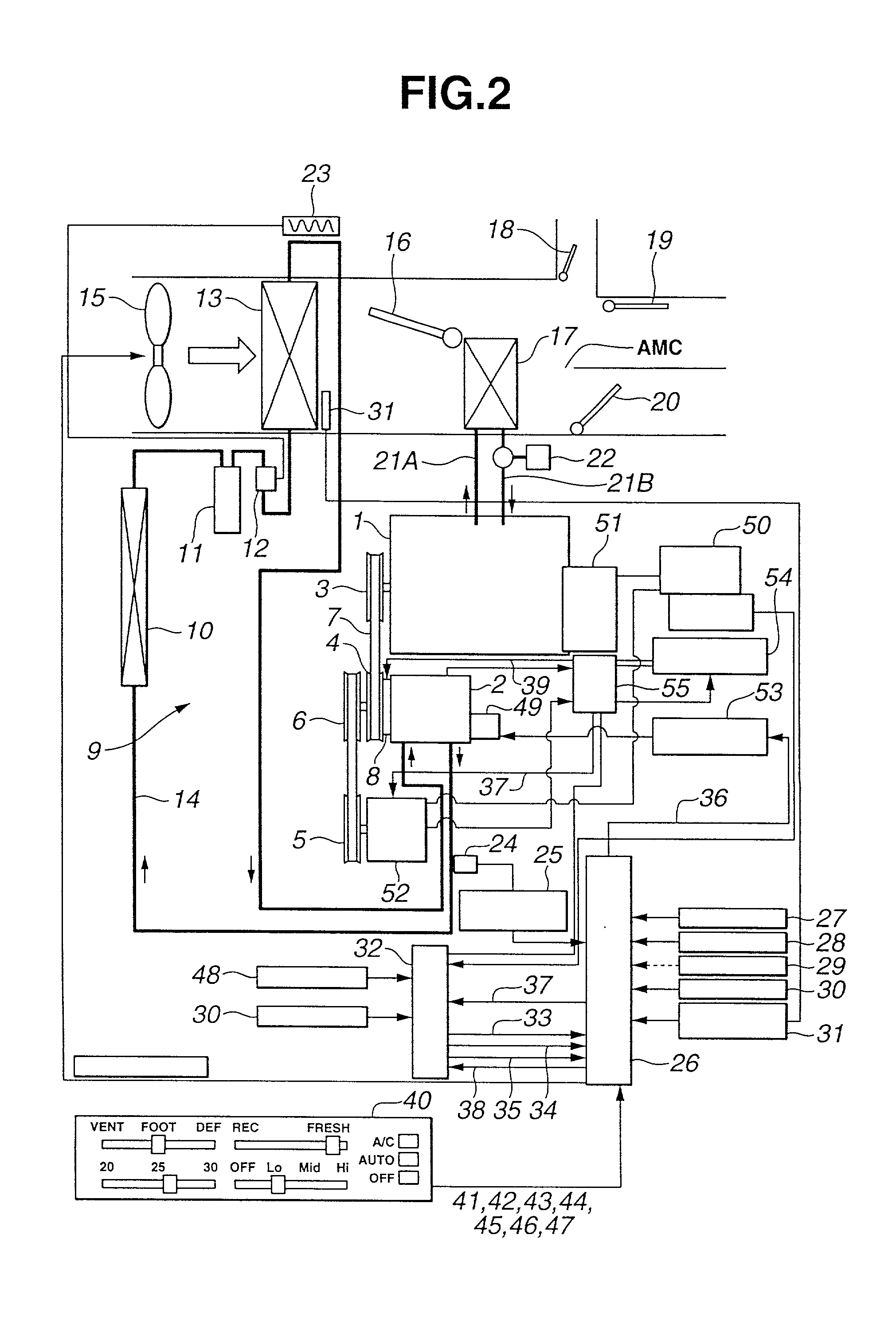

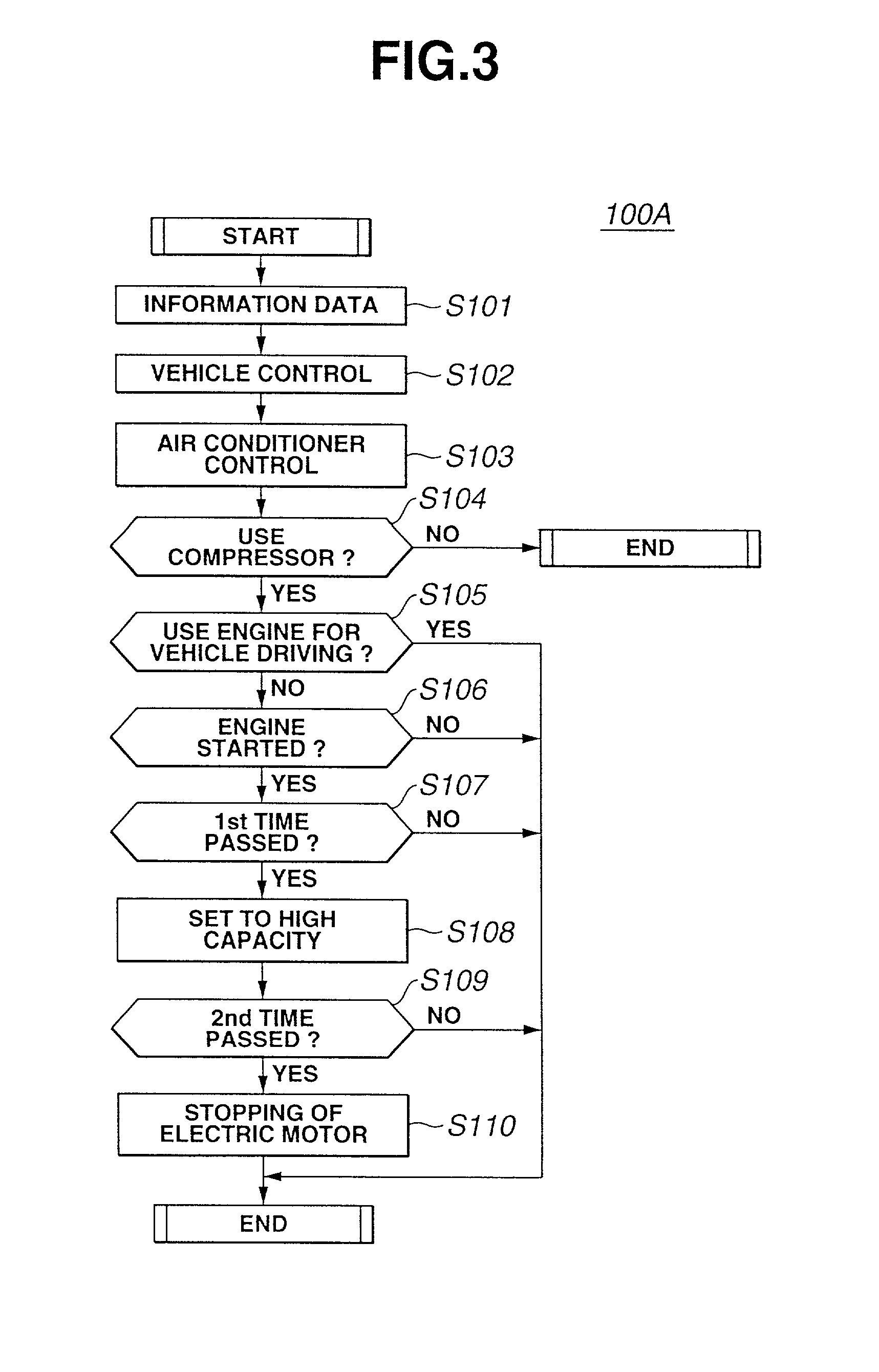

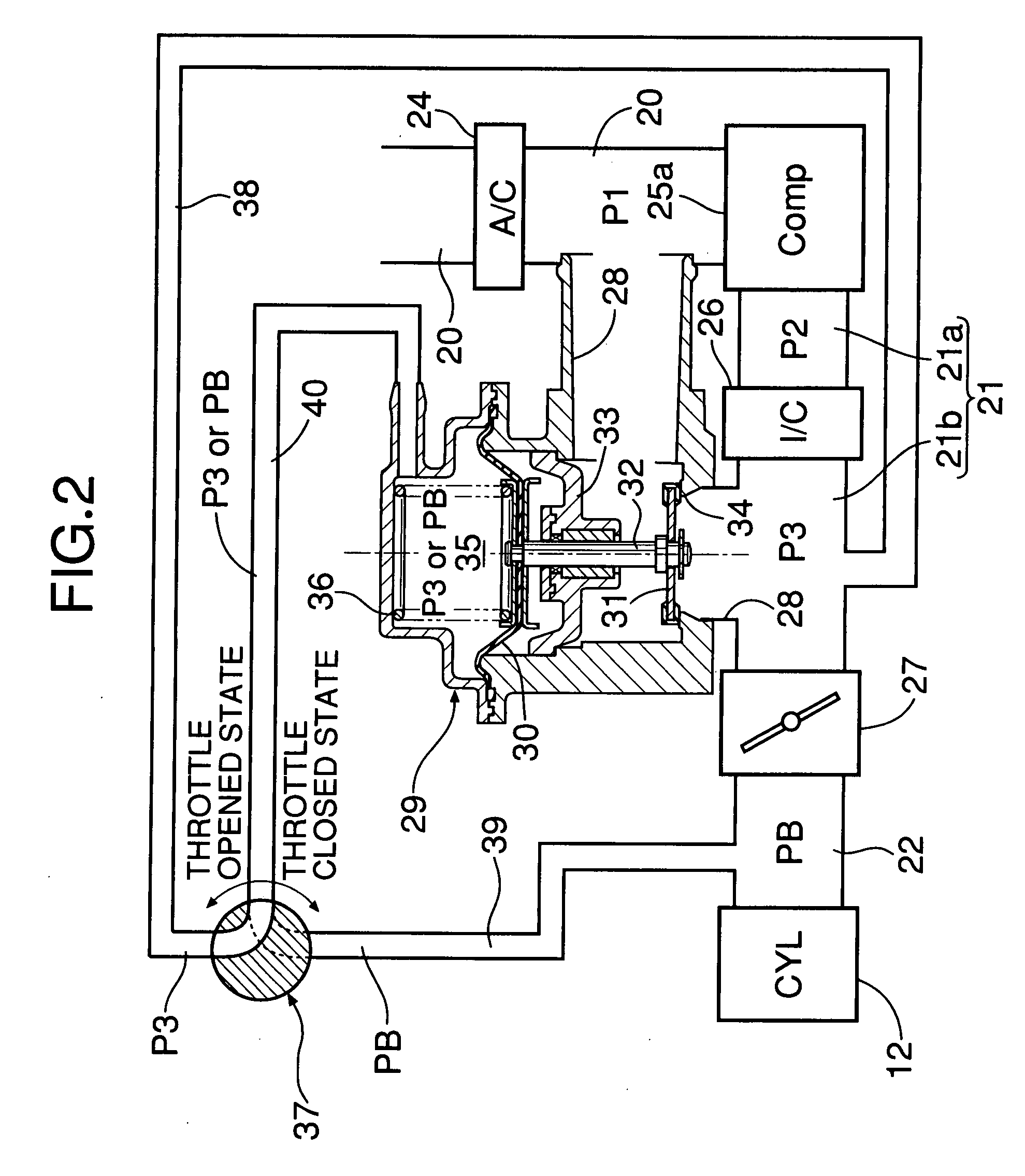

Automotive air conditioning system

An air conditioning system for use in a motor vehicle powered by an internal combustion engine is described. The system comprises an electric motor powered by a battery; a compressor arranged to be powered by at least one of the internal combustion engine and the electric motor; and a control unit that controls the driving of the compressor. The control unit is configured to execute driving the compressor by only the electric motor when the combustion engine is under an idling stop; restarting the combustion engine upon expiration of a first given time from the time when the idling stop has occurred, so that thereafter the compressor is driven by both the combustion engine and the electric motor; and stopping the driving of the compressor by the electric motor upon expiration of a second given time from the restarting of the combustion engine, so that thereafter the compressor is driven by only the combustion engine.

Owner:CALSONIC KANSEI CORP

System and method for regenerating exhaust system filtering and catalyst components

InactiveUS6865883B2Increase exhaust temperatureEasy loadingElectrical controlInternal combustion piston enginesParticulatesAlternator

A system and method for regenerating particulate filters, catalyzed soot filters and NOx catalysts for a vehicle having a compression ignition engine. An engine control module controls engine operation and regeneration functions. The engine preferably includes an integrated starter / alternator / flywheel / retarder assembly. A load bank heater is provided in the exhaust system that is activated to directly heat exhaust gases raising the temperature thereof and approaching the temperatures required for regeneration and desulfation. Activation of the heater applies a load through the integrated starter / alternator / flywheel / retarder assembly that increases the load on the engine and in turn further increases the temperature of the exhaust to levels required for regeneration and desulfation.

Owner:DETROIT DIESEL CORP

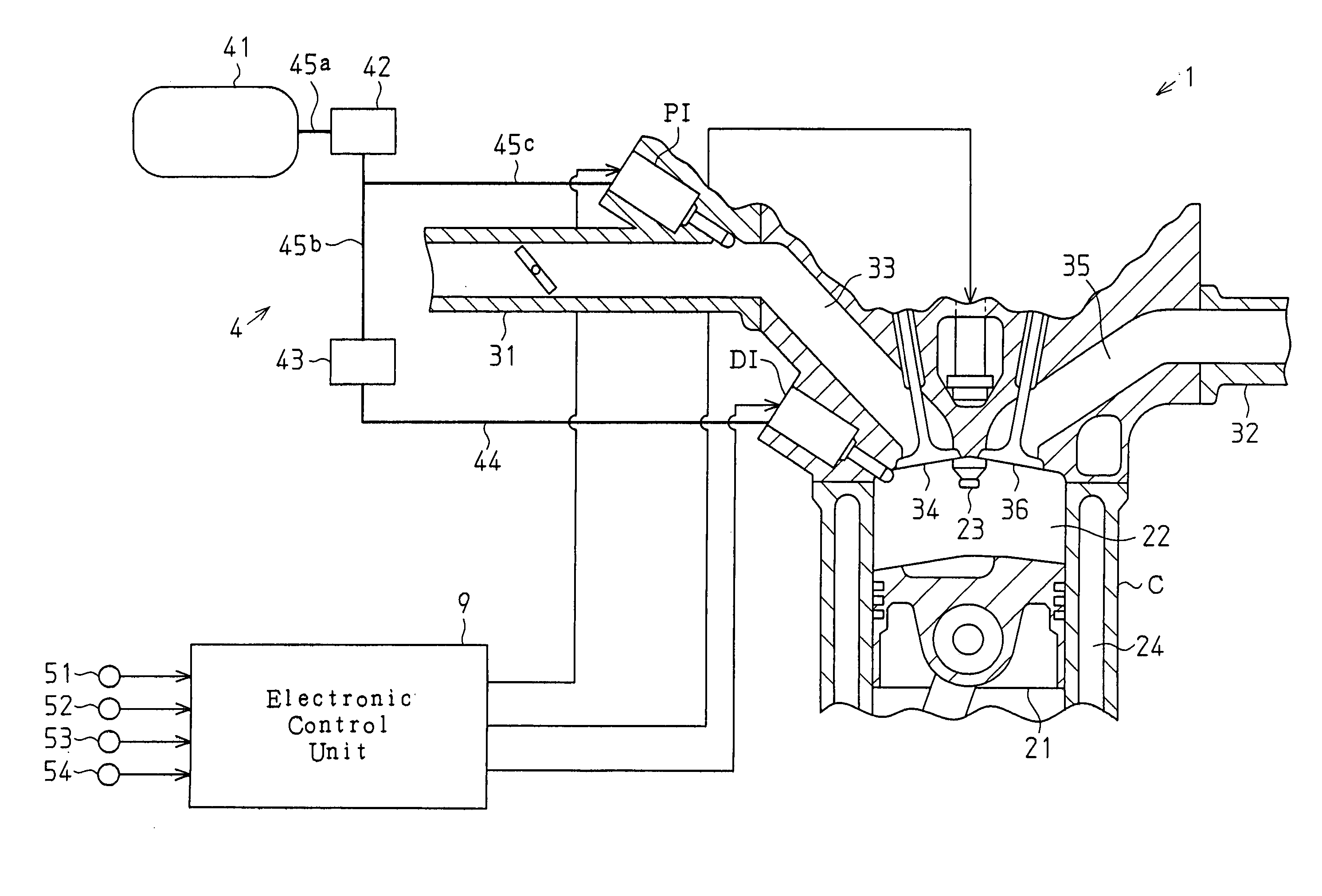

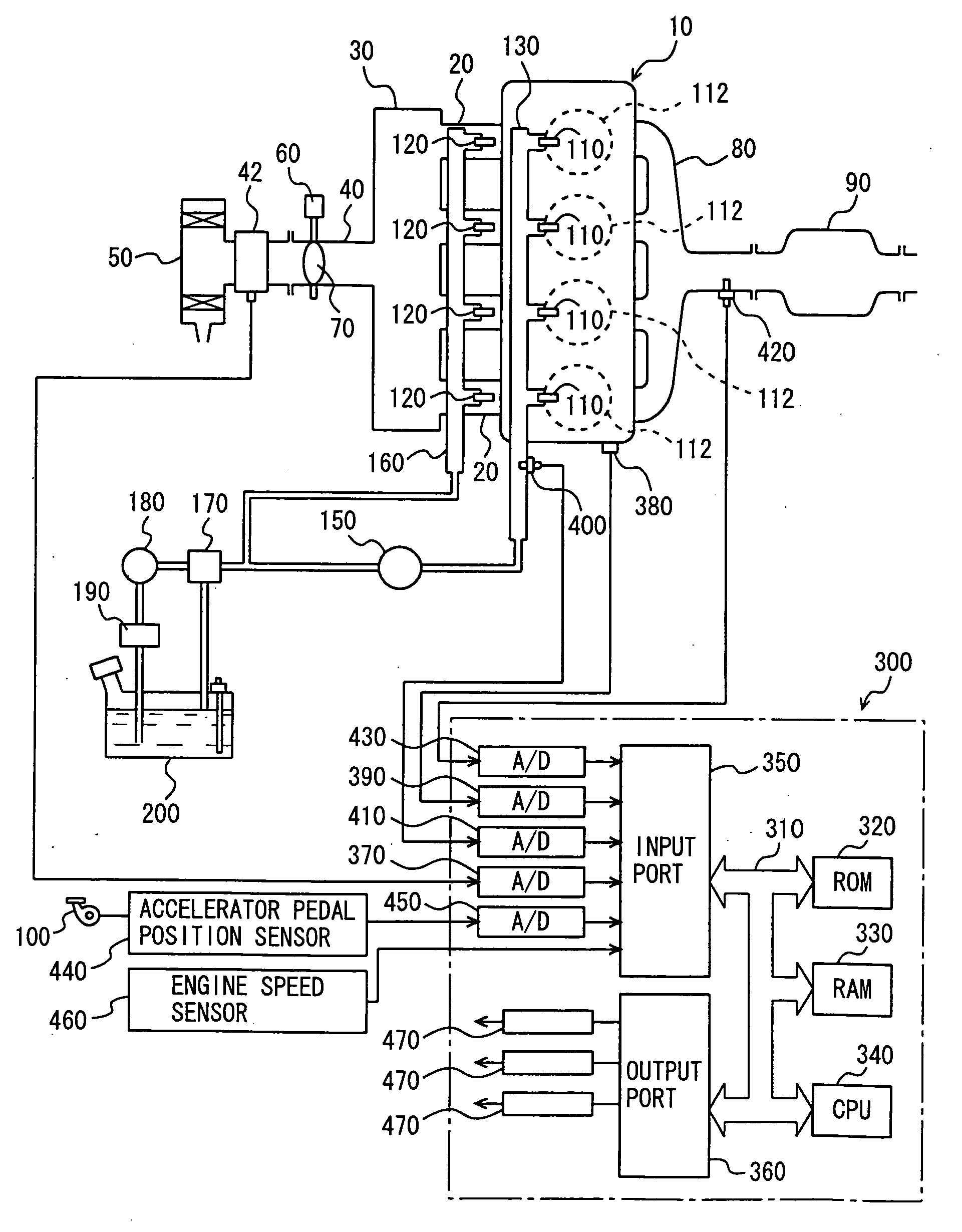

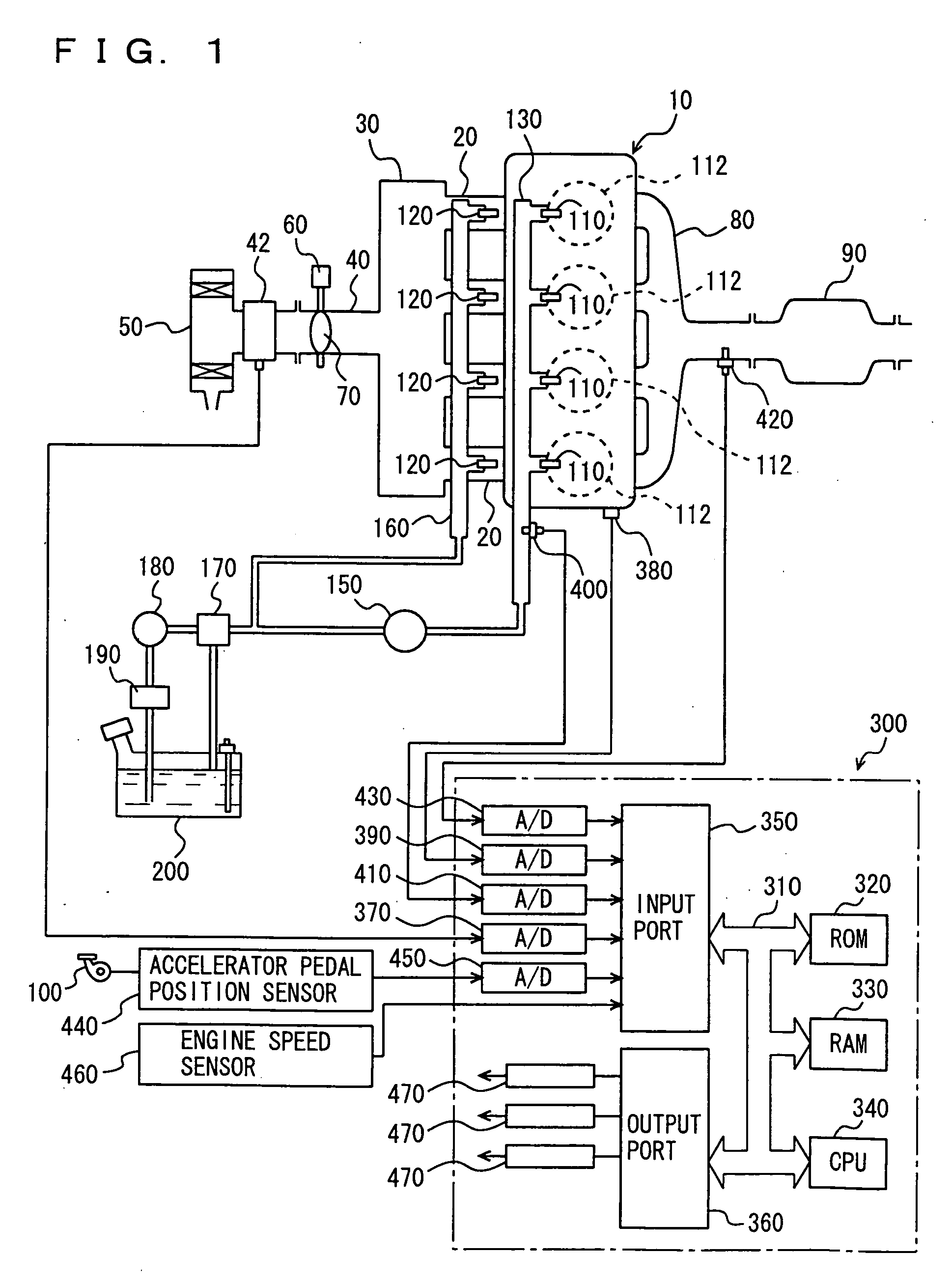

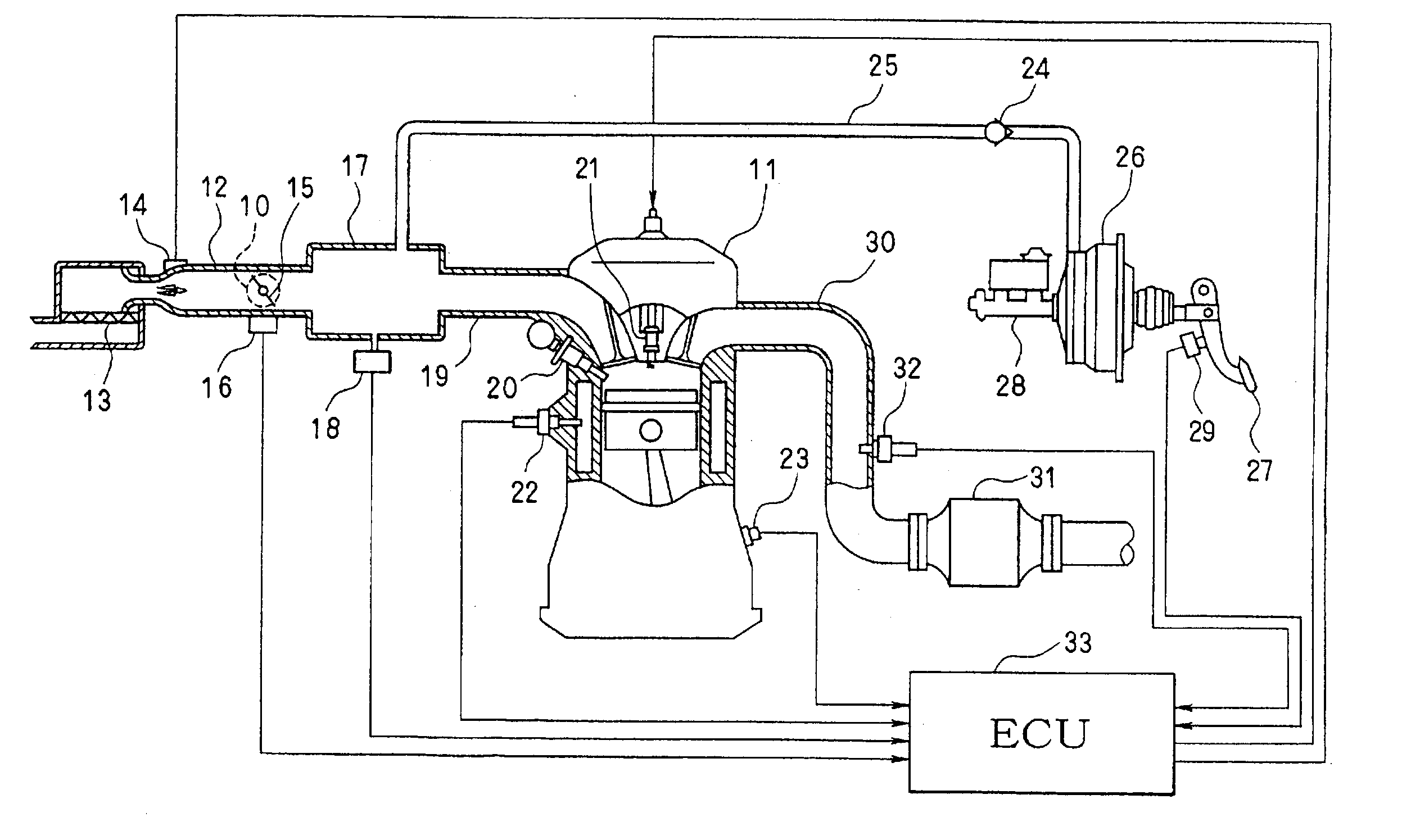

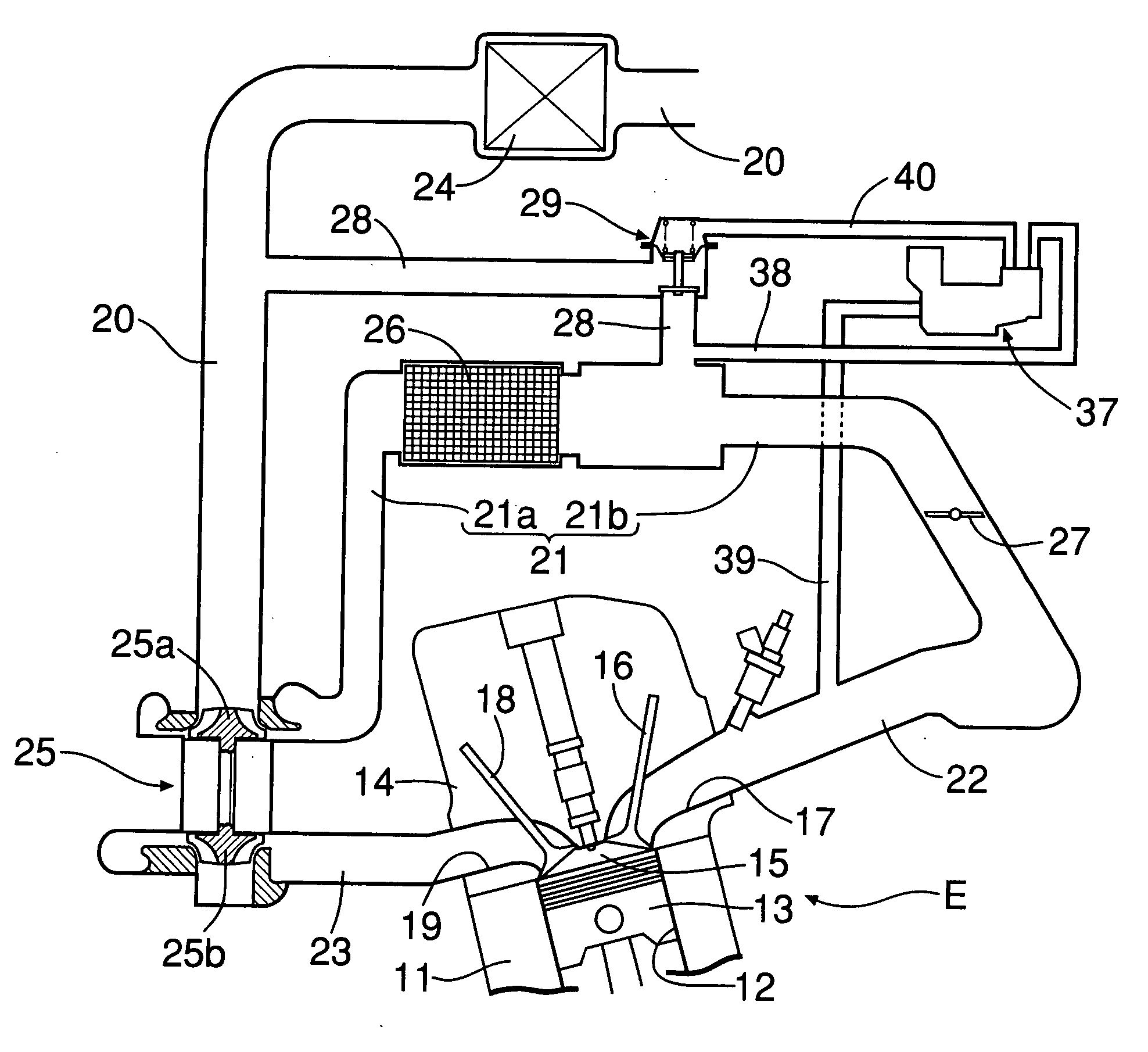

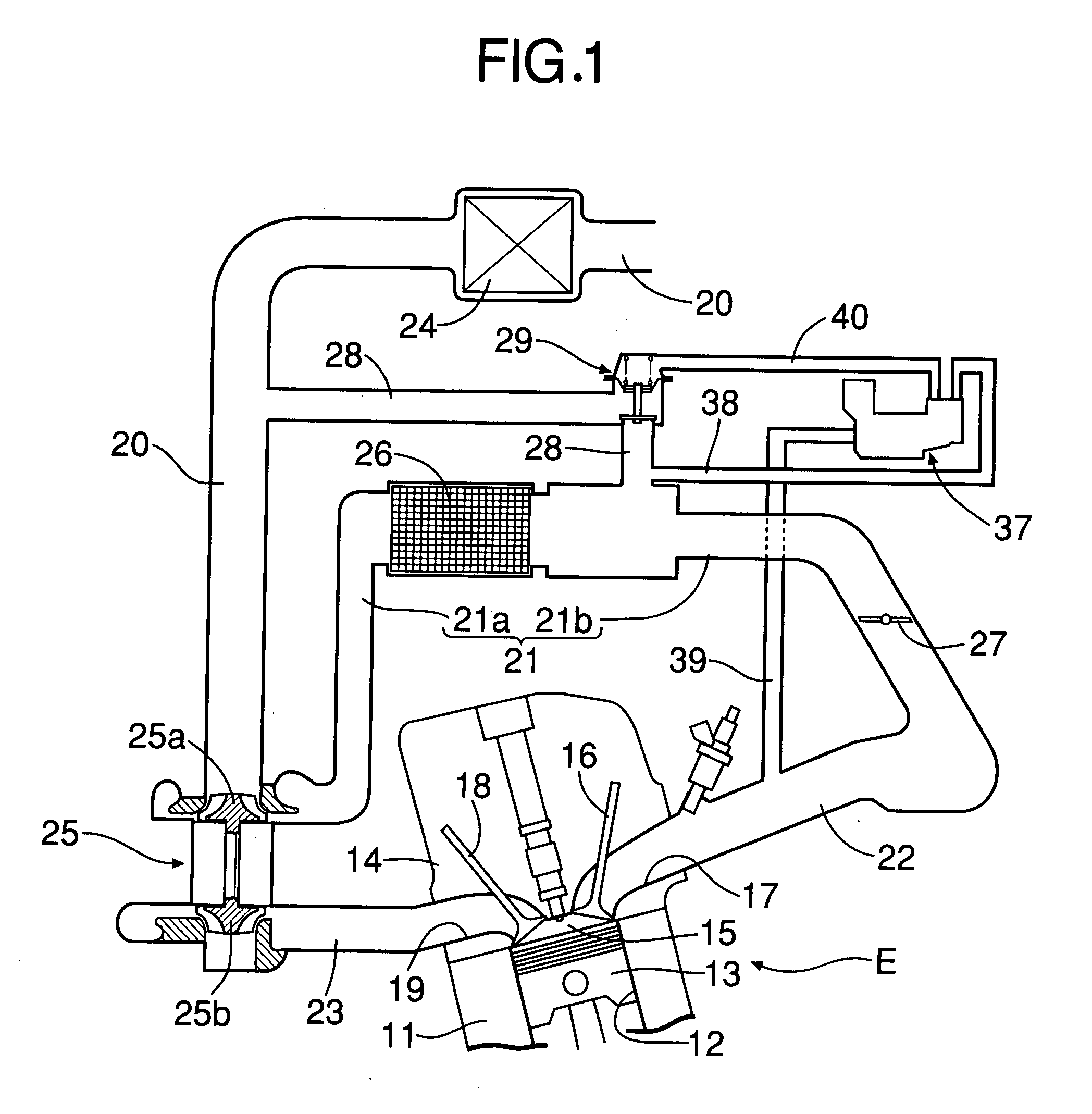

Fuel injection controller for engine

InactiveUS20050178356A1Lowering target speedAvoid procrastinationElectrical controlCombustion enginesFuel injectionInjector

A fuel injection controller for an engine having a direct injector for injecting fuel into a cylinder and an intake injector for injecting fuel into an intake passage. When the engine is idling, the controller reduces a target engine speed while preventing the engine from stalling. The fuel injection controller supplies fuel to the engine through the direct injector and the intake injector when the engine is idling. The electronic control unit determines if there is a possibility of the engine stalling when the engine is idling. When having determined that there is such a possibility, the electronic control unit increases the fuel injection amount of the direct injector.

Owner:TOYOTA JIDOSHA KK

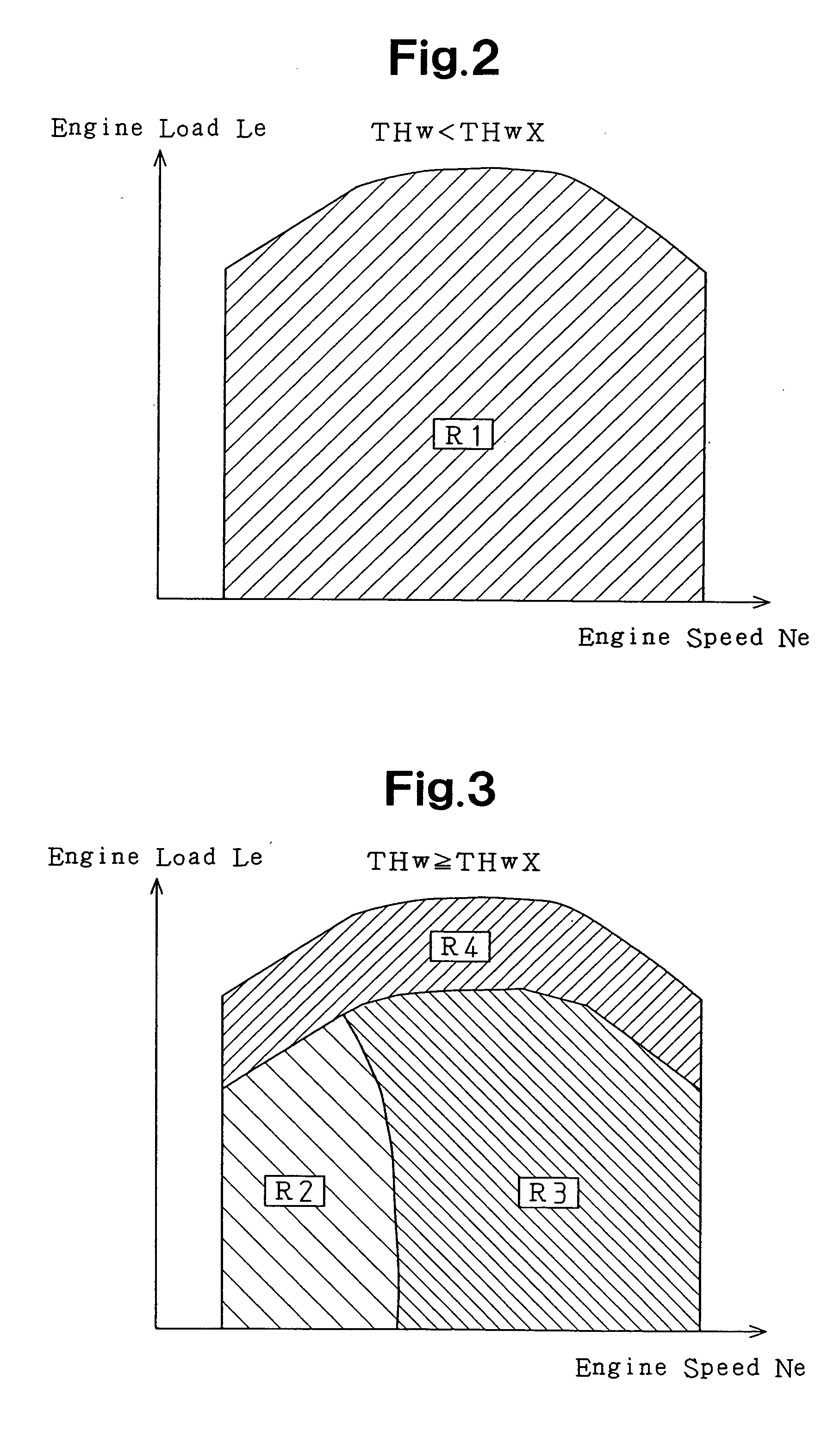

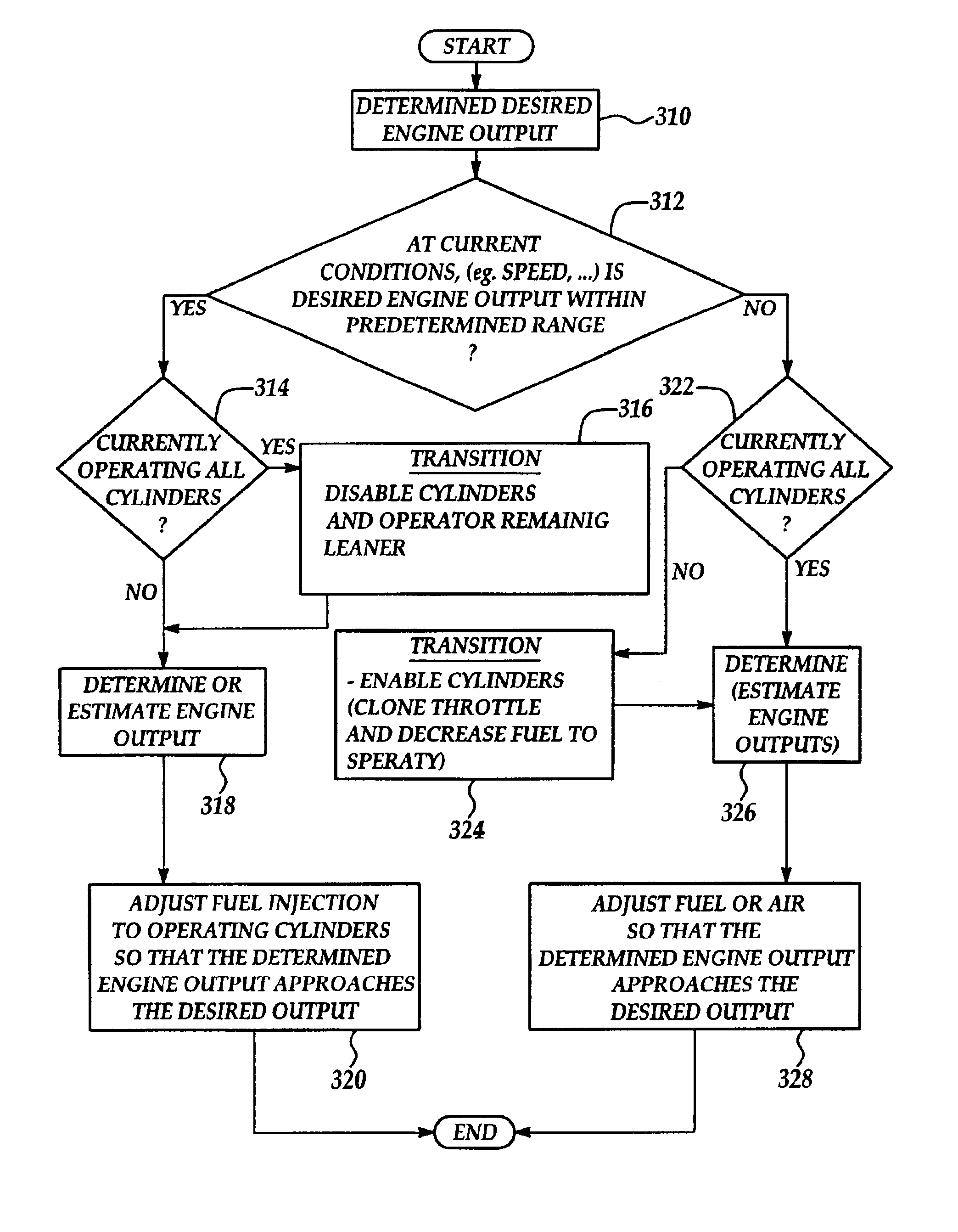

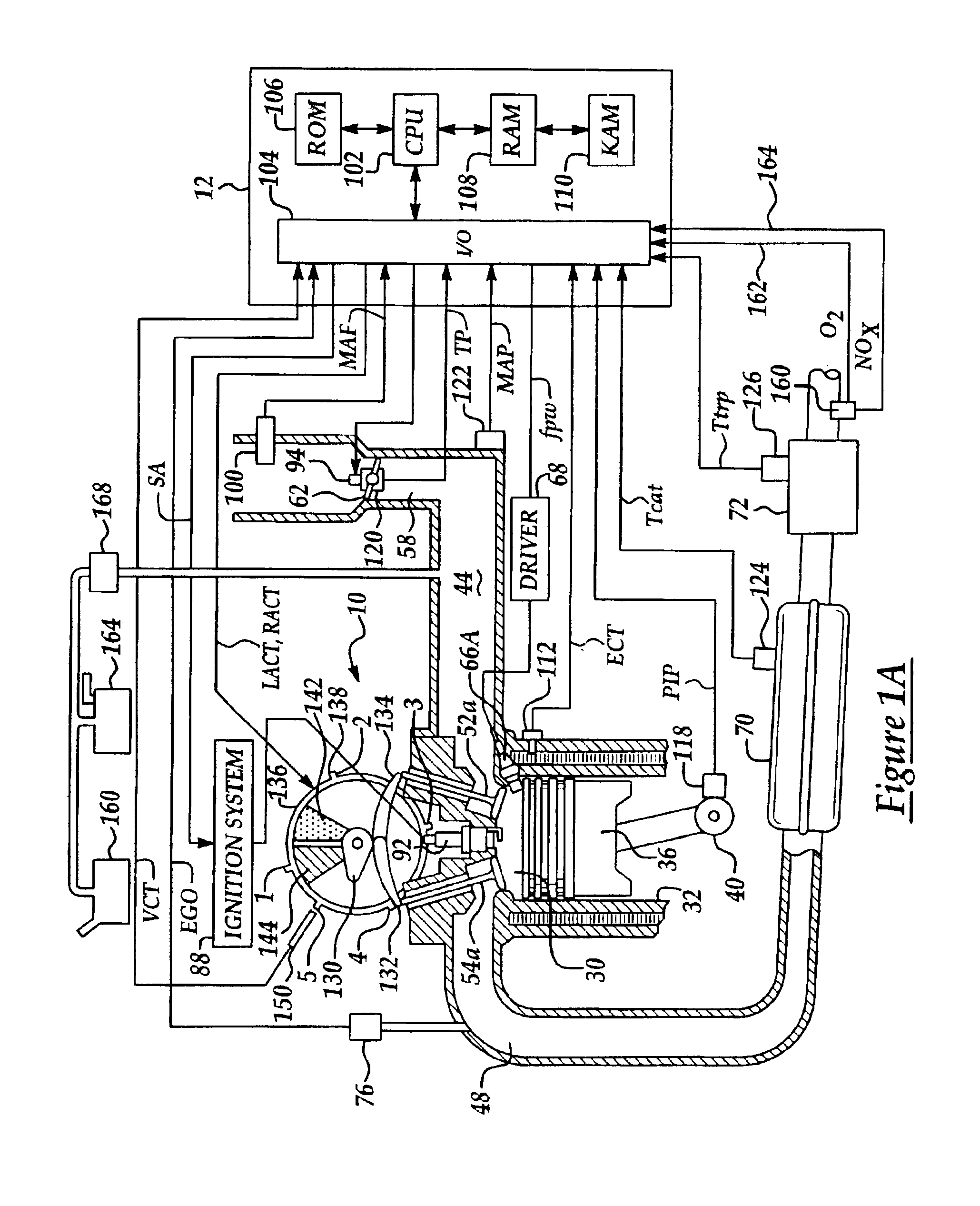

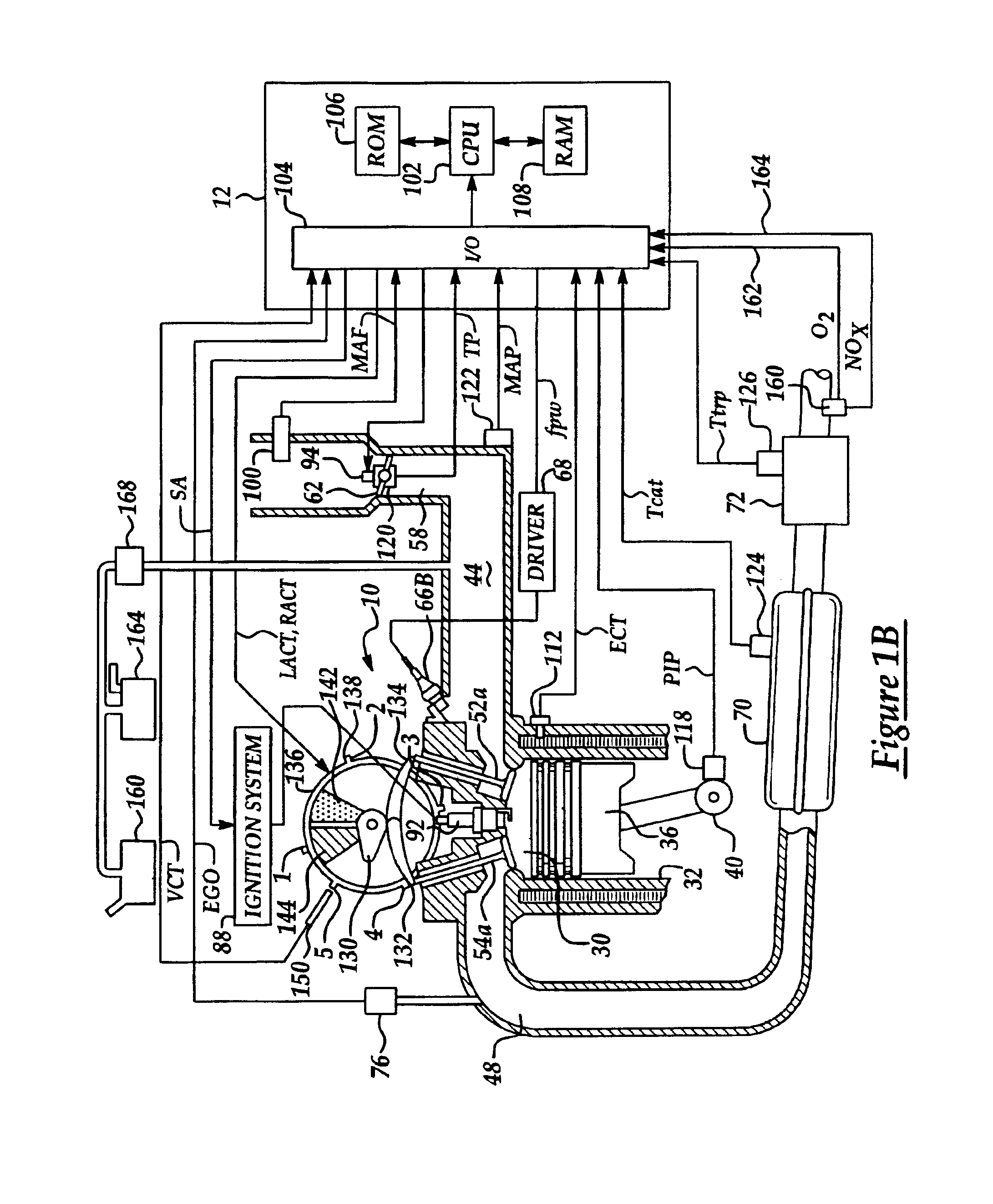

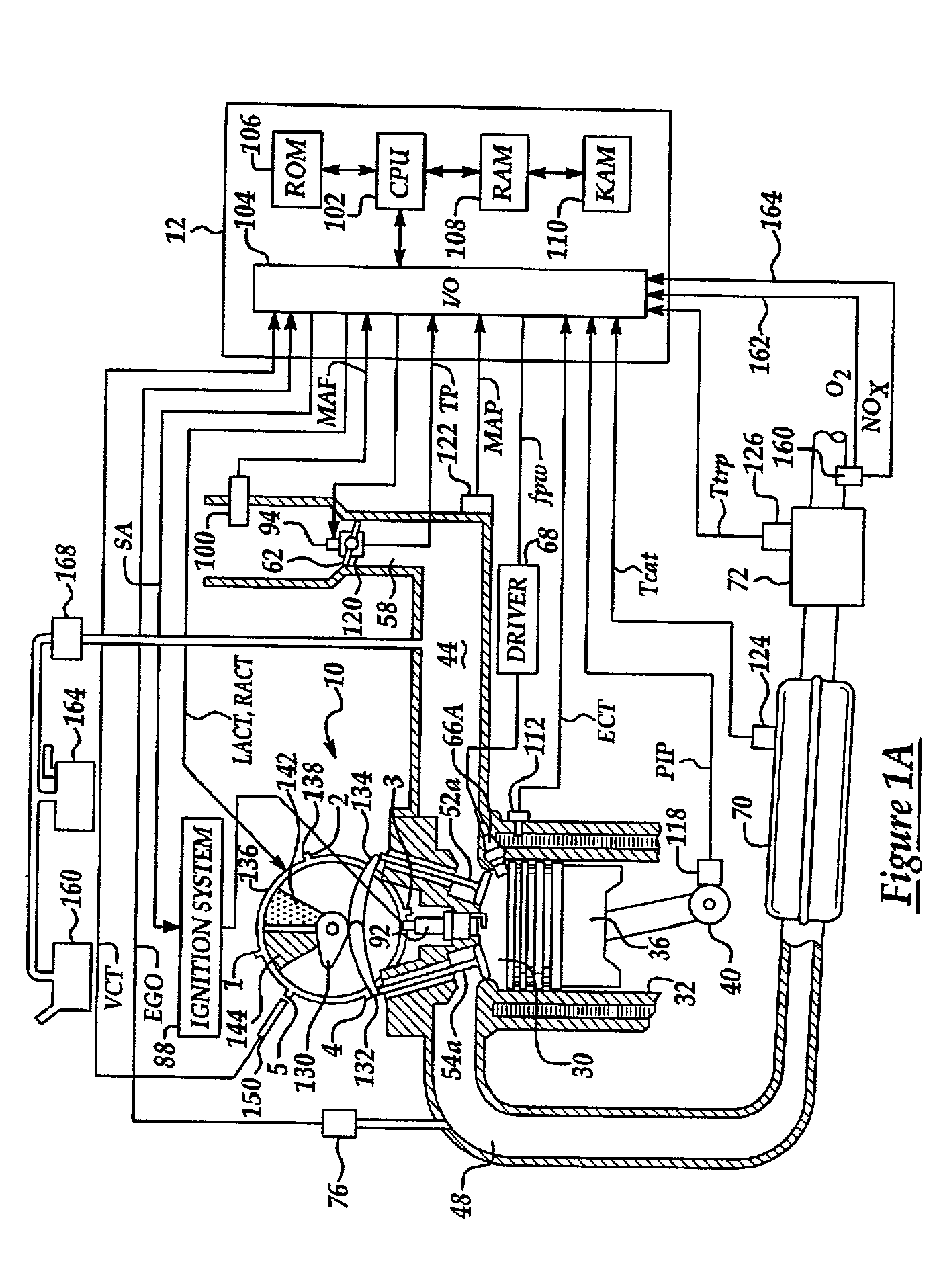

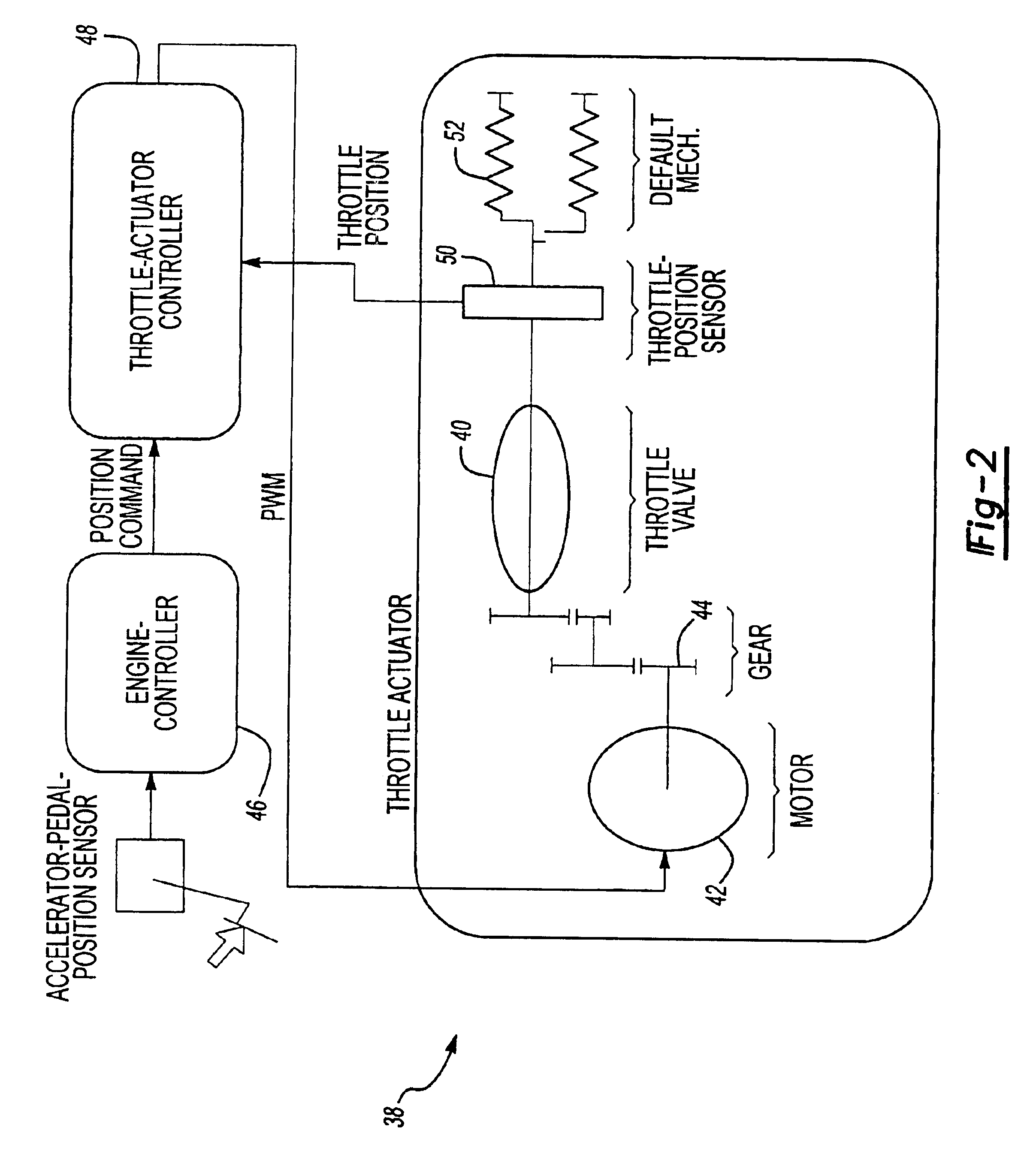

Idle speed control for lean burn engine with variable-displacement-like characteristic

InactiveUS6769398B2Easy to operateDegradation of combustionElectrical controlIdling devicesAdaptive learningIdle speed control

A method is disclosed for controlling operation of a engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air-fuel mixture and a second group of cylinders pumping air only (i.e. without fuel injection.) In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: auto speed control, sensor diagnostics, air-fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, and default operation. In addition, the engine control method also disables the split air / lean operating mode under preselected operating conditions.

Owner:FORD GLOBAL TECH LLC

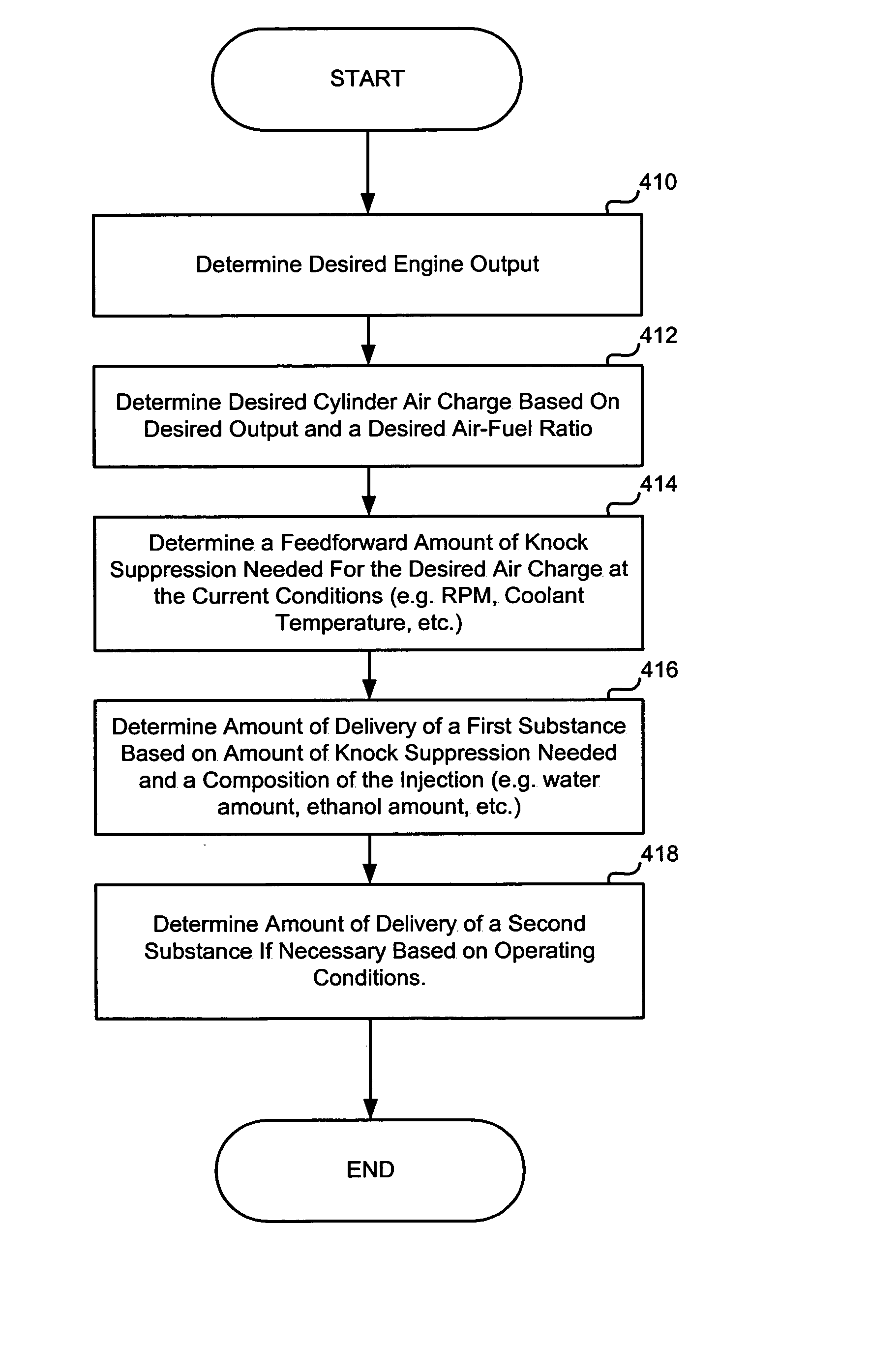

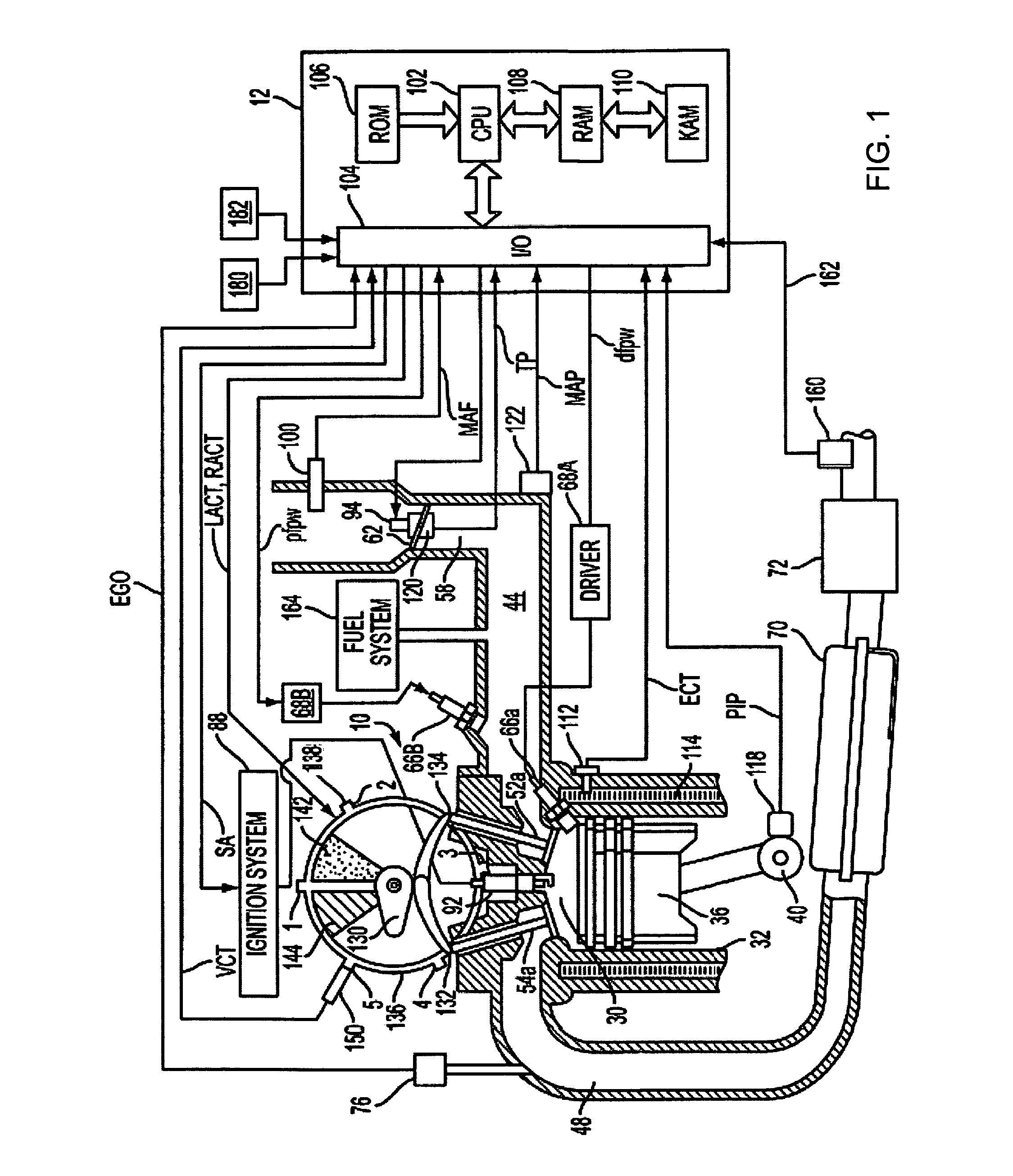

Combustion control system for an engine utilizing a first fuel and a second fuel

A system for an engine of a vehicle, comprising of a combustion chamber, a delivery system configured to deliver a fuel and a fluid to the combustion chamber, an ignition system including a spark plug configured to deliver a spark to the combustion chamber, and a control system configured to respond to a change in a condition of the ignition system by varying at least one of an amount of the fuel and an amount of the fluid delivered to the combustion chamber to vary a ratio of the fluid and the fuel.

Owner:FORD GLOBAL TECH LLC

System and method for identifying fuel savings opportunity in vehicles

ActiveUS7877198B2Reduce fuel consumptionLow costVehicle testingAnalogue computers for vehiclesIn vehicleSimulation

A system and method of identify fuel savings opportunity in a fleet of vehicles based on a determination of fuel consumption due to modifiable use conditions is described. Modifiable use conditions, such as unauthorized usage, speeding and excessive idling, which represent opportunities for fuel savings are identified and fuel consumption based on the modifiable use conditions is determined. A user-defined statistical metric for the fleet, or a portion of the fleet, can be determined for each of the modifiable use conditions evaluated. Fuel consumption of an individual vehicle, or a group of vehicles, resulting from modifiable use conditions can be compared with a larger group of vehicle, or the fleet, to determine vehicles which correspond to a metric of the fleet. Fleet managers can use this information to modify the use conditions of individual or group of vehicles to provide fuel savings for the fleet.

Owner:GE GLOBAL SOURCING LLC

Method for split ignition timing for idle speed control of an engine

InactiveUS20030221664A1High load conditionMore ignition timingAnalogue computers for vehiclesElectrical controlTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

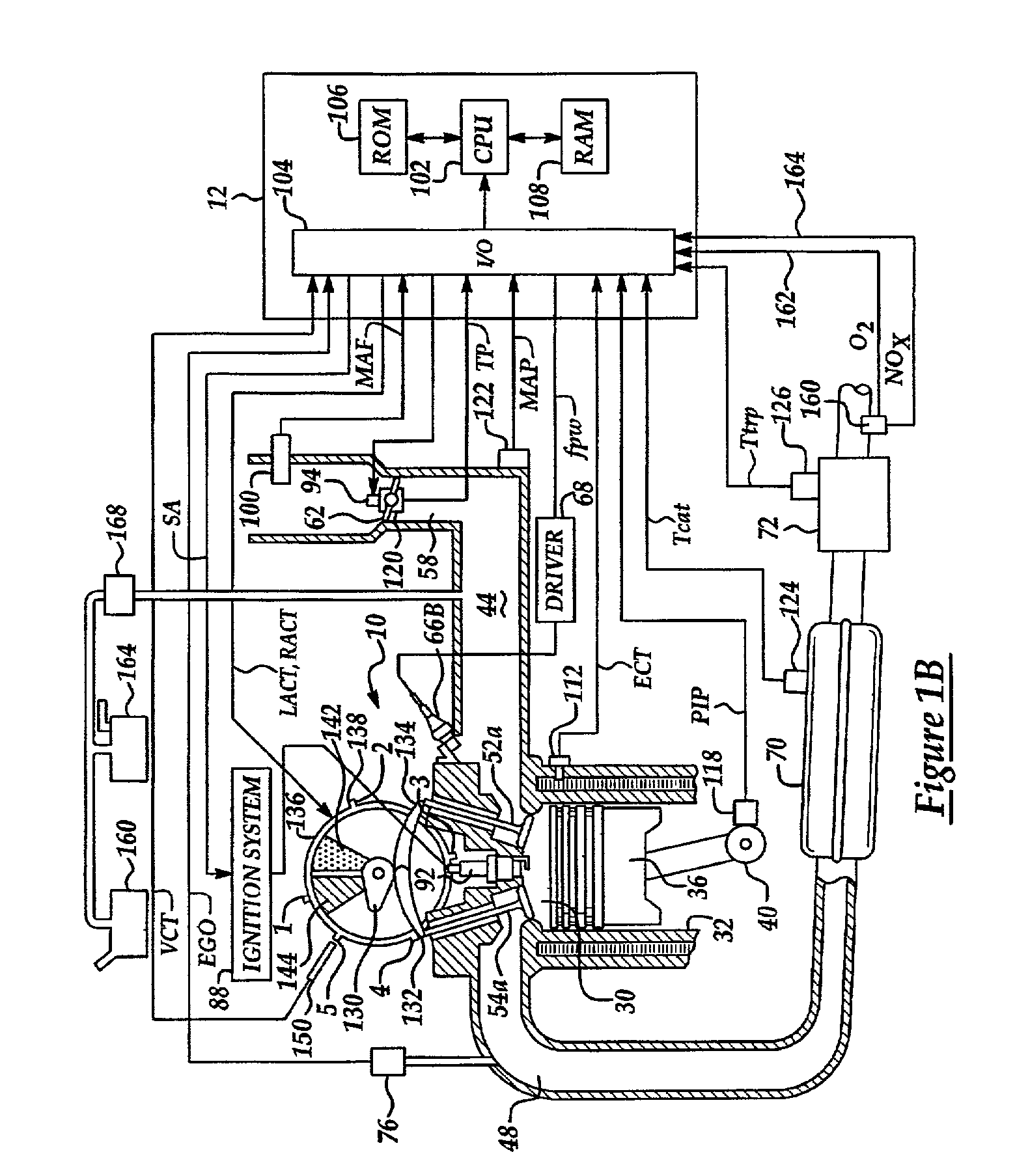

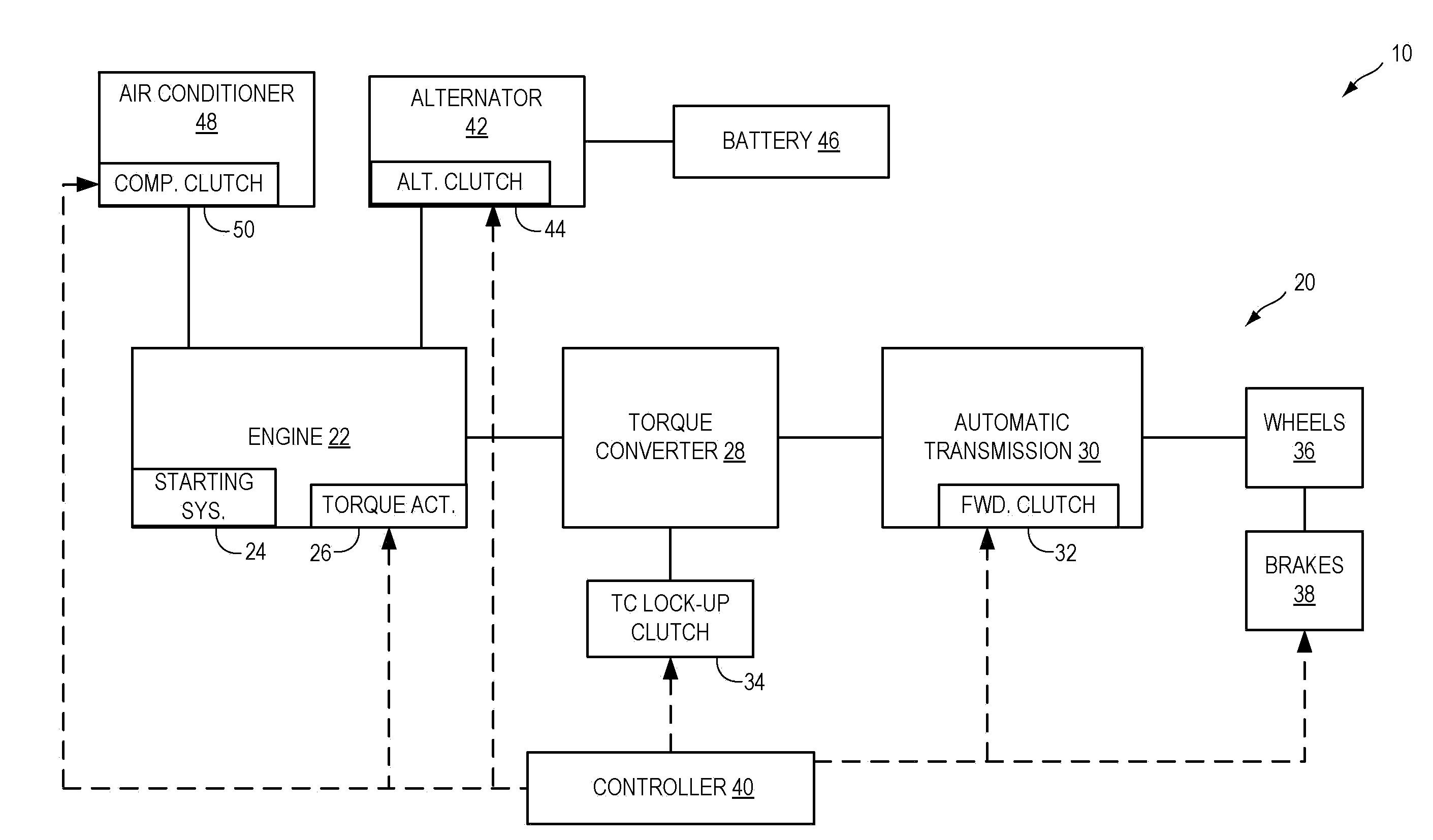

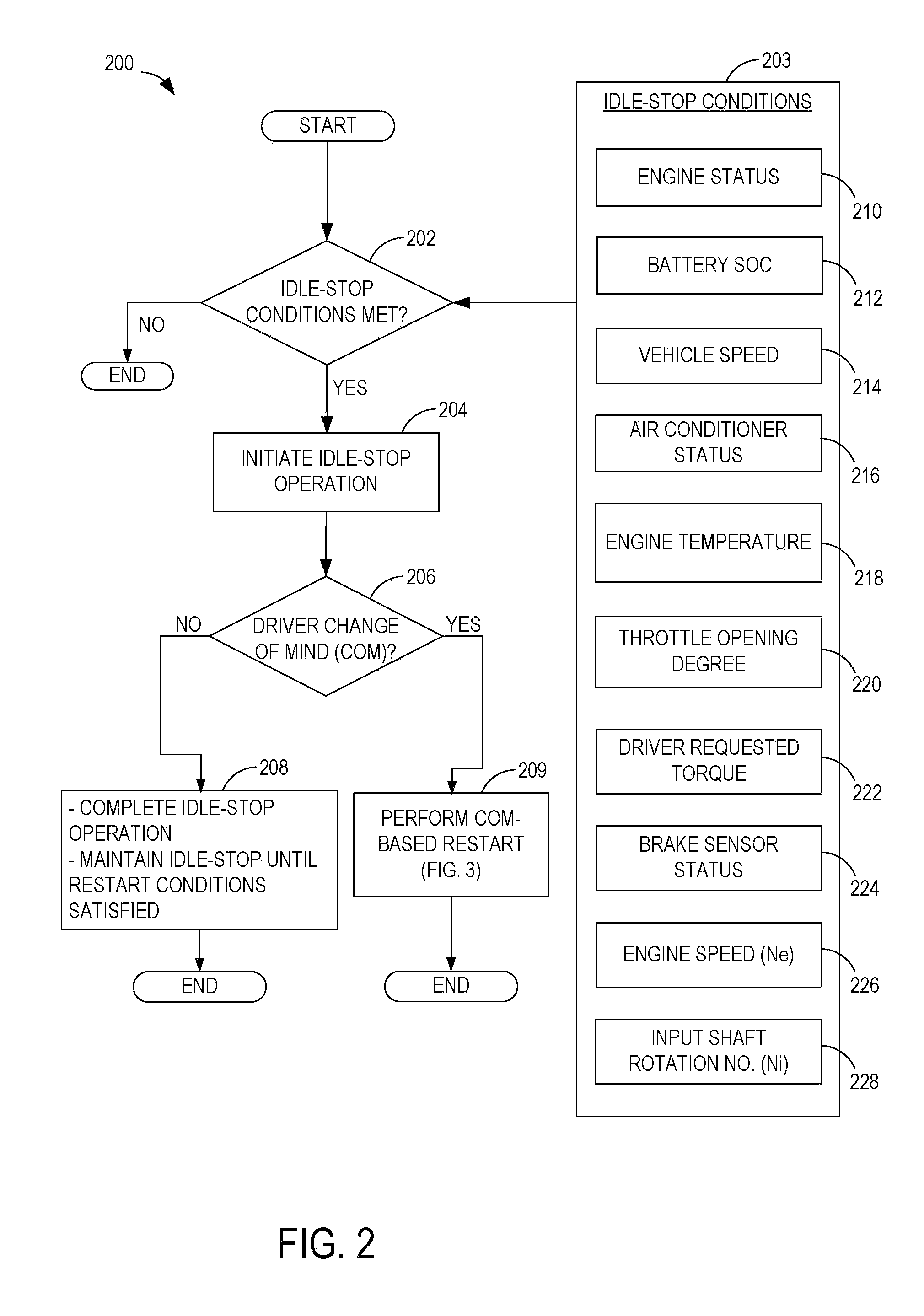

Methods and systems for assisted direct start control

ActiveUS20100174473A1Reduce exhaust emissionsSave fuelAnalogue computers for vehiclesPower operated startersBrake torqueRotary engine

Method and systems are provided for controlling a vehicle system including an engine that is selectively deactivated during engine idle-stop conditions. One example method comprises, adjusting a brake torque applied to a deactivated rotating engine after an engine restart request, the brake torque applied to slow the engine to at least a predetermined threshold speed without stopping the engine, and engaging a starter to the still rotating engine to increase the engine speed and restart the engine.

Owner:FORD GLOBAL TECH LLC

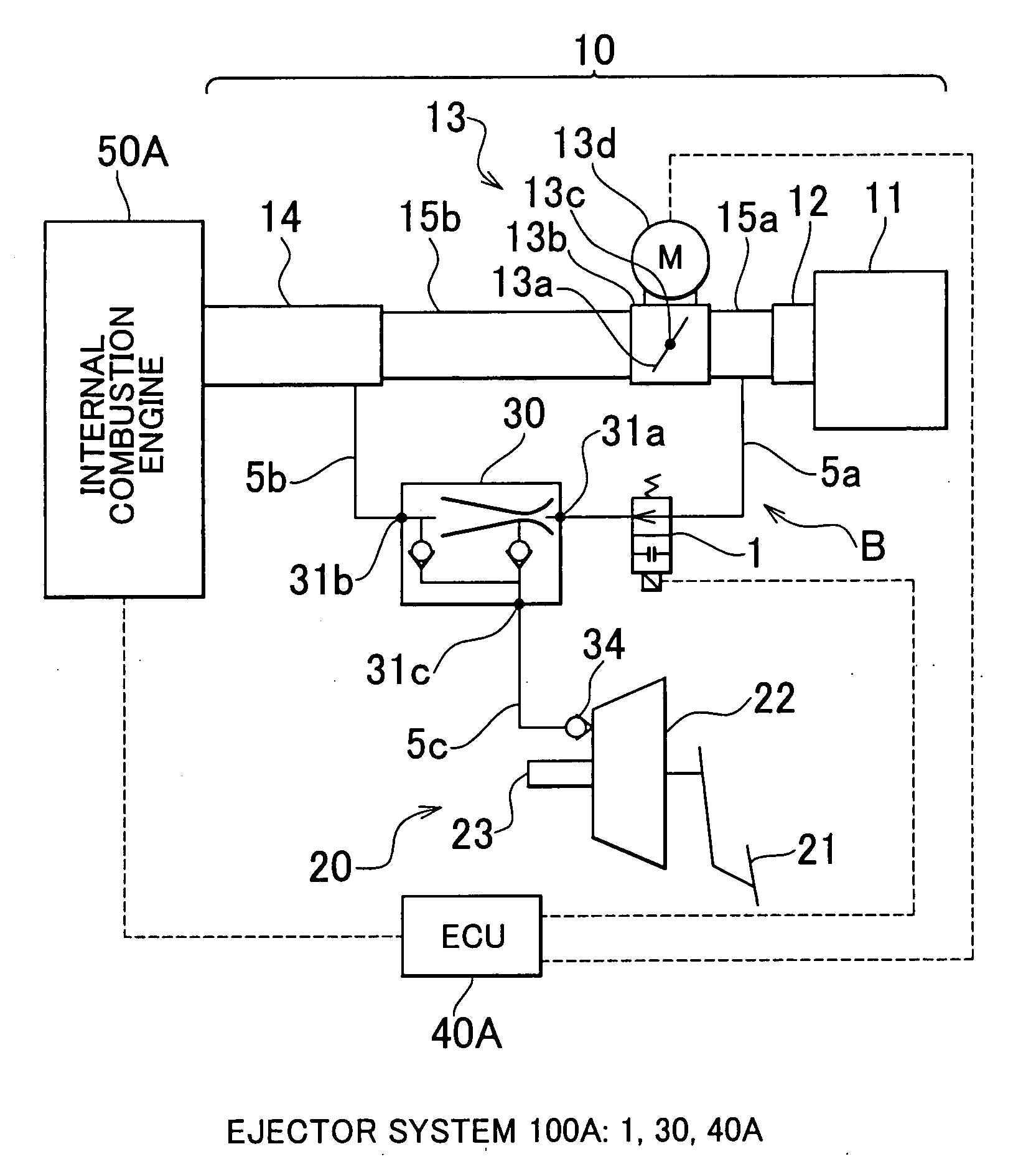

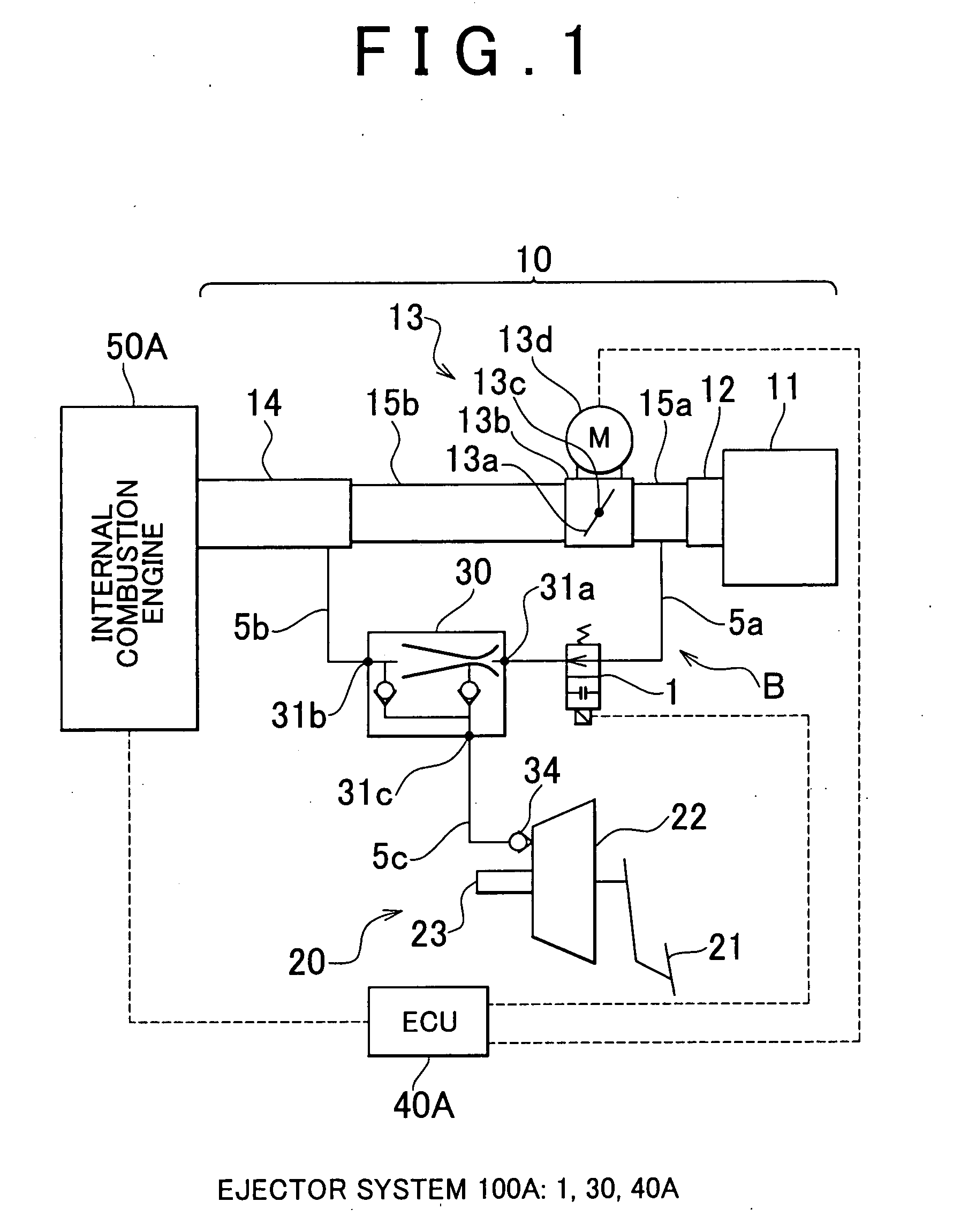

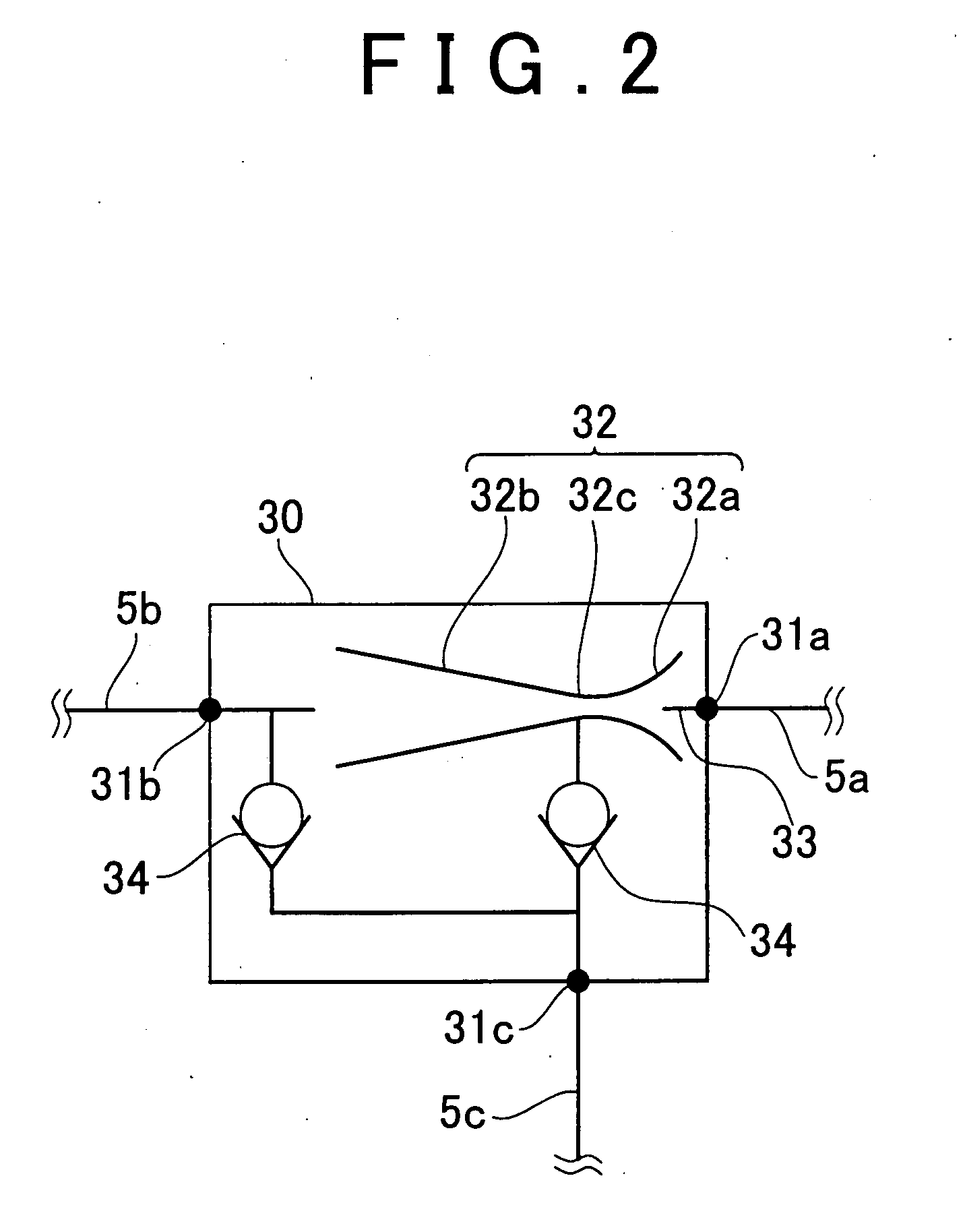

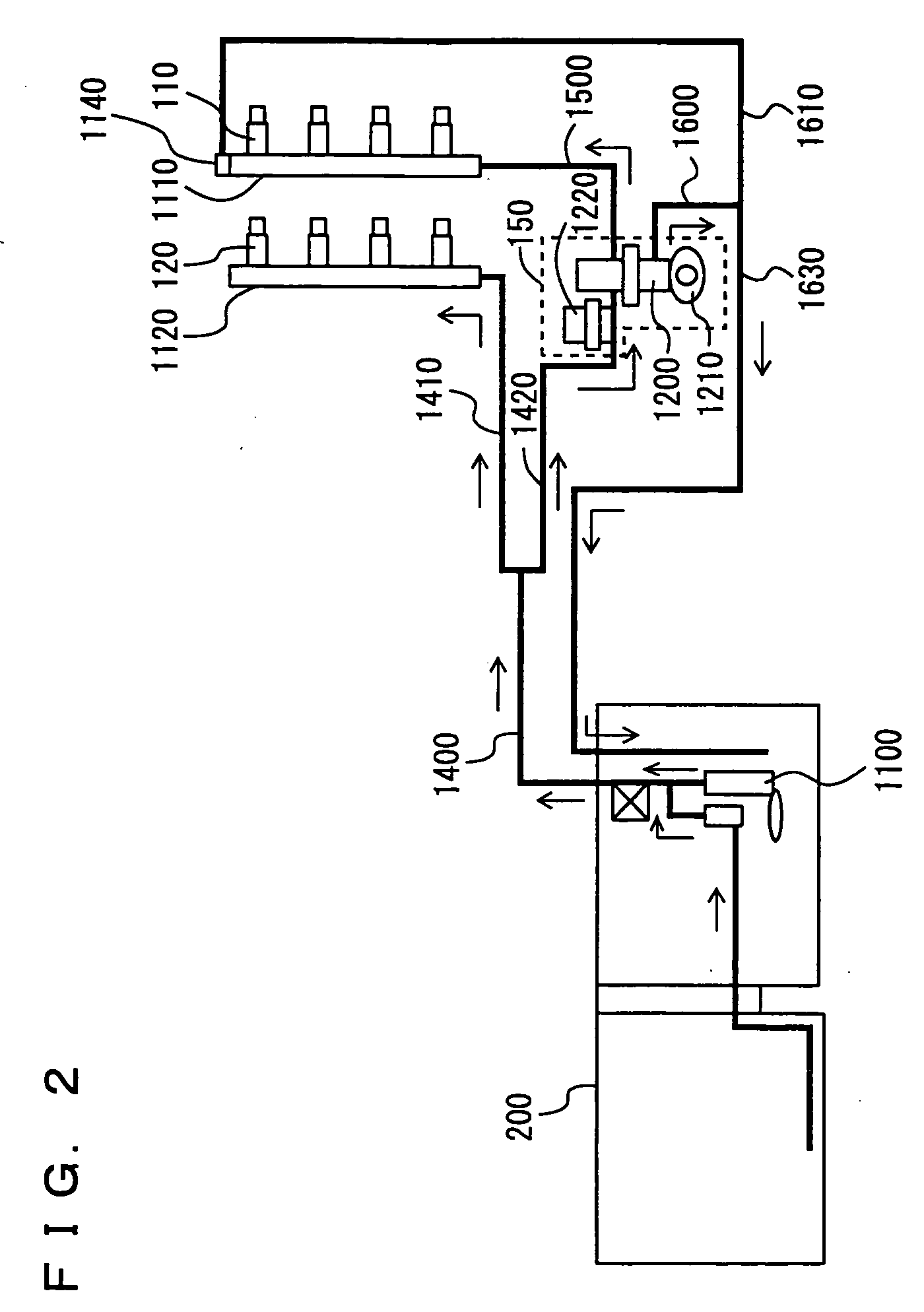

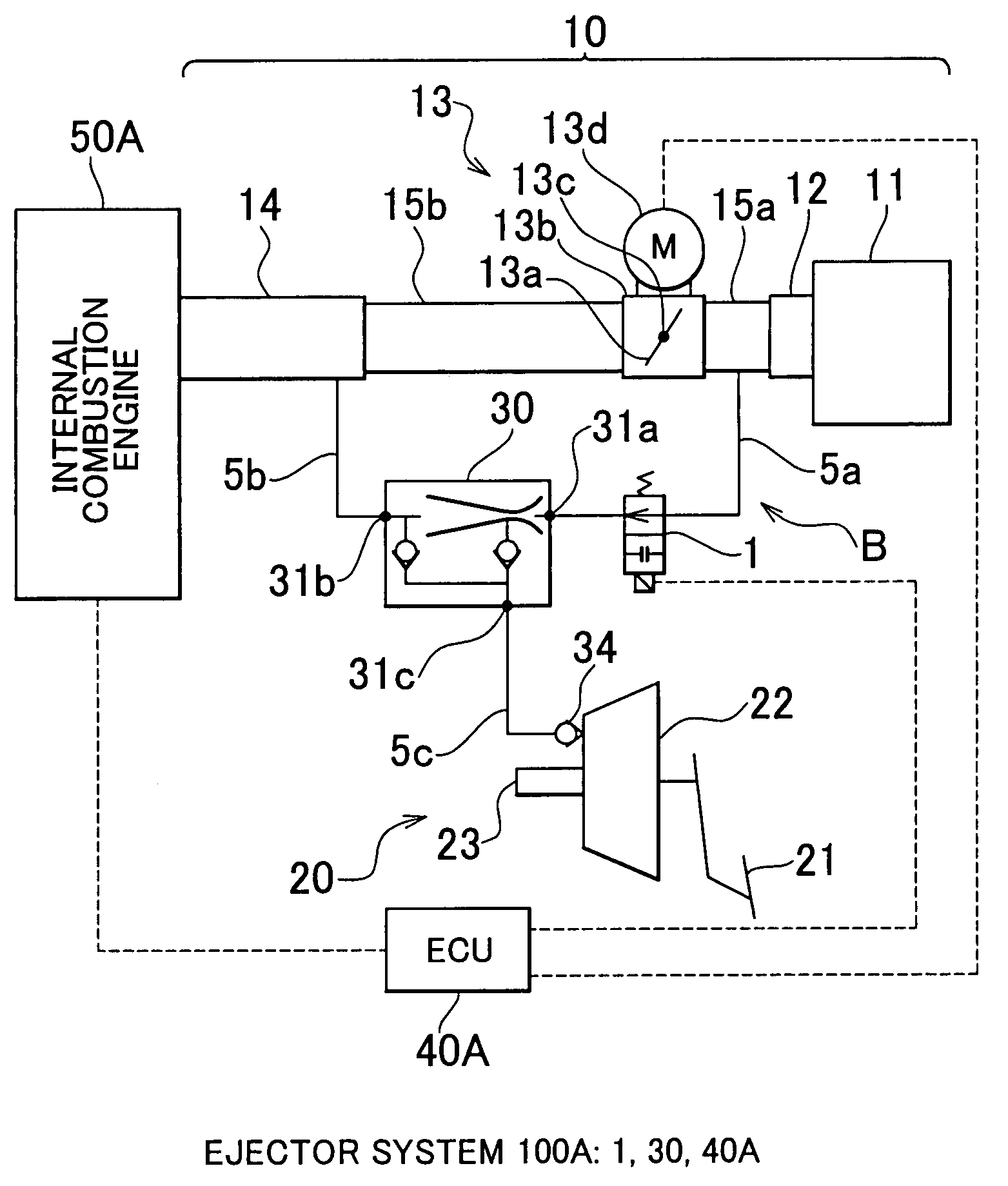

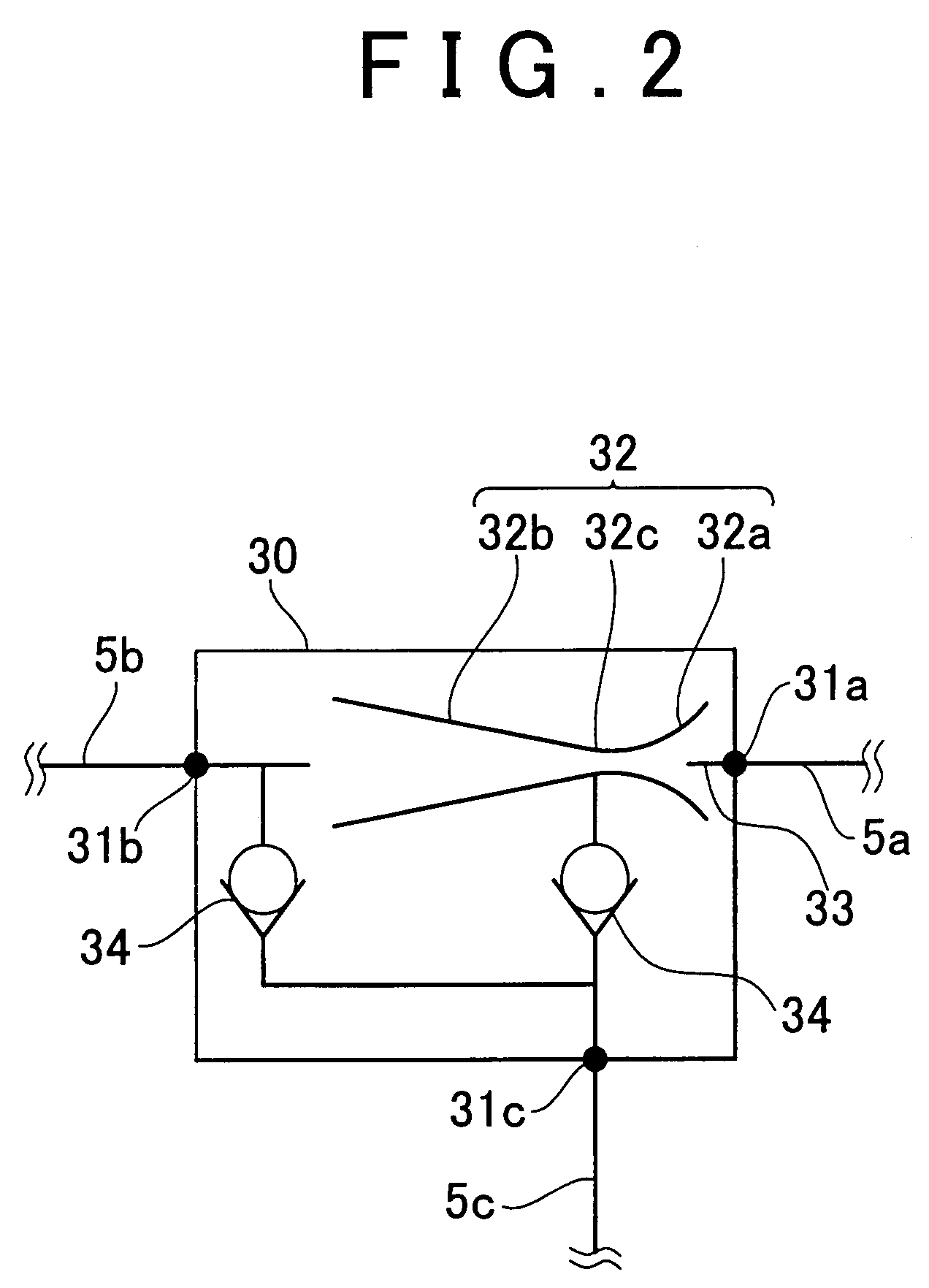

Vehicular ejector system and control method thereof

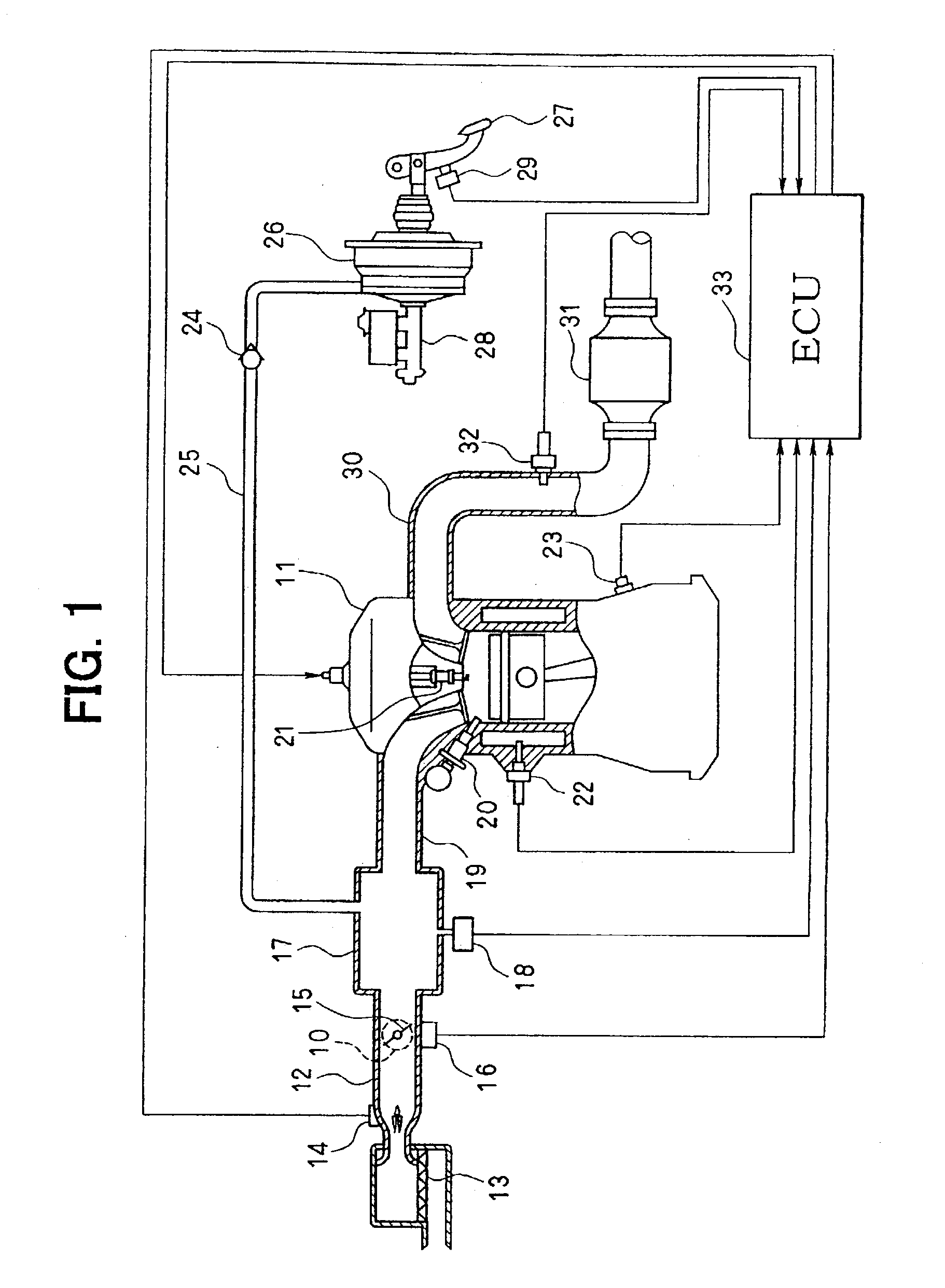

InactiveUS20070295303A1Reduce vehicle costReduce adverse effectsElectrical controlDigital data processing detailsInlet manifoldThrottle

A vehicular ejector system having an ejector that generates a negative pressure that is greater than the intake manifold negative pressure that is to be extracted from an intake manifold, a VSV that causes the ejector to function or stop functioning, and an ECU that controls the VSV. The ECU includes a control device that controls the VSV so as to cause the ejector to function if an ISC request amount for controlling, during idling, a throttle valve that adjusts the intake air flow amount supplied to the internal combustion engine is greater than a predetermined amount.

Owner:TOYOTA JIDOSHA KK

Automotive air conditioning system

An air conditioning system for use in a motor vehicle powered by an internal combustion engine is described. The system comprises an electric motor powered by a battery; a compressor arranged to be powered by at least one of the internal combustion engine and the electric motor; and a control unit that controls the driving of the compressor. The control unit is configured to execute driving the compressor by only the electric motor when the combustion engine is under an idling stop; restarting the combustion engine upon expiration of a first given time from the time when the idling stop has occurred, so that thereafter the compressor is driven by both the combustion engine and the electric motor; and stopping the driving of the compressor by the electric motor upon expiration of a second given time from the restarting of the combustion engine, so that thereafter the compressor is driven by only the combustion engine.

Owner:CALSONIC KANSEI CORP

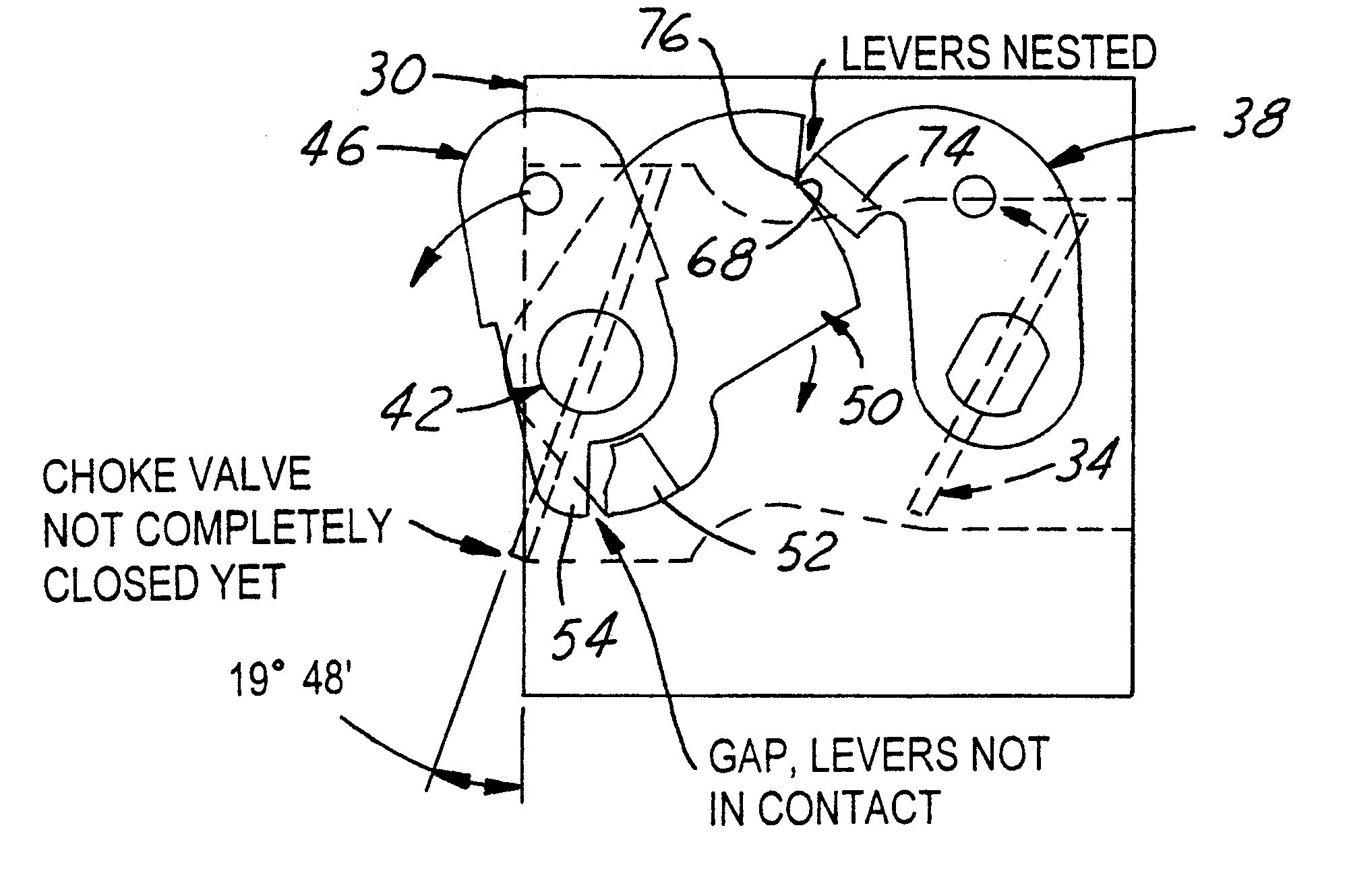

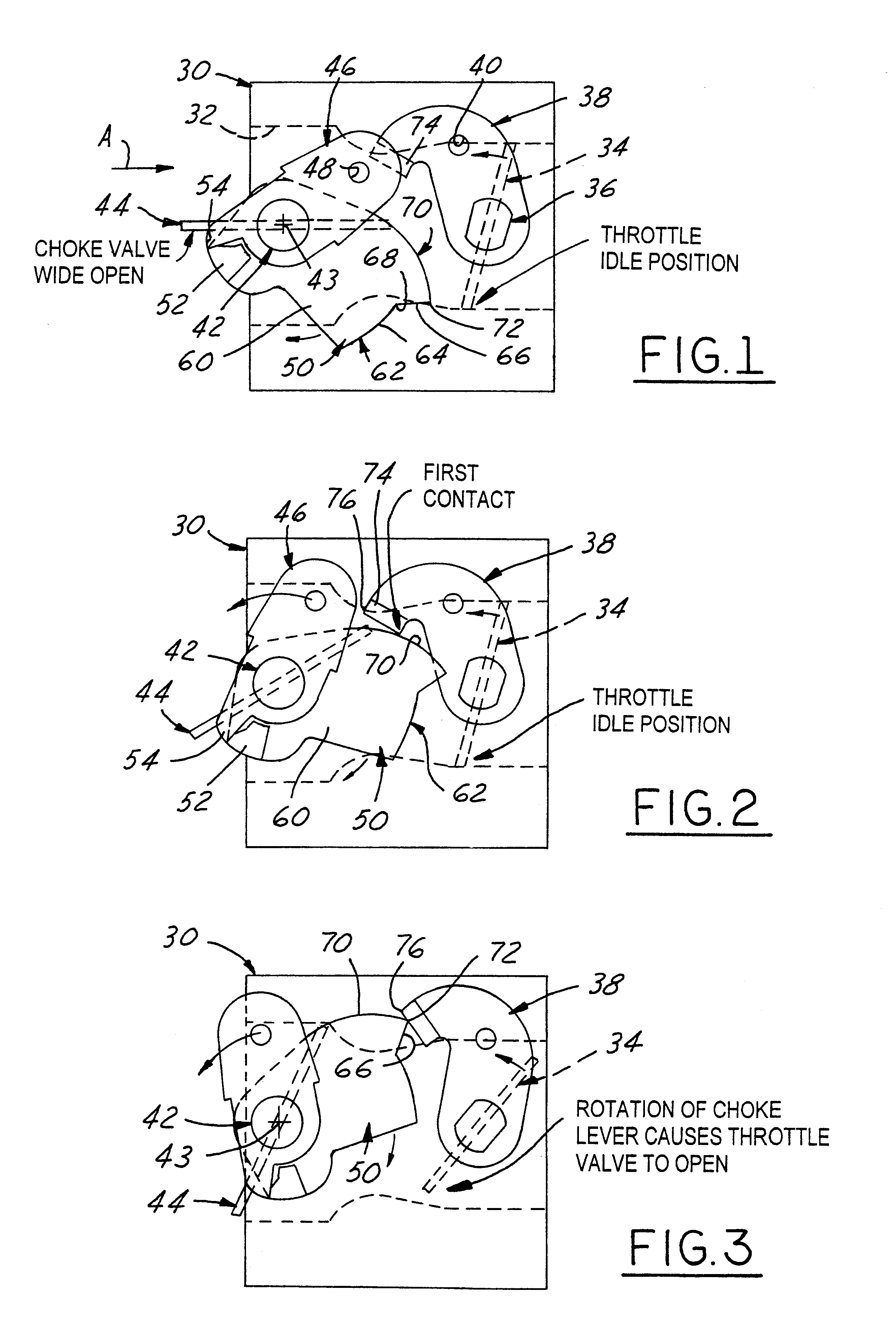

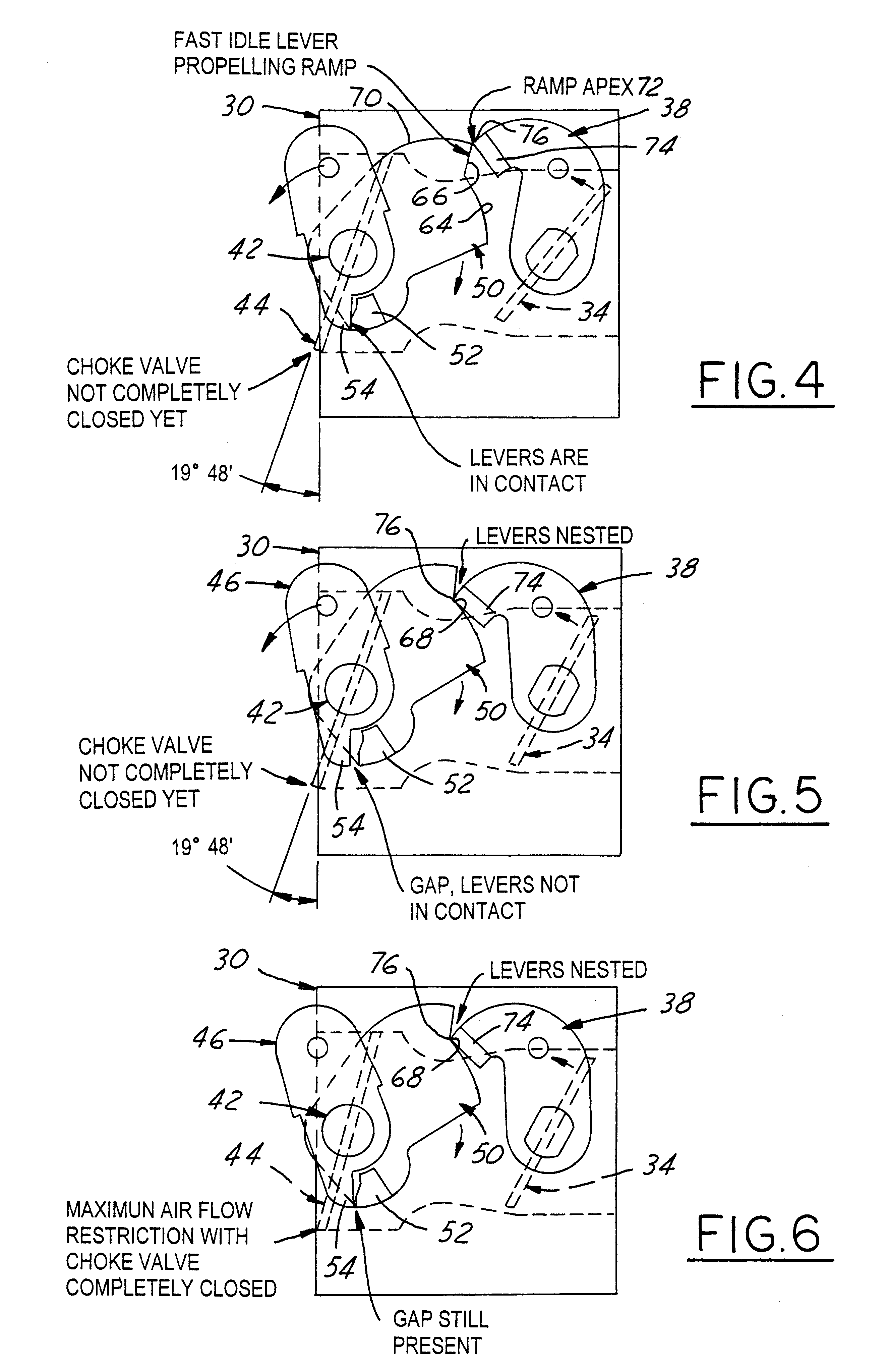

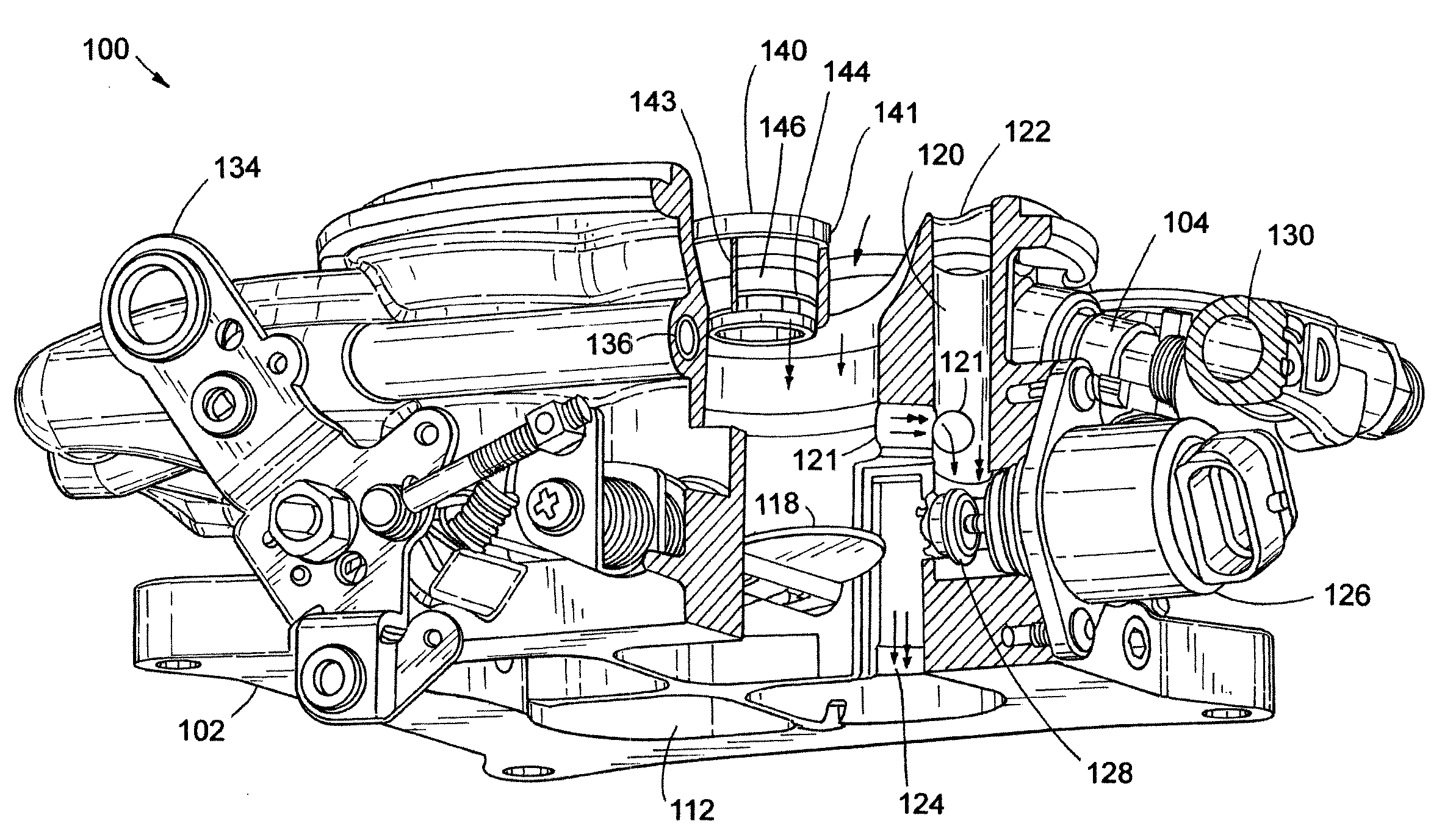

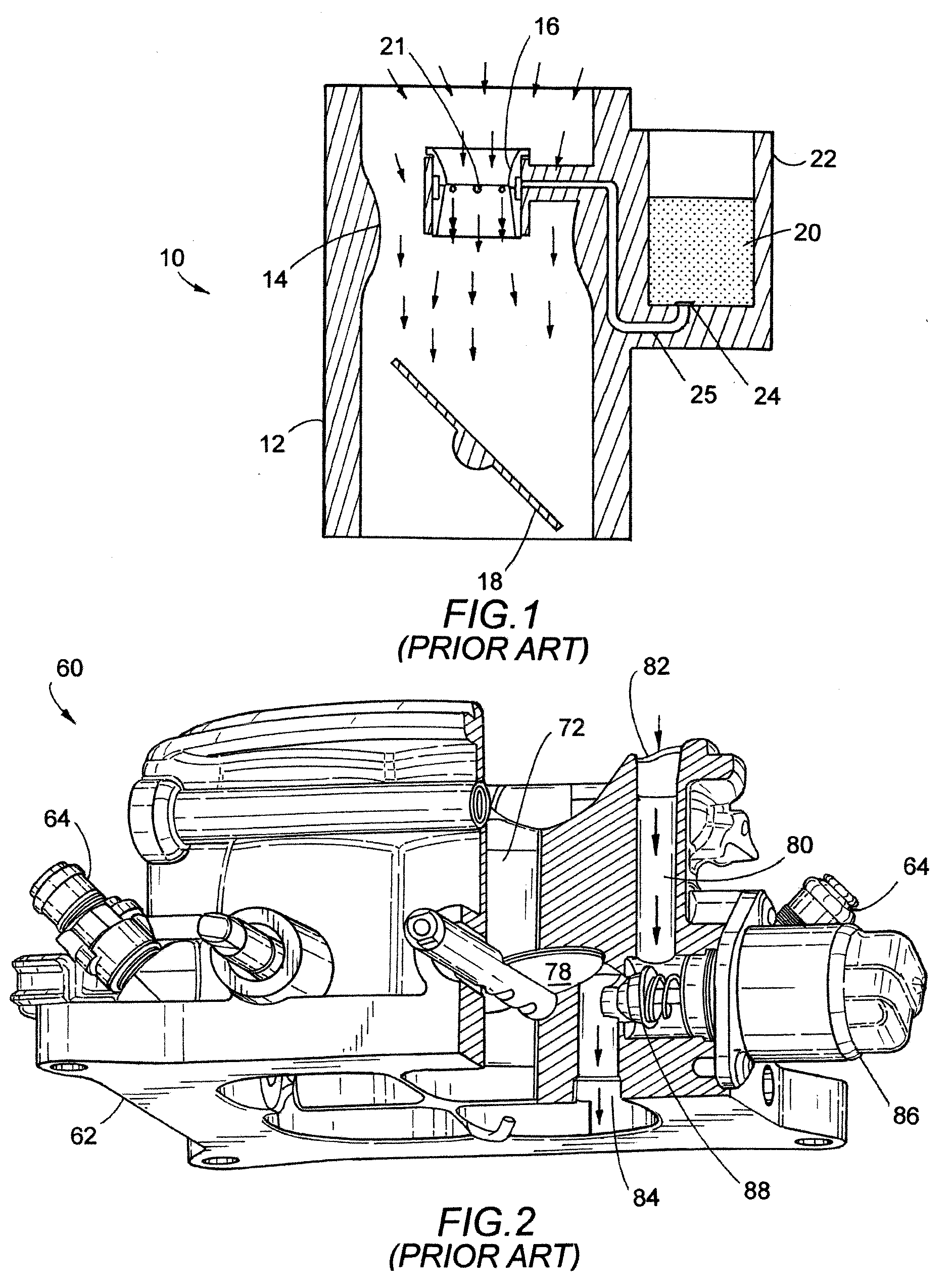

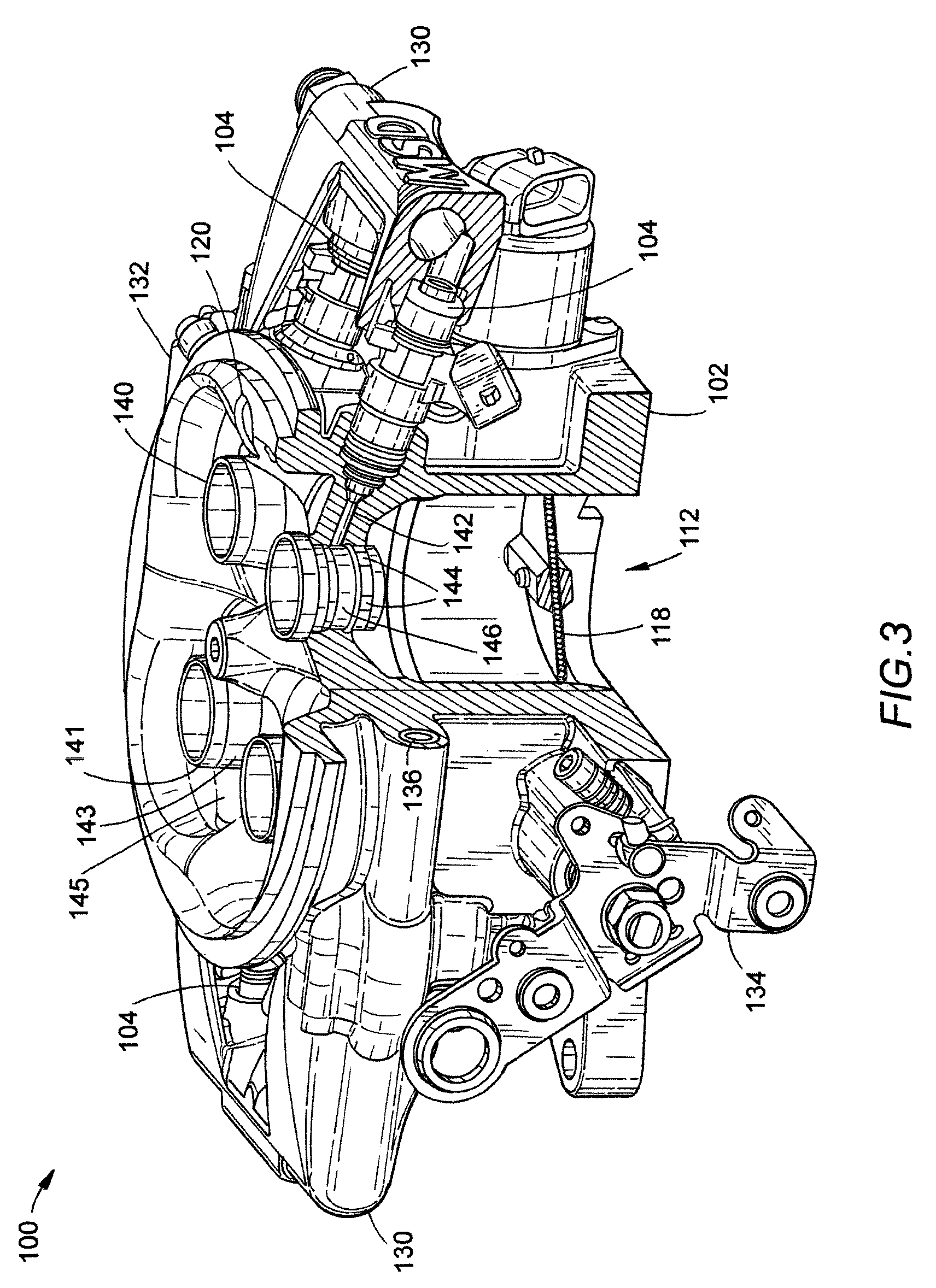

Carburetor throttle and choke control mechanism

InactiveUS6439547B1Low costEasy to modifyElectrical controlLighting and heating apparatusEngineeringAbutment

A carburetor throttle and choke control mechanism incorporating a choke-throttle cold-start fast idle setting latch mechanism having, in a first embodiment, a blade of a fast idle lever specially contoured for creating upon interengagement with a tang on a throttle lever initial torque resistance to co-rotation of the fast idle lever toward latched condition and then effecting force reversal for creating aiding torque to accelerate the fast idle lever relative to choke lever and thereby open a gap in the push coupling that remains in the latched position of the choke and throttle valves. The choke lever has a relatively rigid pusher leg portion adapted for abutment in push relation with a fast idle lever tang. In a second embodiment an extension of the leg portion in the form of a generally U-shaped resilient spring hook portion is adapted to overlap the tang and releasably hook engage the same when the leg portion is brought into full push abutment with said tang. The U-shaped hook portion is resiliently flexible to act as a spring to develop a torque on the choke by pulling the choke valve fully closed when said fast idle lever is moved to fully latched condition while flexing so that the gap remains between the pusher leg portion and the tang.

Owner:WALBRO LLC

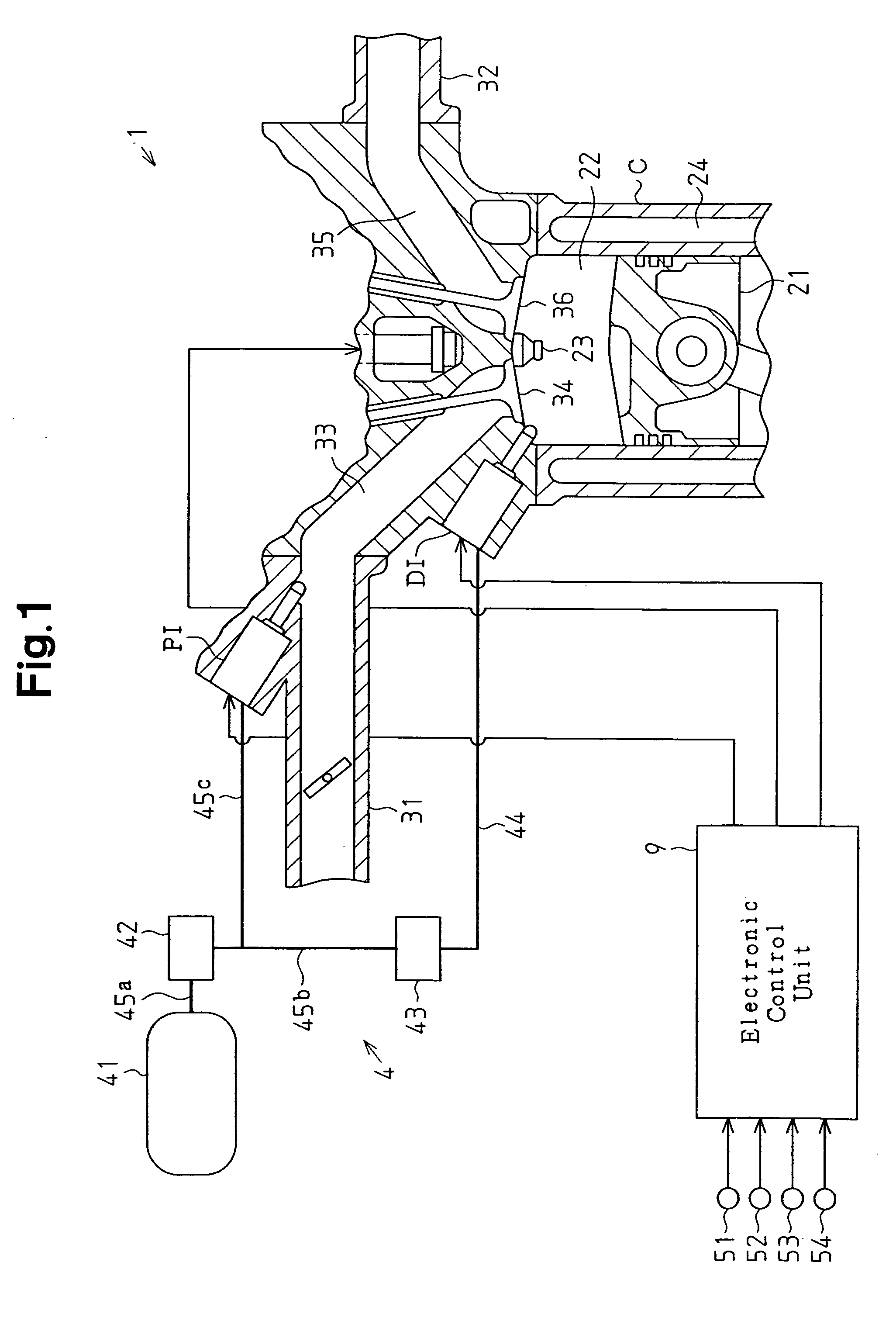

Control apparatus for internal combustion engine

InactiveUS20070000478A1Suppress generationStable combustionElectrical controlDigital data processing detailsTransitional RegionIdle speed

An engine ECU executes a program including the steps of: detecting an engine speed NE, engine load, and engine coolant temperature (S100, S110, S115); when determination is made of being in an idle region (YES at S120), determining whether in a cold idle region, a transitional region, or a warm idle region (S130); injecting fuel from an intake manifold injector alone when in the cold idle region (S140); injecting fuel from the intake manifold injector and injecting fuel from an in-cylinder injector at the feed pressure when in the transitional region (S150); and injecting fuel from the in-cylinder injector at the feed pressure when in the warm idle region (S160).

Owner:TOYOTA JIDOSHA KK

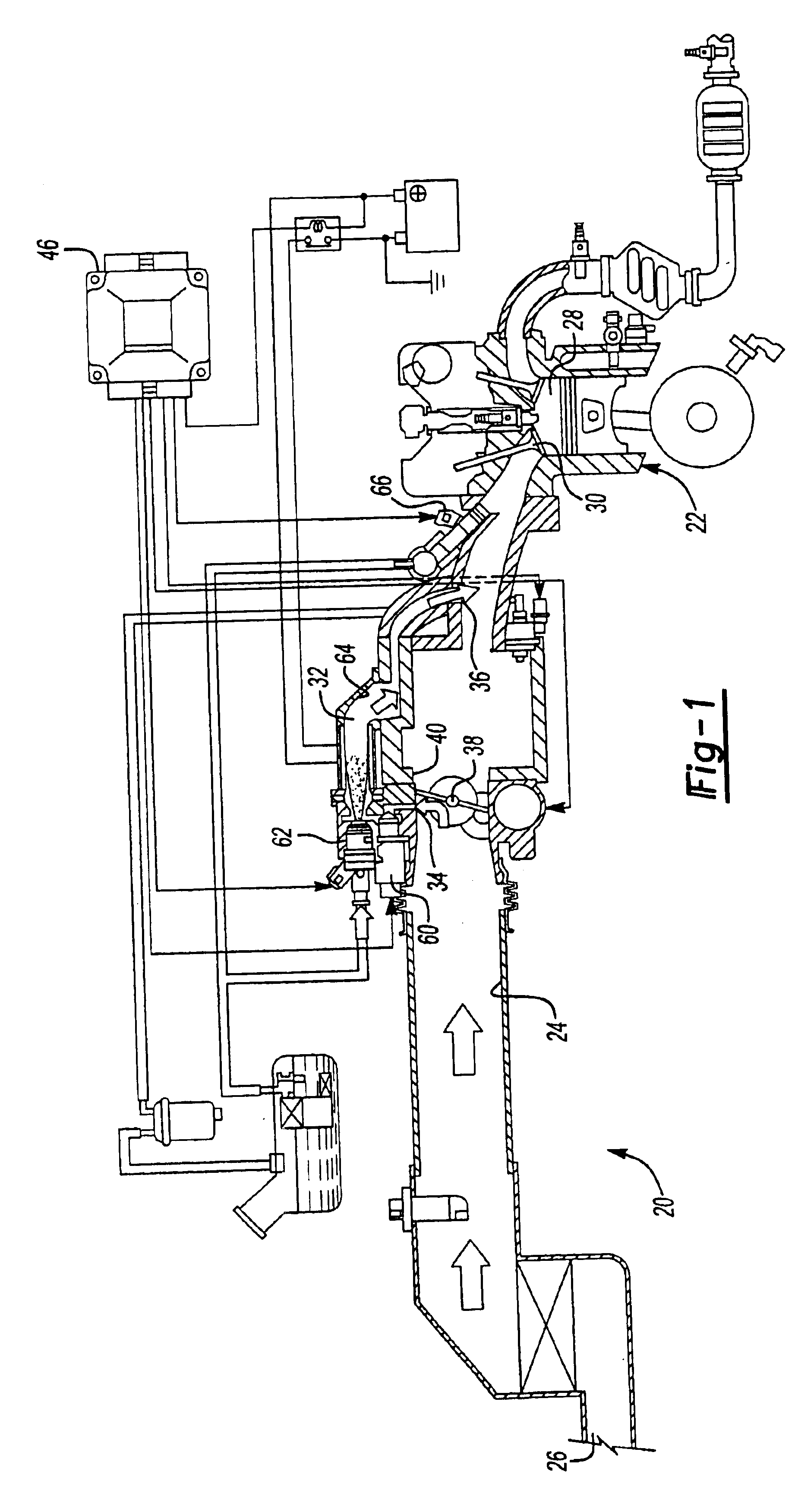

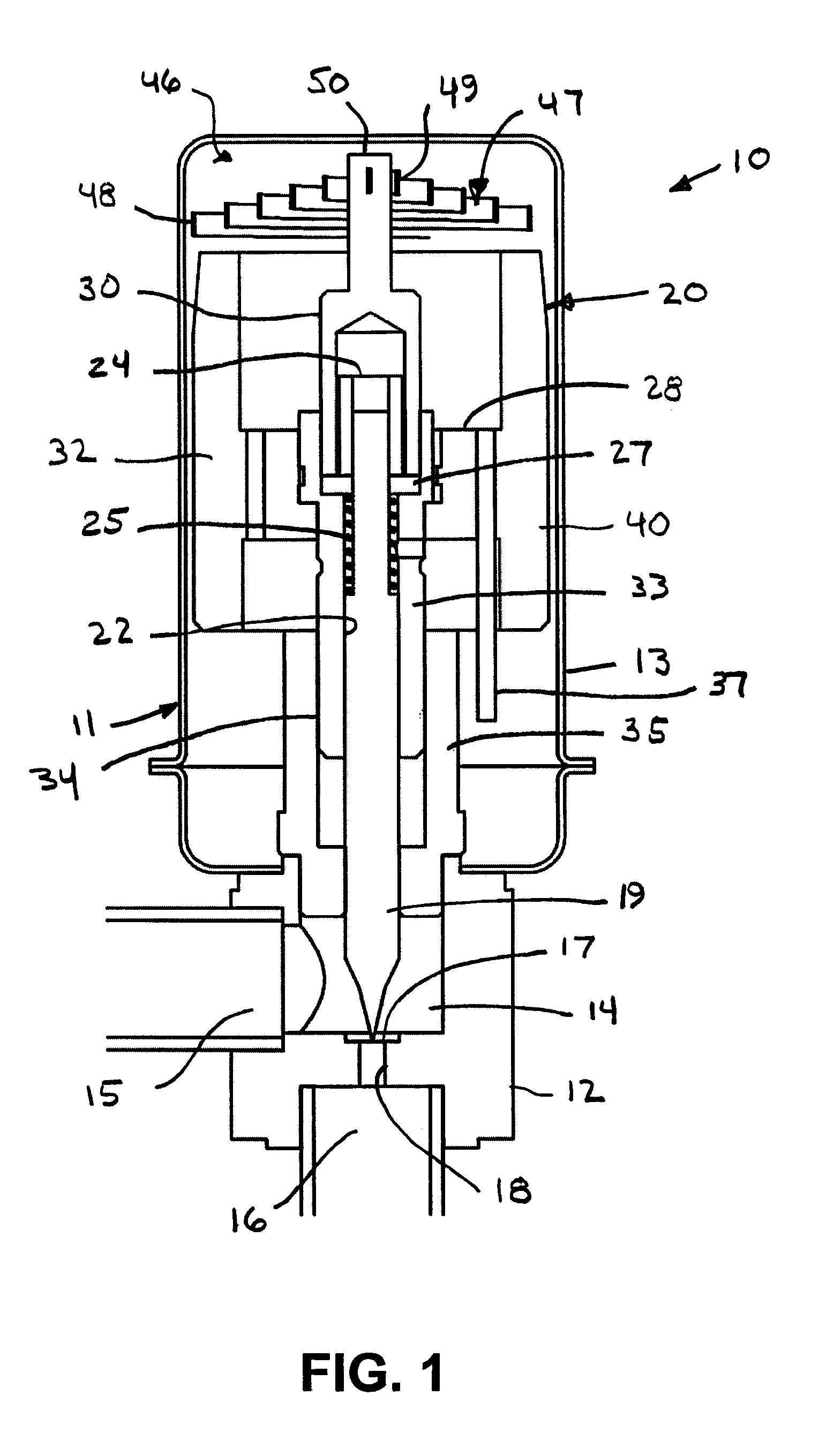

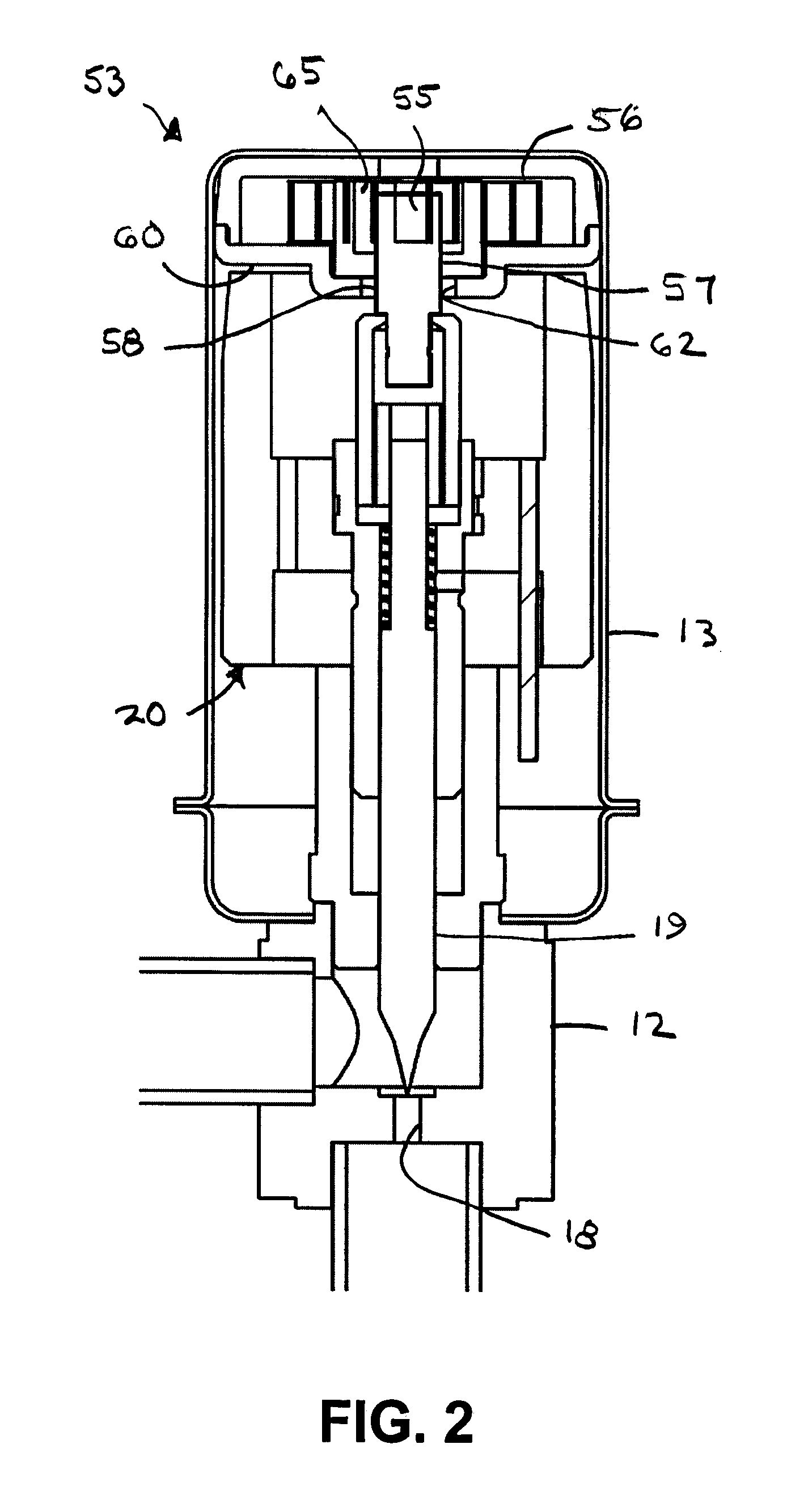

Fuel delivery system for an internal combustion engine

InactiveUS6874467B2Improved vaporizationElectrical controlNon-fuel substance addition to fuelEngine efficiencyIdle speed control

A fuel delivery system having an electronically controlled throttle valve operatively disposed in an intake manifold. An idle speed control valve is operatively disposed within a bypass gas flow passageway. A control system controls the actuation of both the throttle valve and idle speed control valve to control the delivery of a combustible charge to the internal combustion engine to maximize engine efficiency and minimize noxious emissions.

Owner:HITACHI LTD

Throttle body fuel injection system with improved idle air control

ActiveUS9303578B2Improve performanceOptimal fuel distribution and idle control circuitryElectrical controlInternal combustion piston enginesFuel distributionClosed loop

A single point fuel injection throttle body assembly including an idle air control circuit having an port opening into main intake bores downstream of the point of fuel distribution into the air stream. When the idle air control circuit is open, an air / fuel mixture, rather than simply air, is drawn into the into the intake manifold, thereby reducing the tendency for a lean fuel mixture at idle. A unique engine control unit “feed forward” algorithm controls the fuel injection as a function of the position of the idle air control motor so that as the idle air control circuit is opened, the pulse widths of the fuel injector signals are increased. This feature allows the initial open-loop-based fuel mixture supplied by system to be more accurate and eliminates rough unstable idle associated with closed-loop control lag times.

Owner:MSD LLC

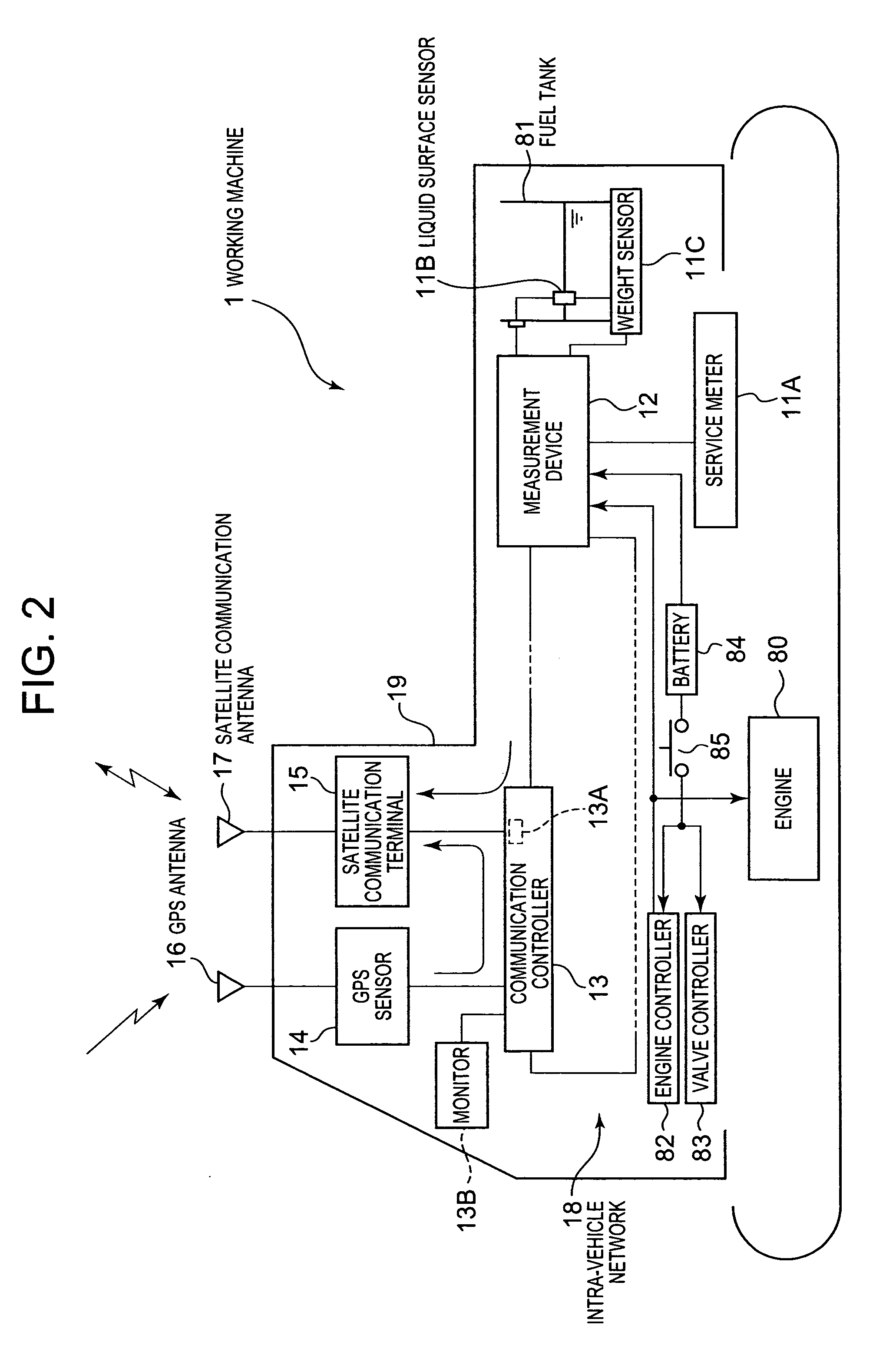

Working machine fuel management system and fuel managing method

A fuel management system detects theft of fuel from the fuel tank (81) of a working machine (1) or insertion of foreign matter into the fuel tank, and issues an alarm. The total operating hours of the working machine (1) and the actual volume and weight of the contents of the fuel tank (81) are measured immediately after the start and stop of the working machine (1), and transmitted to a server (10) which calculates the fuel consumption amount from the total operating hours, calculates the volume and weight of the fuel assumed to remain in the fuel tank (81) from the fuel consumption amount, and compares the calculated volume and weight with the actual volume and weight. If a large difference is detected in the volume or weight, an alarm is transmitted to a user terminal (20) and to the working machine.

Owner:KOMATSU LTD

Vehicular ejector system and control method thereof

InactiveUS7610140B2Reduce vehicle costReduce adverse effectsElectrical controlDigital data processing detailsInlet manifoldThrottle

A vehicular ejector system having an ejector that generates a negative pressure that is greater than the intake manifold negative pressure that is to be extracted from an intake manifold, a VSV that causes the ejector to function or stop functioning, and an ECU that controls the VSV. The ECU includes a control device that controls the VSV so as to cause the ejector to function if an ISC request amount for controlling, during idling, a throttle valve that adjusts the intake air flow amount supplied to the internal combustion engine is greater than a predetermined amount.

Owner:TOYOTA JIDOSHA KK

Torque controller for internal combustion engine

InactiveUS20060102143A1Increment of exhaust gas temperature can be restrictedElectrical controlIdling devicesIgnition delayIgnition timing

A throttle position corresponding to a R-R torque representing a torque in which a reserve torque is added to a required torque at MBT is computed. The throttle position is offset by an amount of a reserve torque in a torque increasing direction. An ignition retard amount for obtaining the required torque is computed based on a ration between the required torque and the R-R torque to cancel an increment in torque due to the offset of the throttle position. Because the offset amount of the ignition timing in the retard direction can be computed without an estimated torque which is determined based on the intake air flow rate including the leak air, it is restricted that the ignition retard amount becomes too large even if the large amount of leak air is generated at the throttle valve.

Owner:DENSO CORP

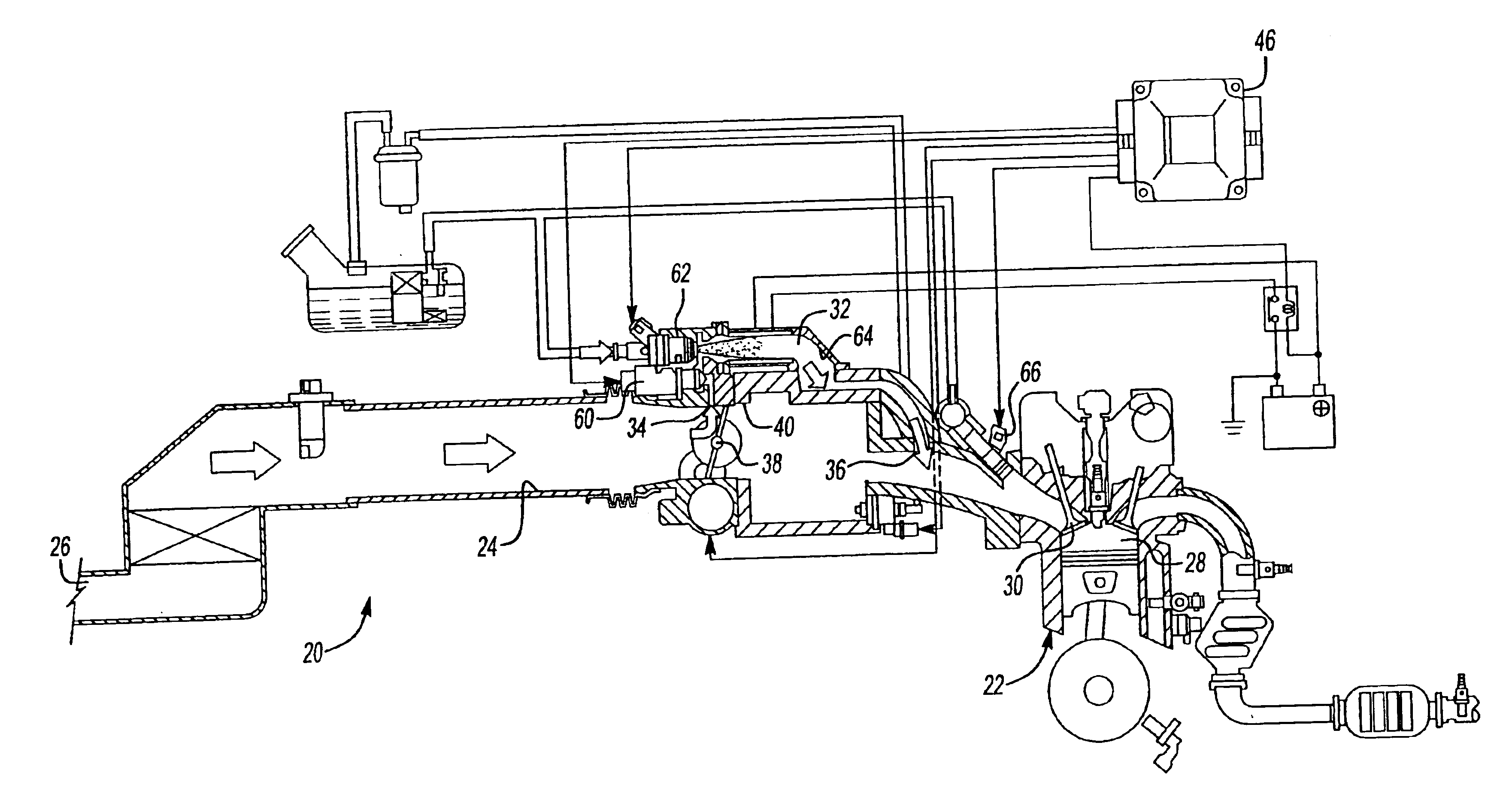

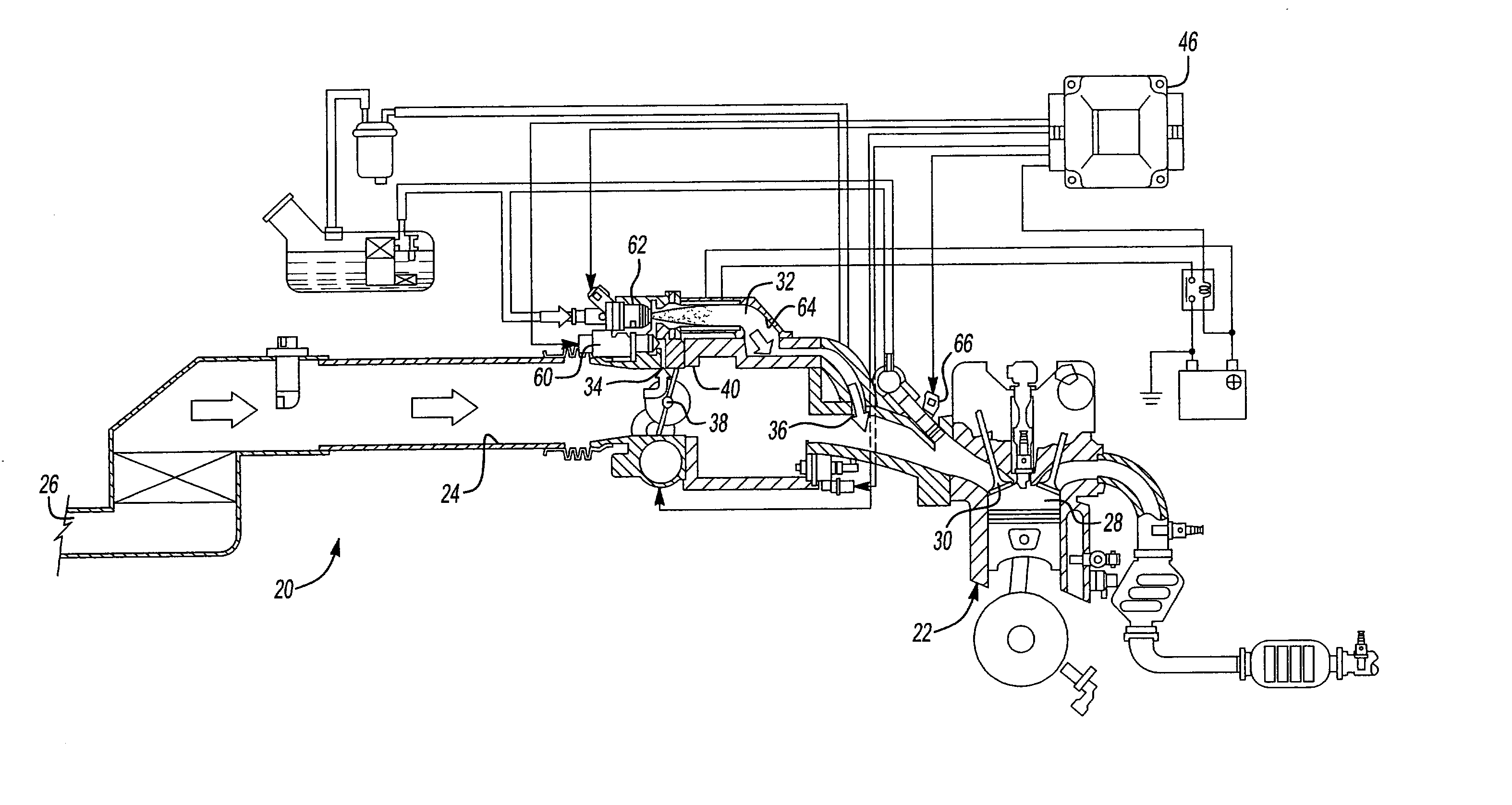

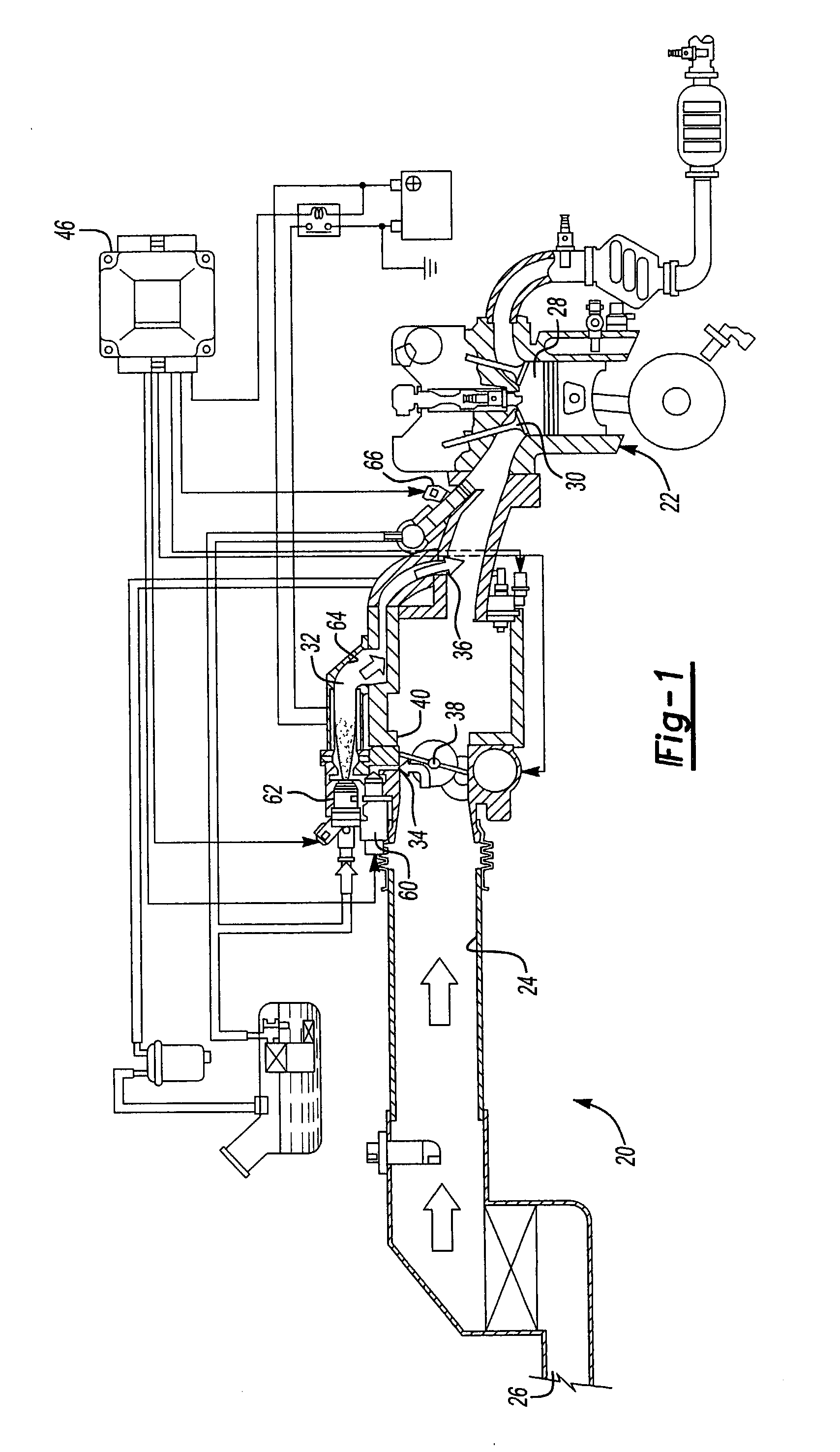

Fuel delivery system for an internal combustion engine

InactiveUS20040025837A1Improved vaporizationElectrical controlNon-fuel substance addition to fuelEngine efficiencyIdle speed control

A fuel delivery system for an internal combustion engine of the type having an intake manifold selectively fluidly connected to a combustion chamber and a bypass gas flow passageway having an inlet open to the intake manifold and an outlet open to the intake manifold downstream for the inlet is disclosed. The system includes an electronically controlled throttle valve operatively disposed in the intake manifold and movable between an open and a closed position to control air flow through the intake manifold. An idle speed control valve is operatively disposed within the bypass gas flow passageway, and the idle speed control valve is also movable between an open and a closed position to control air flow through the bypass gas flow passageway. A control system controls the actuation of both the throttle valve and idle speed control valve to control the delivery of a combustible charge to the internal combustion engine to maximize engine efficiency and minimize noxious emissions. Optionally, a cold start fuel injector is disposed within the bypass gas flow passageway to provide the fuel charge to the engine during a cold start condition. In an alternate form of the invention, two electronically controlled throttle valves are disposed within the intake manifold to control both the air flow through the intake manifold as well as the air flow through the bypass gas flow passageway.

Owner:HITACHI LTD

Air bypass valve failure detection device in supercharging device for engine

InactiveUS7578128B2Accurate detectionElectrical controlInternal combustion piston enginesTurbochargerEngineering

An air bypass valve failure detecting device outputs an opening command to an air bypass valve when a throttle valve suddenly closes, thereby prevent surging from occurring in a second intake passage between a turbocharger and a throttle valve. When the opening command is outputted to the air bypass valve, failure detection for the air bypass valve is permitted only if an intake air quantity of an engine immediately before a closing command is changed to the opening command is equal to or larger than a predetermined value. Thus, it is possible to prevent the failure detecting device from erroneously determining that the air bypass valve is normal although valve closing failure of the air bypass valve has occurred. This is because, when the intake air quantity is smaller than the predetermined value, surging does not occur in the second intake passage even if the valve closing failure of the airy bypass valve has occurred.

Owner:HONDA MOTOR CO LTD

Step motor valve assembly with fail-safe feature

InactiveUS20060238039A1Electrical controlOperating means/releasing devices for valvesRotational axisEngineering

A step motor valve assembly comprises a housing including a threaded portion, a rotor having rotational axis and a threaded portion in threaded engagement with the threaded portion of the housing such that rotation of the rotor will effect axial movement of the rotor relative to the housing, a valve member carried by the rotor for axial movement toward and away from a valve seat upon rotation of the rotor in respective opposite directions, and a return mechanism for moving the valve member to a fail-safe position upon a loss of power to the step motor valve assembly.

Owner:PARKER HANNIFIN CORP

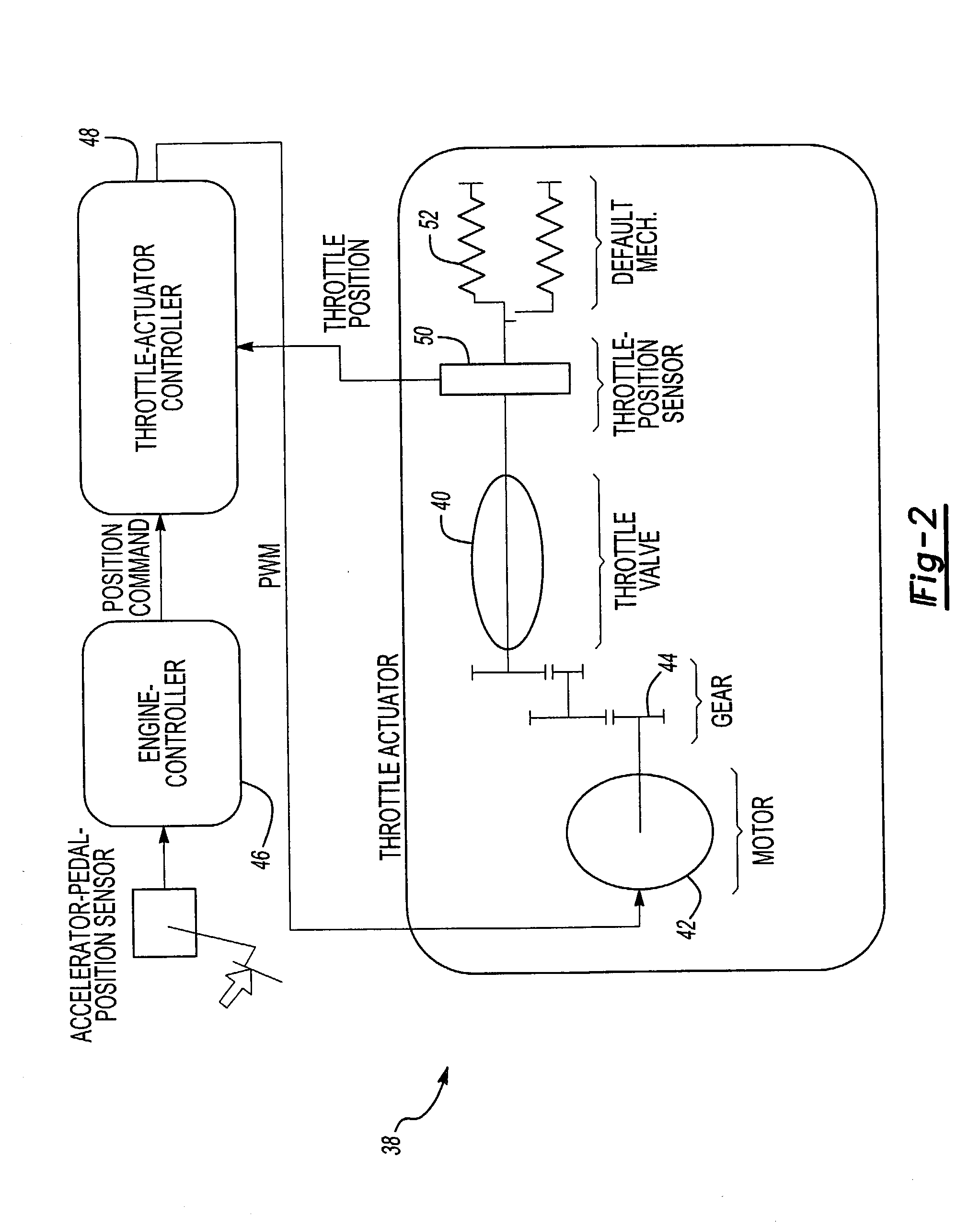

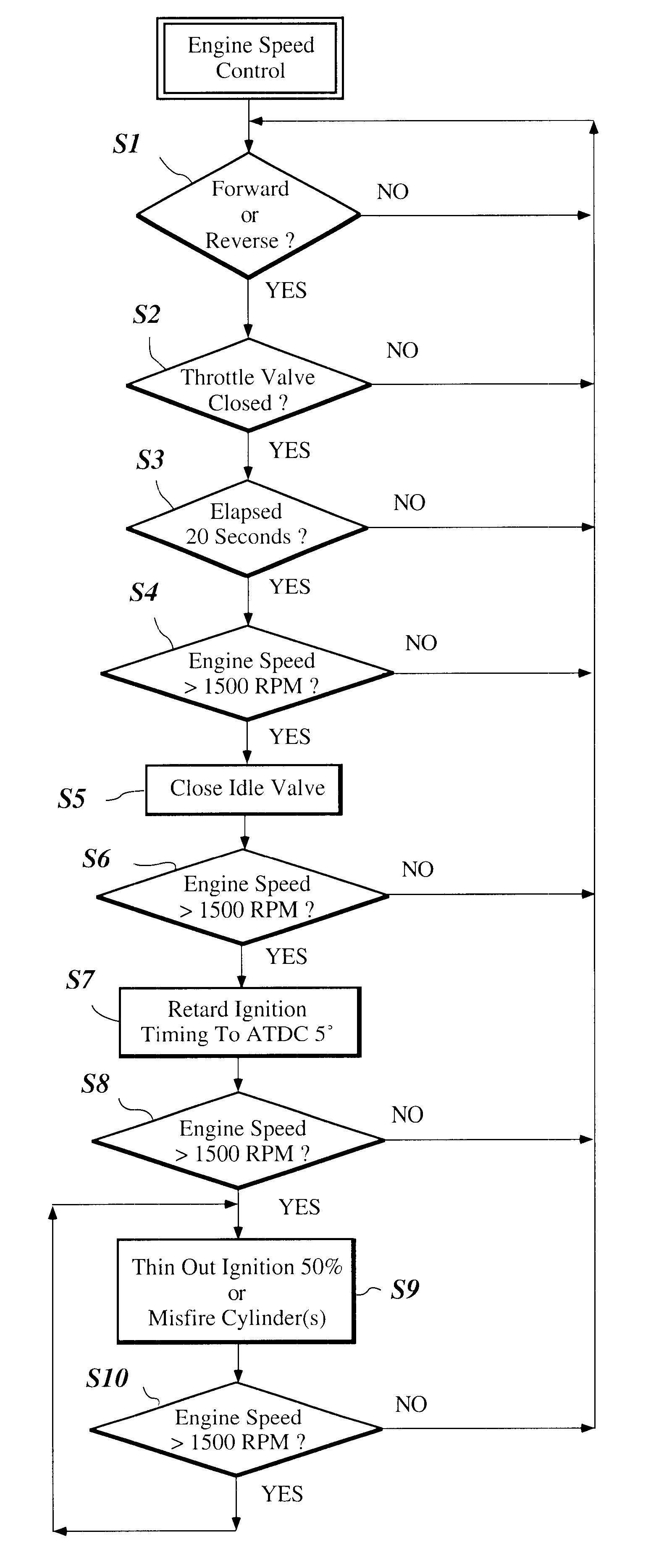

Engine control system

An engine control system includes an improved construction that can release an engine from an abnormal engine speed so that, for example, the operator can operate a shift actuator without any overload. The engine includes an air induction system that introduces air to the combustion chamber and includes a throttle valve. The throttle valve admits the air to flow through the air induction system unless placed in a closed position. A throttle valve position sensor is arranged to sense the position of the throttle valve. An engine speed sensor is also arranged to sense a rotational speed of the crankshaft. A control device is provided for slowing down the engine speed based upon a throttle position signal from the throttle valve position sensor and a speed signal from the engine speed sensor. In one operating mode, the slow down control is made when the throttle position signal indicates that the throttle valve is generally at the closed position and the speed signal indicates that the engine speed exceeds a preset speed.

Owner:SANSHIN KOGYO CO LTD

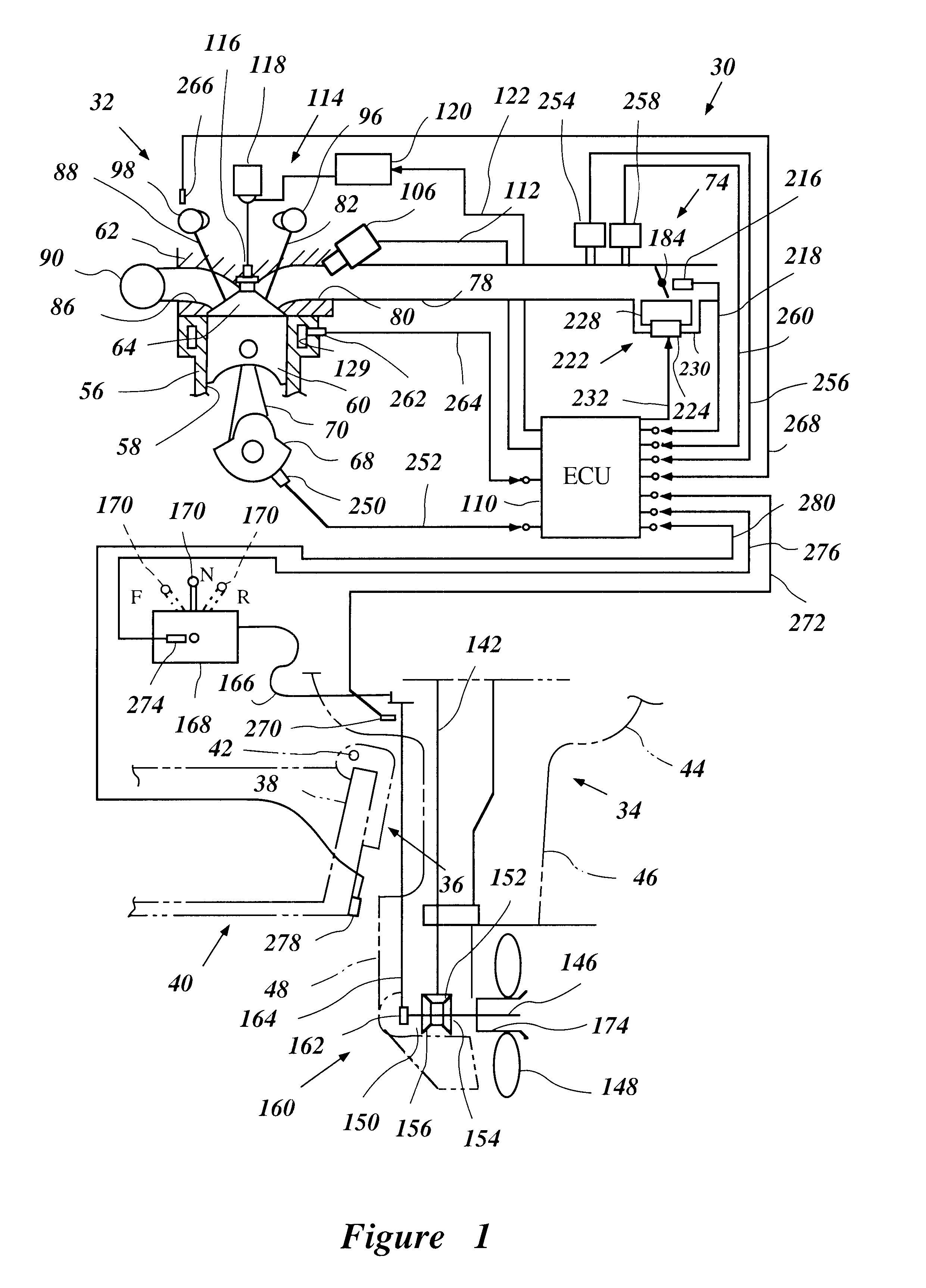

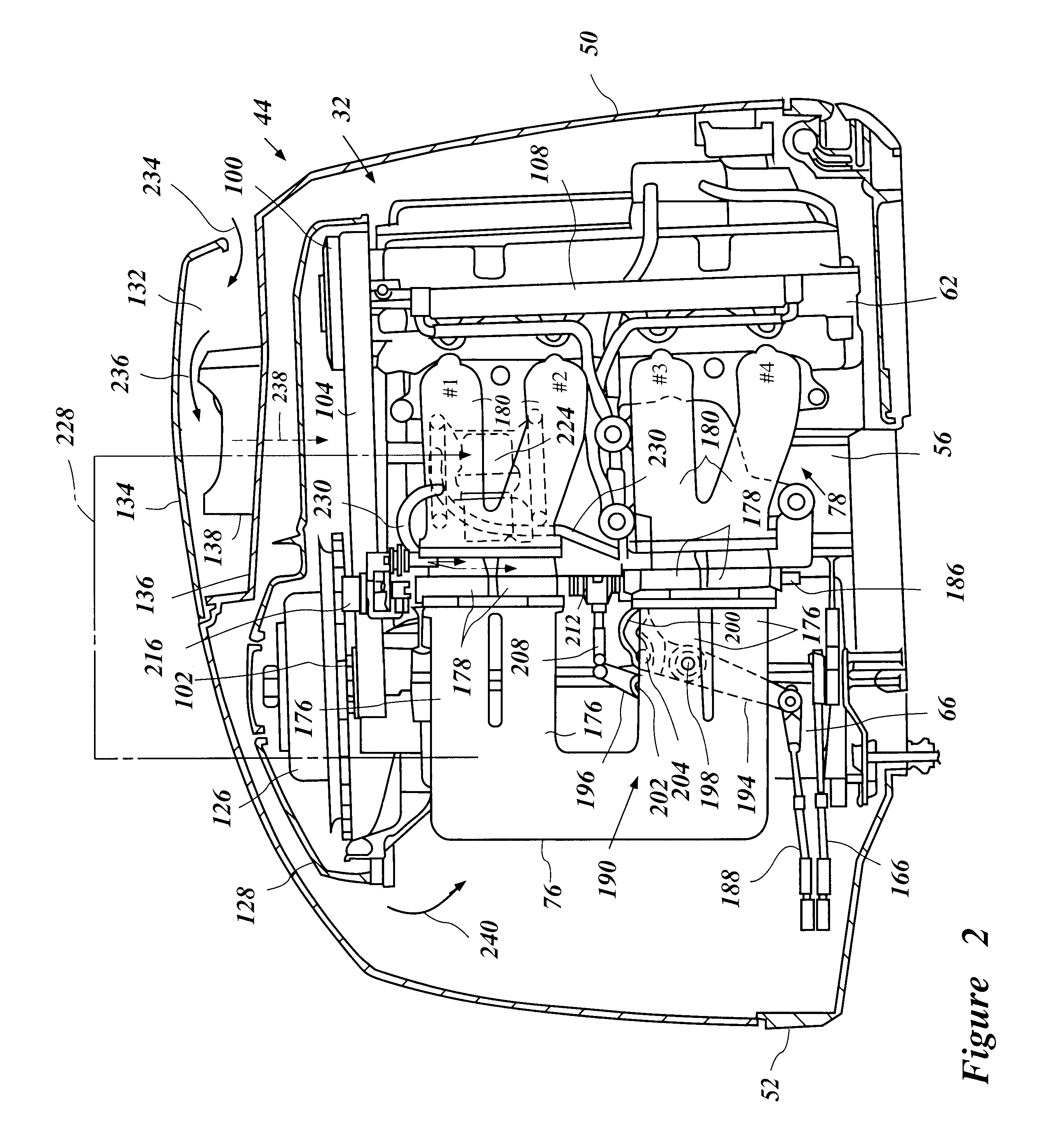

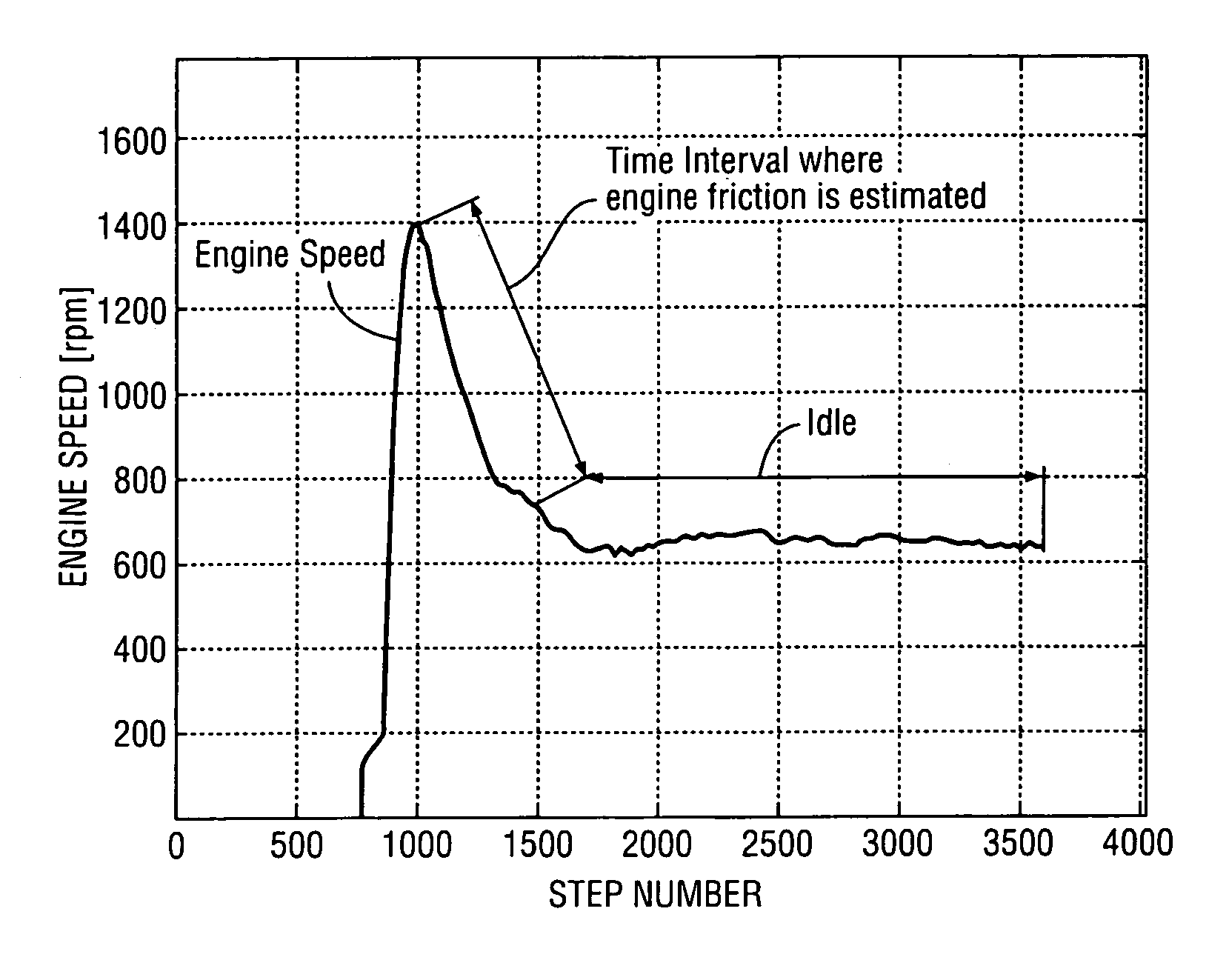

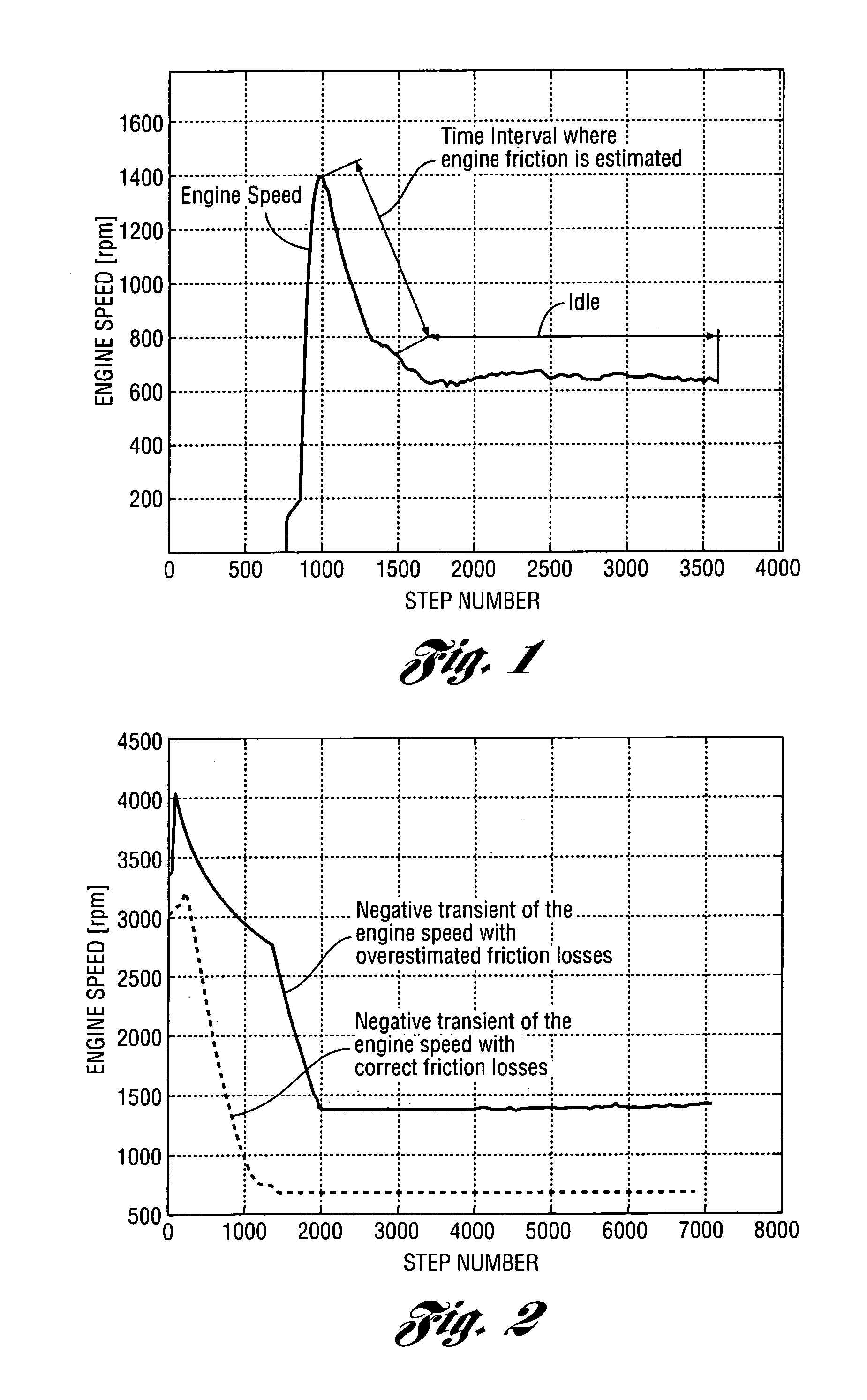

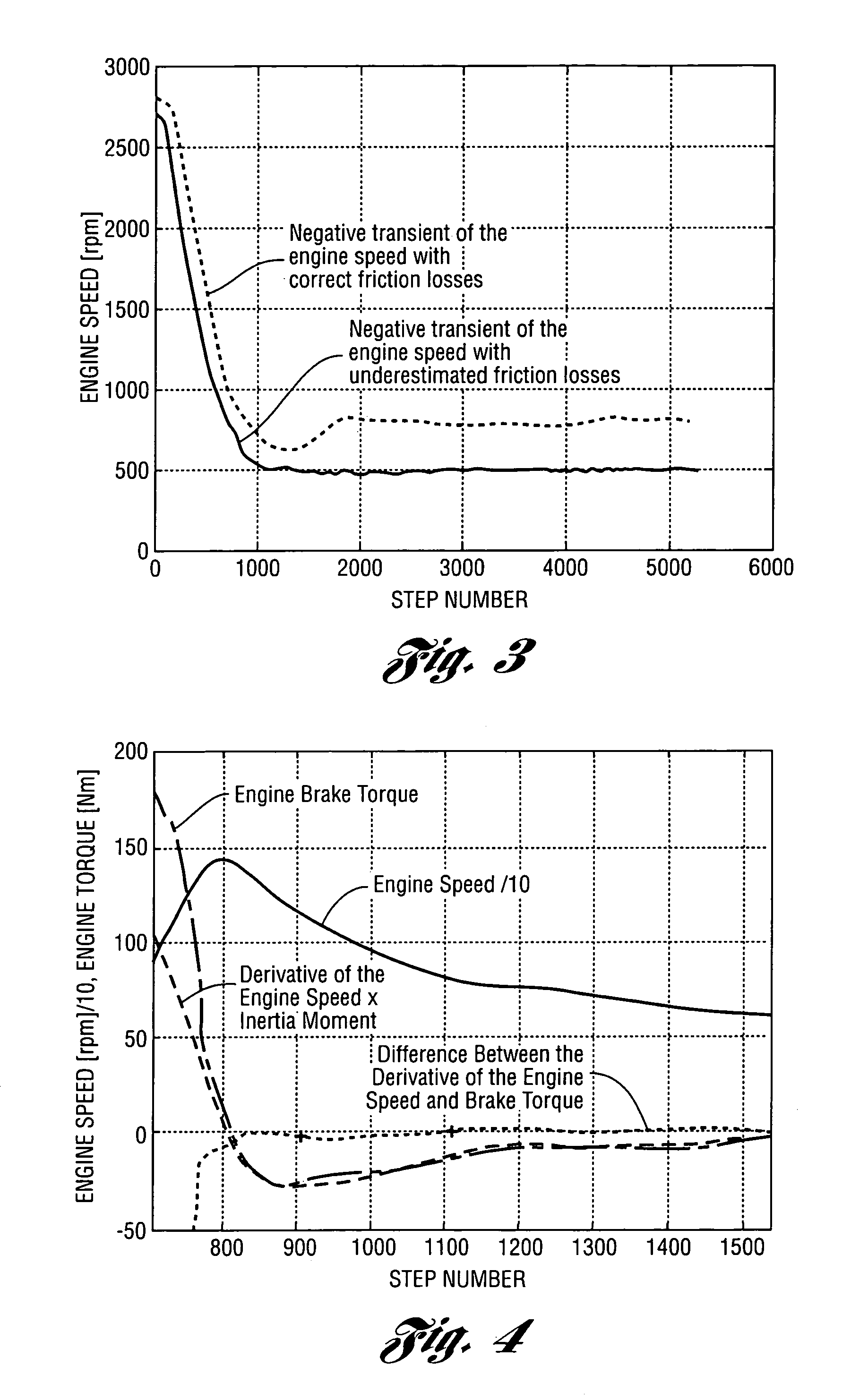

Method for estimating engine friction torque

ActiveUS7054738B1Lighten the computational burdenAnalogue computers for vehiclesElectrical controlFriction torqueEngineering

Algorithms for real-time estimation of the engine friction torque in a vehicle powertrain are disclosed. Engine friction torque is estimated at start and at engine idle. Recursive and computationally efficient algorithms allow prediction of friction torque for a wide range of speeds and loads even with few new measured points by taking into account physical dependencies used for adaptation of the sites of the look-up tables (static maps). The algorithms make it possible to avoid drivability problems that could result from errors in estimating engine friction torque.

Owner:VOLVO CAR CORP

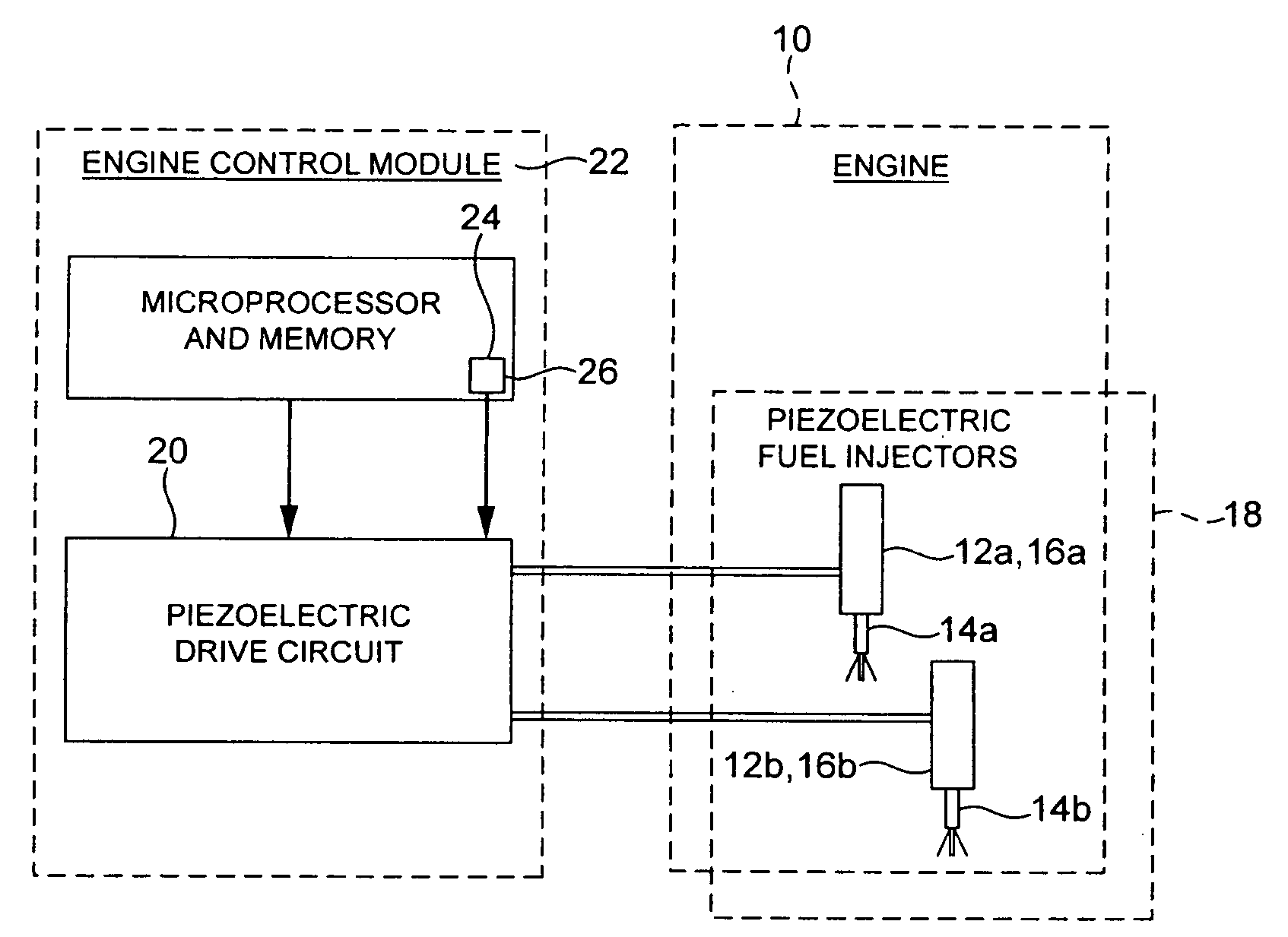

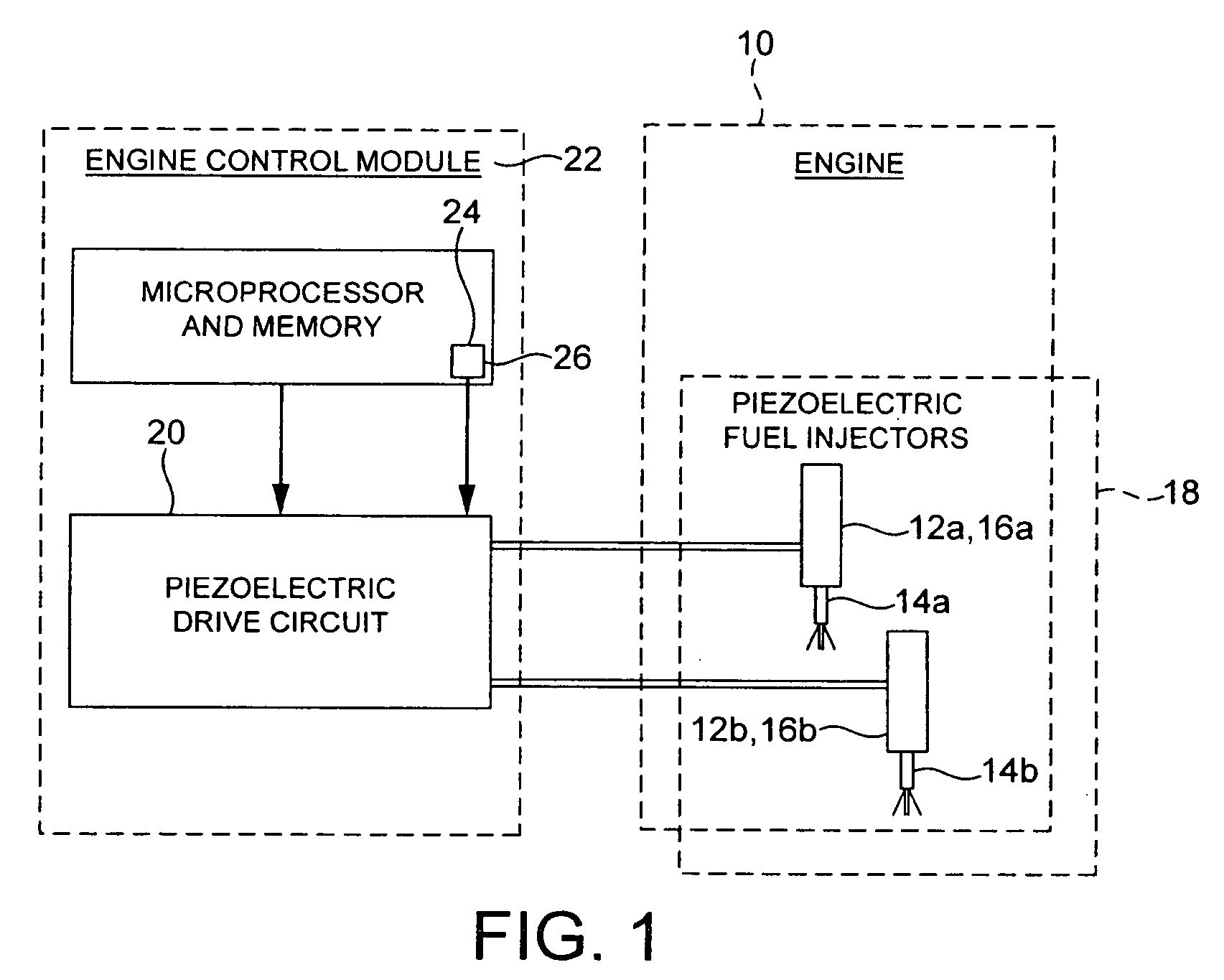

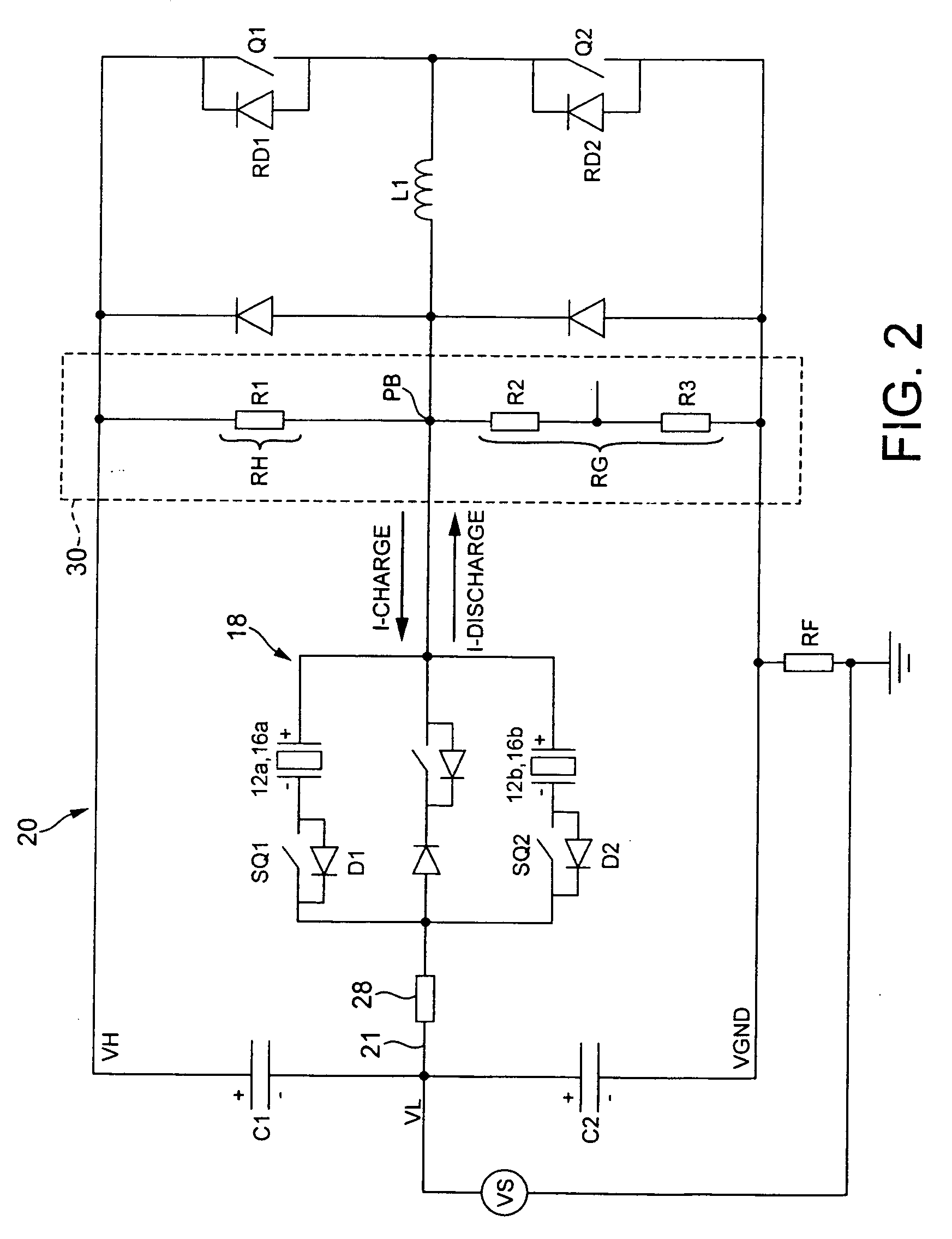

Detection of faults in an injector arrangement

InactiveUS20080319699A1Increase resistanceLow component requirementsVehicle testingAnalogue computers for vehiclesThreshold currentDischarge current

A fault detection method for detecting short circuit faults in an injector arrangement at engine start-up. The injector arrangement comprises one or more piezoelectric fuel injectors, which are connected in a drive circuit. In one aspect of the invention, the potential at a bias point in the drive circuit is determined and compared with a predicted voltage. A short circuit fault signal is generated if the potential at the bias point is not within a predetermined tolerance voltage of the predicted voltage. In another aspect of the invention, a first charge pulse is applied to the injectors to charge the injectors. A discharge current path is provided during a delay period following the first charge pulse by closing a discharge switch. A faulty injector will discharge through the discharge current path during the delay period. A second charge pulse is applied to the injectors following the delay period. Current flow is sensed during the second charge pulse, and a short circuit warning signal is generated if the current flow during the second charge pulse exceeds a predetermined threshold current.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

Throttle body having fuel return passage and vehicle

InactiveUS20060236980A1Smooth returnAvoid accumulationElectrical controlIdling devicesThrottle position sensorControl theory

A throttle body includes a housing that accommodates a connector for a rotation shaft of a throttle valve disposed in the throttle body and a throttle position sensor, a fuel return passage that communicates the housing with an air intake passage in the throttle body, a T-shaped pipe that communicates with the air intake passage upstream from the throttle body to function as a pressure control chamber, and an air inflow passage that communicates the housing with the T-shaped pipe. The throttle body smoothly returns the fuel accumulated in a housing that accommodates a connector that connects a throttle position sensor to the end of the rotation shaft of a throttle valve to an air intake passage.

Owner:YAMAHA MOTOR CO LTD

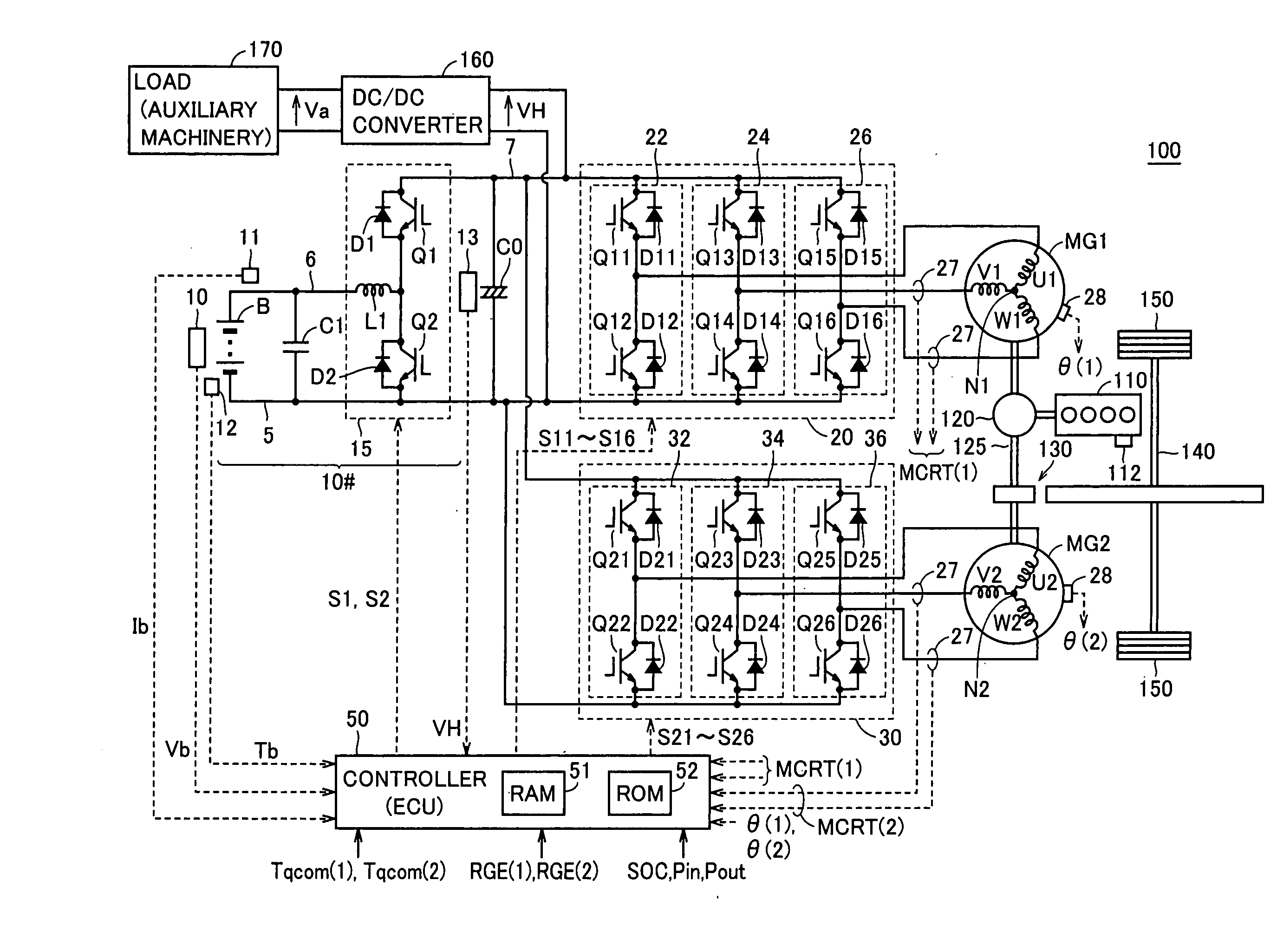

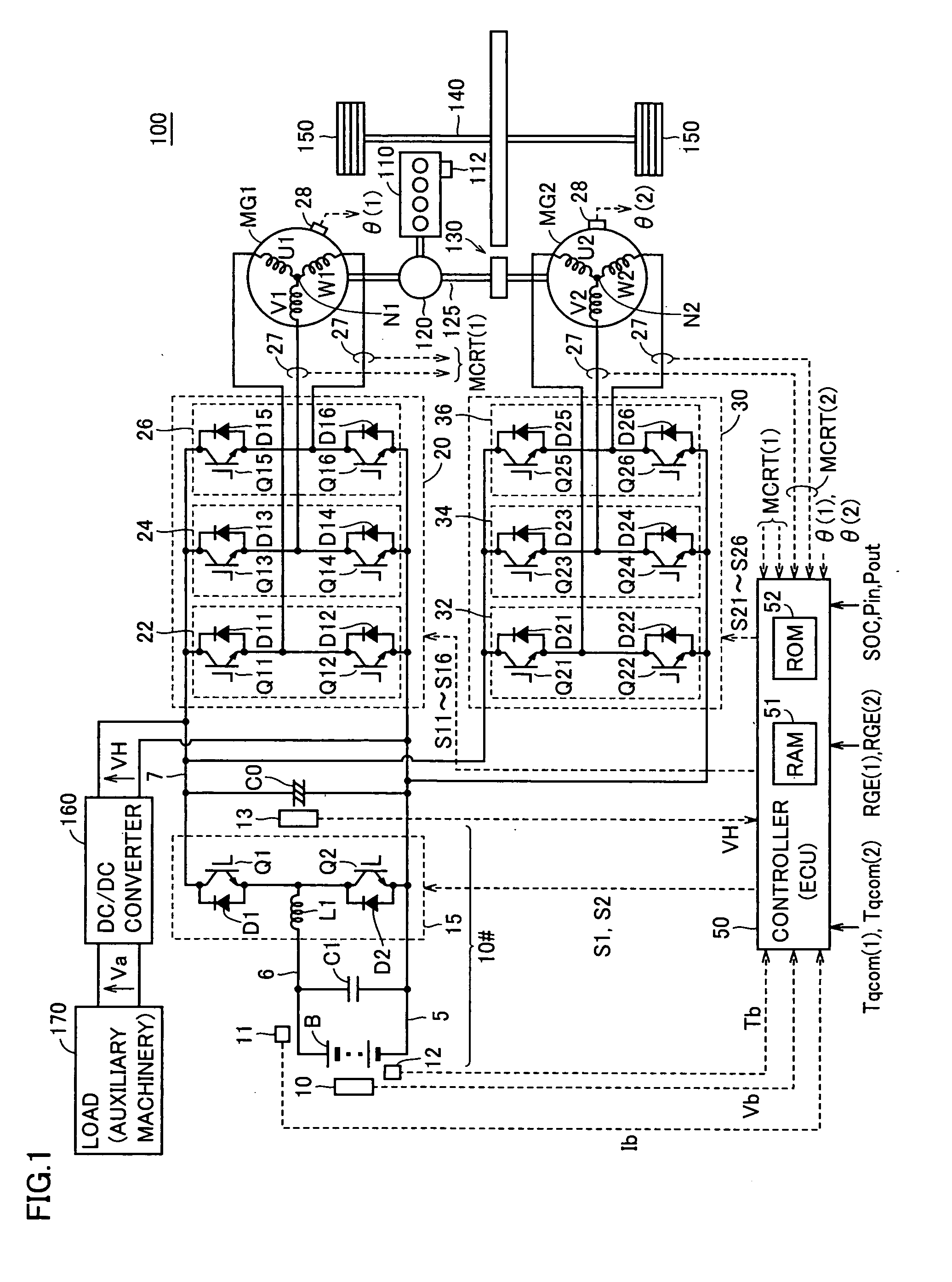

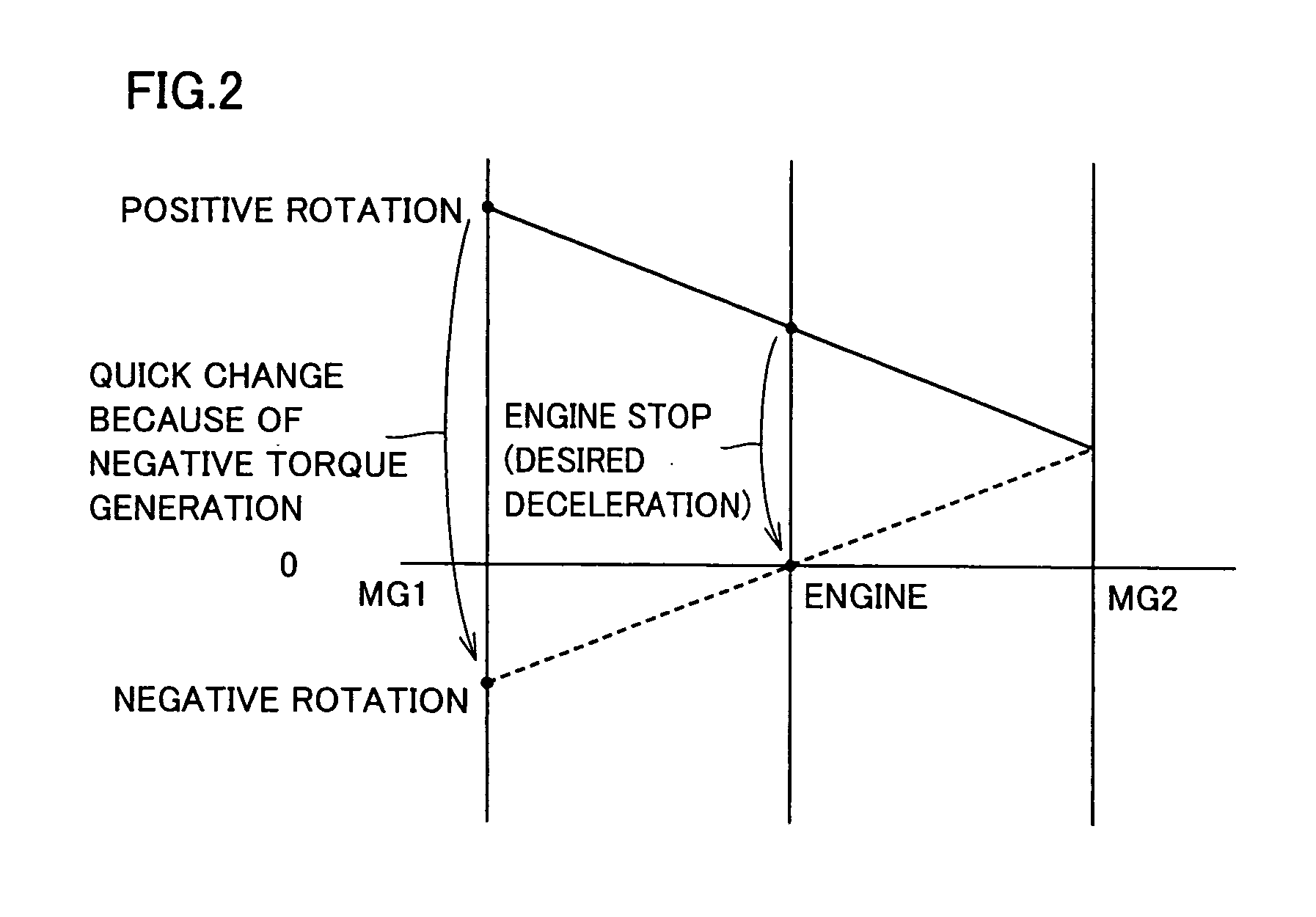

Internal Combustion Engine Stop Controller and Stop Control Method

InactiveUS20090171554A1Excessive chargingMore powerAnalogue computers for vehiclesAC motor controlElectric machineEngineering

When engine stop control is executed, an ECU estimates input power to a power storage device in accordance with an estimation of power generated by a generator and estimation of total power consumption of circuitry from the generator to the power storage device in the current state of operation. Further, the ECU compares the estimated input power with a tolerable input power to the storage device. When the generated power is excessive, the state of operation of the circuitry is changed such that the total power consumption by the circuitry increases, and then, torque output of the generator is permitted, to attain desired deceleration at the engine stop. Accordingly, in the engine stop control in which stopping force is generated by the power generating operation by the rotating electric machine, excessive charging caused by excessive power input to the power storage device can be prevented.

Owner:TOYOTA JIDOSHA KK

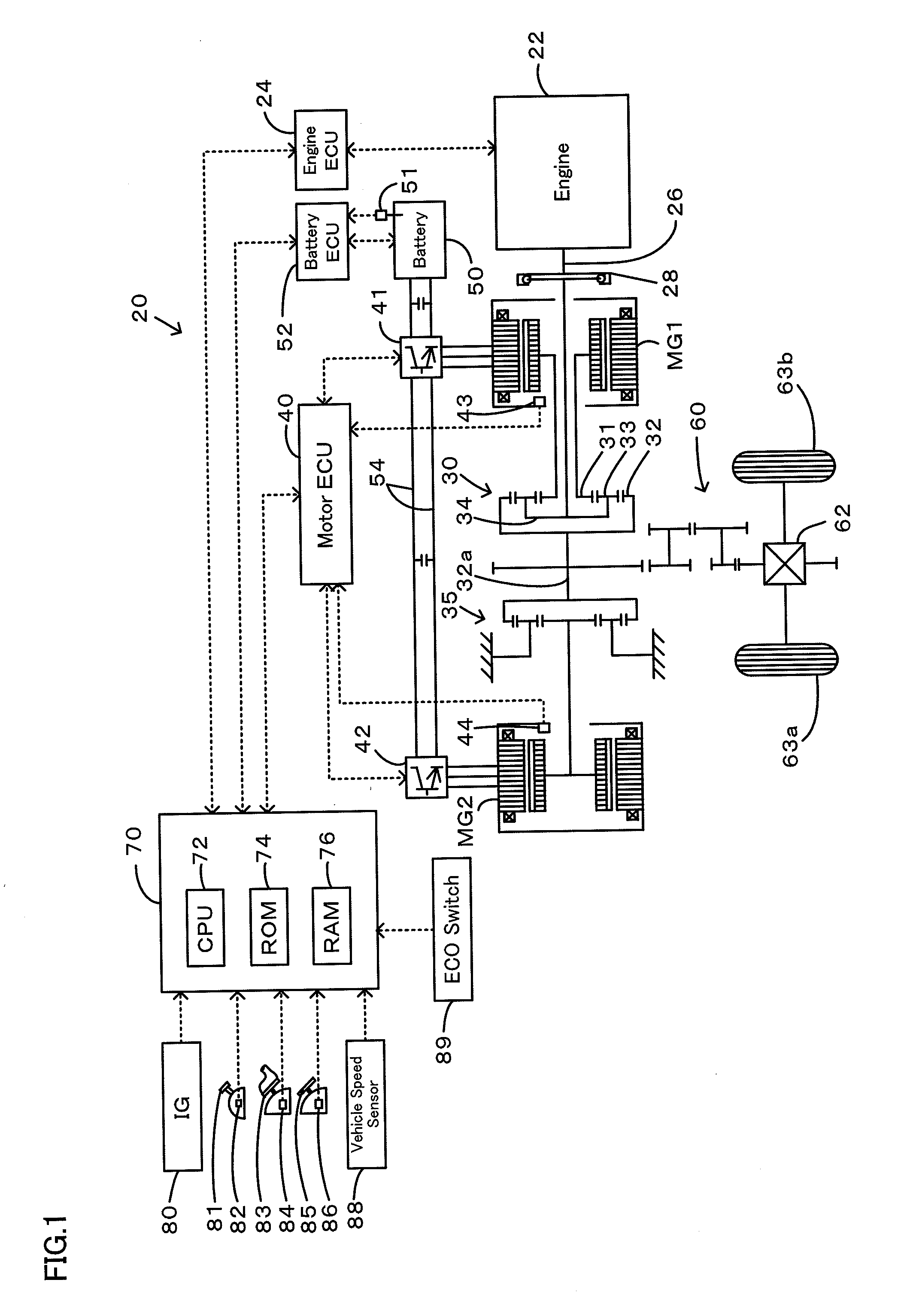

Hybrid vehicle and control method thereof

InactiveUS20090125172A1Improve performanceIncrease fuel consumptionHybrid vehiclesAnalogue computers for vehiclesState of chargeHybrid vehicle

In an OFF condition of an ECO switch, a stop decision reference value Wstop is set to a value W1 (step S420). In an ON condition of the ECO switch, the stop decision reference value Wstop is set to a value W2 (step S430). When an output limit Wout of a battery set according to a battery temperature and a state of charge of the battery is not less than the set stop decision reference value Wstop, the engine is permitted to stop (step S450). When the output limit Wout is less than the set stop decision reference value Wstop, the engine is prohibited from stopping (step S460). The value W1 is specified as a value of electric power required for a smooth restart of the engine after its stop during a drive of the vehicle. The value W2 is specified to be close to a value of minimum electric power required for a restart of the engine after its stop during a drive of the vehicle and is set to be smaller than the value W1.

Owner:TOYOTA JIDOSHA KK

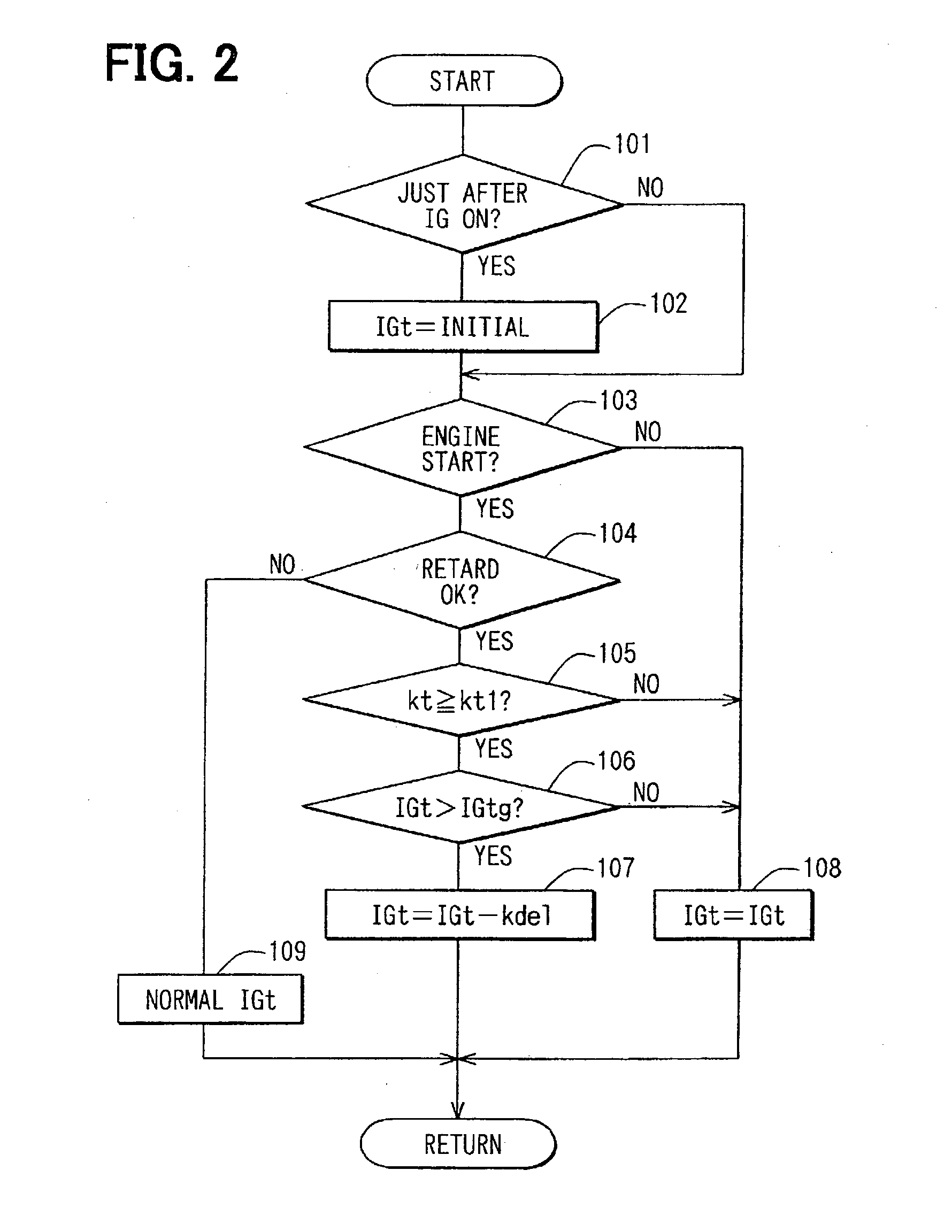

Control apparatus of internal combustion engine

InactiveUS20030116131A1Improve the heating effectRetardation quantityValve arrangementsElectrical controlIgnition timingExhaust emission

The ignition timing is sustained at an initial value during a predetermined time beginning at a start of an engine, and is retarded after the predetermined time is elapsed to heat a catalyst at an early time. The predetermined time ends when the negative pressure of an intake pipe or the negative pressure of a brake booster reaches to a predetermined value. That is, the predetermined time is a period, which begins at a start of the engine and ends when a proper negative pressure can be sustained in the brake booster. As a result, it is possible to assure a negative pressure in the brake booster at an early time and to reduce exhaust emission at a start of the engine simultaneously.

Owner:DENSO CORP

Air bypass valve failure detection device in supercharging device for engine

InactiveUS20080022968A1Accurate fault detectionAccurate detectionElectrical controlInternal combustion piston enginesTurbochargerControl theory

An air bypass valve failure detecting device outputs an opening command to an air bypass valve when a throttle valve suddenly closes, thereby prevent surging from occurring in a second intake passage between a turbocharger and a throttle valve. When the opening command is outputted to the air bypass valve, failure detection for the air bypass valve is permitted only if an intake air quantity of an engine immediately before a closing command is changed to the opening command is equal to or larger than a predetermined value. Thus, it is possible to prevent the failure detecting device from erroneously determining that the air bypass valve is normal although valve closing failure of the air bypass valve has occurred. This is because, when the intake air quantity is smaller than the predetermined value, surging does not occur in the second intake passage even if the valve closing failure of the airy bypass valve has occurred.

Owner:HONDA MOTOR CO LTD

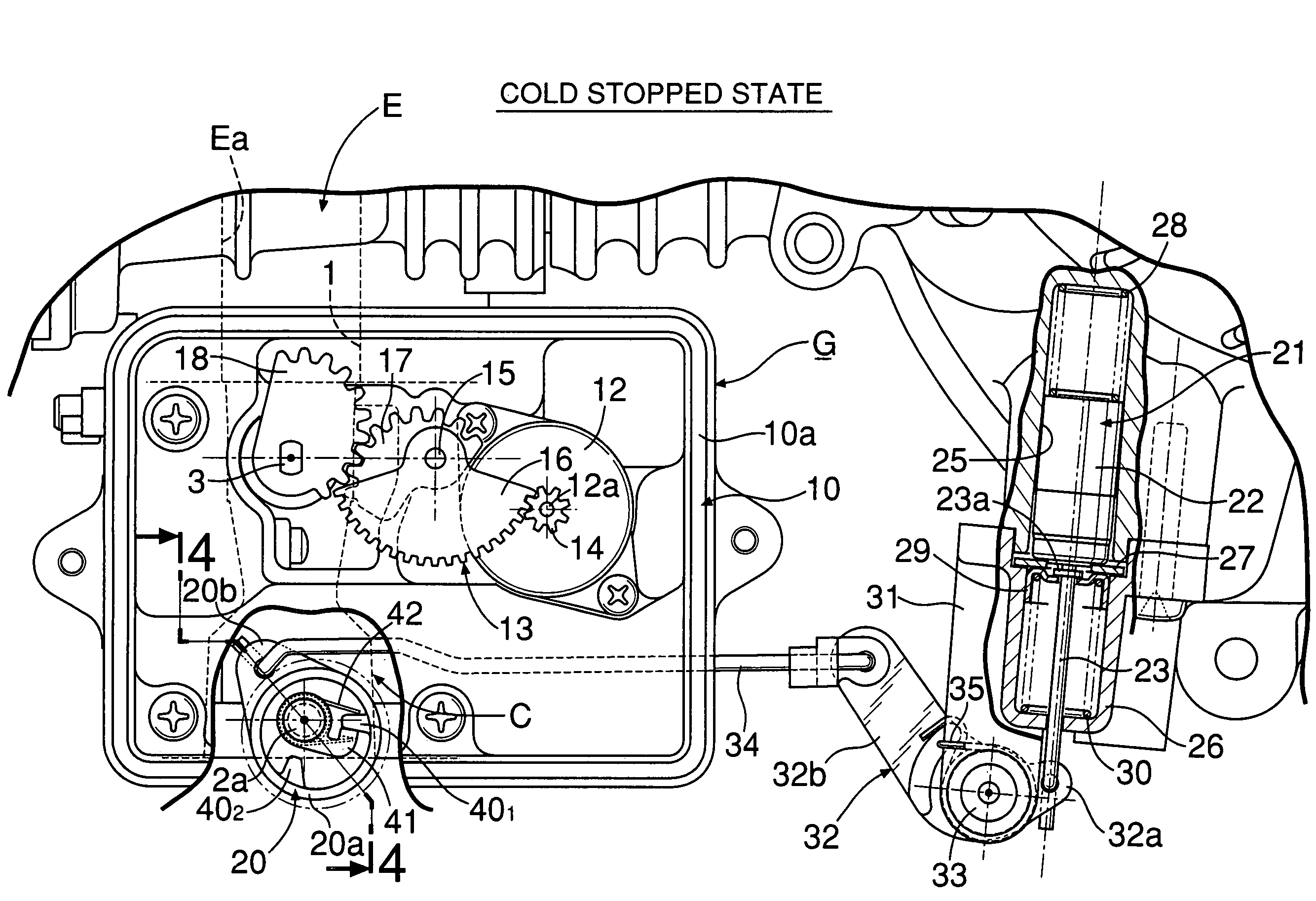

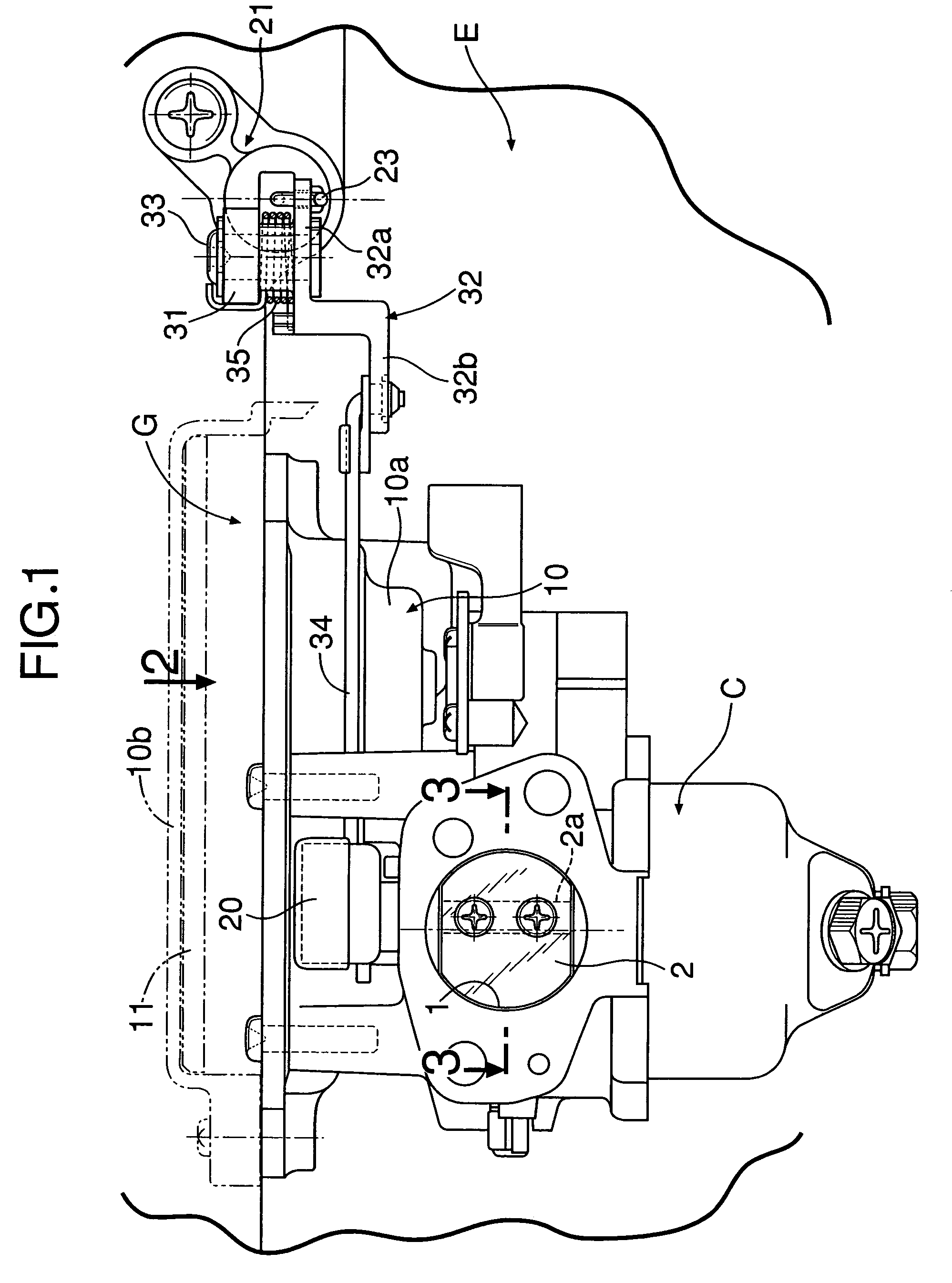

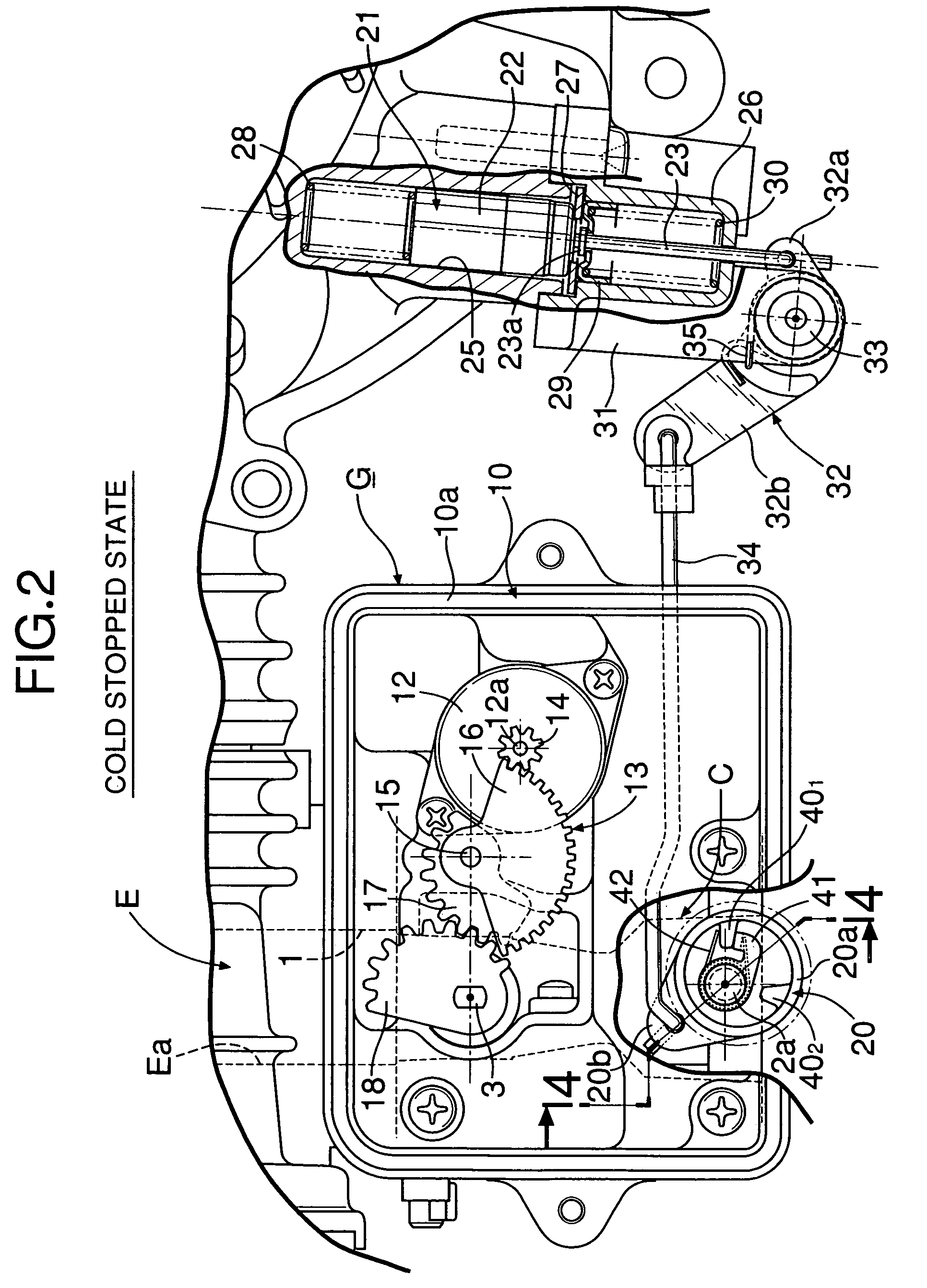

Carburetor automatic control system in engine

ActiveUS7331326B2Increase fuel consumptionElectrical controlLighting and heating apparatusAutomatic controlVacuum pressure

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com