Hearth and combustor cooling type surface cold flame premixing gas boiler

A gas boiler and burner technology, applied in the direction of burner, combustion type, gas fuel burner, etc., can solve the problems of environmental pollution, poor economy, high cost, etc., and increase the convective heat transfer and radiation heat transfer in the furnace , Reduce the formation of NOx, the effect of reducing the formation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

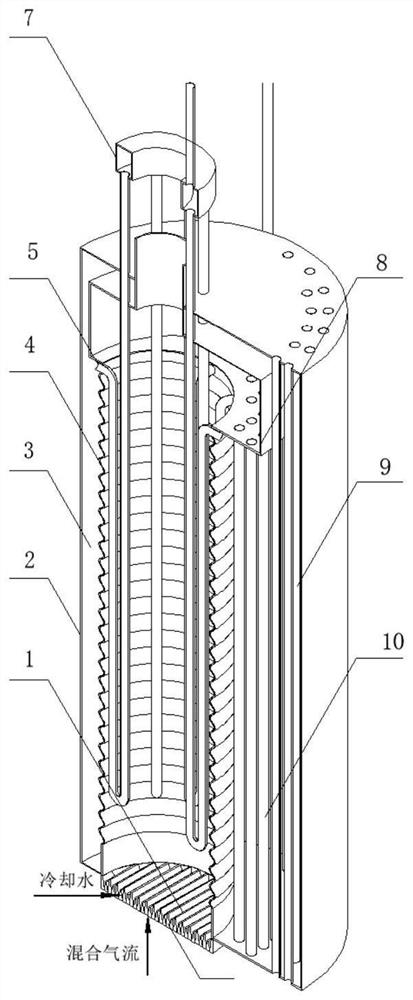

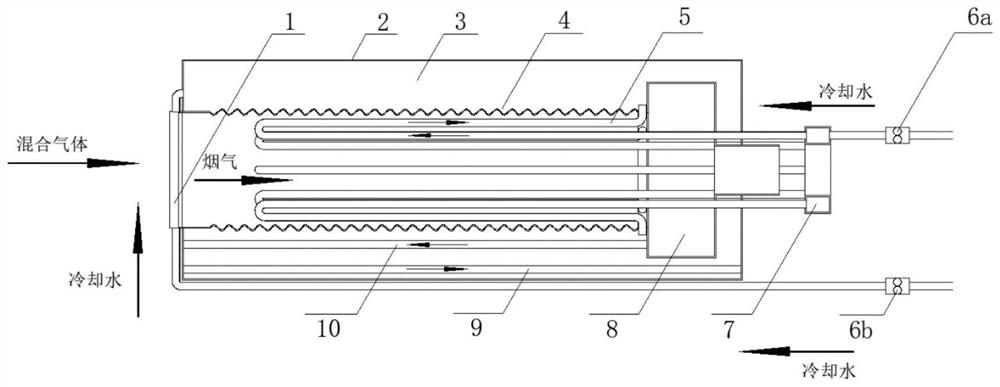

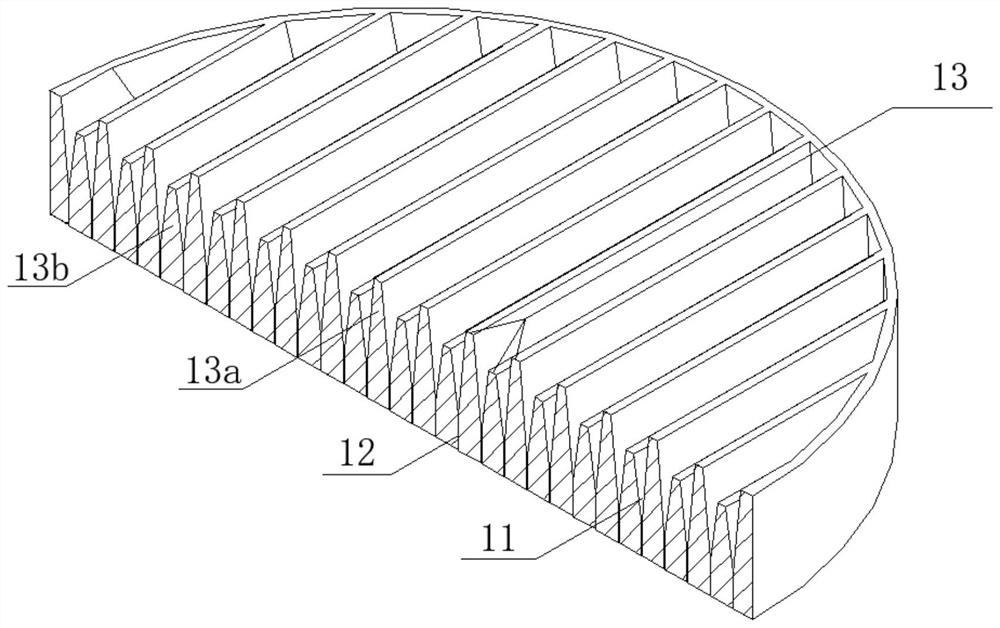

[0022] Such as Figure 1-Figure 3 As shown, the water-cooled burner coupling furnace cooling system in the present invention can realize the mixed gas low temperature and low NO x Uniform surface combustion ensures a uniform low-temperature atmosphere inside the furnace while improving the compactness of the boiler and reducing the footprint. Its main structure is that the inlet of the mixed gas flow is provided with an anti-tempering inlet microchannel 12, the cross-sectional size of the gradually expanding gas channel 11 gradually increases along the propagation direction of the premixed flame, and the high and low cooling components 13a and 13b on both sides are arranged alternately to form an up and down staggered Continuous water-cooling channel 13; U-shaped water-cooling component 5 is arranged in the furnace 4

[0023] Inside, its water inlet is even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com