Cooling flame-retardant recovery system for combustible solid waste particles

A recovery system and particulate matter technology, which is applied in the field of combustible solid waste particulate matter cooling and flame-retardant recovery system, can solve the problems of pipelines prone to deflagration and explosion accidents, and achieve the effects of reducing labor intensity, production costs, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

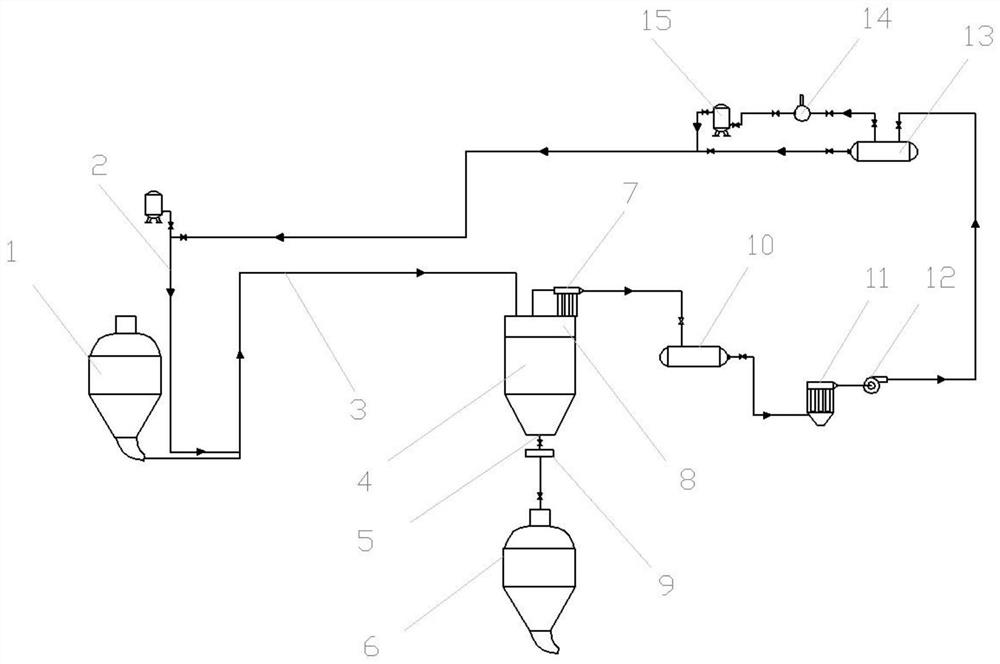

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. In this embodiment, the purified ash produced by the calcium carbide furnace purification device is taken as an example.

[0015] figure 1 A cooling and flame-retardant recovery system for combustible solid waste particles is shown, including a cooling bin pump delivery pipeline 3, the inlet end of the cooling bin pump delivery pipeline 3 is connected to a calcium carbide furnace 1 purification device and a high-pressure nitrogen main pipeline 2, and the cooling bin pump The outlet end of the conveying pipeline 3 is connected to the top of the low-temperature material bin 4, and the outlet 5 at the bottom of the low-temperature material bin 4 is provided with a conveying bin pump 9, and the conveying bin pump 9 is connected to the combustible solid waste boiler 6 through an air conveying pipe; The top of the low-temperature material bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com