Cylindrical low-nitrogen energy-saving pressure-bearing water pipe boiler

A water-tube boiler, cylindrical technology, applied in the field of gas-fired boilers, can solve the problems of inconvenient maintenance of the furnace body, difficult to clean, easy carbon deposition and blockage of water-cooled tube bundles, etc., so as to reduce heat dissipation loss, increase burner power, and improve average heat exchange. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The patent will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

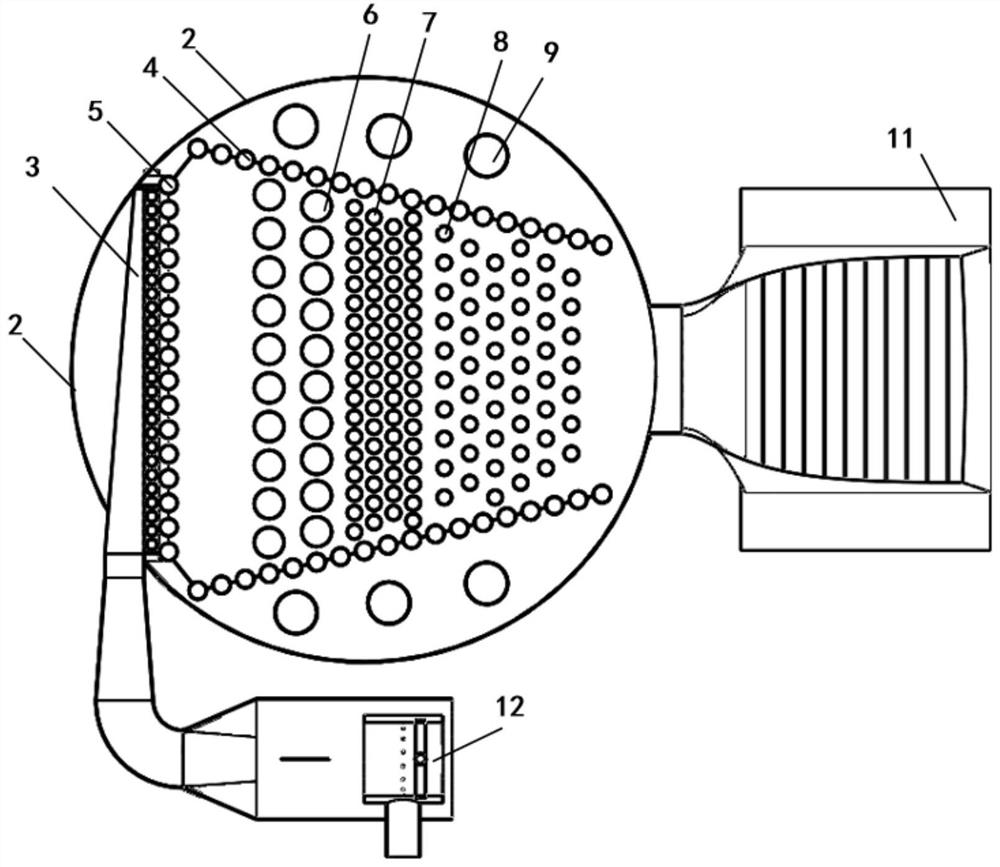

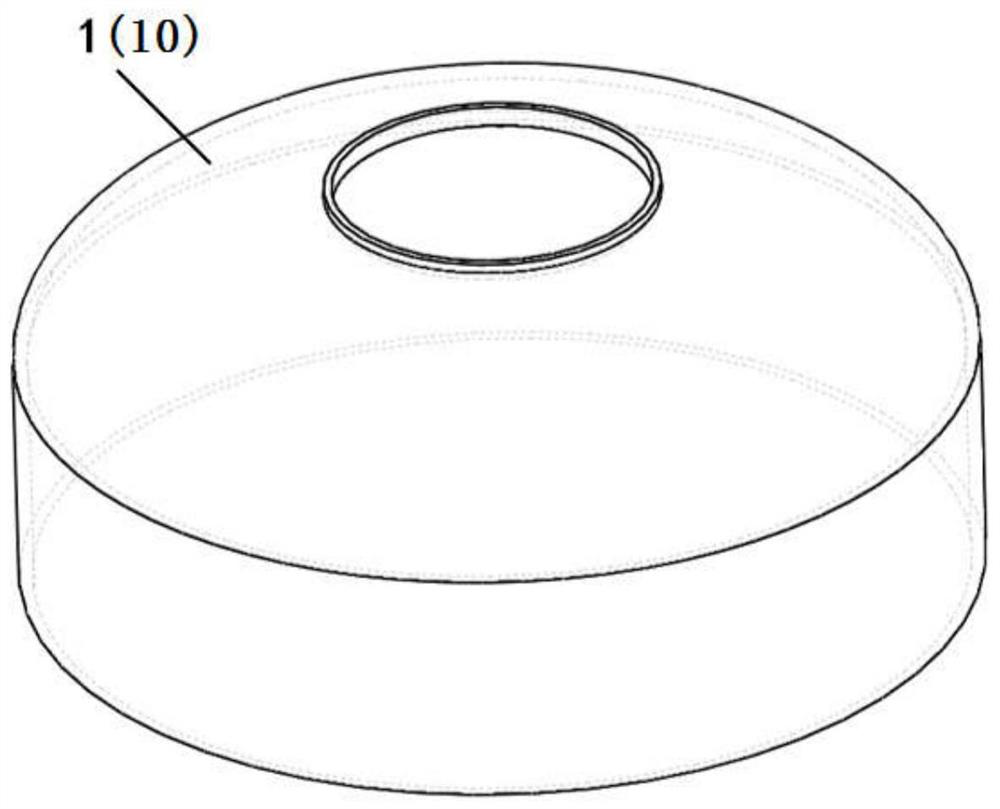

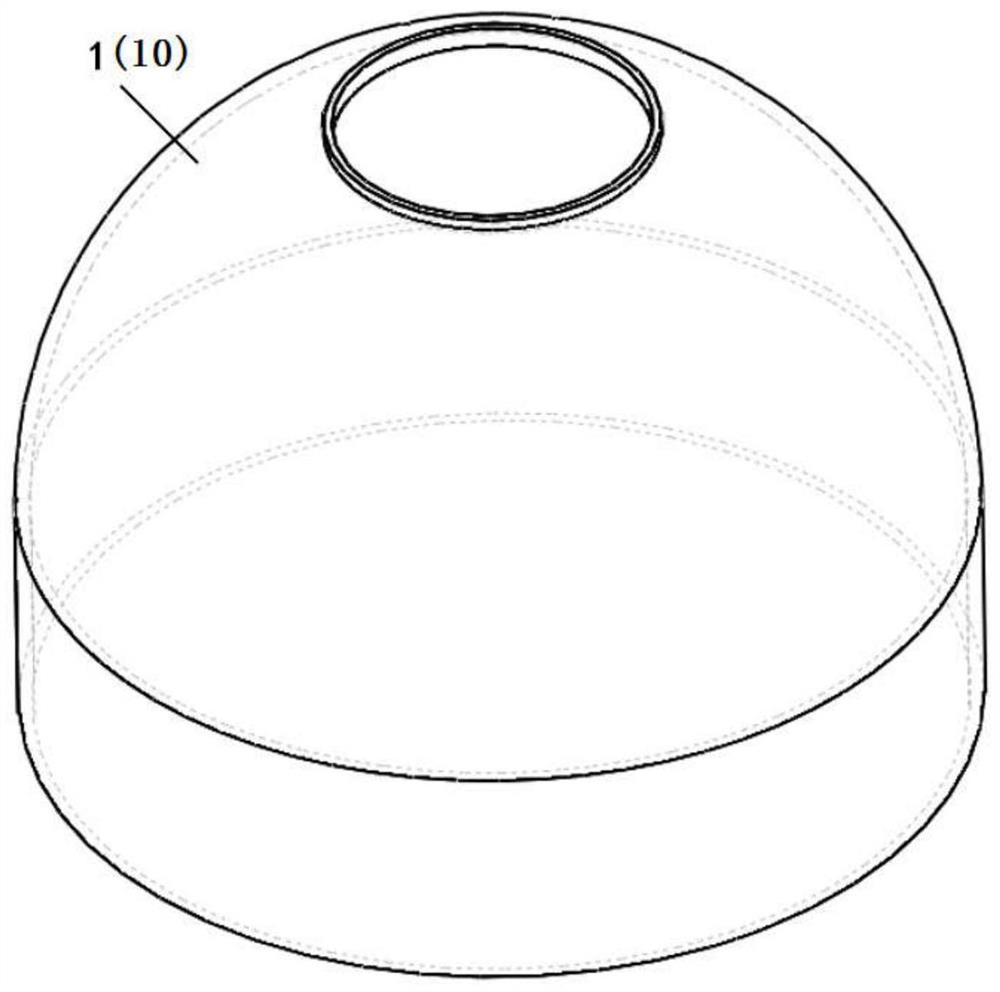

[0033] like figure 1 As shown, a cylindrical low-nitrogen energy-saving pressurized water tube boiler of the present invention includes an upper head 1, a shell 2, a burner distribution head 3, a membrane water wall tube bundle 4, a water-cooled flame tube bundle 5, a radiation tube bundle 6, and a high-temperature convection Tube bundle 7, low-temperature convection tube bundle 8, descending tube bundle 9, lower head 10, external condenser 11, pre-mixer 12, and supporting fans, feed water pumps, gas valve groups, and controllers; the membrane water wall tube bundle 4 , water-cooled flame tube bundle 5, radiation tube bundle 6, high-temperature convection tube bundle 7, low-temperature convection tube bundle 8, and descending tube bundle 9 are all connected between the upper head 1 and the lower head 10; the membrane-type water-cooled wall tube bundle 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com