Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2697results about How to "Reduce replacement costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy savings and improved security through intelligent lighting systems

ActiveUS20090262189A1Facilitates proactiveFacilitates appropriate security responseImage analysisElectroluminescent light sourcesIntelligent lightingLight equipment

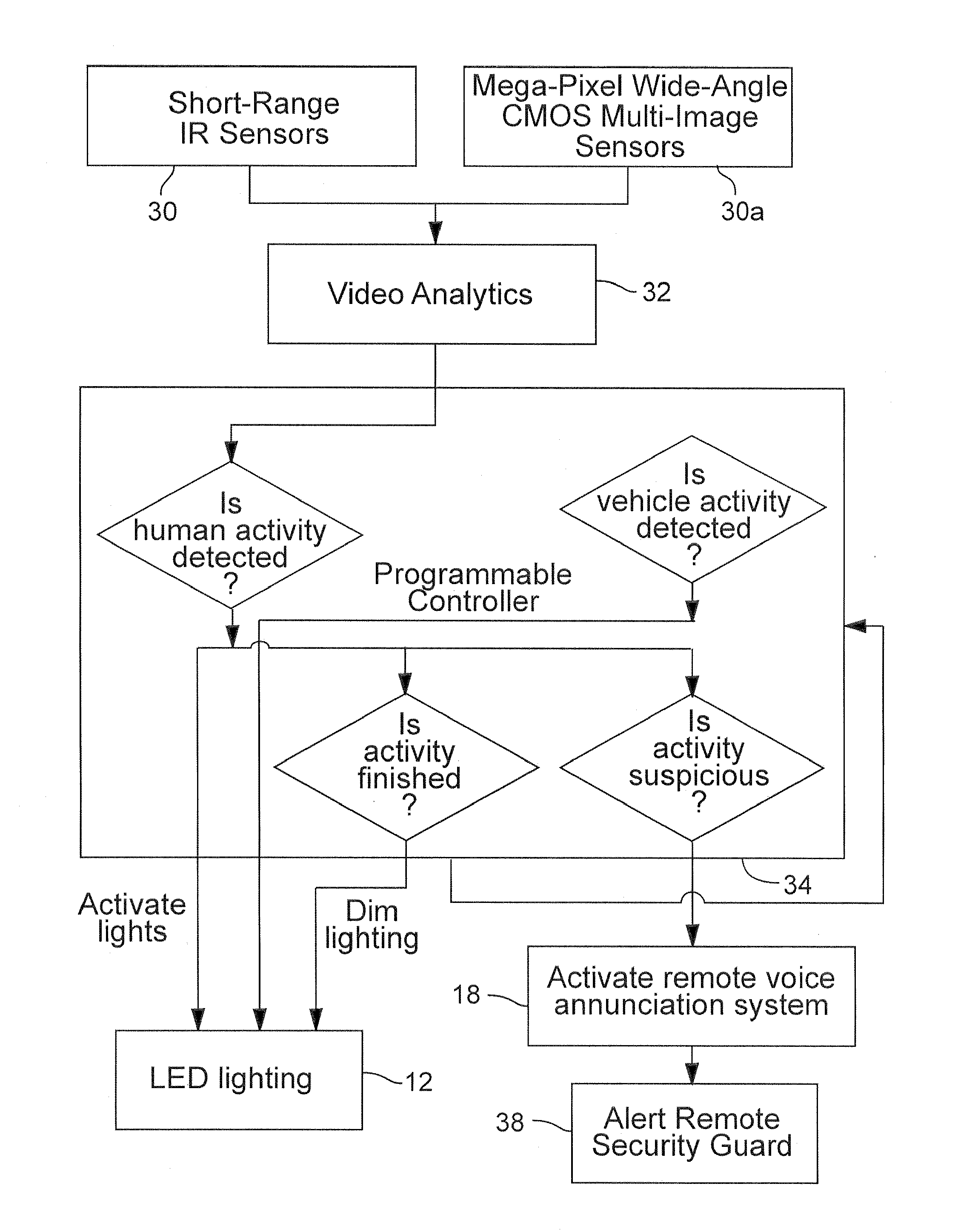

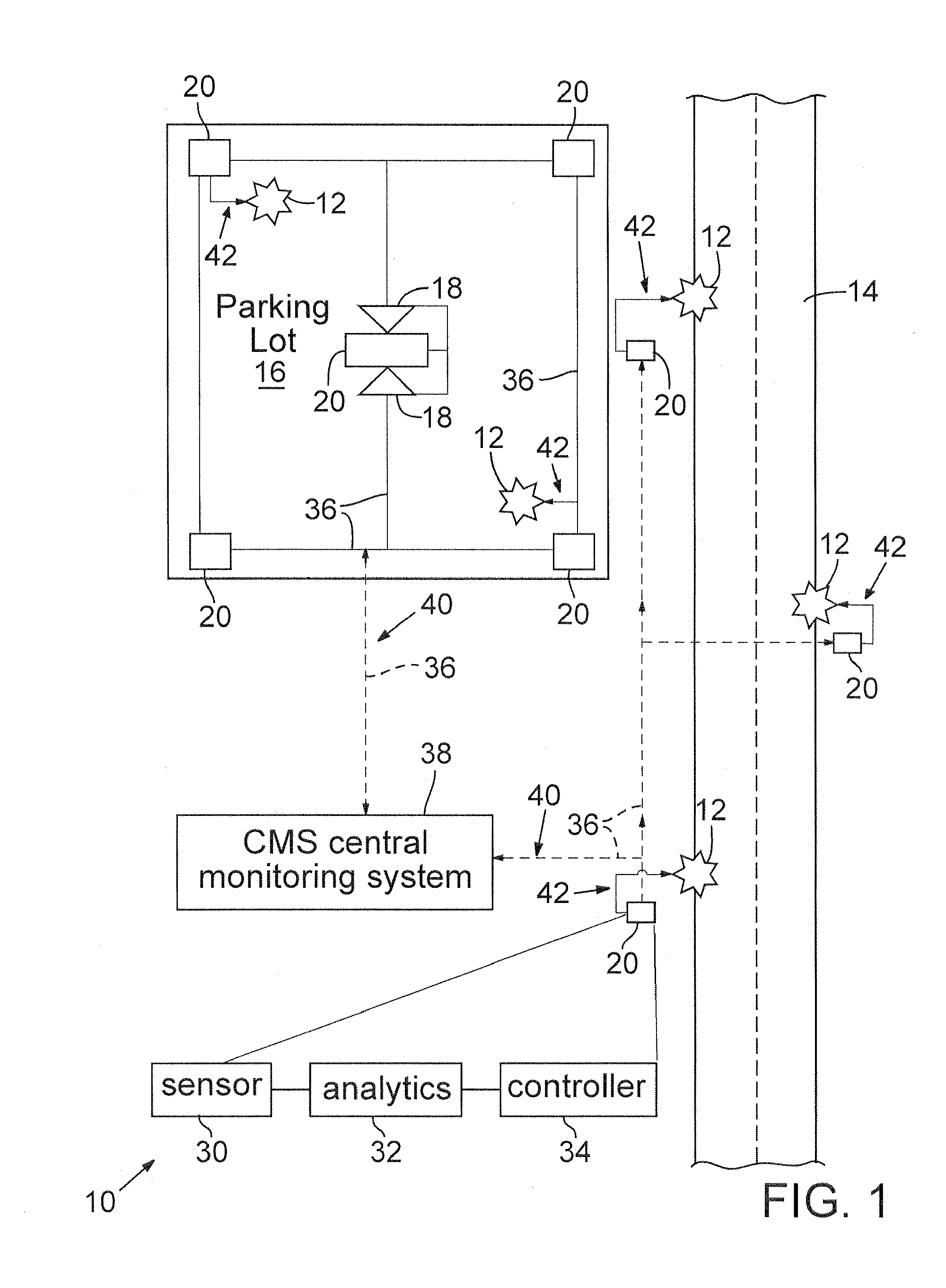

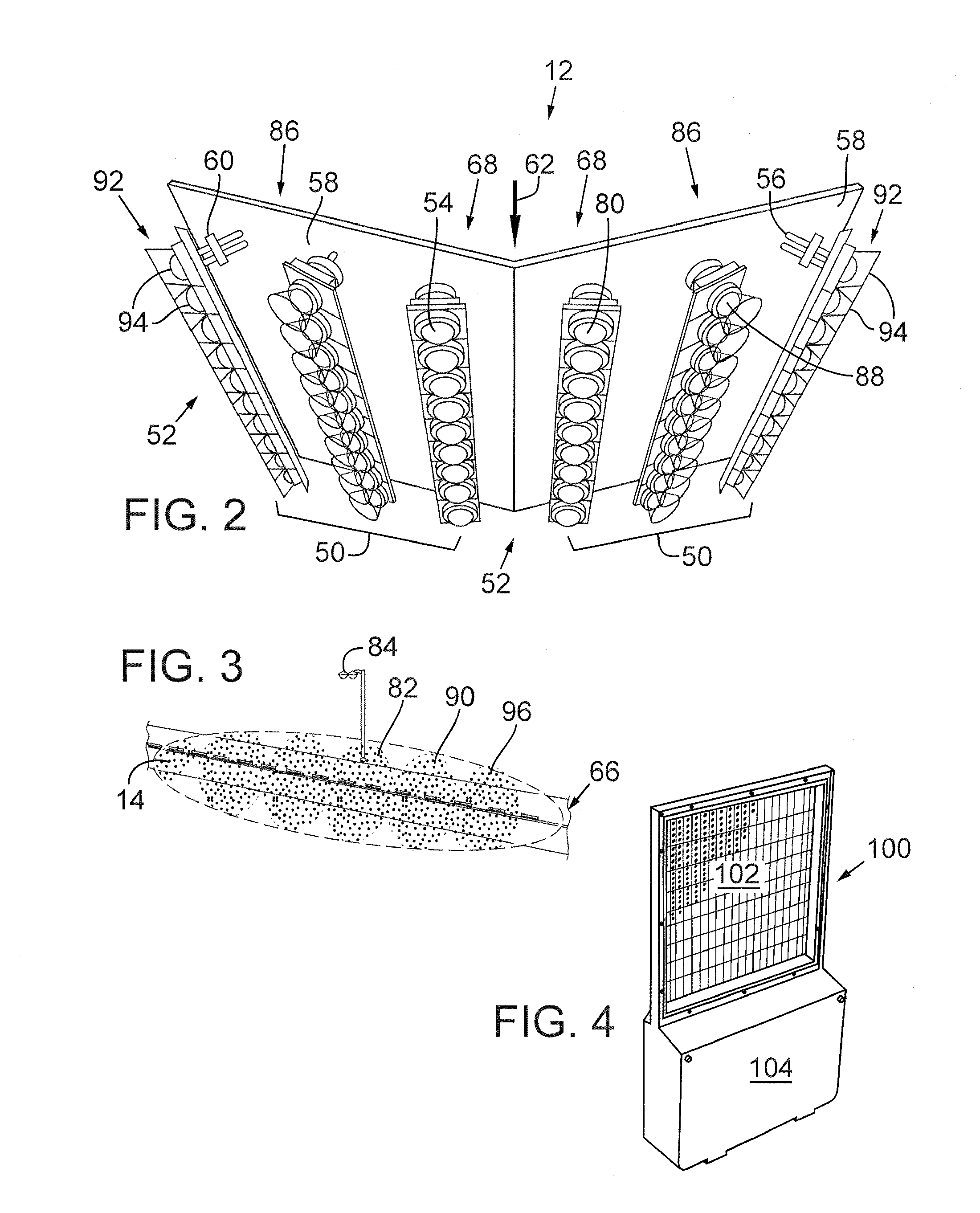

An intelligent lighting system employs energy efficient outdoor lighting and intelligent sensor technology in cooperation with video analytics processing. The lighting system selectively illuminates outdoor spaces and identifies and evaluates events in a scene monitored by a video camera, thereby to facilitate proactive and appropriate security responses to those events. Selective use of advanced lighting fixtures may significantly reduce costs of lighting areas that are monitored by security systems such as streets, public parks, and parking lots, while simultaneously improving security, safety, and traffic control. Energy savings alone, for a properly designed system, are estimated at 50%-90% of current usage. When combined with remote monitoring, such systems may prevent accidents and criminal activity.

Owner:MOTOROLA SOLUTIONS INC

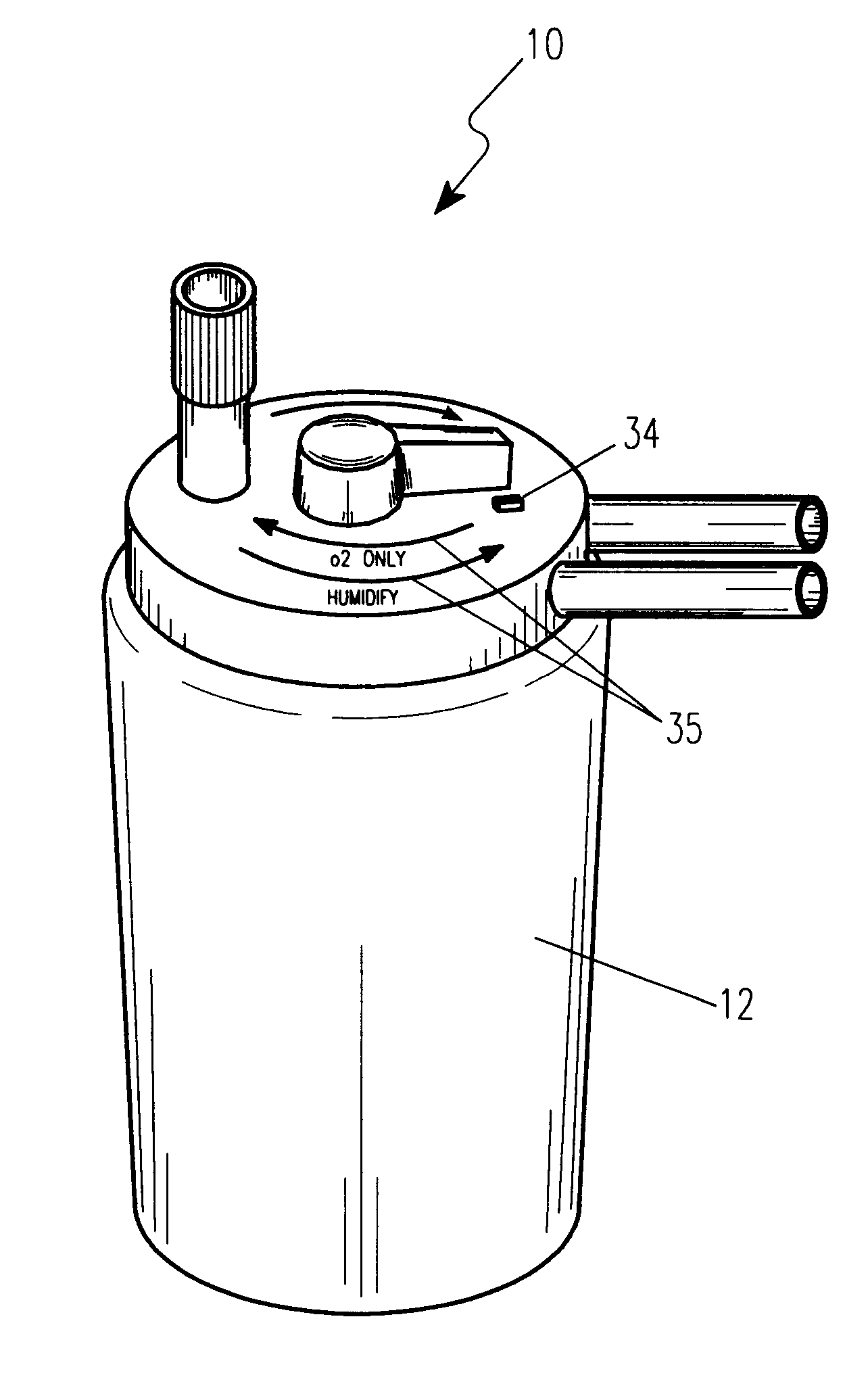

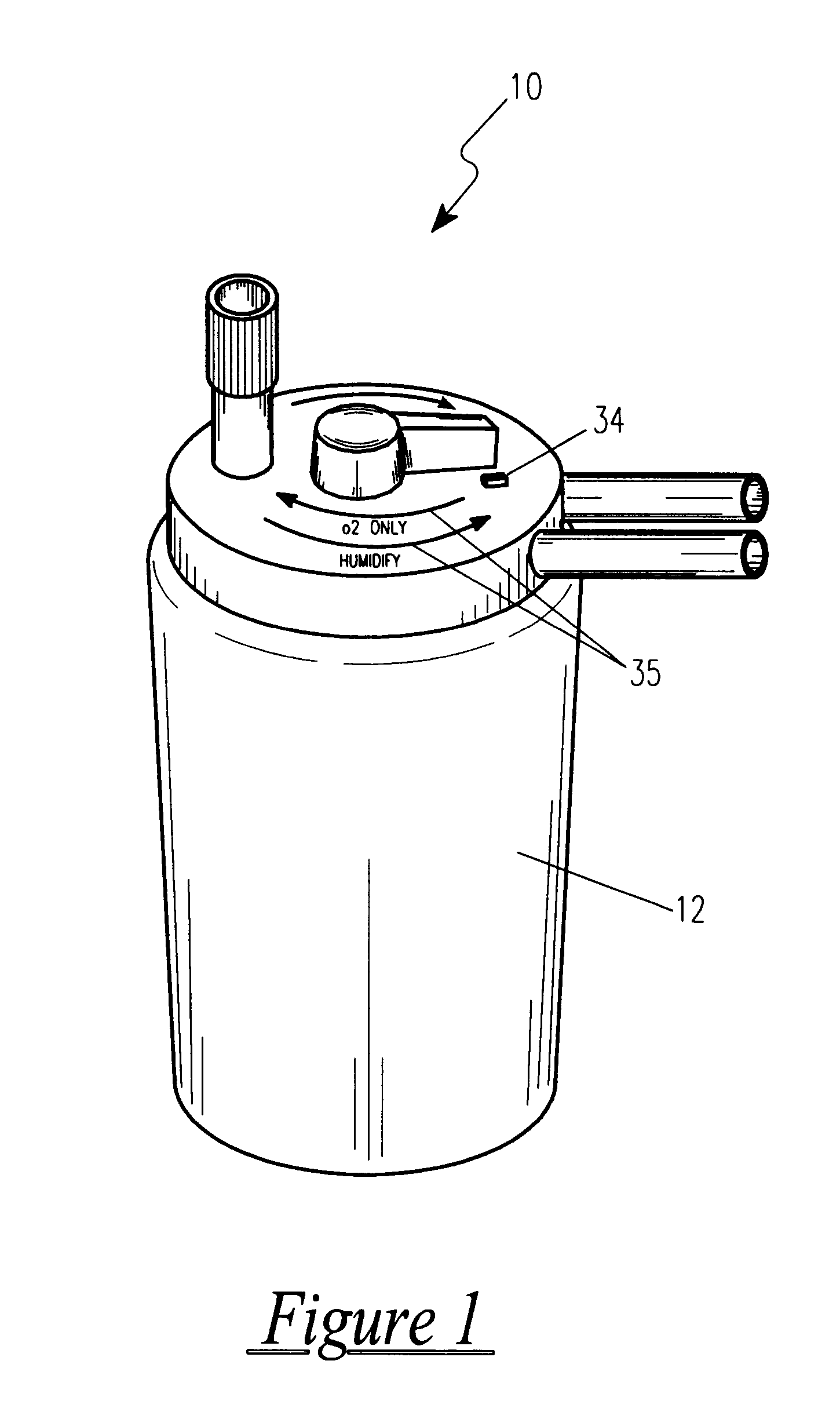

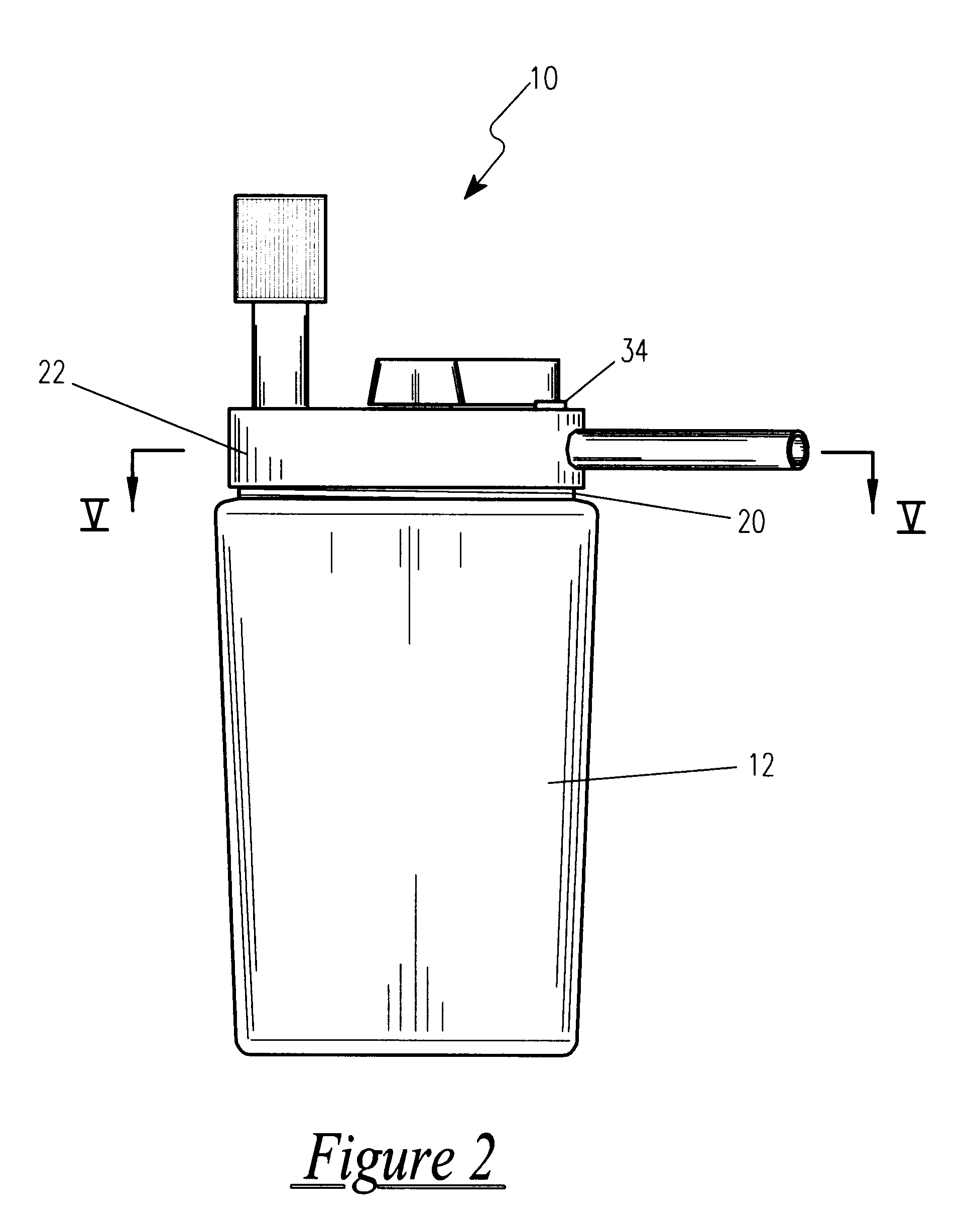

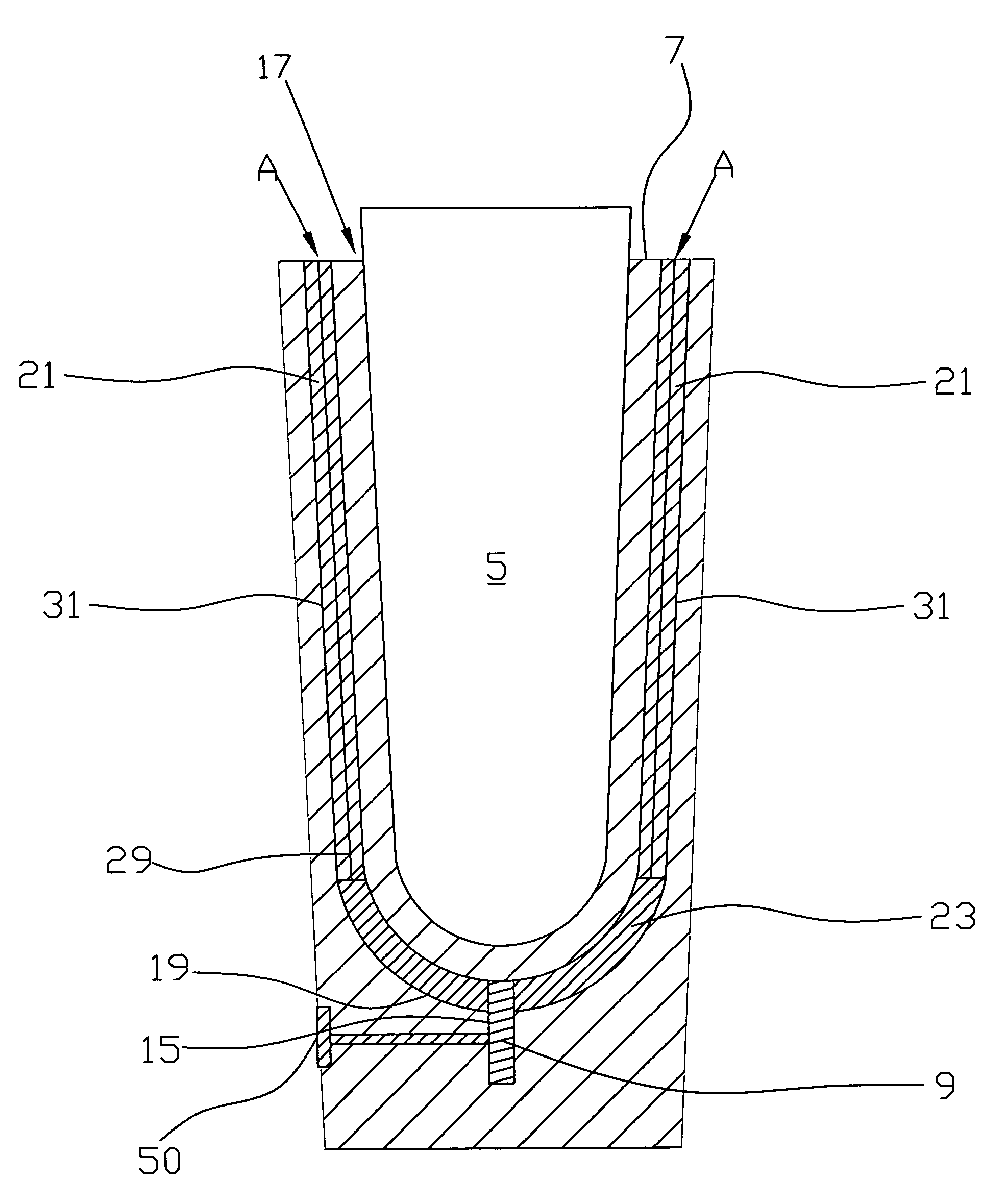

Dual port medical oxygen humidifier

InactiveUS6189870B1Easy to switchReduces and eliminates possibilityLighting and heating apparatusTransportation and packagingEngineeringMoisture

An improved disposable bubble oxygen humidifier is provided having a humidifying chamber included for the blending of oxygen and moisture. A slide switch on the top of the humidifier directs pure oxygen to the patient, or alternately, routes the oxygen through the humidifier and on to the patient. Hoses are attached at an inlet supply port and an outlet discharge port.

Owner:WITHALL GORDON

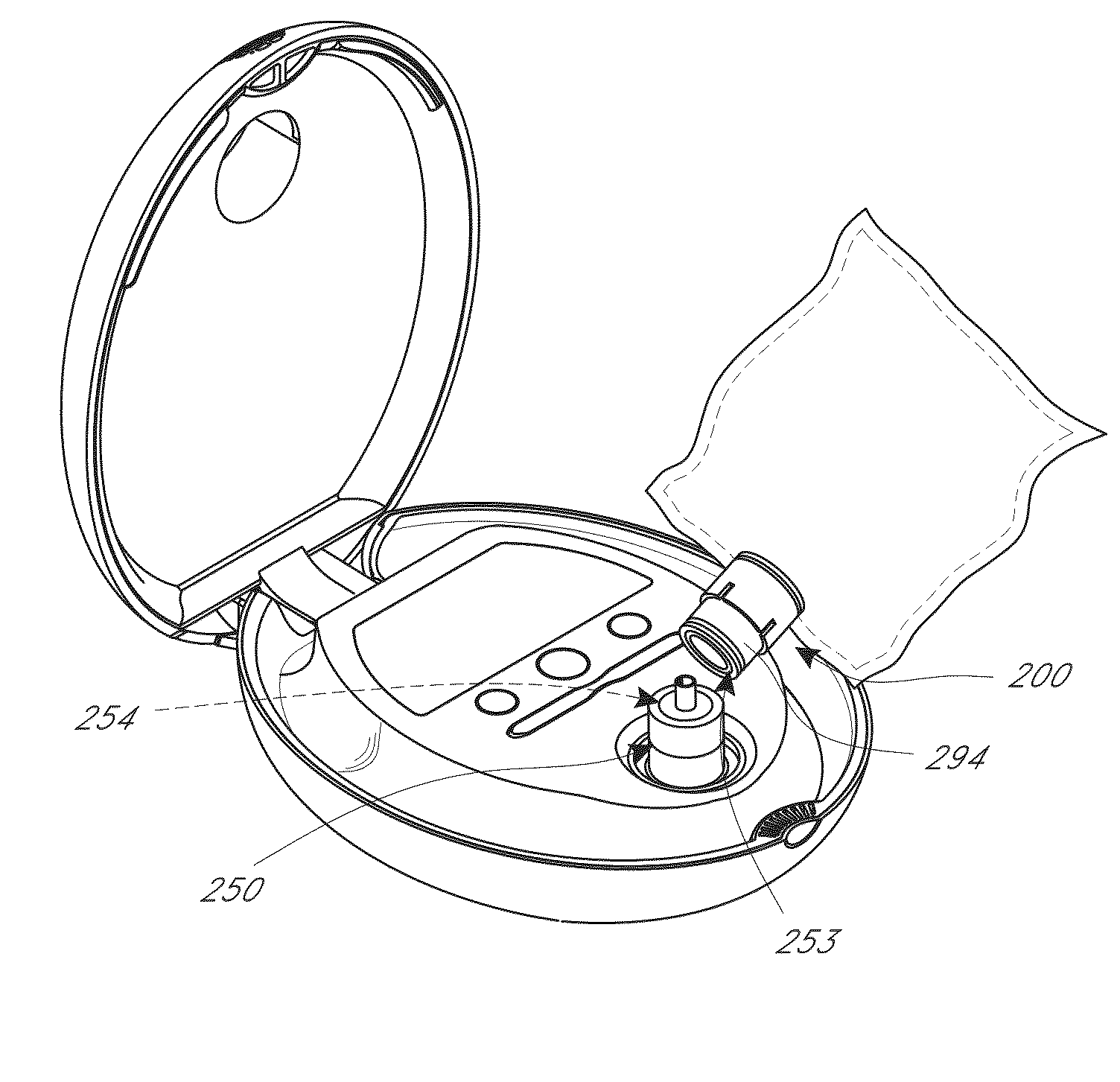

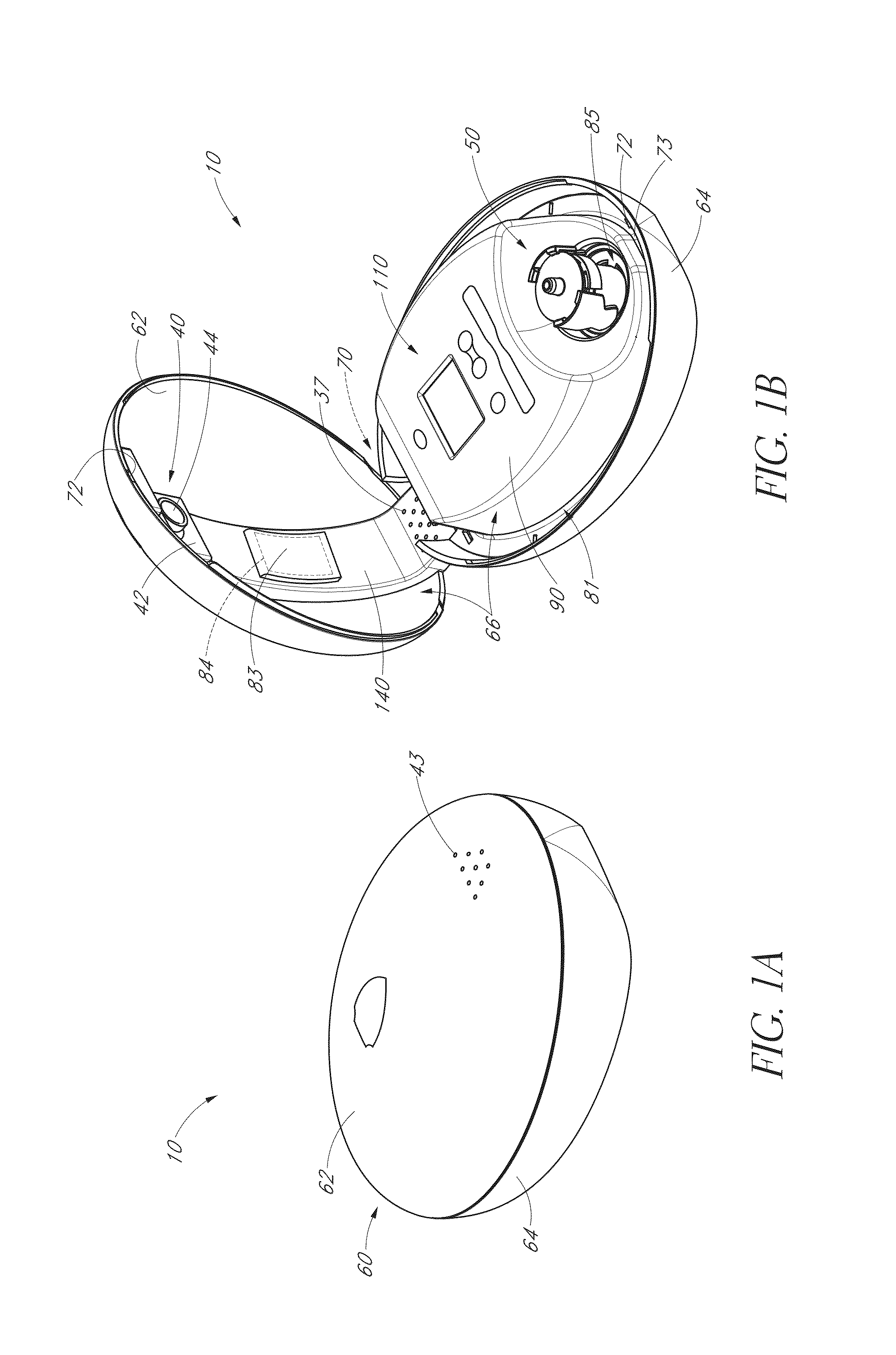

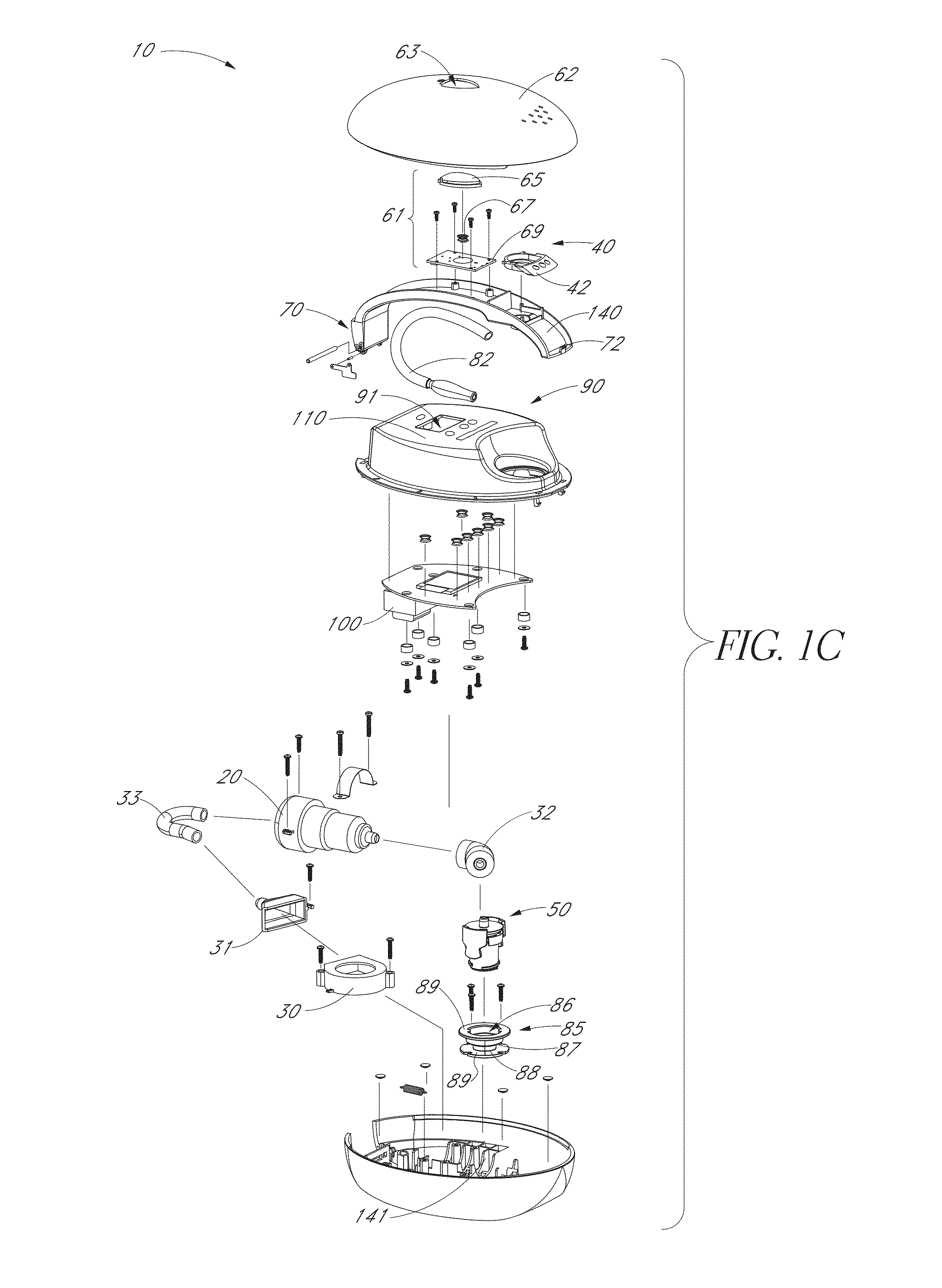

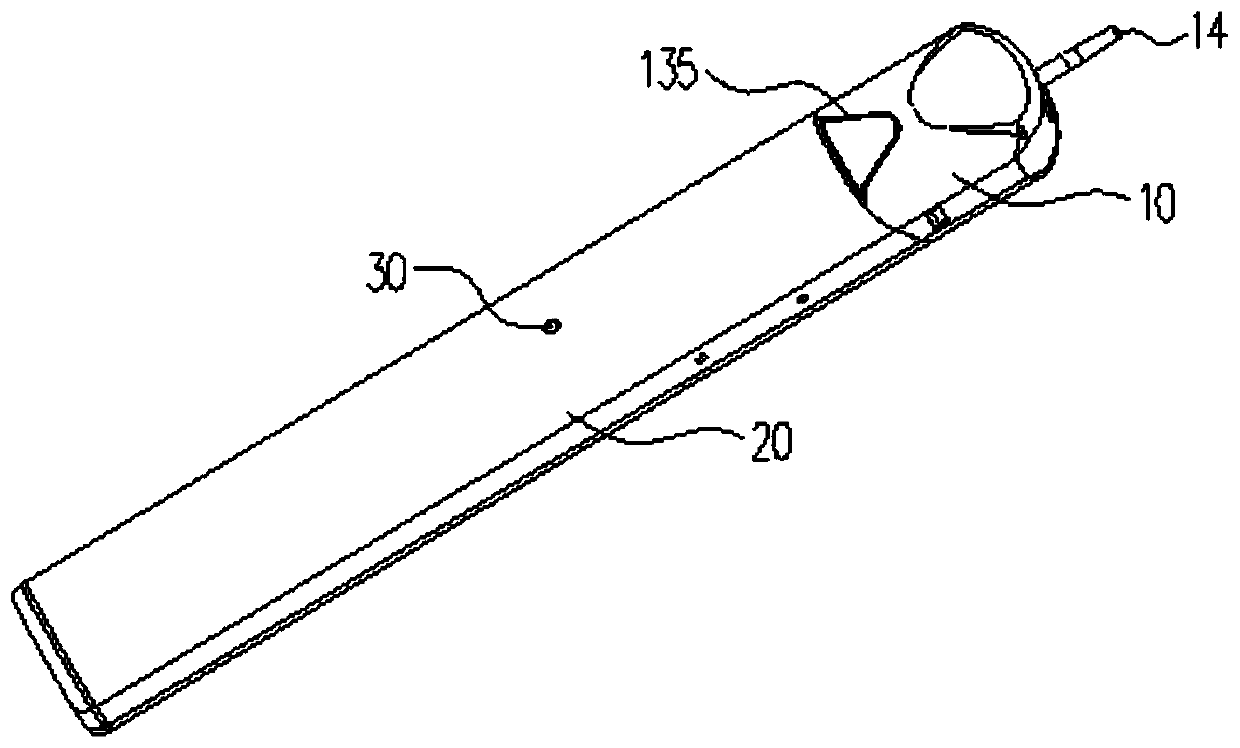

Transversely-activated valve for a therapeutic vaporizer bag attachment system

InactiveUS20140158129A1Reduce quality problemsQuality improvementRespiratorsMedical devicesInhalationCoupling

A therapeutic vaporizer inhalation bag attachment system with an integrated valve is disclosed. The attachment system includes a body having a lumen extending between the two openings of the body, a bag coupling, and a valve positioned within the lumen. A method of using the inhalation bag attachment system is also disclosed.

Owner:PRATT ROBERT IRVING JR

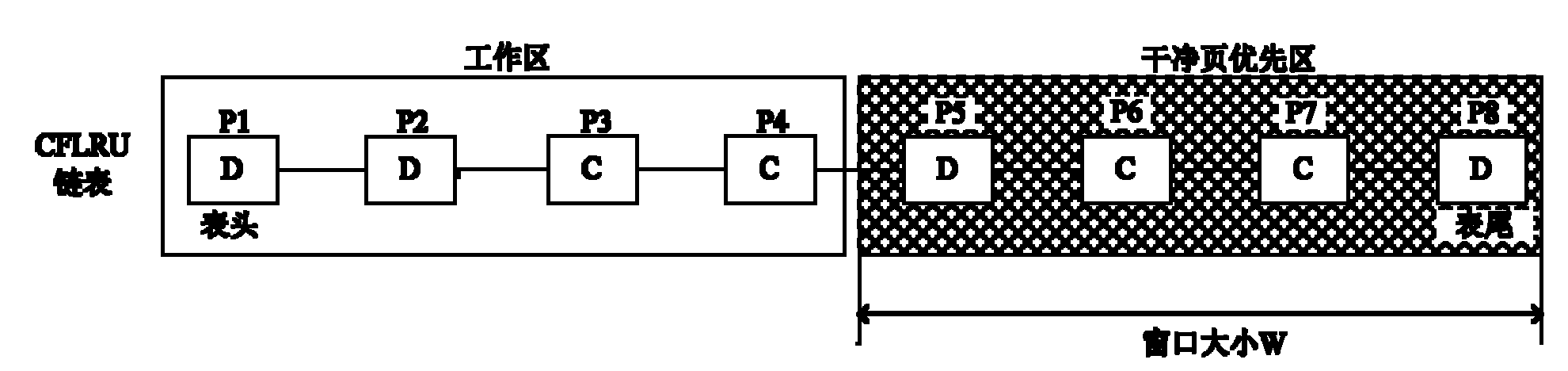

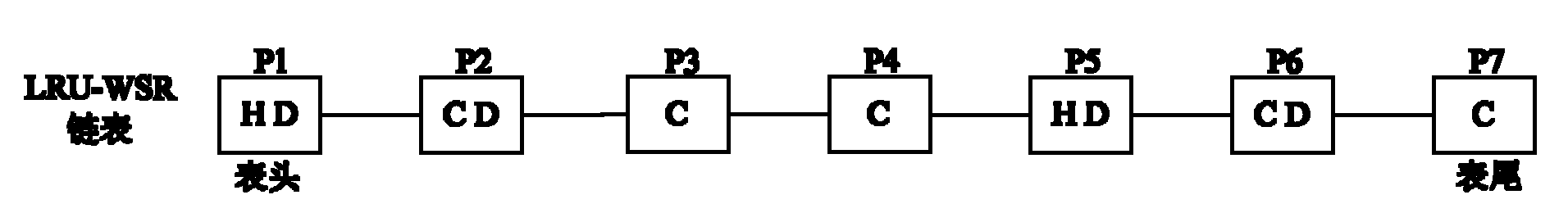

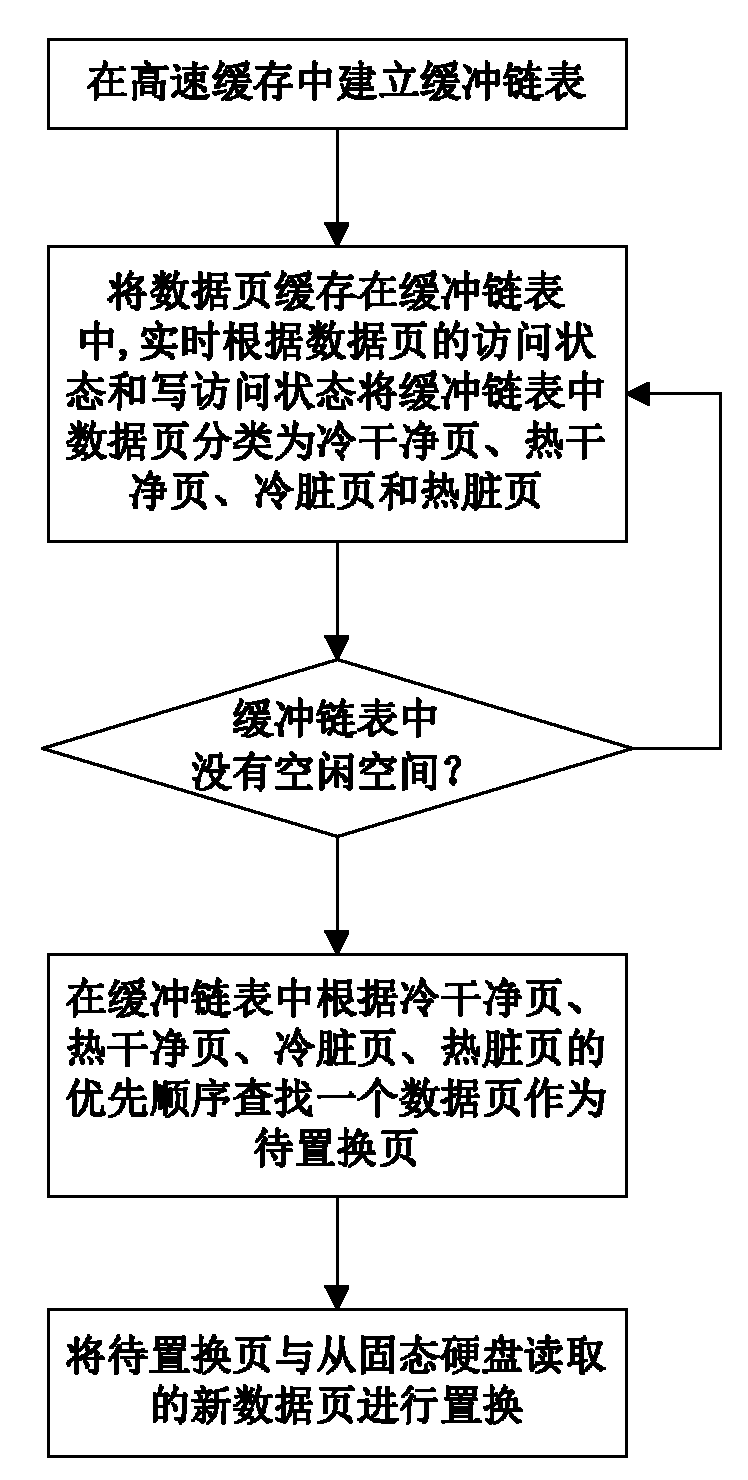

Data page caching method for file system of solid-state hard disc

ActiveCN102156753AReduce overheadImprove hit rateSpecial data processing applicationsDirty pageExternal storage

The invention discloses a data page caching method for a file system of a solid-state hard disc, which comprises the following implementation steps of: (1) establishing a buffer link list used for caching data pages in a high-speed cache; (2) caching the data pages read in the solid-state hard disc in the buffer link list for access, classifying the data pages in the buffer link list into cold clean pages, hot clean pages, cold dirty pages and hot dirty pages in real time according to the access states and write access states of the data pages; (3) firstly searching a data page as a page to be replaced in the buffer link list according to the priority of the cold clean pages, the hot clean pages, the cold dirty pages and the hot dirty pages, and replacing the page to be replaced with a new data page read from the solid-state hard disc when a free space does not exist in the buffer link list. In the invention, the characteristics of the solid-state hard disc can be sufficiently utilized, the performance bottlenecks of the external storage can be effectively relieved, and the storage processing performance of the system can be improved; moreover, the data page caching method has the advantages of good I / O (Input / Output) performance, low replacement cost for cached pages, low expense and high hit rate.

Owner:NAT UNIV OF DEFENSE TECH

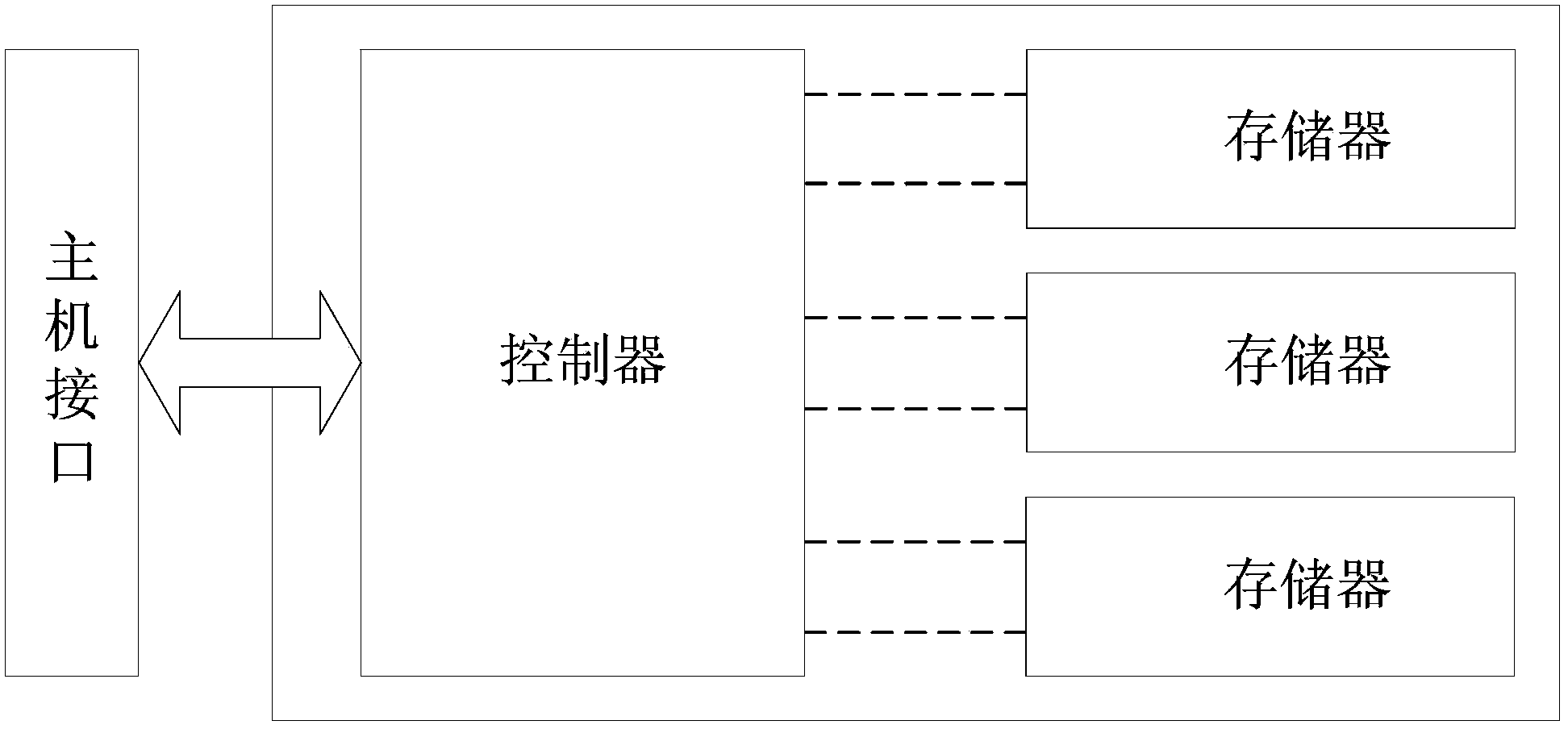

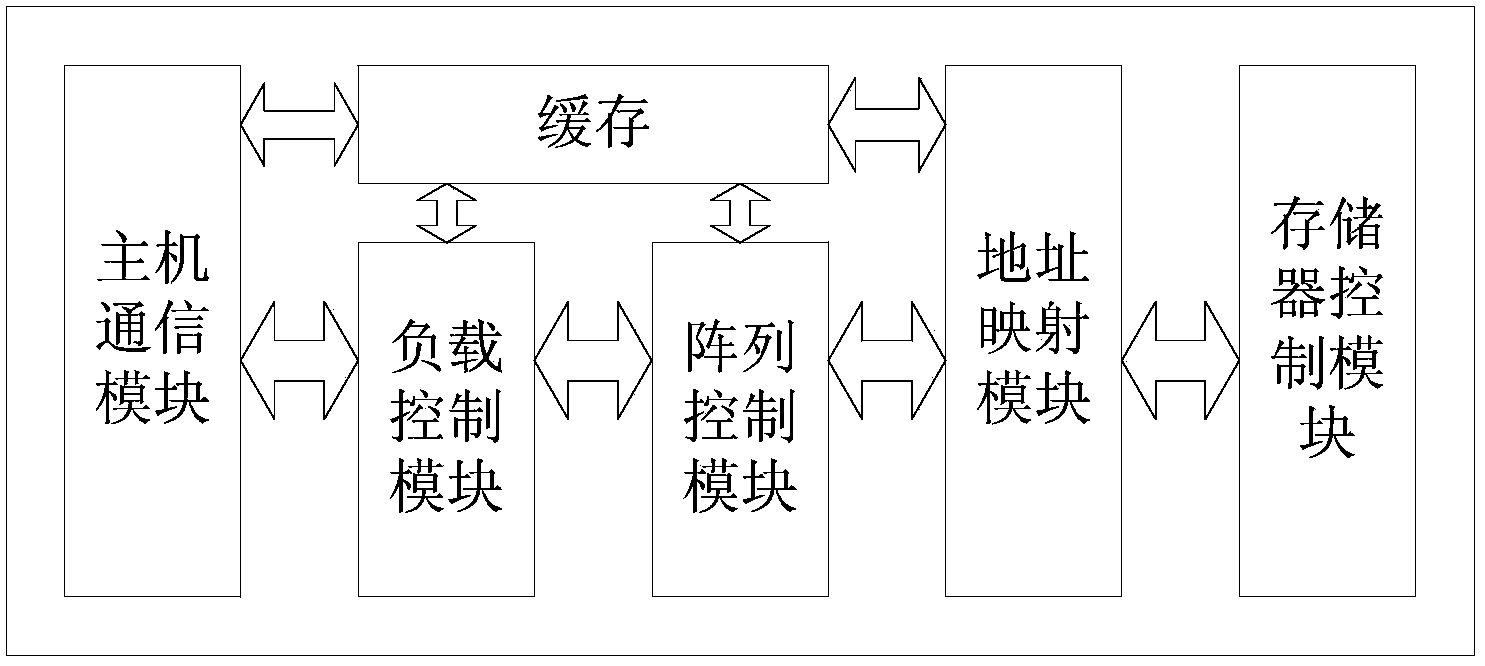

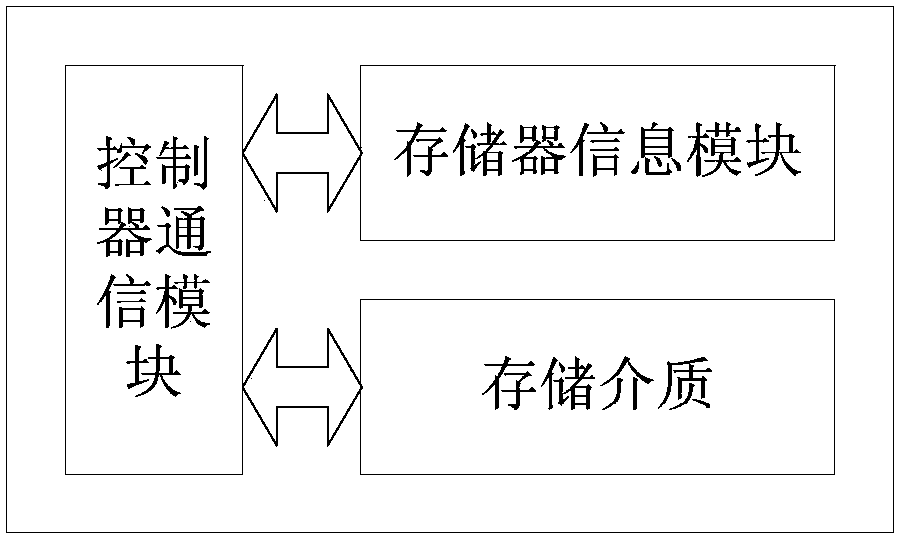

Hybrid storage system

ActiveCN103455283AImplement hybrid storageImprove acceleration performanceInput/output to record carriersMedia controlsHybrid storage system

The invention discloses a hybrid storage system, which belongs to the field of computer storage and is used for solving the problems of high system complexity and high cost due to the need of a plurality of controllers and single storage medium controlled by each controller existing in the conventional mixed storage system. The hybrid storage system consists of N storages and a controller, wherein each storage comprises a controller communication module, a storage medium and a storage information module; and the controller comprises a host communication module, a load control module, an array control module, an address mapping module, a storage control module and a buffer. The controller can be used for identifying reading and writing requests reaching a host and judging the cold and hot degree and magnitude of the writing request to perform load control so as to realize hybrid storage of multiple types of storages. The storage is a storage medium chip as well as a simple information storage chip, so that the replacement cost of the hybrid storage system is reduced; and data recovery is performed by using the array control module in the controller, so that the performance of the hybrid storage system is enhanced, the service life of the hybrid storage system is prolonged, and the establishment and use costs of the hybrid storage system are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

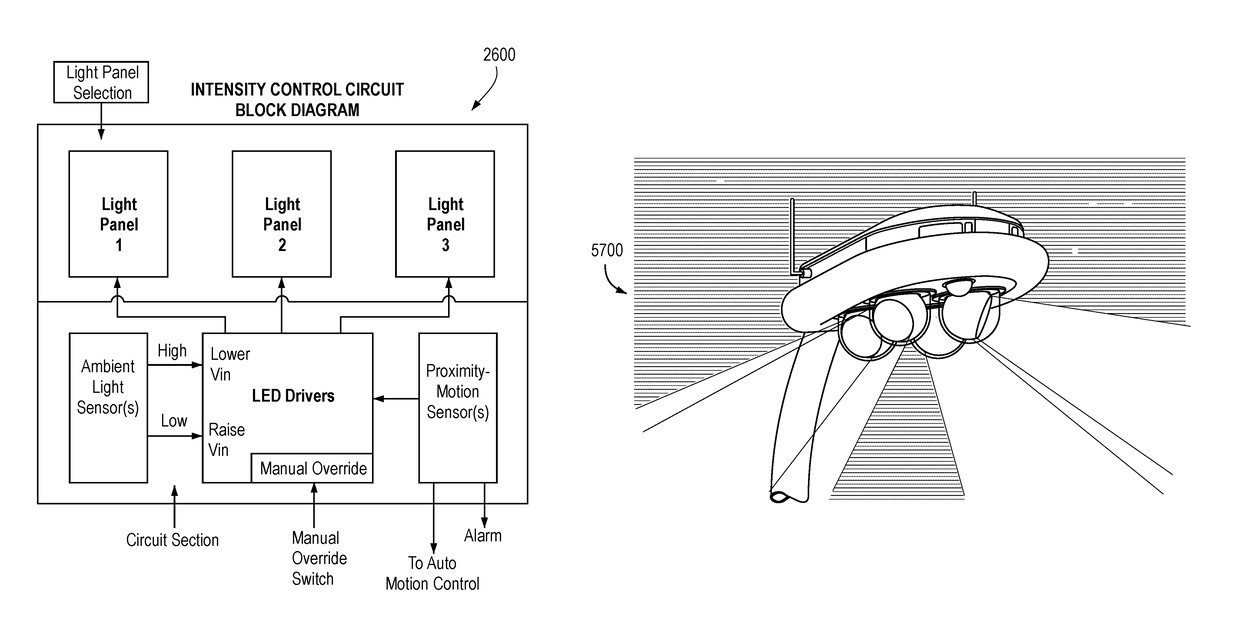

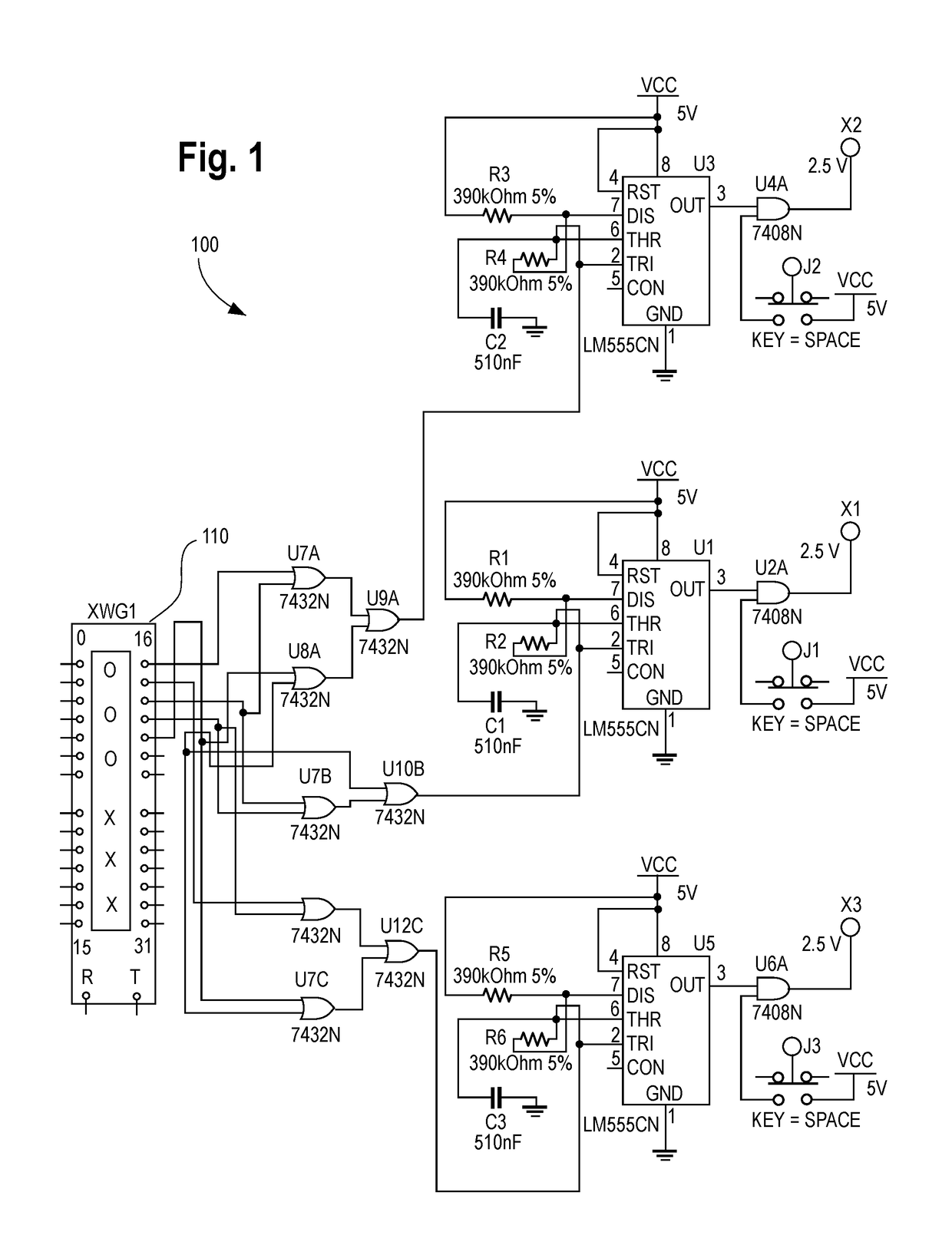

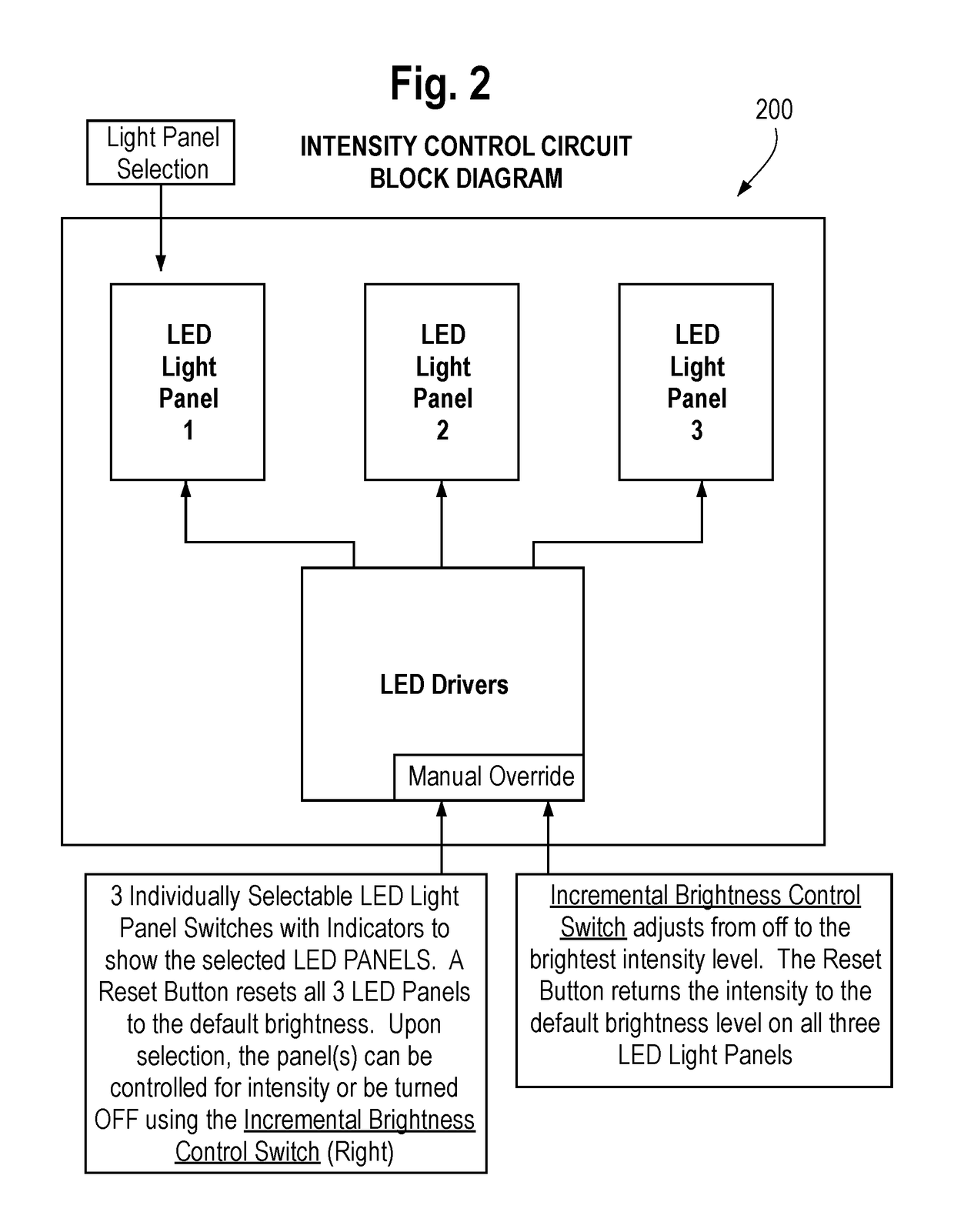

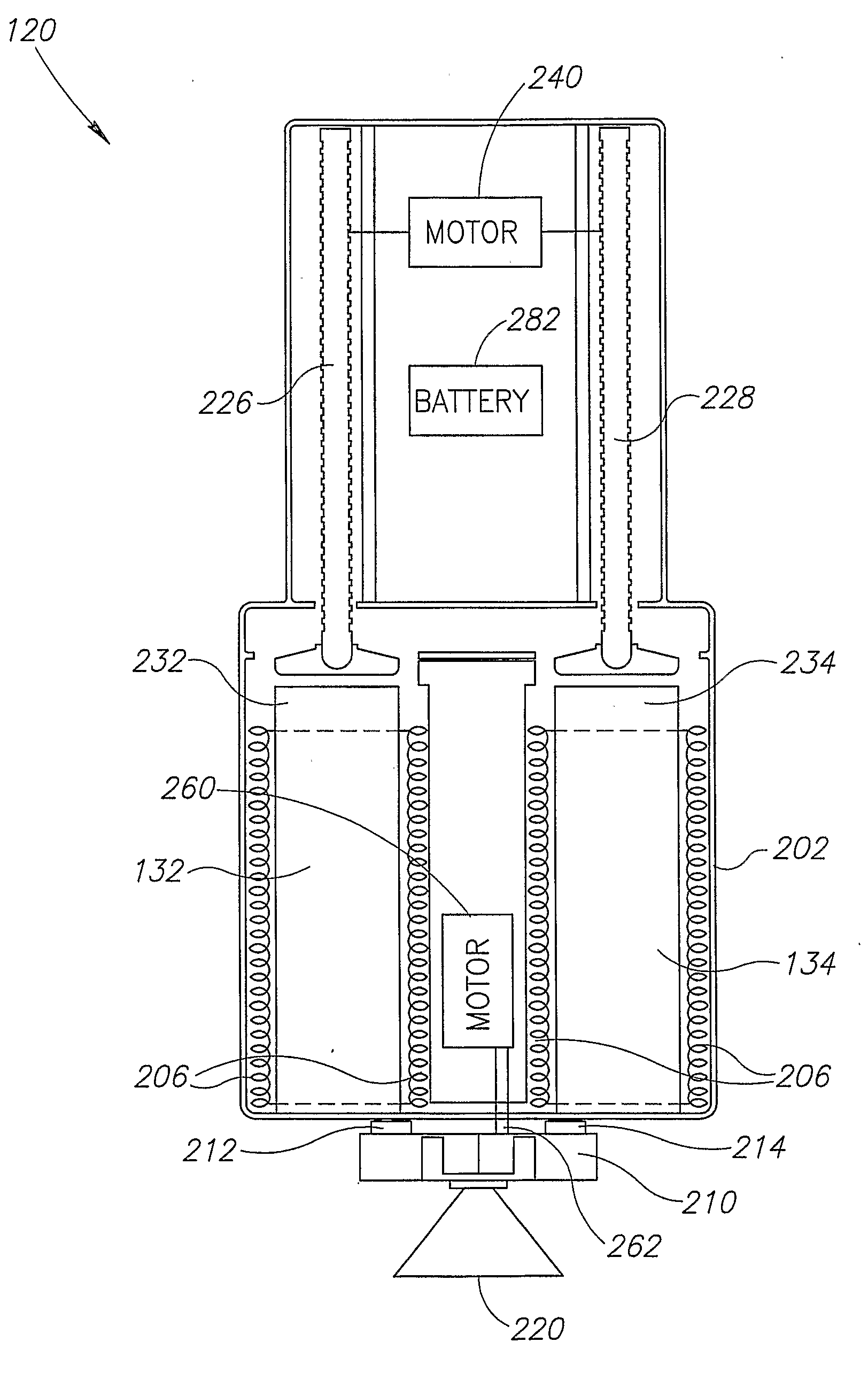

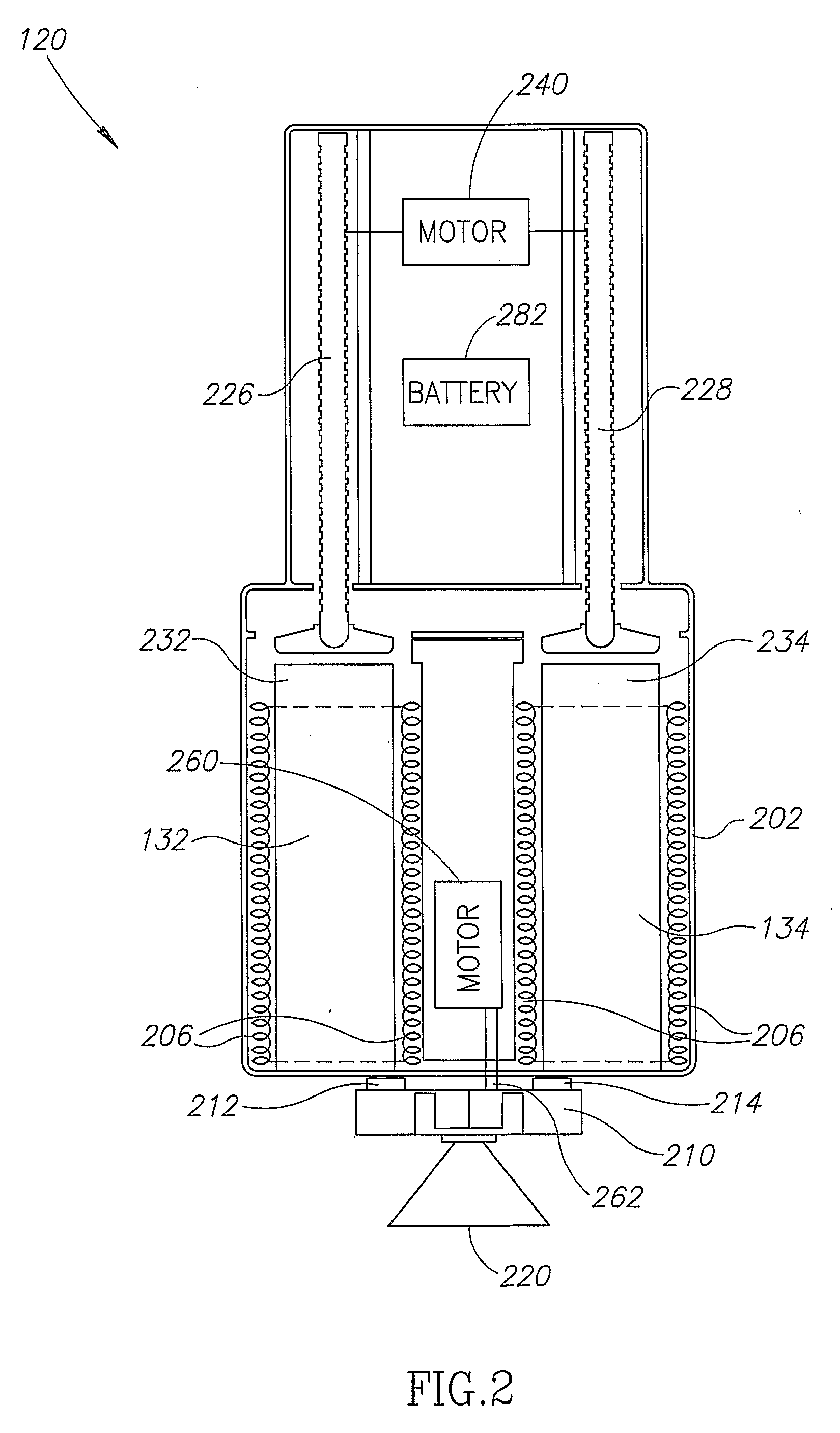

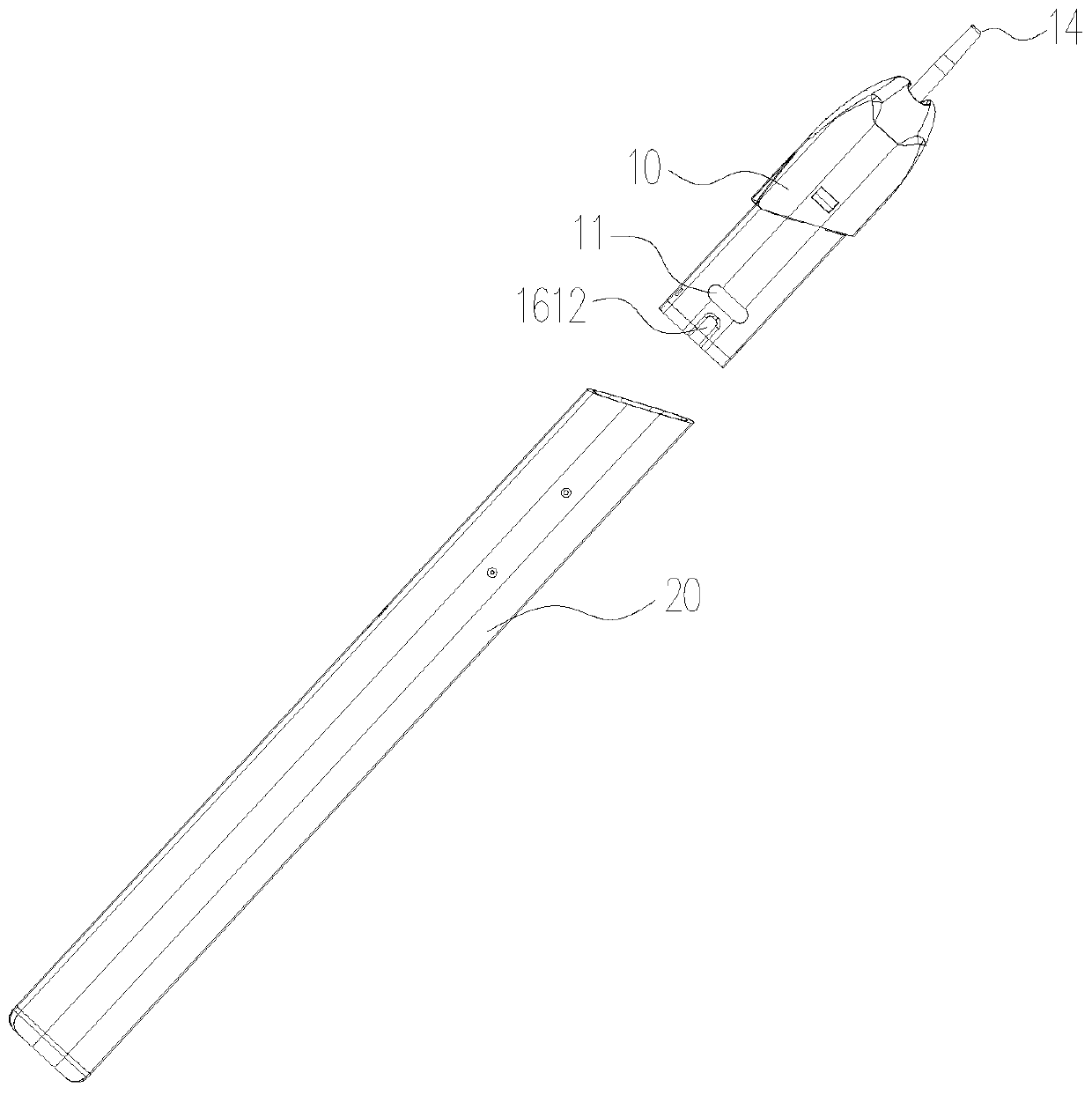

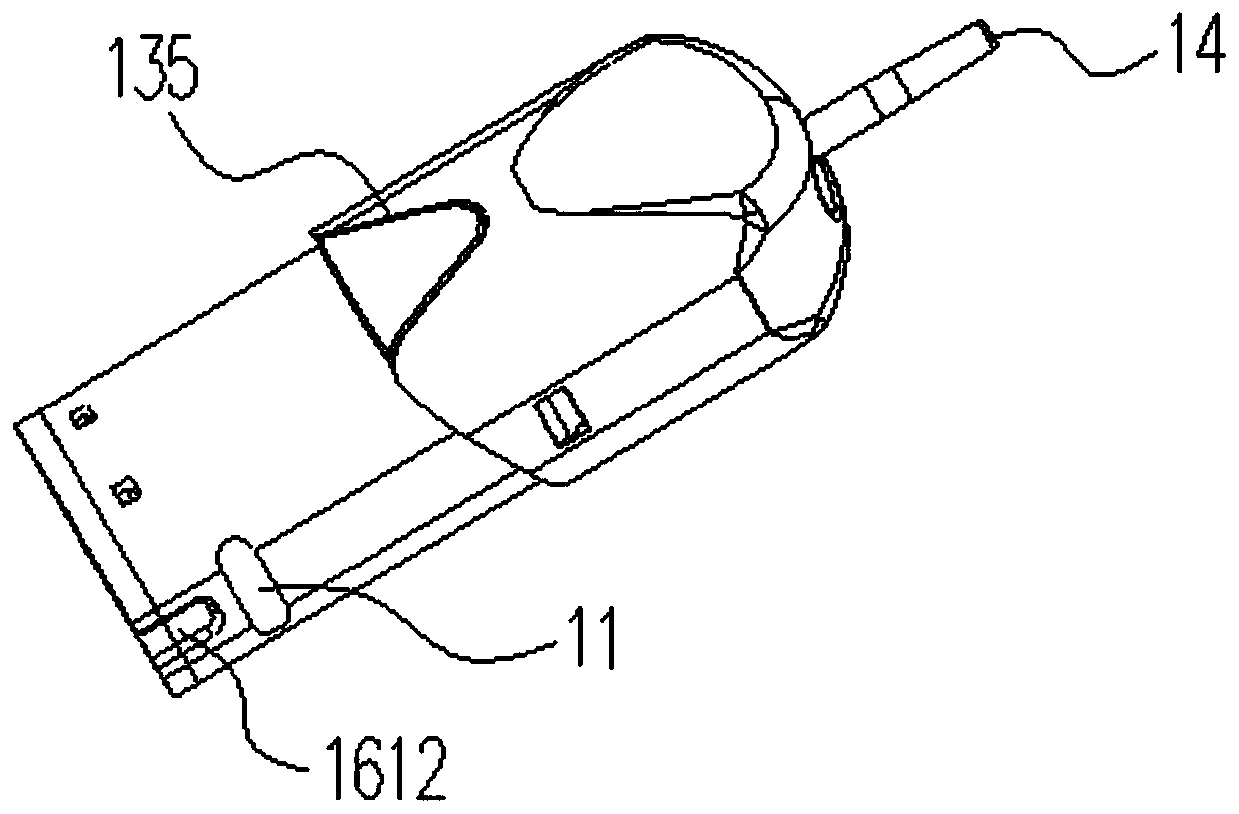

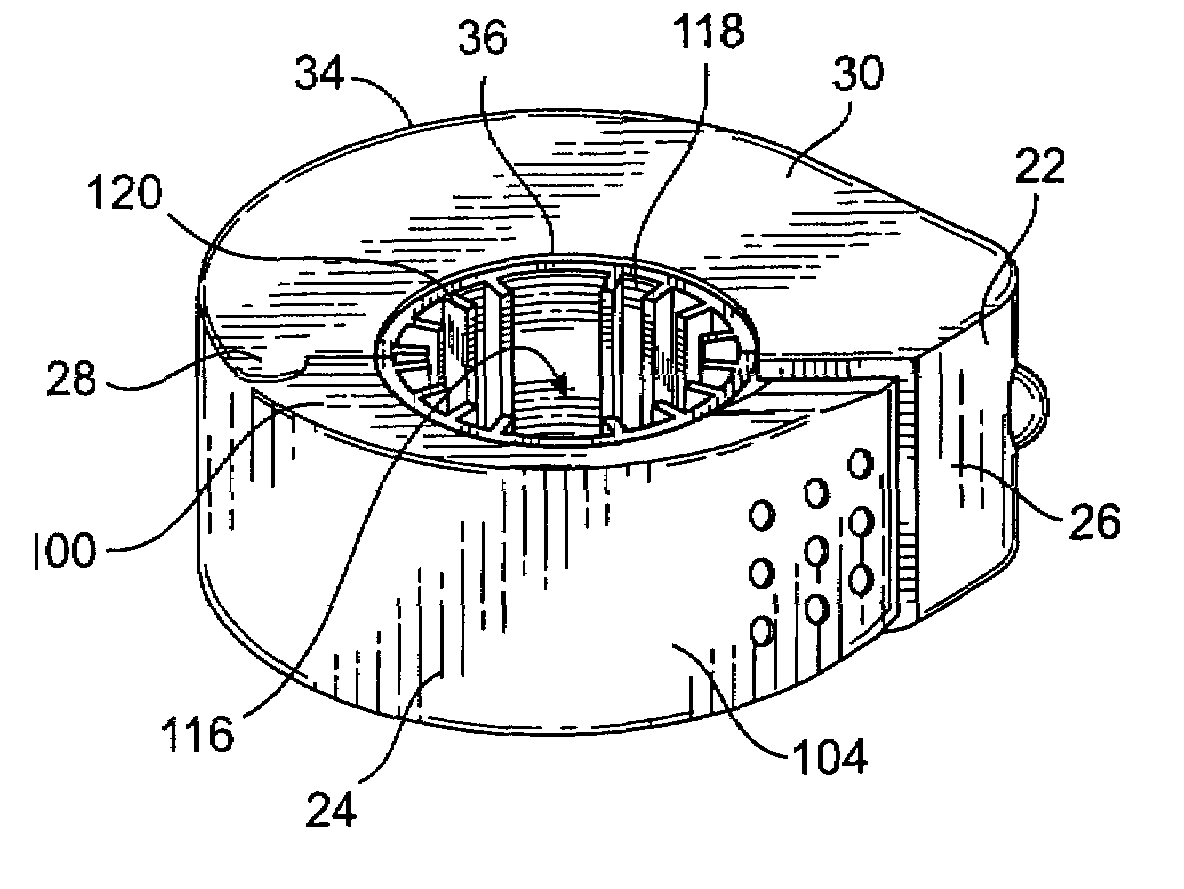

Sensor-based controllable LED lighting system with repositionable components and method

ActiveUS9629220B2Reduce replacement costsLow luminairePlanar light sourcesLight source combinationsCommunications systemLighting system

A lighting system is provided having a movement system, a light source repositionable via the movement system, a sensor, a controller, and a communication system. The controller may control characteristics of the light emitted by the light source, rotation of the panel by the movement system, and receiving signal information from the sensor. The communication system exchange data between the controller and an external device, the light source and the movement system being remotely controllable by logic received using the controller via the communication system. The light source, the movement system, the controller, the sensor, and the communication system are installable in a drone. Wearable apparatus may be used with the system. Objects may be tracked and illuminated.

Owner:PANOPOULOS PETER J

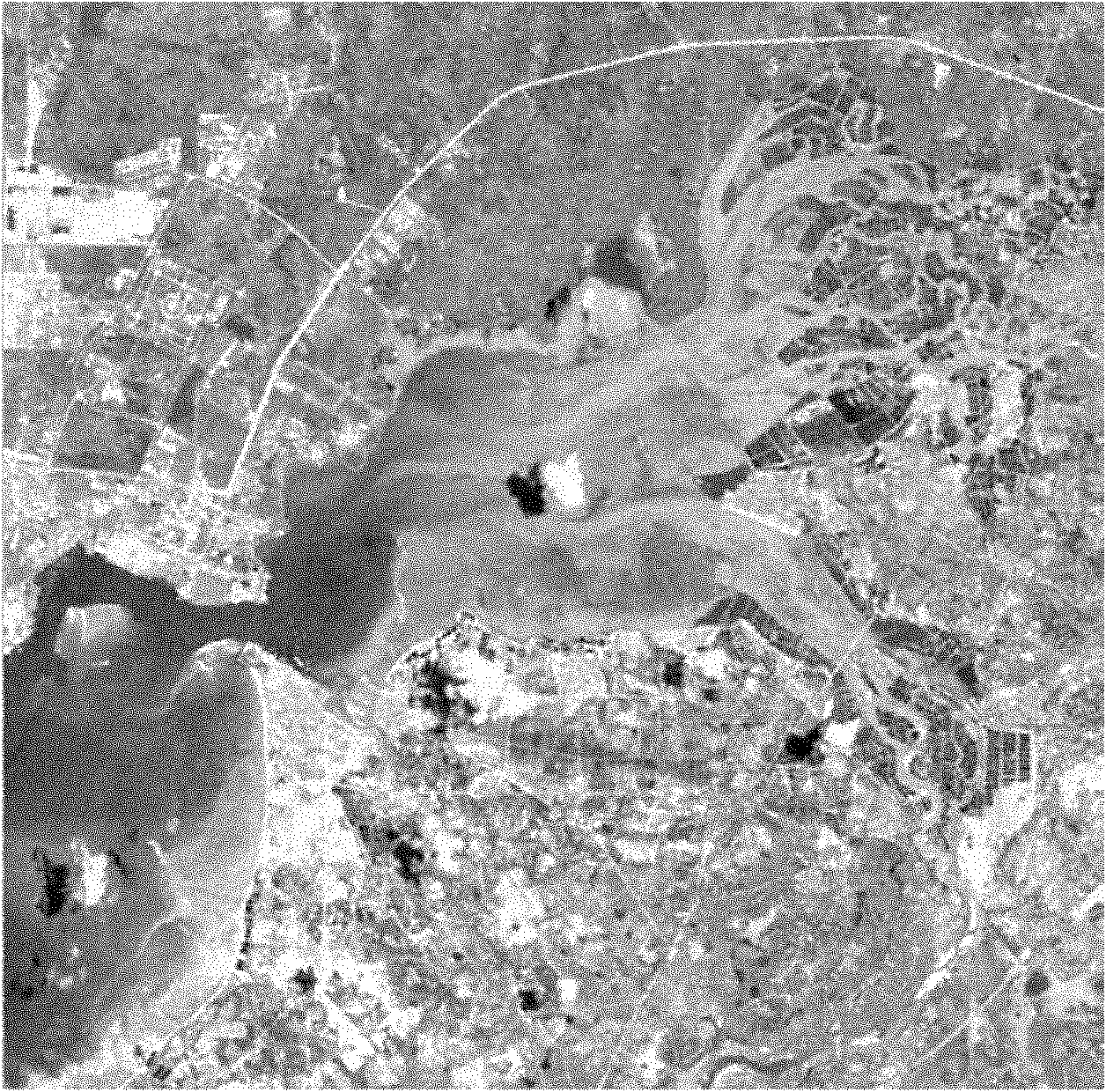

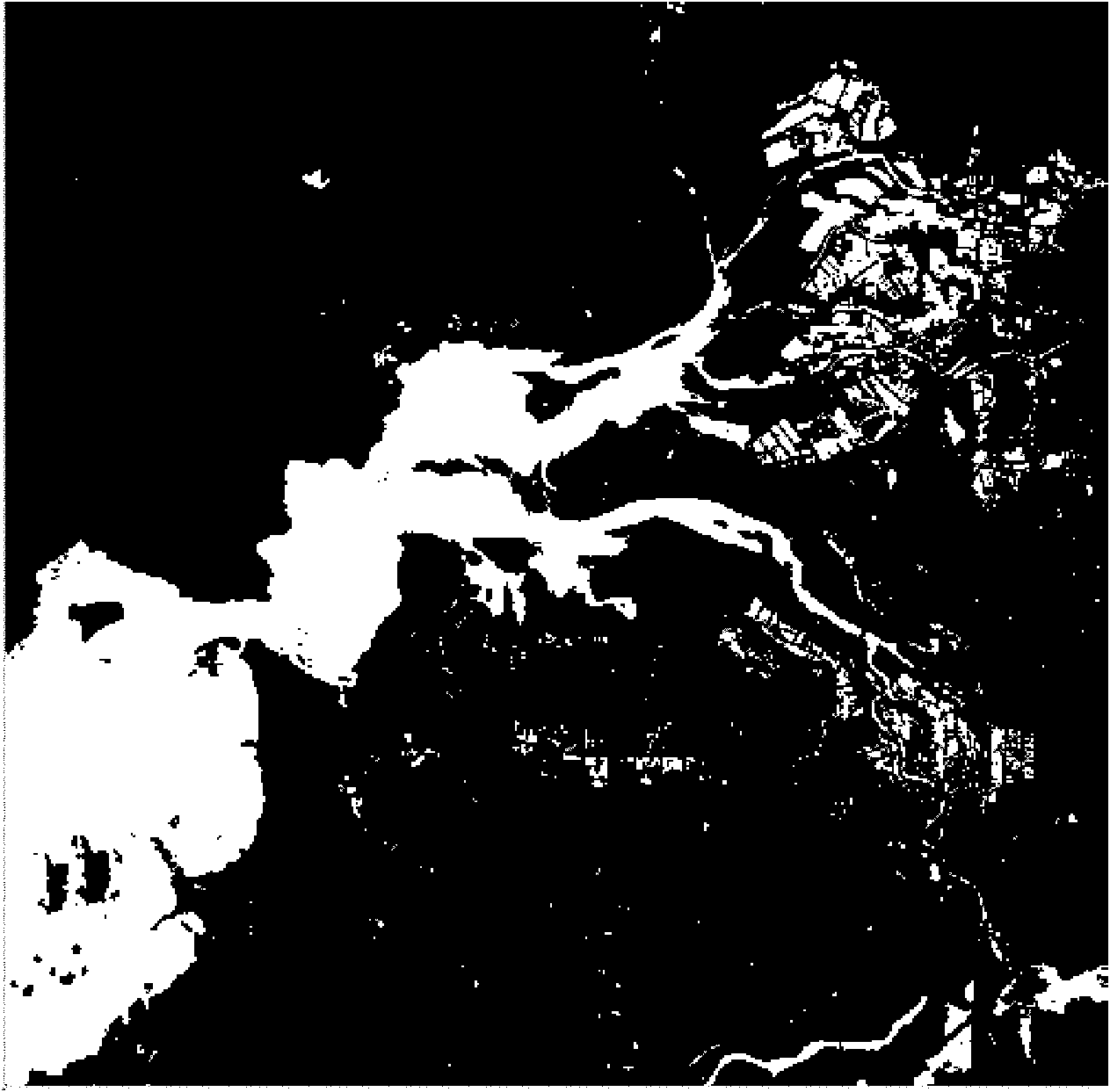

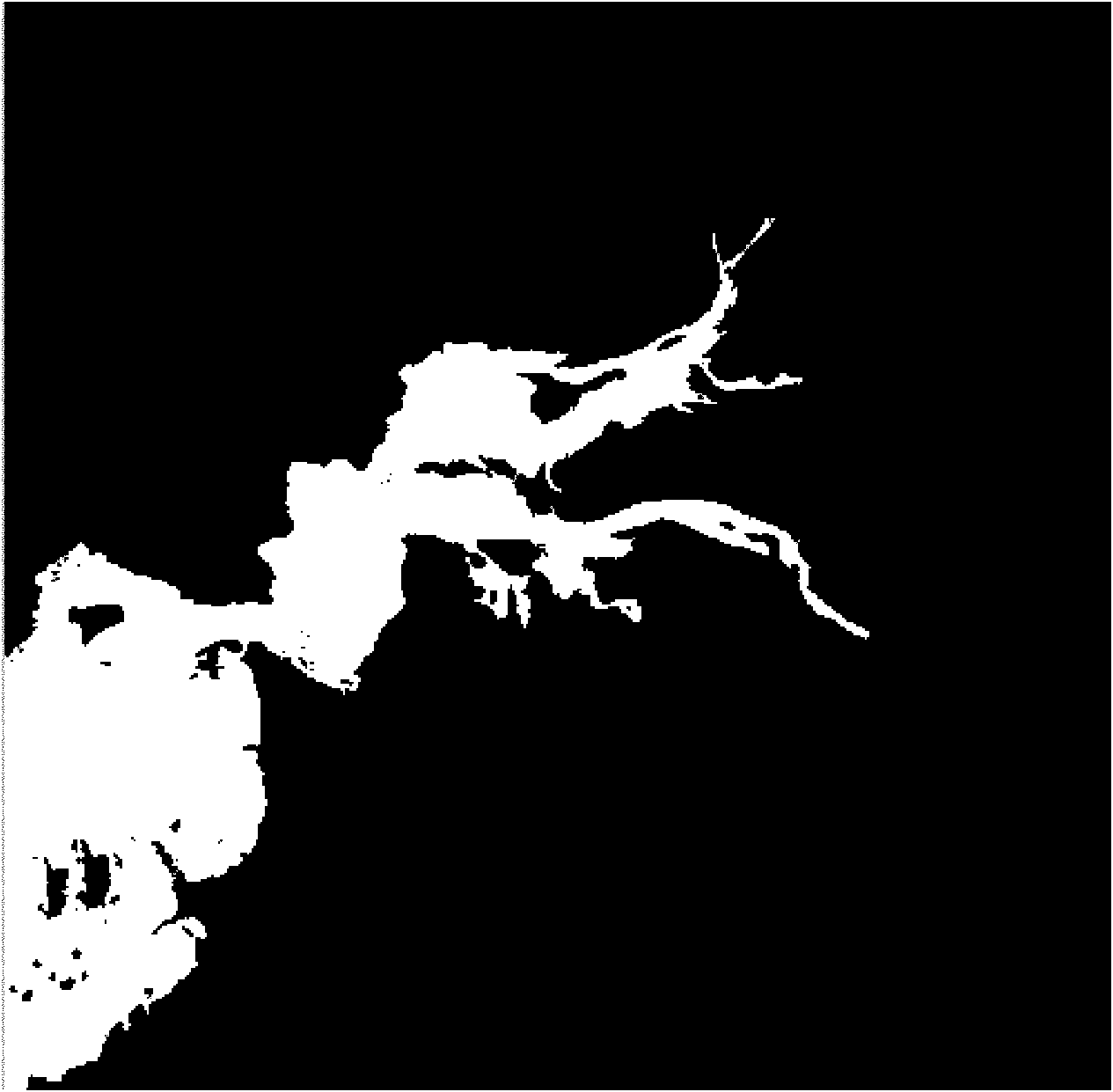

Object-oriented remote sensing image coastline extraction method

InactiveCN102013015AImprove extraction accuracyImprove accuracyCharacter and pattern recognitionClassification treatmentComputer science

The invention discloses an object-oriented remote sensing image coastline extraction method which belongs to the field of full automatic remote sensing image coastline extraction. The steps are as follows: carrying out filtering treatment on a remote sensing image; selecting the segmentation algorithm to segment the remote sensing image; utilizing sample points for classifying the remote sensing image after segmentation; utilizing the seed growth method for extracting a seawater region; and finally utilizing the corresponding judgment criterion to extract a coastline. By utilizing the method disclosed by the invention, the accuracy of the existing coastline extraction algorithm can be improved, the correct rate of seawater extraction after segmentation and classification treatment throughthe object-oriented method is improved and the accuracy of the coastline extraction is ensured. As the coastline changes frequently, the method can provide convenience for maintenance and updating ofcoastline information of all levels of national fundamental geographic information databases.

Owner:NANJING UNIV

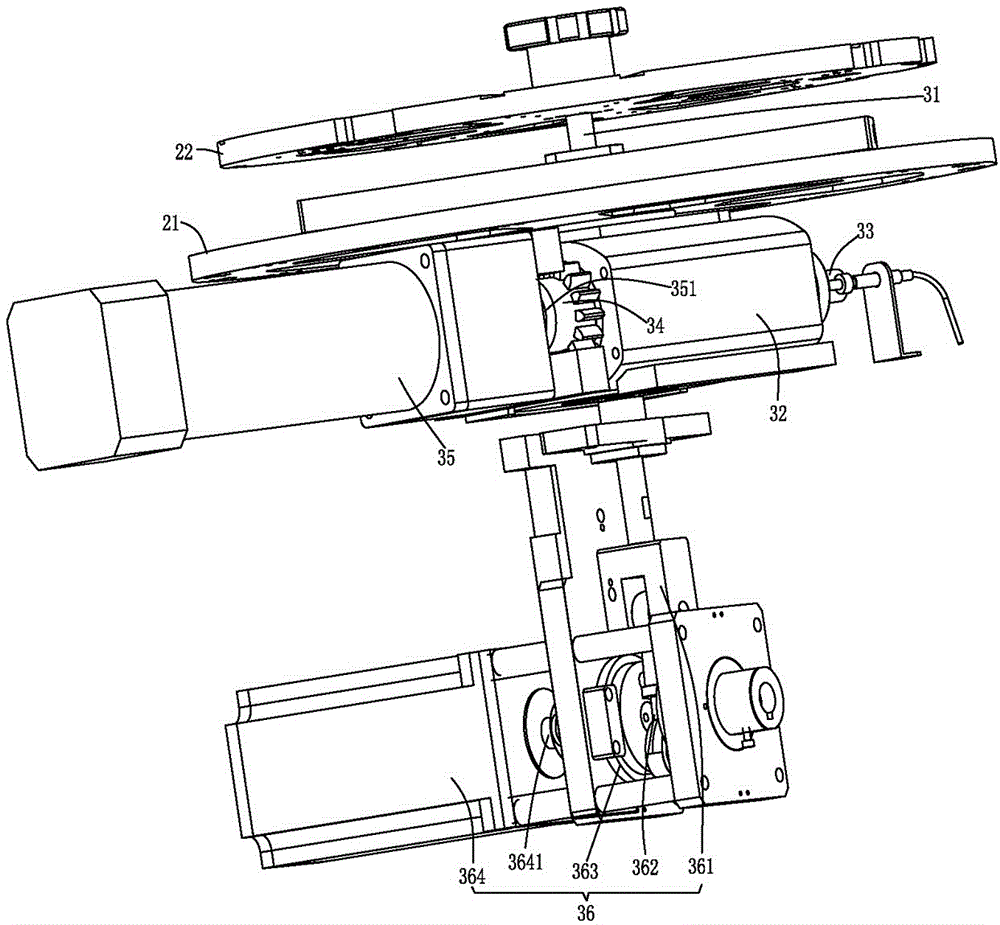

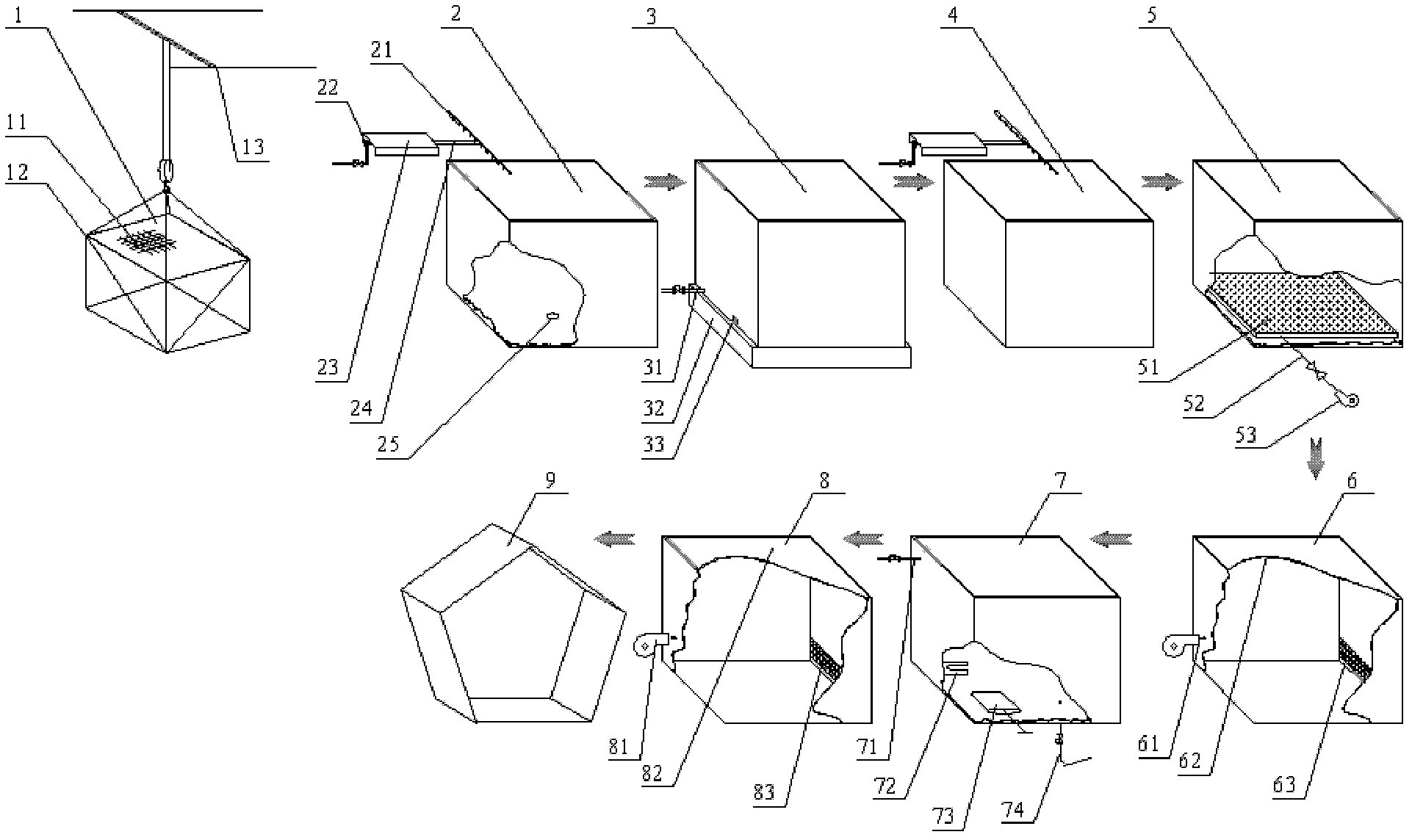

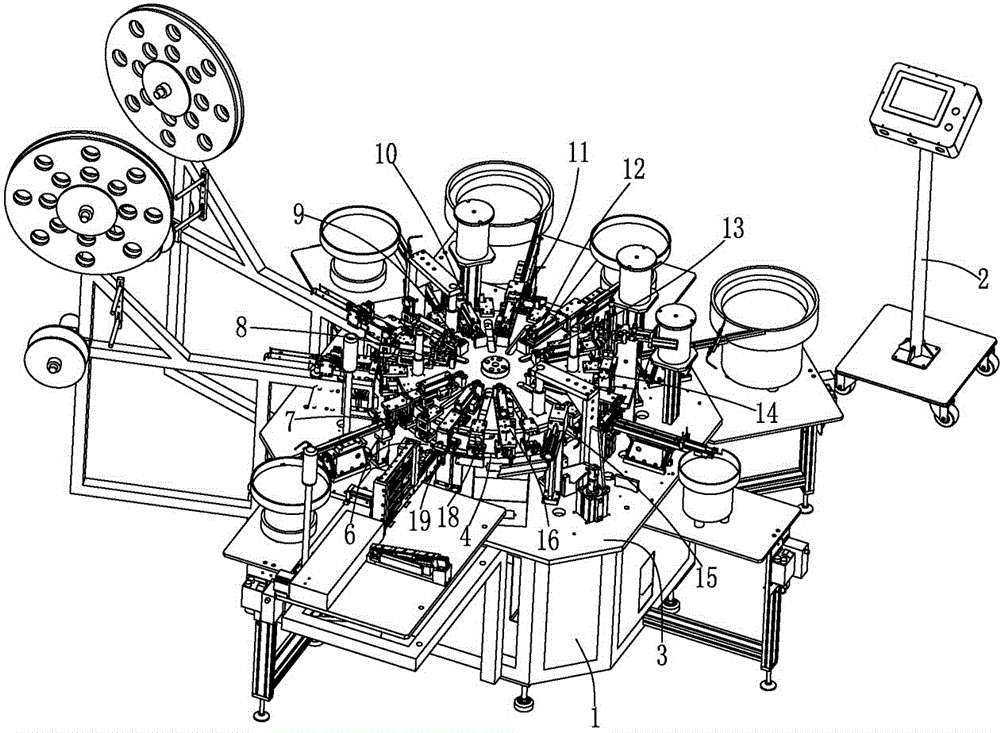

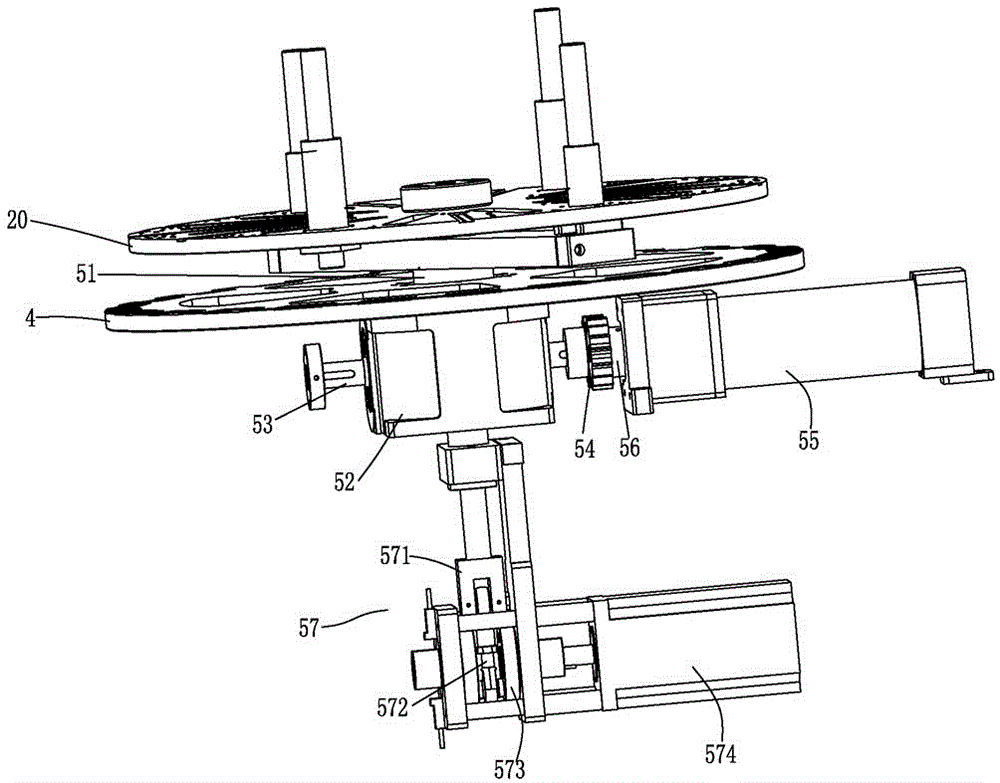

Automatic assembling machine for assembling vehicle-mounted encoder

ActiveCN106736540AImprove assembly yieldHigh degree of automationAssembly machinesMetal working apparatusEngineeringCam

Disclosed is an automatic assembling machine for assembling a vehicle-mounted encoder. The automatic assembling machine comprises a rotating table assembly, a cam indexer assembly, a support feeding mechanism, a manual pendulum shaft core and shaft sleeve feeding mechanism, a first rotor feeding mechanism, a first drive plate feeding mechanism, a second rotor and second drive plate assembling mechanism, a manual pendulum body feeding mechanism, a riveting mechanism and a discharging mechanism, wherein the rotating table assembly, the cam indexer assembly, the support feeding mechanism, the manual pendulum shaft core and shaft sleeve feeding mechanism, the first rotor feeding mechanism, the first drive plate feeding mechanism, the second rotor and second drive plate assembling mechanism, the manual pendulum body feeding mechanism, the riveting mechanism and the discharging mechanism are arranged on the top of a machine box. The automatic assembling machine further comprises two shape trimming assemblies and a plurality of detection assemblies, wherein the shape trimming assemblies are used for shape trimming of supports. A plurality of station clamps are arranged on the circumferential edge of a rotating table of the rotating table assembly in an array mode. A rotating pendulum assembly is further arranged on the top of the machine box in a matched mode. The feeding mechanisms are matched with the movement of the rotating table assembly to conduct feeding in sequence, the riveting mechanism conducts riveting on parts of the encoder to form an encoder finished product, the discharging mechanism enables the encoder finished product to be discharged into a collecting box, the shape trimming assemblies conduct opening shape trimming and inward extrusion shape trimming on the supports, and the rotating pendulum assembly is used for transmitting a second rotor and second drive plate assembly assembled by the second rotor and second drive plate assembling mechanism to the matched station clamp.

Owner:广东钺河智能科技有限公司

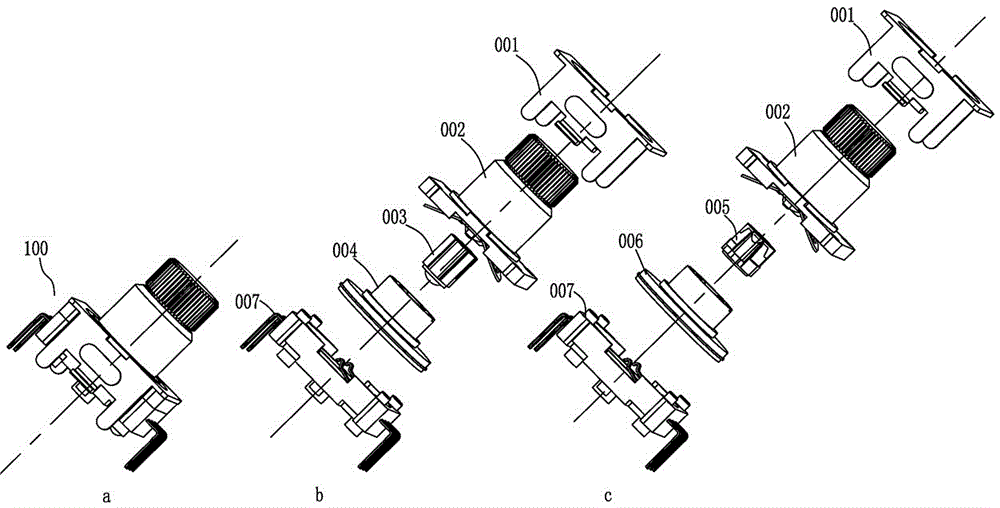

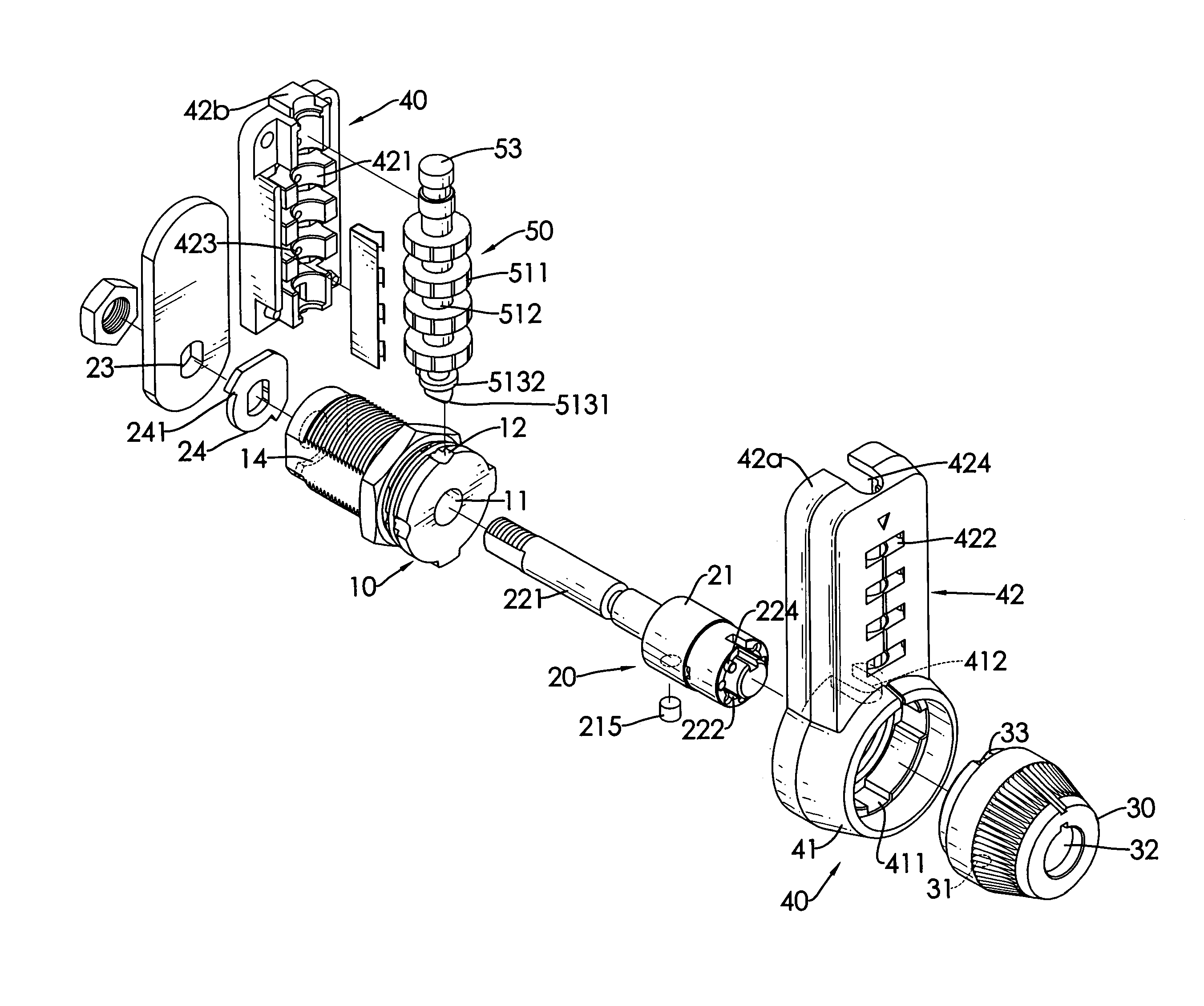

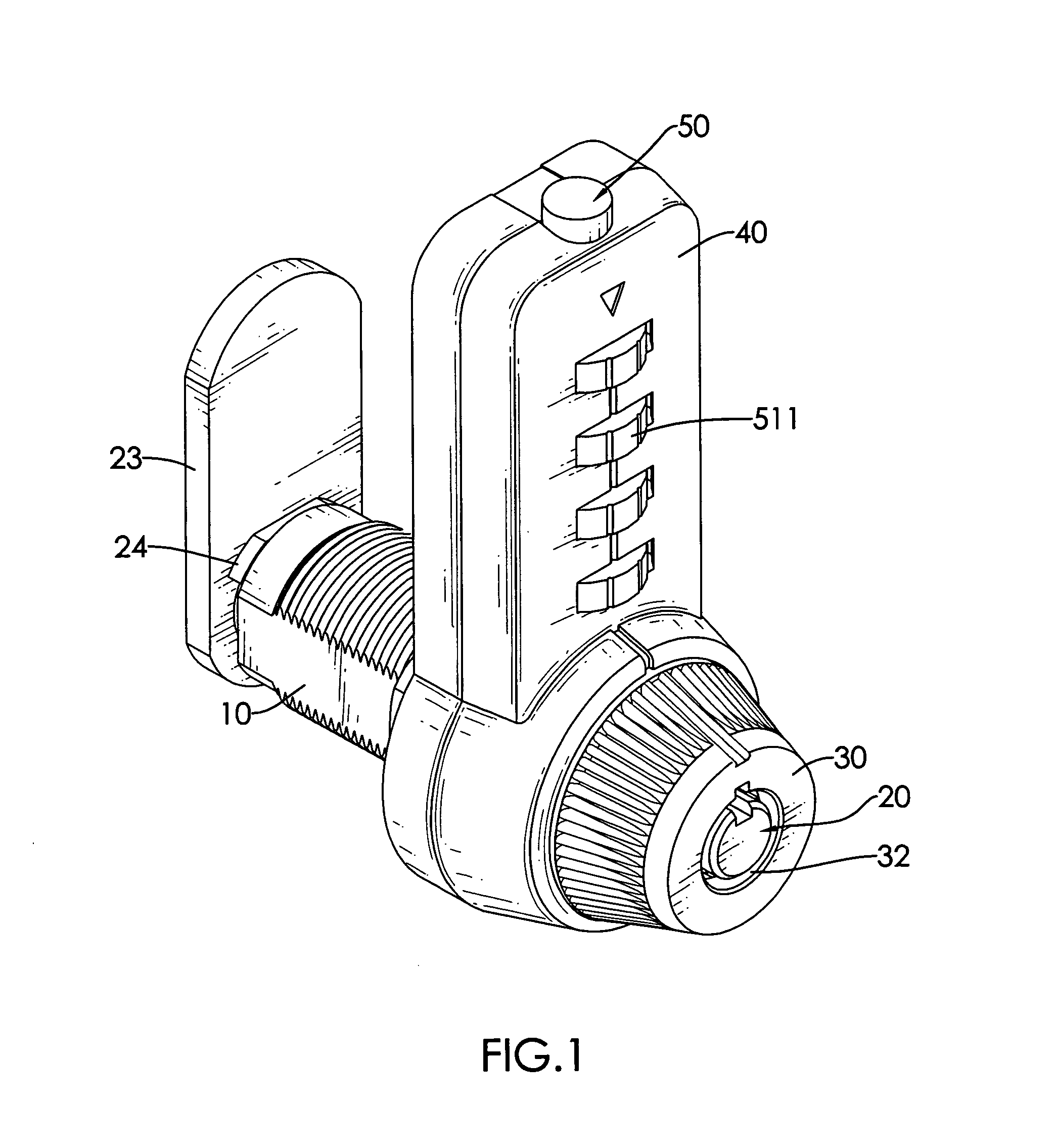

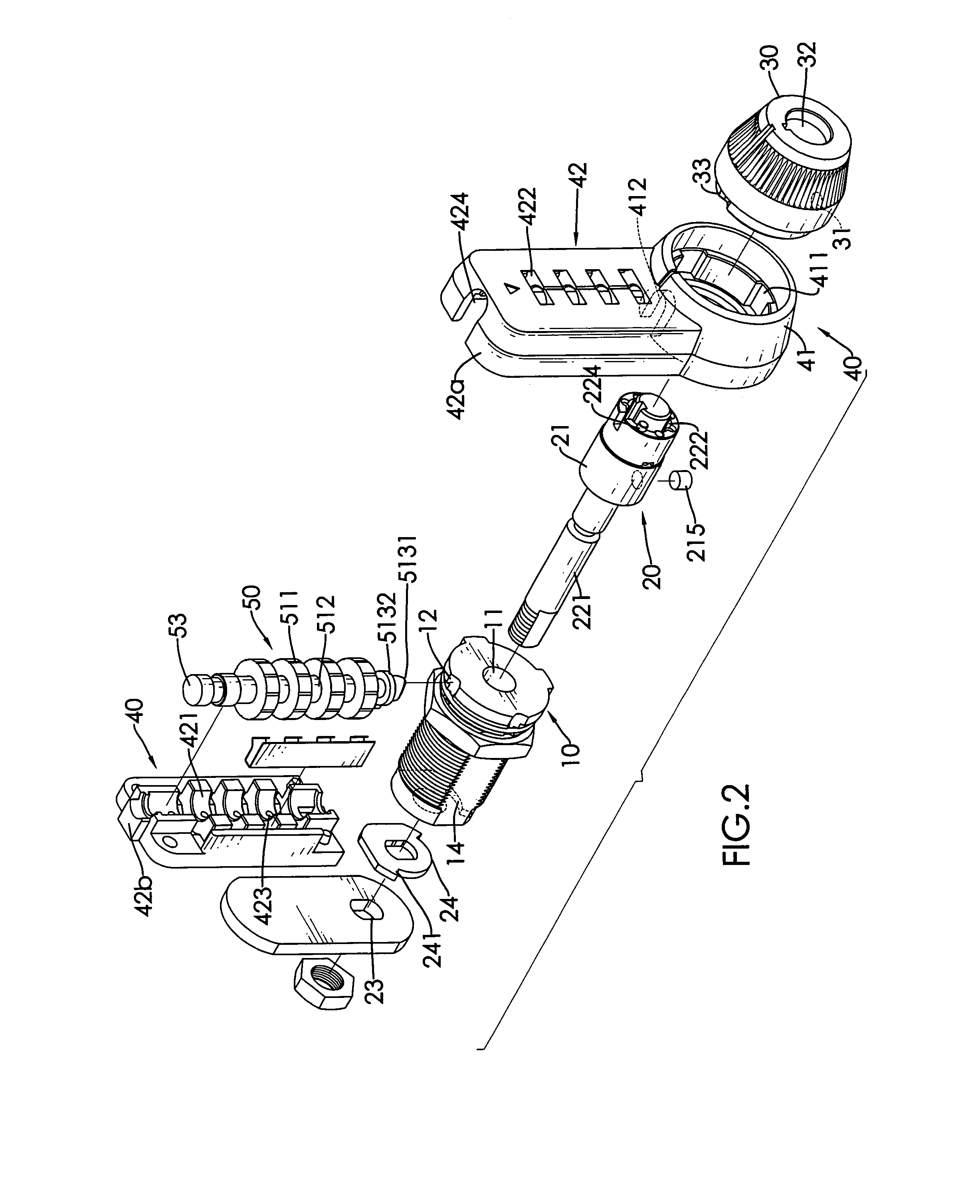

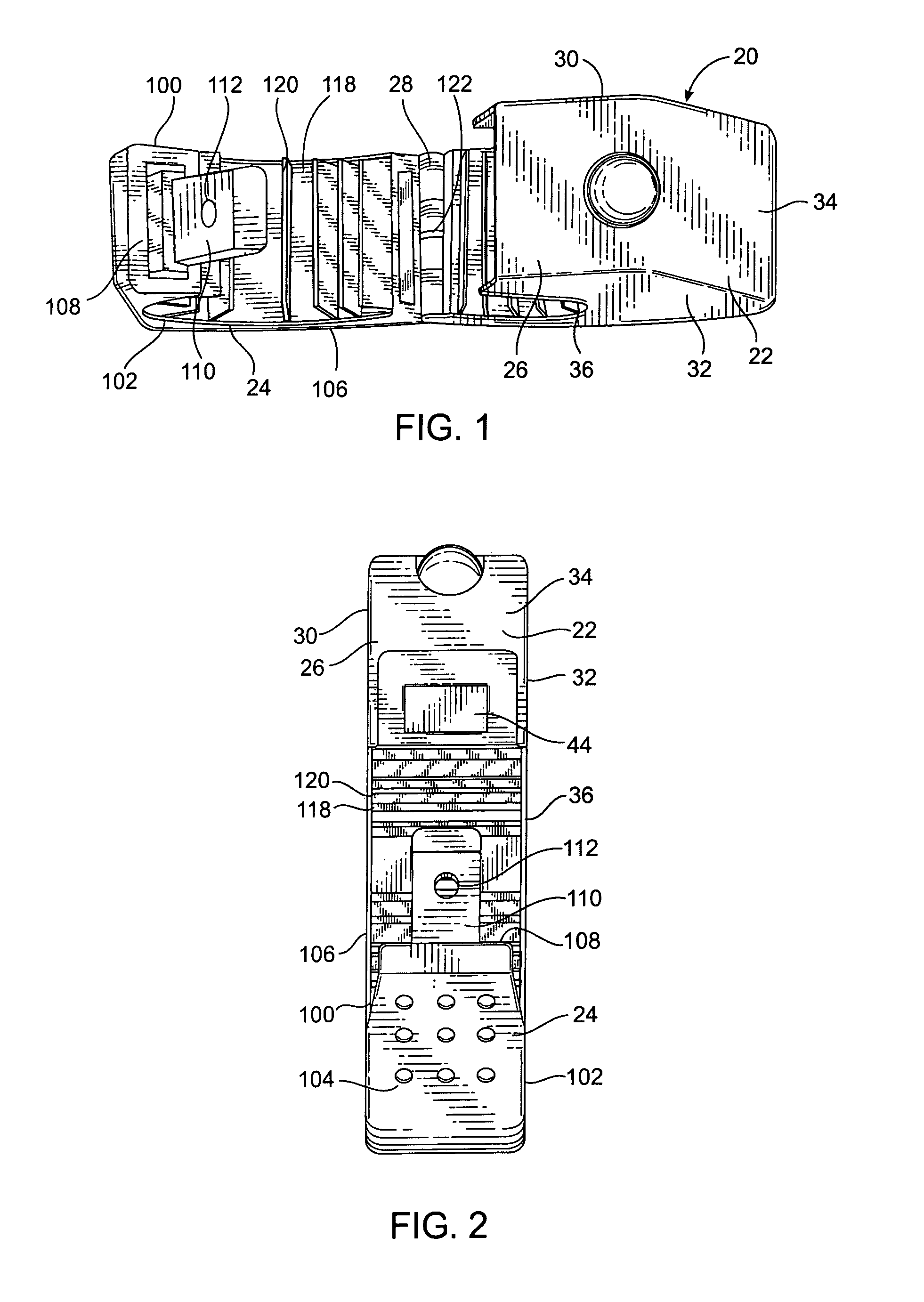

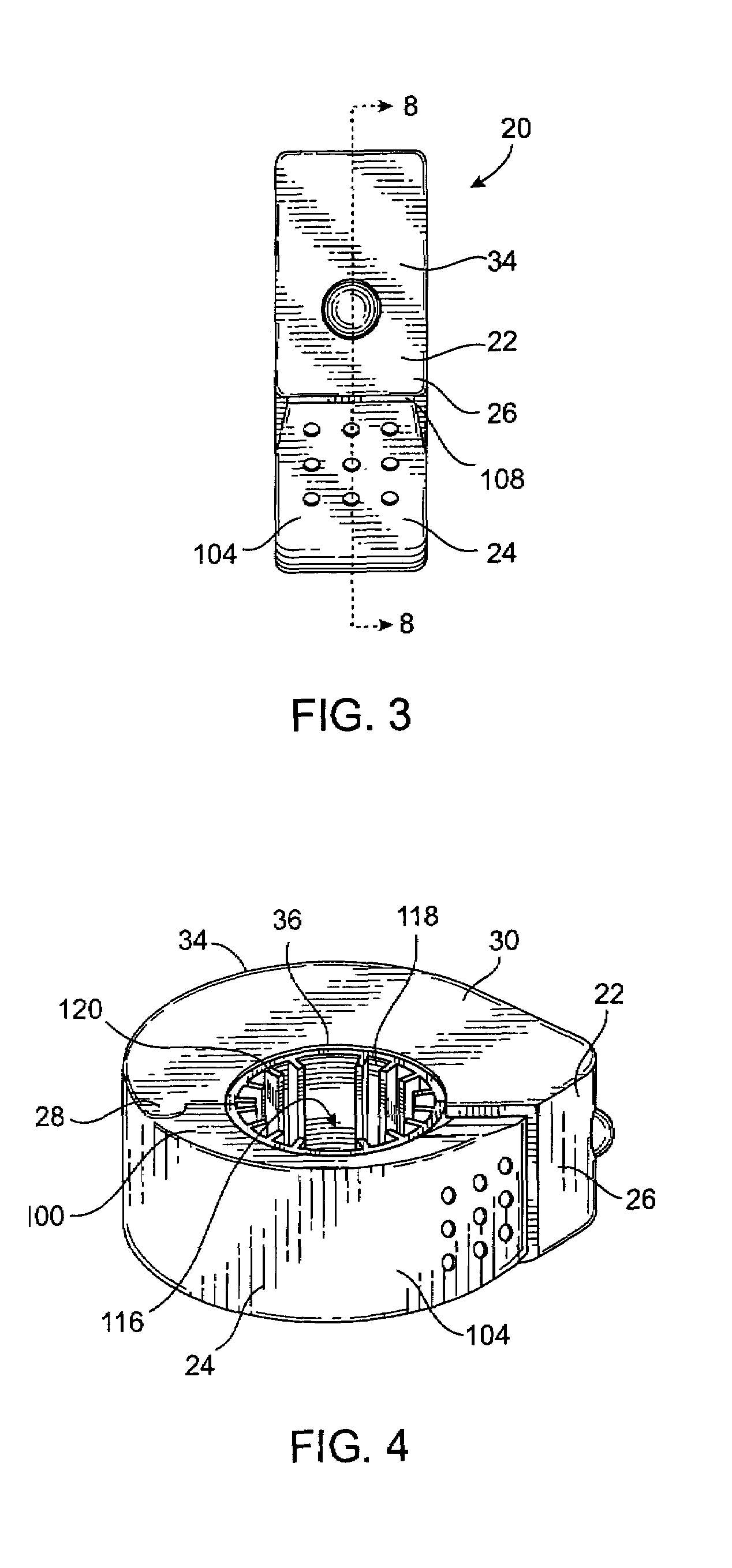

Dual-mode lock for lockers

ActiveUS7444844B1Reducing building management stressReduce replacement costsAnti-theft cycle devicesAnti-theft devicesDual modeEngineering

A dual-mode lock for a locker has a base, a knob, a key lock assembly, a housing and a combination lock assembly. The base is mounted through the locker. The knob is attached to the base. The key lock assembly is mounted in the knob, and has a lock core mounted rotatably through the base and having a latch for locking the locker. The housing is attached to the base and has a combination mount. The combination lock assembly is mounted in the combination mount to selectively lock or allow the lock core to rotate. Therefore, if a combination is forgotten or lost, the dual-mode lock may be opened quickly with a corresponding key and the combination reset reducing building management stress and preventing replacement costs.

Owner:ABA UFO INT CORP

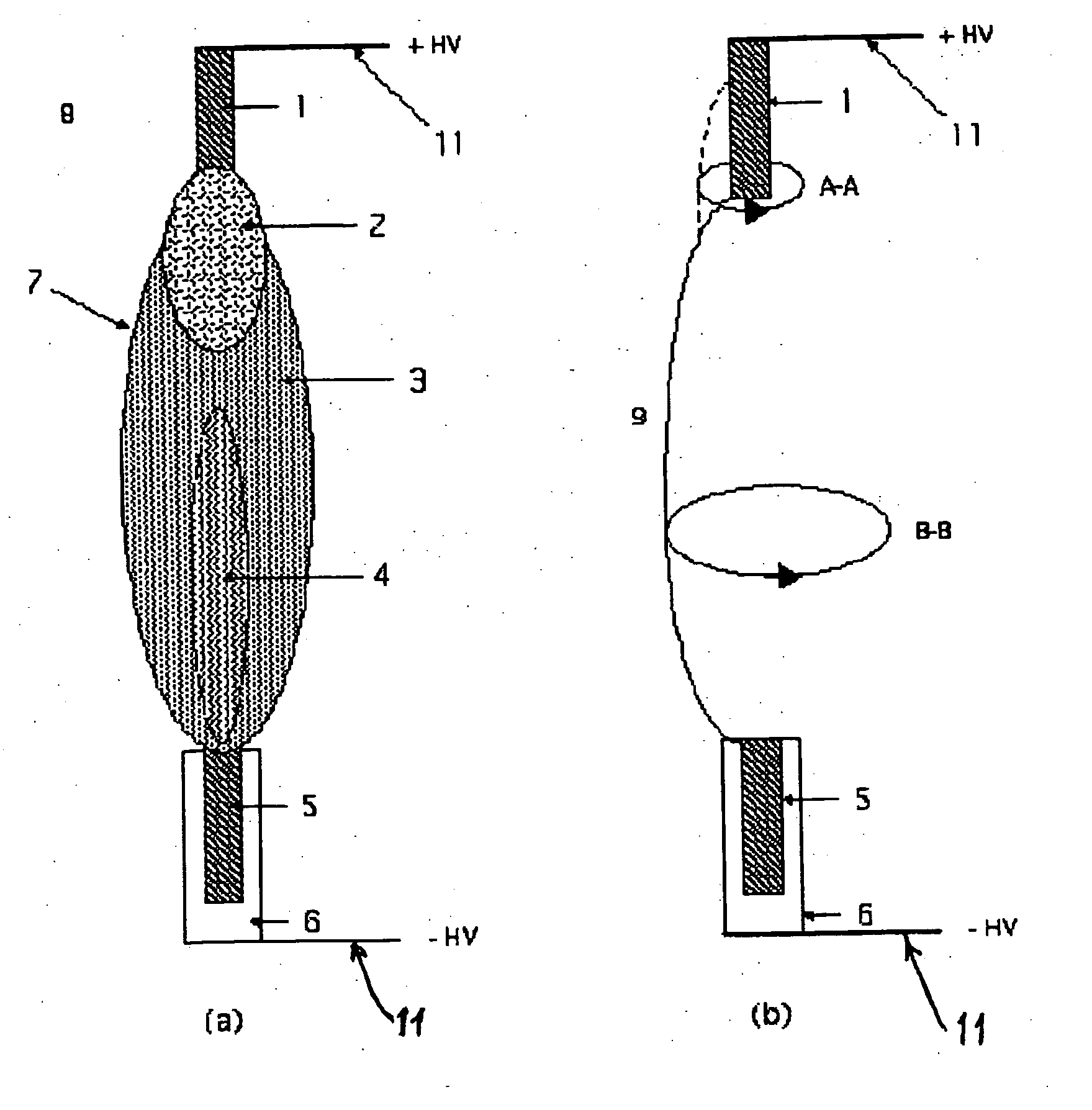

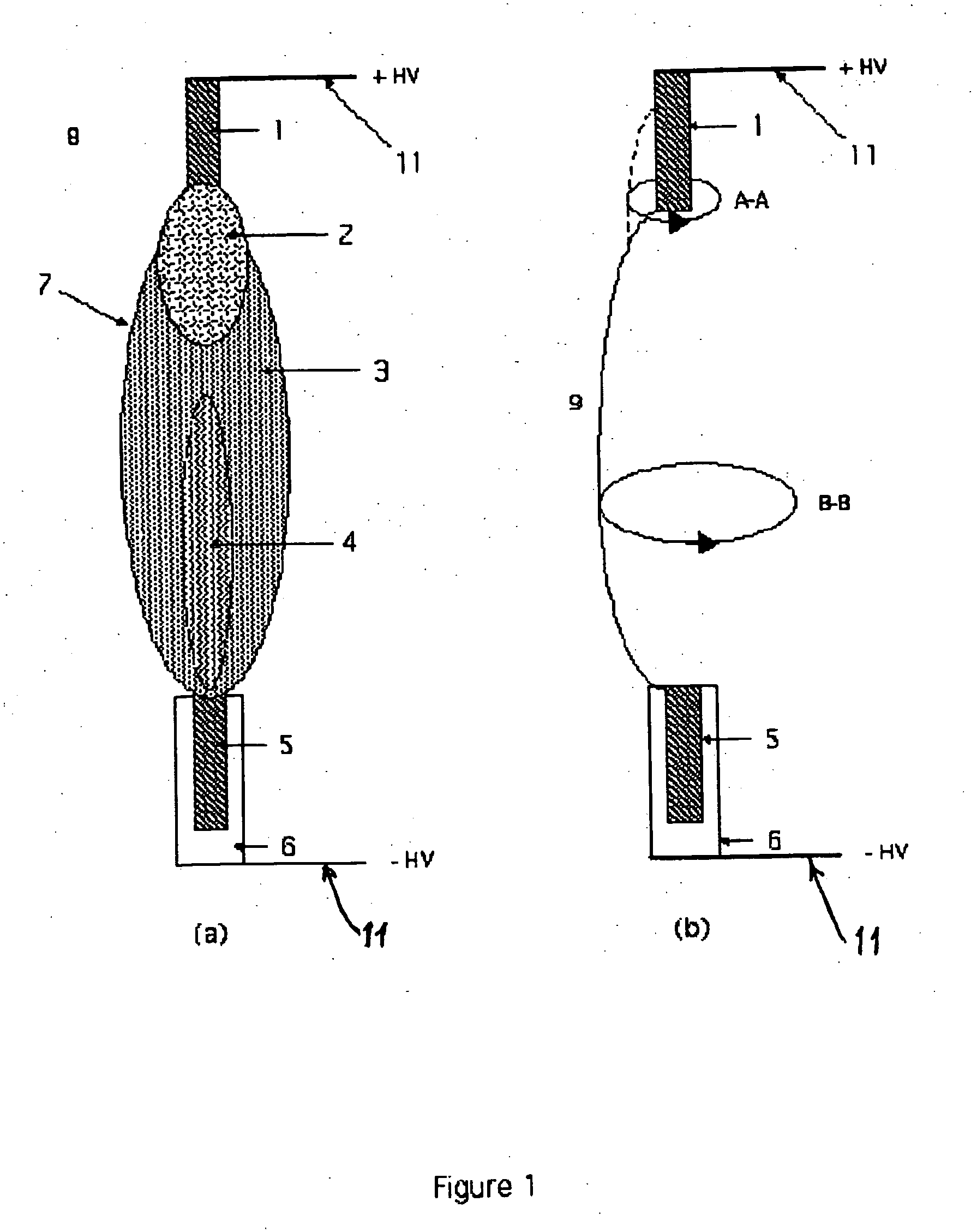

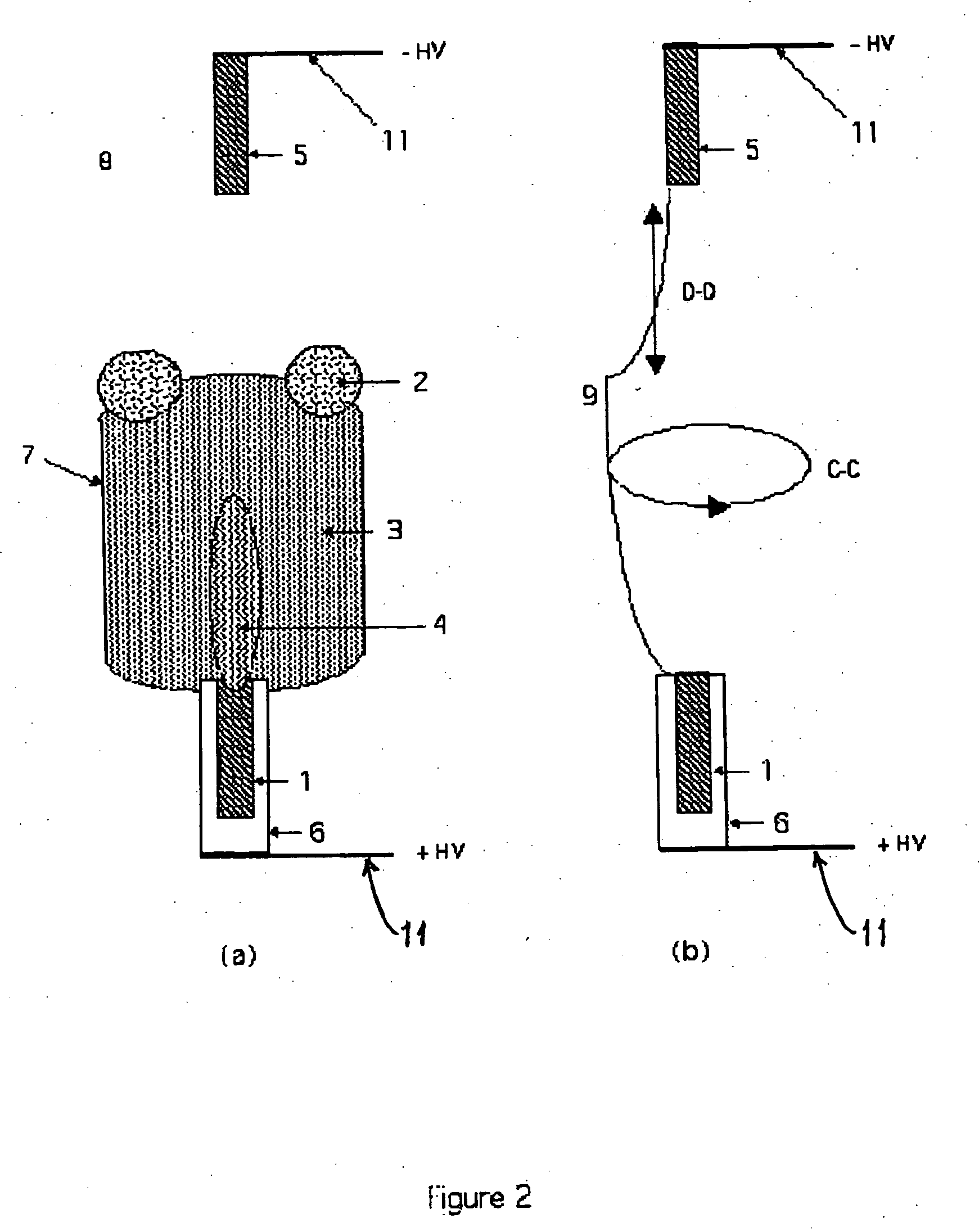

System, method, and apparatus for an intense ultraviolet radiation source

InactiveUS20060165555A1Increased energy inputImprove efficiencyNitrous oxide captureHydrogenThermal energyElectromagnetic radiation

An intense ultraviolet radiation source is disclosed that may be operated in substantially any arbitrary gas environment, without regard to a containment envelope for the ultraviolet radiation source. The intense ultraviolet radiation source can be generated by applying a pulsed or continuous electrical discharge to a partially ionized combustion flame via two electrodes. The combustion flame and electrical discharge can be focused, contained, or confined by gas pressure, electric fields, and / or magnetic fields. Optionally, the thermal energy in the flame and the electrical discharge power input may be augmented with an electromagnetic radiation source, such as a radio-frequency induction heater, a laser, or a microwave generator. Impurities may be placed in contact with or added to the fuel and / or the oxidizer to further alter the emitted ultraviolet radiation spectral brightness as needed. The ultraviolet source may be applied to the molecular dissociation of pollutants in exhaust gas streams of combustion systems. The efficient dissociation of such pollutants requires UV in the wavelength ranges of the vacuum ultraviolet band (100 nm-180 nm) and the UV-C band (180 nm-280 nm).

Owner:ABQ ULTRAVIOLET POLLUTION SOLUTIONS

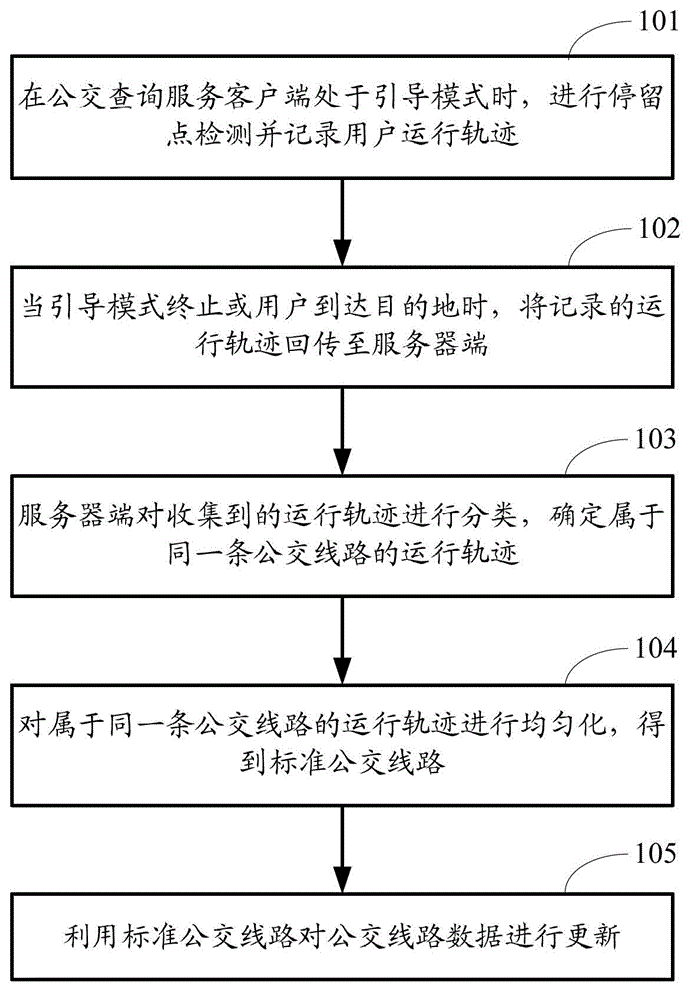

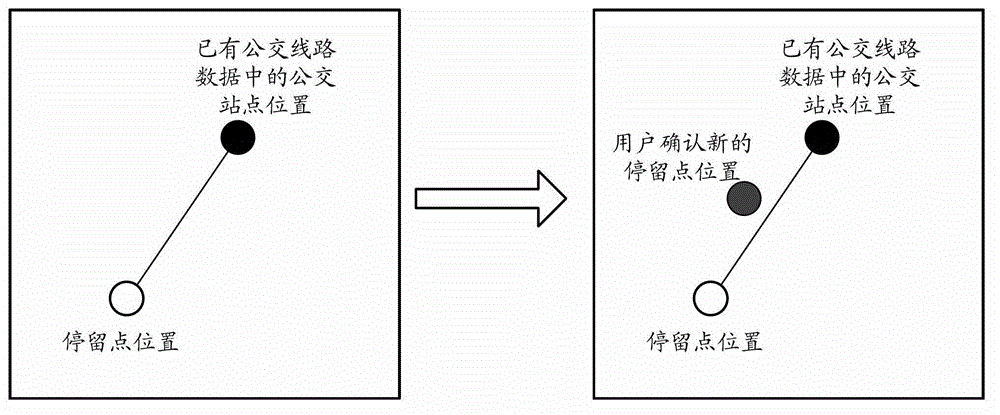

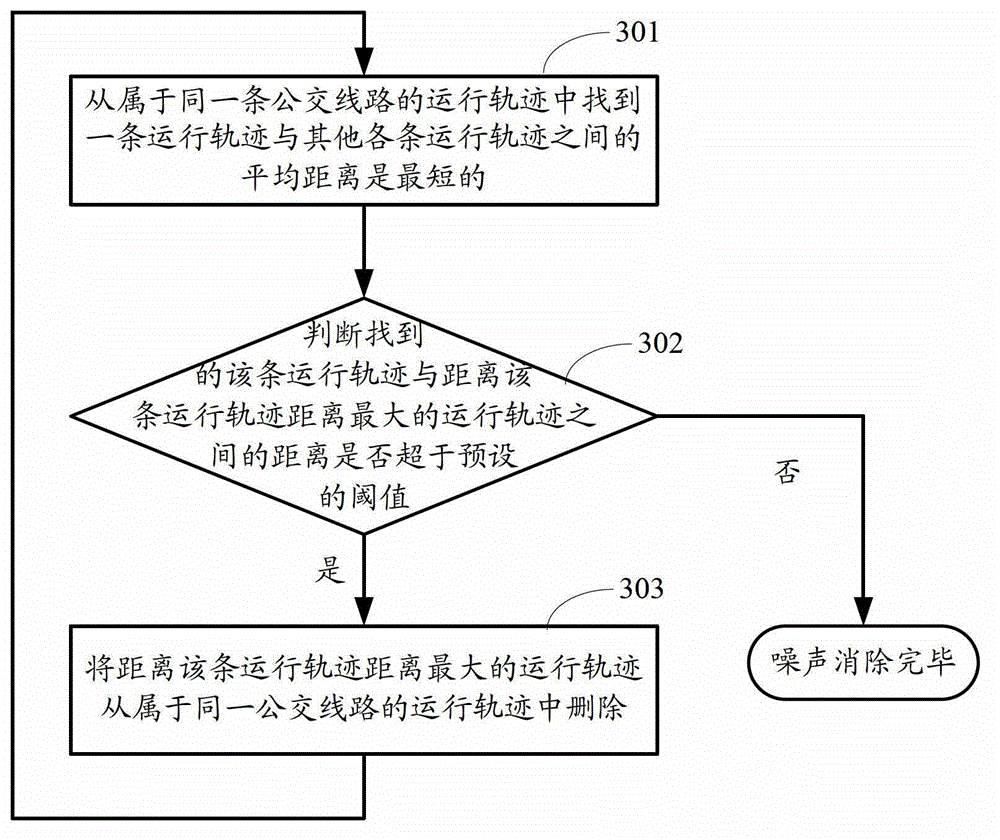

Method, device and system for updating bus route data

ActiveCN103150177AGuaranteed timelinessReduce replacement costsProgram loading/initiatingTransmissionData acquisitionData profiling

The invention provides a method, a device and a system for updating bus route data, wherein the method comprises the steps of: in a data acquiring stage: when a bus inquiring service client end is in a guide mode, recording a moving trajectory of a user; when a navigation mode is ended or the user arrives at a destination, re-transmitting the moving trajectory to a server end; in a data analyzing stage: classifying the collected moving trajectory by the server end, determining moving trajectories belonging to the same bus route; homogenizing the moving trajectories belonging to the same bus route to obtain a standard bus route; and updating the bus route data by using the standard bus route. According to the invention, data is acquired in real time without using an unprofessional person so that the updating cost is lowered, and the timeliness of updating the bus route data is ensured.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

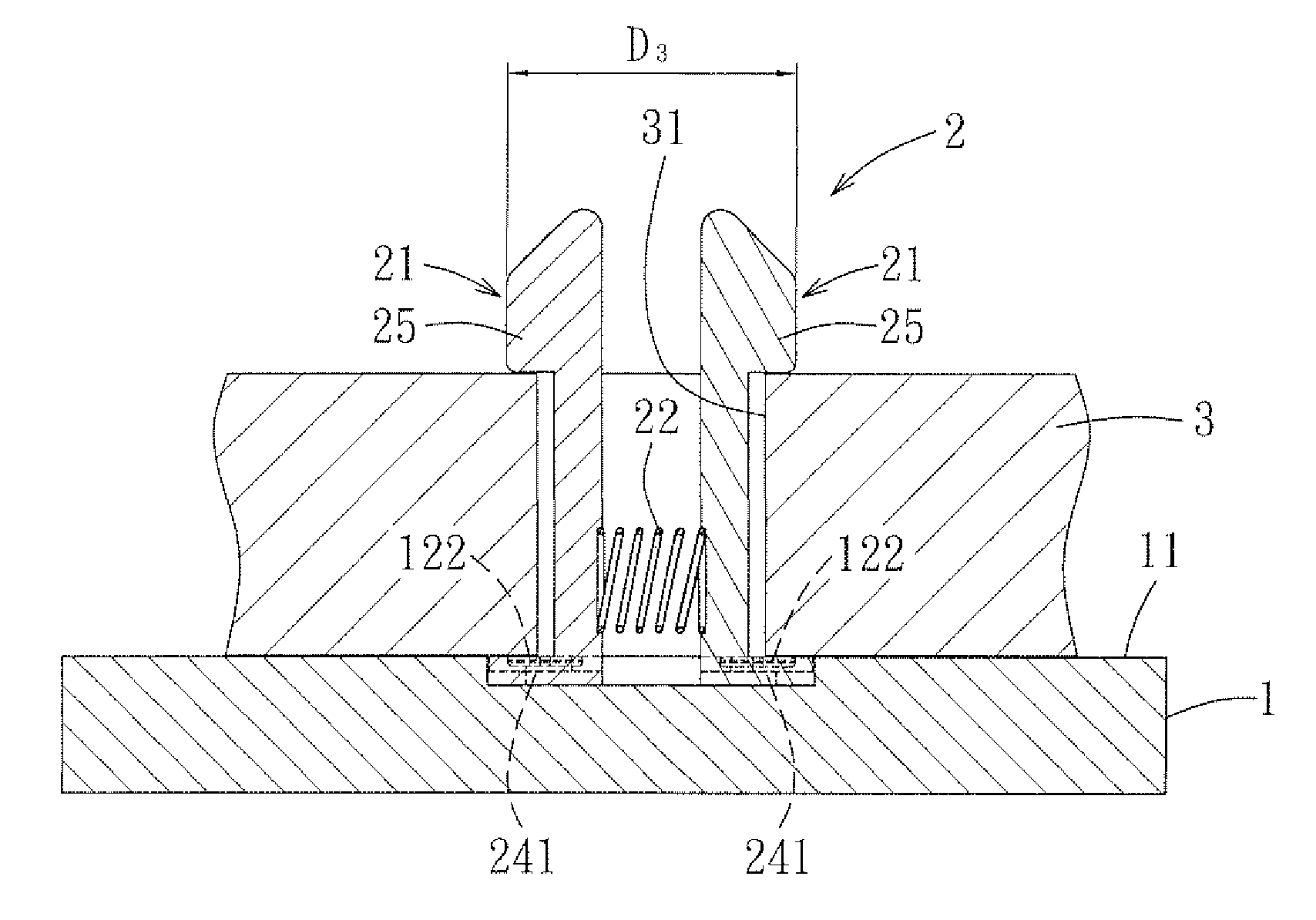

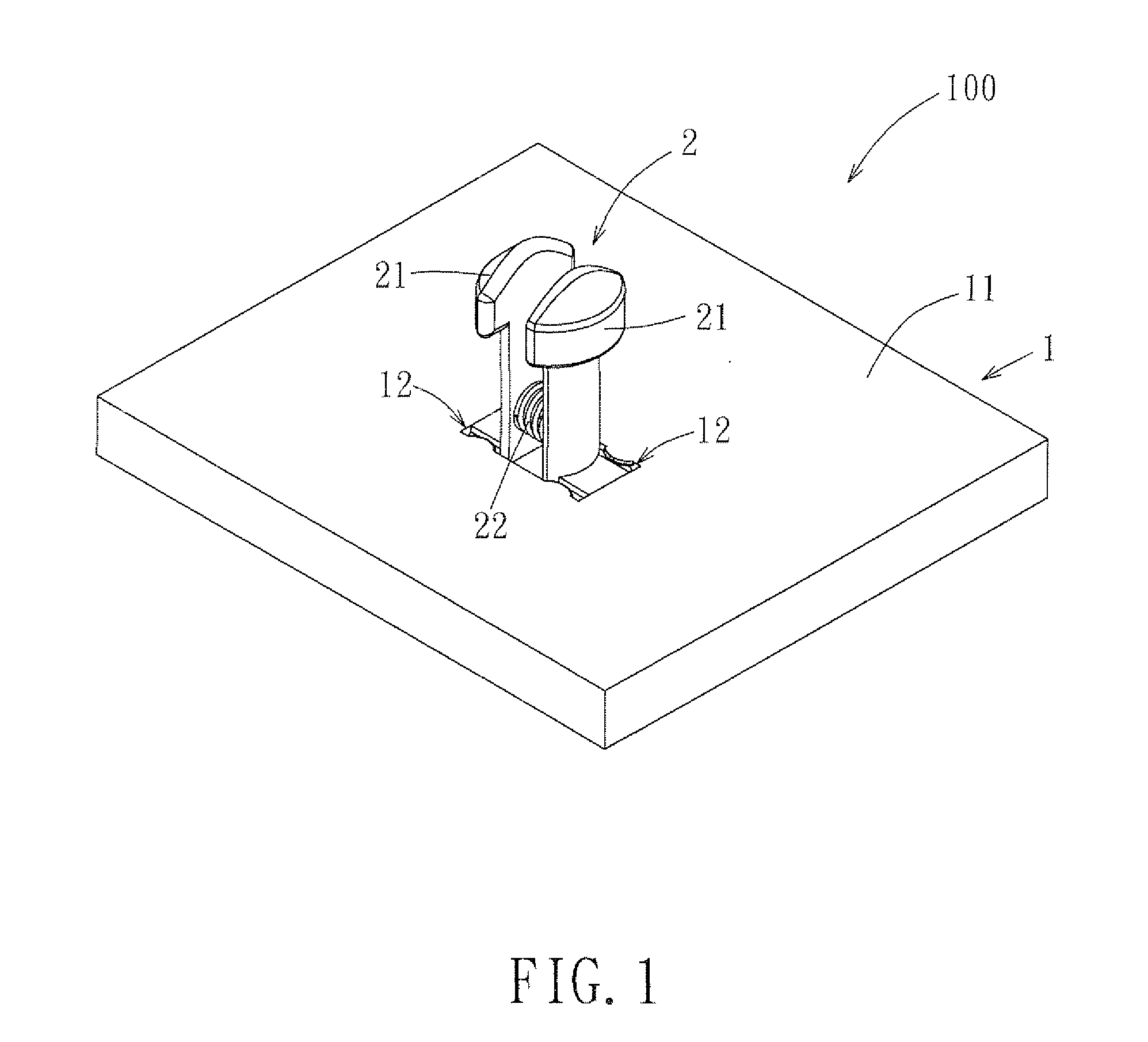

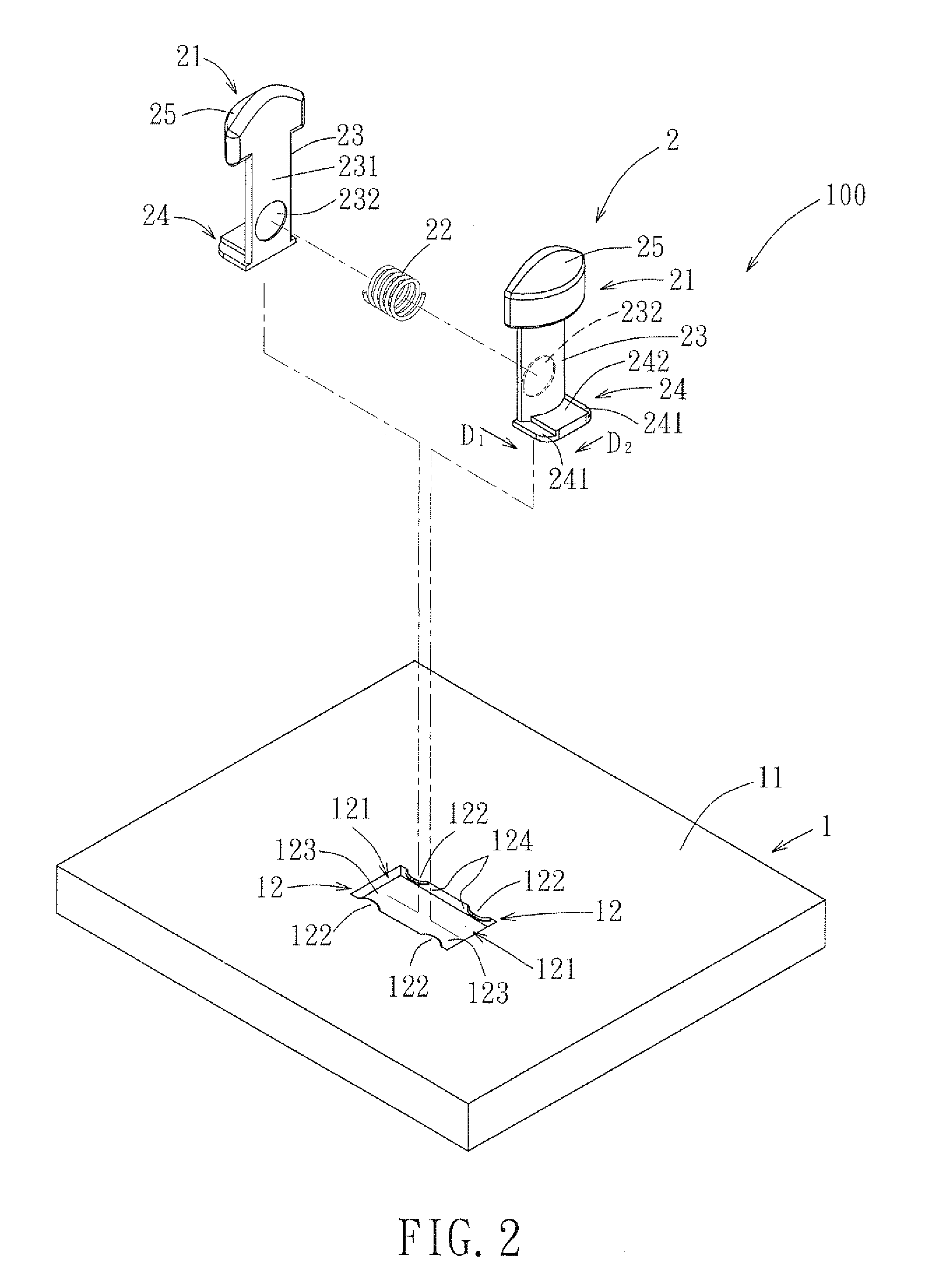

Retaining module and component assembly having the same

InactiveUS20120020726A1Reduce replacement costsCouplings for rigid shaftsSheet joiningEngineeringMechanical engineering

A component assembly includes a retaining module and a component. The component has a surface and two first engaging portions disposed at the surface. The retaining module includes a pair of engaging arms and a resilient member. Each of the engaging arms has an upright elongate arm body, a second engaging portion disposed at a bottom end of the arm body, and a head portion disposed at a top end of the arm body. The second engaging portions of the engaging arms engage respectively the first engaging portions of the component so as to connect the engaging arms with the component. The engaging arms are adapted to extend through a hole in a connecting member, and are convertible between a locking stat and a release state. The resilient member biases the engaging arms into the locking state.

Owner:WISTRON CORP

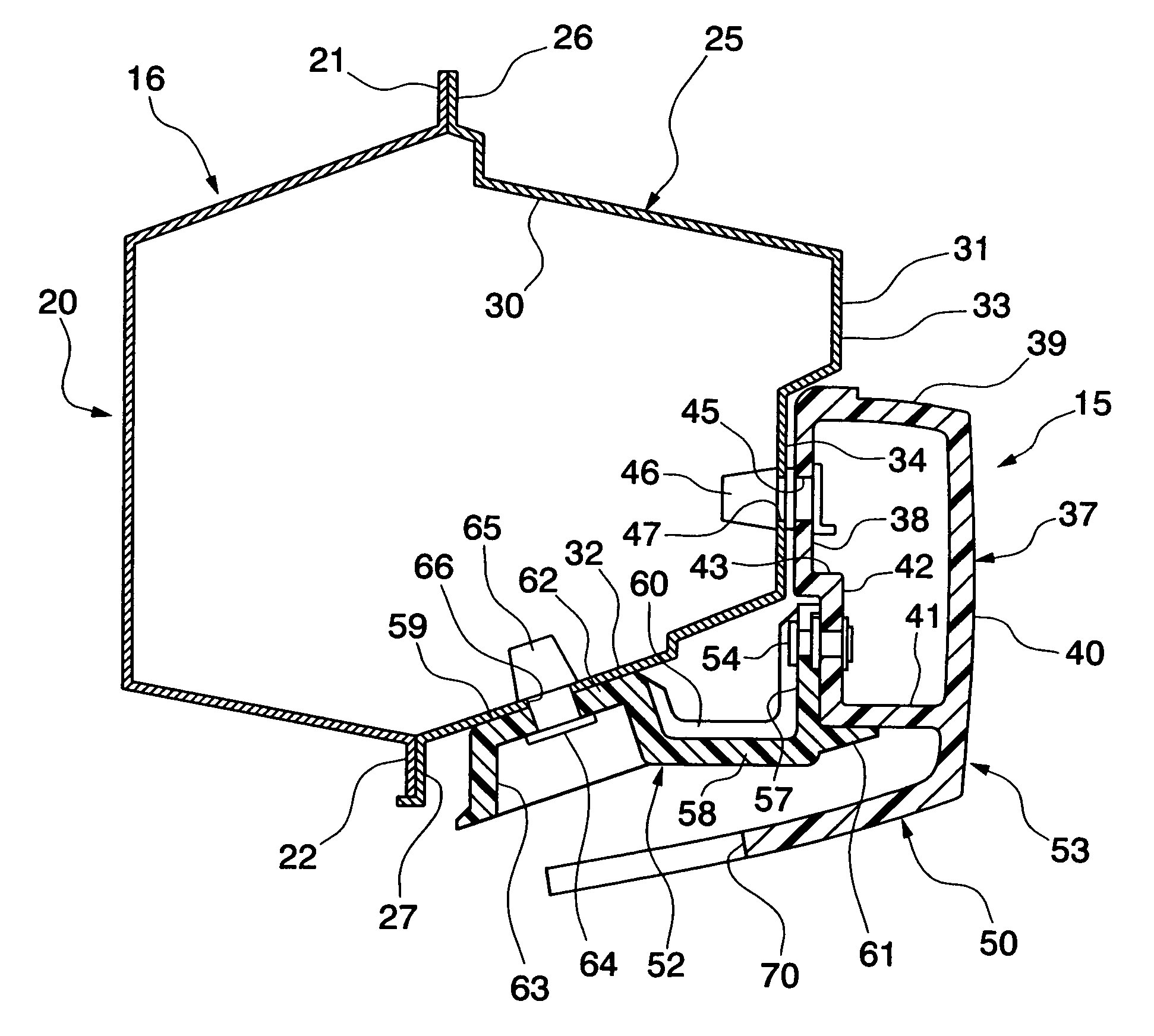

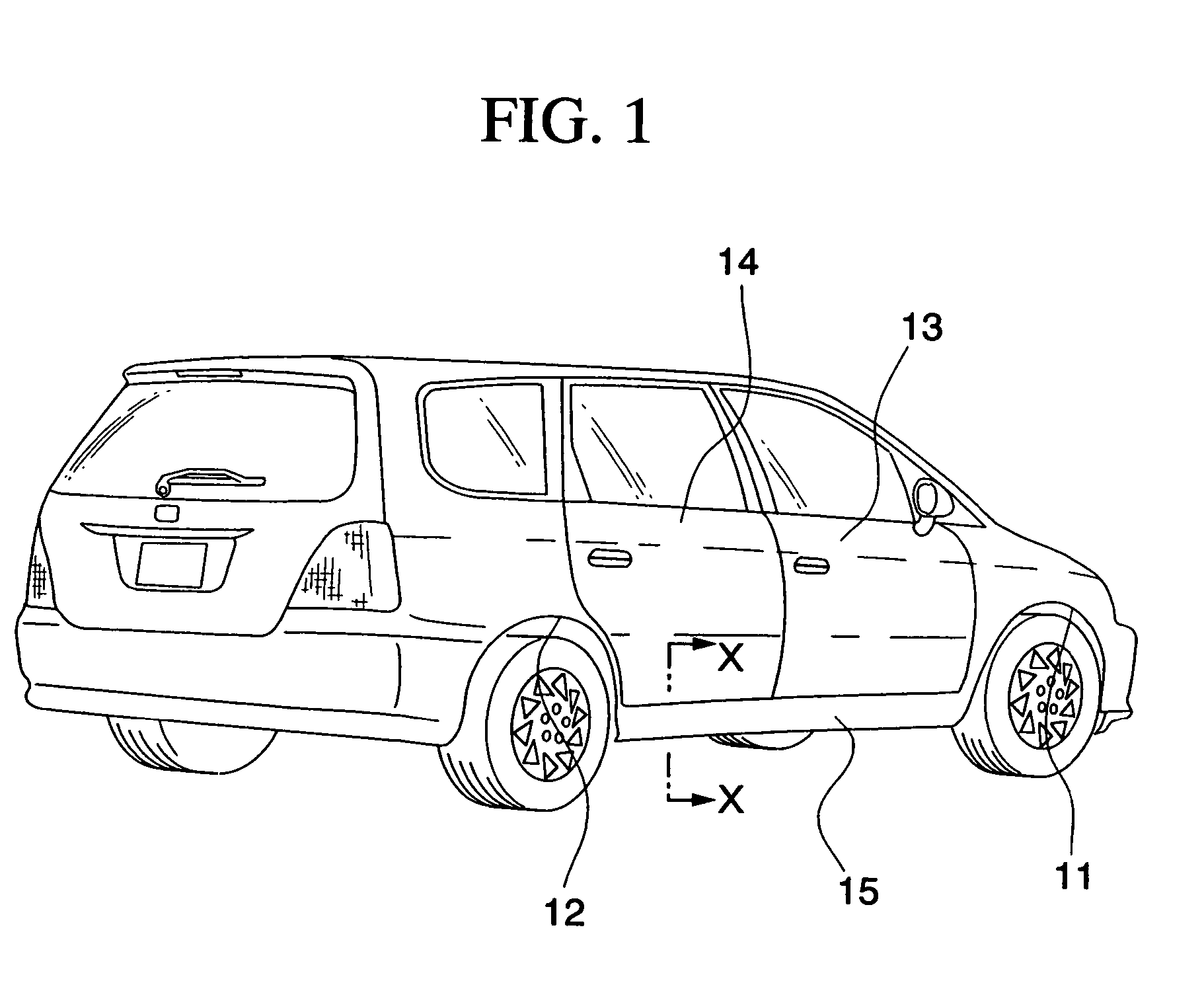

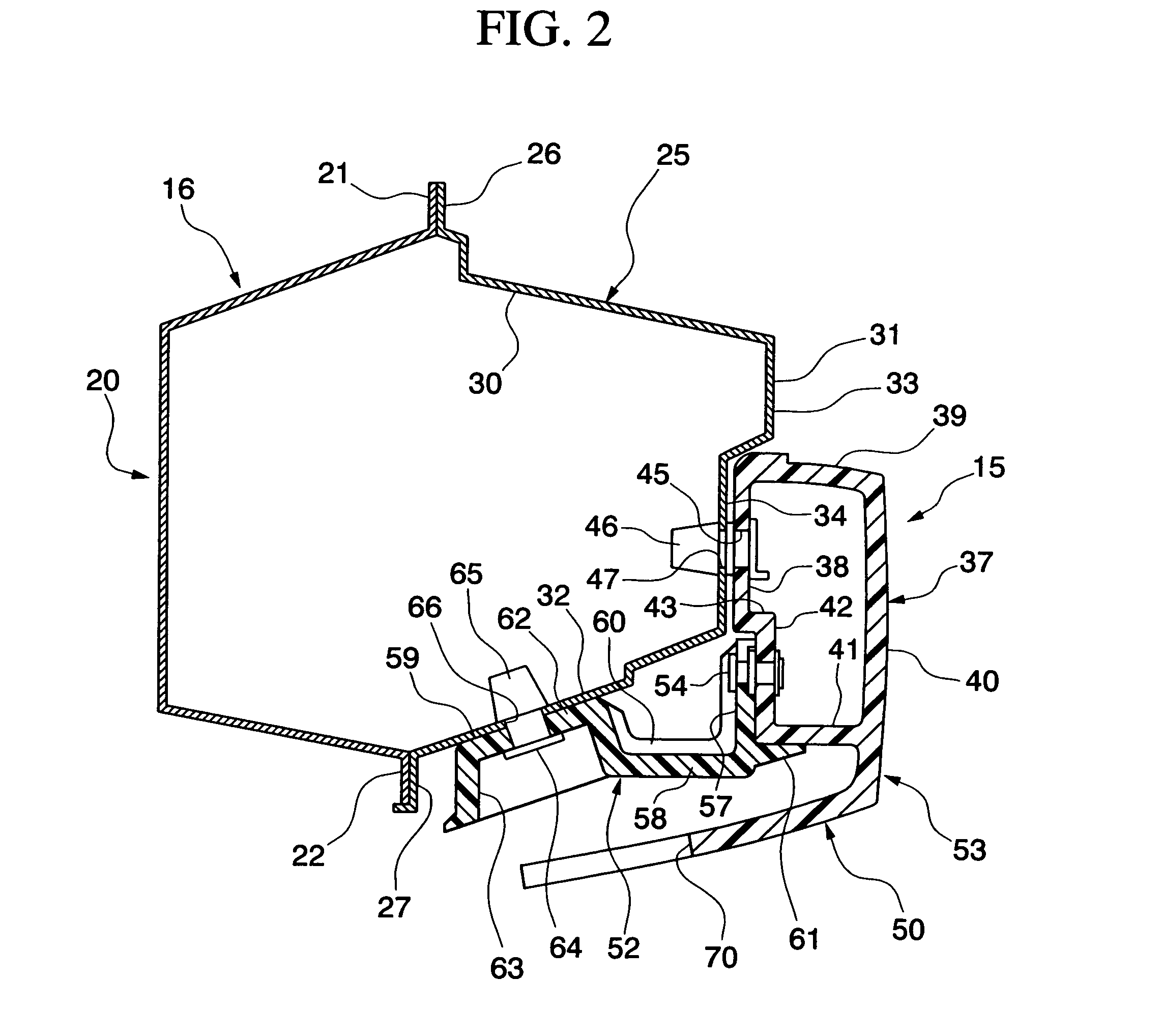

Installation structure for a side sill garnish

InactiveUS7040682B2Reduce replacement costsVehicle seatsBuilding componentsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

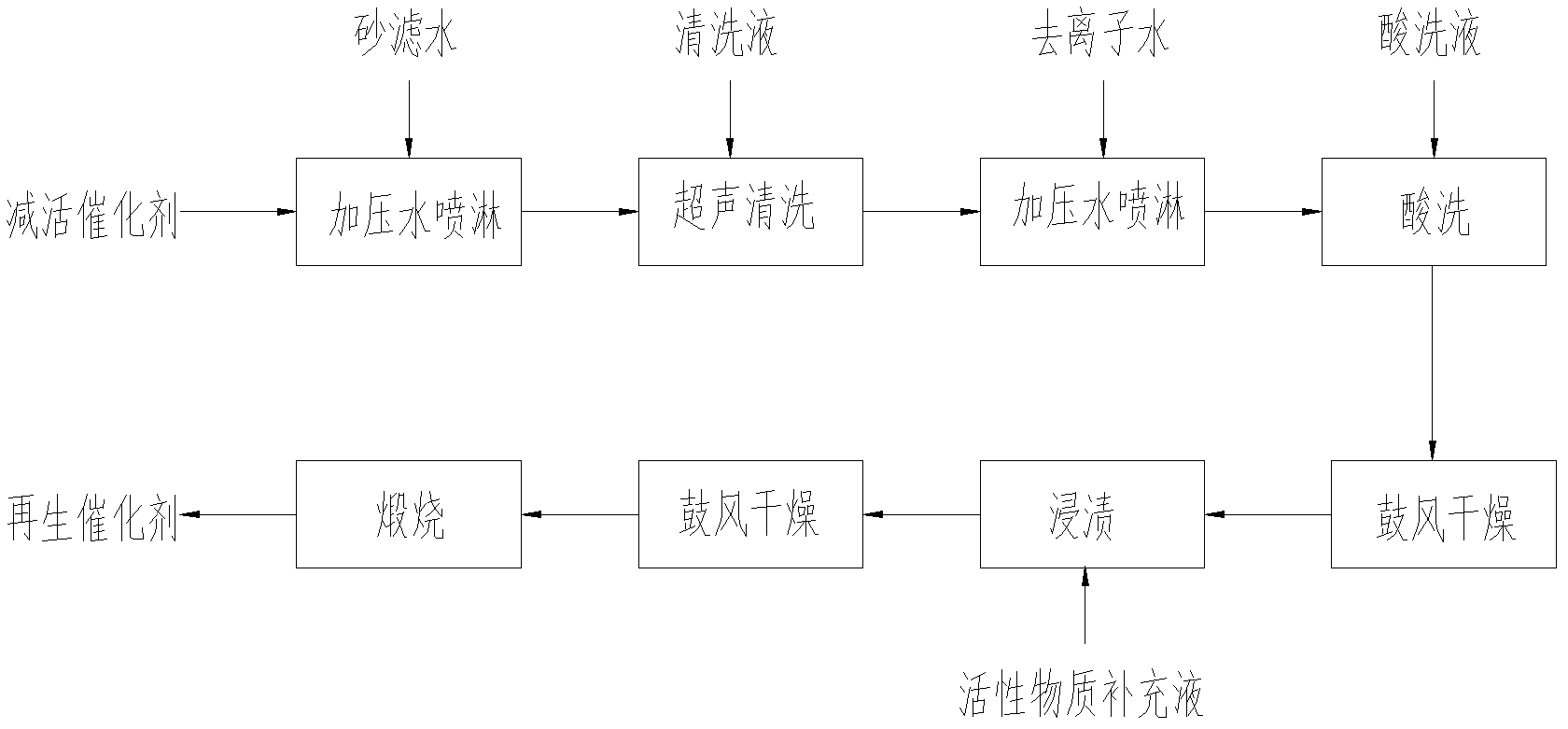

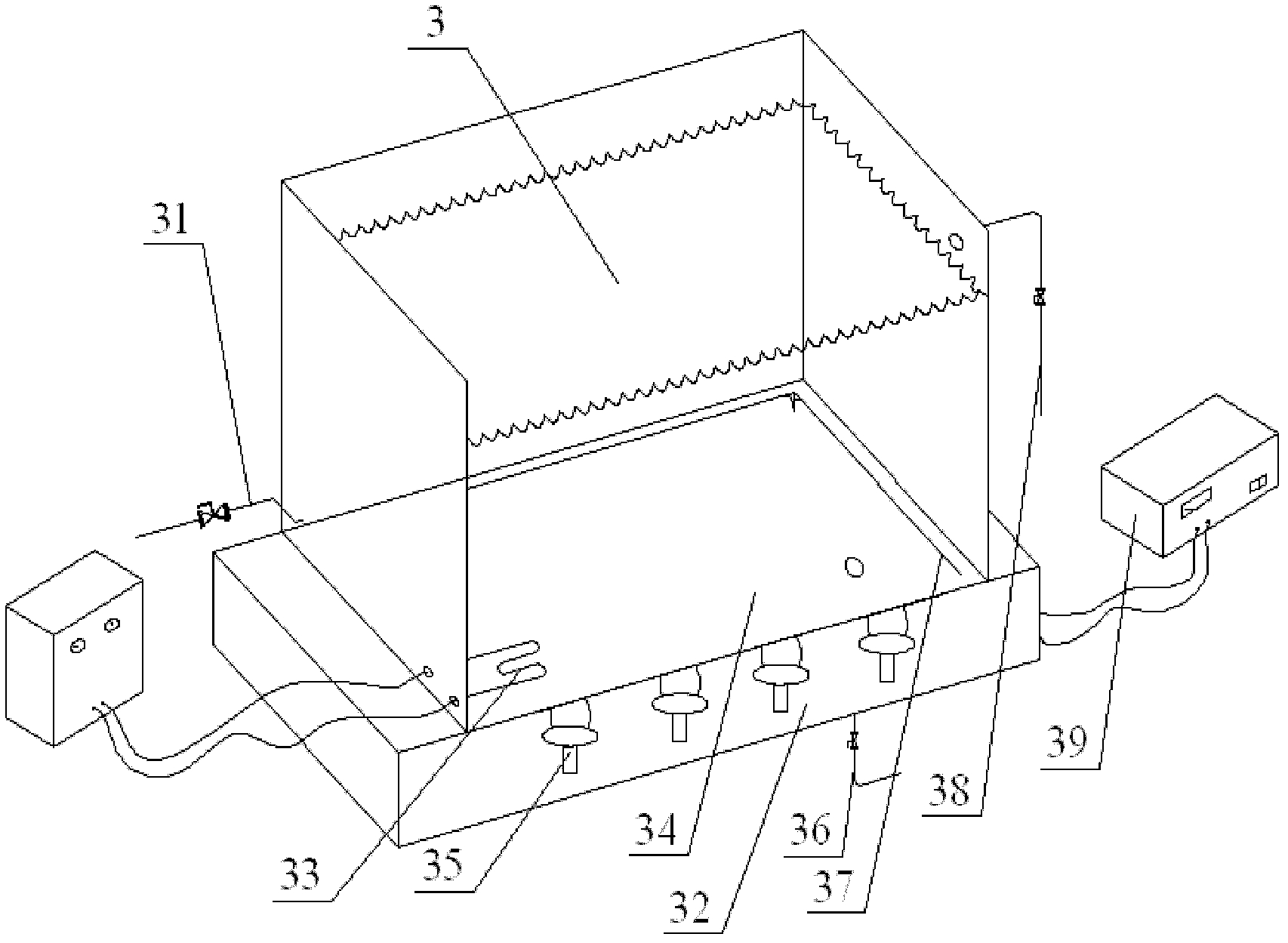

Regeneration technology of V-Ti-based honeycomb SCR denitration catalyst, and apparatus thereof

InactiveCN102658170AGuaranteed structural strengthImprove surface conditionDispersed particle separationCatalyst regeneration/reactivationActive componentHoneycomb

The invention discloses a regeneration technology of a V-Ti-based honeycomb SCR denitration catalyst, and an apparatus thereof. A deactivated catalyst in the technology is regenerated through steps of pressurized water spraying, ultrasonic cleaning, secondary pressurized water spraying, air blow drying, active component supplement, secondary air blow drying, step calcining, and the like. Parameters of the regeneration technology, which comprise components of a cleaning solution, a pickling solution and an active supplement solution, are provided. By adopting the technology, the denitration activity of the deactivated catalyst is recovered, the structural strength of the catalyst is maintained, and the SO2 oxidation frequency is reduced. The apparatus used for realizing the technology comprises a pressurized water spraying pool, an ultrasonic cleaning pool, a secondary pressurized water spraying pool, a pickling pool, an air blow drying pool, an active component supplement pool, a secondary air blow drying pool, a calciner and the like which are sequentially arranged, and the device can realize the hoisting transport regeneration of a regeneration module, and has the characteristics of simplicity, convenient operation, and high efficiency.

Owner:XI AN JIAOTONG UNIV

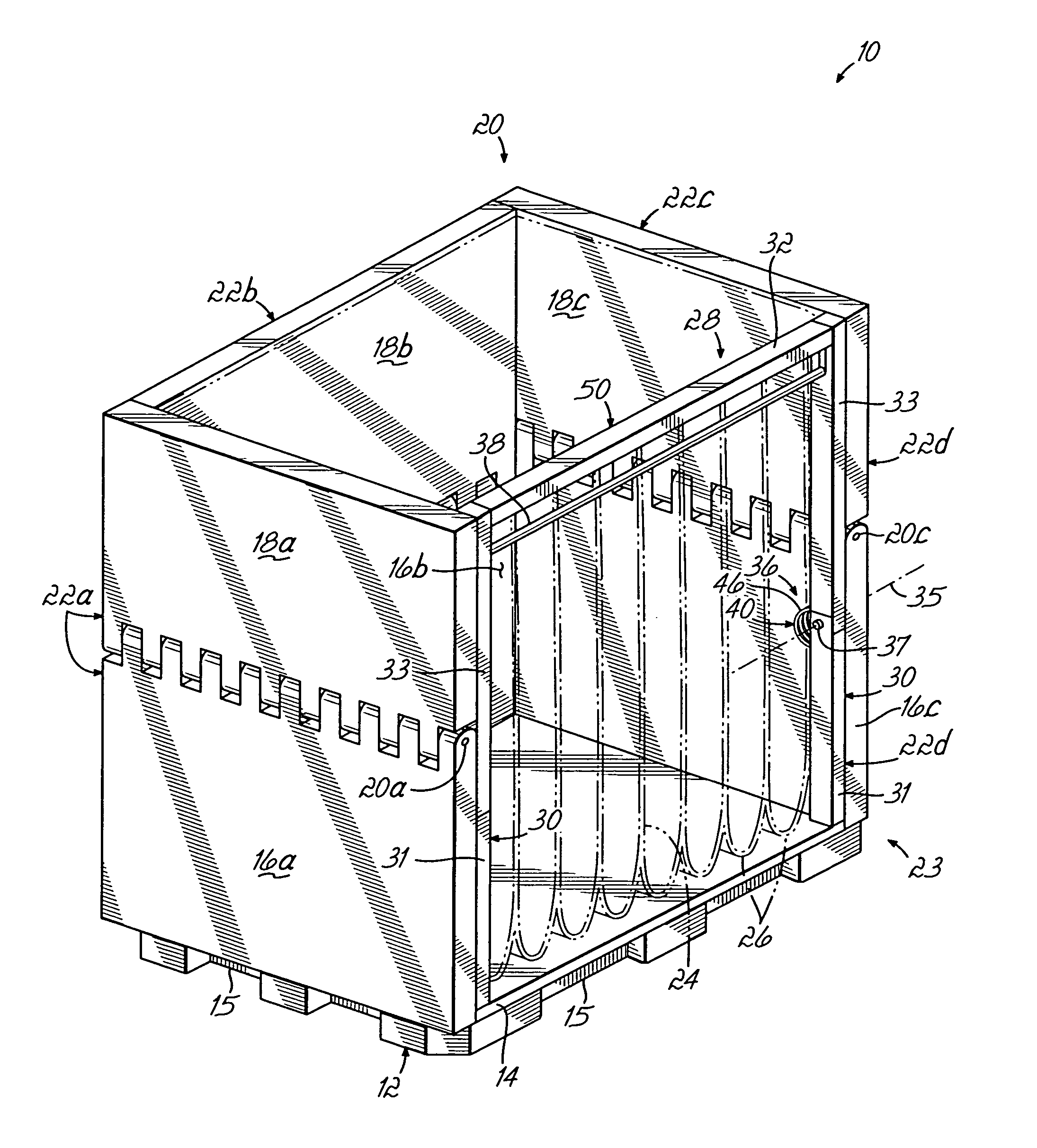

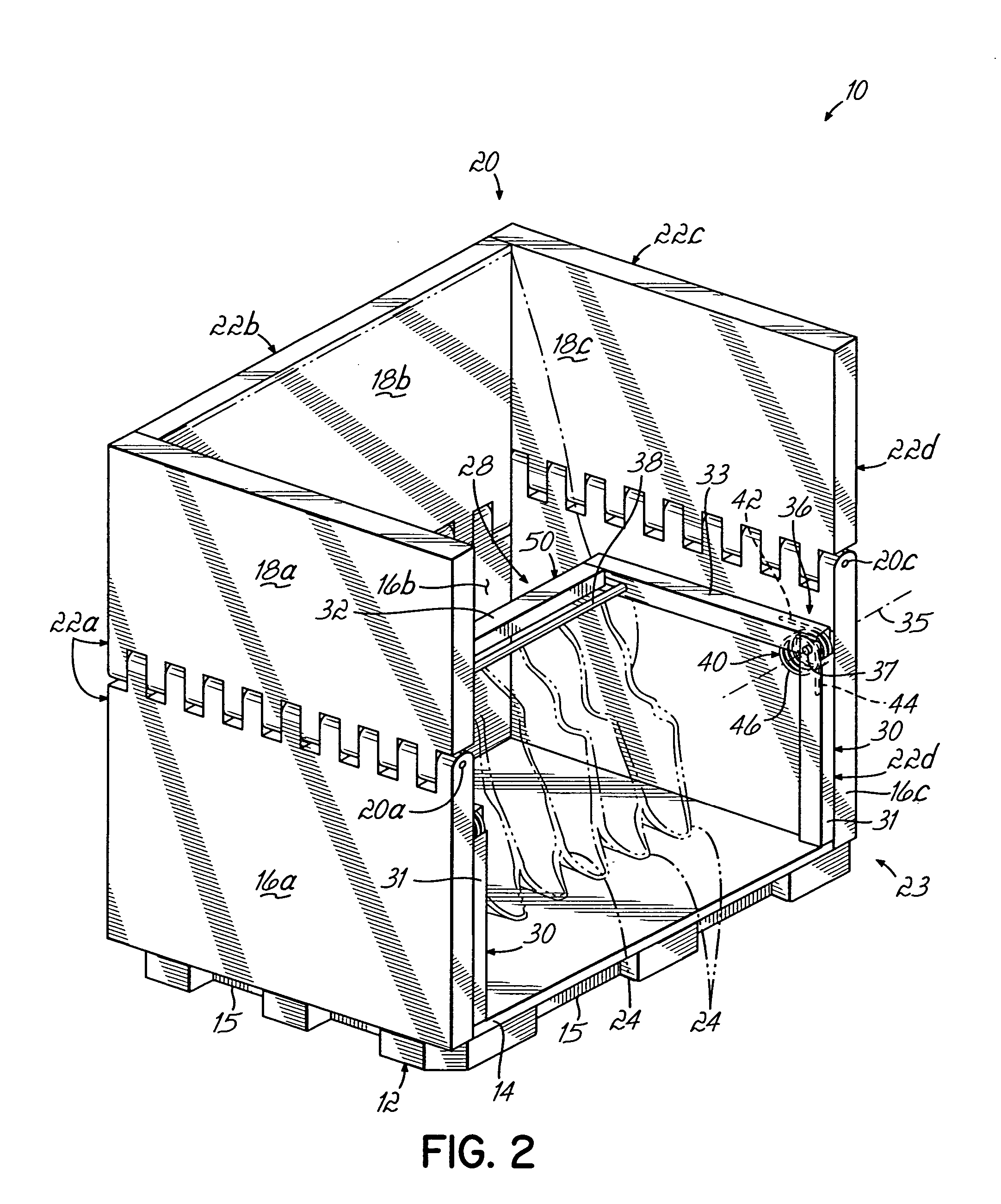

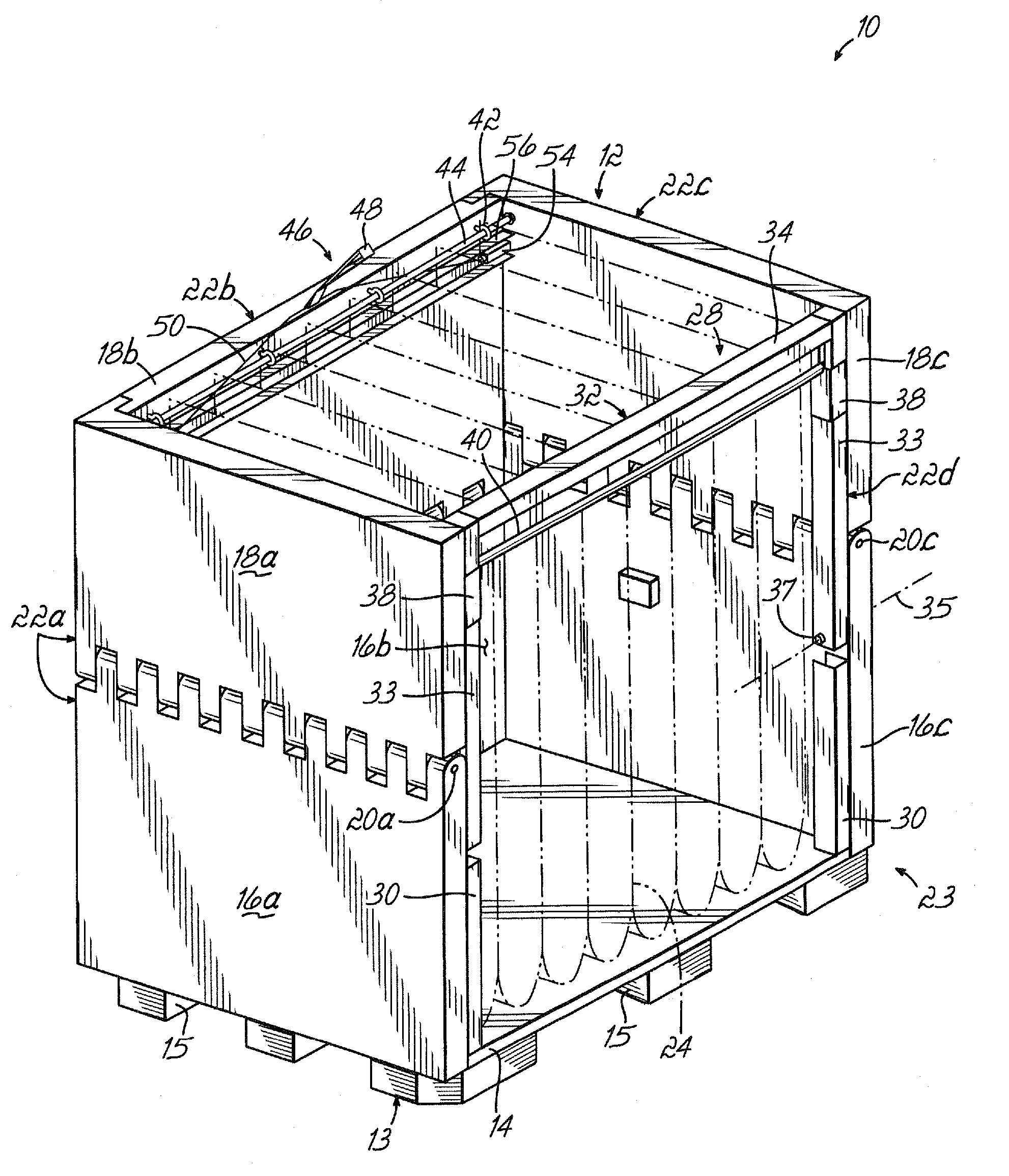

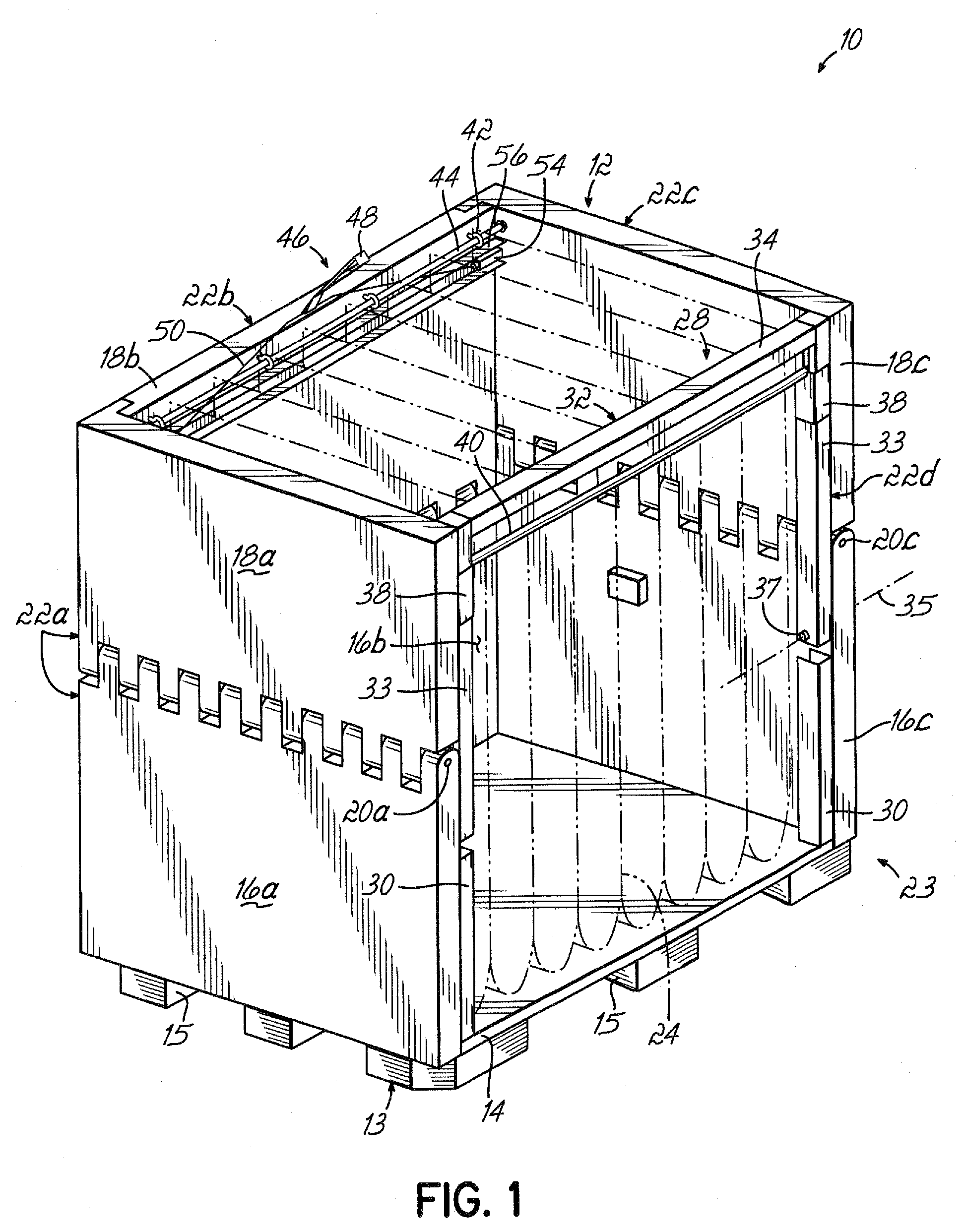

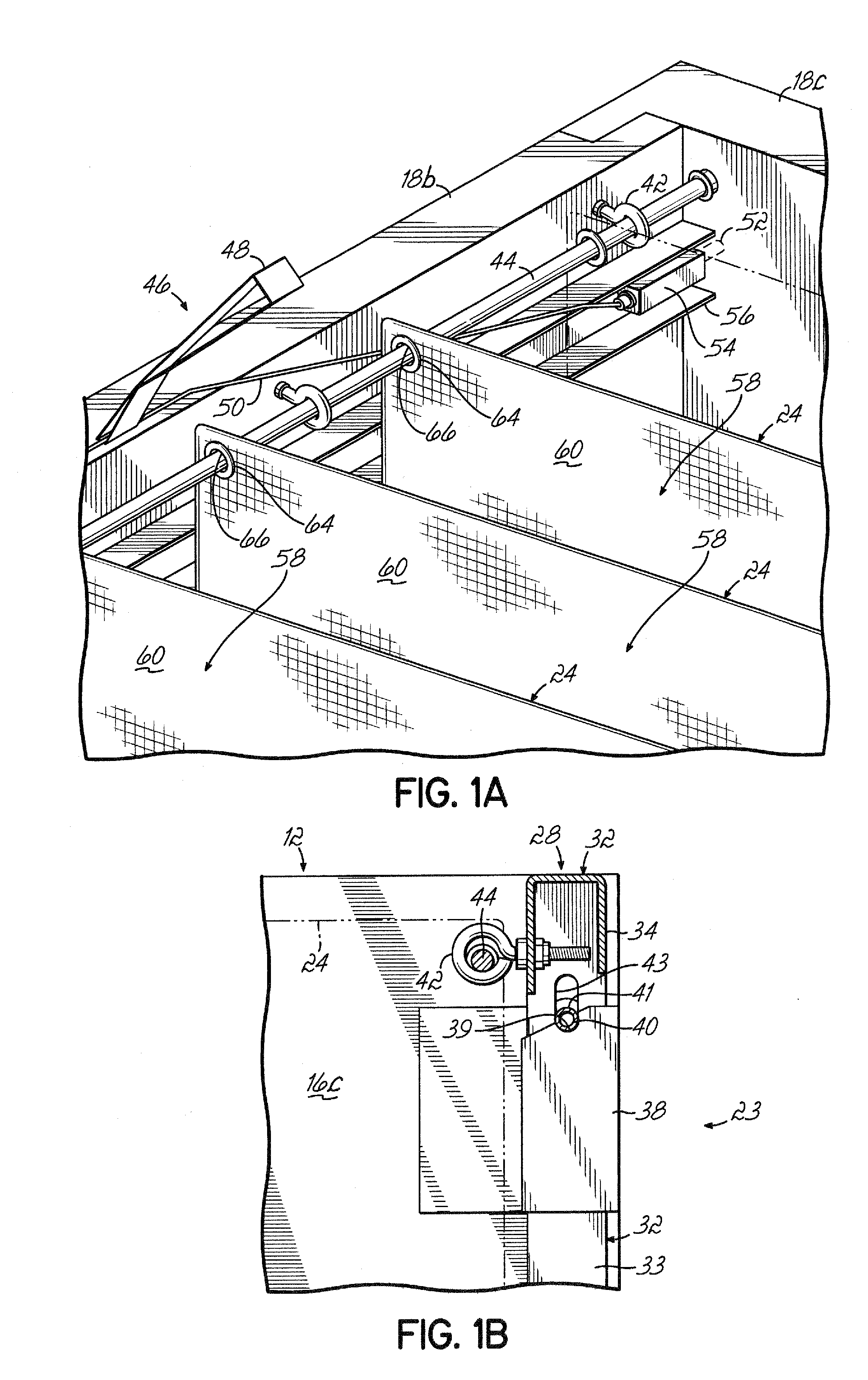

Collapsible container with dunnage erection biaser

InactiveUS7083369B2Reduce replacement costsReduce labor costsPackage recyclingLoad securingDunnageTorsion spring

A reusable and returnable container for holding product therein during shipment and subsequently being returned without product comprises a body having at least two opposed side structures, collapsible dunnage operably connected to the side structures, and a dunnage erection biaser operably connected to one of the side structures. The force needed to erect the dunnage is minimized due to the dunnage erection biaser. The dunnage erection biaser, in one embodiment is a pair of torsion springs. However, the biaser may be any elastic or non-elastic device to facilitate erection of collapsed dunnage.

Owner:BRADFORD CO

Self Contained Foam Dispenser

InactiveUS20080272148A1High quality foam mixingReduce wasteFlow mixersLarge containersMechanical engineeringMixing chamber

A self-contained foam dispensing device includes a casing, a mixing chamber, a port adapted to receive one or more containers including a plurality of chemicals in a plurality of compartments and a flow generator adapted to induce flow of chemicals from the compartments toward a mixing chamber, the flow generator being located between the mixing chamber and the port. When the one or more containers are in the port the one or more containers move with movement of the casing.

Owner:P G UNITED STATES ISRAEL

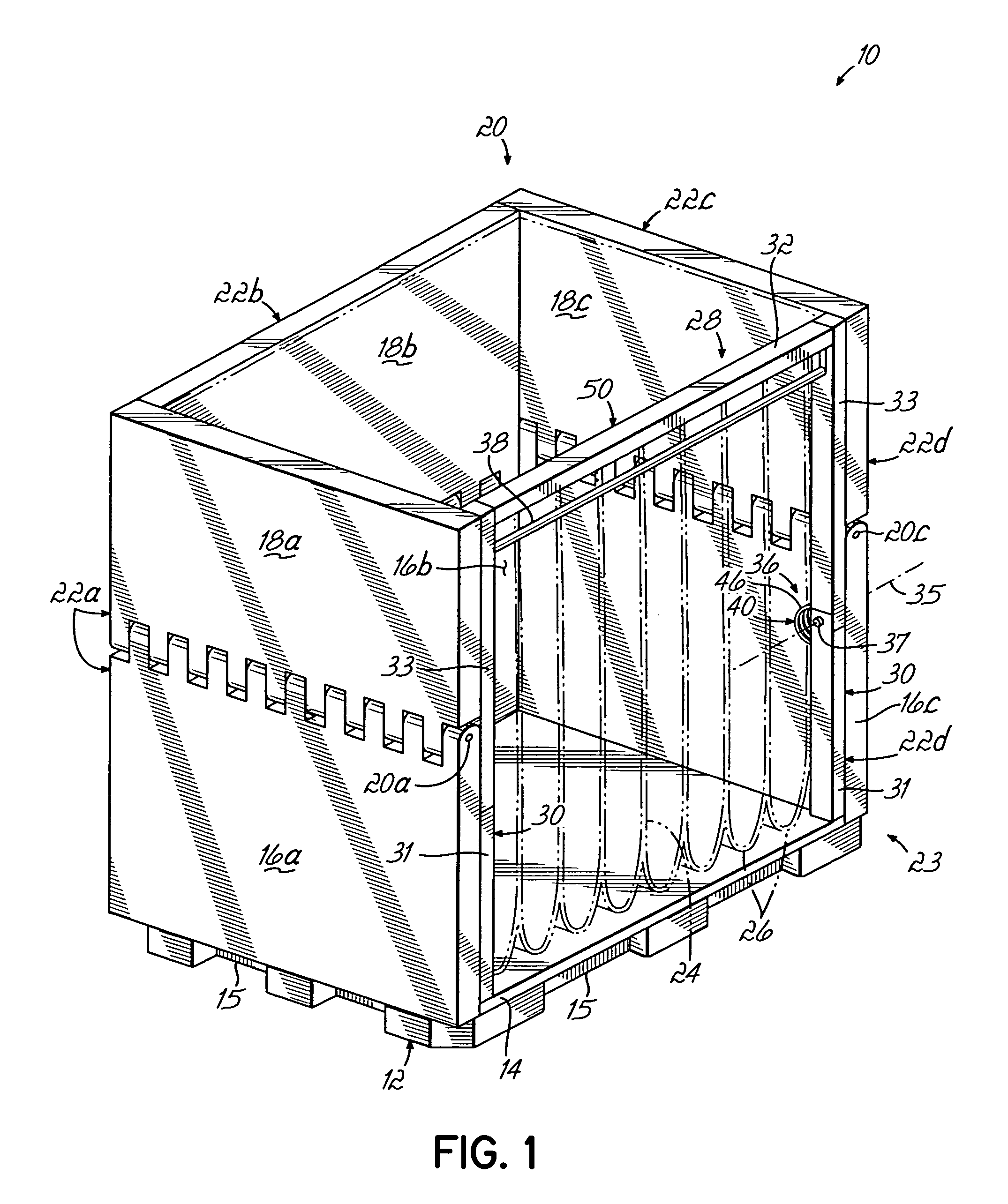

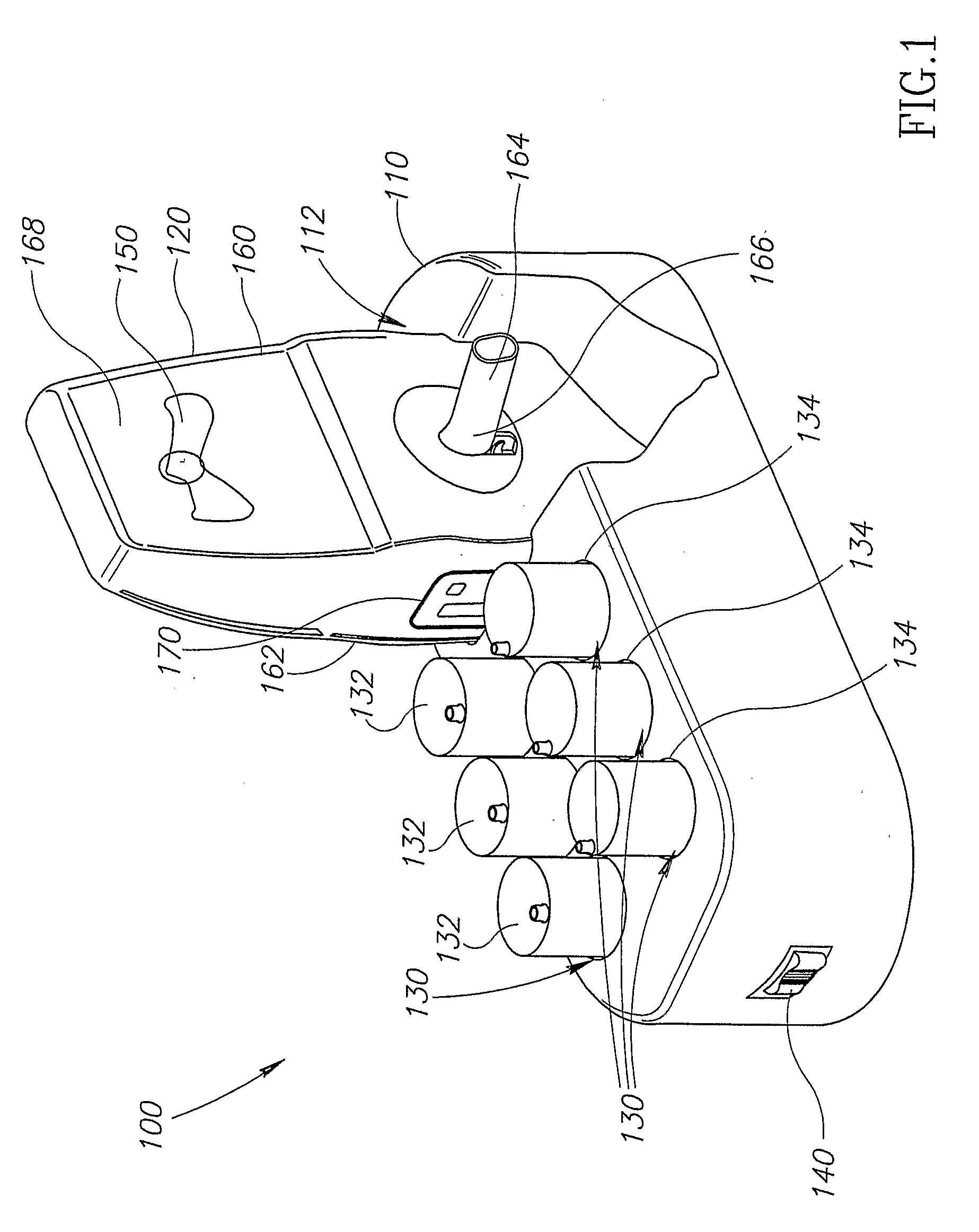

Container Having Dunnage With Integral Stabilizing Members

InactiveUS20080023470A1Easy and efficient transferUnnecessary lifting of the products is reduced and/or eliminatedLarge containersContainers to prevent mechanical damageDunnageEngineering

This invention provides a container for holding product therein during shipment and being returned for reuse that has a body including at least two side structures with support members attached thereto. Dunnage is suspended from the support members. The dunnage comprises a plurality of flexible members, at least some of the flexible members having stabilizers attached to the flexible member for stabilizing and protecting product being shipped. In one embodiment, tracks may be attached to opposite sides of the body, and support member assemblies extend between the tracks. Dunnage is suspended from the support member assemblies. Portions of the support member assemblies move in the tracks to move products suspended by the dunnage to a more ergonomically friendly position for loading or unloading.

Owner:BRADFORD CO

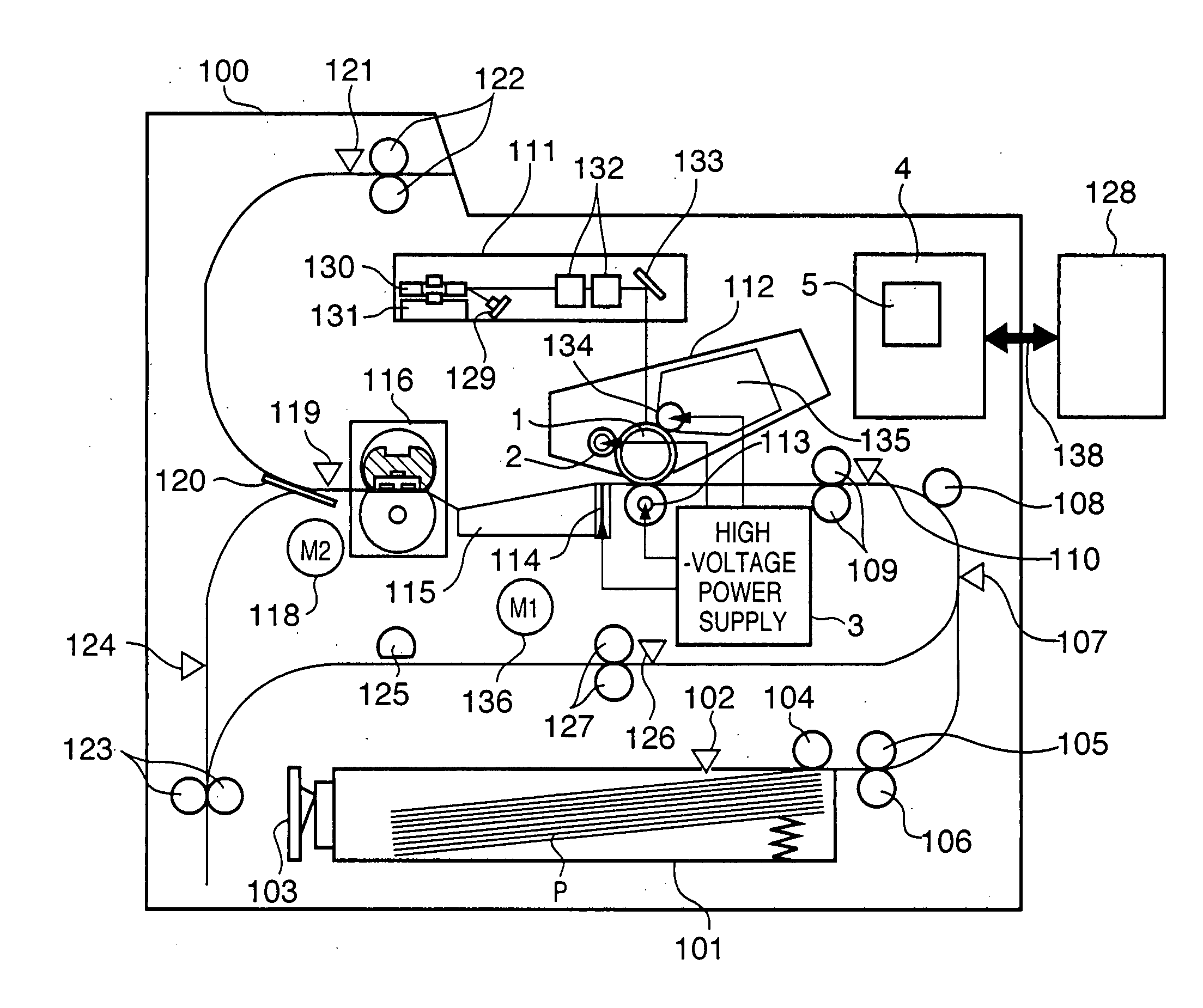

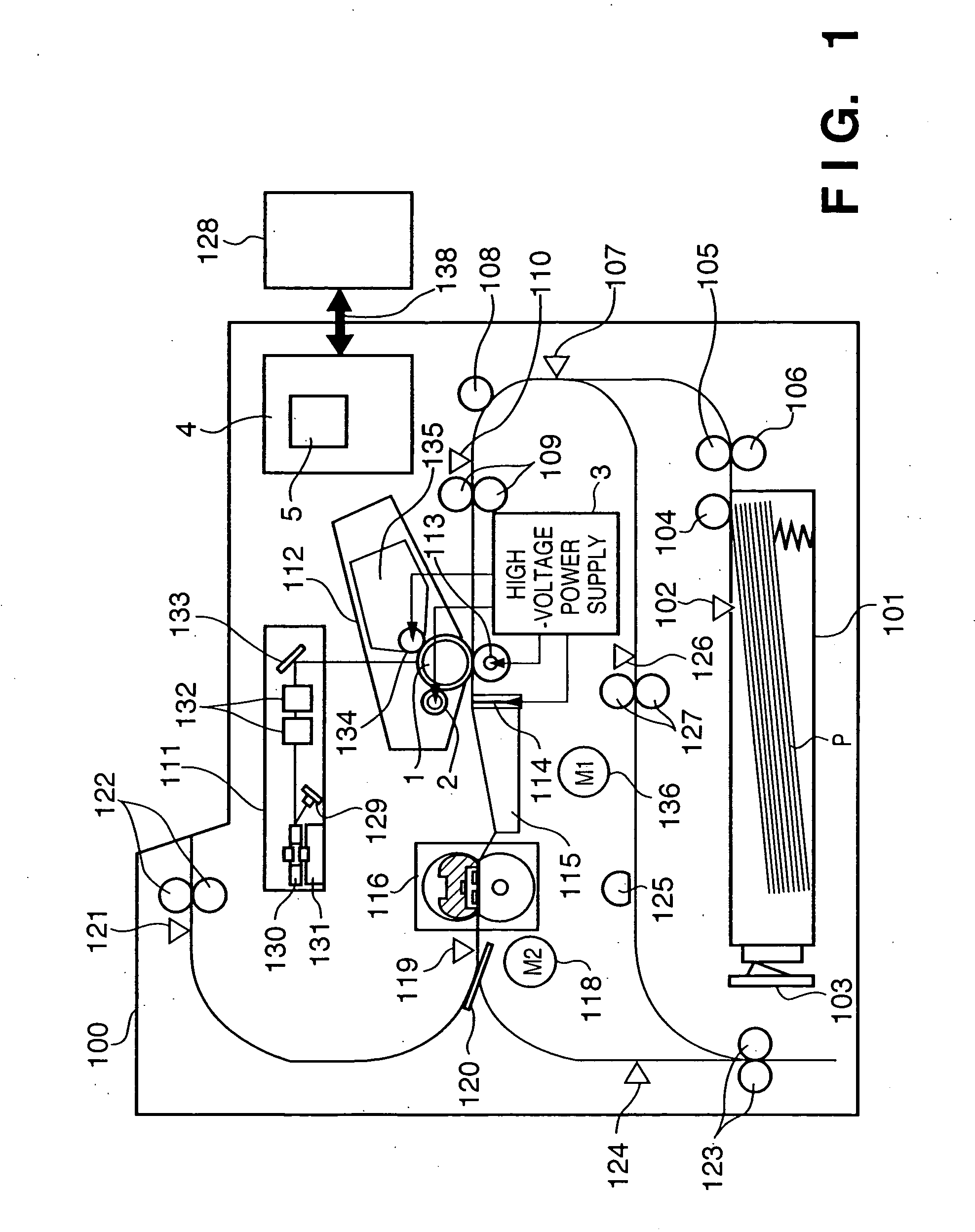

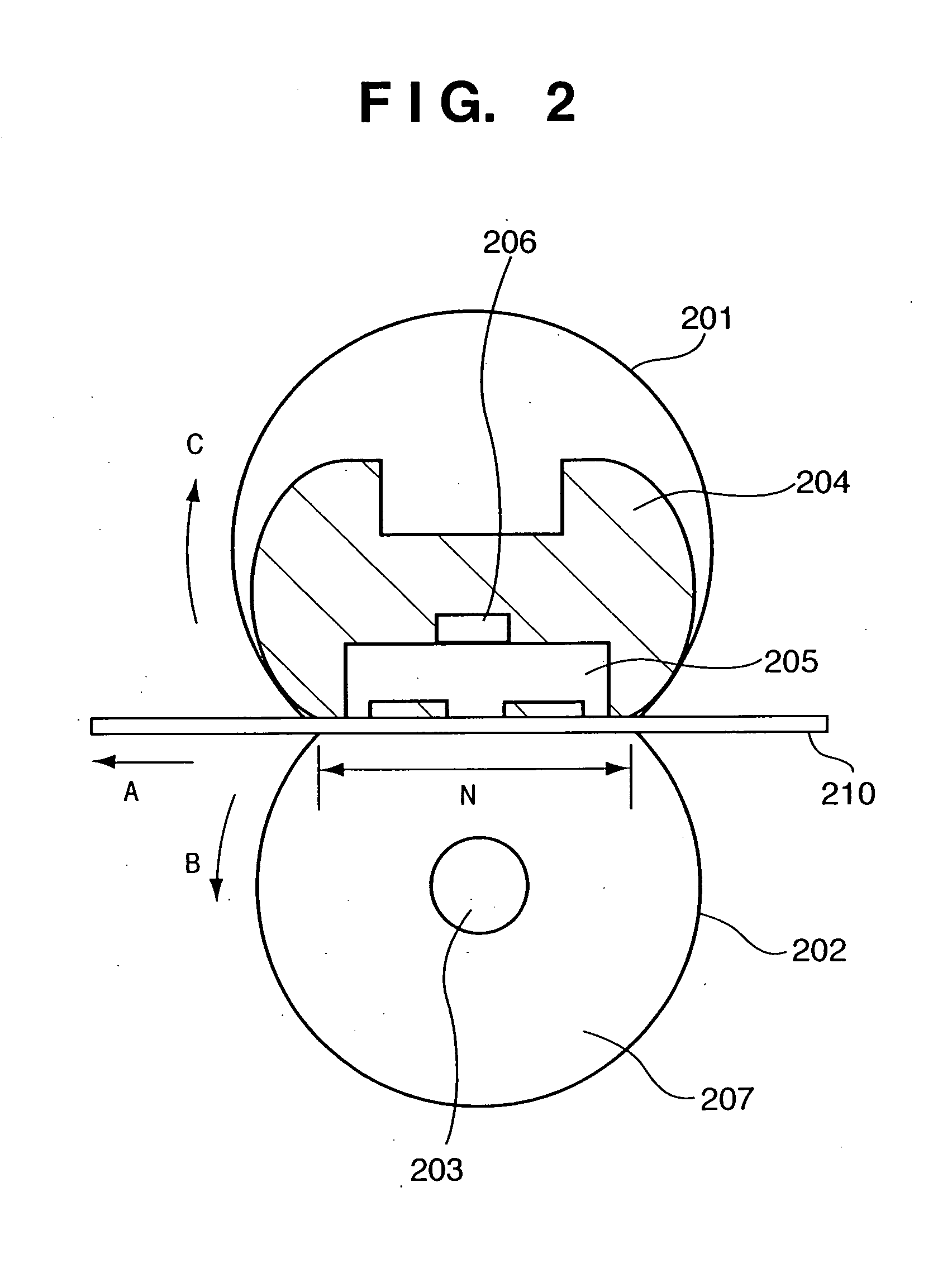

Heat fusing apparatus, method of controlling same and image forming apparatus

ActiveUS20050258158A1Minimizing apparatus damageReduce replacement costsTemperatue controlOhmic-resistance heating detailsImage formationHot melt

Disclosed is a heat fusing apparatus for thermally fusing toner that has been transferred to a printing medium from a toner image formed on an image bearing member using an electrophotographic process. Temperature is detected at the surface of a heating element or in the vicinity thereof. If control is performed so as to interrupt supply of power to the heating element based upon result of comparing the detected temperature and a reference value, the amount of current that flows into the heating element is detected and the reference value is changed over in accordance with the result of detection. Further, a pressure roller, which is a rotation member placed opposite the heating element, presses the printing medium against the heating element and transports the printing medium. The state of rotation of the roller is detected and the reference value is changed over in accordance with the result of detection. The apparatus prevents, without malfunction at the time of normal operation, the occurrence of a situation in which the entire fusing apparatus and peripheral devices must be repaired or replaced owing to overheating, and minimizes apparatus damage to thereby minimize the cost of replacement parts and service cost.

Owner:CANON KK

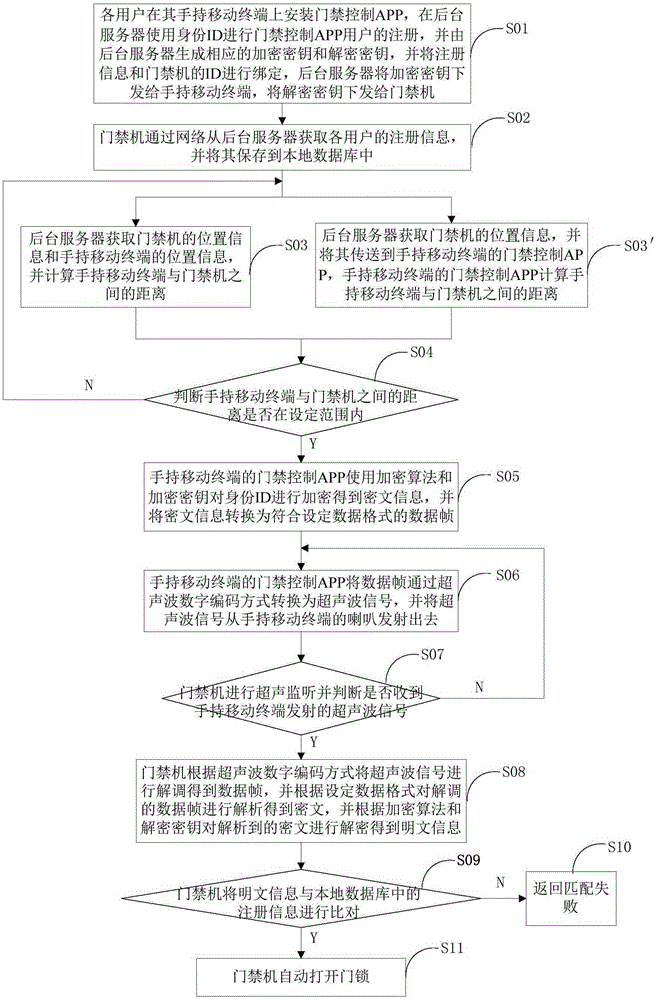

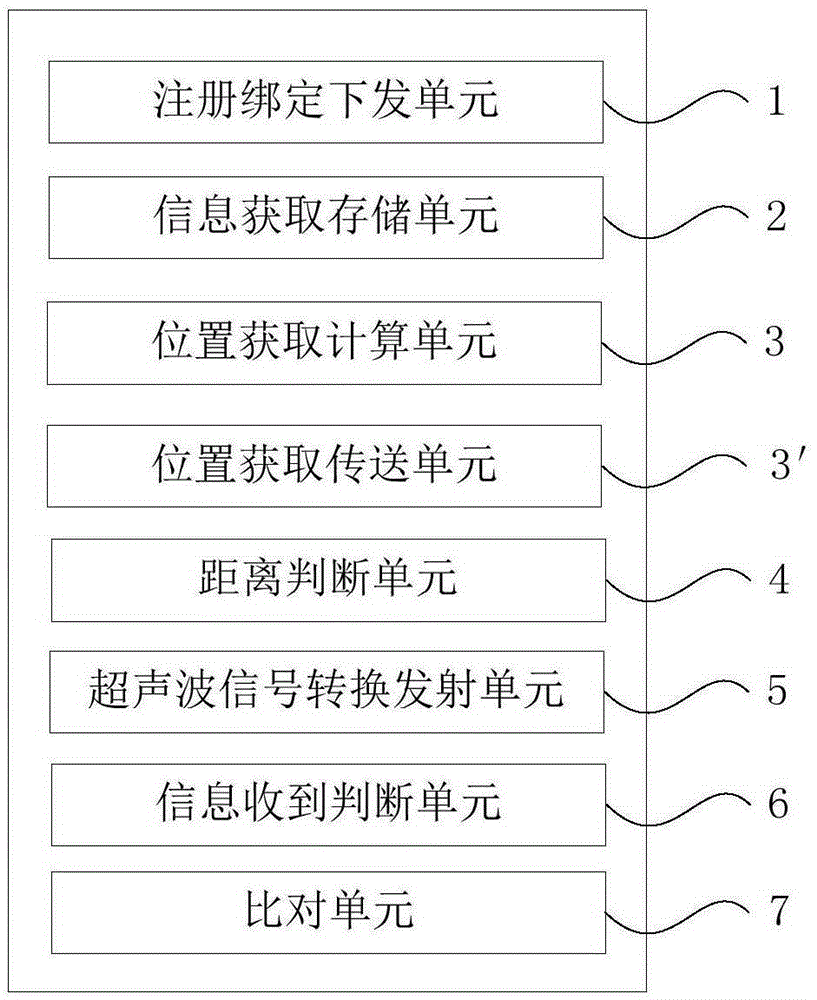

Method and device for identifying access control identity based on ultrasonic waves

ActiveCN105303659AImprove securityFlexible managementSonic/ultrasonic/infrasonic transmissionTelephonic communicationHand heldComputer terminal

The invention provides a method and a device for identifying access control identity based on ultrasonic waves. The method comprises the following steps of enabling each user to install an access control APP (application) at a hand-held mobile terminal, and use the ID (identity) to register as the user of the access control APP; generating an encrypting key and a decrypting key; enabling an access control machine to obtain the information of the users, and storing into a local database; when the distance between the hand-held mobile terminal and the access control machine is controlled within the setting range, using an encrypting algorithm and the encrypting key to encrypt the ID to obtain encrypting information, converting the encrypting information into a data frame, converting the data frame into an ultrasonic signal by an ultrasonic digital encoding type, transiting the ultrasonic signal via a loudspeaker, enabling the access control machine to receive the ultrasonic signal and convert the ultrasonic signal into the data frame, demodulating, and decrypting to obtain a plain text; if the plain text is matched with the information of the local database, automatically opening a door. The method and the device for identifying the access control identify based on the ultrasonic waves have the beneficial effects that the safety is higher, the use cost is reduced, and the reliability is higher.

Owner:SHENZHEN YUDI TECH CO LTD

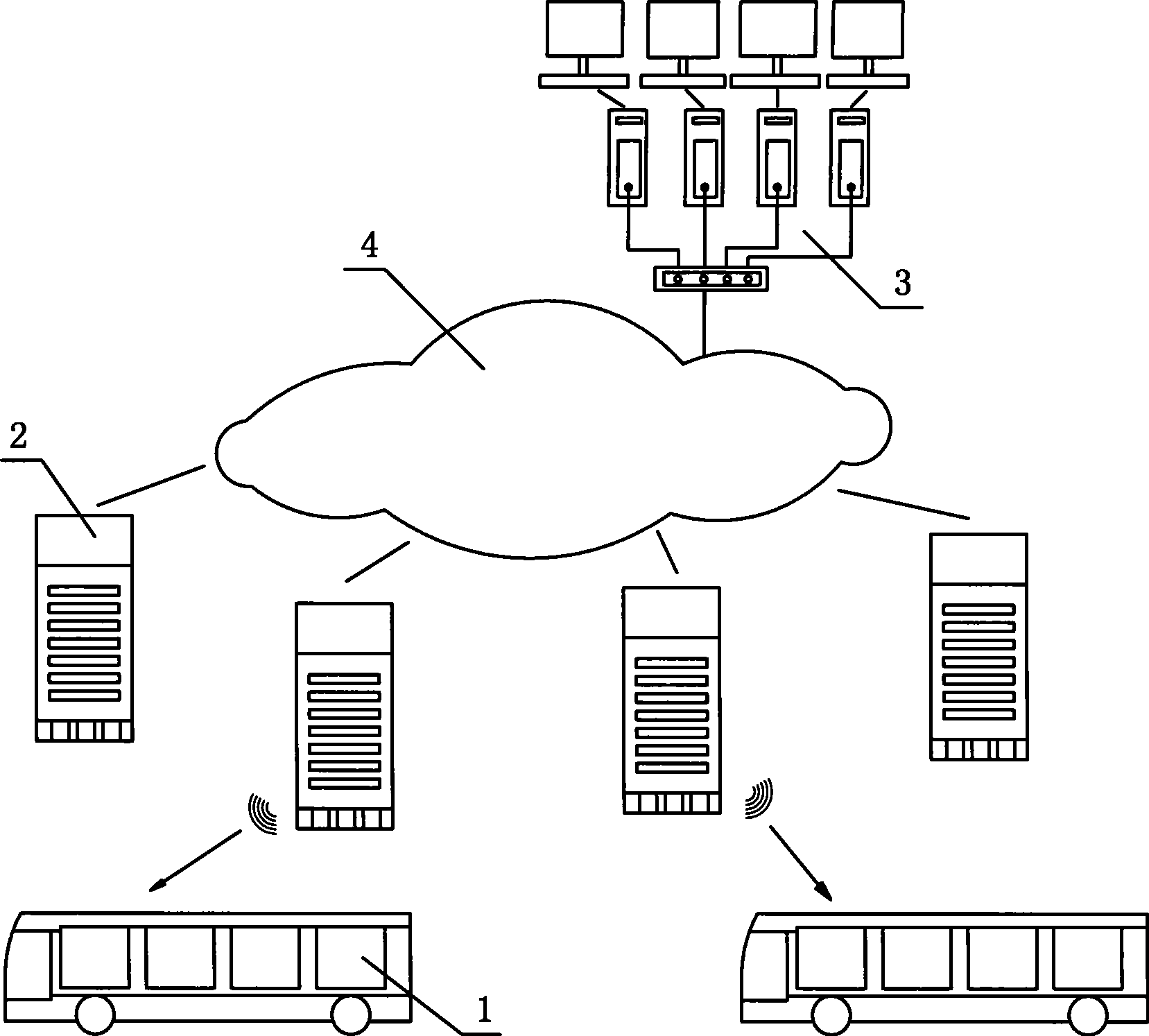

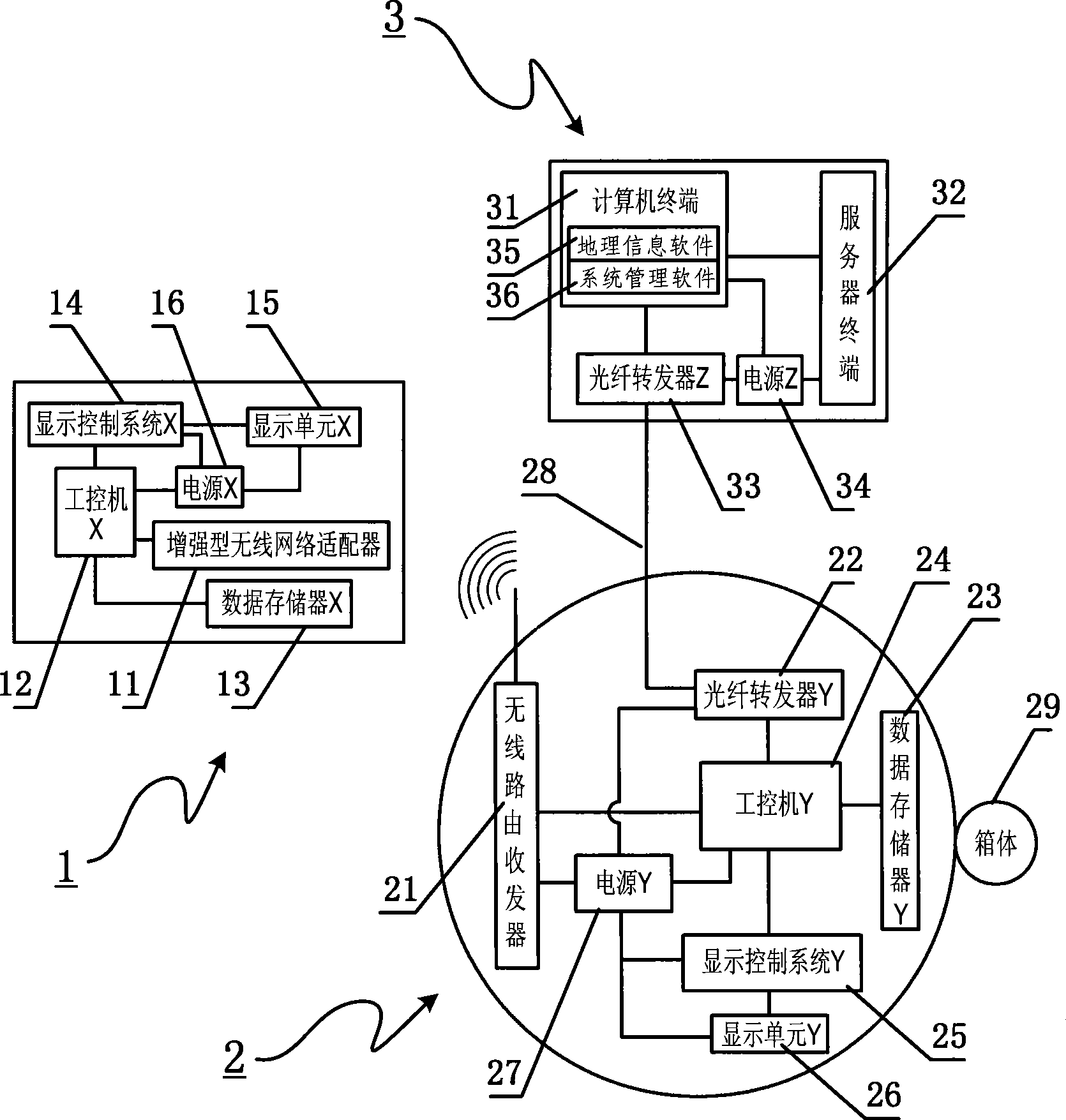

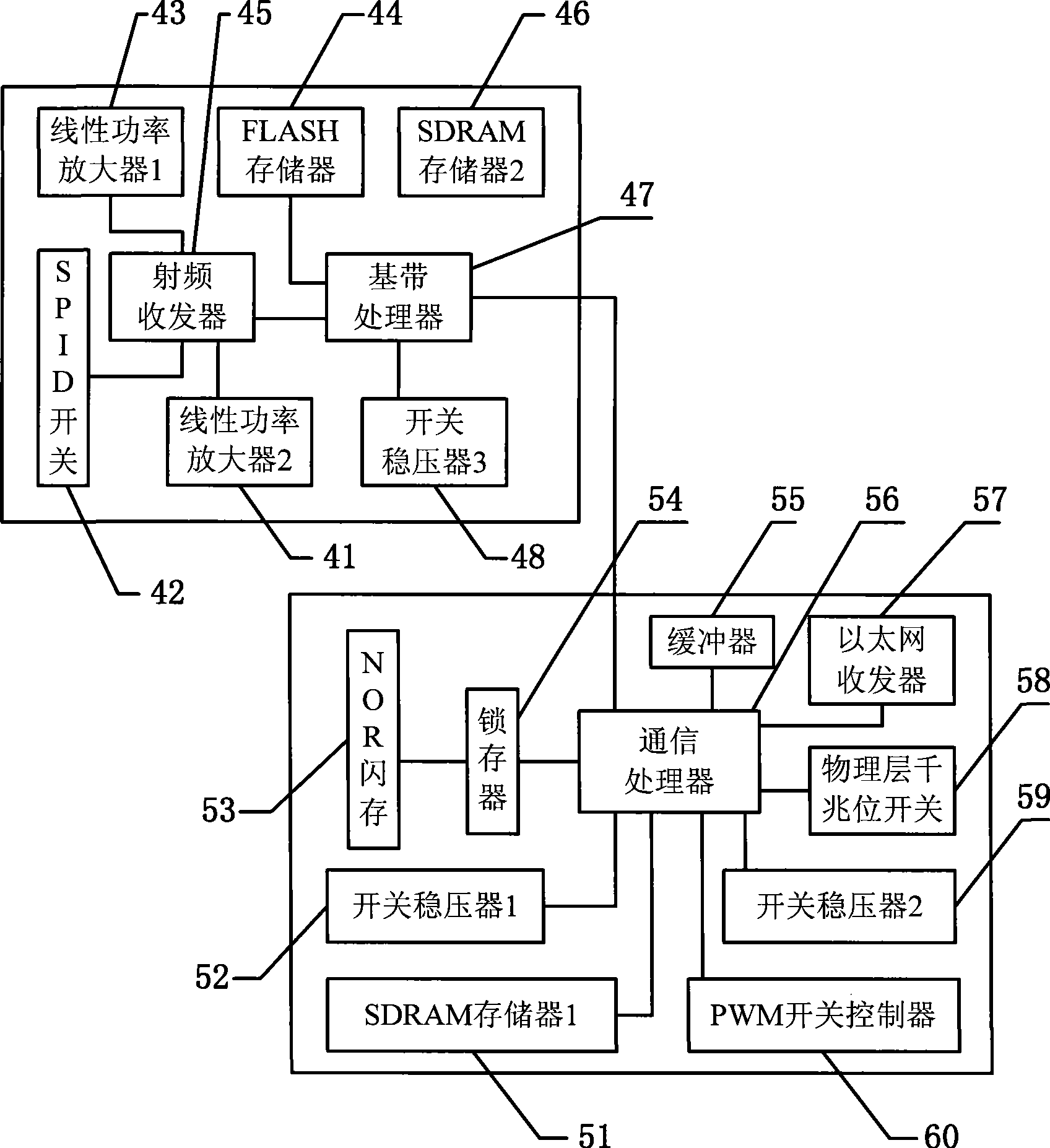

Digital public transport information publishing and cluster controlling method and device

InactiveCN101398975AWide coverageIntegrity guaranteedDetection of traffic movementTelecommunications linkEngineering

The invention relates to a method used for digital bus information releasing and group control and a device thereof. The technical measure comprises the following steps: a vehicle terminal system, an electronic station board system and a vehicle technical information management centre are arranged, the electronic station board system is the vehicle technical information management centre are connected into a bi-directional communication network by line link, the vehicle terminal system transmits the vehicle information to the electronic station board system in a wireless communication, the electronic station board system reports the information to the vehicle technical information management centre, the bus coming to station at each station can be found out by inquiring a database, the station arriving time of the bus is calculated according to experimental data including average running speed, average running time between the stations and the like, finally, the arriving time is fed back to the electronic station board system, and the arriving time is displayed to the waiting passengers in a digital way. The method can effectively solve the problems of bus reduction in city and dispatching, information releasing, passenger facilitation, intelligent management control and the like. Therefore, the method realizes intelligent bus dispatching.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

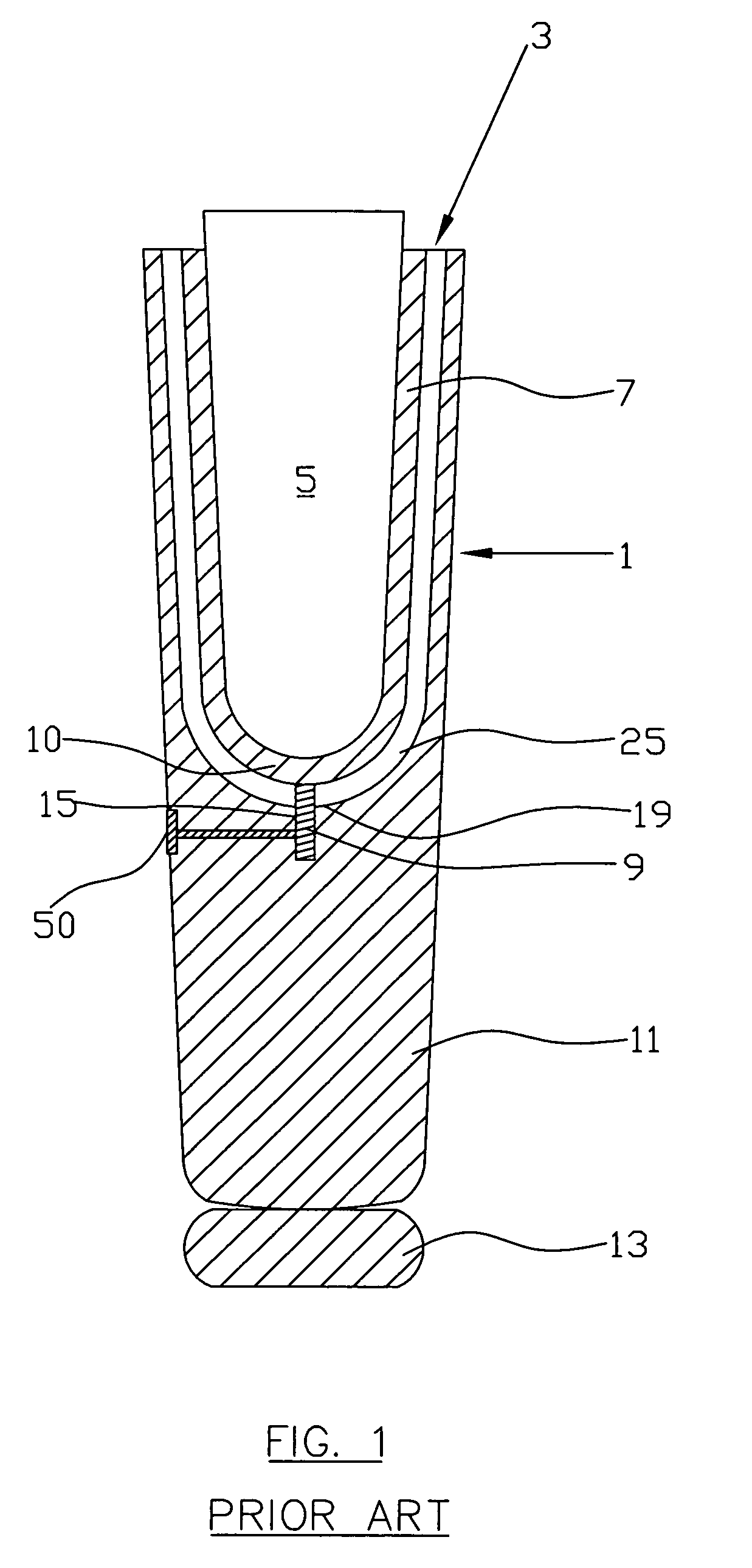

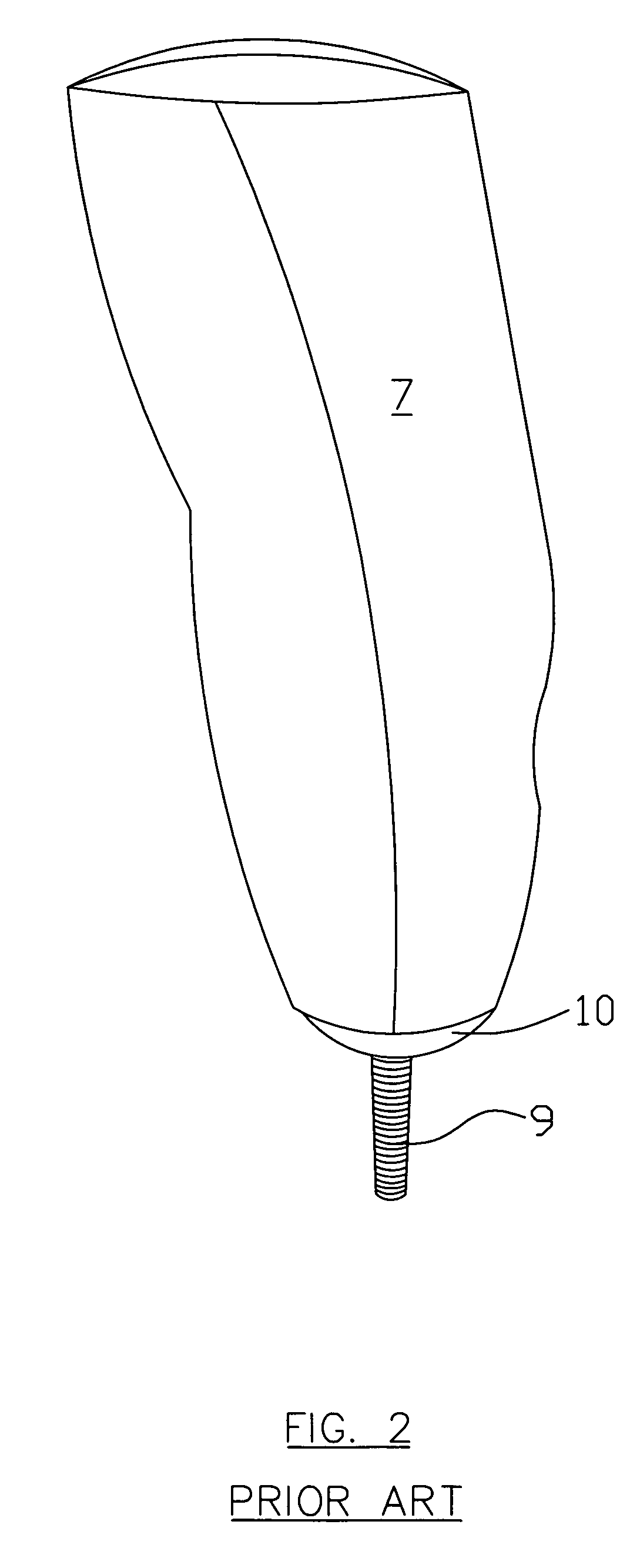

Prosthetic interior casting process and product

InactiveUS7240414B2Low costExtend equipment lifeMetal rolling stand detailsArc welding apparatusShell moldingFurring

A method of sizing, resizing or reshaping the interior of a prosthetic device includes placing a lightweight moldable or shape assuming, pliable material that adheres and hardens on the interior sides of a socket of a prosthetic device. An end of a residual limb is placed into the socket causing the moldable material to conform to the shape of the residual limb. The limb is maintained in position for a few minutes in the socket until the moldable material has sufficiently hardened. After hardening, the molded material is dressed down, sanded or feathered to remove any burrs or sharp edges. Low spots or holes may be filled in with more moldable material and the fitting process repeated.

Owner:TAYLOR SR MATTHEW T

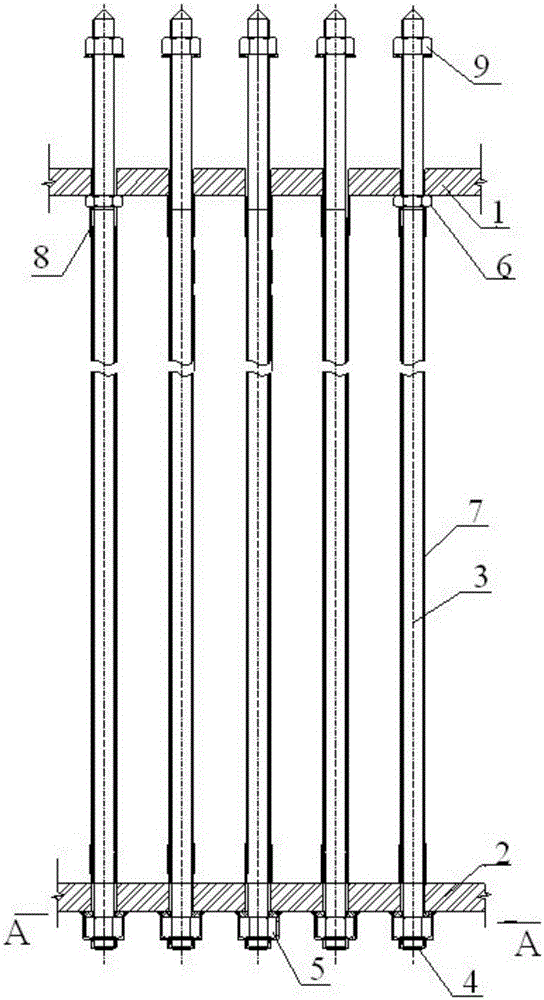

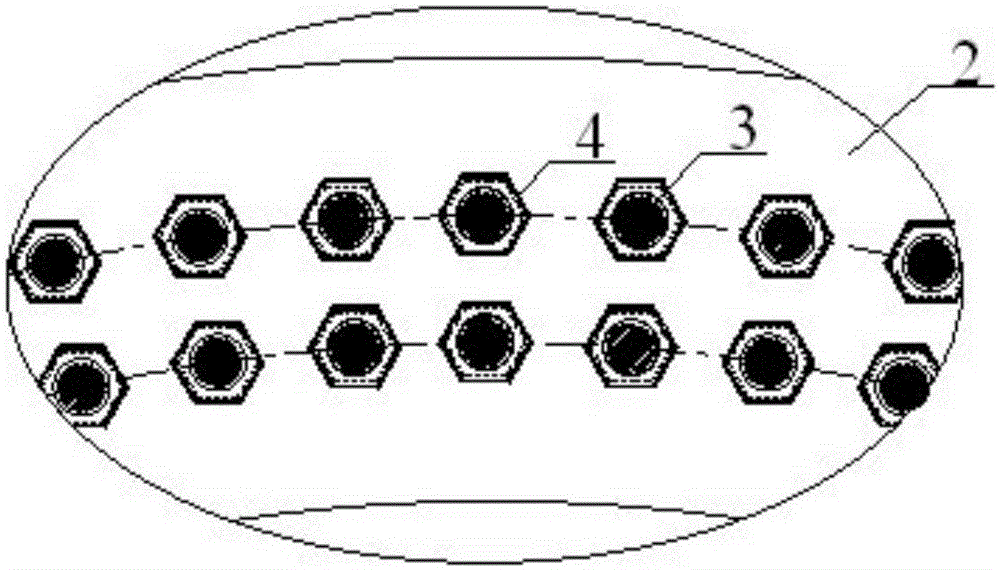

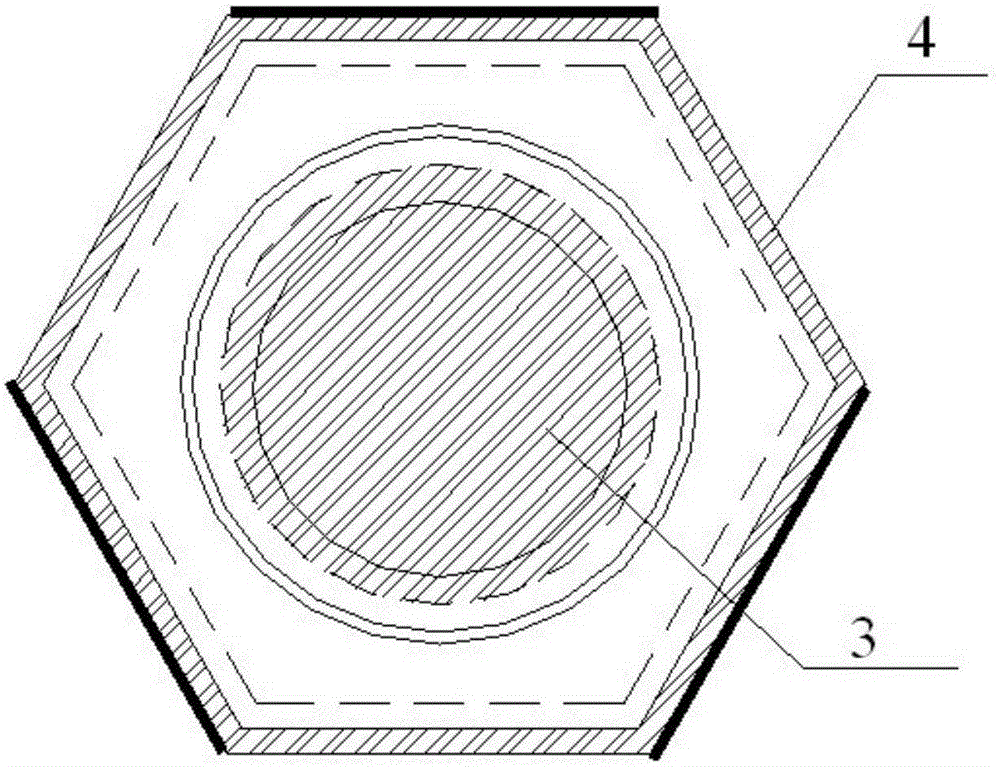

Replaceable prestressed anchor bolt device and mounting and replacement construction method thereof

ActiveCN105155571AReasonable structural designAvoid the influence of forceFoundation engineeringMaterial resourcesAnchor bolt

The invention discloses a replaceable prestressed anchor bolt device. The replaceable prestressed anchor bolt device comprises an upper anchor plate (1), a lower anchor plate (2), anchor bolts (3) connected with the upper anchor plate (1) and the lower anchor plate (2) and plastic casing pipes (7) arranged on the peripheries of the anchor bolts (3) in a sleeving manner. The upper ends and the lower ends of the plastic casing pipes (7) are shrunk and sealed by thermal shrinkable sleeves (8). Nonmetal leveling nuts (6) are arranged on the thermal shrinkable sleeves (8) at the upper ends of the plastic casing pipes (7), and upper nuts (9) are arranged at the tops of the anchor bolts (3). The bottoms of the anchor bolts (3) and bottom sealing assemblies (4) are fixed. The replaceable prestressed anchor bolt device is reasonable in structural design, each anchor bolt can be freely replaced after a concrete foundation is completed or a fan runs, and a large amount of manpower and a large number of material resources can be saved; replacement cost is low, and efficiency is high; and many defects in the prior art can be overcome.

Owner:JIANGSU JINHAI NEW ENERGY TECH +1

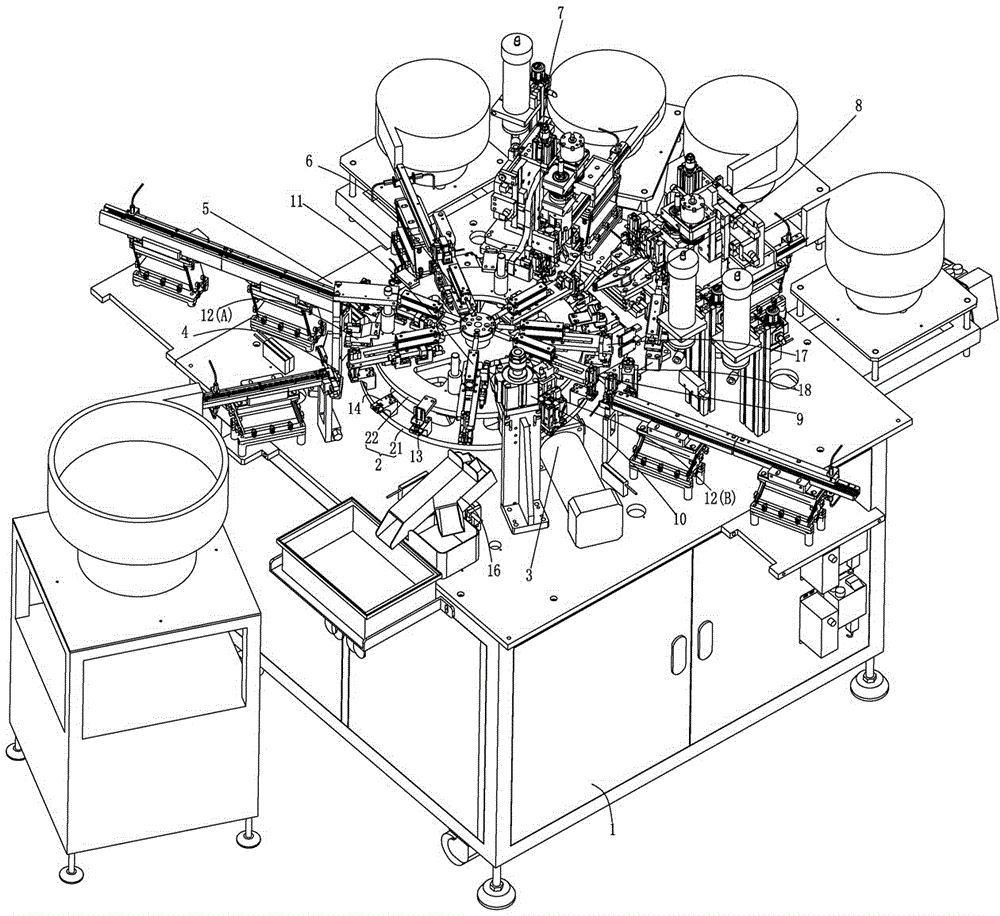

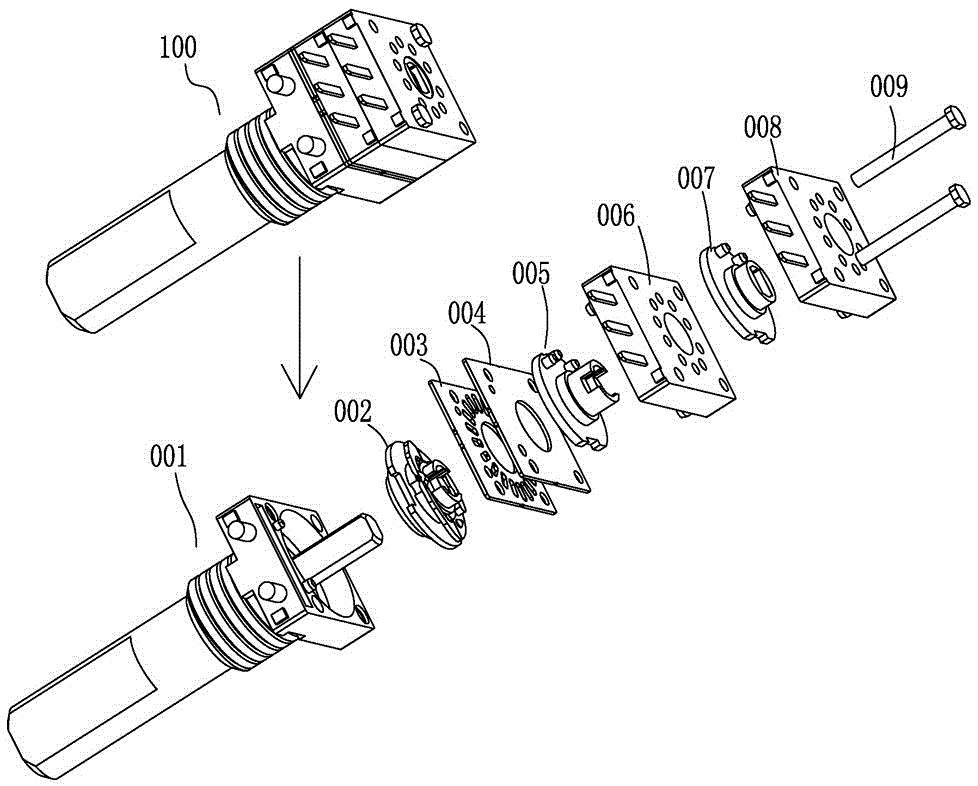

Automatic assembly machine for assembling encoder for intercom

ActiveCN106736538AHigh degree of automationImprove assembly productivityAssembly machinesMetal working apparatusEngineeringCam

The invention discloses an automatic assembly machine for assembling an encoder for an intercom. The automatic assembly machine includes a case, a controller, a rotation disc, a cam divider assembly, an upper manual placement mechanism, a stopping base mounting mechanism, a first film sheet mounting mechanism, a second film sheet mounting mechanism, a first rubber rotation sheet mounting mechanism, a first body mounting mechanism, a second rubber rotation sheet mounting mechanism, a second body mounting mechanism, an oil coating mechanism, a riveting mechanism, a discharging mechanism and detection assemblies; a plurality of working station clamps are movably arranged on a circumferential edge of the rotation disc; In assembly, the upper manual placement mechanism transfers a manual placement shaft core sleeve to a matched working station clamp, and then the stopping base, the first film sheet, the second film sheet, the first rubber rotation sheet, the first body, the second rubber rotation sheet, the second body are mounted successively, the oil coating mechanism performs oil coating after the second body is mounted, the riveting mechanism rivets all the parts through rivets to form a finished product, and the discharging assembly sends the finished product to a collection box. The automatic assembly machine is easy to use, is high in assembly efficiency, is high in yield, is simple to maintain, and is long in service life.

Owner:广东钺河智能科技有限公司

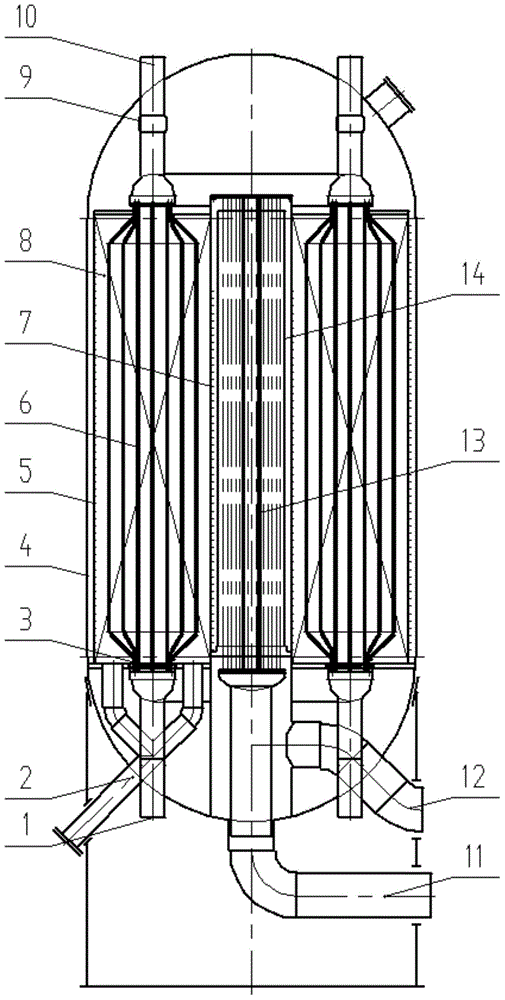

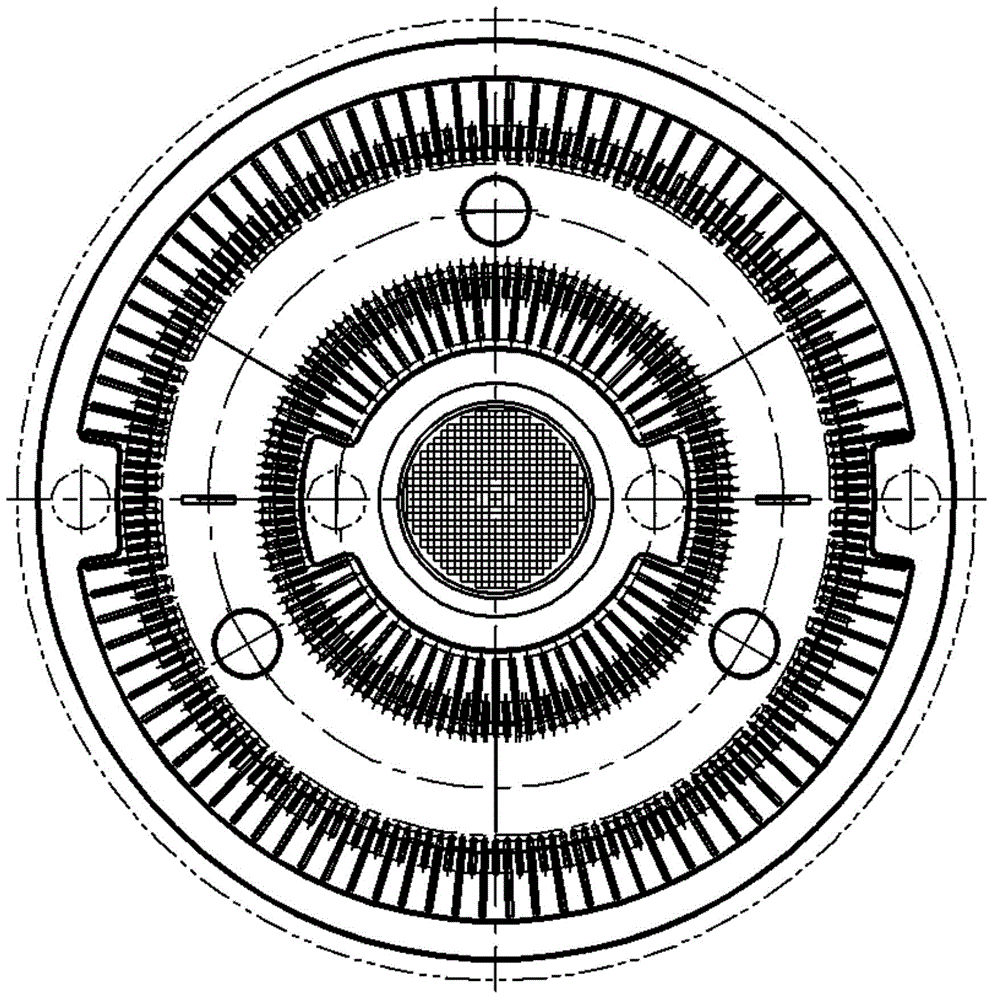

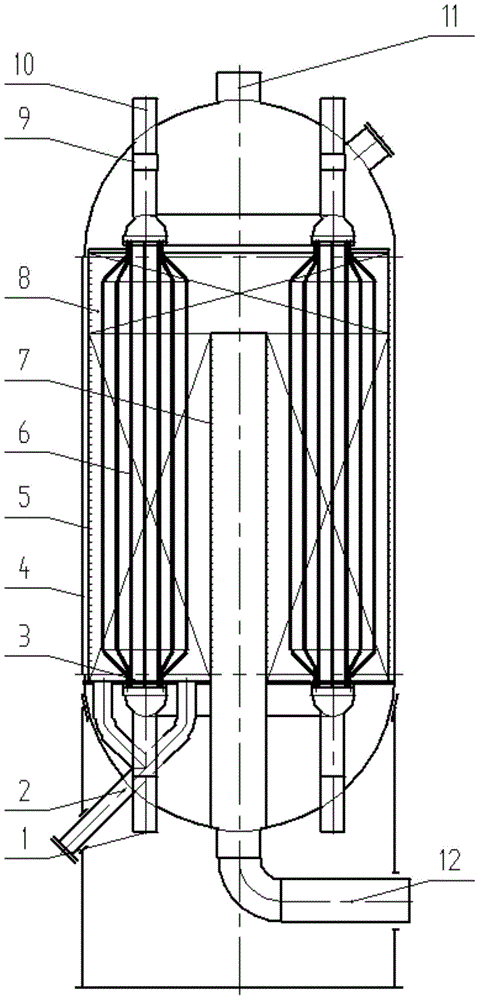

Pipe-bundle-builtin isothermal-shift reactor

ActiveCN105457563AFrom burningExtend your lifeHydrogenChemical/physical processesEngineeringHigh heat

The invention relates to a pipe-bundle-builtin isothermal-shift reactor. According to the pipe-bundle-builtin isothermal-shift reactor, axial annular pipe bundles, which are builtin and are uniformly distributed in a catalyst bed layer along circumferential direction, are adopted to shift out heat of reaction, so as to realize isothermal shift; and a central pipe bundle which is built in a central pipe is adopted to preheat raw material gas entering the reactor, so as to realize the builtin of a gas-gas heat exchanger. The isothermal-shift reactor comprises a pressure-bearing shell, a catalyst basket, the axial annular pipe bundles, the central pipe and the central pipe bundle; and the axial annular pipe bundles consist of upper and lower annular pipe boxes, upper and lower annular pipe sheets and heat exchange tubes. According to the pipe-bundle-builtin isothermal-shift reactor, due to builtin pipe bundles, the manufacturing cost of equipment is effectively reduced; due to an end-part bent structure for the heat exchange tubes, the size of the pipe sheets is effectively reduced; due to a heat insulating layer laid between the pipe sheets and the high-temperature catalyst bed layer, the contact between pipe end weld spots and a bed layer high-temperature area is effectively isolated, the probability of leakage is lowered, and the reliability of equipment is improved; and the pipe-bundle-builtin isothermal-shift reactor is compact in structure, low in manufacturing cost, relatively easy in maintenance, high in reliability, complete in function and high in applicability.

Owner:CHANGZHENG ENG

Electronic cigarette

ActiveCN109717519APrevent leakagePrevent spoilageTobacco devicesElectrical batteryElectronic cigarette

The invention discloses an electronic cigarette. The electronic cigarette comprises a cartridge and a battery device which are detachably connected, the battery device comprises a battery, a heating piece, a detection assembly, a sensor and a first control panel, and the detection assembly is used for generating a connecting signal when the cartridge is connected with the battery device; the sensor is used for generating a smoking signal under the smoking effect, and if and only if the detection assembly generates the connecting signal, and the sensor generates the smoking signal, the first control panel controls the battery to supply power to the heating piece, so that the heating piece conducts atomizing operation. According to the electronic cigarette, if and only if the detection assembly generates the connecting signal, and the sensor generates the smoking signal, the first control panel can control the battery to supply power to the heating piece, and the function of protecting safety of children is achieved.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

High pressure, high flow rate tubing assembly for a positive displacement pump

InactiveUS20110180172A1Increased tube lifeReduce replacement costsFlexible member pumpsPipe elementsPeristaltic pumpWorking life

A tubing assembly is provided that can comprise a plurality of tubes or lumens that can be disposed within a head of a peristaltic pump. The tubing assembly can provide a flow rate or volume capacity that is generally equal to or greater than that achieved with a comparable prior art tube while operating at higher pressures than that possible using the prior art tube. Further, in accordance with some embodiments, the tubing assembly can achieve a longer working life than a comparable prior art tube, and the load on the pump motor can be reduced such that the pump life is increased and / or a larger pump motor is not required to achieve such advantageous results.

Owner:BLUE WHITE INDS

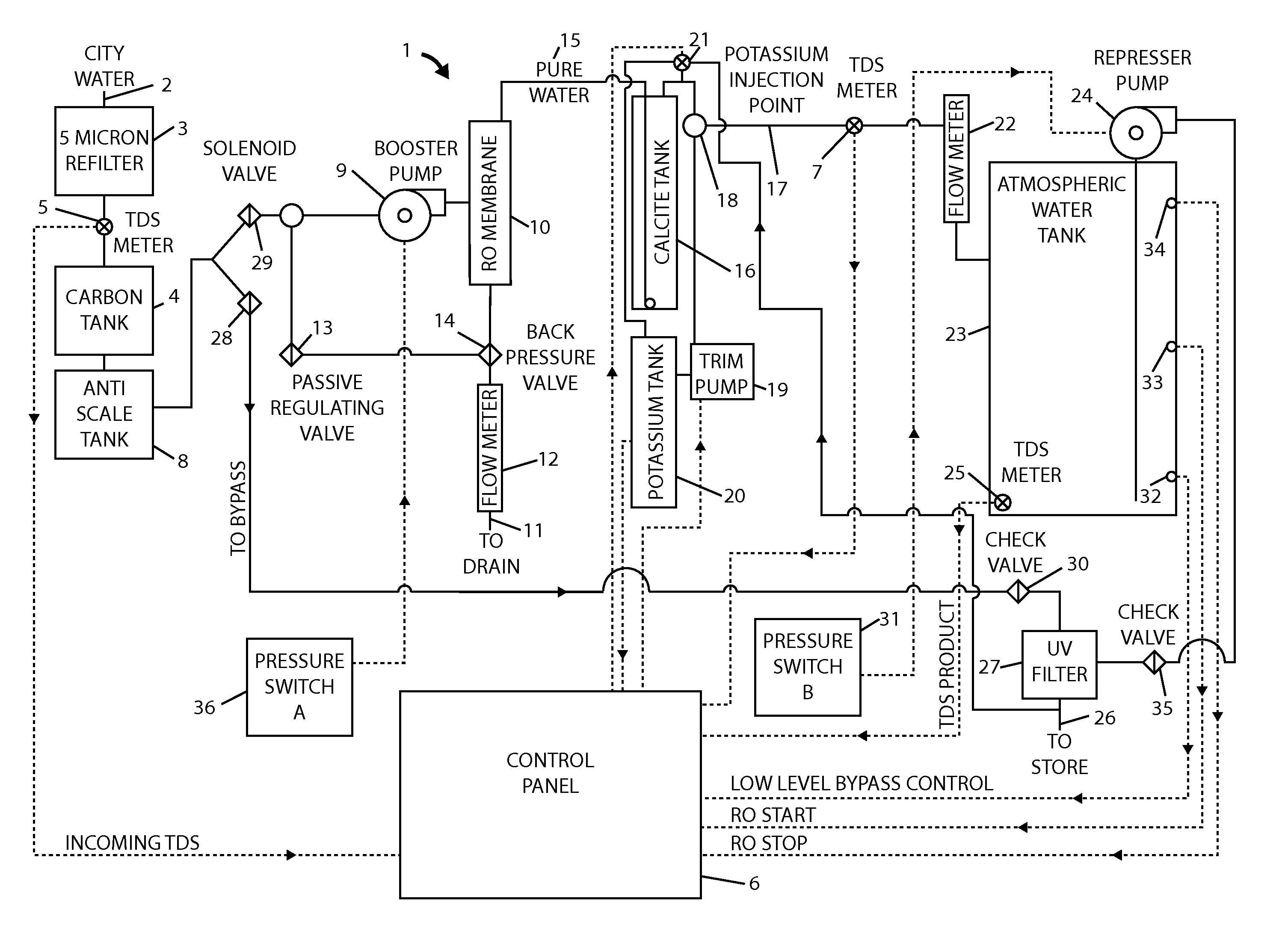

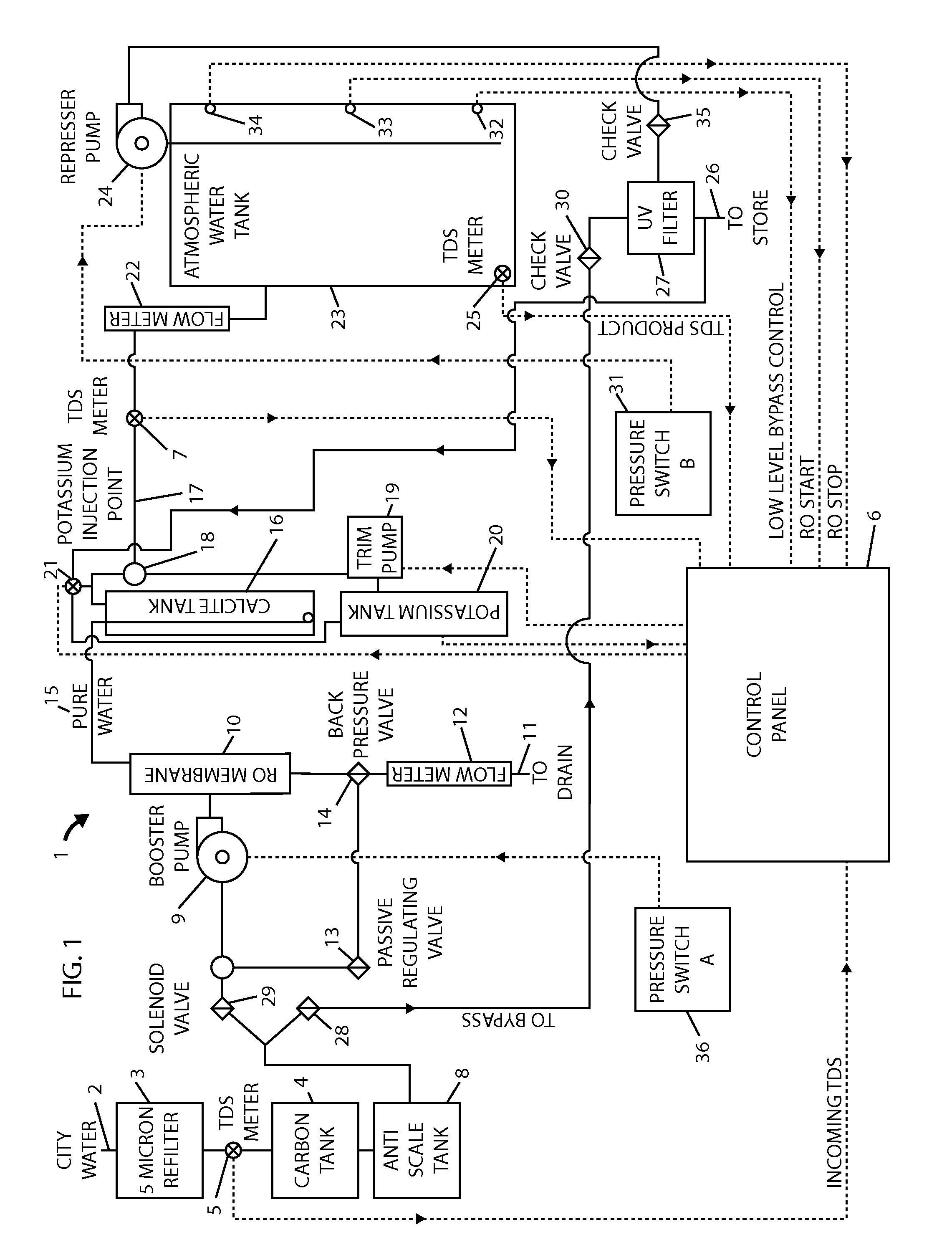

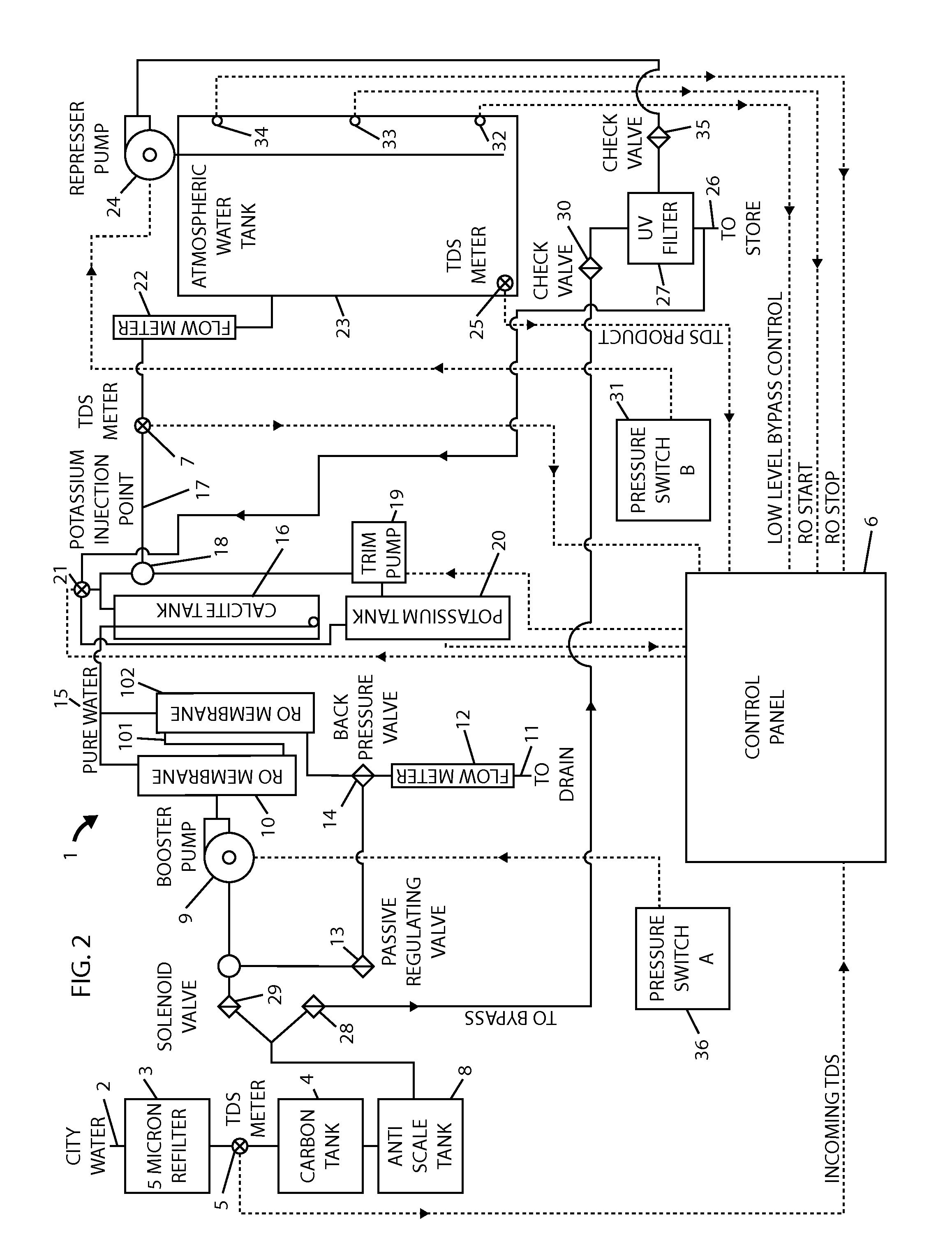

Beverage water maker

InactiveUS8790513B1Eliminated all salt usageLow costWater treatment parameter controlWater/sewage treatment by irradiationTotal dissolved solidsCalcite

Convenience stores are provided a beverage water processor for coffee and beverages. The “ideal” total dissolved solids (TDS) of perhaps 110 parts per million is achieved without a blendback process. The R / O water is remineralized with a flow through calcite bath. A potassium chloride source is used to inject the exact amount of potassium chloride needed to reach the ideal TDS on the fly before the water reaches the storage reservoir. Alarms trigger a bypass loop to keep the store in business during shutdown. All output water passes through a UV sterilizer.

Owner:BOULTER ROGER

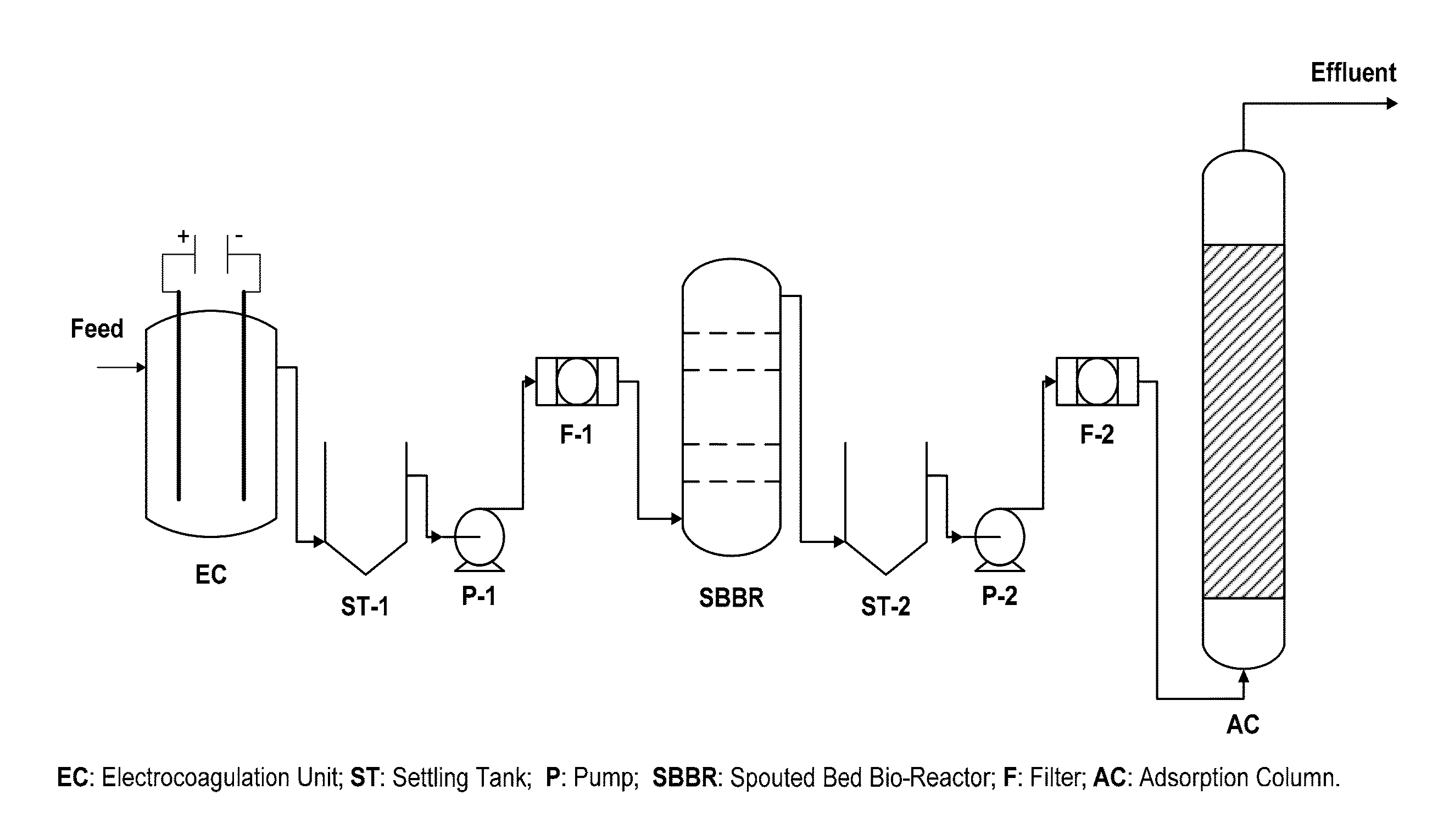

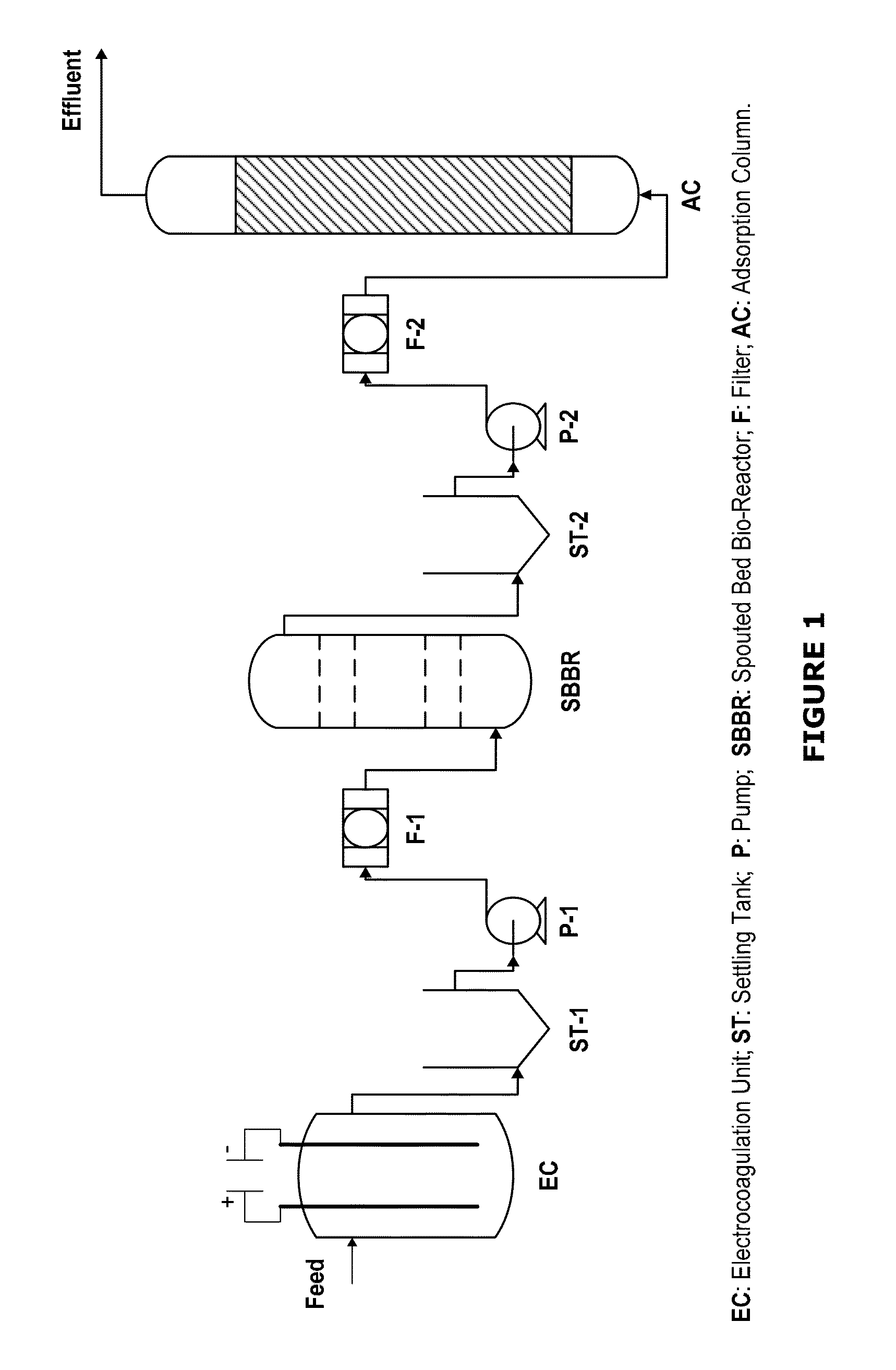

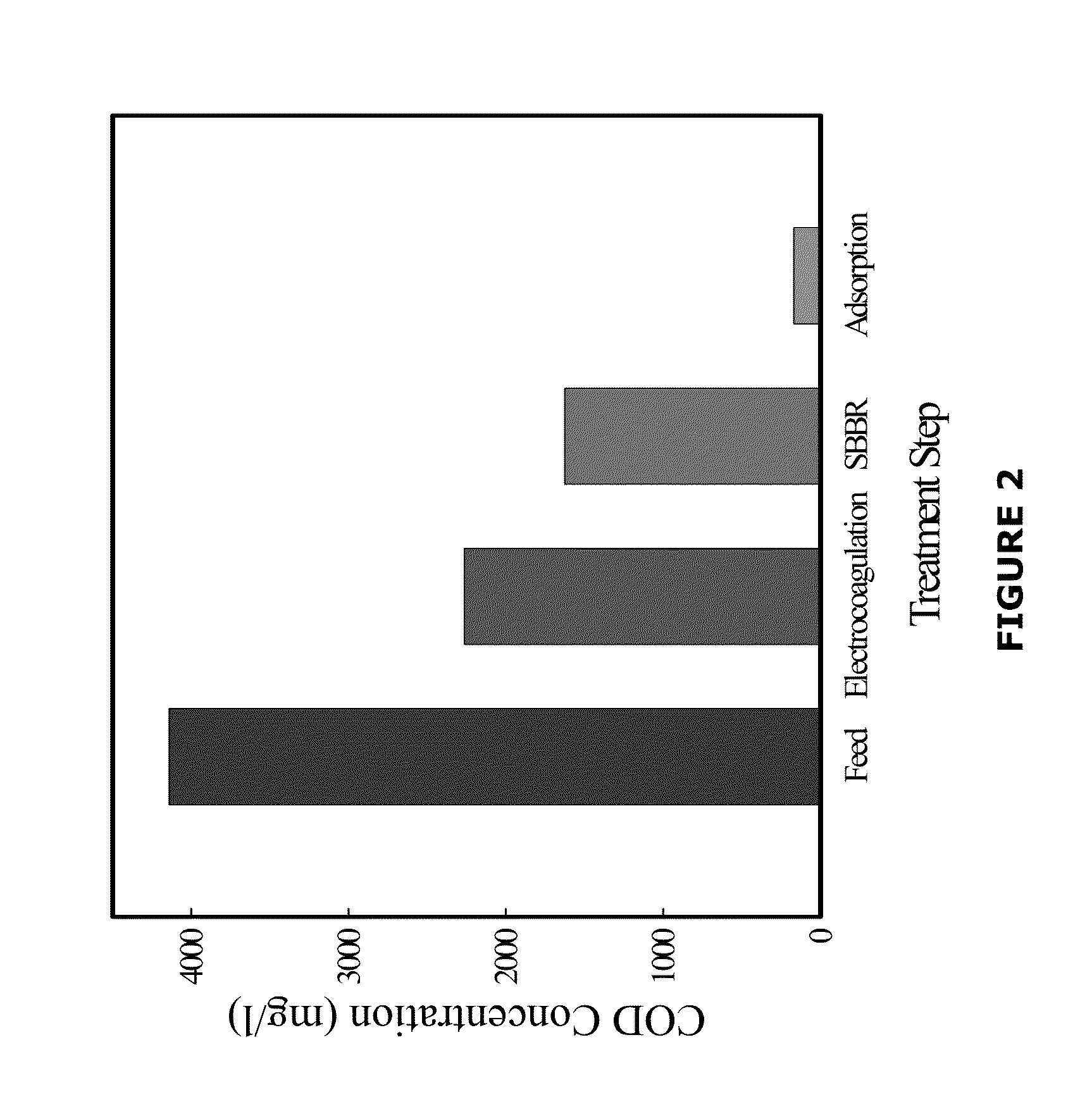

Process And System For The Treatment Of Industrial And Petroleum Refinery Wastewater

InactiveUS20130206688A1Reduce concentrationReduce replacement costsTreatment using aerobic processesWater contaminantsElectrocoagulationAfter treatment

There is provided a process of reducing concentration of contaminants in a contaminated wastewater stream, such as contaminated wastewater output from a refinery, such as an oil-refinery; the process comprising: first, passing the contaminated wastewater stream into an electrocoagulation reactor for coagulating dispersed particles, filtering the wastewater stream after electrocoagulation for removing the coagulated dispersed particles, and providing a first stream of treated wastewater after the first filtration; second, passing the first stream of treated wastewater into a Spouted Bed Bio-Reactor (SBBR) containing a micro-organism or bacterium immobilized in polyvinyl alcohol (PVA) gel, filtering the first stream after treatment by the SBBR and providing a second stream of treated wastewater after the second filtration; and third, passing the second stream of treated wastewater into an adsorption column containing granular activated carbon (GAC) and providing a third stream of treated wastewater. There is also provided a system for doing the same.

Owner:UNITED ARAB EMIRATES UNIVERSITY +1

Theft deterrent tag

InactiveUS7394376B1Low costReduce labor timeLoop antennas with ferromagnetic coreLocks for portable objectsEngineering

Owner:SAYEGH ADEL O +2

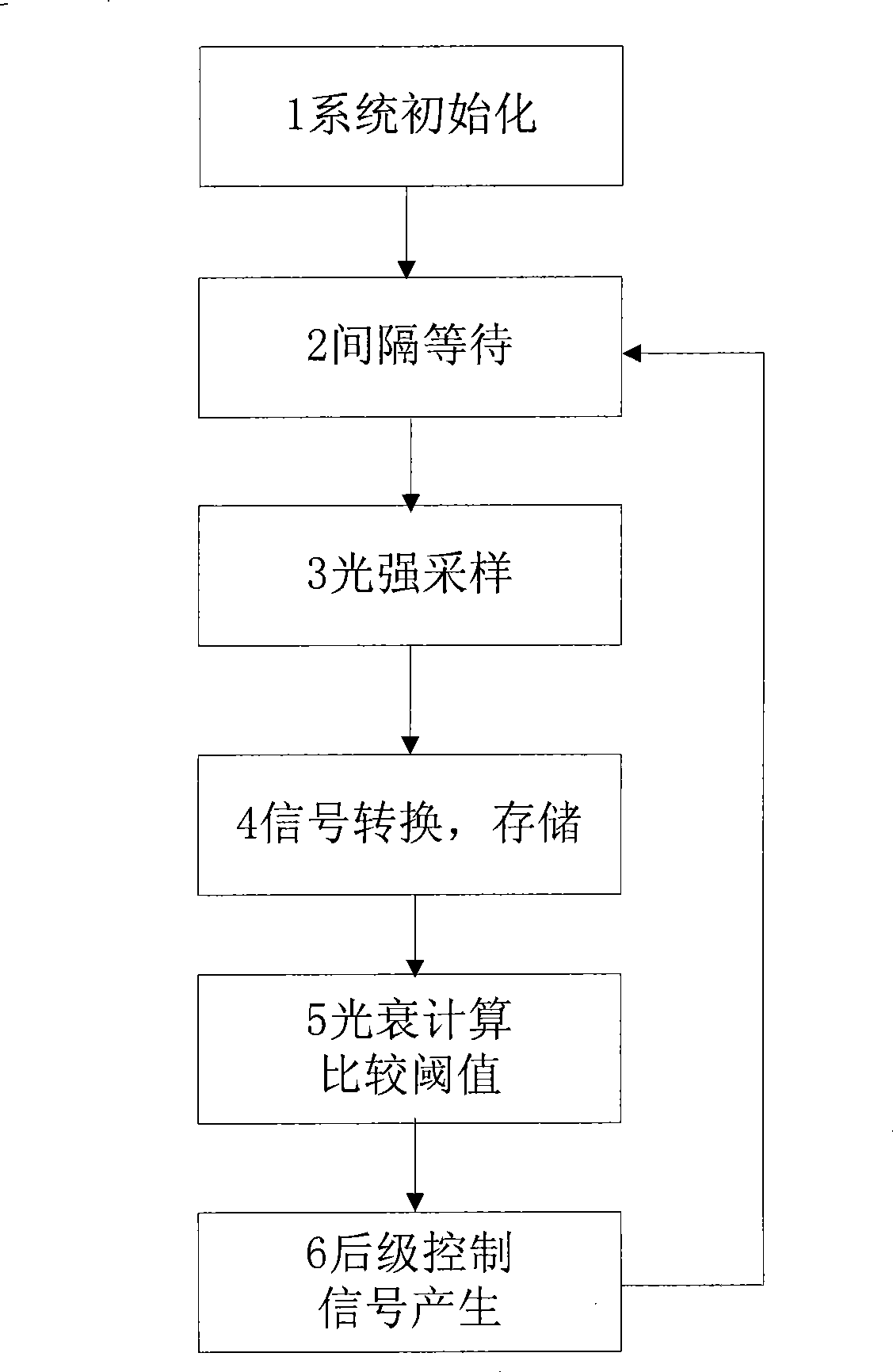

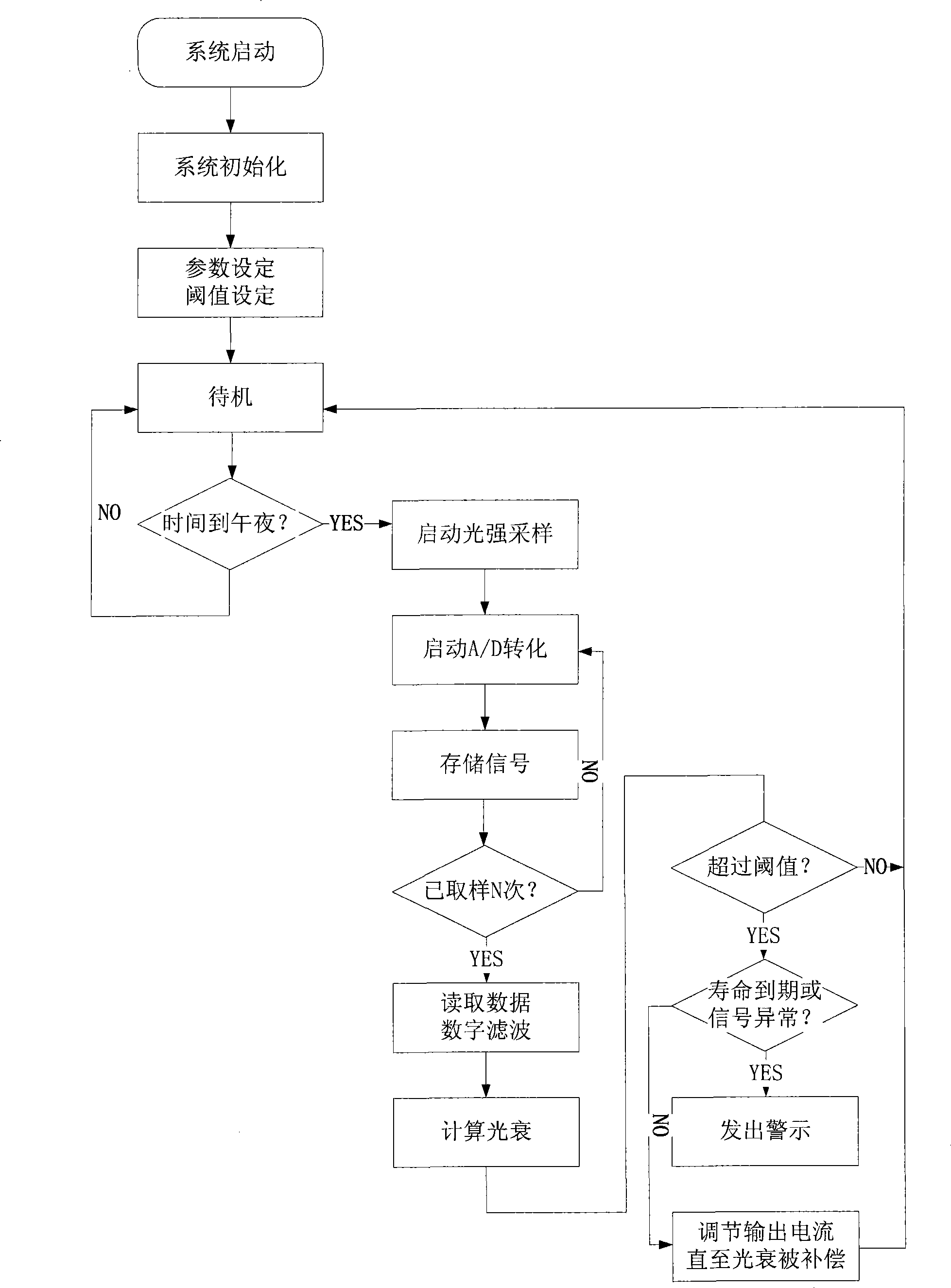

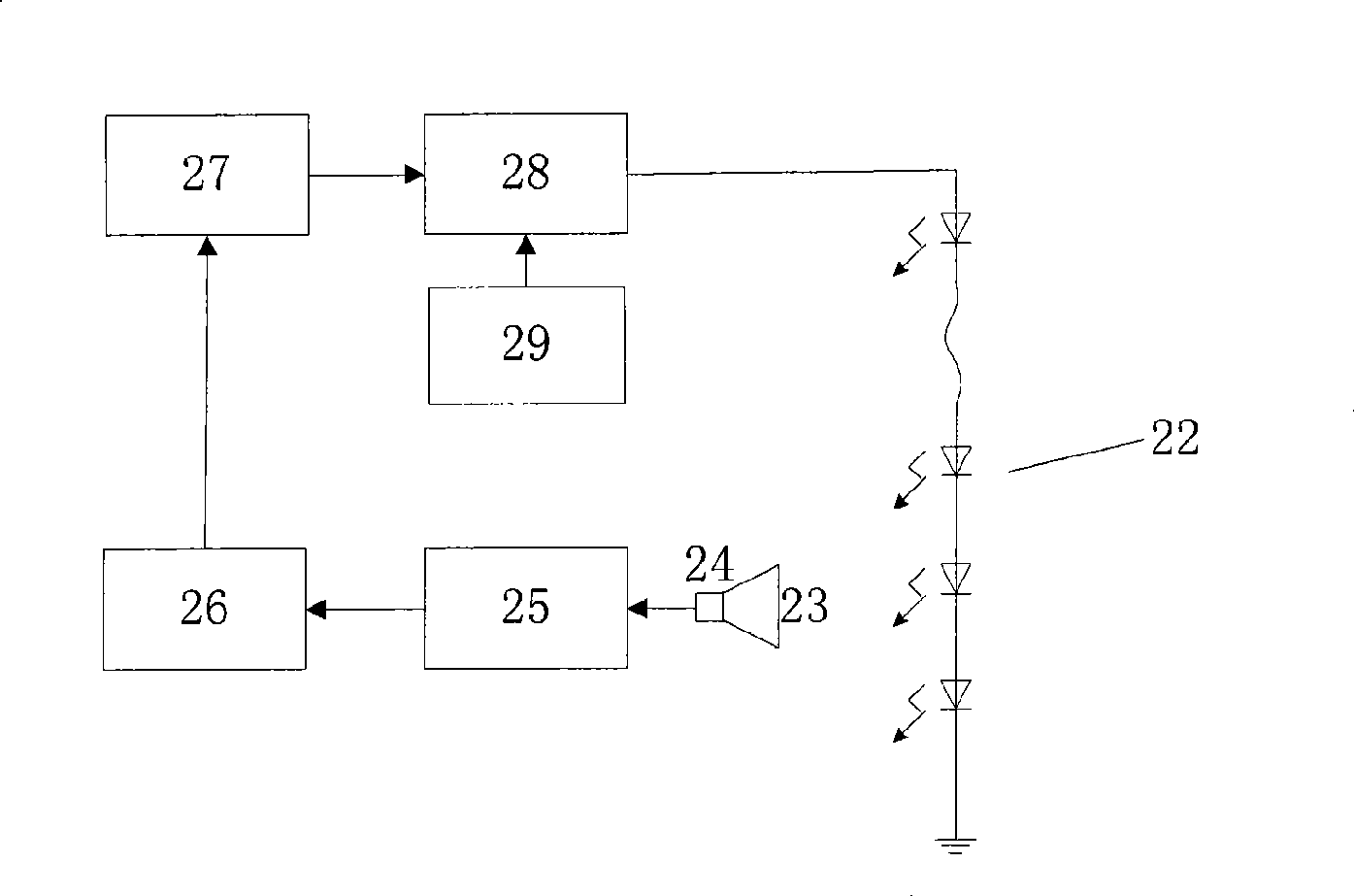

Control method and apparatus for implementing long-term maintained light strength by high power LED road lamp

InactiveCN101478850AExtended service lifeStable outputElectric light circuit arrangementEnergy saving control techniquesLuminous intensityClosed loop

The invention belongs to the field of high-power LED street lamp technology, concretely relating to a control method and a device for realizing long service life light intensity of a high-power light emitting diode street lamp. The invention has an adoption of closed-loop digital control; output light of LED is maintained to be strong in the whole service life span; and light decay thereof is compensated, thus guaranteeing a satisfactory luminous intensity in the service period of the street lamp; meanwhile, the service life of the LED street lamp can be prolonged. Concretely, optical signal output by the LED is detected, amplified, and converted by the device; the signal is filtered and judged and false signals are removed. In turn, light output of the lamp is regulated according to the light decay size obtained by calculation. The control method and a device for realizing long service life light intensity of a high-power light emitting diode street lamp also comprises a method for judging expiration of the service life of the lamp and sending out warning signal to an upper system at the expiration of the service life.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com