Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Cool flame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

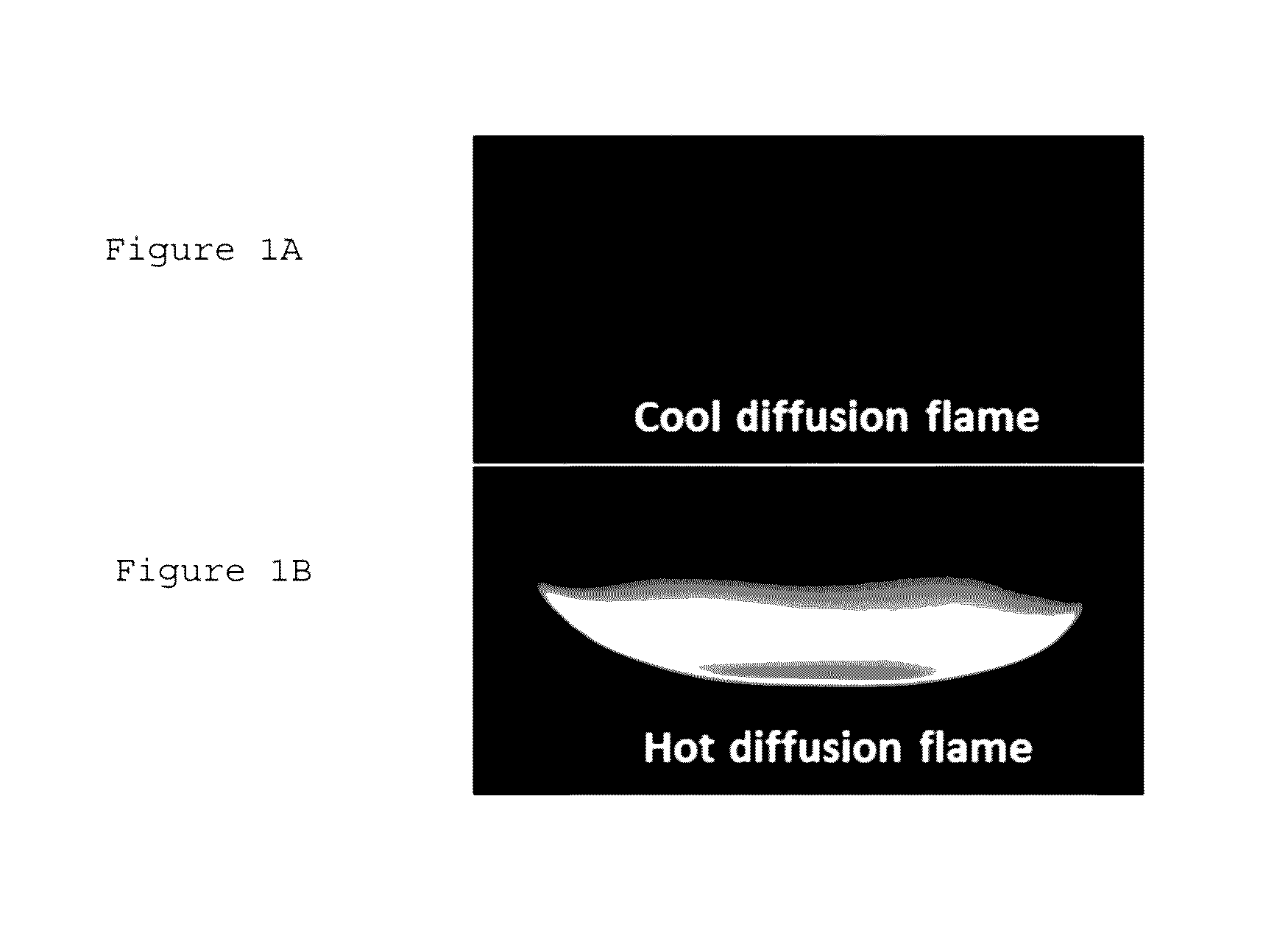

A cool flame is a flame having maximal temperature below about 400 °C (752 °F). It is usually produced in a chemical reaction of a certain fuel-air mixture. Contrary to conventional flame, the reaction is not vigorous and releases very little heat, light, and carbon dioxide. Cold fires are difficult to observe and are uncommon in everyday life, but they are responsible for engine knock – the undesirable, erratic, and noisy combustion of low-octane fuels in internal combustion engines.

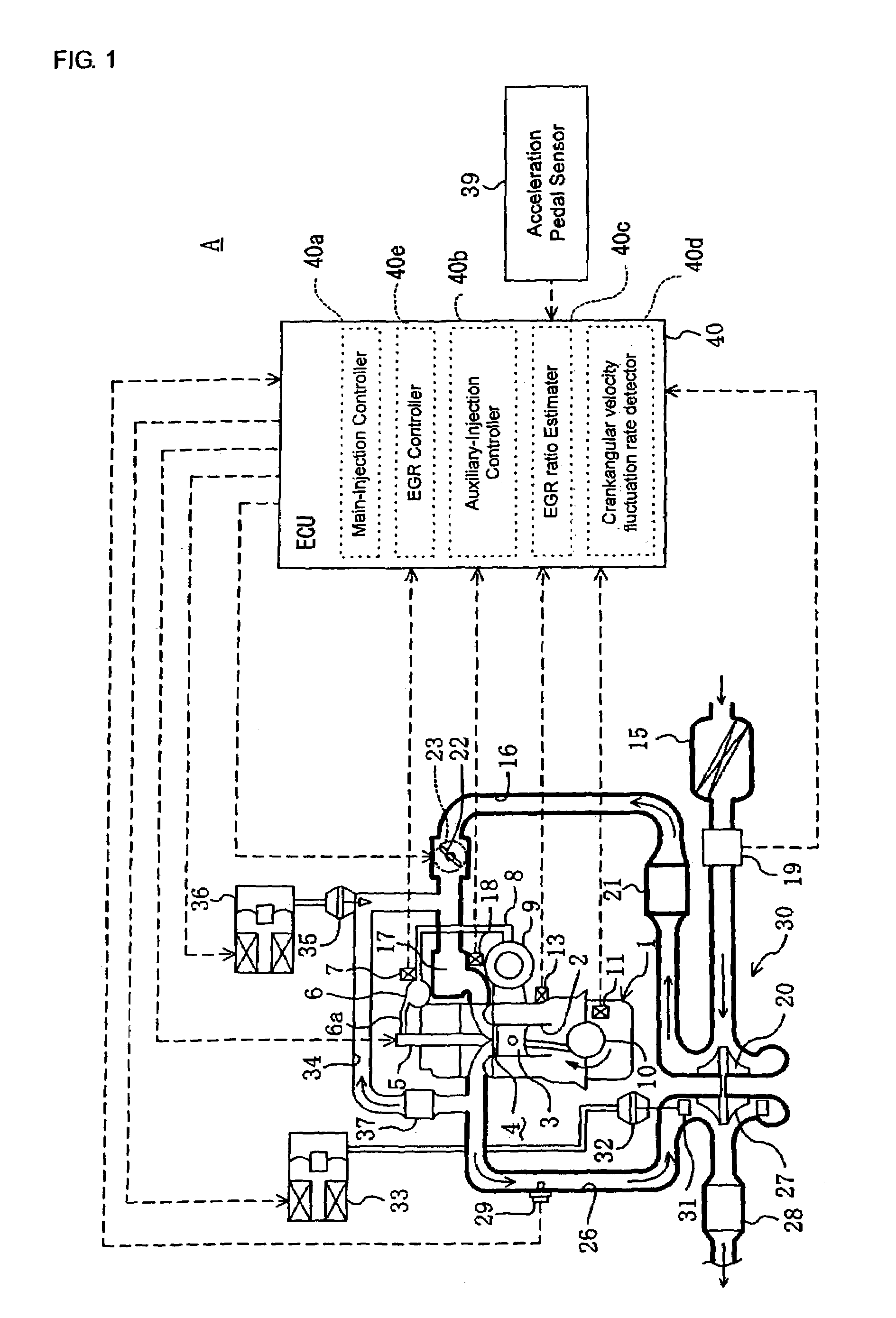

Combustion control apparatus for an engine

InactiveUS6964256B2Improve fuel efficiencyElectrical controlNon-fuel substance addition to fuelCombustion chamberLow load

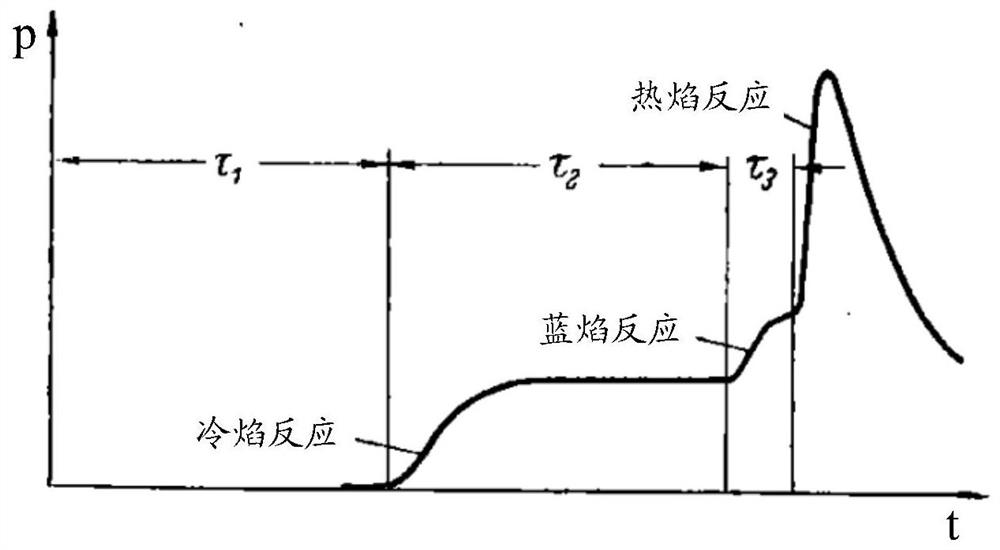

To optimize an ignition timing of premixture for improving fuel efficiency regardless of significant change in an EGR ratio or a fluctuation in temperature of recirculated exhaust gas and temperature in a combustion chamber, there is provided a control apparatus for a diesel engine which controls an injector extending into the combustion chamber to execute a main-injection for injecting fuel and increasing the EGR ratio, so as to attain the premixed compressive ignition combustion while the engine is in the premixed combustion region on the low load side. Just before or after a cool flame reaction occurs in the mixture formed by the main-injection, an auxiliary-injection is executed so that the latent heat of vaporization of the fuel decreases the temperature of the mixture to delay the ignition to a timing near TDC. The auxiliary-injection amount is adjusted according to the estimated value of EGR ratio or the change in the crank angular velocity to optimize the ignition timing of the mixture.

Owner:MAZDA MOTOR CORP

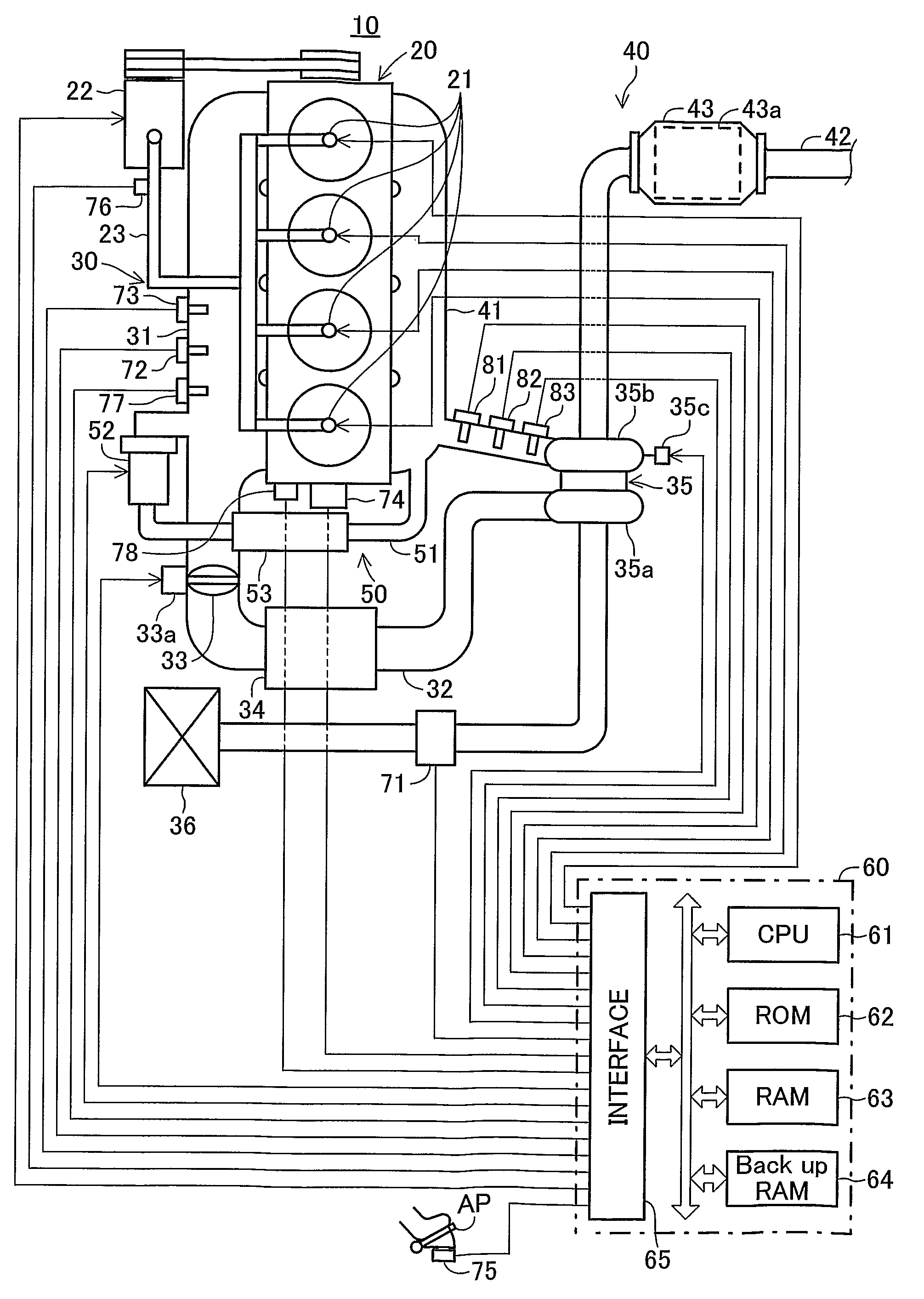

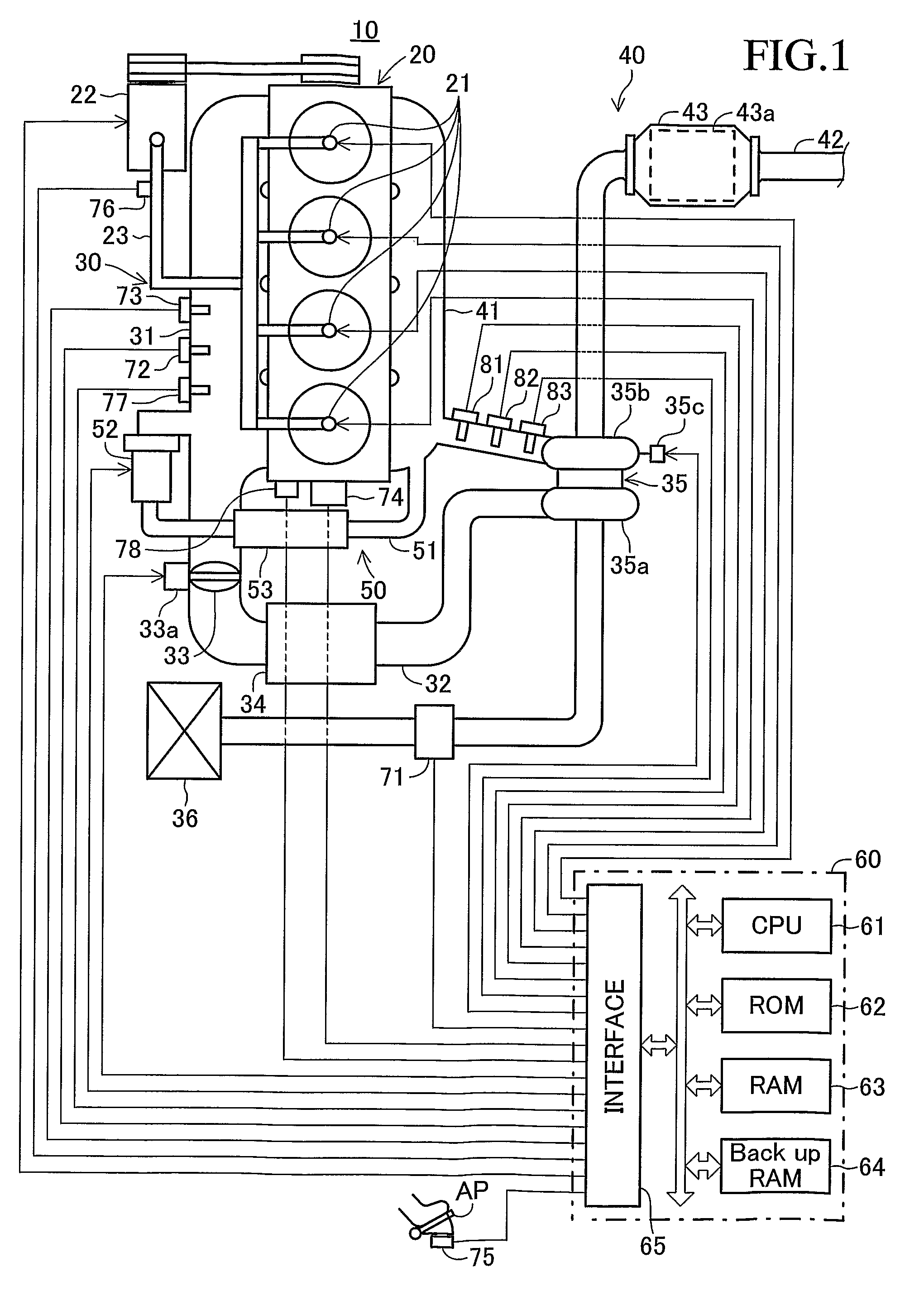

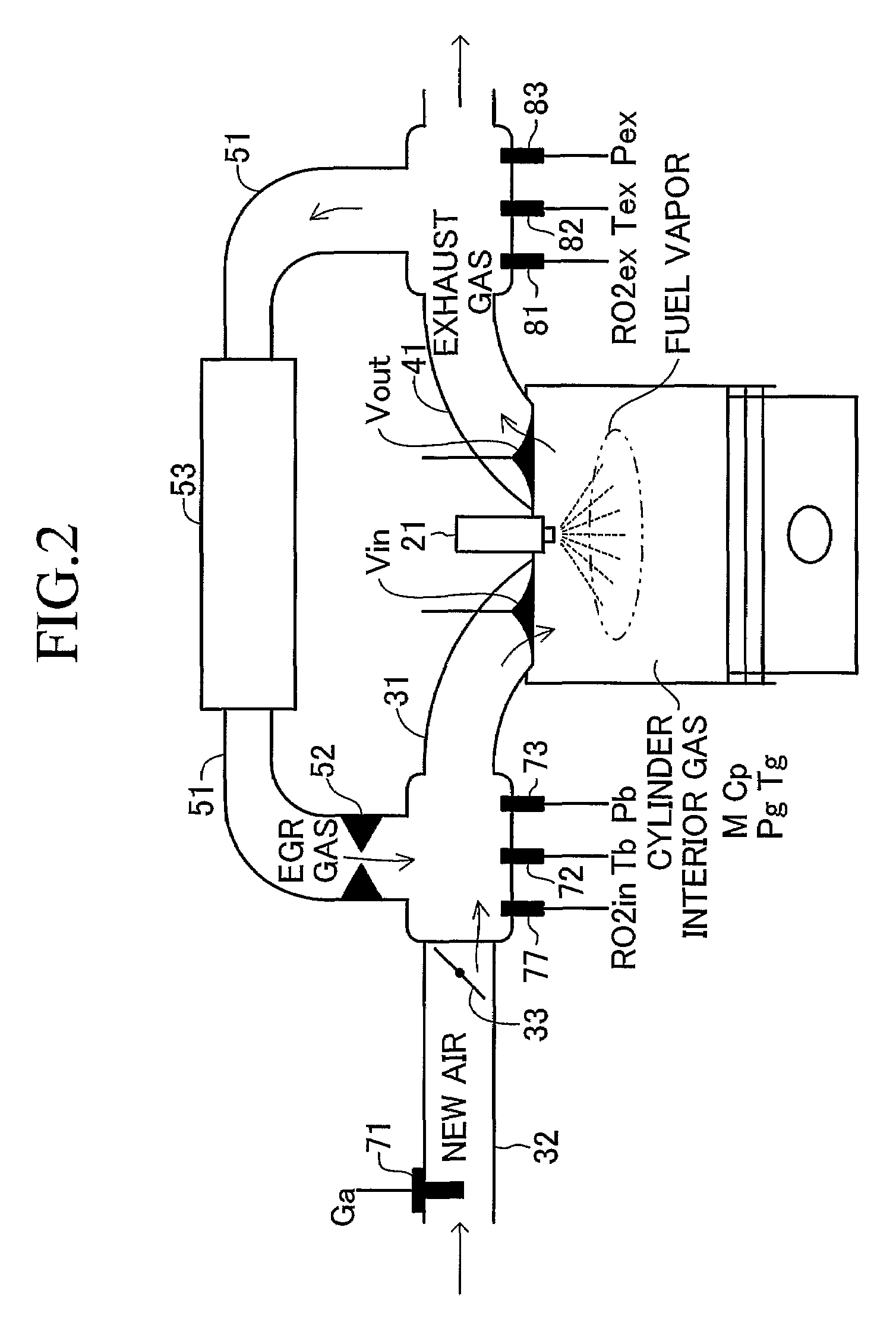

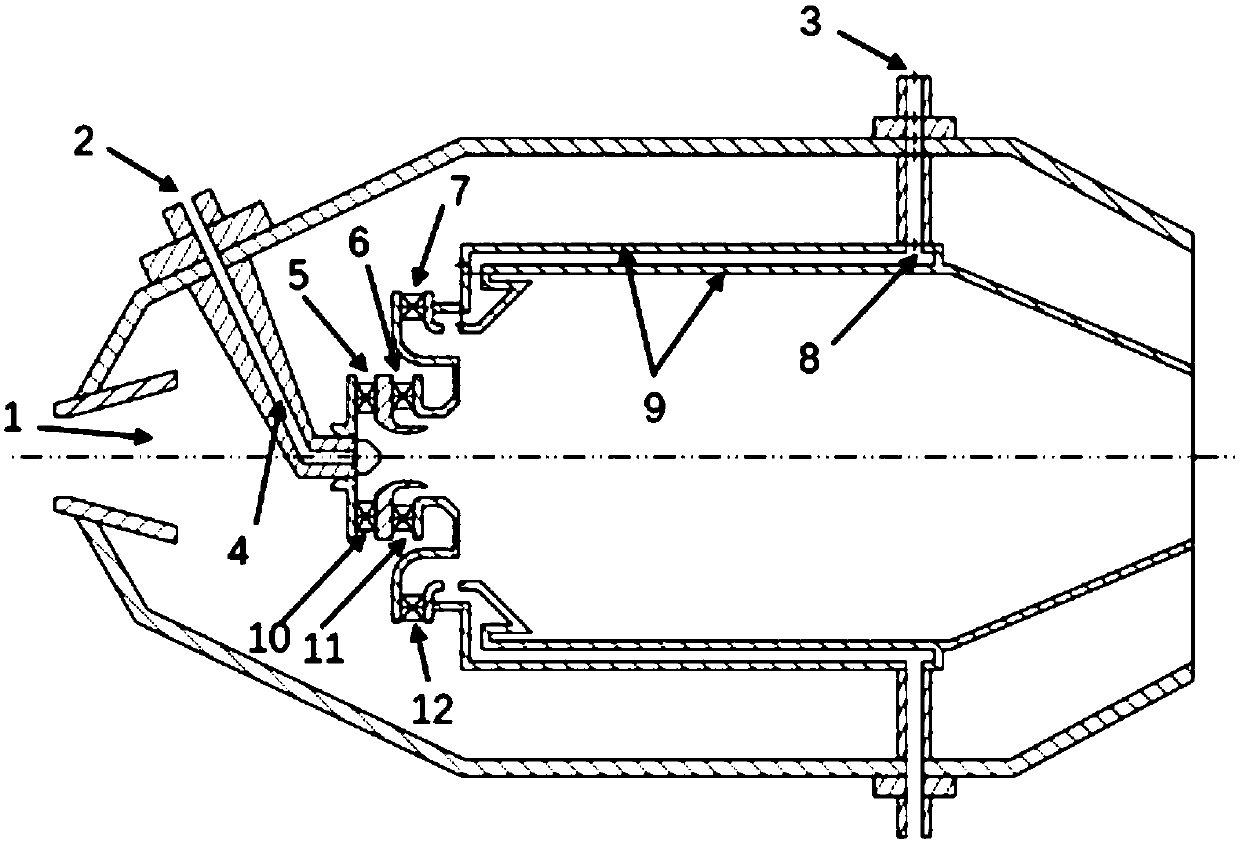

Gas-mixture-ignition-time estimation apparatus for internal combustion engine, and control apparatus for internal combustion engine

InactiveUS7337766B2Accurate estimateAnalogue computers for vehiclesElectrical controlStart timeExternal combustion engine

A gas-mixture-ignition-time estimation apparatus for an internal combustion engine estimates the temperature of a premixed gas mixture for PCCI combustion (i.e., cylinder interior temperature Tg), while relating it to the angle CA, on the basis of a state quantity of the cylinder interior gas at the time of start of compression (CAin) (heat energy of the cylinder interior gas at the time of start of compression), the amount of a change in the state quantity of the cylinder interior gas attributable to compression in a compression stroke (minute piston work), and the heat generation quantity of a cool flame generated in PCCI combustion prior to autoignition (hot flame) (cool flame heat generation quantity Aqlto). A time when the cylinder interior temperature Tg reaches a predetermined autoignition start temperature Tig is estimated as an autoignition start time (Caig) of the premixed gas mixture related to PCCI combustion. Since the cool flame heat generation quantity Oqlto is taken into consideration, the autoignition start time related to PCCI combustion can be estimated accurately.

Owner:TOYOTA JIDOSHA KK

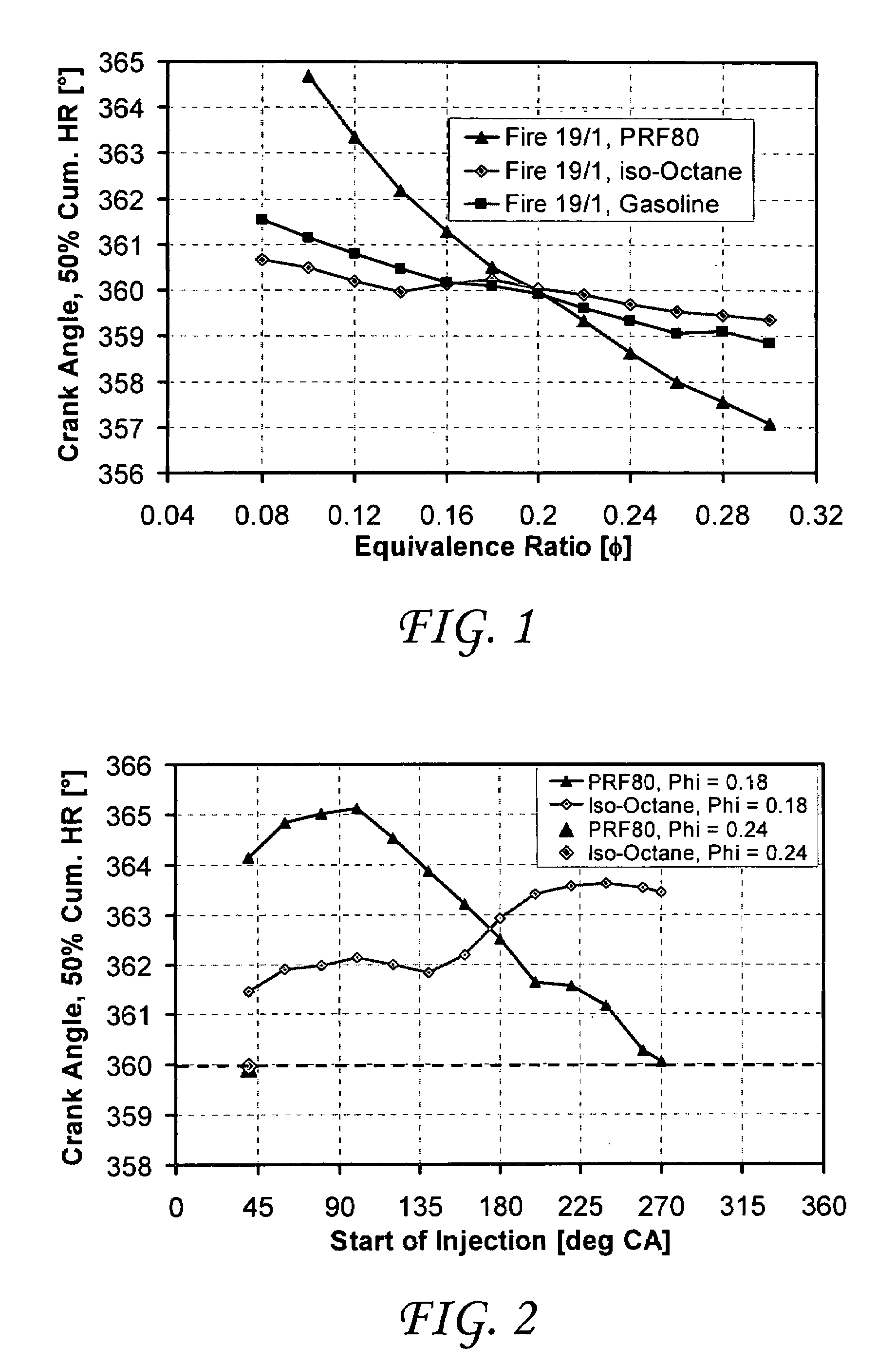

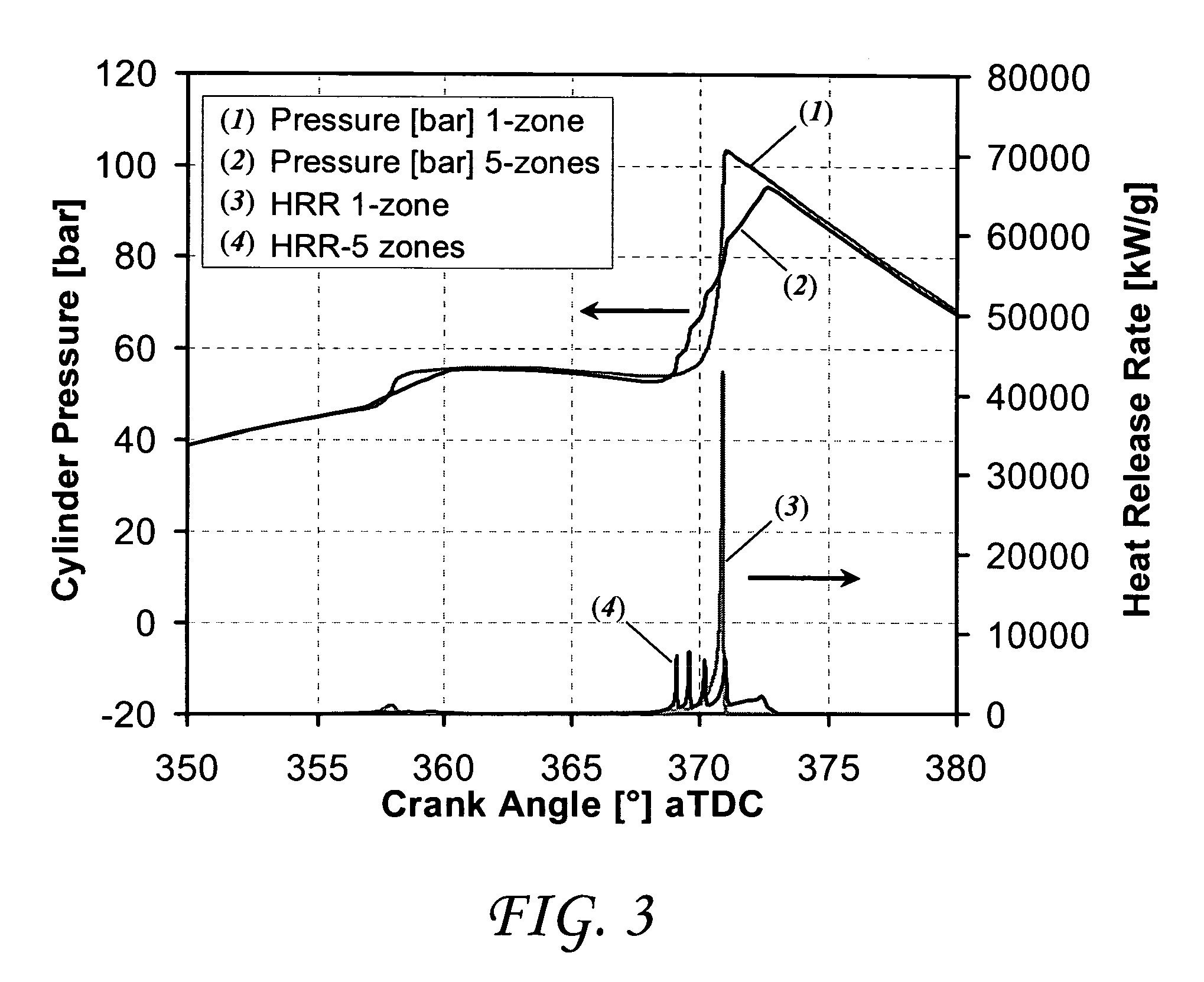

Fuel mixture stratification as a method for improving homogeneous charge compression ignition engine operation

ActiveUS7128046B1Improve efficiencyHigh engine loadInternal combustion piston enginesCool flameAutomotive engineering

A method for slowing the heat-release rate in homogeneous charge compression ignition (“HCCI”) engines that allows operation without excessive knock at higher engine loads than are possible with conventional HCCI. This method comprises injecting a fuel charge in a manner that creates a stratified fuel charge in the engine cylinder to provide a range of fuel concentrations in the in-cylinder gases (typically with enough oxygen for complete combustion) using a fuel with two-stage ignition fuel having appropriate cool-flame chemistry so that regions of different fuel concentrations autoignite sequentially.

Owner:SANDIA NAT LAB

Staged combustion device of with fuel oil cooling flame tube wall surface

PendingCN107763667AReduce dosageFast temperature riseContinuous combustion chamberIndirect carbon-dioxide mitigationCool flameFuel oil

The invention provides a staged combustion device with fuel oil cooling a flame tube wall surface. The staged combustion device with the fuel oil cooling the flame tube wall surface comprises a main combustion stage fuel inlet, a main combustion stage fuel channel, a flame tube circumferential side wall and a main combustion stage air channel. The main combustion stage fuel inlet is located on themiddle back portion of the outer wall of the staged combustion device. One end of the main combustion stage fuel channel communicates with the main combustion stage fuel inlet, and the other end of the main combustion stage fuel channel is adjacent to an outlet of the main combustion stage air channel. The flame tube circumferential side wall is a double-layered wall surface.

Owner:AERO ENGINE ACAD OF CHINA

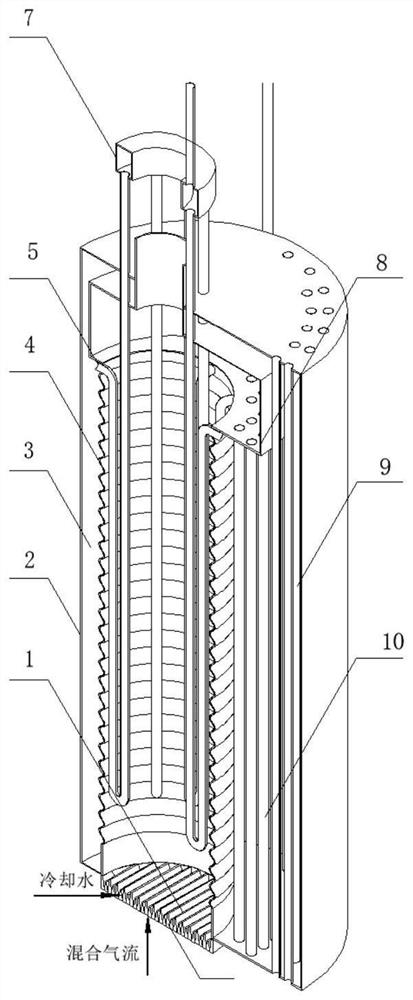

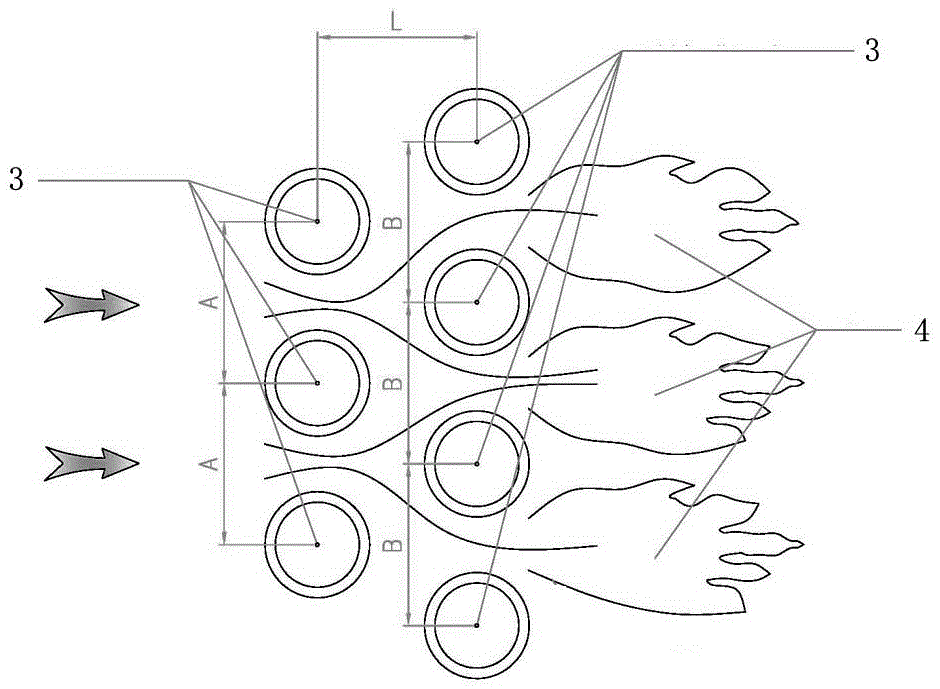

Low-emission cold flame multistage premixed combustor

ActiveCN106949471APre-mixed wellIndirect carbon-dioxide mitigationGaseous fuel burnerNitrogen oxidesFlue gas

The invention provides a low-emission cold flame multistage premixed combustor. The low-emission cold flame multistage premixed combustor comprises an ignition gun and a gas injection pipe. The gas injection pipe is provided with three gas injection outlets, and staged combustion is conducted through combustion areas. A premixed flame is injected at a high speed from the gas injection outlets and rapidly makes contact with a heat transfer pipe, the temperature of the flame is rapidly lowered, and the flame making contact with a refrigerant is reflected back to form a combustion gas curtain, so that combusted waste gas participates in secondary combustion and serves as flue gas to be recycled, and generation of nitrogen oxides is effectively reduced. Through a unique Venturi premixed structure, air and fuel are mixed more sufficiently. By means of the ignition gun which is high in adjusting ratio and wide in air excess coefficient range, the effect that the flame can be successfully built is ensured.

Owner:ANDERSON THERMAL SOLUTION SUZHOU CO LTD

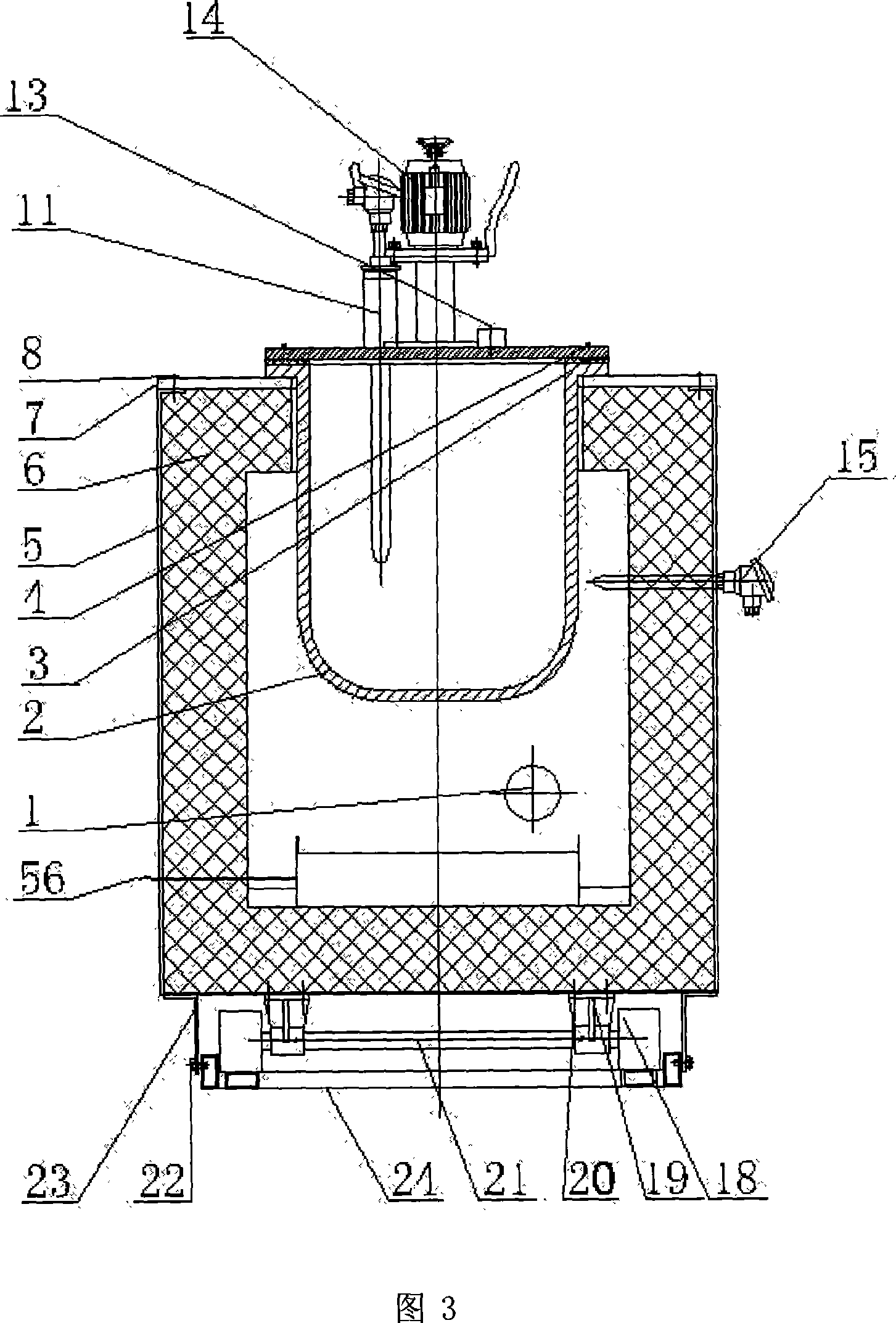

Gas type magnesium alloy quantitative melting heat insulation furnace

A heat insulation furnace of Mg alloy quantitative-melting in fuel gas type is prepared hanging crucible in shell of furnace through crucible hole set on furnace cover, setting material feeding hole and material mixing hole separately on cover of crucible and arranging material feeding device and material mixing device at two said hole accordingly, setting liquid leakage detector on internal wall of furnace shell and under crucible and erecting industrial cool flame nozzle separately on each of two side shell walls on furnace.

Owner:天津镁特威科技有限公司

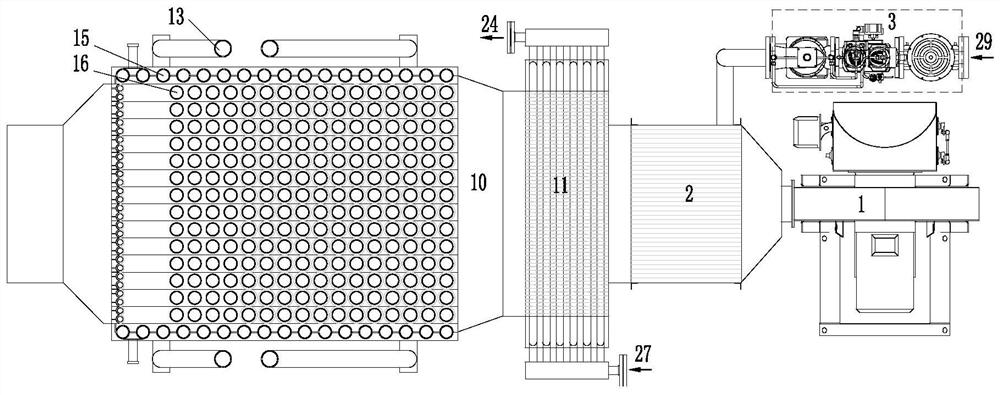

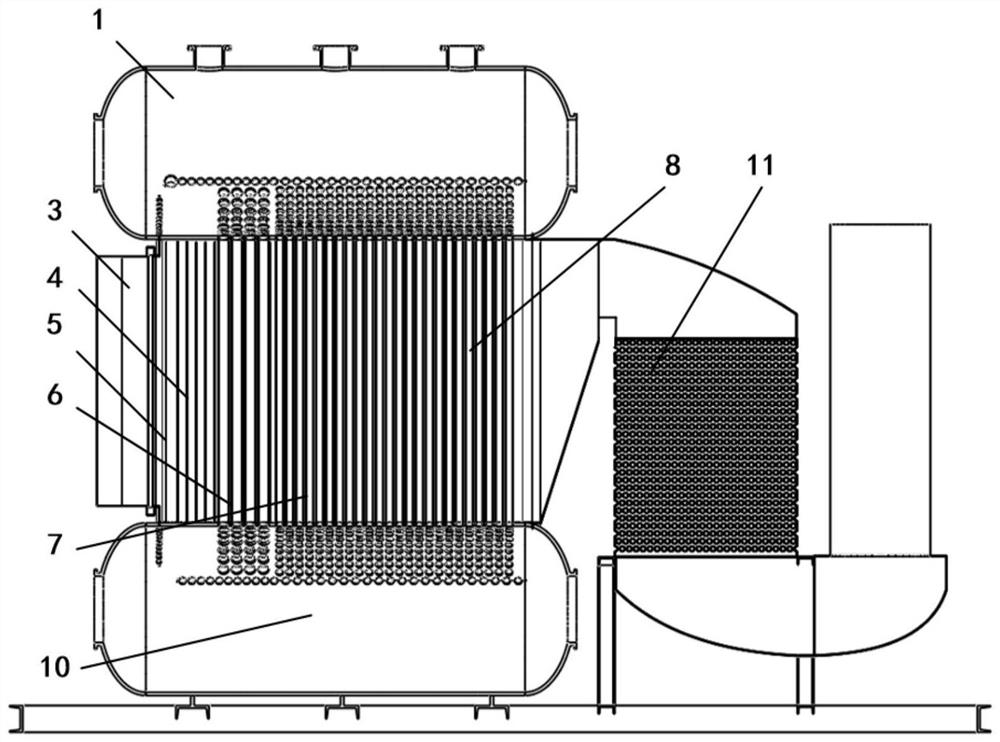

Cylindrical low-nitrogen energy-saving pressure-bearing water pipe boiler

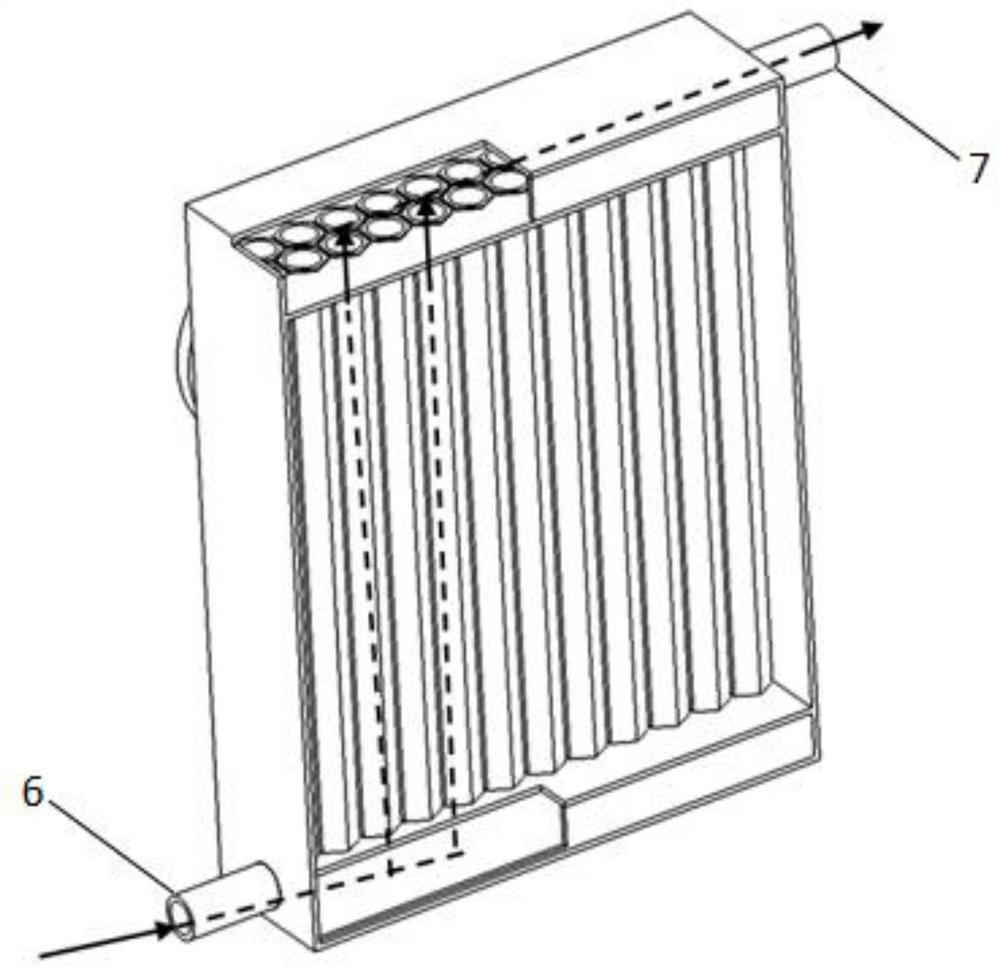

PendingCN111853747AReduce heat lossIncrease the average heat transfer coefficientWater-tube boilersThermodynamicsCombustor

The invention discloses a cylindrical low-nitrogen energy-saving pressure-bearing water pipe boiler which comprises an upper seal head, a shell, a burner distribution head, a water-cooled wall tube bundle, a water-cooled flame tube bundle, a radiation tube bundle, a high-temperature convection tube bundle, a low-temperature convection tube bundle, a descending tube bundle, a lower seal head, an external condenser, a pre-mixer and a matched fan, a water supply pump, a gas valve group, a controller and the like. A burner achieves side face gas feeding, and densely-arranged pipes, a metal pore plate, a ceramic pore plate and the like are adopted for preventing fire return and stabilizing flame. The burner is detachable, thereby facilitating maintenance and repair. The water-cooled flame tubebundle of the burner distribution head is arranged in a plane or convex shape, so that the space of a hearth is utilized to be maximum; and the water-cooled flame tube bundle on a boiler body is adopted to cool the flame, so that the heat distribution problem of the water-cooled burner is solved. Machine-boiler integration of plane and curved surface burners is achieved, the structure is compact,low-nitrogen and ultra-low-nitrogen combustion are achieved at lower excess air coefficients, and the technical monopoly of foreign low-nitrogen burner manufacturers in the field of steam boilers is broken through.

Owner:BRIGHT THERMAL EQUIP CO LTD

Hearth and combustor cooling type surface cold flame premixing gas boiler

The invention discloses a hearth and combustor cooling type surface cold flame premixing gas boiler. The boiler comprises a hearth, a water cooling combustor is installed at the position of an inlet of the hearth, an outlet of the hearth is connected to a reversal chamber, U-shaped water cooling components are evenly arranged in the hearth in the circumferential direction, inlets of the U-shaped water cooling components are evenly connected to an annular pipeline in the circumferential direction, and water outlets of the U-shaped water-cooling components and a water outlet of the water coolingcombustor are connected to a boiler water tank. According to the hearth and combustor cooling type surface cold flame premixing gas boiler, by the adoption of the water cooling combustor, uniform gascombustion can be achieved, the flame root combustion temperature is reduced while a local high-temperature area is not generated, generation of thermal NOx at the flame root is reduced, and meanwhile, a hearth cooling system is adopted, a U-shaped pipeline cooling structure is arranged, the compact structure and manufacturing economy of the boiler are achieved while the uniform low-temperature atmosphere in the boiler is guaranteed, and generation of the NOx during gas fuel combustion is further remarkably reduced.

Owner:XI AN JIAOTONG UNIV

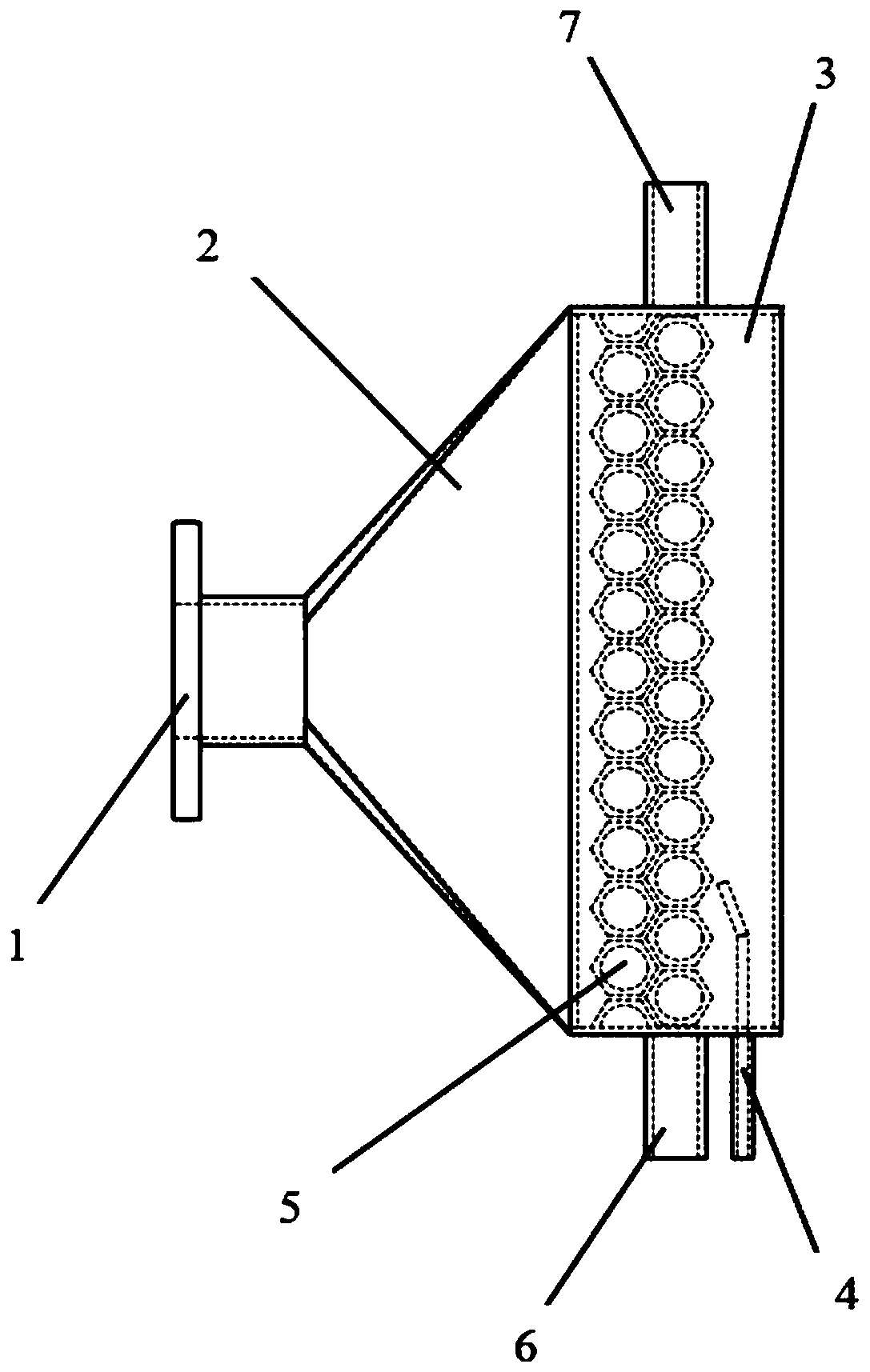

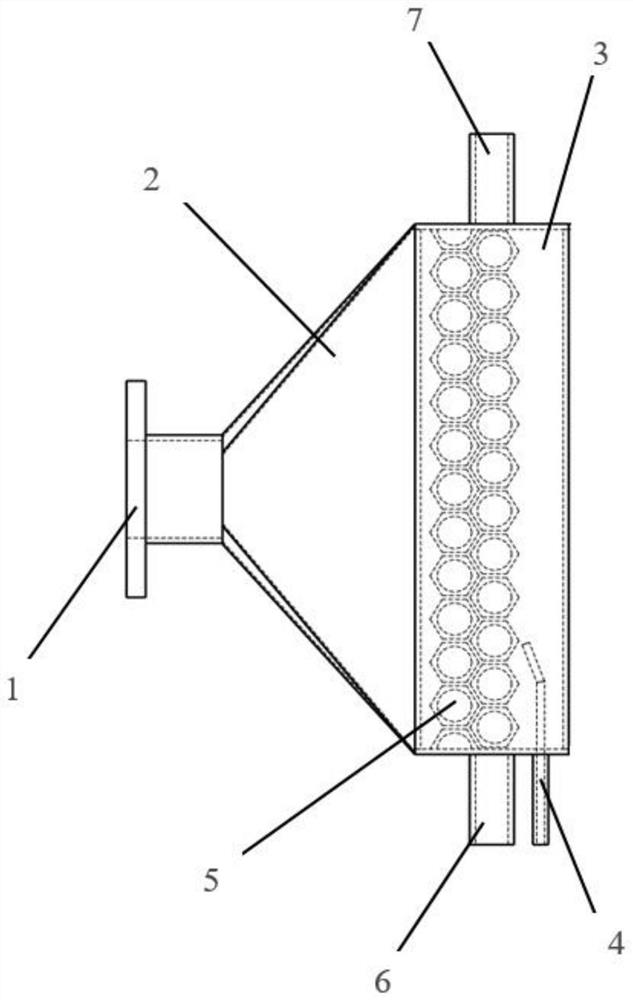

Cooling flame low nitrogen combustion device and combustion method thereof

ActiveCN110360558AAvoid concentrationBurning flame area increasesGaseous fuel burnerCombustion chamberNitrogen oxides

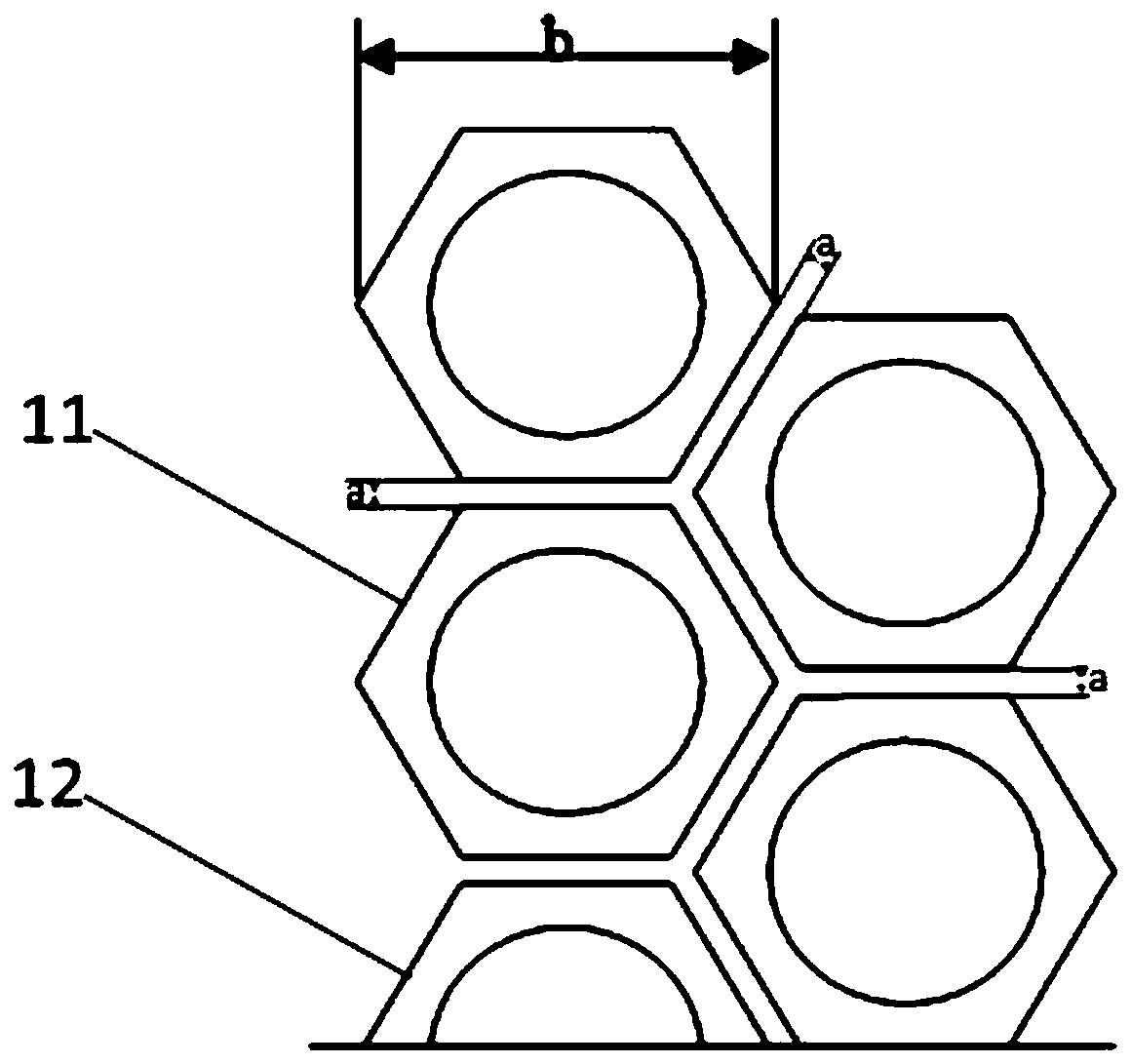

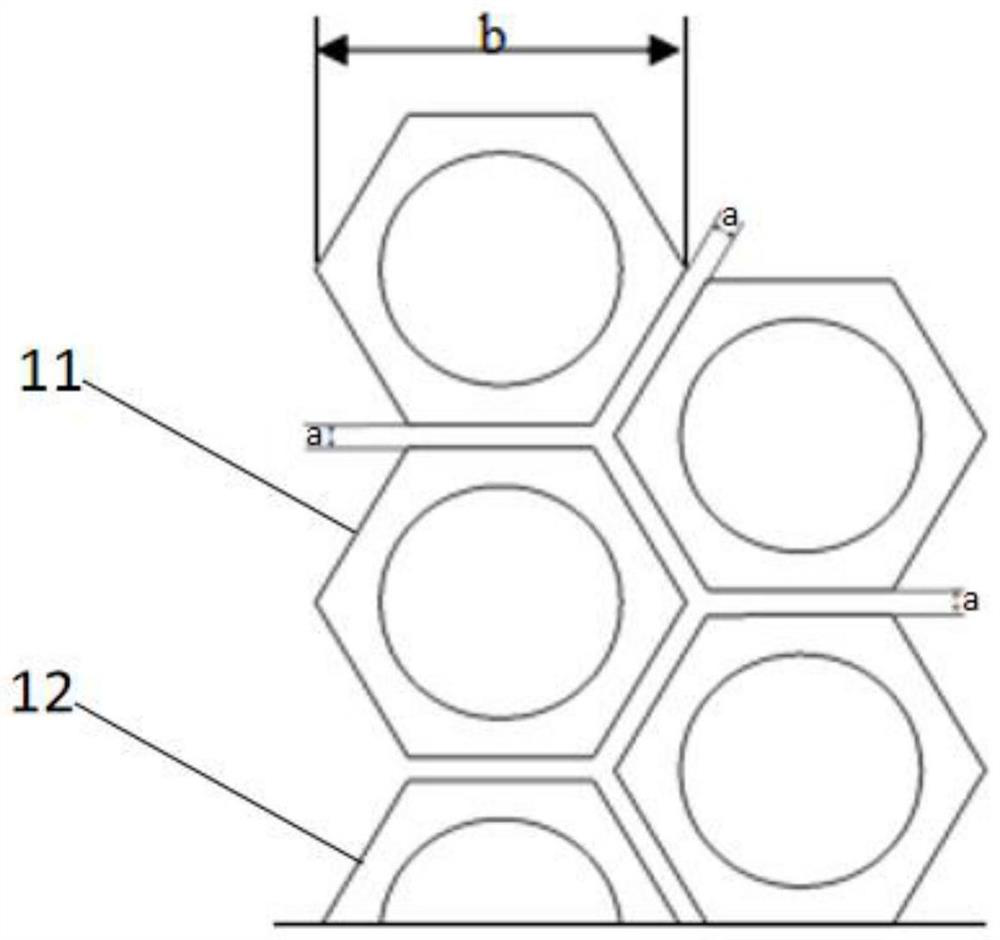

The invention relates to a cooling flame low nitrogen combustion device. The device comprises a premixed gas inlet and a combustion chamber, wherein a first heat exchange tube assembly and an igniterin the flow direction of premixed gas are successively arranged in the combustion chamber; the first heat exchange tube assembly is composed of a plurality of outer hexagonal tubes arranged in parallel, and gaps are formed between the adjacent outer hexagonal tubes to allow the premixed gas to pass through; and the position of the igniter opposite to the first heat exchange tube assembly is set insuch a way that the igniter can directly ignite the premixed gas passing through the gaps. Cooling fluid circulates in the outer hexagonal tubes, and the temperature of a flame is reduced duo to thecold wall effect of the cooling fluid, so that the formation of nitrogen oxides is inhibited; and at the same time, when the flame propagation speed is greater than the air flow speed, and the flame returns into the gaps between the outer hexagonal tubes, the energy of the flame becomes smaller and smaller under the cooling effect of the cooling fluid until the flame goes out in the gaps, so thatthe explosion caused by the tempering phenomenon is avoided.

Owner:江苏泷涛环境技术有限公司

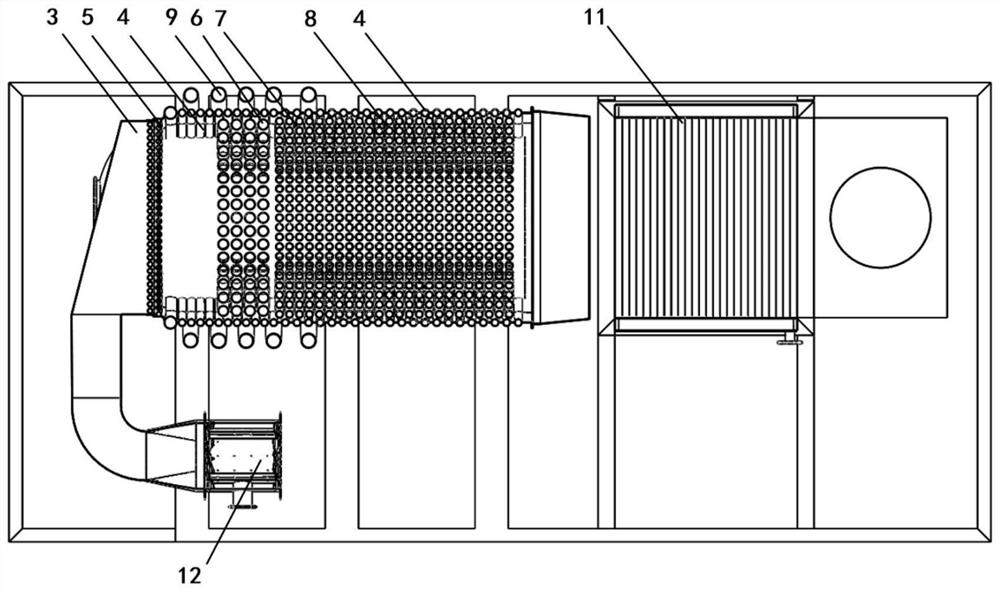

Ultra-low-nitrogen combustion equipment with post-premixing cold flame combustion coupling matrix tube mode wall structure

ActiveCN112815312AGuaranteed stabilityReduce the temperatureGaseous fuel burnerCombustion chamberAir volume

The invention relates to ultra-low-nitrogen combustion equipment with a post-premixing cold flame combustion coupling matrix tube mode wall structure. The ultra-low-nitrogen combustion equipment comprises a fuel gas regulation and control device, an air volume regulation and control device, an air-gas mixing device, a cold flame combustion device, a matrix tube and mode wall device and a comprehensive controller. The fuel gas regulation and control device provides fuel gas for the air-gas mixing device; the air volume regulation and control device provides combustion-supporting air for the air-gas mixing device; the air-gas mixing device conducts jet flow mixing on combustible gas provided by the fuel gas regulation and control device and the combustion-supporting air provided by the air volume regulation and control device, and the combustible gas and the combustion-supporting air are evenly mixed through the air-gas mixing device and then injected into the cold flame combustion device; the mixed gas sequentially passes through a double-layer rectifying plate, a hexagonal heat pipe type cooling fire-retardant tube nest and a flame cooling tube nest in the cold flame combustion device and then enters a combustion chamber for combustion; and after combustion, high-temperature flue gas is subjected to radiation and convective heat exchange in the combustion chamber, then exchanges heat with a medium in the matrix tube and mode wall device and then is discharged into a flue.

Owner:BEIJING BOOSTER BOILER

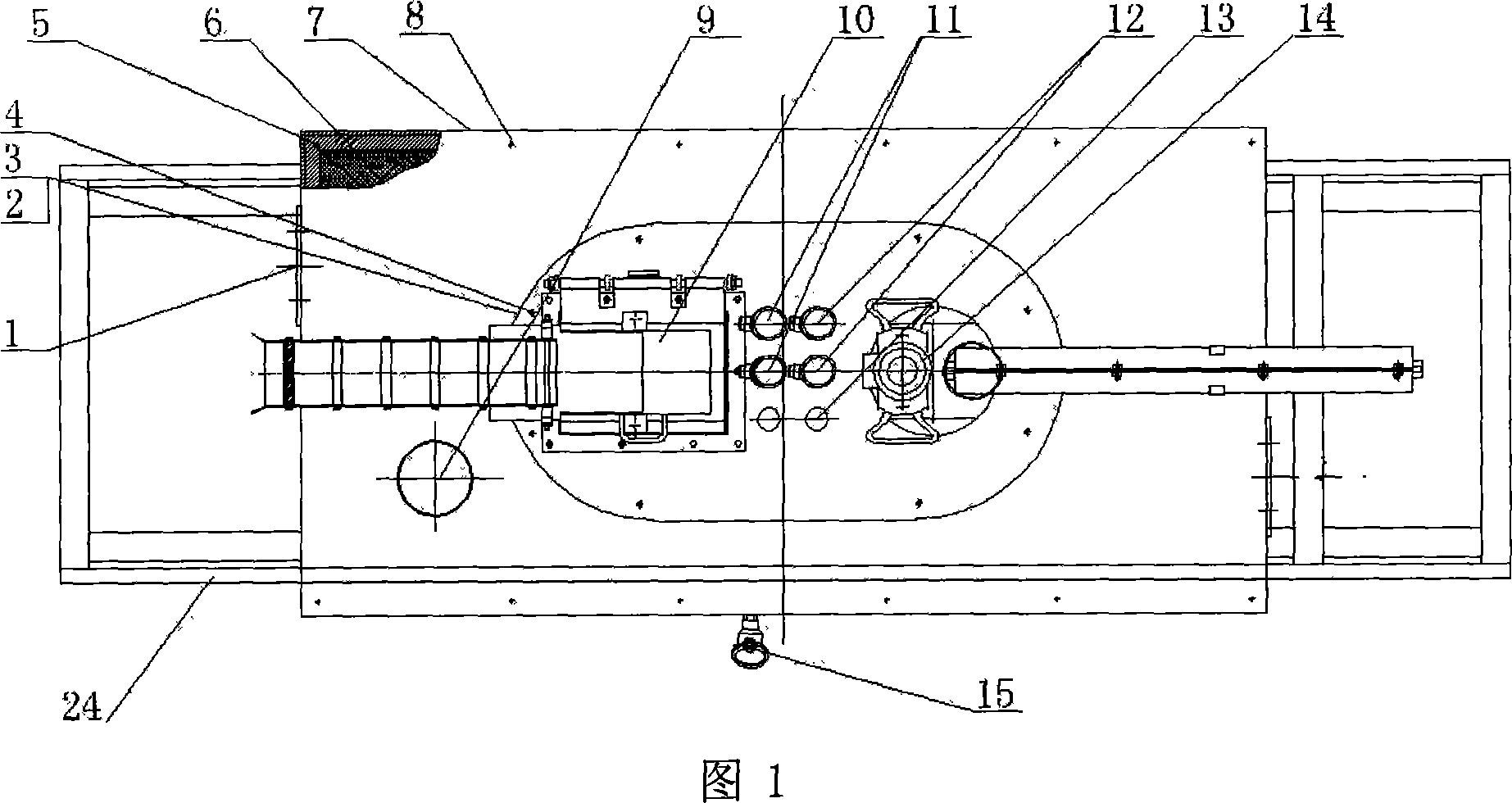

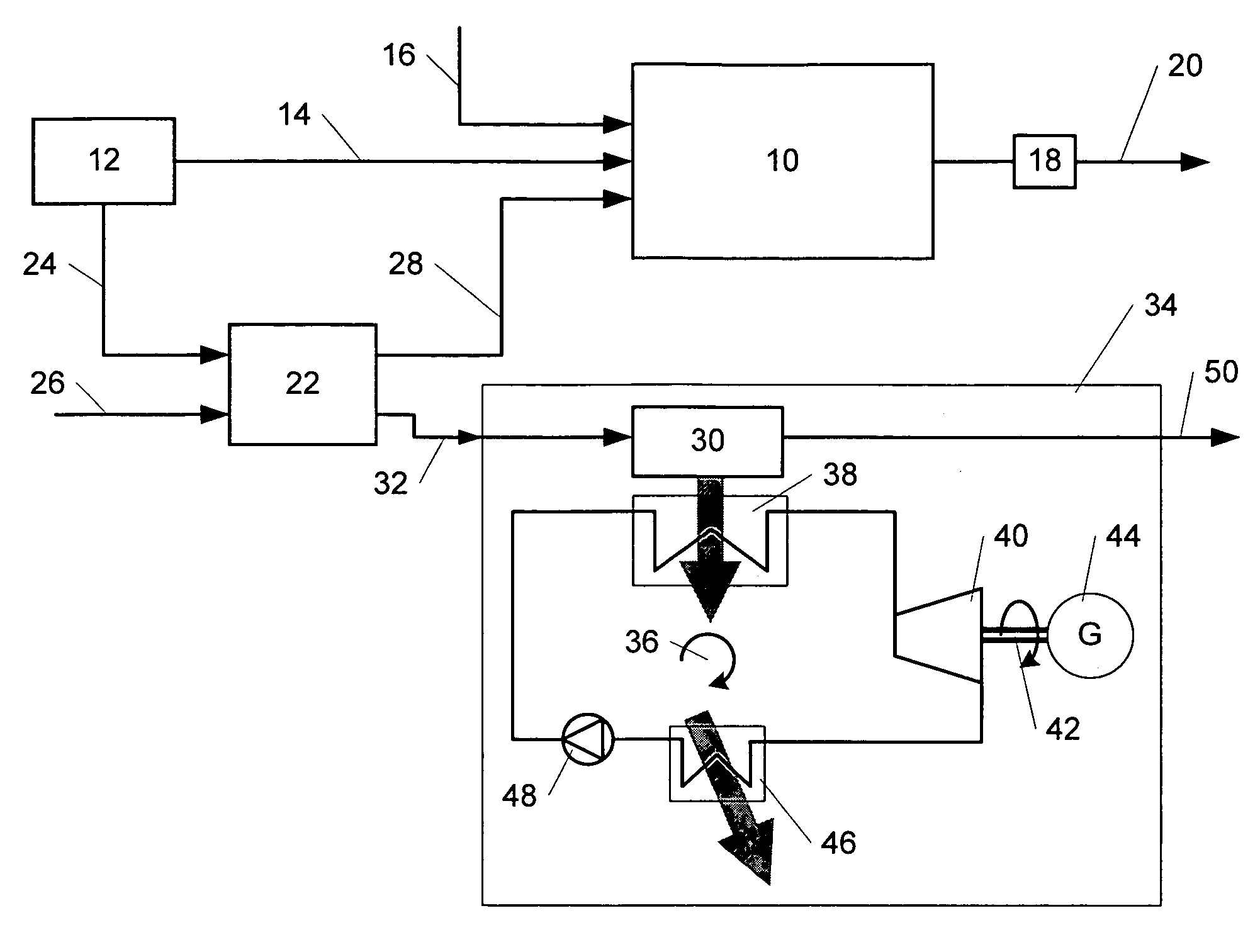

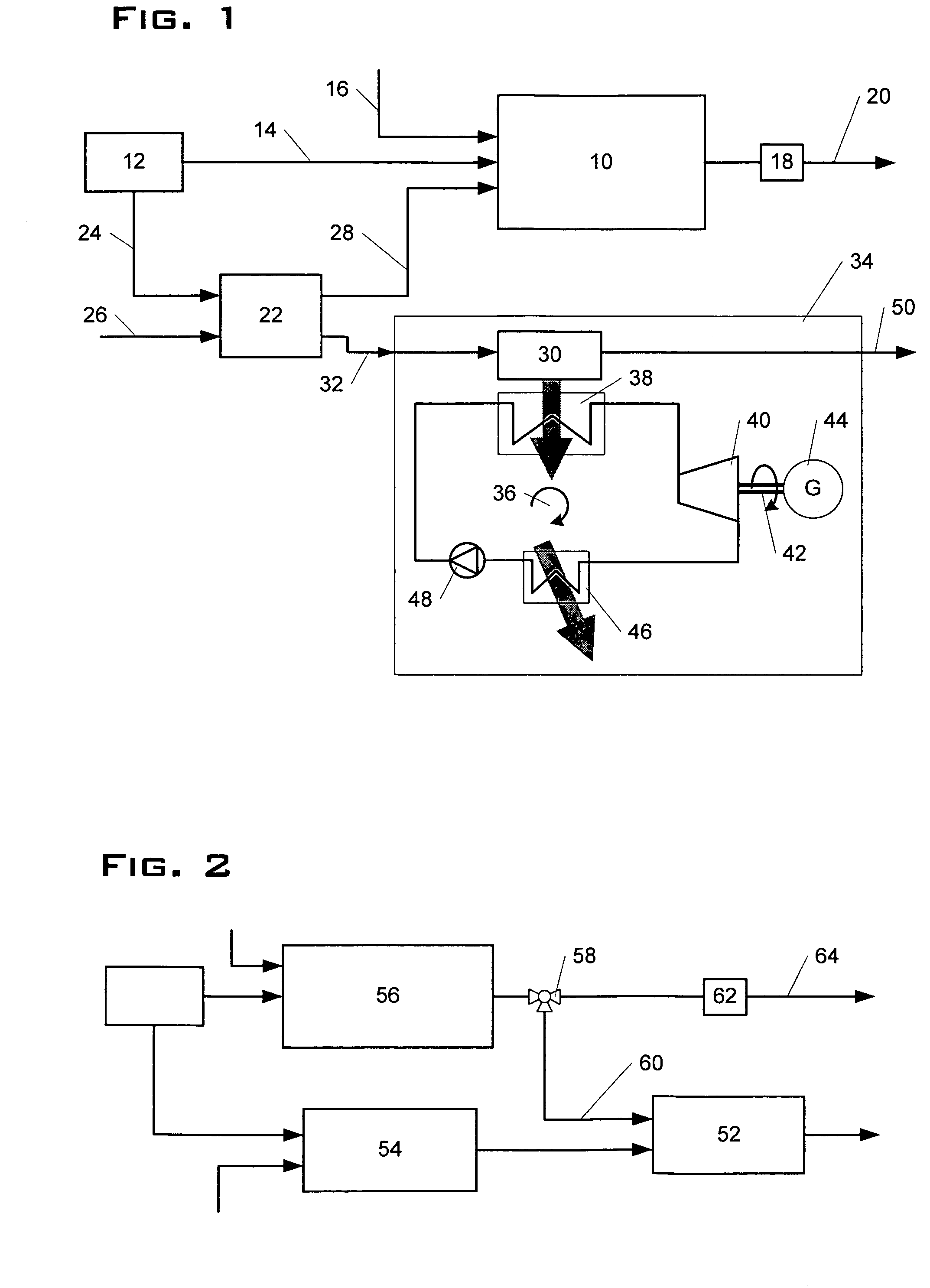

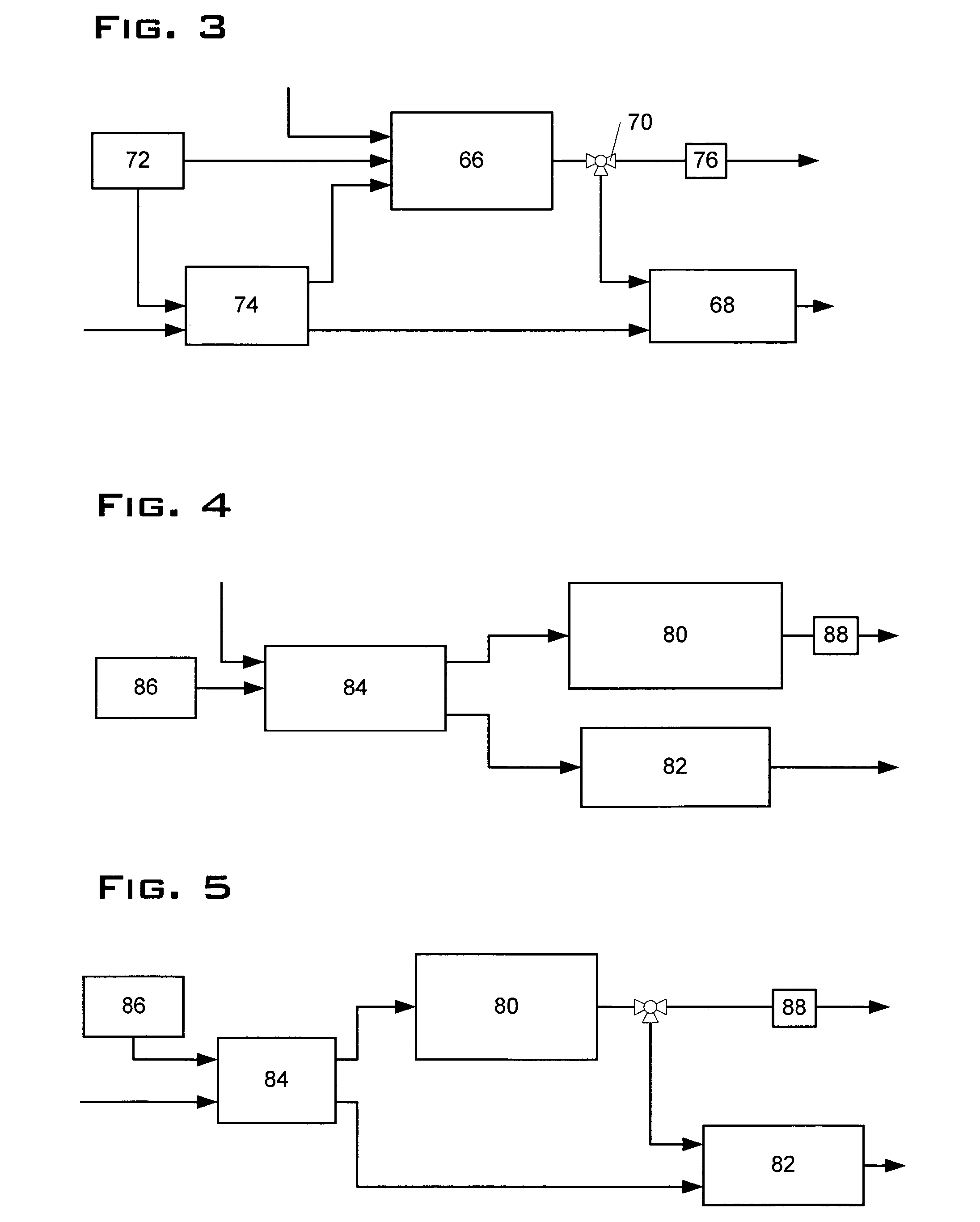

Engine system and method for substantially NOx-free combustion of a fuel in a compression ignition engine

InactiveCN101849088AInternal combustion piston enginesExhaust apparatusCombustion chamberPartial oxidation

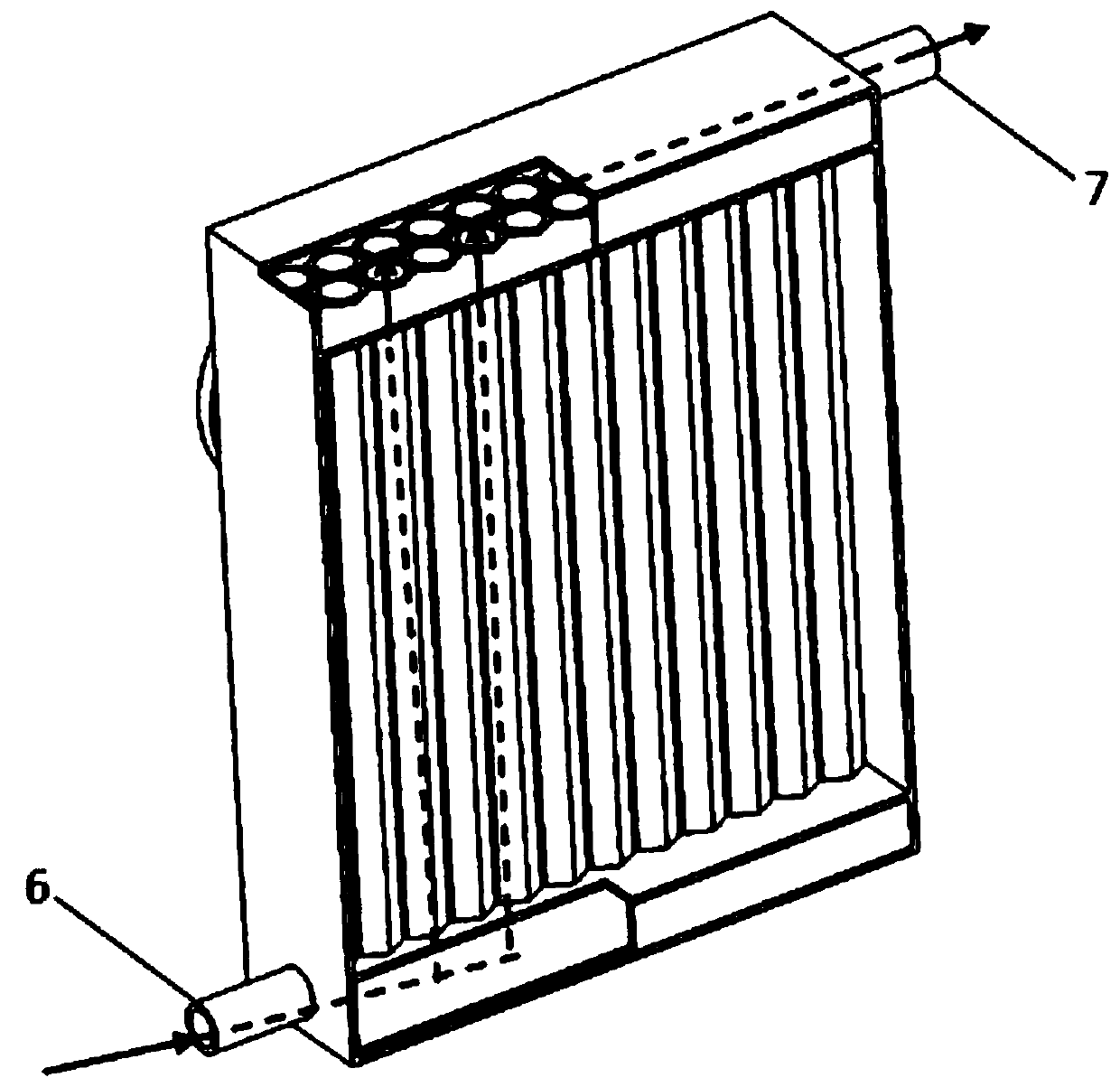

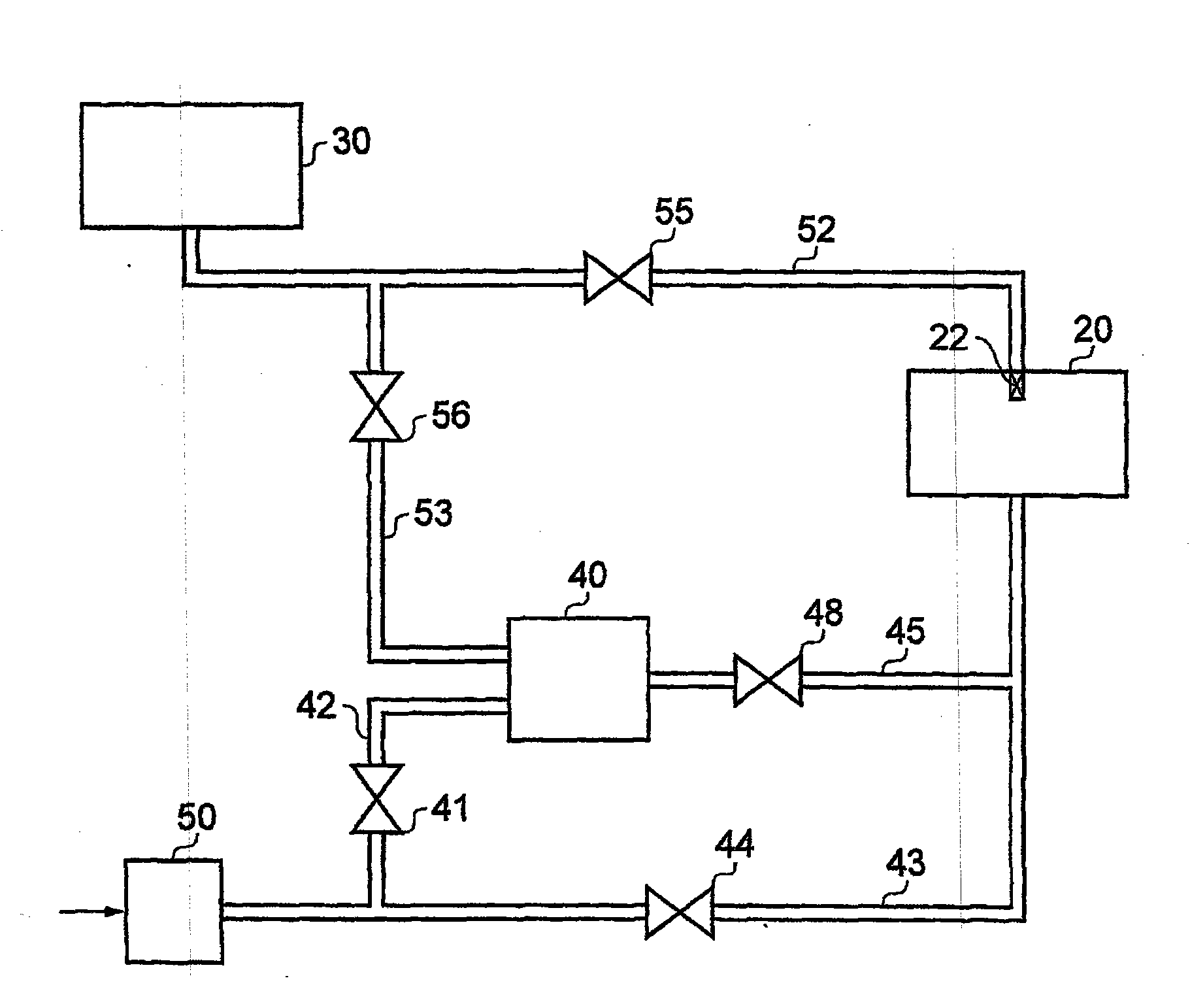

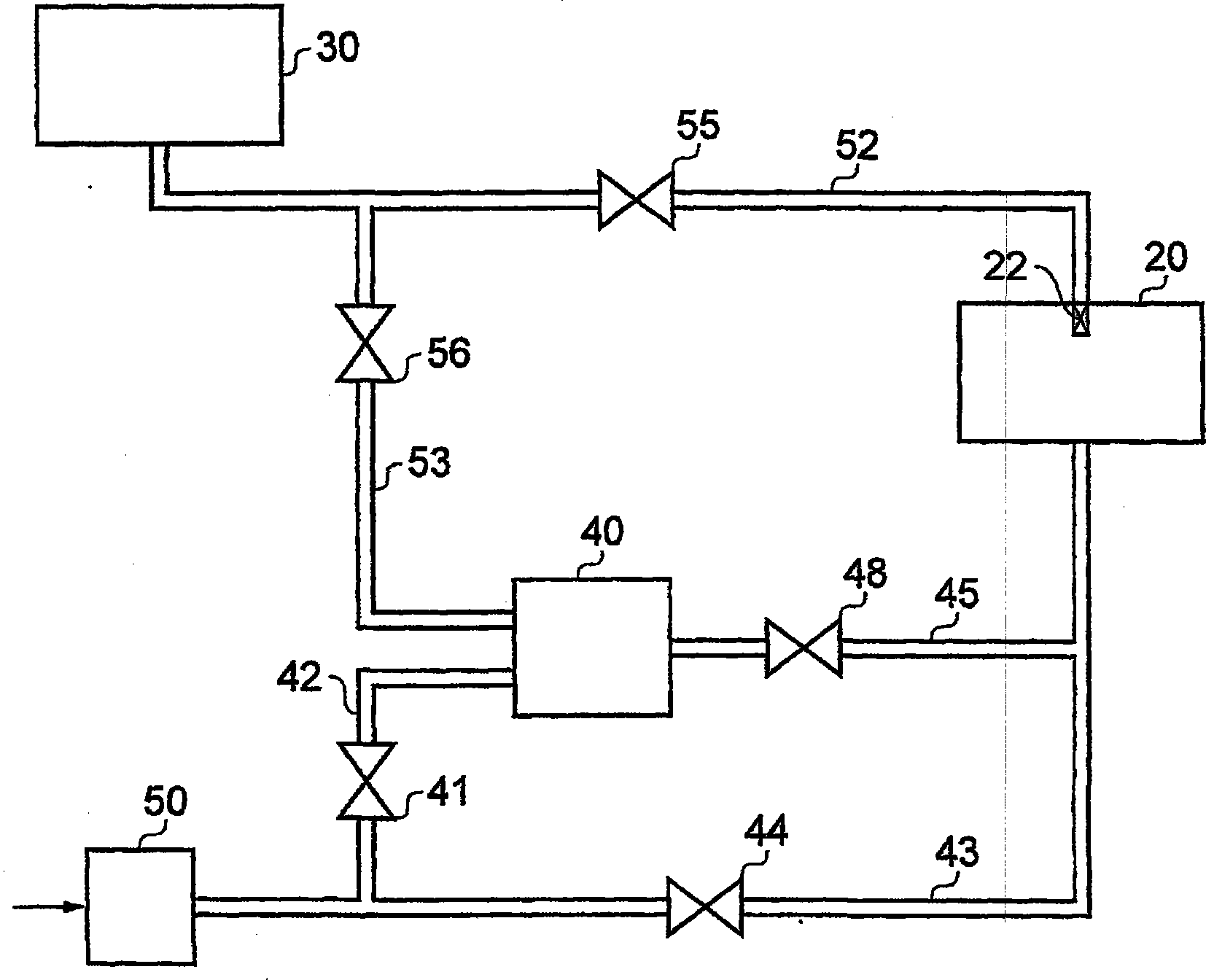

Engine system comprising a compression ignition engine (20) including at least one combustion chamber and a cold flame vaporizer (40) in which a fuel is partially oxidized in preheated air to form a cold flame gas. The cold flame vaporizer (40) is in fluid communication with the combustion chamber of the compression ignition engine (20). There is further provided means (50) for supplying air such that the cold flame gas can be mixed with the additional air before being injected into the combustion chamber, and means (22) for injecting a pilot fuel into the combustion chamber, thereby producing a pilot flame in the combustion chamber which ignites the mixture of cold flame gas and air. There is also provided a method for a substantially NOx-free combustion of diesel fuel in a compression ignition engine (20).

Owner:COOL FLAME TECH AS

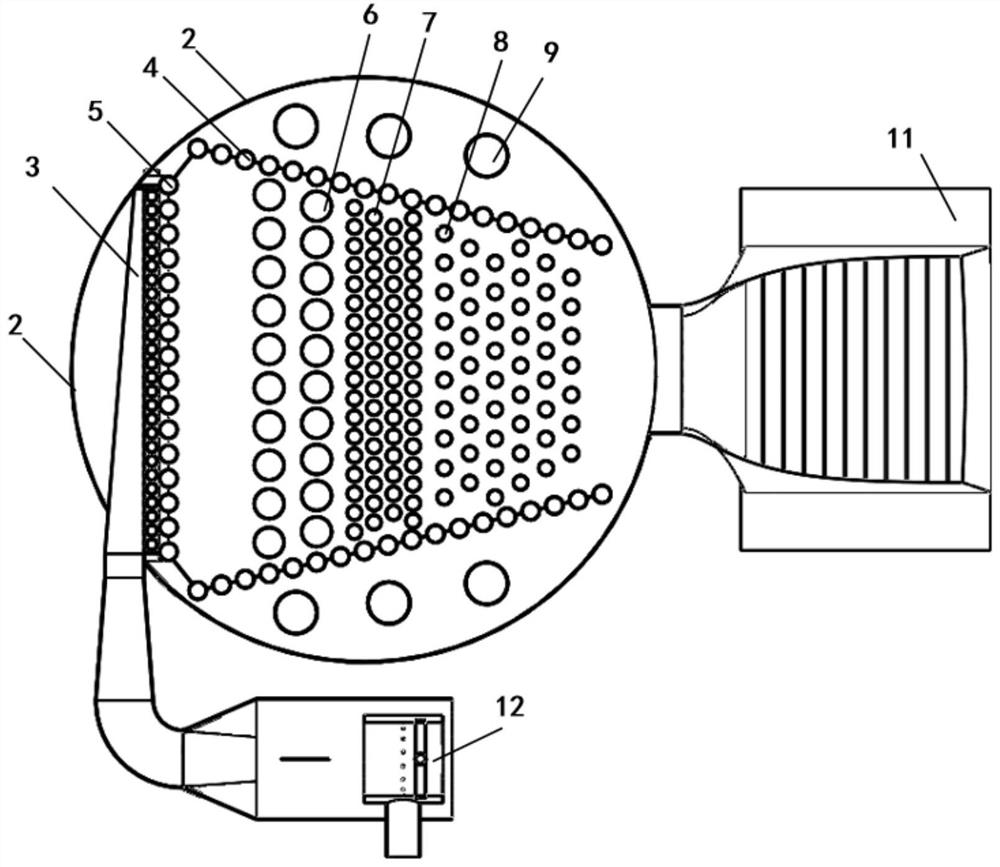

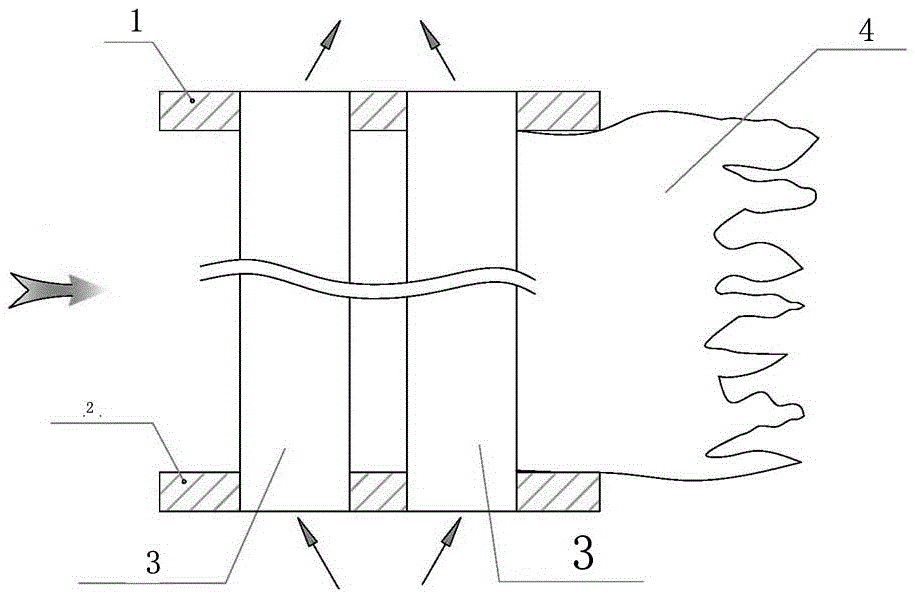

Cooling flame frontal surface device capable of inhibiting generation of NOx in hearth of gas-fired boiler

The invention discloses a cooling flame frontal surface device capable of inhibiting generation of NOx in a hearth of a gas-fired boiler. The device mainly comprises an upper pipe plate and a lower pipe plate, and two sets of cooling water pipes mounted between the upper pipe plate and the lower pipe plate and used for passing through cooling water; the two sets of cooling water pipes are adjacently arranged in front and back two rows in a flame combustion direction; the cooling water pipes in two rows are arranged in a staggered manner; gas flame in the hearth of the boiler is horizontal; the front and back two rows of cooling water pipes are arranged front and back in a direction perpendicular to the horizontal flame; the cooling water flowing direction of the cooling water pipes is from bottom to top; and the flow and speed control of the flowing cooling water uses the flame frontal surface temperature of 1450-1550 DEG C as standard. The device has such characteristics as simple and compact structure, convenience for use and control, capability of effectively inhibiting generation of NOx, improvement of combustion efficiency and amelioration of combustion conditions.

Owner:LIJU THERMAL EQUIP TECH

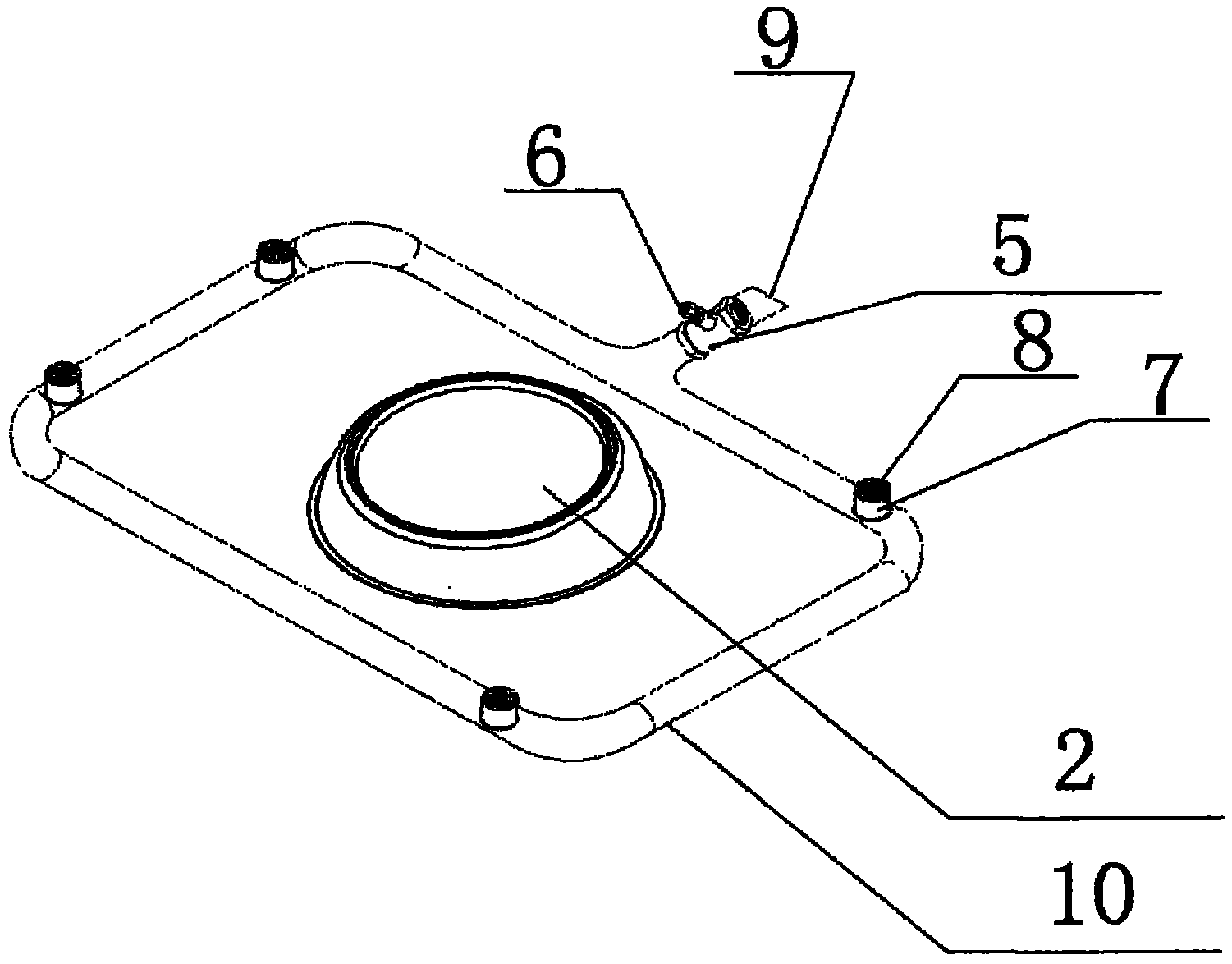

Annular surface cold flame ultralow-nitrogen combustor

The invention discloses an annular surface cold flame ultralow-nitrogen combustor. The annular surface cold flame ultralow-nitrogen combustor comprises a mixed gas cylinder body for inputting air andgas, a water outlet pipe, a water inlet pipe, a water inlet tank, a water outlet tank, an outer water pipe and an inner water pipe; a mixer is connected with the mixed gas cylinder body; the mixed gascylinder body is connected with a water outlet porous plate of the water outlet tank; the water inlet pipe penetrates through the mixed gas cylinder body to communicate with a water inlet porous plate of the water inlet tank; the water outlet pipe communicates with the water outlet tank; two ends of the outer water pipe and the inner water pipe correspondingly communicate with the water inlet porous plate and the water outlet porous plate; and a plurality of porous plates sleeve the internal water pipe. The annular surface cold flame ultralow-nitrogen combustor can effectively reduce the NOxemission, can replace and transform a traditional combustor and a premixing combustor, can preferably match with a boiler through changing the diameter and the length of a combustion surface of the combustor according to the power of the boiler and the space size of a combustion chamber, and realizes stable, uniform and complete combustion of flame on the combustion surface.

Owner:欧保(中国)环境工程股份有限公司

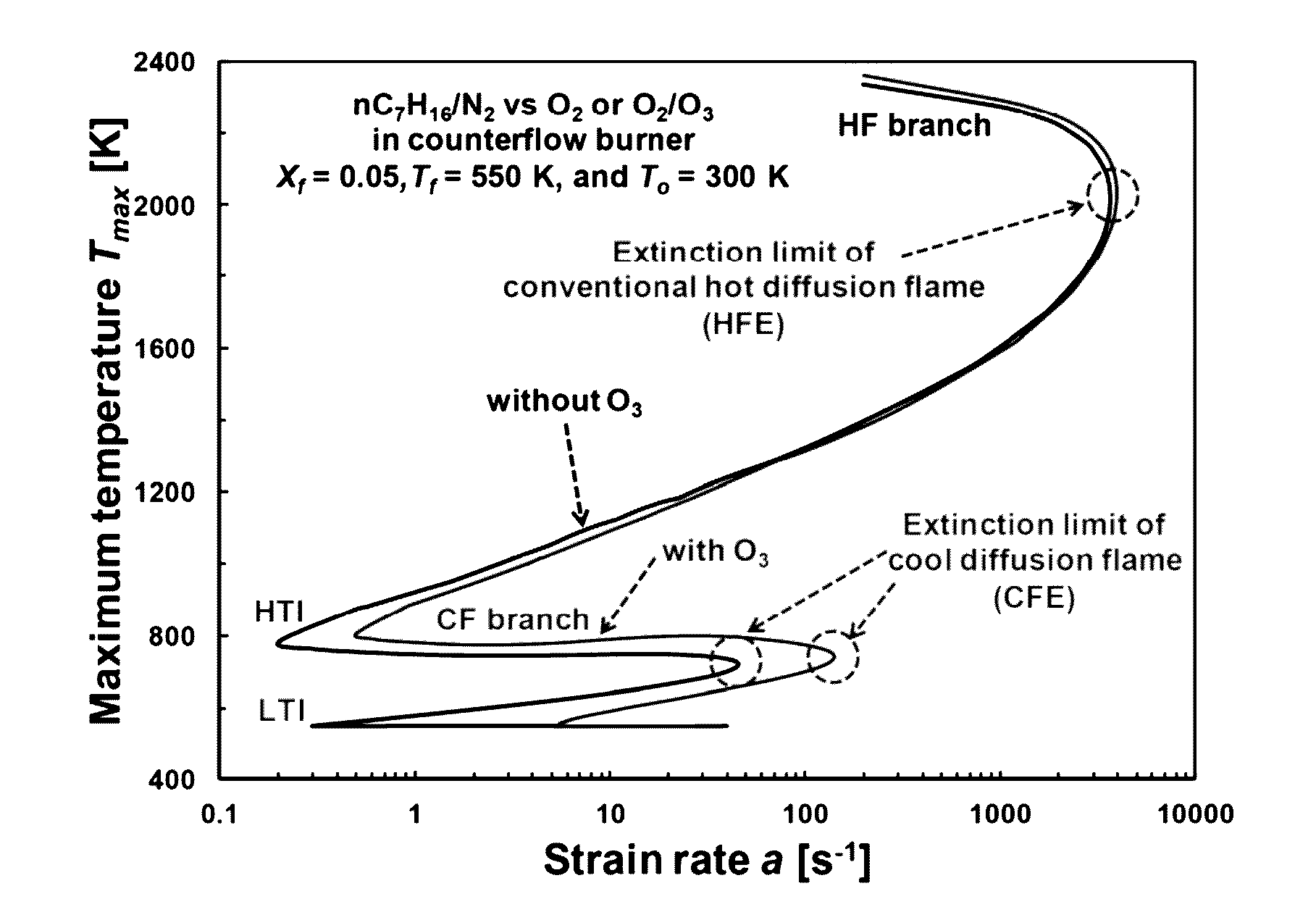

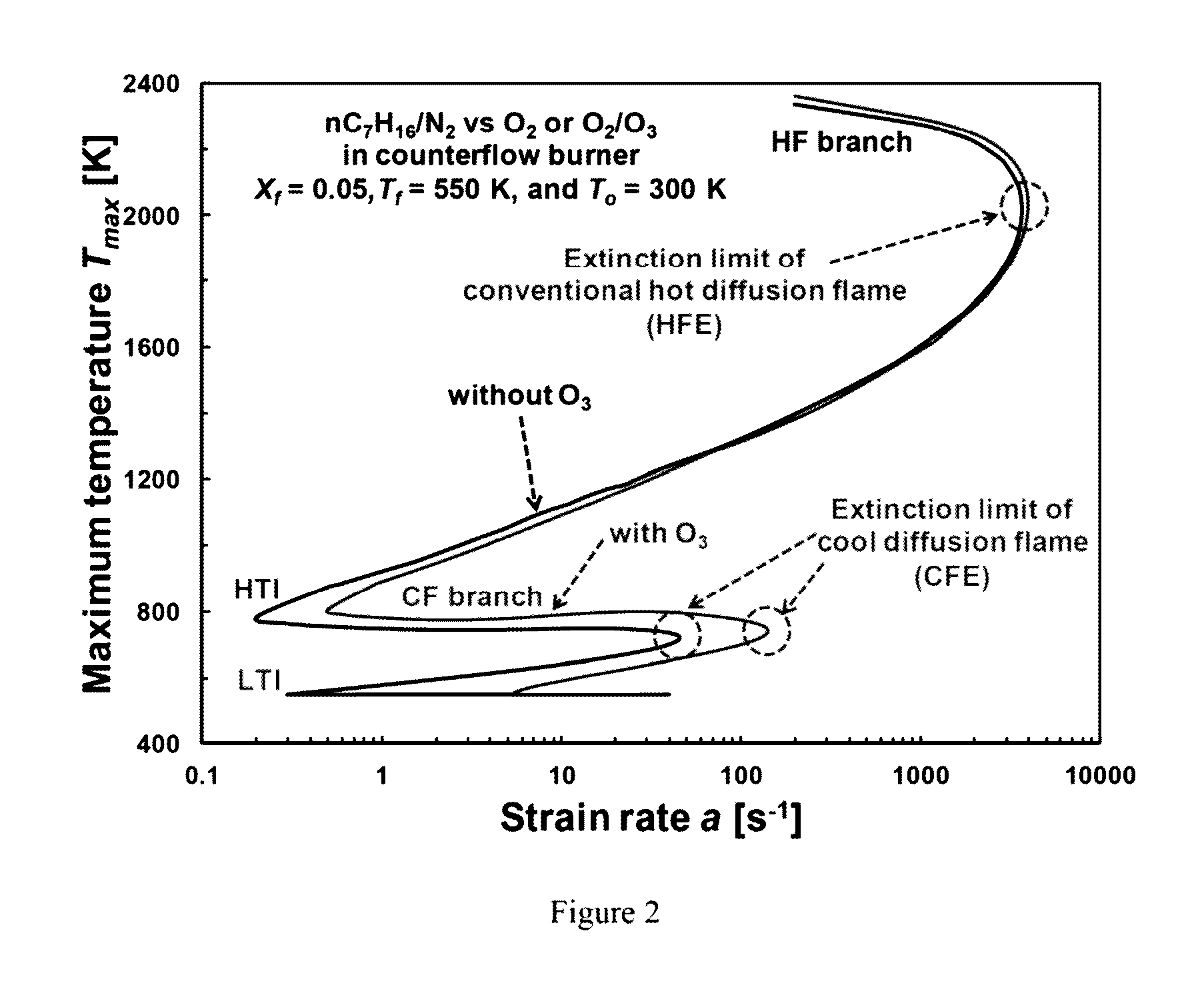

Process for generating cool frame and flameless fuel oxidation using non-equilibrium plasma activation

An exemplary embodiment can be an exemplary method, which can include, for example, generating a cool flame(s) using a plasma-assisted combustion, and maintaining the cool flame(s). The cool flame(s) can have a temperature below about 1050 Kelvin, which can be about 700 Kelvin. The cool flame(s) can be further generated using a heated counterflow burning arrangement and a an ozone generating arrangement. The heated counterflow burning arrangement can include a liquid fuel vaporization arrangement. The ozone generating arrangement can include a micro plasma dielectric barrier discharge arrangement. The plasma-assisted combustion can be generated using (i) liquid n-heptane, (i) heated nitrogen, and (iii) ozone.

Owner:THE TRUSTEES FOR PRINCETON UNIV

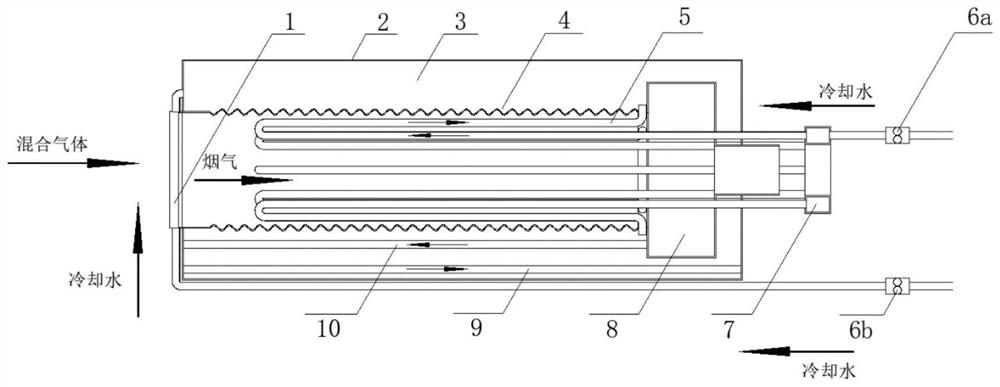

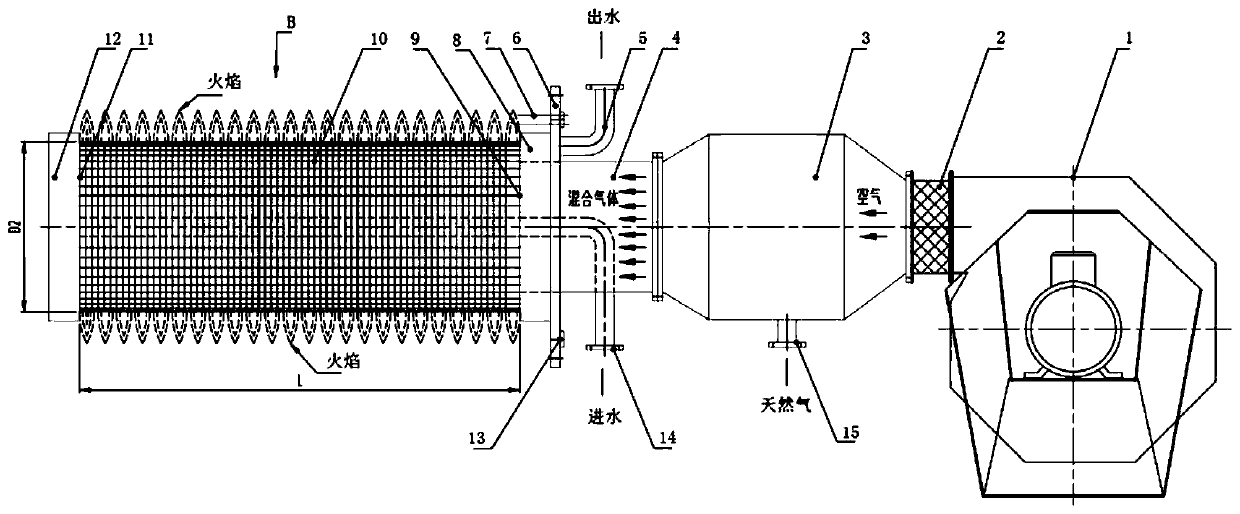

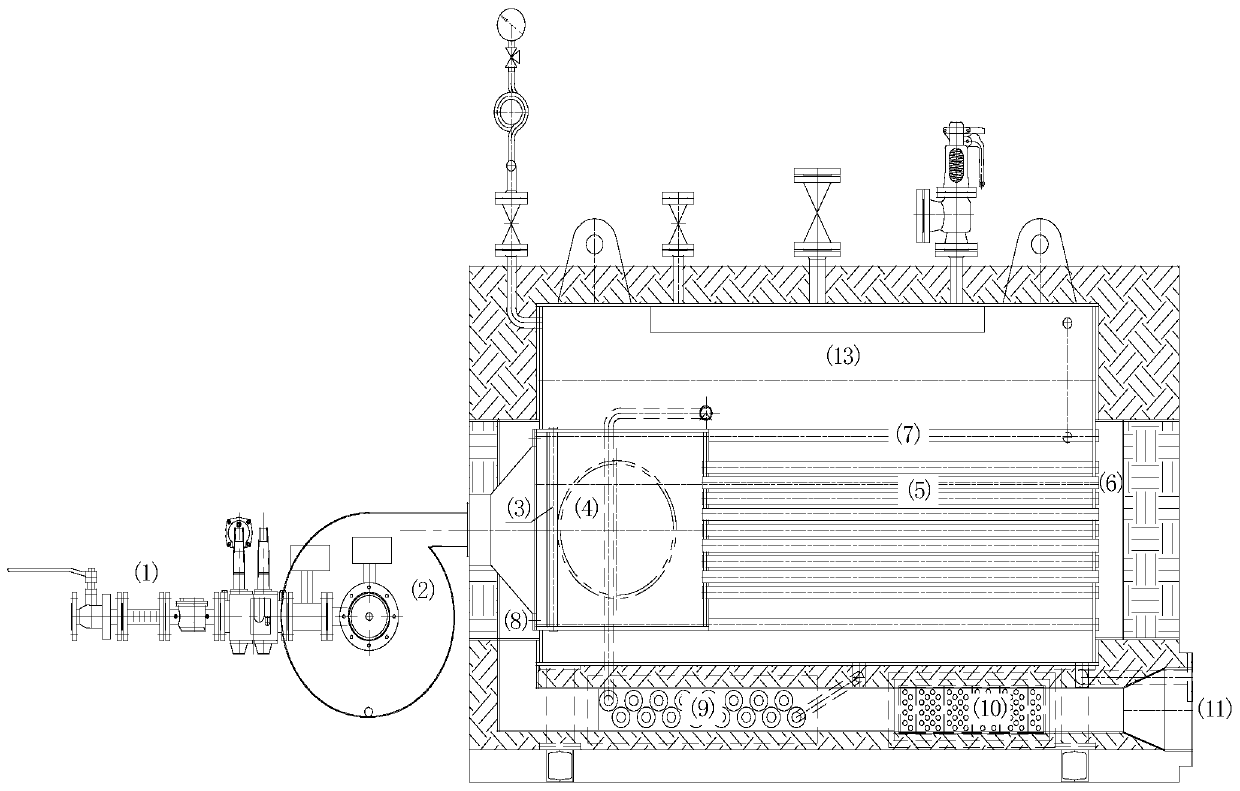

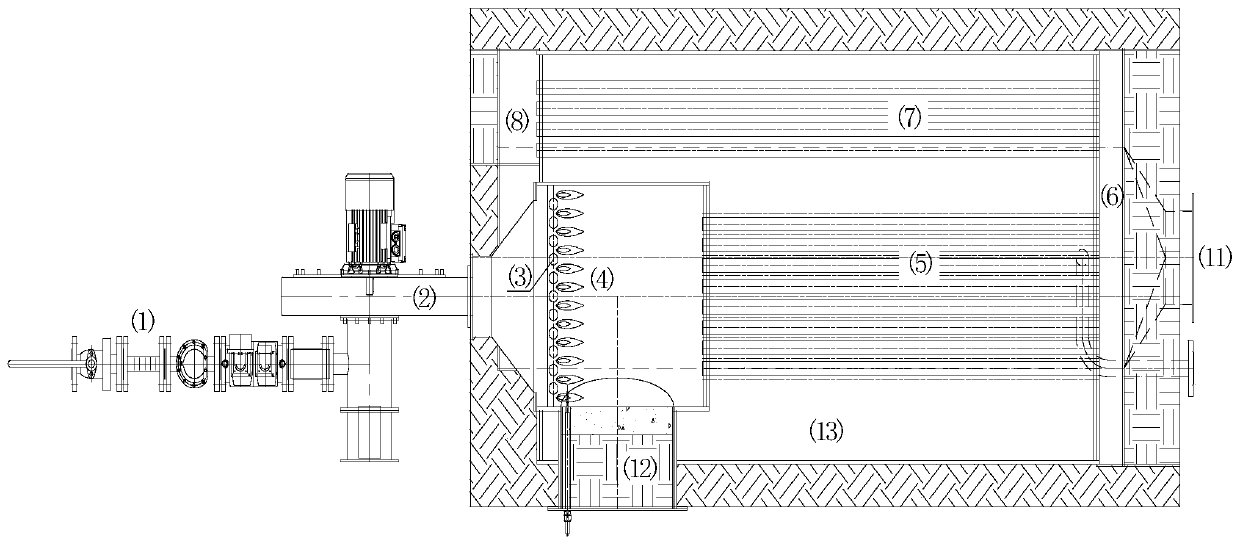

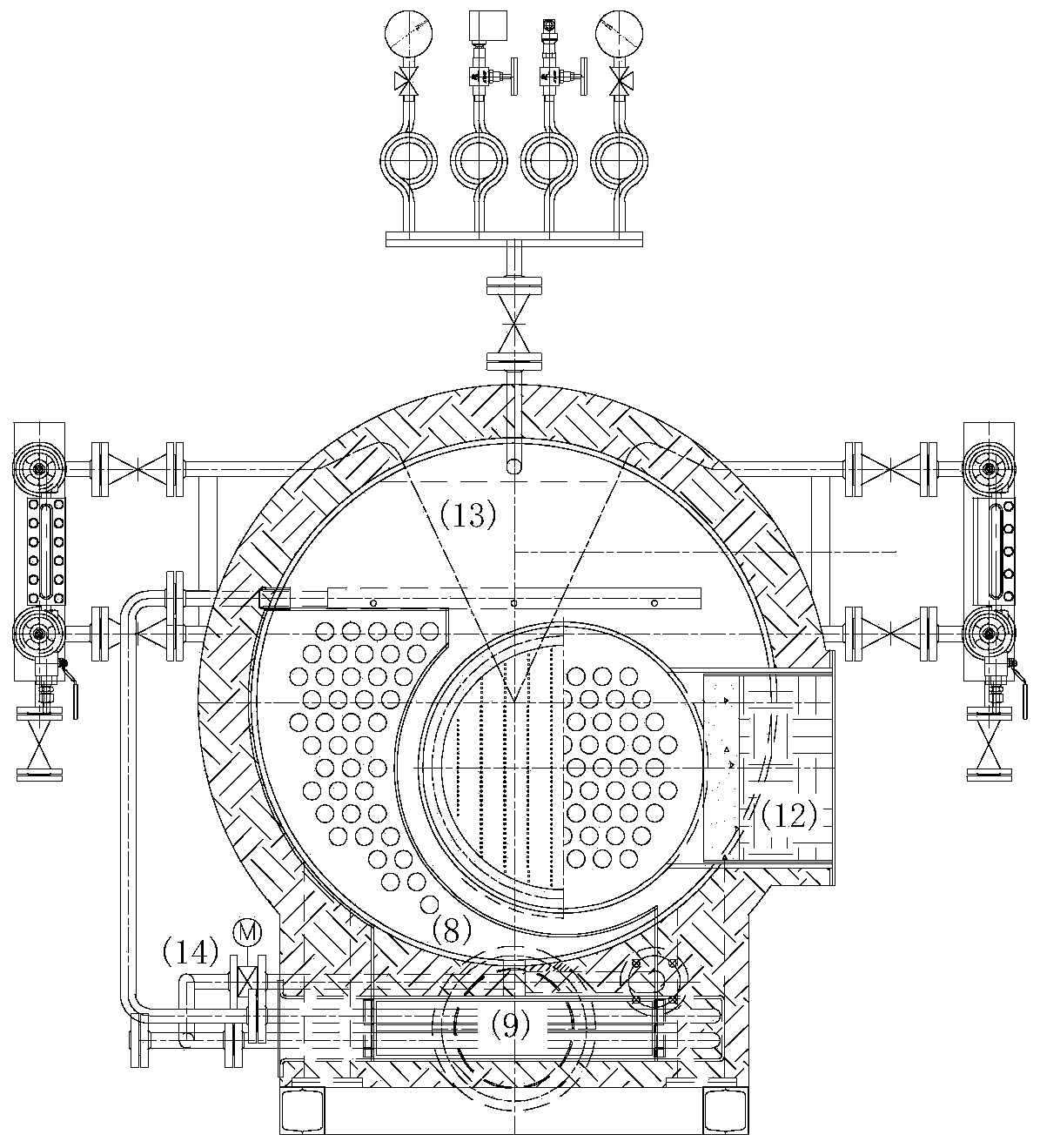

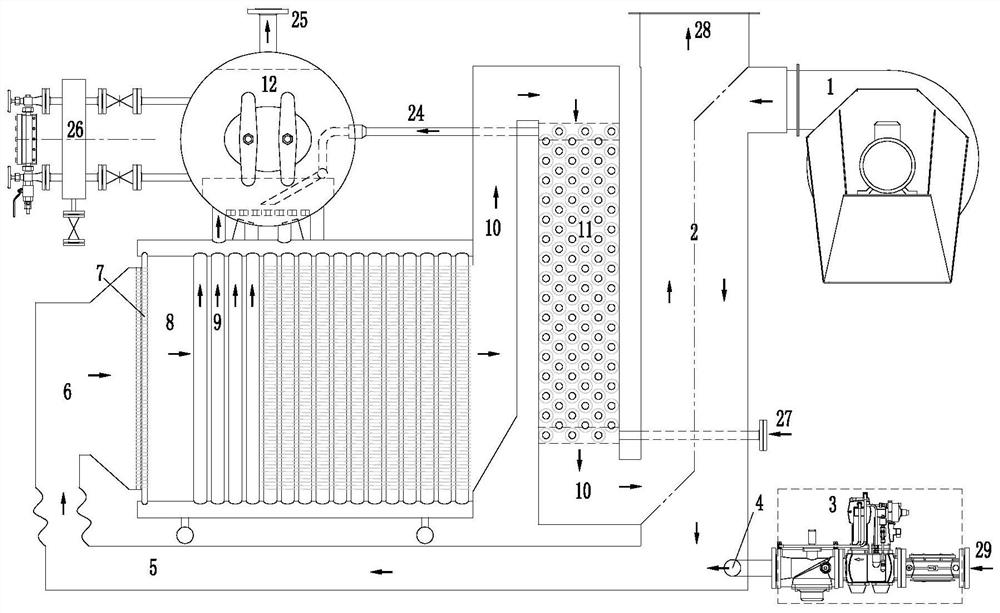

Natural gas cold flame horizontal type fire tube steam boiler

InactiveCN110887032AReduce length dimensionLower exhaust gas temperatureBoiler controlWater-tube boilersThermodynamicsEngineering

The invention discloses a natural gas cold flame horizontal type fire tube steam boiler which comprises a fuel gas valve group (1), an anti-explosion fan (2), a burning head, a hearth (4), a first return stroke thread smoke tube (5), a rear smokebox (6), a second return stroke thread smoke tube (7), a turning smoke chamber (8), an energy saver (9), a condenser (10), a smoke outlet (11), a hearth access door (12), a shell cylinder (13) and a recycling pipeline (14); the burning head is a cold flame burning head; the outlet of the anti-explosion fan is connected with the cold flame burning head;mixed gas is sprayed into the hearth via the cold flame burning head for combustion; the hearth, the first return stroke thread smoke tube and the second return stroke thread smoke tube are arrangedin the shell cylinder; the first return stroke thread smoke tube is directly connected with the back of the hearth; the first return stroke thread smoke tube and the second return stroke thread smoketube are connected in series through the rear smokebox; a single row of water tube bundles is vertically arranged at the front end of the hearth; a mixed gas spray hole (a steel plate is a spray holecarrier) is formed between every two adjacent tube bundles; the energy saver is arranged at the lower part of the shell cylinder and is connected with the second return stroke thread smoke tube through the turning smoke chamber; the condenser is connected with the back of the energy saver; and a smoke outlet is formed in the back of the condenser.

Owner:JIANGSU SHUANGLIANG BOILER

Kitchen cooking apparatus capable of self-extinguishing

The invention discloses a kitchen cooking apparatus capable of self-extinguishing. When a set temperature is reached, a temperature-sensitive valve actuator (6) mounted on a cooking apparatus backboard (3) or a cooking apparatus substrate (1) begins to work, which leads to opening of an automatic temperature-sensitive valve (5); a fire extinguishing medium enters into a system pipe network (10) through a medium inlet (9); a nozzle protective device (8) automatically falls off, spray nozzles (7) begin to spray water mist, and water mist spayed by a plurality of the spray nozzles (7) from different angles forms a sector shape above a burning mouth table (2) so as to cover the burning mouth table (2), thereby achieving the effects of cooling flames, moistening / cooling fuels, removing oxygen and fuel steam used for combustion and reducing radiant heat; when the temperature drops to a set safe range, the automatic temperature-sensitive valve (5) automatically closes; and the above-mentioned operations are repeatedly carried out.

Owner:BEIJING YUETONG HOTEL EQUIP

Mixed cooling flame tube used for low-pollution gas turbine

ActiveCN113739208AReduce generationLess likely to exceed the standardContinuous combustion chamberEfficient propulsion technologiesCombustion chamberCooling effect

The invention discloses a mixed cooling flame tube used for a low-pollution gas turbine. The mixed cooling flame tube comprises a fairing, an inner wall, an outer wall and a head structure, the fairing is arranged in a combustion chamber, a gas circulation channel is formed between the fairing and the inner wall of the combustion chamber, the head structure is arranged on one side close to the combustion chamber outer corridor; one end of the inner wall and one end of the outer wall are both connected to the head structure, the inner wall is arranged on the side close to a combustion chamber inlet, one end of the fairing is an open end arranged towards an outlet of the combustion chamber, and the middle of the inner wall and the middle of the outer wall are both connected with the open end of the fairing, a plurality of rows of impact holes are distributed in the fairing, and a swirl nozzle is arranged in the head structure. The flame tube is cooled in a sectional mode, the good cooling effect is achieved, and CO pollutants are not prone to exceeding the standard.

Owner:成都中科翼能科技有限公司

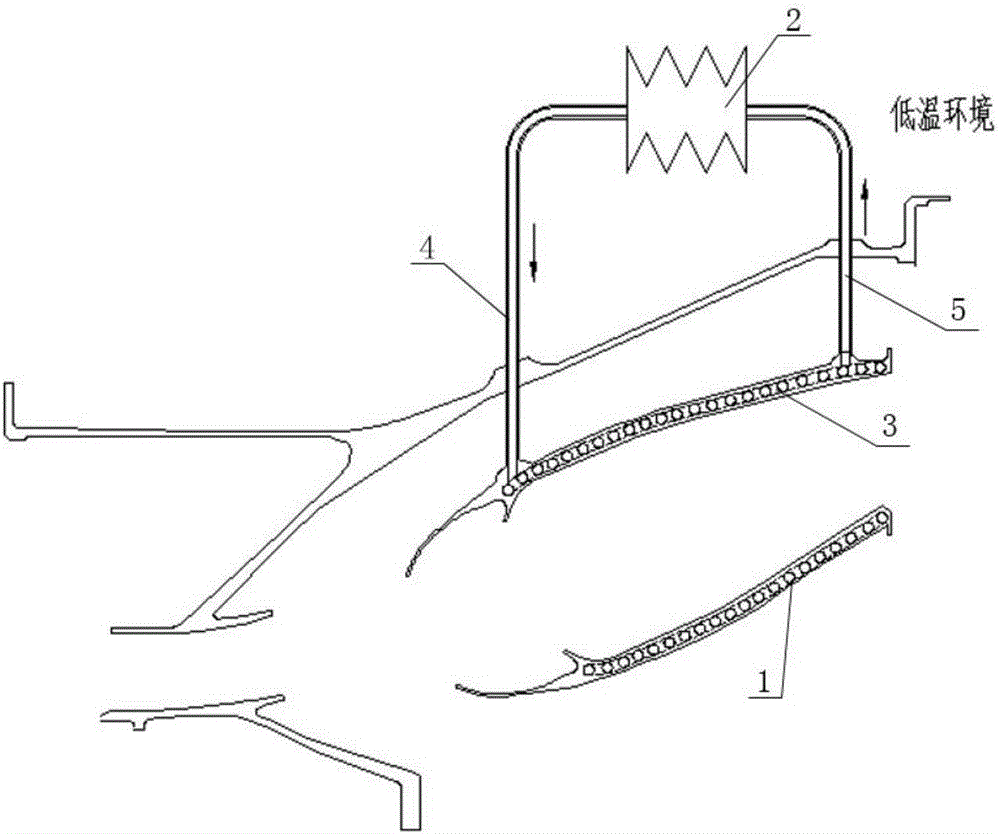

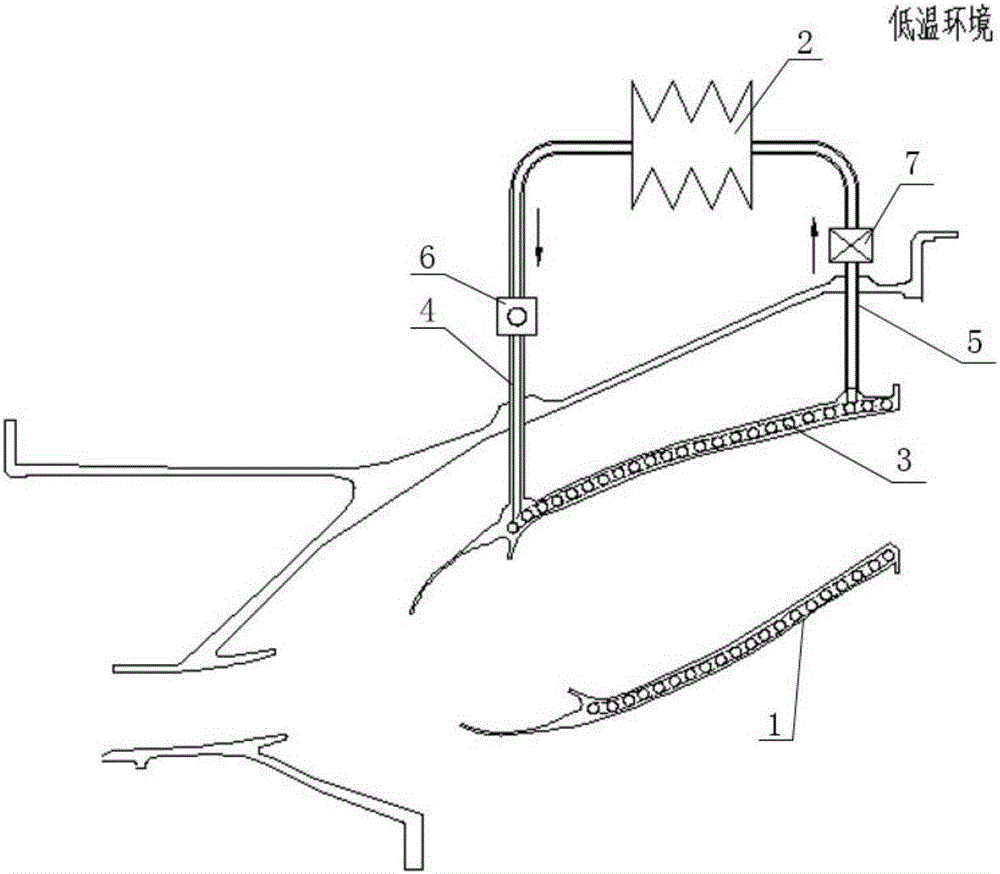

Method and structure for cooling flame tube of combustor

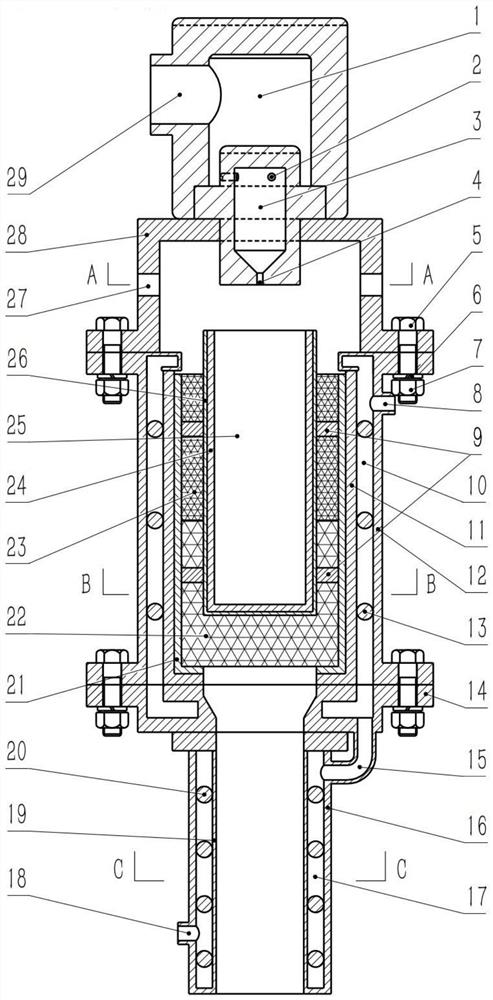

InactiveCN105042639AAchieve coolingMeet working conditionsContinuous combustion chamberCombustion chamberCombustor

The invention discloses a method for cooling a flame tube of a combustor. A heat dissipater (2) is additionally arranged in an external low-temperature environment of the flame tube (1). When the flame tube (1) works, a cooling agent circulates between a cavity (3) in the wall of the flame tube (1) and the heat dissipater (2) to transfer heat of the wall of the flame tube (1) to the external low-temperature environment. The invention further discloses a flame tube cooling structure adopting the method. The method and the structure have the advantages that the cooling agent and a heat exchanger are adopted for cooling the flame tube, air of an outlet of an air compressor does not need to be used for cooling the flame tube, and the saved air can be used for increasing the temperature of the combustor or cooling a turbine part; the cooling effect is good, and therefore an existing high-temperature alloy can be adopted without using a new high-cost material.

Owner:AECC SHENYANG ENGINE RES INST

Vehicle with combustion engine and auxiliary power unit

InactiveUS7464550B2Emission reductionReduce pollutant emissionsInternal combustion piston enginesElectric propulsion mountingMobile vehicleCombustor

Motor vehicle comprises a combustion engine with internal combustion of fuel and / or cold-flame product for driving the motor vehicle and thereby producing exhaust gas and an auxiliary power unit comprising an external burner and an expansion machine. A fuel tank with fuel provides energy to the burner and the combustion engine. The motor vehicle has a cold-flame-reactor with means for feeding the fuel from the fuel tank to the cold-flame reactor, and at least a portion of the fuel is pre-combusted to a cold-flame product in the cold-flame reactor.

Owner:AMOVIS

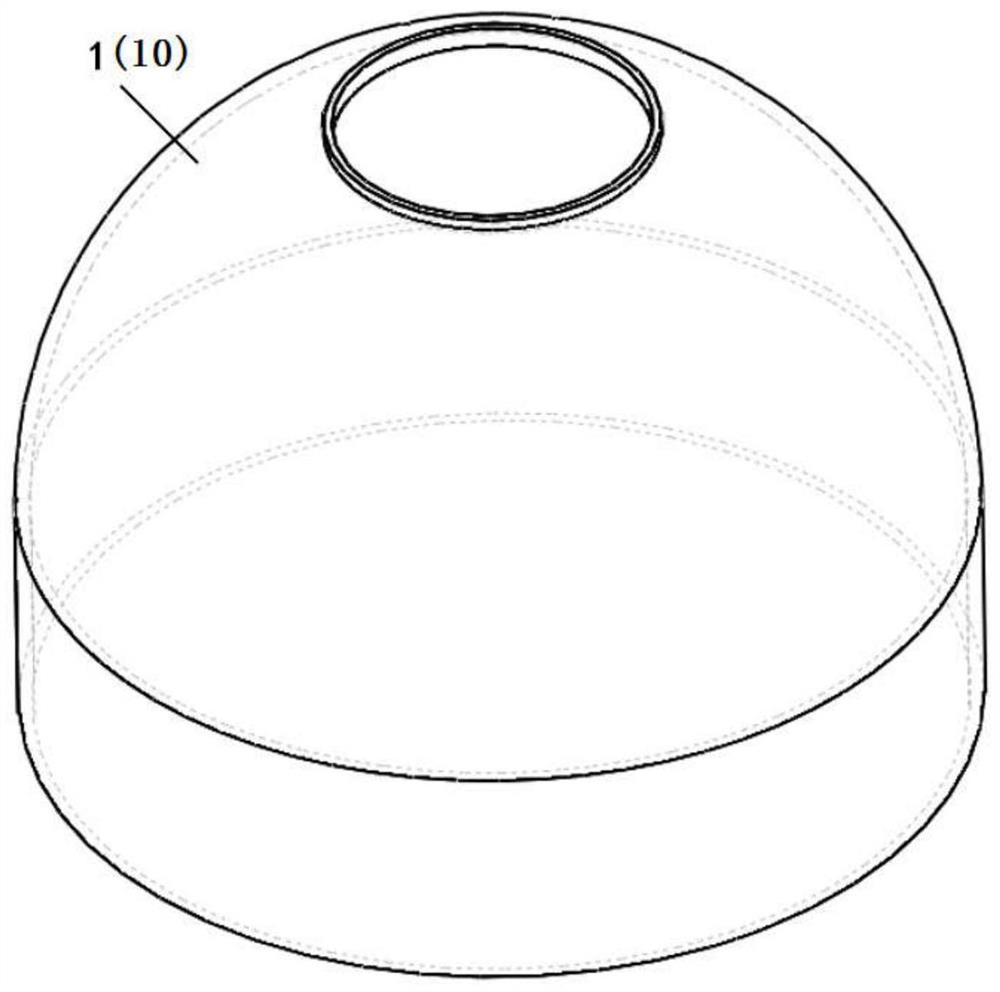

Novel low-nitrogen-emission cold flame combustion integrated steam boiler

PendingCN112032698AHigh degree of standardizationSimple quality control managementBoiler water tubesCombustion processAir preheaterLight pipe

The invention relates to a novel low-nitrogen-emission cold flame combustion integrated steam boiler which comprises a draught fan, an air preheater, a gas valve set, a gas distribution pipe, an air flue, an air distribution chamber, water cooling fire grates, hearths, convection areas, a flue, an energy saver, a steam pocket, a descending pipe, a descending communication pipe and a water level controller. A heating surface adopts a standard modular design and consists of two groups of membrane wall modules and a plurality of groups of fire grate convection area modules; the capacity of the boiler can be randomly combined and adjusted through the number of the fire grate convection area modules; each fire grate convection area module is composed of a module leading-in pipe, a module lowercollecting box, a fire grate finned pipe, a convection area light pipe, a convection area finned pipe, a module upper collecting box and a module leading-out pipe; each module can be divided into three functional areas, namely a water-cooling fire grate, a hearth and a convection area; the water-cooling fire grates are composed of porous ceramics and finned pipes; and mixed gas of air and naturalgas evenly flows to spiral fin areas on the finned pipes through small holes in the porous ceramics, and enters the hearths so as to be combusted after being preheated along channels among spiral fins.

Owner:JIANGSU SHUANGLIANG BOILER

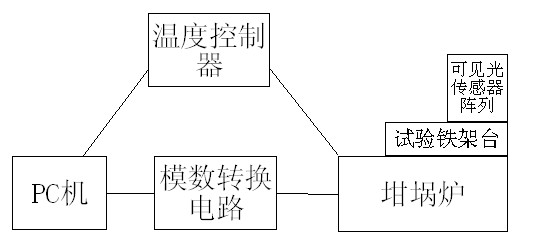

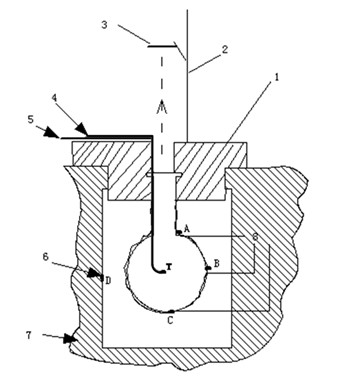

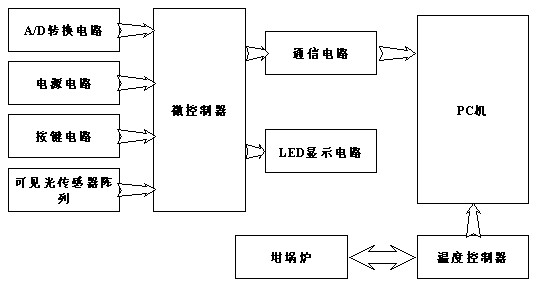

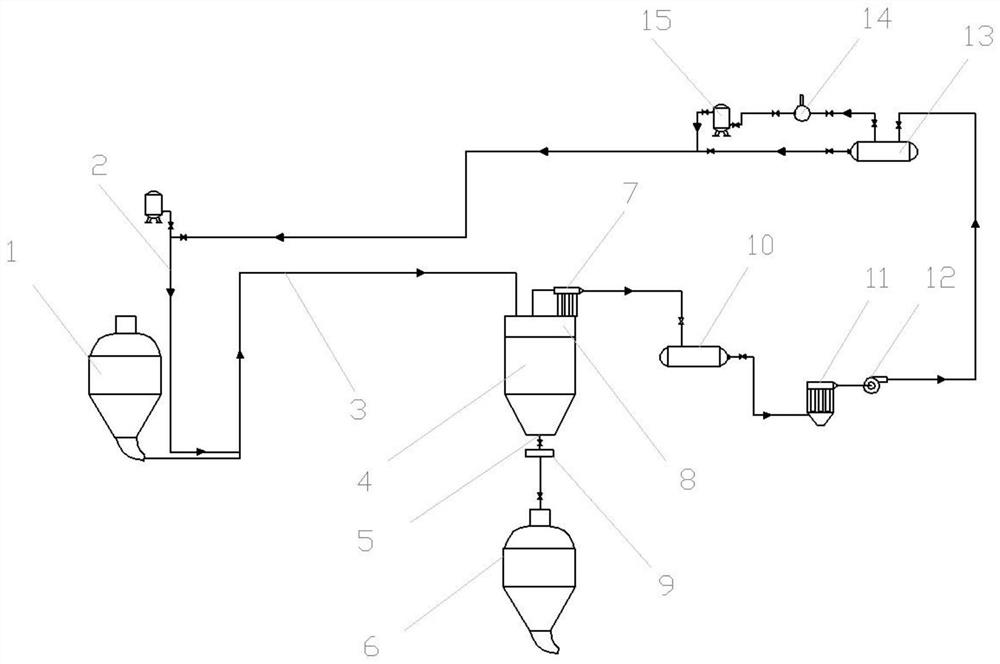

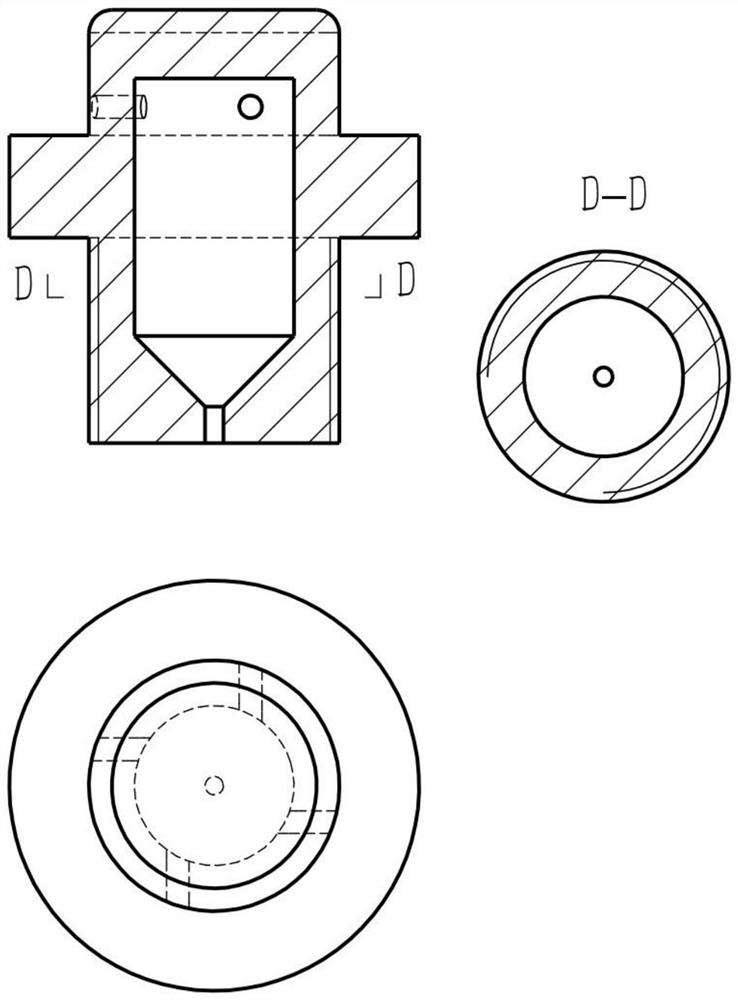

Detection apparatus for liquid chemical product spontaneous combustion temperature

InactiveCN102495097AAccurate autoignition temperature pointReduce mistakesInvestigating phase/state changeSpontaneous combustionReaction temperature

The invention discloses a detection apparatus for liquid chemical product spontaneous combustion temperature, in the current device, the reaction speed is slow and the large error can be generated due to artificial factors. The apparatus comprises an integral test detection apparatus, a data acquisition circuit and anaphase data treatment. The process comprises the following steps: starting the detection apparatus, placing an inflammable liquid chemical sample in the apparatus, carrying out real time data acquisition through various sensors, sending data to a computer and carrying out data processing to display the values to be measured such as flame spontaneous combustion temperature, cool flame spontaneous combustion temperature, time delay, air pressure value and initial reaction temperature. According to the invention, the security, accuracy and precision of the test are fully considered, the artificial portion can be maximally simplified, the measured value error caused by the manual operation can be reduced, and the each parameter of liquid chemical product spontaneous combustion can be rapidly detected with high efficiency.

Owner:杭州量泰科技有限公司

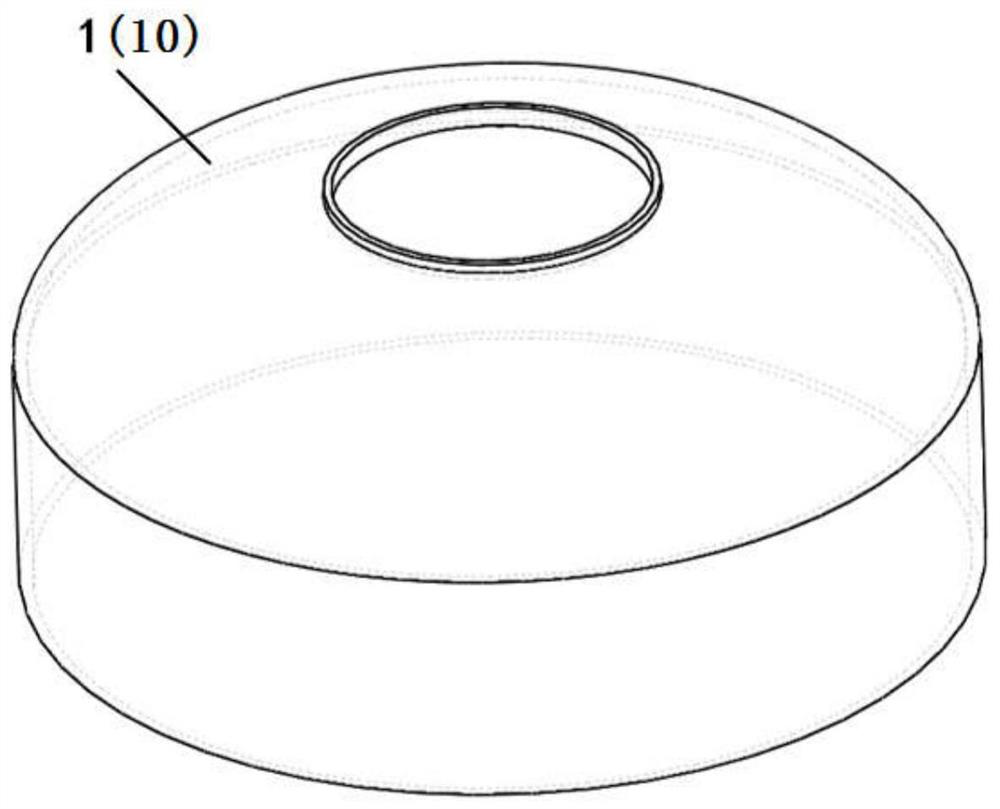

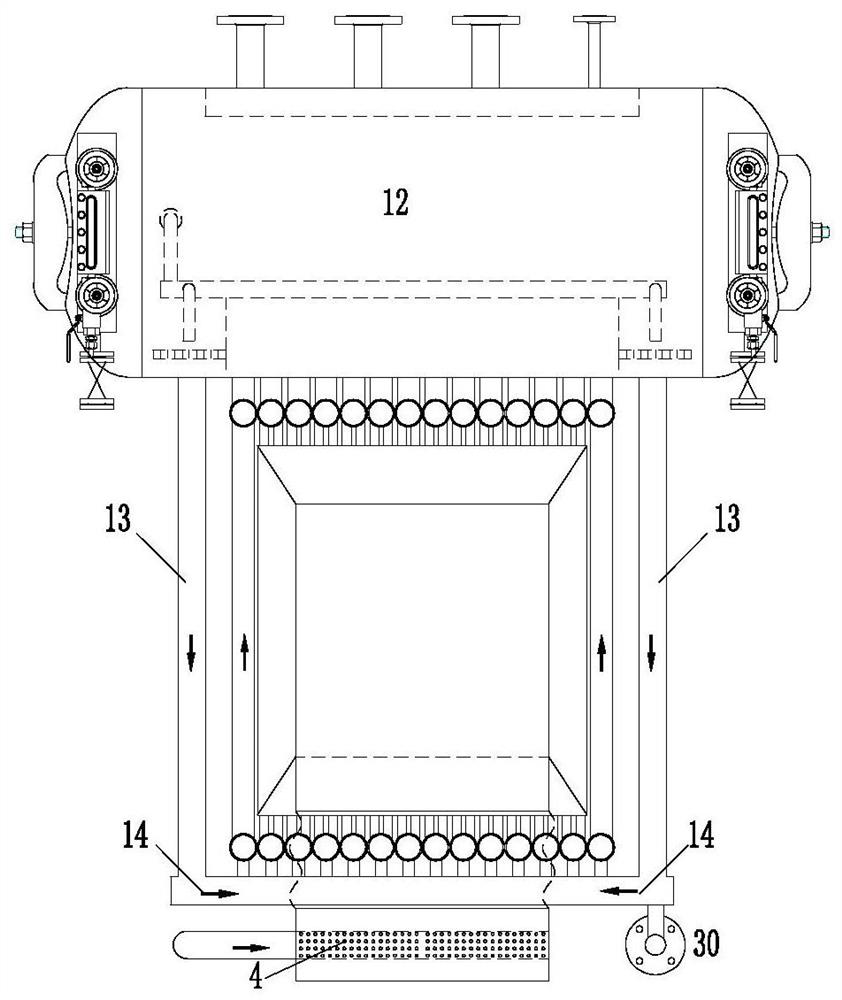

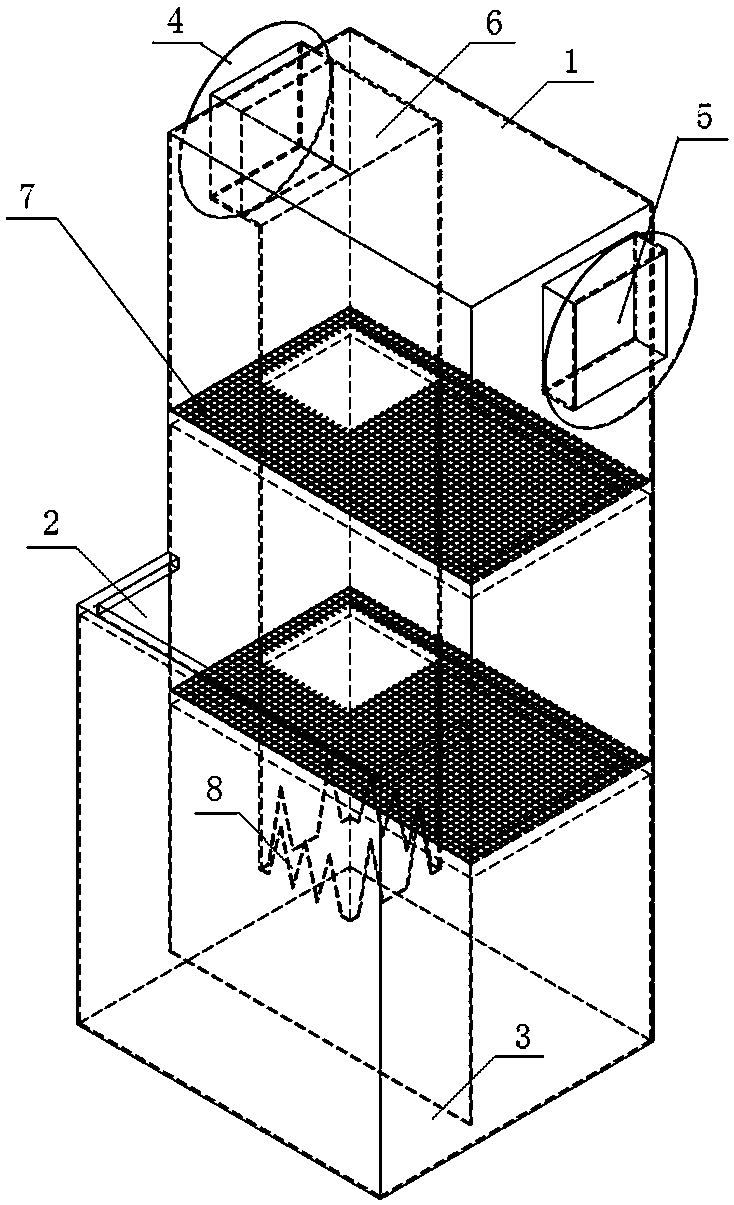

Low-nitrogen water tube boiler saving energy and bearing pressure

PendingCN112032696AReduce heat lossIncrease the average heat transfer coefficientBoiler water tubesSteam/vapor condensersCombustorEngineering

The invention discloses an efficient low-nitrogen water tube boiler bearing pressure. The boiler comprises an upper boiler cylinder, a shell, a combustor distributing head, a film type water cooling wall tube bundle, a water cooling flame tube bundle, a radiation tube bundle, a high-temperature convection tube bundle, a low-temperature convection tube bundle, a descending tube bundle, a lower boiler cylinder, an externally-arranged condenser, a pre-mixer, a matched fan, a water supply pump, a fuel gas valve set, a controller and the like. A closely-spaced tube, a metal hole plate, a ceramic hole plate and the like are adopted in the combustor distributing head, and are used for equalizing flow, preventing fire return and stabilizing flames, detachable design is adopted, and ash can be cleared in time. The water cooling flame tube bundle of the combustor distributing head is arranged in a plane or concave manner, and hearth space can be utilized to the maximum. The water cooling flame tube bundle on a boiler body is adopted for cooling flames, and the problem of heat distribution of a water cooling combustor is solved. According to the boiler, combustor and boiler integration of theplane / concave and convex curve combustor is achieved, the structure is compact, low-nitrogen and superlow-nitrogen combustion is achieved under the low excess air ratio, and technology monopoly of low-nitrogen combustor manufacturers at abroad in the field of steam boilers is broken through.

Owner:XI AN JIAOTONG UNIV +1

Cooling flame-retardant recovery system for combustible solid waste particles

PendingCN113654361AIncrease delivery speedReduce labor intensityCharge manipulationControl devices for furnacesParticulatesProcess engineering

The invention belongs to the technical field of chemical production recovery, and particularly relates to a cooling flame-retardant recovery system for combustible solid waste particles. The system comprises a cooling conveying pipeline, the inlet end of a cooling conveying bin pump is connected with a calcium carbide furnace purification device and a high-pressure nitrogen main pipeline, the outlet end of the cooling conveying bin pump pipeline is connected with the top of a low-temperature material bin, the solid waste is conveyed to the top of the low-temperature material bin through low-temperature nitrogen, a nitrogen recovery dust collector is further arranged at the top of the low-temperature material bin, recovered nitrogen is filtered through a precision filter and then pressurized through a nitrogen compressor, the pressurized nitrogen is introduced into a nitrogen recovery main pipeline again to be recycled, and the bottom of the low-temperature material bin is connected with a combustible solid waste boiler through an air conveying bin pump conveying pipeline. According to the system, the labor intensity of field workers is reduced, the production cost is reduced, and the field environmental pollution is reduced.

Owner:吴忠市同盛化工有限公司

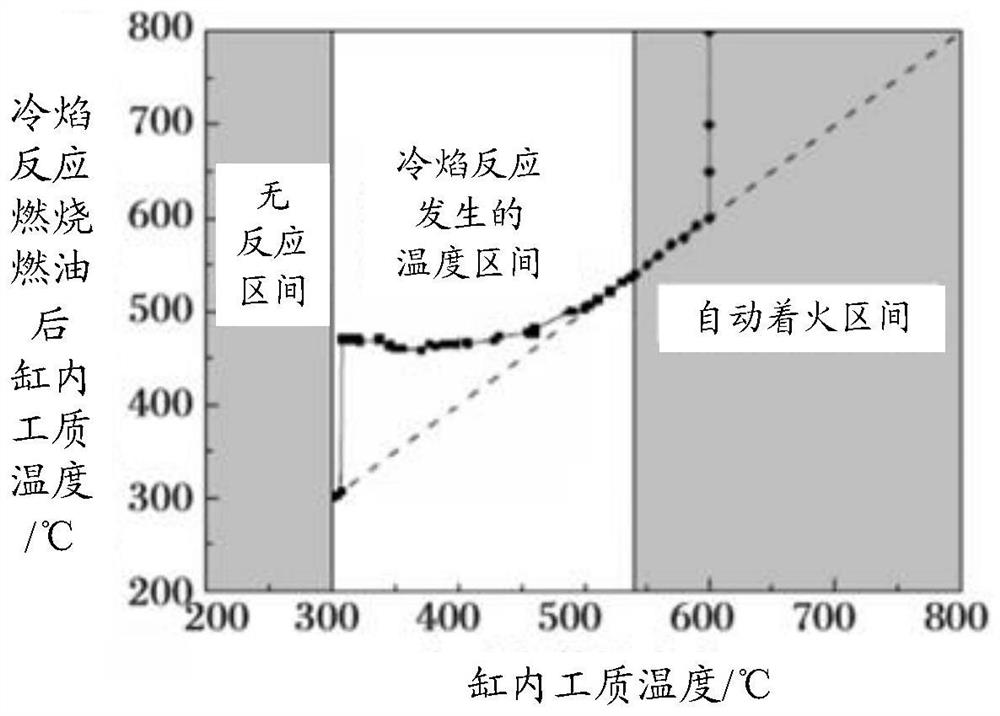

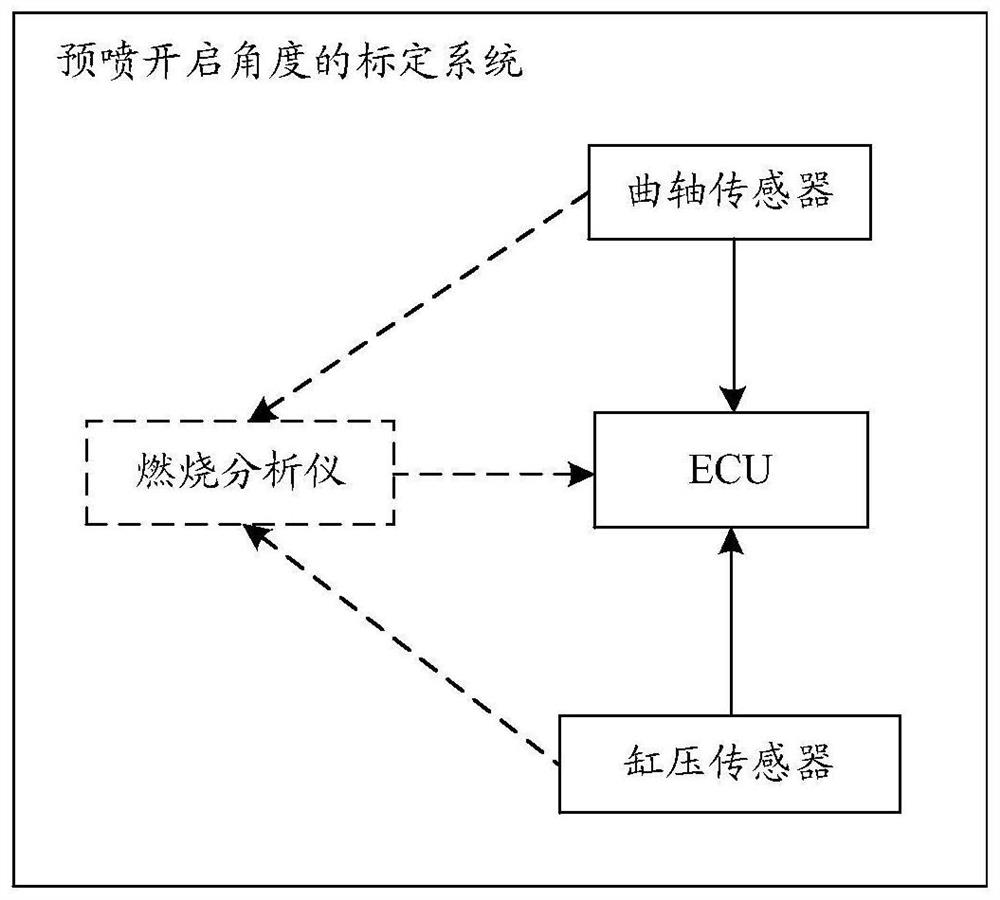

Calibration method, device and equipment for pilot injection opening angle and storage medium

PendingCN114720138AInternal-combustion engine testingInternal combustion piston enginesSpontaneous combustionRail pressure

The invention relates to the technical field of engine calibration, in particular to a calibration method and device for a pilot injection opening angle, equipment and a storage medium. The method is used for reasonably setting the pilot injection opening angle of an engine and improving the low-temperature starting performance of the engine and comprises the steps that after it is determined that the operation mode of the engine is a starting mode and a rail pressure instantaneous value is not smaller than a rail pressure threshold value, a corresponding cylinder interior working medium temperature instantaneous value is obtained based on a cylinder pressure instantaneous value collected by a cylinder pressure sensor; when it is determined that a crank angle instantaneous value collected by a crank sensor is located in a preset crank angle interval and a working medium temperature instantaneous value in a cylinder reaches a working medium temperature threshold value, the crank angle instantaneous value at the moment is determined as a pilot injection opening angle calibration value corresponding to the starting mode; in this way, the temperature of the working medium in the cylinder can be increased through heat released by the cold flame reaction, so that fuel oil rapidly reaches the spontaneous combustion temperature of the fuel oil to be ignited and combusted, the starting time of the engine is shortened, and the low-temperature starting performance of the engine is improved.

Owner:WEICHAI POWER CO LTD

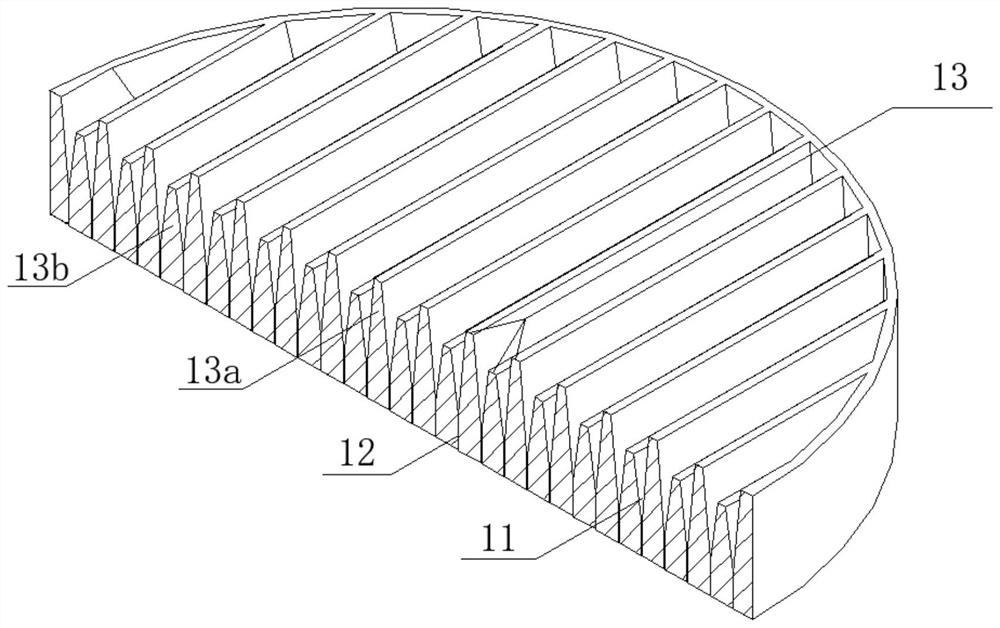

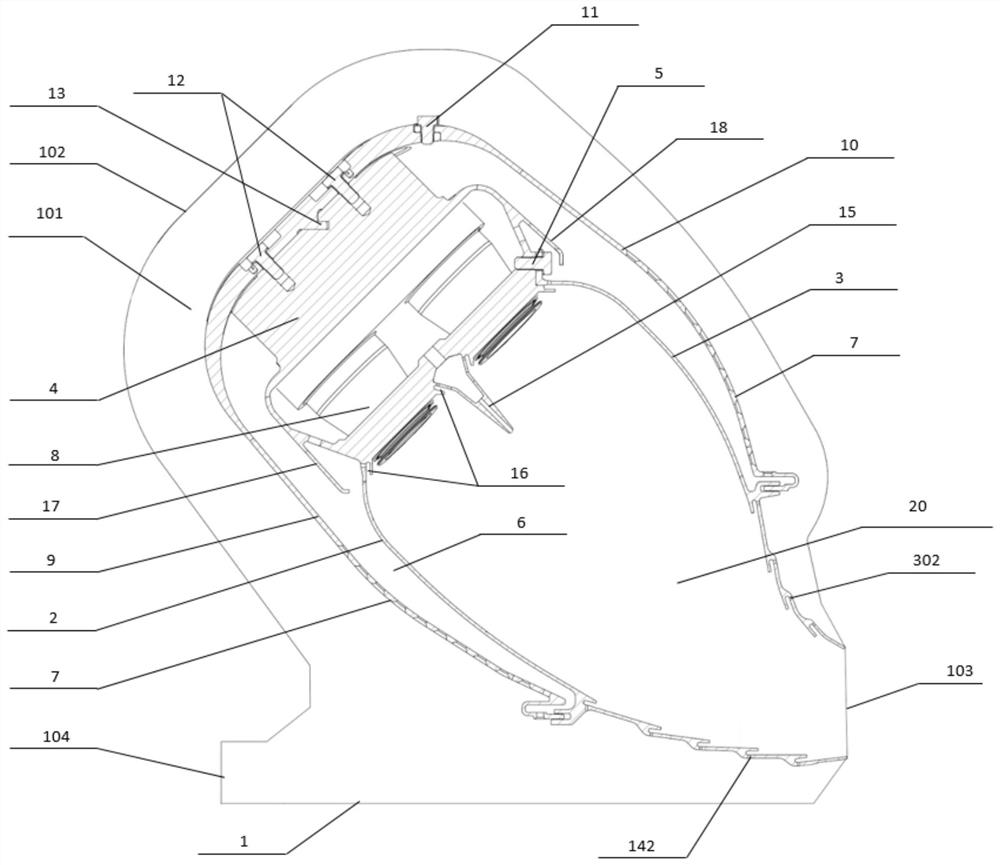

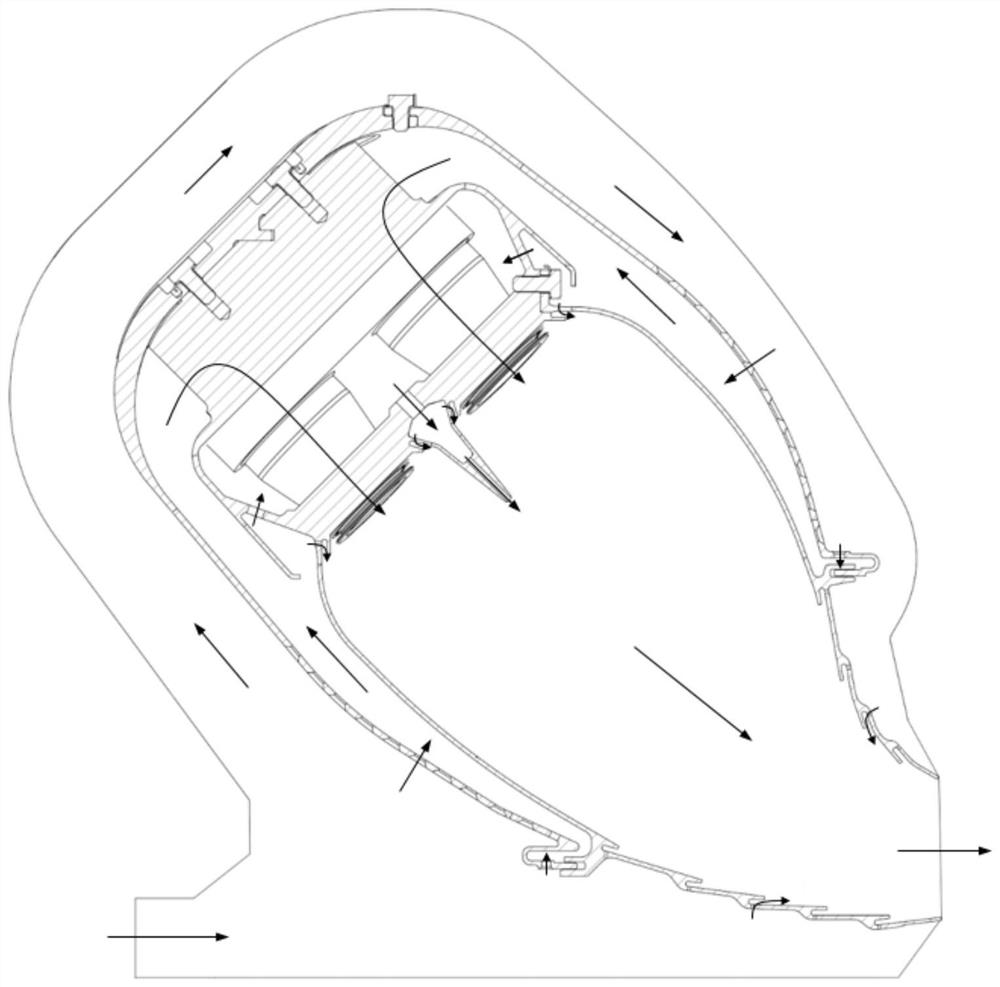

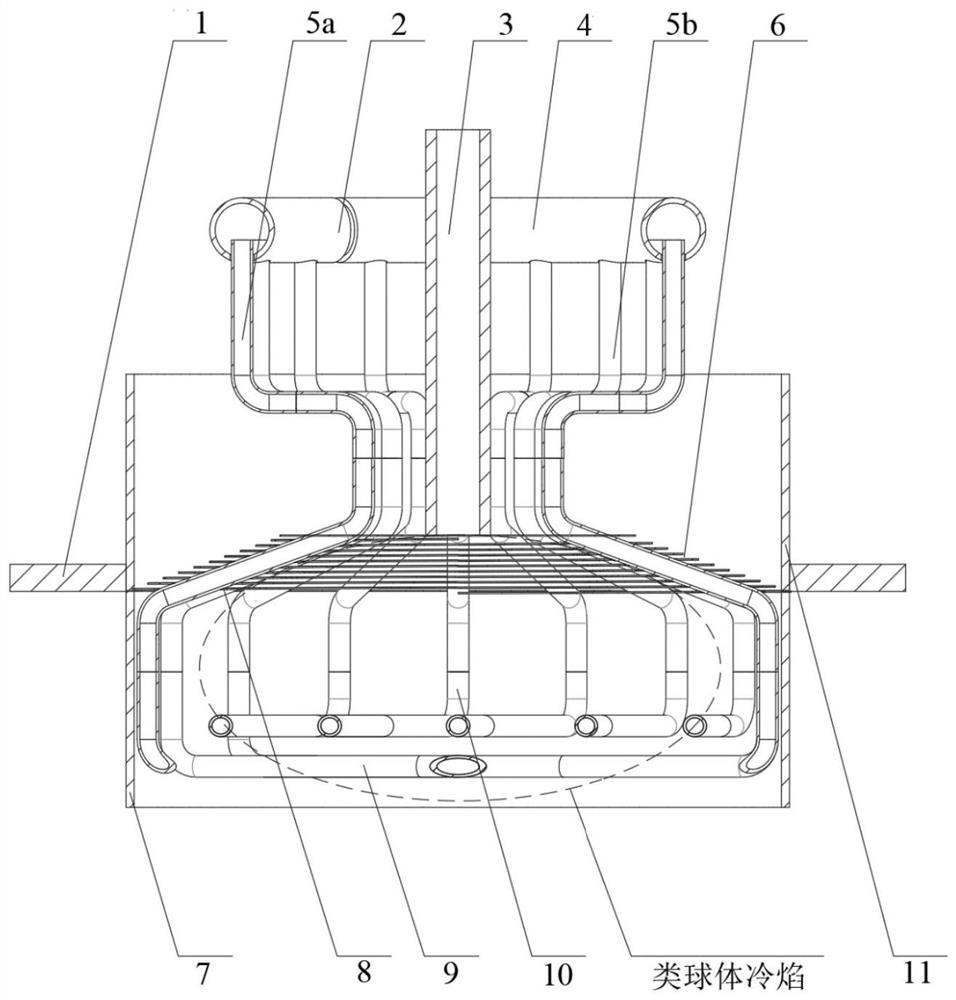

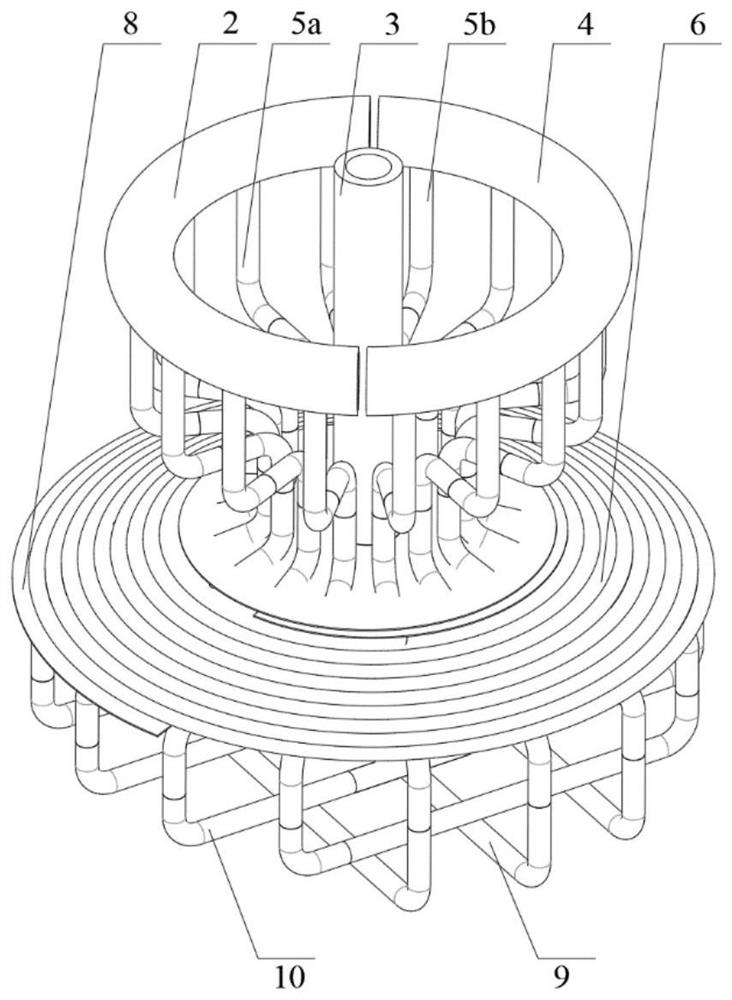

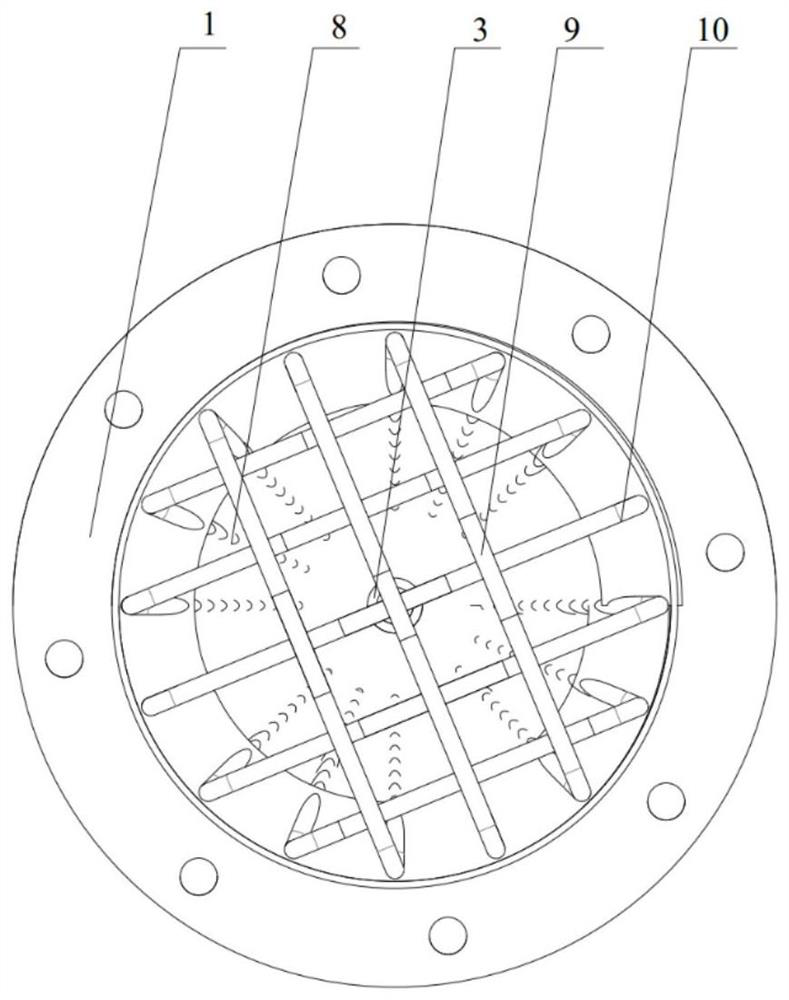

A kind of spiral ribs cold -type cold flame gas burner

ActiveCN113757668BGuaranteed safe operationUniform surface burnBurner coolingIndirect carbon-dioxide mitigationCombustion chamberEngineering

The invention discloses a spiral annular rib water-cooled cold flame gas burner, comprising a surface combustion device and a three-stage water-cooled circulation device: the surface combustion device includes spiral annular rib, the spiral annular rib is provided with multiple layers, and the multi-layer spiral annular rib is combined with the combustion The axis of the radiator is arranged at a certain angle to form a spiral stepped isobaric air intake chamber. The inner side of the multi-layer spiral ring rib is provided with a firing gun hole / central secondary air duct; the three-stage water cooling circulation device includes a water inlet header and an outlet header. The water header and the outlet header are respectively connected with the annular cooling water pipe to form a closed water circulation loop. The annular cooling water pipe is arranged through the spiral ring rib to form the first-stage water cooling surface. The tube bundle constitutes the second-stage water-cooling surface and the third-stage water-cooling surface, forming a sphere-like cold flame combustion surface as a whole. The invention ensures stability, high efficiency, cleanliness and safety during combustion of the gas fuel, and can also realize water cooling of the flame surface, and the cooling pipes form a closed circulation loop.

Owner:XI AN JIAOTONG UNIV

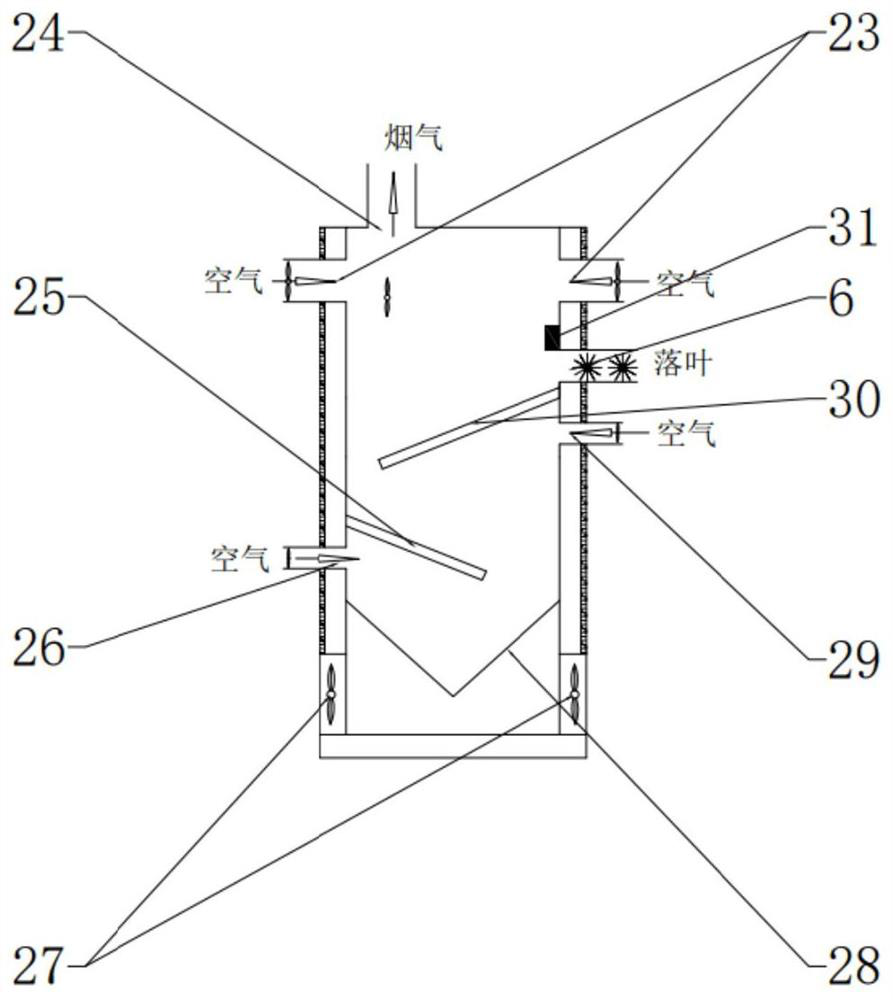

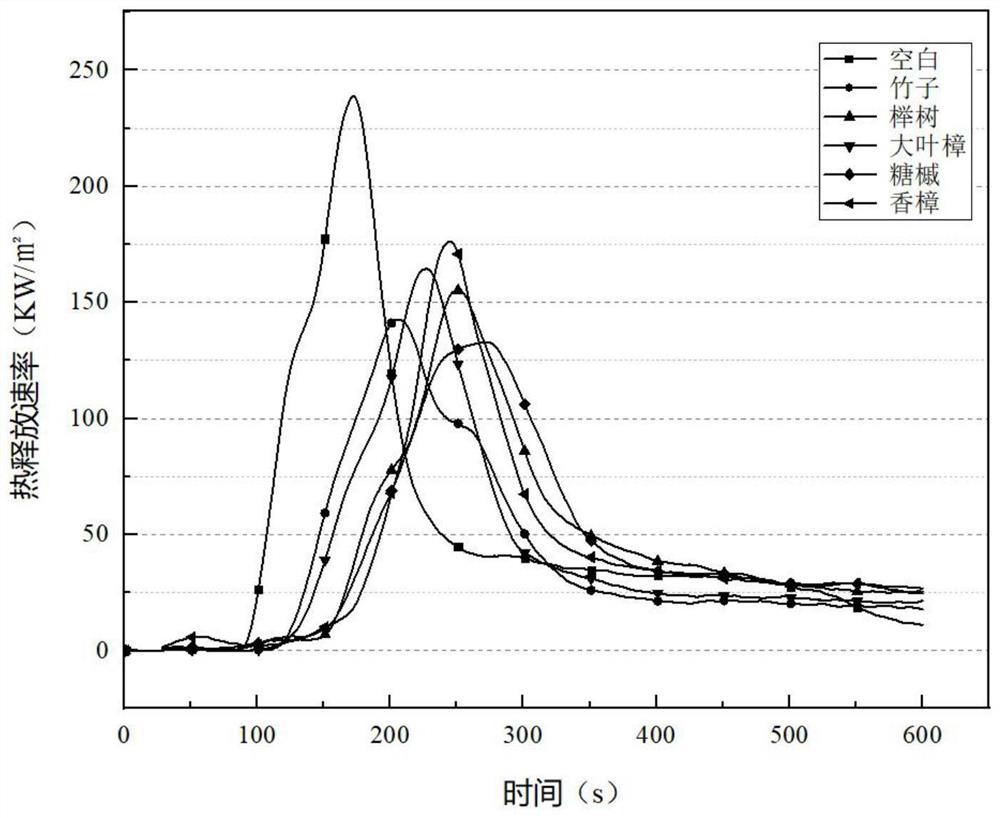

Forest combustible self-energized combustion trolley based on comprehensive heat management

ActiveCN113266830AAchieve self-supplyReduce carbon contentIncinerator apparatusHeat managementFlue gas

The invention provides a forest combustible self-energized combustion trolley based on comprehensive heat management, and belongs to the field of forest fire prevention equipment. The trolley comprises a feeding unit, a combustion unit and a power unit, wherein the feeding unit collects fallen leaves on the ground and feeds the fallen leaves into the combustion unit, the combustion unit comprises a gasification incinerator and an ash laying assembly, a secondary air inlet, a first air inlet, a second air inlet and a feeding port are formed in the side wall of the gasification incinerator, meanwhile, a first metal plate with holes and a second metal plate with holes are arranged inside the gasification incinerator, then the fallen leaves are gasified into flame-retardant ash, the ash laying assembly is arranged below the gasification incinerator and used for cooling flame-retardant ash and laying the flame-retardant ash on the ground, and a heat utilization assembly of the power unit is connected to a flue gas outlet, so that heat of flue gas is utilized to provide electric energy for a driving assembly, and the driving assembly of the trolley converts electric energy into kinetic energy. According to the forest combustible self-energized combustion trolley, the flame-retardant ash can be obtained by reducing the carbon content of the ash content, and the possibility of forest fire can be reduced by laying the flame-retardant ash on the ground.

Owner:HUAZHONG UNIV OF SCI & TECH

Cooling anti-explosion watertight valve for gas pipeline

InactiveCN108953721AAvoid it happening againImprove securityIncinerator apparatusValve housingsFiltrationDecompression chamber

The invention discloses a cooling anti-explosion watertight valve for a gas pipeline. The cooling anti-explosion watertight valve comprises a valve body provided with a cooling flame retardant chamberand a decompression chamber. The cooling flame retardant chamber and the decompression chamber are connected side by side. A partition between the cooling flame retardant chamber and the decompression chamber reserves bottom gaps at the bottoms of the cooling flame retardant chamber and the decompression chamber. The cooling flame retardant chamber and the decompression chamber are filled with liquid and communicate with each other through the bottom gaps. The cooling flame retardant chamber is provided with a valve gas inlet and a valve gas outlet. An inner gas inlet pipe is arranged from the valve gas inlet to the inside of the cooling flame retardant chamber. A gas outlet of the inner gas inlet pipe is located in the filling liquid. The top of the decompression chamber is open. The valve body is provided with the cooling flame retardant chamber and the decompression chamber, gas is guided into the filling liquid to achieve cooling through the inner gas inlet pipe arranged in the cooling flame retardant chamber, bubbles are prevented by teeth, a steel wire mesh layer and a polygonal ball form a filtration demisting structure, burning occurs after passing of the cooling flame retardant chamber, if backfire occurs, the cooling flame retardant chamber conducts the cooling flame retardance, the decompression chamber conducts decompression, and safety of the gas pipeline is improved greatly.

Owner:淮北杰森环保科技有限公司

Cooling flame low-nitrogen combustion device and combustion method thereof

ActiveCN110360558BAvoid concentrationBurning flame area increasesGaseous fuel burnerCombustion chamberThermodynamics

Owner:江苏泷涛环境技术有限公司

Heat conductive rubber for cooling flame retardant high-power LED and production method thereof

InactiveCN106221234AImprove thermal conductivityImprove flame retardant performanceInorganic material artificial filamentsEngineeringFumed silica

The invention discloses heat conductive rubber for cooling a flame retardant high-power LED. The heat conductive rubber is prepared from, by weight, 1-12 parts of PVP, a proper amount of dichloromethane, a proper amount of DMF, 100-104 parts of 107 silicon rubber, 5-5.4 parts of dimethicone, 4.2-4.4 parts of tetraethoxysilane, 1-1.3 parts of dibutyltin dilaurate, 1.7-1.9 parts of a silane coupling agent kh-550, 170-190 parts of ethyl alcohol, 10-11 parts of fumed silica, 100-105 parts of 40-50 micrometer aluminum nitride, 20-21 parts of nanometer aluminum nitride, 1.8-2.3 parts of polysaccharide from semen raphani, 1.4-1.6 parts of octacosanol, 1.4-1.6 parts of zinc hydroxystannate and 1.2-1.4 parts of nanometer aluminum hydroxide. By using polysaccharide from semen raphani, zinc hydroxystannate and nanometer aluminum hydroxide, the flame retardance, tenacity and oxidation resistance of the rubber are improved, the service life is prolonged, and the heat conductivity is improved.

Owner:滁州君越高分子新材料有限公司

A liquid fuel porous medium burner with cold flame evaporation

ActiveCN111853771BEasy to addAccelerate emissionsBurnersIndirect carbon-dioxide mitigationCombustion chamberInsulation layer

The invention discloses a liquid fuel porous medium burner with cold flame pre-evaporation, which belongs to the field of micro-energy. The invention includes a pressure swirl nozzle, a cold flame gasifier fixing ring, a cooling water outlet, a combustion chamber water cooling channel, a combustion chamber shell, a cooling water drainage channel, a flue gas channel water cooling channel, a cooling water inlet, and a combustion chamber thermal insulation layer. Porous medium in combustion section, porous medium in preheating section, cold flame gasifier, insulation layer of cold flame gasifier, air inlet and burner upper cover, etc. The liquid fuel porous media burner combines cold flame pre-evaporation and micro-combustion technology, which can improve the combustion efficiency of the burner, reduce pollutant emissions, and has a wide burner power adjustment range and combustion equivalence ratio range. Users only need to supply liquid fuel to the pressure swirl nozzle to obtain the energy generated by combustion, which has the advantages of environmental protection, high efficiency and portability. The present invention generates energy by pre-evaporating the liquid fuel and then burning it, and can be used as an energy source for micro-miniature equipment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com