Gas type magnesium alloy quantitative melting heat insulation furnace

A technology for magnesium alloys and holding furnaces, which is applied to furnaces, crucible furnaces, furnace types, etc., can solve the problems of complex mechanical structure, high local temperature, and large weight of the charging system of the holding furnace, and achieves low replacement cost of spare parts. Ensure equipment and personal safety, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

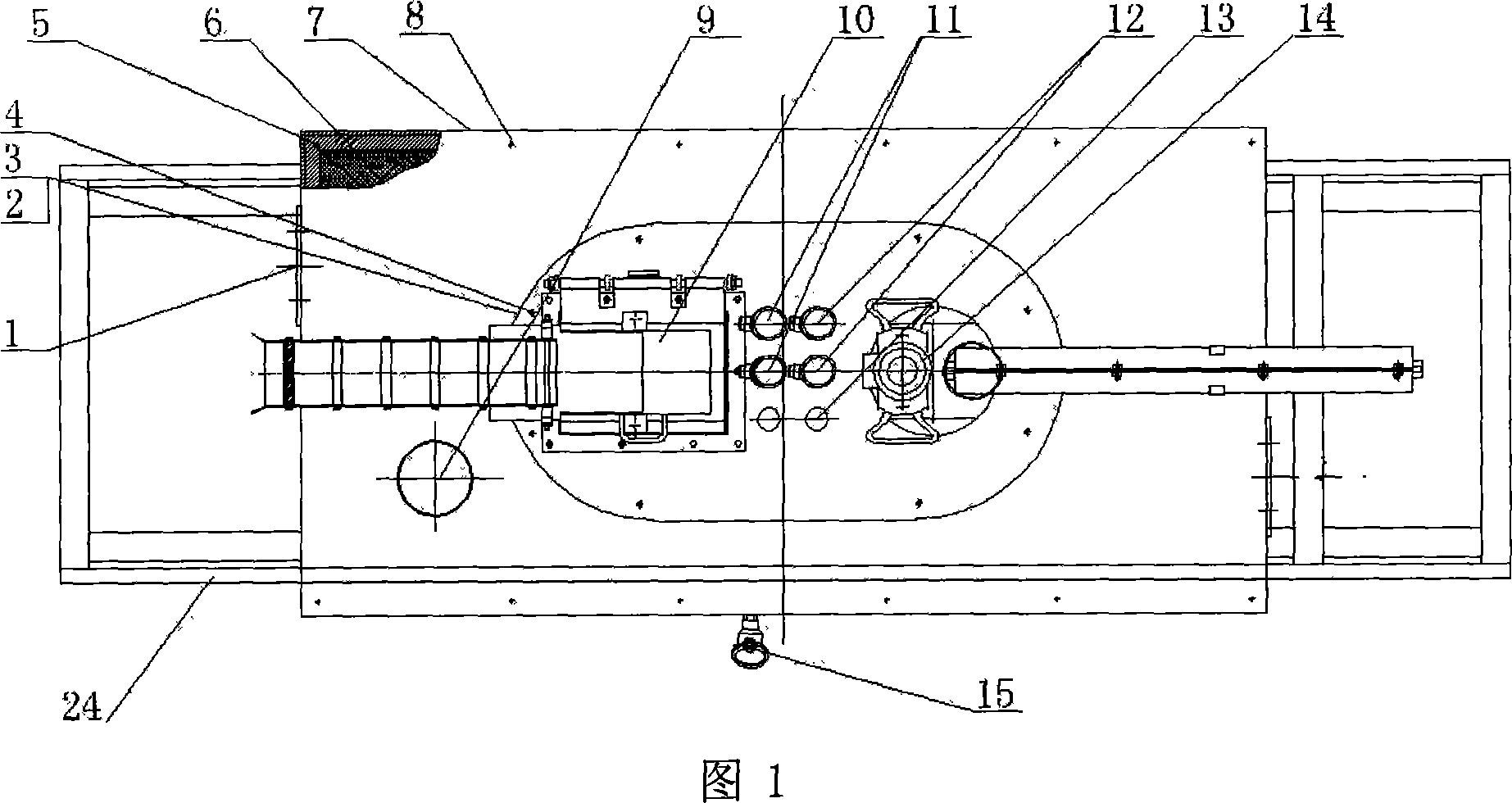

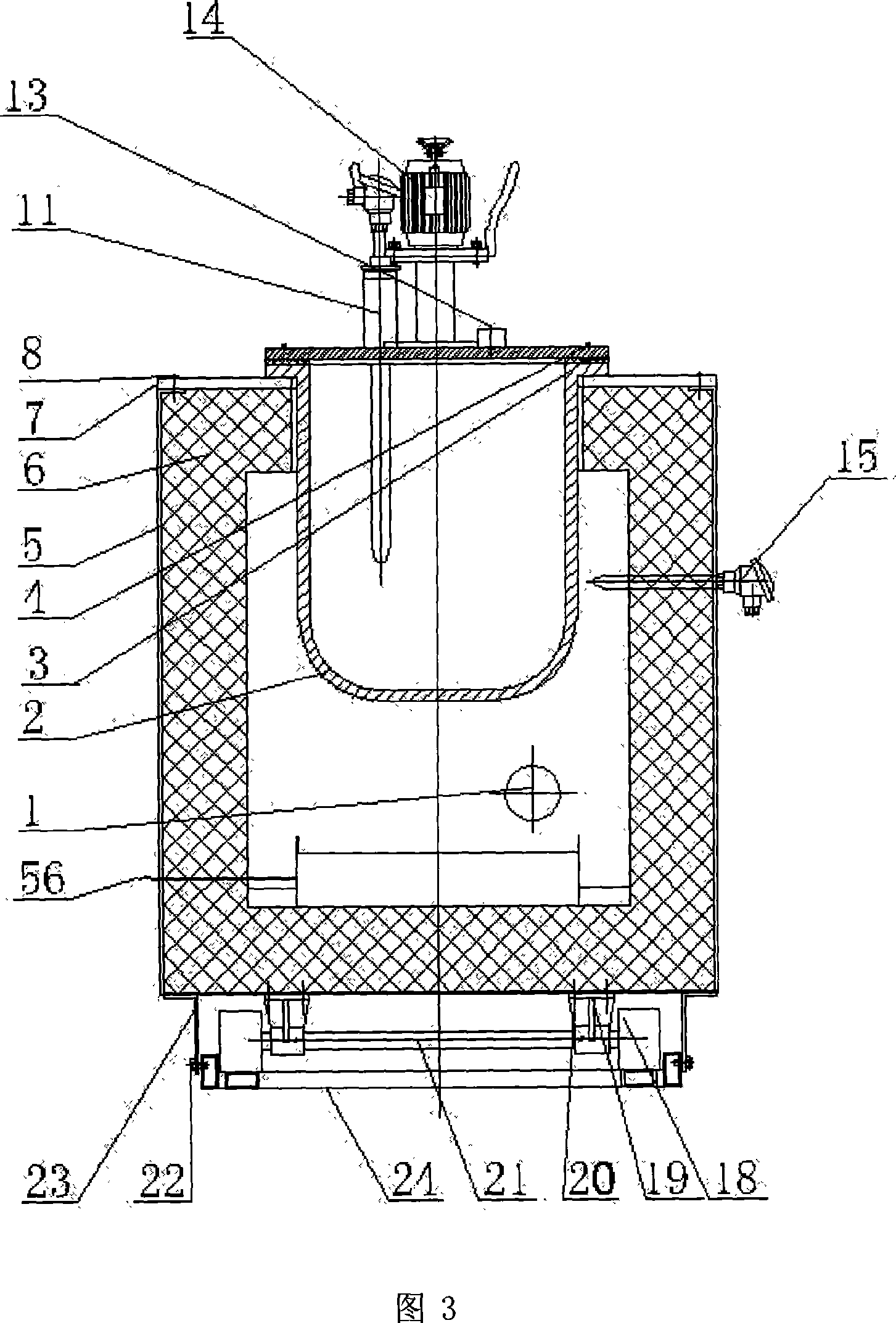

[0024] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0025] As shown in the figure, the gas-fired magnesium alloy quantitative melting and holding furnace of the present invention includes a furnace shell 5 and a crucible 2 lined with an insulating material 6 on the inner wall. The top of the furnace shell is covered with a furnace cover 7, and the crucible 2 passes The crucible hole provided on the furnace cover 7 is suspended in the furnace shell, the crucible is covered with a crucible cover 3, and a smoke exhaust pipe 9 passes through the smoke exhaust port provided on the furnace cover and The inside of the furnace shell is communicated, two temperature measuring thermocouples 11 and temperature measuring probes 12 are inserted into the crucible 2 through the holes provided on the crucible cover 3, and the two protector sockets pass through the The holes provided on the crucible cover 3 communicate with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com